- The principle of operation of wind generators

- Wind generator for the home is no longer a rarity

- Principle of operation

- Types of wind turbines and which one is better for a private house

- Video review

- Which setting to choose?

- Additional components

- Spare parts and accessories for wind turbines

- Calculation of wind loads

- Look at the beautiful ideas implemented in Alprom

- Installation Tips

- Wind turbine payback calculation

- What determines the efficiency of a wind turbine?

- wind load

- Method of calculation

- Description of the advertising structure

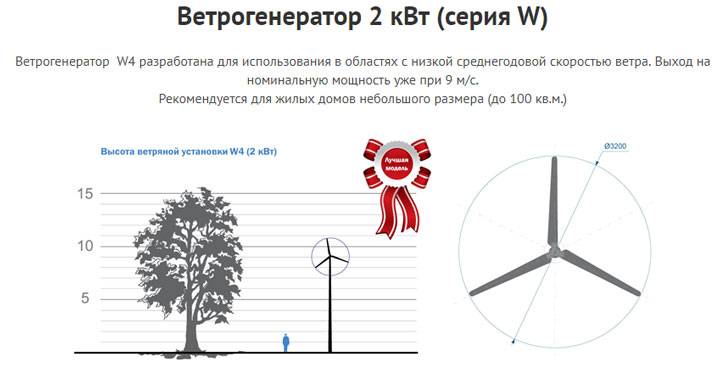

- Calculation and selection of a wind generator

- A little about the cost

- General recommendations

- Renovated wind turbines - what is it?

- An example of calculating the blades from the 160th pipe for this generator

- Do-it-yourself principles for making blades for a wind generator

- Materials and tools

- Drawings and calculations

- Production from plastic pipes

- Making blades from billets of aluminum

- fiberglass screw

- How to make a blade out of wood?

- Design value of wind load

- Frequently asked questions (FAQ)

- Payback and efficiency

The principle of operation of wind generators

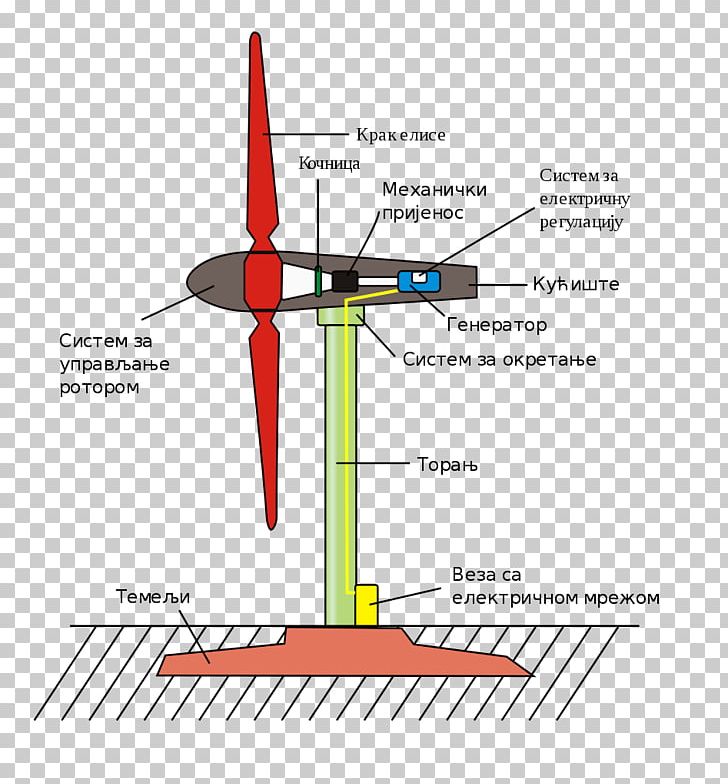

In homemade or branded wind devices with a vertical or horizontal axis of rotation, the blades begin to move as a result of the force of the wind. The main elements of the equipment make the rotor assembly rotate by means of a special drive unit.The presence of a stator winding contributes to the conversion of mechanical energy into electrical current. Axial propellers have aerodynamic features, as a result of which they provide fast scrolling of the turbine of the unit.

Then, in rotary generators, the rotational force is converted into electricity, which is collected in the battery. In fact, the stronger the air flow, the faster the blades of the unit scroll, which contributes to the generation of energy. Since the operation of the generator equipment is based on the maximum use of an alternative source, one part of the blades has a more rounded shape. The second one is flat. When the air flow passes through the rounded part, a vacuum section is formed, this contributes to the suction of the blade and leads it to the side.

This leads to the formation of energy, the impact of which leads to the spinning of the blades with a small wind.

