- The concept of hydraulic calculation

- Method of calculation

- Collection of initial data on the heat load object

- Energy audit of the building

- Technical report

- Inspection with a thermal imager

- General calculations

- Boiler

- Pipes

- Expansion tank

- Radiators

- Calculation of the number of sections of heating radiators by volume

- Calculation of the number of sections of heating radiators according to the area of \u200b\u200bthe room

- Accurate calculation of the number of radiator sections

- Options for approximate calculations

- Specificity and other features

- Energy survey of the designed modes of operation of the heat supply system

- Calculation of annual heat consumption for heating

- Calculation rules

- How to choose a circulation pump

- Easy Ways to Calculate Heat Load

- The dependence of heating power on the area

- Enlarged calculation of the thermal load of the building

- We consider the heat consumption by quadrature

- General calculations

- Boiler

- Expansion tank

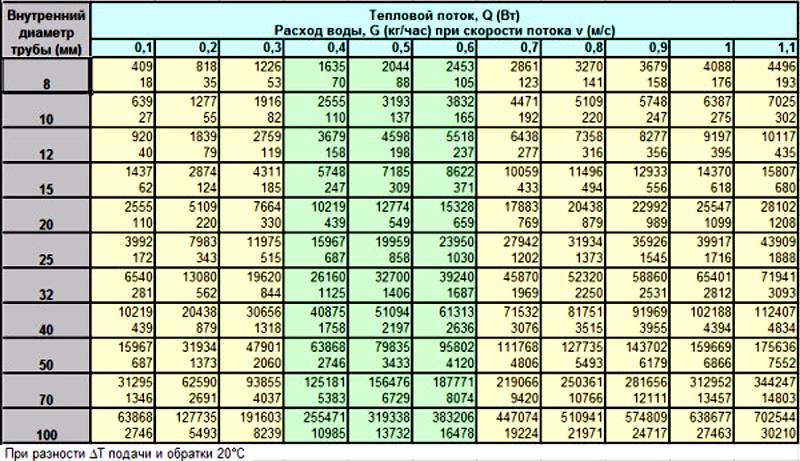

The concept of hydraulic calculation

The determining factor in the technological development of heating systems has become the usual savings on energy. The desire to save money makes us take a more careful approach to the design, choice of materials, methods of installation and operation of heating for a home.

Therefore, if you decide to create a unique and, first of all, economical heating system for your apartment or house, then we recommend that you familiarize yourself with the calculation and design rules.

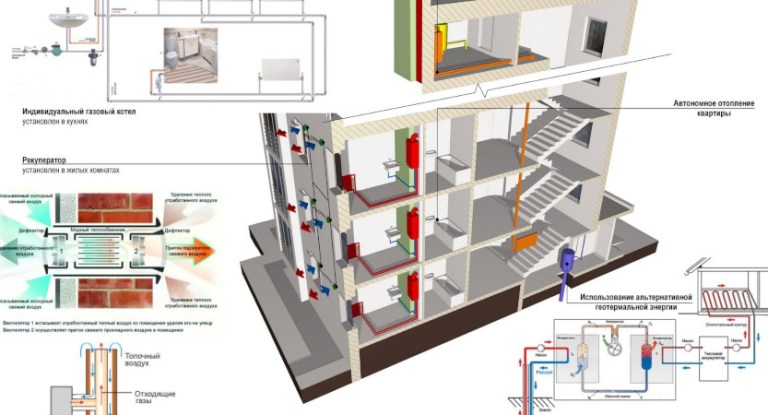

Before defining the hydraulic calculation of the system, it is necessary to clearly and clearly understand that the individual heating system of an apartment and a house is conventionally located an order of magnitude higher than the central heating system of a large building.

A personal heating system is based on a fundamentally different approach to the concepts of heat and energy.

The essence of the hydraulic calculation lies in the fact that the flow rate of the coolant is not set in advance with a significant approximation to the real parameters, but is determined by linking the diameters of the pipeline with the pressure parameters in all the rings of the system

It suffices to make a trivial comparison of these systems in terms of the following parameters.

