- Differences between glue and cement mortar - why is it better

- Tips for choosing adhesive mixtures

- Features of laying gas silicate blocks on glue

- The use of reinforcing mesh

- At what temperature can you work

- What glue to choose in the store

- Tips

- Applying glue when laying

- Comparison of cement mortar and adhesive

- How to choose?

- Savings Secrets

- What type of glue gives the least consumption, and what the most?

- Conclusion

Differences between glue and cement mortar - why is it better

The technology for the correct laying of foam concrete differs from the methods for installing other wall materials, and cement mortar is poorly suited for its implementation. The thermal insulation properties of foam concrete blocks are higher than those of mortar, and the thick layers of the latter make the building ventilated and cold. When using this method of installation, it will be necessary to equip additional thermal insulation from the inside or outside of the wall.

The use of a special adhesive composition solves the problem. It forms a thin seam - strong, airtight and waterproof, so the room will be noticeably warmer. In addition, laying blocks on glue is easier, faster, it hardens faster, reducing construction time.The cement mortar contains a lot of water, which immediately begins to be absorbed into the porous structure of the blocks, so you will also have to spend money on a water-repellent primer.

There are cases when it is still possible to lay blocks on a regular solution:

- material size - about 30 cm;

- incorrect geometry of products;

- height deviations - more than 1.5 cm;

- the presence of chips.

Tips for choosing adhesive mixtures

The range of adhesives for laying aerated concrete on the market is quite extensive. All compositions are divided into gray and white. The first are considered universal. They can be used at any time of the year. They contain additives that increase frost resistance. Such glue has certain temperature limits for use.

White compositions are suitable for work in the warm season. They contain Portland cement. This substance gives the mixture a light shade. White glue should be used for laying blocks indoors. The seam is aesthetic and does not require additional processing.

Usually, a gray type of glue is used for the construction of aerated concrete houses. This is due to the fact that such a composition is universal and is more common on sale.

Adhesives for gas blocks of such companies are very popular: Ceresit, Kreisel, UDK, Ytong, Real. Products of new firms regularly appear on sale. Therefore, not all builders can comment on the quality of a particular brand of glue. A little-known mixture for laying gas blocks can be no worse than branded products in quality.

Due to the fact that the range of adhesives for aerated concrete blocks is wide, many have problems with the choice. The question of which glue is best suited for building a house is quite relevant.There are different ways to figure out which mixture to use.

Experts advise paying attention to the composition. It should contain a lot of binders and a minimum concentration of additional inclusions, which are used to reduce the cost of products.

The choice is made by testing and comparing.

Builders recommend purchasing 2-3 types of glue in quantities up to 1 kg and checking their quality in practice. The solution should be prepared according to the manufacturer's instructions. Next, glue two blocks with each mixture. Leave to freeze for a day. After a day, try to break the structure in the seam area.

Buy glue for laying gas blocks should be in reliable companies. It is better to choose well-known and proven brands. This guarantees a high quality mix.

The result will show how good the glue was used. If the fracture coincides with the seam, then it is better not to use this mixture. If only the aerated concrete block was damaged, then this indicates the high quality of the adhesive. A similar composition can be safely used for any type of work.

If the fault has partially touched the seam, this means that the adhesive mixture will not provide sufficient structural strength, so it is better not to use it, especially when building multi-storey buildings.

Another way to determine the quality and choice of glue is to check its weight after curing. It is necessary to buy several types of adhesive compositions for testing and pour them in equal quantities into containers of the same size.

Wait a day and evaluate the result. To do this, you need to weigh each of the containers. Preference should be given to the glue, the weight of which, after solidification, has decreased the most. This suggests that a lot of moisture has gone and the composition has become more durable.

If you bought glue of an unknown brand, then it is better not to start building a house using it until the quality is checked. Correcting the situation later will be more difficult

Testing the adhesive in the above ways is troublesome, costly in time, effort and money. But such a check will help to accurately assess the quality of the composition. After all, the promises of manufacturers do not always correspond to reality.

Testing makes sense to carry out when planning large-scale construction. This will help not only to check the quality of the adhesive, but also to more accurately calculate its consumption.

Features of laying gas silicate blocks on glue

First, you should prepare the solution based on the manufacturer's recommendations indicated on the package. To prepare the glue, special tools are used that will help to thoroughly mix the components and speed up the process. The time of using the finished adhesive should not exceed four hours. Before you start laying out the first layer, you need to make sure that the surface is even, and also clean it from dust and dirt. It is also necessary to provide a waterproofing layer. To do this, you can take roofing material, polymers or bitumen. The first layer is a cement mortar with a thickness of three centimeters.