When scrolling, the axis of the screws rotates, which are connected to the rotary mechanism. This device has twelve magnetic elements that scroll inside. This leads to the formation of an alternating electric current with a frequency, as in household outlets. The resulting energy can not only be generated, but also transmitted over distances, but it cannot be accumulated.

To collect it, it will be necessary to convert it to direct current, this is the purpose of the electrical circuit located inside the turbine. To obtain a large amount of electricity, industrial equipment is manufactured; wind parks usually include dozens of such installations.

The principle of operation of the wind generator makes it possible to use the unit in the following versions:

- for autonomous operation;

- with solar panels;

- in parallel with the backup battery;

- together with a gasoline or diesel generator set.

When the air flow is moving at a speed of about 45 km / h, the power generation of the turbine is approximately 400 watts. This is enough to illuminate the suburban suburban area. If necessary, you can implement the accumulation of electricity in the battery.

To charge the battery, special equipment is used. With a decrease in the amount of subcharge, the speed of rotation of the blades will begin to fall. If the battery is completely discharged, the elements of the generator equipment will scroll again. This principle makes it possible to maintain the charging of the device at a specific level. With a higher air flow rate, the unit's turbine will be able to produce more energy.

The user Darkhan Dogalakov, using the example of the SEAH 400-W model, spoke about the principle of operation of wind equipment.

Wind generator for the home is no longer a rarity

Wind power plants have long been used on an industrial scale. But, the complexity of the design, as well as the complexity of its installation, did not make it possible to use this equipment in private homes, such as solar panels.

However, now, with the development of technology and the increase in demand for "green energy", the situation has changed. Manufacturers have launched the production of small-sized installations for the private sector.

Principle of operation

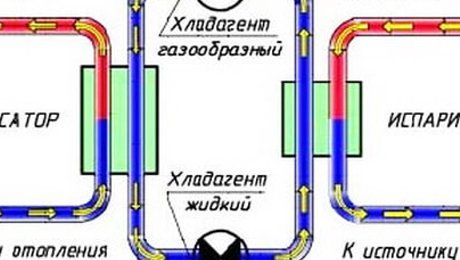

The wind rotates the rotor blades mounted on the generator shaft. As a result of rotation in the windings, an alternating current is generated. To increase the number of revolutions, and, accordingly, the amount of generated energy, a reduction gear (transmission) can be used. It can also block the rotation of the blades completely, if the need arises.

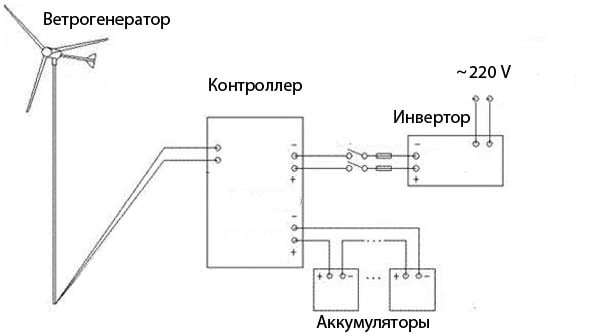

The resulting alternating current is converted to direct 220 W using an inverter. Then it goes to the consumer or, through the charge controller, to the batteries for accumulation.

A complete diagram of the operation of the installation from energy generation to its consumption.

Types of wind turbines and which one is better for a private house

At the moment there are two types of this design:

- With horizontal rotor.

- With vertical rotor.

The first type with horizontal rotor. This mechanism is considered the most effective. The efficiency is about 50%. The disadvantage is the need for a minimum wind speed of 3 m per second, the design creates a lot of noise.

For maximum efficiency, a high mast is required, which, in turn, complicates installation and further maintenance.

The second type with vertical. A wind generator with a vertical rotor has an efficiency of no more than 20%, while a wind speed of only 1-2 m per second is sufficient. At the same time, it works much quieter, the level of emitted noise is not more than 30 dB, and without vibration. Does not require a large space to work, while not losing efficiency.

Installation does not require a tall mast. Equipment can be mounted on the roof of the house even with your own hands.

The absence of an anemometer and a rotary mechanism, which is not needed at all with this design, makes this type of wind generator cheaper compared to the first option.

Video review

Which setting to choose?

Before answering this question, you need to understand your requirement, financial capabilities and operational priorities.

If you want to get the most power and are willing to spend money on periodic generator maintenance, choose the first option. By investing in a high mast once, and paying for bearings or oil replacement once every 5-10 years, you will get complete energy independence, and even if you live in Ukraine or EU countries, you will be able to sell excess electricity.

The high noise level of this station requires choosing a place as far as possible from residential buildings. This point also needs to be taken into account, because infrasound will not go unnoticed by your neighbors.