- The central heating system (boiler-house-apartment) is based on standard types of energy carrier - coal, gas. In a stand-alone system, almost any substance that has a high specific heat of combustion, or a combination of several liquid, solid, granular materials can be used.

- DSP is built on the usual elements: metal pipes, "clumsy" batteries, valves. An individual heating system allows you to combine a variety of elements: multi-section radiators with good heat dissipation, high-tech thermostats, different types of pipes (PVC and copper), taps, plugs, fittings, and of course your own more economical boilers, circulation pumps.

- If you enter the apartment of a typical panel house built 20-40 years ago, we see that the heating system is reduced to the presence of a 7-section battery under the window in each room of the apartment plus a vertical pipe through the whole house (riser), with which you can “communicate” with upstairs/downstairs neighbors. Whether it's an autonomous heating system (ACO) - allows you to build a system of any complexity, taking into account the individual wishes of the residents of the apartment.

- Unlike DSP, a separate heating system takes into account a fairly impressive list of parameters that affect transmission, energy consumption and heat loss. Ambient temperature conditions, the required temperature range in the rooms, the area and volume of the room, the number of windows and doors, the purpose of the rooms, etc.

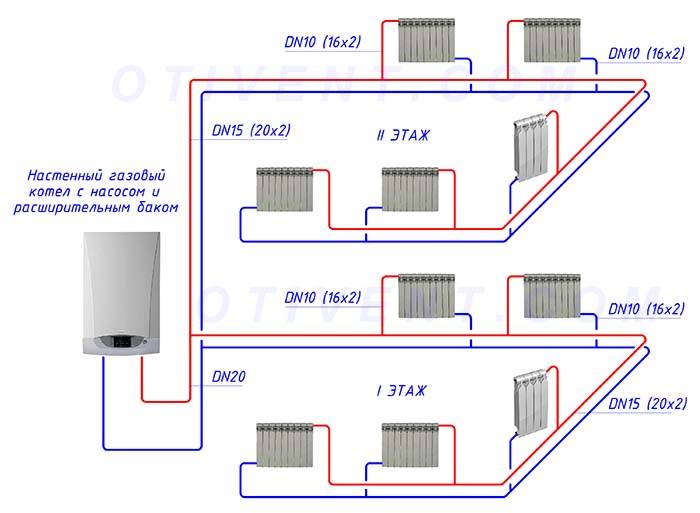

Thus, the hydraulic calculation of the heating system (HRSO) is a conditional set of calculated characteristics of the heating system, which provides comprehensive information about such parameters as pipe diameter, number of radiators and valves.

This type of radiators was installed in most panel houses in the post-Soviet space. Savings on materials and the lack of a design idea “on the face”

GRSO allows you to choose the right water ring pump (heating boiler) for transporting hot water to the final elements of the heating system (radiators) and, in the end, to have the most balanced system, which directly affects financial investments in home heating.

Another type of heating radiator for DSP. This is a more versatile product that can have any number of ribs. So you can increase or decrease the heat exchange area

Method of calculation

To calculate or recalculate the heat load on the heating of buildings already in operation or newly connected to the heating system, the following work is carried out:

- Collection of initial data about the object.

- Conducting an energy audit of the building.

- Based on the information obtained after the survey, the heat load for heating, hot water and ventilation is calculated.

- Drawing up a technical report.

- Coordination of the report in the organization providing heat energy.

- Signing a new contract or changing the terms of an old one.

Collection of initial data on the heat load object

What data needs to be collected or received:

- Agreement (copy) for heat supply with all annexes.

- A certificate issued on company letterhead on the actual number of employees (in the case of industrial buildings) or residents (in the case of a residential building).

- BTI plan (copy).

- Data on the heating system: one-pipe or two-pipe.

- Top or bottom filling of the heat carrier.