The first layer is a cement mortar with a thickness of three centimeters.

The first layer is a cement mortar with a thickness of three centimeters.

The use of reinforcing mesh

Reinforcement is necessary to strengthen the structure and the subsequent distribution of the load. Reinforcing mesh should be laid every 3-4 rows. You can use both mesh and reinforcement made of fiberglass or metal. The easiest way is to use a special mesh that is laid on the adhesive composition. In the case of window openings, reinforcement is carried out along the bottom row.

Reinforcement is necessary to strengthen the structure and the subsequent distribution of the load.

Reinforcement is necessary to strengthen the structure and the subsequent distribution of the load.

At what temperature can you work

When buying a material, you should pay attention to its variety. "Summer" compositions can be used in the construction of facilities at a temperature not lower than +4 degrees

If the temperature is below the specified parameter, then preference is given to "winter" compositions. They include special fillers that prevent premature hardening of the composition. You can work with them at a temperature not lower than -15 degrees.

Laying gas silicate blocks on glue does not require certain skills. All you need is basic information and basic instructions.

For example, it is important to choose blocks with the correct geometry, uniform color, even surface

It is important to choose blocks with the correct geometry, uniform color, even surface.

Glue should be mixed only with a drill with a nozzle or a construction mixer. The manual mixing process will not help prevent lumps from forming. When working in the summer, the blocks should be constantly moistened with water, and in the winter they need to be warmed up a little.

What glue to choose in the store

High-quality glue is distinguished by the content of special fillers and additives, which determine high rates in terms of such parameters as the level of moisture protection, thermal protection, elasticity and durability of the masonry.

Masonry adhesive solutions on the building materials market vary not only in terms of quality, but also in terms of affordability.

Important! It should be understood that miracles do not happen, and the cheapest adhesives contain fewer additives and plasticizers, and more sand. Therefore, it is better to focus on the average price. It is also worth knowing about the preferences of your builders

They have worked with different masonry materials and can advise what is definitely not worth taking.

It is also worth learning about the preferences of your builders. They have worked with different masonry materials and can advise what is definitely not worth taking.

It is important to ensure the quality of such mixtures and the availability of all necessary certification documentation. When choosing, it is recommended to give preference to materials from well-known and well-established manufacturers.

Tips

When choosing a particular brand of glue, you should be guided by the following criteria.

Manufacturer's name. Very often there are insidious one-day firms that produce low-quality promotional materials that turn out to be fiction and do not bring the desired result, and sometimes harm the building. In order not to make a mistake and not fall for the bait of scammers, it is better to trust well-known and trusted brands, and also remember that a quality product cannot be cheap.

Packaging and storage conditions

When choosing a product in the warehouse, immediately pay attention to how it is stored. Increased humidity in the room, a sharp change in temperature, damage to the packaging, a bag with blurry letters and the company logo - all these are clear witnesses of a poor-quality mixture

This material is as good as long as the rules for its storage are observed, as it is disgusting when at least one parameter is not true.

By weight. Never agree to purchase glue for gas silicate blocks without packaging.No one can give you a 100% guarantee that there are no low-quality impurities.

Having decided on the brand-manufacturer of the adhesive for gas silicate blocks, you can proceed to the calculation of material consumption. Often, all companies indicate this value on the packaging of their products, however, this information is only for reference, therefore, for each individual case, it is necessary to calculate the consumption of glue per cube of blocks individually.

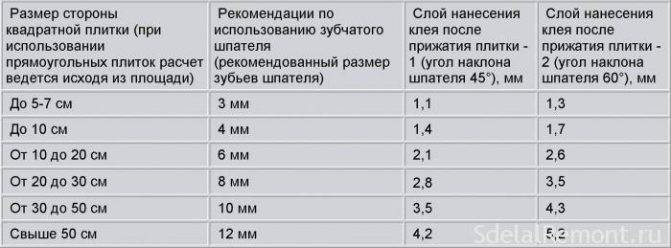

The main parameter on which the amount of solution consumption per 1 m3 depends is the layer thickness. If this indicator is no more than 3 mm, then the amount of glue will average from 8 to 9 kg per cubic meter. With a layer thickness of 3 mm or more, the consumption of the finished mixture increases by 3 times and amounts to 24-28 kg for the same surface area.

To somehow optimize the consumption of glue, you can resort to the following technological tricks.

- Surface preparation. One of the important criteria when laying gas silicate blocks using specialized glue is perfect evenness. The smoother the blocks, the less will be the consumption of the building mixture.