To obtain an equivalent output in relation to the first option, it will be necessary to supply 3 wind turbines of this type. However, in terms of price, approximately the same amount is obtained (subject to self-assembly).

Video review of an expert in the field of alternative energy sources

Additional components

- The controller, which occupies a place in the electrical circuit behind the generator, is necessary to control the blades and charge the battery by converting the generated alternating current into direct current.

- The battery stores the charge for use in calm weather. In addition, it stabilizes the output voltage of the generator, so that even with strong gusts of wind, there are no power outages.

- Heading sensors and an anemoscope collect data on wind direction and speed.

- ATS automatically switches between power sources with a frequency of 0.5 seconds. The automatic power switch allows you to combine the windmill with the public power grid, diesel generator, etc.

Important: the network cannot operate simultaneously from several power sources. inverters

As you know, most household devices do not use direct current to work, so there is an inverter in the chain between the battery and appliances that performs the reverse operation, i.e. converting direct current into alternating voltage 220v, necessary for the operation of devices

Inverters. As you know, most household devices do not use direct current to work, so there is an inverter in the chain between the battery and appliances that performs the reverse operation, i.e. converting direct current into alternating voltage 220v, necessary for the operation of devices.

All of the above transformations “take” a certain part from the received energy - up to 20 percent.

Spare parts and accessories for wind turbines

The main basic set of equipment, without which the operation of wind power generators is impossible, includes:

- electric generator (motor);

- wind turbine, blades, rotor;

- fastenings;

- rotary mechanism;

- wind sensor;

- mast;

- cable.

Batteries, non-grid and grid inverters, controller, azimuth drive system (tail), other additional equipment are selected individually for each installation.

It is required to replace spare parts of the wind turbine during maintenance and, in extreme cases, repair

Basic components and spare parts are best ordered directly from the manufacturer. You can contact companies supplying from Germany and other European countries renovated (used) wind turbines and accessories suitable for them for repair work.

It is required to have access to the main components for the repair of the installation

When placing an order for spare parts, you should provide information about the manufacturer of the generator, indicate its model and capacity. A detailed description of the part is required (it can be in the form of a photograph), indicating its functional and technical characteristics.

Calculation of wind loads

So, you coordinated for a long time, made and finally mounted your best outdoor advertising.

The beauty! Everyone is happy. But chu ... after the first strong wind, an angry client calls you with shocking news - advertising has fallen!

The advertiser's nightmare came true... What happened?

And the following happened - when designing outdoor advertising, the calculation of the wind load on outdoor advertising was ignored or performed incorrectly: on the material and on the fasteners.

How to avoid this, how to protect yourself from such a deplorable outcome of your work?

Let's remember the simple formula for calculating the wind load, which is measured in kg / sq.m.:

Pw = k*q

Deciphering tricky letters

Pw is the wind pressure normal to the receiving surface. This pressure is considered positive.

k is the aerodynamic coefficient depending on the shape and position of the subject to the wind

object.

q - wind speed head (kg / sq.m), corresponding to the highest wind speed for a given place, taking into account special gusts.

The value of q depending on the wind speed is determined as follows:

q = 7 / g * sq. V / 2

7 - air weight (1.23 kg / m3) at Patm. = 760 mm Hg. and tatm.= 15 °С

g - acceleration of gravity (9.81 m / sq. sec)

V is the highest wind speed (m / s) at a given height h, i.e.

Height h above ground level, m

Wind speed V, km/h m/s

Velocity head q, kg/sq.m

| Height h above ground level, m | Wind speed V, km/h m/s | Velocity head q, kg/sq.m |

| 0 — 8 | 103,7 28,8 | 51 |

| 8 — 20 | 128,9 35,8 | 80 |

q = sq. V / 16

Vertically installed canvas, fixed in a frame or stretched on cables

| Construction - b-width, d-height | Size ratio | Area, S | Aerodynamic coefficient, k |

| Vertically installed canvas, fixed in a frame or stretched on cables | d/b < 5 | b*d | 1,2 |

| d/b >= 5 | b*d | 1,6 |

So it turns out everything is quite simple.

Do you want to learn more about the calculation of wind loads and get advice from our experts?