All these data are required, because. based on them, the heat load will be calculated, as well as all the information will be included in the final report. The initial data, in addition, will help determine the timing and volume of work. The cost of the calculation is always individual and may depend on factors such as:

- area of heated premises;

- type of heating system;

- availability of hot water supply and ventilation.

Energy audit of the building

Energy audit involves the departure of specialists directly to the facility. This is necessary in order to conduct a complete inspection of the heating system, to check the quality of its insulation. Also, during the departure, the missing data about the object are collected, which cannot be obtained except by means of a visual inspection.The types of heating radiators used, their location and number are determined. A diagram is drawn and photographs are attached. Be sure to inspect the supply pipes, measure their diameter, determine the material from which they are made, how these pipes are connected, where the risers are located, etc.

As a result of such an energy audit (energy audit), the customer will receive a detailed technical report, and on the basis of this report, the calculation of the heat loads for heating the building will already be carried out.

Technical report

The technical report on the heat load calculation should consist of the following sections:

- Initial data about the object.

- Scheme of the location of heating radiators.

- DHW outlet points.

- The calculation itself.

- Conclusion based on the results of the energy audit, which should include a comparative table of the maximum current thermal loads and contractual ones.

- Applications.

- Certificate of membership in the SRO energy auditor.

- Floor plan of the building.

- Explication.

- All appendices to the contract for energy supply.

After drawing up, the technical report must be agreed with the heat supply organization, after which changes are made to the current contract or a new one is concluded.

Inspection with a thermal imager

Increasingly, in order to increase the efficiency of the heating system, they resort to thermal imaging surveys of the building.

These works are carried out at night. For a more accurate result, you must observe the temperature difference between the room and the street: it must be at least 15 o. Fluorescent and incandescent lamps are switched off. It is advisable to remove carpets and furniture to the maximum, they knock down the device, giving some error.

The survey is carried out slowly, the data are recorded carefully.The scheme is simple.

The first stage of work takes place indoors

The device is moved gradually from doors to windows, paying special attention to corners and other joints.

The second stage is the examination of the external walls of the building with a thermal imager. The joints are still carefully examined, especially the connection with the roof.

The third stage is data processing. First, the device does this, then the readings are transferred to a computer, where the corresponding programs complete the processing and give the result.

If the survey was conducted by a licensed organization, then it will issue a report with mandatory recommendations based on the results of the work. If the work was carried out personally, then you need to rely on your knowledge and, possibly, the help of the Internet.

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't like watching movies. However, even in the best cinema there are errors that the viewer can notice.

9 Famous Women Who Have Fallen In Love With Women Showing interest in someone other than the opposite sex is not unusual. You can hardly surprise or shock someone if you admit it.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she broke into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Never do this in a church! If you're not sure if you're doing the right thing in church or not, then you're probably not doing the right thing. Here is a list of the terrible ones.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair.It seems that youth was created for experiments on appearance and bold curls. However, already

13 Signs You Have the Best Husband Husbands are truly great people. What a pity that good spouses do not grow on trees. If your significant other does these 13 things, then you can.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear of the heater, as well as significant energy consumption.

Boiler

The calculation of the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio at which 1 kW of thermal energy is sufficient to efficiently heat 10 m2 of living space. This ratio is valid in the presence of ceilings, the height of which is not more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

Pipes

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross section of the pipeline according to the formula - S = π × R2, where:

- S - cross section;

- π is a constant constant equal to 3.14;

- R is the inner radius of the pipes.