- Compliance with the technology of preparation of the solution. Just taking and kneading glue for laying gas silicate blocks, like dough for pies, will not work. It also has its own system: firstly, the glue powder is poured directly into the water collected in a clean container (a plastic or galvanized bucket is ideal); secondly, stirring occurs in two stages, with a short break (5-7 minutes, no more); thirdly, you should not immediately direct a large volume of the mixture, since you may not have time to use it all before it solidifies (for most manufacturers, this time is limited to 2 hours).

- Application methods also play an important role in reducing adhesive consumption. So, for example, the main tool for laying the mixture is a spatula with teeth. It is better to lay gas silicate blocks 10 minutes after applying the glue, pressing firmly and tapping the surface with a rubber mallet.

The first row of blocks is never glued. Always under the initial "line" of the entire structure is the foundation: concrete screed, screw piles, and so on. So the whole building will be much more stable and durable.

These are the main tricks that you need to use in your work in order to minimize the consumption of glue for gas silicate structures without compromising quality.

In order to position the blocks as accurately as possible, and between them - layers of glue, it is necessary to use mixtures intended for a specific individual case: for interior or exterior work, for laying gas silicate blocks at high or low temperatures.

It must also be remembered that the minimum curing time for the adhesive in a block or panel structure is a day. But the best and final result is observed not earlier than the third day after laying.

Compliance with the main indicators of temperature and humidity allows the construction of a gas silicate structure using special glue quickly, simply and efficiently even for a novice builder who does not have additional skills or education

Of course, it is very important to enlist the support of professional masons and experienced builders in this difficult matter, so that later you can only rejoice and enjoy the positive result of your own efforts.

How to choose glue for gas silicate blocks, see the following video.

Applying glue when laying

The laying of building material in the form of blocks is carried out quite quickly. This largely depends on the new tool for controlling the thickness of the adhesive laying. It is called a bucket trowel, aerated concrete carriage, a special container. This tool allows you to apply glue with maximum economy, which significantly reduces the cost of construction work. Special glue for gas blocks has several advantages over other compounds:

- small seam thickness;

- low humidity;

- constant composition of glue for aerated concrete;

- the presence of antifreeze additives;

- the remains of the finished glue are used as putty;

- winter products are produced for operation at low temperatures;

- the product does not shrink.

The filler has a very fine fraction, due to which a high plasticity of the adhesive is achieved. It allows you to form a layer with a thickness of 2-3 mm. At the same time, the consumption of glue for aerated concrete per 1 m3 decreases by about 4 times, and the degree of thermal insulation of the walls increases. You need only 5.5 liters of water per 1 bag of dry mix (25 kg). This protects the aerated concrete blocks from excessive moisture. The composition of the solution always remains the same, which makes it possible to have identical indicators of gluing the material in all sections of the wall. The adhesive does not freeze at sufficiently low temperatures due to special additives. The remains of the adhesive mixture for aerated concrete can putty various surfaces.

It is recommended to store dry mixes in a warm and dry place. When laying aerated concrete blocks should not lie under the snow. Tools for work are best kept in water. A bag weighing 25 kg is enough for 1 cube of building blocks.How to choose the right composition? If possible, test:

- Blocks are glued together in pairs with several types of glue. After a day, the gluing site is broken. If the seam remains intact, but the stone collapses, this is the best glue. The fracture occurred along the very seam - the adhesive composition is of very low quality.

- Knead 1 kg of each glue and put it in equal containers. Weigh each container after a day. The best glue will have the lightest weight.

The technology of laying aerated concrete blocks on glue is not limited to purely adhesive compositions. In European countries, foam has been used for a long time and very actively for these purposes. The usual dry composition is packed in 25 kg bags. From this amount, you can prepare 18 liters of glue. How much glue is consumed per 1m3? Consumption with a layer thickness of 1-3 mm will be 16-17 kg. It is necessary to take this into account when calculating the consumption of glue per 1 m² or cubic meter. The life of the finished composition is a maximum of 3 hours. You can correct the position of the blocks within 10-15 minutes.

The calculation of glue consumption per cubic meter also depends on the size of the blocks. Usually blocks of 600x300 mm in size are taken. But it is better to make all calculations with some margin. You need to prepare the working mass correctly. It is done like this:

- the right amount of water is taken;

- water is poured into a container for diluting the dry mixture;

- the mixture is gradually poured into the prepared water;

- mixing is best done with a mixer for 4-5 minutes;

- take a break for 10 minutes;

- mix everything again;

- periodically mix the finished solution.

A lot of mortar for aerated concrete blocks should not be prepared, as it dries quickly. It is enough to knead such an amount that it takes half an hour to lay a gas block.When can block walls be laid? This largely depends on various factors:

- ambient air humidity;

- his temperature.