Look at the beautiful ideas implemented in Alprom

- All

- Banners

- Volumetric letters

- High-altitude work

- light boxes

- roof advertising

- Large format printing

- LED advertising

Volumetric letters for Lexusadmin2017-02-26T06:44:37+00:00

Gallery

Volumetric letters for Lexus

Volumetric letters, LED advertising

Light box 11 meters long made of composite with LEDs in Samara from Alpromadmin2017-02-26T06:51:17+00:00

Light box 11 meters long made of composite with LEDs in Samara from Alprom

Gallery

Light box 11 meters long made of composite with LEDs in Samara from Alprom

Illuminated boxes, LED advertising

Light boxes Trial Sport in Togliattiadmin2017-02-26T06:56:06+00:00

Light boxes Trial Sport in Togliatti

Gallery

Light boxes Trial Sport in Togliatti

Illuminated boxes, LED advertising

Volumetric illuminated letters NOBEL AUTOMOTIVE in Togliattiadmin2017-02-26T07:04:28+00:00

Volumetric illuminated letters NOBEL AUTOMOTIVE in Tolyatti

Gallery

Volumetric illuminated letters NOBEL AUTOMOTIVE in Tolyatti

Volumetric letters, LED advertising

Entrance group Inglot in Togliattiadmin2017-02-26T07:19:43+00:00

Entrance group Inglot in Tolyatti

Gallery

Entrance group Inglot in Tolyatti

Illuminated boxes, LED advertising

Volumetric letters OKAY in Tolyattiadmin2017-02-26T07:27:31+00:00

Volumetric letters OKAY in Tolyatti

Gallery

Volumetric letters OKAY in Tolyatti

Volumetric letters, High-rise works, LED advertising

3D foam letters Botek Wellness in Tolyattiadmin2017-02-26T07:40:55+00:00

Volume letters from polyfoam Botek Wellness in Tolyatti

Gallery

Volume letters from polyfoam Botek Wellness in Togliatti

Volumetric letters, LED advertising

Roof advertising construction of Lada Arena in Togliattiadmin2017-02-26T08:19:20+00:00

Roof advertising construction of Lada Arena in Tolyatti

Gallery

Roof advertising construction of Lada Arena in Tolyatti

Volumetric letters, Roof advertising, LED advertising

Installation Tips

Probably, everyone understands that a wind generator should be installed in those places where the maximum wind force is. These are steppes, coastal zone, other open spaces that are remote from buildings. The wind turbine must not be placed next to trees. You can’t even put it near small trees, because they will grow over time.

Wind generator with Darrieus rotor

As for sharing with the power grid or just a wind generator, the choice here is yours. In any case, the purchase should be economically justified, and not just pay tribute to the fashion trend.

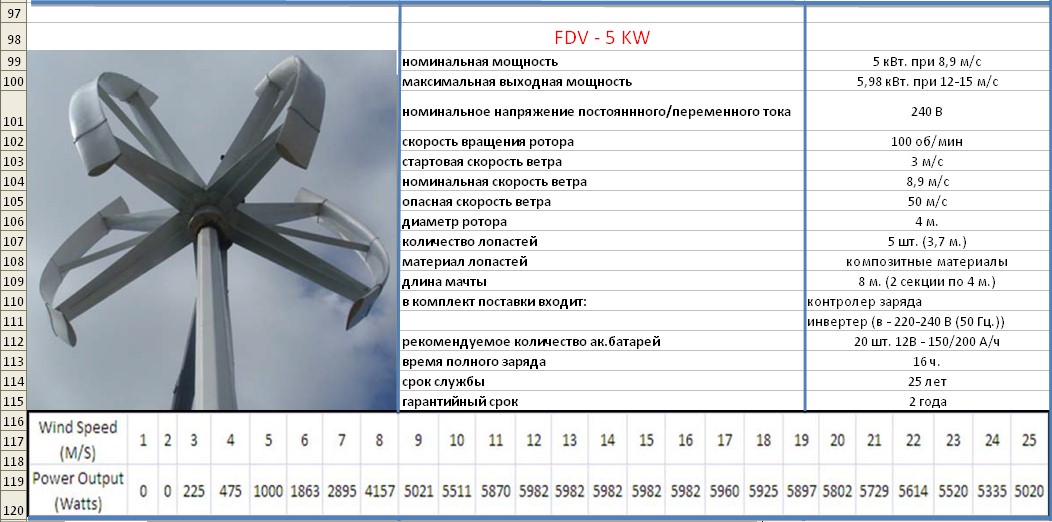

Wind turbine payback calculation

Having invested hundreds of thousands of rubles in the purchase of the device, the new owner has the right to count on its obvious benefits and the payback of the windmill. Let's try to calculate the price of a kilowatt of electricity on a standard model of a 4-5 kW generator.

With a wind speed of 4-5 m / s, the device will give about 350 kW per month, or 4200 kW per year. The service life of the generator is about 25 years, the cost of most models of devices is within 280,000 rubles.

Divide the cost by the product of annual production and service life:

280,000 / 4200*25 = 2.666 rubles

Thus, the cost of a kilowatt of energy of a payback wind generator will be just over 2.5 rubles. Compared to the current price level, there is a benefit, but it is not as great as we would like when using alternative energy sources.

The above calculations give a different result if the wind speed is about 7-8 m/s. A wind generator with a capacity of 6-7 kW will produce about 780 kW per month or 9000 kW per year.

With the cost of such windmills about 310,000, we get the following result:

310,000 / 9000 * 25 = 1.3722 rubles This cost is an obvious benefit, especially for energy-intensive facilities.

What determines the efficiency of a wind turbine?

As already mentioned, the efficiency of a wind generator is derived from its technical condition, the type of turbine, and the design features of this model. From the school physics course, it is known that efficiency is the ratio of useful work to total work. Or the ratio of the energy expended on the performance of work to the energy received as a result.

In this regard, an interesting point arises - the wind energy used is obtained completely free of charge, no effort has been made on the part of the user. This makes efficiency a purely theoretical indicator that determines the purely constructive qualities of the device, while for owners, operational characteristics are more important.

That is, a situation arises in which efficiency is not so important, all attention is given to purely practical tasks.

However, with changes in operating parameters in one direction or another, the efficiency automatically changes, which indicates its interconnection with the general state of the device.

wind load

Method of calculation

Design Description

Geometric characteristics of elements

Determining the wind load

Wind at an angle of 90 degrees to the shield

Wind at an angle of 45 o to the shield 5 Calculation of the rack

Part 2. Calculation for sustainability

Method of calculation

This project is typical for wind regions from the 3rd to the 5th.

1. Wind area - III, IV, V

2. Type of terrain when determining the wind load - A

3. Responsibility level - 3, for which the load-reducing coefficient γp is taken equal to 0.8-0 95 (in this project γp = 09)

4. The service life of the structure is 10 years

5 Estimated outdoor temperature t ≥ -w°c, as the average temperature of the coldest five-day period according to SNiP 23-01-99 "Construction climatology", which corresponds to the climatic region of construction II4, II5

6. Humidity zone - “wet” SNiP 23-01-99 (Fig. 2)

7. The degree of aggressive impact of the environment on metal structures is medium aggressive, according to SNiP 2.0311-85 "Protection of building structures from corrosion", table. 24, for gas group "B" in a humid environment

Description of the advertising structure

Figure 1 shows a diagram of a collapsible double-sided advertising panel with a stand height from 2 to 5 m to the bottom of the panel. The dimensions of the advertising panel are 6180x3350x 410mm. rack axis, and with an offset of 3/4 (shown in Figure 1). The rack is fixed with 8 foundation anchors on a deep foundation All variable parameters depending on the wind area of \u200b\u200bthe installation and the height of the rack are given in Table 1

Advertising design drawing. Rice. one

The main geometric dimensions and fasteners of the advertising structure, depending on the wind area. Table 1

| Rack height, m | Structural elements | wind region | ||

| III | IV | V | ||

| 2 | Rack | Ф325х8 (С245) | Ф325х8 (С245) | Ф325х8 (С245) |

| Foundation | 2.5×1.9×0.5 m | 2.8×2.1×0.5m | 3.2×2.1×0.5m | |

| Ankera | M 30 | M 30 | M 30 | |

| Cross beams | Gnshv.236×70 | Gnshv.236×70 | Gnshv.236×70 | |

| headroom | 160x160x8(С245) | 160x160x8(С245) | 160x160x8(С245) | |

| 2,5 | Rack | Ф325х8 (С245) | Ф325х8 (С245) | Ф325х8 (С245) |

| Foundation | 2.7×1.9×0.5m | 3×2.1×0.5m | 3.6×2.1×0.5m | |

| Ankera | M 30 | M 30 | M 30 | |

| Cross beams | Gnshv.236×70 | Gnshv.236×70 | 2 shafts.236×70 | |

| headroom | 160x160x8(С245) | 160x160x8(С245) | 160x160x8(С345) | |

| 3 | Rack | Ф325х8 (С245) | Ф325х8 (С245) | Ф325х10 (С245) |

| Foundation | 3×1.9×0.5 m | 3.6×2.1×0.5m | 4×2.1×0.5m | |

| Ankera | M 30 | M 30 | M36 | |

| Cross beams | Gnshv.236×70 | Gnshv.236×70 | 2 mains.width 236×70 | |

| headroom | 160x160x8(С245) | 160x160x8(С245) | 160x160x8(С345) | |

| 3,5 | Rack | Ф325х8 (С245) | Ф325х8 (С245) | Ф325х10 (С245) |

| Foundation | 3.4×1.9×0.5m | 3.8×2.1×0.5m | 4.2×2.1×0.5m | |

| Ankera | M 30 | M 30 | M36 | |

| Cross beams | Gnshv.236×70 | M.W.236×70 | 2 shafts.236×70 | |

| headroom | 160x160x8(С245) | 160x160x8(С245) | 160x160x8(С345) | |

| 4 | Rack | Ф325х8 (С245) | Ф325х10 (С245) | Ф325х10 (С345) |

| Foundation | 3.6×1.9×05m | 4×2.1×0.5m | 4.4×2.1×0.5m | |

| Ankera | M 30 | M36 | M36 | |

| Cross beams | Gnshv.236×70 | M.W.236×70 | 2 shafts.236×70 | |

| headroom | 160x160x8(С245) | 160x160x8(С245) | 160x160x8(С345) | |

| 4,5 | Rack | Ф325х8 (С245) | Ф325х10 (С345) | Ф325х10 (С345) |

| Foundation | 3.8×1.9×0.5m | 4.2×2.1×0.5m | 4.6×2.1×0.5m | |

| Ankera | M 30 | M36 | M36 | |

| Cross beams | Gnshv.236×70 | 2 shafts.236×70 | 2 shafts.236×70 | |

| headroom | 160x160x8(С245) | 160x160x8(С245) | 160x160x8(С345) | |

| 5 | Rack | Ф325х10 (С245) | Ф325х10 (С345) | — |

| Foundation | 4×1.9×0.5 m | 4.4x21x0.5m | — | |

| Ankera | M36 | M36 | — | |

| Cross beams | Gnshv.236×70 | 2 shafts.236×70 | — | |

| headroom | 160x160x8(С245) | 160x160x8(С345) | — |

up

Calculation and selection of a wind generator

What you need to pay attention to when choosing a wind turbine. To begin with, understand that foreign expensive models are not necessarily the best solution.

Here you need to proceed from your needs in generating electricity. So, calculate how much electricity you will spend.

Wind generator with helicoid rotor

The power of the wind generator directly depends on the diameter of the circle that the blades form. Approximately, you can calculate the power using the following formula:

P = D^2 * R^3 / 7000, where

D is the diameter of the blades;

R is the wind speed.

If the diameter is 1.5 meters, and the speed in your area is 5 meters per second, then the power will be approximately 0.04 kilowatts. As you can see, power can be increased in two ways: by increasing the diameter and wind speed. And the last parameter does not depend on us.

When buying, pay attention to the capacity of the batteries.Calm can be almost everywhere, except for coastal areas

And during such periods, your electrical appliances will take electricity from batteries. Their capacity is limited. Therefore, it is better to have an additional backup power supply.

How much electricity does a typical family need? In an ordinary apartment, we run about 360 kWh per month. A wind generator with a capacity of 5 kilowatts will generate this amount even at low wind speeds, which usually happen in central Russia. But if the energy consumption is high (for example, there is an electric heater, an electric boiler, etc.), then a wind generator with a capacity of 5 kilowatts is no longer enough. Unless it is installed near the sea or a large body of water.

A little about the cost

As you can see, the price range is very large. AT average installation per 1 kW will cost from 25,000 to 300,000 rubles. More expensive models have a number of significant advantages, from higher efficiency to various additional features.

General recommendations

Obviously, in order to select the most optimal diameter of the wind turbine propeller, it is necessary to know the average wind speed at the site of the planned installation. The amount of electricity produced by a windmill increases in cubic ratio with the increase in wind speed. For example, if the wind speed increases by 2 times, then the kinetic energy generated by the rotor will increase by 8 times. Therefore, it can be concluded that wind speed is the most important factor affecting the power of the installation as a whole.

To select the installation site of a wind-generating electrical installation, areas with a minimum number of wind barriers (without large trees and buildings) at a distance of at least 25-30 meters from a residential building are most suitable (do not forget that wind turbines hum very loudly during operation). The height of the center of the wind turbine rotor should be at least 3-5 meters higher than the nearest buildings. There should be no trees or buildings on the line of the windy passage. Hilltops or mountain ranges with open landscape are most suitable for wind turbine location.

If your country house is not planned to be connected to a common network, then you should consider the option of combined systems:

- WPP + Solar panels

- WPP + Diesel

Combined options will help solve problems in regions where the wind is changeable or depends on the season, and this option is also relevant for solar panels.

Renovated wind turbines - what is it?

Wind power equipment can be considered one of the most reliable, if not the most reliable, in the energy industry. The reason for this is not only the high technology used in its manufacture, but also the relatively small loads to which it is subjected. Therefore, wind turbines regularly serve for many years, often exceeding 20 years. Since each wind park and each wind generator are tied to a specific piece of land, it is advisable to replace the wind farm or wind generator with more powerful ones when the payback period of a particular project is reached, that is, when the investment invested in it is returned and the planned profit is received.Existing wind turbines are usually in good condition, and it is advisable to sell them as “used wind turbines” or “used wind turbines”. The world market for such equipment in the world is very large. The demand for such equipment is also high. The reason is the large load of companies producing wind energy equipment. As a rule, only a small part of such “used” equipment has already been dismantled and is in stock.

"Used" wind turbines undergo pre-sale preparation according to special work regulations and become the so-called. "refurbished". Usually, during renovation, the following work is carried out: replacement of bearings in the gearbox, regardless of their wear, troubleshooting and repair of gears of the gearbox, generator, frame, blades, painting. After the renovation work, the wind turbines are sent to their new owner. As a rule, after the sale of such equipment, it is covered by a guarantee for a period of one year.

An example of calculating the blades from the 160th pipe for this generator

speed

I got the best result from the 160th pipe with a diameter of 2.2m and speed Z3.4 - 6 blades, but it is better not to make such a screw diameter from a 160mm pipe, too thin and flimsy blades will turn out. At 3 m / s, the nominal speed of the screw was 84 rpm and the power of the screw was 25 watts, that is, it is approximately suitable. It is necessary, of course, with a margin for the efficiency of the generator, but the 160th pipe is already thin and most likely already at 7 m / s a flutter will be observed. But for example it will go

Now, if you change the wind speed in the table, you can see that the power of the propeller and its speed will approximately coincide with the parameters of the propeller, which is what we need, since it is important that the propeller is not overloaded and not underloaded - otherwise it will go haywire in a big wind.

>

So with a different wind, I received such propeller data. Below in the screenshot are the propeller data at 3m/s, the maximum propeller power (KIEV) at speed Z3.4. In this case, the revolutions and power approximately coincide with the generator power at these revolutions

Generator speed 100 rpm - 2 Amperes 30 watts

>

Next, we enter the speed of 5 m / s, as you can see in the screenshot, 141 rpm of the propeller and the power on the propeller shaft is 124 watts, which also approximately coincides with the generator. Generator speed 150 rpm - 8 Amperes 120 watts

At 7 m / s, the propeller starts to bypass the generator in terms of power and, naturally, underloaded, it picks up high speed, so I raised the speed to Z4, it also turned out to be an approximate match in terms of power and speed with the generator. Generator speed 200 rpm -14 Amperes 270 watts

At 10 m / s, the propeller became much more powerful than the generator at nominal speed, as slow-revving and cannot spin the generator faster. So with Z4, the propeller power is 991 watts, and the revolutions are only 332 rpm. Generator speed 300 rpm - 26 Amperes 450 watts. But an underloaded generator allows the propeller to spin up to speed Z5 and higher, while KIEV screw falls, and hence the power, but at the same time the speed increases, so it turned out that the screw will spin the generator a little more, but at the same time it will lose power and balance will come somewhere.In this case, the data approximately coincides with the generator, but the propeller clearly overtakes the generator in terms of power, so with this wind it’s time to make protection by moving the propeller out of the wind.

So we fitted a PVC pipe screw with a diameter of 160mm under the generator. I must say right away that it was the six-bladed propeller of such speed that turned out to be the most suitable. And so you can consider a screw of any diameter and number of blades. It's just that a three-bladed propeller with a diameter of 2.3 m turned out to be too fast for this generator and it would not gain momentum for its maximum KIEV, since the generator would immediately begin to slow it down.

Therefore, by increasing the number of blades, I lowered the speed of the propeller and kept its power. So the propeller turned out to be suitable for the generator, but the 160th pipe introduced its own limitations, in particular, the diameter is too large and in the wind from 7m / s, the propeller with flimsy and thin blades will most likely get a flutter and will rumble like a helicopter taking off. Yes, and with this propeller we remove from the generator, roughly speaking, with a wind of 10 m / s, only 600-700 watts, but it can be twice as much if we increase the speed of the propeller and slightly increase its diameter.

Below is a screenshot from the Blade Geometry tab. These are the dimensions for cutting the blade from the pipe

Do-it-yourself principles for making blades for a wind generator

Often, the main difficulty is determining the optimal dimensions, since its performance depends on the length and shape of the wind turbine blades.

Materials and tools

The following materials form the basis:

- plywood or wood in another form;

- fiberglass sheets;

- rolled aluminum;

- PVC pipes, components for plastic pipelines.

DIY wind turbine blades

Choose one type of what is available in the form of residues after repair, for example. For their subsequent processing, you will need a marker or a pencil for drawing, a jigsaw, sandpaper, metal scissors, a hacksaw.