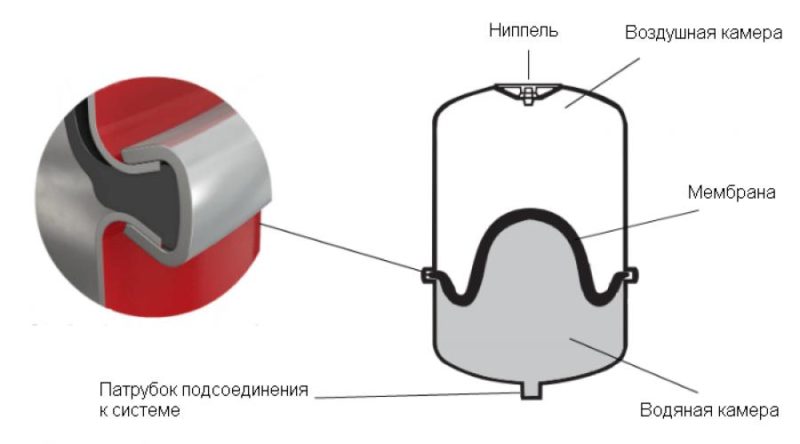

Expansion tank

It is possible to determine what capacity the expansion tank should have, having data on the coefficient of thermal expansion of the coolant. For water, this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank \u003d (V syst × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K is the expansion coefficient;

- D - the efficiency of the expansion tank (indicated in the technical documentation).

Radiators

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first calculate their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the technical data sheet of the product. In the absence of such information, you can navigate according to the average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 \u003d 12 liters.

Calculation of the number of sections of heating radiators by volume

Most often, the value recommended by SNiP is used, for panel-type houses per 1 cubic meter of volume, 41 W of thermal power is required.

If you have an apartment in a modern house, with double-glazed windows, insulated outer walls and plasterboard slopes. then for the calculation the value of the thermal power of 34W per 1 cubic meter of volume is already used.

An example of calculating the number of sections:

Room 4*5m, ceiling height 2.65m

We get 4 * 5 * 2.65 \u003d 53 cubic meters The volume of the room and multiply by 41 watts.Total required thermal power for heating: 2173W.

Based on the data obtained, it is not difficult to calculate the number of radiator sections. To do this, you need to know the heat transfer of one section of the radiator you have chosen.

Let's say: Cast iron MS-140, one section 140W Global 500.170W Sira RS, 190W

It should be noted here that the manufacturer or seller often indicates an overestimated heat transfer calculated at an elevated temperature of the coolant in the system. Therefore, focus on the lower value indicated in the product data sheet.

Let's continue the calculation: we divide 2173 W by the heat transfer of one section of 170 W, we get 2173 W / 170 W = 12.78 sections. We round up towards a whole number, and we get 12 or 14 sections. Some sellers offer a service for assembling radiators with the required number of sections, that is, 13. But this will no longer be a factory assembly.

Some sellers offer a service for assembling radiators with the required number of sections, that is, 13. But this will no longer be a factory assembly.

This method, like the next one, is approximate.

Calculation of the number of sections of heating radiators according to the area of \u200b\u200bthe room

It is relevant for the height of the ceilings of the room 2.45-2.6 meters. It is assumed that 100W is enough to heat 1 square meter of area.

That is, for a room of 18 square meters, 18 square meters * 100W = 1800W of thermal power is required.

We divide by the heat transfer of one section: 1800W / 170W = 10.59, that is, 11 sections.

In which direction is it better to round the results of calculations?

The room is corner or with a balcony, then we add 20% to the calculations. If the battery is installed behind the screen or in a niche, then heat loss can reach 15-20%

But at the same time, for the kitchen, you can safely round down, up to 10 sections. In addition, in the kitchen, electric underfloor heating is often installed. And this is at least 120 W of thermal assistance per square meter.

Accurate calculation of the number of radiator sections

We determine the required heat output of the radiator using the formula

Qt \u003d 100 watt / m2 x S (rooms) m2 x q1 x q2 x q3 x q4 x q5 x q6 x q7

Where the following coefficients are taken into account:

Glazing type (q1)

Triple glazing q1=0.85

Double glazing q1=1.0

Conventional (double) glazing q1=1.27

Wall insulation (q2)

High-quality modern insulation q2=0.85

Brick (in 2 bricks) or insulation q3= 1.0

Poor insulation q3=1.27

The ratio of window area to floor area in the room (q3)

Minimum outdoor temperature (q4)

Number of outer walls (q5)

Type of room above settlement (q6)

Heated room q6=0.8

Heated attic q6=0.9

Cold attic q6=1.0

Ceiling height (q7)

100 W/m2*18m2*0.85 (triple glazing)*1 (brick)*0.8 (2.1 m2 window/18m2*100%=12%)*1.5(-35)* 1.1 (one outdoor) * 0.8 (heated, apartment) * 1 (2.7 m) = 1616W

Poor thermal insulation of the walls will increase this value to 2052 W!

number of heating radiator sections: 1616W/170W=9.51 (10 sections)

We considered 3 options for calculating the required thermal power and, on the basis of this, we were able to calculate the required number of sections of heating radiators. But here it should be noted that in order for the radiator to give out its nameplate power, it should be installed correctly. Read the following articles on the official website of the Remontofil Repair School on how to do it right or control the not always competent employees of the housing office

Options for approximate calculations

At the same time, there are simpler methods that allow you to approximately estimate the amount of required thermal energy and you can do them yourself:

- Often, the calculation of heating power by area is used (in more detail: “Calculation of heating by area - we determine the power of heating devices”). It is believed that residential buildings are built according to projects developed taking into account the climate in a certain region, and that the design decisions include the use of materials that provide the required thermal balance. Therefore, when calculating, it is customary to multiply the value of the specific power by the area of \u200b\u200bthe premises. For example, for the Moscow region, this parameter is in the range from 100 to 150 watts per "square".

- A more accurate result will be obtained if the room volume and temperature are taken into account. The calculation algorithm includes the height of the ceiling, the level of comfort in the heated room and the features of the house.The formula used is as follows: Q = VхΔTхK/860, where:

V is the volume of the room; ΔT is the difference between the temperature inside the house and outside on the street; K is the heat loss coefficient.

The correction factor allows you to take into account the design features of the property. For example, when determining the thermal output of a building's heating system, for buildings with a conventional double brick roof, K is in the range of 1.0–1.9. - The method of aggregated indicators. Similar in many ways to the previous option, but it is used to calculate the heat load for heating systems in multi-apartment buildings or other large facilities.

Specificity and other features

Another specificity is also possible for the premises for which the calculation is made, but not all of them are similar and exactly the same. These can be indicators such as:

- the coolant temperature is less than 70 degrees - the number of parts will have to be increased accordingly;

- the absence of a door in the opening between the two rooms. Then it is required to calculate the total area of both rooms in order to calculate the number of radiators for optimal heating;

- double-glazed windows installed on the windows prevent heat loss, therefore, fewer battery sections can be mounted.

When replacing old cast-iron batteries, which provided a normal temperature in the room, with new aluminum or bimetallic ones, the calculation is very simple. Multiply the heat output of one cast iron section (average 150W). Divide the result by the amount of heat of one new part.

Energy survey of the designed modes of operation of the heat supply system

When designing, the heat supply system of CJSC Termotron-Zavod was designed for maximum loads.

The system was designed for 28 heat consumers. The peculiarity of the heat supply system is that part of the heat consumers from the outlet of the boiler house to the main building of the plant. Further, the heat consumer is the main building of the plant, and then the rest of the consumers are located behind the main building of the plant. That is, the main building of the plant is an internal heat consumer and a transit heat supply for the last group of heat load consumers.

The boiler house was designed for steam boilers DKVR 20-13 in the amount of 3 pieces, operating on natural gas, and hot water boilers PTVM-50 in the amount of 2 pieces.

One of the most important stages in the design of heat networks was the determination of the calculated heat loads.

The estimated heat consumption for heating each room can be determined in two ways:

- from the heat balance equation of the room;

- according to the specific heating characteristic of the building.

The design values of thermal loads were made according to aggregated indicators, based on the volume of buildings according to the invoice.

Estimated heat consumption for heating the i-th industrial premises, kW, is determined by the formula:

, (1)

where: - coefficient of accounting for the area of construction of the enterprise:

(2)

where - specific heating characteristic of the building, W / (m3.K);

— volume of the building, m3;

- design air temperature in the working area, ;

- the design temperature of the outside air for calculating the heating load, for the city of Bryansk is -24.

The calculation of the estimated heat consumption for heating for the premises of the enterprise was carried out according to the specific heating load (Table 1).

Table 1 Heat consumption for heating for all premises of the enterprise

| No. p / p | Object name | Building volume, V, m3 | Specific heating characteristic q0, W/m3K | Coefficient e | Heat consumption for heating , kW |

| 1 | Canteen | 9894 | 0,33 | 1,07 | 146,58 |

| 2 | Malyarka Research Institute | 888 | 0,66 | 1,07 | 26,46 |

| 3 | NII TEN | 13608 | 0,33 | 1,07 | 201,81 |

| 4 | El. engines | 7123 | 0,4 | 1,07 | 128,043 |

| 5 | model plot | 105576 | 0,4 | 1,07 | 1897,8 |

| 6 | Painting department | 15090 | 0,64 | 1,07 | 434,01 |

| 7 | Galvanic department | 21208 | 0,64 | 1,07 | 609,98 |

| 8 | harvesting area | 28196 | 0,47 | 1,07 | 595,55 |

| 9 | thermal section | 13075 | 0,47 | 1,07 | 276,17 |

| 10 | Compressor | 3861 | 0,50 | 1,07 | 86,76 |

| 11 | Forced ventilation | 60000 | 0,50 | 1,07 | 1348,2 |

| 12 | HR department extension | 100 | 0,43 | 1,07 | 1,93 |

| 13 | Forced ventilation | 240000 | 0,50 | 1,07 | 5392,8 |

| 14 | Packaging shop | 15552 | 0,50 | 1,07 | 349,45 |

| 15 | plant management | 3672 | 0,43 | 1,07 | 70,96 |

| 16 | Class | 180 | 0,43 | 1,07 | 3,48 |

| 17 | Technical department | 200 | 0,43 | 1,07 | 3,86 |

| 18 | Forced ventilation | 30000 | 0,50 | 1,07 | 674,1 |

| 19 | Sharpening section | 2000 | 0,50 | 1,07 | 44,94 |

| 20 | Garage - Lada and PCh | 1089 | 0,70 | 1,07 | 34,26 |

| 21 | Liteyka /L.M.K./ | 90201 | 0,29 | 1,07 | 1175,55 |

| 22 | Research institute garage | 4608 | 0,65 | 1,07 | 134,60 |

| 23 | pump house | 2625 | 0,50 | 1,07 | 58,98 |

| 24 | research institute | 44380 | 0,35 | 1,07 | 698,053 |

| 25 | West - Lada | 360 | 0,60 | 1,07 | 9,707 |

| 26 | PE "Kutepov" | 538,5 | 0,69 | 1,07 | 16,69 |

| 27 | Leskhozmash | 43154 | 0,34 | 1,07 | 659,37 |

| 28 | JSC K.P.D. build | 3700 | 0,47 | 1,07 | 78,15 |

TOTAL FOR THE PLANT:

Estimated heat consumption for heating CJSC "Termotron-Zavod" is:

The total heat generation for the entire enterprise is:

Estimated heat losses for the plant are determined as the sum of the estimated heat consumption for heating the entire enterprise and total heat emissions, and are:

Calculation of annual heat consumption for heating

Since CJSC "Termotron-zavod" worked in 1 shift and with days off, the annual heat consumption for heating is determined by the formula:

(3)

where: - average heat consumption of standby heating for the heating period, kW (standby heating provides the air temperature in the room);

, - the number of working and non-working hours for the heating period, respectively. The number of working hours is determined by multiplying the duration of the heating period by the coefficient for taking into account the number of working shifts per day and the number of working days per week.

The company works in one shift with days off.

(4)

Then

(5)

where: - average heat consumption for heating during the heating period, determined by the formula:

. (6)

Due to non-round-the-clock operation of the enterprise, the standby heating load is calculated for the average and design outdoor air temperatures, according to the formula:

; (7)

(8)

Then the annual heat consumption is determined by:

Graph of the adjusted heating load for the average and design outdoor temperatures:

; (9)

(10)

Determine the temperature of the beginning - end of the heating period

, (11)

Thus, we accept the temperature of the beginning of the end of the heating period = 8.

Calculation rules

To implement a heating system on an area of 10 square meters, the best option would be:

- use of 16 mm pipes with a length of 65 meters;

- the flow rates of the pump used in the system cannot be less than two liters per minute;

- the contours must have an equivalent length with a difference of no more than 20%;

- the optimal indicator of the distance between the pipes is 15 centimeters.

It should be taken into account that the difference between the temperature of the surface and the heating medium can be about 15 °C.

The best way when laying the pipe system is represented by a "snail". It is this installation option that contributes to the most even distribution of heat over the entire surface and minimizes hydraulic losses, which is due to smooth turns. When laying pipes in the area of external walls, the optimal step is ten centimeters. To perform high-quality and competent fastening, it is advisable to carry out preliminary marking.

Table of heat consumption of various parts of the building

How to choose a circulation pump

You can’t call a cozy home if it’s cold in it

And it doesn’t matter what kind of furniture, decoration or appearance in general is in the house. Everything starts with heat, and it is impossible without the creation of a heating system.

It is not enough to buy a "fancy" heating unit and modern expensive radiators - first you need to think over and plan in detail a system that will maintain the optimum temperature in the room

And it doesn't matter whether this refers to a house where people constantly live, or whether it is a large country house, a small cottage. Without heat, there will be no living space and it will not be comfortable to be in it.

To achieve a good result, you need to understand what and how to do, what are the nuances in the heating system, and how they will affect the quality of heating.

When installing an individual heating system, it is necessary to provide for all possible details of its operation. It should look like a single balanced organism that requires a minimum of human intervention. There are no small details here - the parameter of each device is important. This may be the power of the boiler or the diameter and type of pipeline, the type and connection diagram of heating devices.

Today, no modern heating system can do without a circulation pump.

Two parameters for choosing this device:

- Q is the coolant flow rate for 60 minutes, expressed in cubic meters.

- H is an indicator of pressure, which is expressed in meters.

Many technical articles and regulatory documents, as well as instrument manufacturers, use the designation Q.

Easy Ways to Calculate Heat Load

Any calculation of the heat load is needed to optimize the parameters of the heating system or improve the thermal insulation characteristics of the house. After its implementation, certain methods of regulating the heating load of heating are selected. Consider non-labor-intensive methods for calculating this parameter of the heating system.

The dependence of heating power on the area

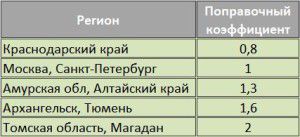

Table of correction factors for various climatic zones of Russia

For a house with standard room sizes, ceiling heights and good thermal insulation, a known ratio of room area to required heat output can be applied. In this case, 1 kW of heat will be required per 10 m². To the result obtained, it is necessary to apply a correction factor depending on the climatic zone.

Let's assume that the house is located in the Moscow region. Its total area is 150 m². In this case, the hourly heat load on heating will be equal to:

The main disadvantage of this method is the large error. The calculation does not take into account changes in weather factors, as well as building features - heat transfer resistance of walls and windows. Therefore, it is not recommended to use it in practice.

Enlarged calculation of the thermal load of the building

The enlarged calculation of the heating load is characterized by more accurate results. Initially, it was used to pre-calculate this parameter when it was impossible to determine the exact characteristics of the building. The general formula for determining the heat load on heating is presented below:

Where q ° is the specific thermal characteristic of the structure. The values \u200b\u200bmust be taken from the corresponding table, and - the correction factor mentioned above, Vn - the external volume of the building, m³, Tvn and Tnro - the temperature values inside the house and on the street.