The masonry norm requires work to be carried out in a dry and fairly warm season. The technology of laying aerated concrete blocks provides for this for the optimal drying speed of the glue. It is not recommended to work during rain and snow, use icy blocks for masonry.

Purchased blocks must be inspected and the defective ones sorted out. In masonry work, only products with a good and clean surface are used. One of the conditions is the permissible level of moisture content of the material. The glue is applied in a thin layer, building material is placed on it, excess adhesive mixture is removed with a trowel or smeared on the wall surface.

Comparison of cement mortar and adhesive

There are still cases when unscrupulous builders install gas silicate blocks on a cement-sand mortar.

There are still cases when unscrupulous builders install gas silicate blocks on a cement-sand mortar.

However, such work is permissible only when laying the first row of aerated concrete on the foundation.

The composition of cellular concrete provides for the use of special adhesive mixtures.

Therefore, any cement mortars will not be able to guarantee high-quality masonry with low thermal conductivity.

For the simple reason that the cement joint is 10-12 mm thick. While the plastic adhesive for cellular blocks, applied to the surface with a notched trowel for aerated concrete, provides a joint thickness of only 1-3 mm. It should be understood that the maximum heat loss in winter will occur through the seams.

Attention! Cement mortars poorly retain moisture, and all highly porous aerated concrete absorb it from such a composition very quickly, which minimizes the “adhesive” qualities of the cement mixture and can cause premature failure of the masonry.

Even preliminary wetting of the surface of the blocks with water before applying the solution will not allow correcting this situation.

Among other things, if the construction of street structures is carried out at low-temperature air indicators, then the moisture absorbed by the aerated concrete block from the cement mortar freezes and causes cracking of the building material. It is for these reasons that special modern adhesive compositions for aerated concrete masonry are used in construction.

Now let's talk about the price. Cement-sand mortar will cost less than glue for gas silicate blocks with special additives and plasticizers. But do not forget about the thickness of the resulting seam. In the case of a solution, it will be 4-5 times thicker. So where is the savings?

How to choose?

To date, two types of glue are common, differing by season:

- White (summer) glue is similar to autoclaved aerated concrete and consists of special Portland cement. This allows you to save on interior decoration. At the same time, the surface turns out to be monophonic and light, there is no need to hide the seams.

- Winter, or universal, consists of special components that allow the use of glue at low temperatures. However, when choosing such a composition, some limitations should be taken into account.

Winter types of glue are most often used in the northern regions. Although they contain special frost-resistant components, temperature limits still exist.Winter solutions cannot be used at air temperatures below -10 C.

During construction work in winter, it must be taken into account that the adhesive for aerated concrete blocks must have a temperature above 0 C. Otherwise, adhesion will deteriorate and damage may occur after repair.

Store winter types of glue only in warm rooms. The concentrate is mixed with warm water at its temperature up to +60 C. The resulting composition should have a temperature not lower than +10 C. In winter, the masonry composition quickly loses its useful properties, so it is recommended to use it within 30 minutes.

The most common composition for aerated concrete blocks is Kreps KGB glue, which has such advantages as economy, high technology, minimum joint thickness. Due to the minimum thickness of the seam, glue is consumed less. An average of 25 kg of dry concentrate is required per cubic meter of material. "Kreps KGB" can be used for both interior and exterior decoration.

The compositions are among the most economical means for laying aerated concrete. They include cement, fine sand and modifiers. The average thickness of interblock seams is obtained no more than 3 mm. Due to the minimum thickness, the formation of cold bridges is reduced to “no”, while the quality of the masonry does not deteriorate. The hardened solution provides reliability in conditions of low temperatures and mechanical influences.

Other equally common winter types of glue for interior and exterior work are PZSP-KS26 and Petrolit, which are easy to use and have good adhesion and frost resistance.

Today, a wide variety of adhesive materials for aerated concrete are presented on the building materials market. The choice of material should be approached wisely, since the integrity of the structure depends on it. Experts recommend trusting only trusted manufacturers with good reviews.

Savings Secrets

If you follow some of the advice of experts, then the consumption of adhesive when laying aerated concrete will be more economical.

Experienced master builders know how to work with aerated concrete, glue. Therefore, they build a house faster and more economically in terms of material consumption. When building a building from gas blocks on your own, you need to be careful and think through everything carefully, take your time

Experienced master builders know how to work with aerated concrete, glue. Therefore, they build a house faster and more economically in terms of material consumption. When building a building from gas blocks on your own, you need to be careful and think through everything carefully, take your time

The use of special tools speeds up the construction process and minimizes the use of glue, and, accordingly, reduces the cost of work. It is recommended to use a ladle, a rubber hammer, a square, a grater with sandpaper, a saw for masonry.