Drawings and calculations

If we are talking about low-power generators, the performance of which does not exceed 50 watts, a screw is made for them according to the table below, it is he who is able to provide high speeds.

Next, a low-speed three-blade propeller is calculated, which has a high starting rate of breakaway. This part will fully serve high-speed generators, whose performance reaches 100 watts. The screw functions in tandem with stepper motors, low-voltage low-power motors, car generators with weak magnets.

From the point of view of aerodynamics, the propeller drawing should look like this:

Production from plastic pipes

Sewer PVC pipes are considered the most convenient material; with a final screw diameter of up to 2 m, workpieces with a diameter of up to 160 mm are suitable. The material attracts with ease of processing, affordable cost, ubiquity and abundance of already developed drawings, diagrams

It is important to choose high-quality plastic to prevent cracking of the blades.

The most convenient product, which is a smooth gutter, it only needs to be cut in accordance with the drawing. The resource is not afraid of exposure to moisture and is undemanding in care, but can become brittle at sub-zero temperatures.

Making blades from billets of aluminum

Such screws are characterized by durability and reliability, they are resistant to external influences and are very durable.But keep in mind that they turn out to be heavier as a result, when compared with plastic ones, the wheel in this case is subjected to scrupulous balancing. Despite the fact that aluminum is considered quite malleable, working with metal requires the presence of convenient tools and minimal skills in handling them.

The form of material supply can complicate the process, since common aluminum sheet turns into blades only after giving the blanks a characteristic profile; for this purpose, a special template must first be created. Many novice designers first bend the metal along the mandrel, after which they move on to marking and cutting blanks.

Blades made of billet aluminum

Aluminum blades show high resistance to loads, do not react to atmospheric phenomena and temperature changes.

fiberglass screw

It is preferred by experts, as the material is capricious and difficult to process. Sequencing:

- cut out a wooden template, rub it with mastic or wax - the coating should repel glue;

- first, one half of the workpiece is made - the template is smeared with a layer of epoxy, fiberglass is laid on top. The procedure is promptly repeated until the first layer has had time to dry. Thus, the workpiece receives the required thickness;

- perform the second half in a similar way;

- when the glue hardens, both halves can be connected with epoxy with careful grinding of the joints.

The end is equipped with a sleeve, through which the product is connected to the hub.

How to make a blade out of wood?

This is a difficult task due to the specific shape of the product, in addition, all the working elements of the screw should eventually turn out to be identical.The disadvantage of the solution also recognizes the need for subsequent protection of the workpiece from moisture, for this it is painted, impregnated with oil or drying oil.

Wood is not desirable as a material for a wind wheel, as it is prone to cracking, warping, and rotting. Due to the fact that it quickly gives and absorbs moisture, that is, it changes mass, the balance of the impeller is arbitrarily adjusted, this negatively affects the efficiency of the design.

Design value of wind load

The standard value of the wind load (1) is:

\({w_n} = {w_m} + {w_p} = 0.1 + 0.248 = {\rm{0.348}}\) kPa. (twenty)

The final calculated value of the wind load, by which the forces in the sections of the lightning rod will be determined, is based on the standard value, taking into account the reliability factor:

\(w = {w_n} \cdot {\gamma _f} = {\rm{0.348}} \cdot 1.4 = {\rm{0.487}}\) kPa. (21)

Frequently asked questions (FAQ)

What does the frequency parameter in formula (6) depend on?

the frequency parameter depends on the design scheme and the conditions for its fixing. For a bar with one end rigidly fixed and the other free (cantilever beam), the frequency parameter is 1.875 for the first mode of vibration and 4.694 for the second.

What do the coefficients \({10^6}\), \({10^{ - 8}}\) mean in formulas (7), (10)?

these coefficients bring all parameters to one unit of measure (kg, m, Pa, N, s).

Payback and efficiency

The cost of the wind generator itself is rather big. And in addition to it, you will still need to buy batteries, an inverter, a controller, a mast, wires, etc. Models of wind turbines with a capacity of 300 watts are now common.These are rather weak models that generate their 300 watt-hours in the event of a wind of 10-12 meters per second, and with a wind of 4-5 meters per second, 30-50 watt-hours are generated. Such installations are enough to provide LED lighting and power small electronics. You do not need to expect that from this wind generator you can provide a TV, microwave, refrigerator and full lighting. The cost of low-power wind turbines starts from 15-20 thousand rubles. The kit does not include batteries, inverter and mast. A complete set will cost at least 50 thousand rubles.

When you are going to provide electricity to a house and a small subsidiary plot, you will need a 3-5 kilowatt wind generator. The price of such a wind turbine lies in the range of 0.3-1 million rubles. The price includes the controller, mast, inverter, batteries.