Table of specific thermal characteristics of buildings

Suppose that it is necessary to calculate the maximum hourly heating load in a house with an external volume of 480 m³ (area 160 m², two-story house). In this case, the thermal characteristic will be equal to 0.49 W / m³ * C. Correction factor a = 1 (for the Moscow region). The optimum temperature inside the dwelling (Tvn) should be + 22 ° С. The outside temperature will be -15°C. We use the formula to calculate the hourly heating load:

Compared to the previous calculation, the resulting value is less. However, it takes into account important factors - the temperature inside the room, on the street, the total volume of the building. Similar calculations can be made for each room. The method of calculating the heating load according to aggregated indicators makes it possible to determine the optimal power for each radiator in a particular room. For a more accurate calculation, you need to know the average temperature values \u200b\u200bfor a particular region.

This calculation method can be used to calculate the hourly heat load for heating. But the results obtained will not give the optimally accurate value of the heat loss of the building.

We consider the heat consumption by quadrature

For an approximate estimate of the heating load, the simplest thermal calculation is usually used: the area of \u200b\u200bthe building is taken according to the external measurement and multiplied by 100 W. Accordingly, the heat consumption of a country house of 100 m² will be 10,000 W or 10 kW. The result allows you to choose a boiler with a safety factor of 1.2–1.3, in this case, the power of the unit is assumed to be 12.5 kW.

We propose to perform more accurate calculations, taking into account the location of rooms, the number of windows and the building region. So, with a ceiling height of up to 3 m, it is recommended to use the following formula:

The calculation is carried out for each room separately, then the results are summarized and multiplied by the regional coefficient. Explanation of formula designations:

- Q is the desired load value, W;

- Spom - the square of the room, m²;

- q - indicator of specific thermal characteristics, related to the area of the room, W / m²;

- k is a coefficient that takes into account the climate in the area of residence.

In an approximate calculation for the total quadrature, the indicator q \u003d 100 W / m². This approach does not take into account the location of the rooms and the different number of light openings. The corridor inside the cottage will lose much less heat than the corner bedroom with windows of the same area. We propose to take the value of the specific thermal characteristic q as follows:

- for rooms with one outer wall and a window (or door) q = 100 W/m²;

- corner rooms with one light opening - 120 W / m²;

- the same, with two windows - 130 W / m².

How to choose the right q value is clearly shown on the building plan. For our example, the calculation looks like this:

Q \u003d (15.75 x 130 + 21 x 120 + 5 x 100 + 7 x 100 + 6 x 100 + 15.75 x 130 + 21 x 120) x 1 \u003d 10935 W ≈ 11 kW.

As you can see, the refined calculations gave a different result - in fact, 1 kW of thermal energy will be spent on heating a particular house of 100 m² more. The figure takes into account the heat consumption for heating outdoor air that enters the dwelling through openings and walls (infiltration).

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear of the heater, as well as significant energy consumption.

The required amount of heating medium is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

The calculation of the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio at which 1 kW of thermal energy is sufficient to efficiently heat 10 m2 of living space. This ratio is valid in the presence of ceilings, the height of which is not more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross section of the pipeline according to the formula - S = π × R2, where:

- S - cross section;

- π is a constant constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the value of the cross-sectional area of \u200b\u200bthe pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

It is possible to determine what capacity the expansion tank should have, having data on the coefficient of thermal expansion of the coolant. For water, this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank \u003d (V syst × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K is the expansion coefficient;

- D - the efficiency of the expansion tank (indicated in the technical documentation).

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first calculate their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the technical data sheet of the product. In the absence of such information, you can navigate according to the average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 \u003d 12 liters.

As you can see, the calculation of the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in the system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, the system is filled by about 90%, after which the performance is checked. Then bleed the accumulated air and continue filling.

During the operation of the heating system, a natural decrease in the level of the coolant occurs as a result of convection processes. In this case, there is a loss of power and productivity of the boiler. This implies the need for a reserve tank with a working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it.