Glue should be applied with a spatula or a special spatula. Then the composition will lie down more evenly and it will be possible to minimize its consumption. Before laying, the blocks must be cleaned of contaminants.

It is important to dry them well so that they are not wet.

What type of glue gives the least consumption, and what the most?

The estimated cost of one bag of the mixture varies from 140 rubles (KLEYZER) to 250 rubles (Ceresit). Below is also a table of the cost of some adhesives for aerated concrete.

| Name (bag 25 kg) | Price, rub |

|---|---|

| Bergauf Pkaktik | 230 |

| Founds T-112 Selform | 117 |

| Adhesive for aerated concrete PSB | 130 |

| Adhesive for aerated concrete Real winter up to -5 | 177 |

| Weber. Bat block | 230 |

| Masonry adhesive for highly porous materials gsb EK 7000 | 230 |

| Glue for "Kamiks-26" | 185 |

| Glue for BIKTON KLEB | 200 |

| Clay HERCULES | 200 |

| Aerated concrete adhesive Bonolit | 220 |

| Adhesive Mounting G-31 "WIN" | 230 |

| Clay Prestige | 170 |

| Adhesive for aerated concrete blocks Azolit-Kr | 185 |

| OMLUX Adhesive for honeycomb blocks | 210 |

| Glue "Azolit-Kr Zima" | 197 |

It is not recommended to purchase and use cheap glue due to the fact that products with a low price bar are worse in terms of their adhesive and binding characteristics.

What is the adhesive for aerated concrete:

- Quartz sand;

- Polymeric substances for plasticity and filling gaps between blocks;

- bonding base;

- Substances for water retention and anti-cracking.

To prepare the composition, you must carefully read the instructions.

Each manufacturer has specific guidelines for this. On average, one bag of dry mix takes 7-8 liters of water.

The finished mix should hold onto the trowel and not be too liquid, as excess moisture reduces strength.

Winter adhesive mixtures are used at a temperature of gas silicate blocks not lower than +5 C. If the air temperature during this period is below this indicator, then antifreeze additives are added to the mixture.

The prepared composition should be used within 20-30 minutes. In summer, dry blocks should be moistened to prevent rapid drying.

Advantages of glue in comparison with cement-sand mortar:

-

Heat. There are no interlayers with high thermal conductivity, which lead to a decrease in heat loss.

-

Convenience of masonry. A thin layer of glue makes the masonry even, and the adjustment time is about 5 minutes.

-

Saving. For a cement-sand mortar, for a volume of 1 cubic meter, it takes about 180 kg. In monetary terms, the mixture for glue is two to two and a half times cheaper than a conventional solution.

-

Strength.Due to the increase in the magnitude of the cohesive nature, the masonry on the adhesive solution is strong in compression.

Builders-practitioners distinguish 4 main manufacturers of glue for aerated concrete: POLiMIN, KLEYZER, Ceresit and PlanoFix.

Three of them are more expensive than KLEYZER, but their masonry mixture is also of better quality. Ceresit differs in that it does not give water to aerated concrete for about an hour.

Use such glue to match only qualified craftsmen

With a cheap KLEYZER, hitching is done within a few minutes. Use such glue to match only qualified craftsmen.

PlanoFix and POLiMIN are intermediate between KLEYZER and Ceresit. They showed excellent adhesion between blocks and are quite comfortable in the laying process.

As we can see, the consumption of glue for aerated concrete depends on various factors. Its price does not differ much from the average value, and the quality of the mixtures can be different, so it is better to take one that is in the average price range.

We advise you to read our article on how to dissolve Super Glue? You may also be interested in reading our material on choosing wallpaper imitating a brick tab.

Conclusion

In addition to the materials that we have provided in our article, you may also find other articles that are indirectly related to our topic useful. Basically, the articles reveal the topic of exterior and interior wall decoration, as well as insulation of walls, floors and ceilings.

- "How to insulate the walls of the house: materials and technology",

- "Insulation of the ceiling from the side of the cold attic",

- "Insulation of the ceiling in the garage: we save the car from frost",

- "What is the cost of finishing the walls of aerated concrete outside and inside the house",

- How to tie walls to prevent your home from collapsing.

If you start building a house in the way that we briefly described above, then at the final stage of work you will definitely need the information from the above list.

That's all, dear reader. Thank you for taking the time to read our article. If you didn't find what you were looking for here, use the site navigation to find the information you need. All the best, dear reader, come again!

P.S. In the video you can see how to lay aerated concrete blocks with your own hands: