- Enter the parameters for calculation in the online calculator

- Pipe Surface Area Calculation

- Calculation of the weight of a stainless pipe: sequence of actions and features

- What are pipes for?

- You can record and print your results

- Steel Pipe Weight Table: Usage Tips

- The simplest method for determining pipe weight

- How to calculate the volume of water in a pipeline

- Methods for calculating specific gravity

- Determination of the specific gravity of the pipe by the formulas

- How to calculate pipe weight

- Determination of the diameter of the pipe material

- Measurement of parameters in difficult conditions

- The nuances of measuring the diameter of pipes for a heating system

Enter the parameters for calculation in the online calculator

We suggest entering the parameters in order to calculate the volume in the online calculator.

Why is it necessary to pre-calculate the volume of liquid in the pipe with a calculator, only after that proceed with purchases? The answer is obvious - in order to determine how much coolant you need to purchase in order to fill the heating system at home

This is especially important for houses of periodic visits, which remain cold for a long time. The water inside such a heating system will inevitably freeze, breaking the conductive elements and radiators.

In addition, you need to consider the points that are listed in the list below.

- Expansion tank capacity.This parameter is always indicated in the passport for this product, but if this is not possible, you can simply fill the container with a certain number of liters of water, and then use this information.

- The capacity of the heating elements - heating radiators. Such data can also be obtained from the technical data sheet or instructions for one section. Then, using the design data, multiply the capacity of one section by their total number.

- The amount of liquid inside various units, as well as control and monitoring systems, for example, heat pumps, pressure gauges, and the like. However, this value will be small, not higher than the statistical error, so the data of the third point are usually ignored.

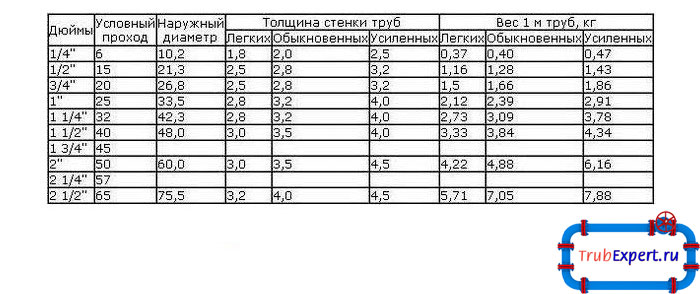

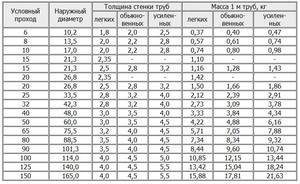

If the water supply or heating system is made of metal products, some of their features must be taken into account. So, the water and gas pipeline assortment according to GOST 3262-84 is produced in three series:

- light;

- average;

- heavy.

At the same time, the difference lies precisely in the thickness of the walls, which, if the external size is equal, indicates a decrease in the internal section for different designs.

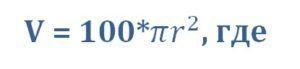

Therefore, when purchasing, you should pay attention to this particular indicator so that the internal passage is the same along the entire length of the water supply or heating. Calculation of the volume of liquid in the pipe using a calculator can be done using the following formula:

- V is the volume of a meter of pipe, cm3.

- 100 - length, cm.

- The number "pi", equal to 3.14.

- The radius of the inner channel, see here, is the cross-sectional area of the inner cavity.

When calculating, you must be guided not by the certificate data or the sign of the seller.It is advisable to carefully measure the size of the inner hole using a caliper, and when calculating, be guided by these data.

In addition to belonging to the same series, as mentioned above, it is necessary to take into account the possibility of using the source material at minus tolerances, which will naturally affect the size of the section in the direction of its increase. If it is possible to use the Internet when purchasing, you can use the built-in software calculator to calculate the volume of water in the pipe online. But at the same time, the initial data must be driven real. We strongly recommend that you read the instructions before using the calculator, in which case the calculations will be correct with a 100% guarantee.

Using them, other parameters of the system should also be calculated, including the weight of a running meter and so on. Specially designed tables have found wide application in performing such operations. But they are valid only for nominal sizes, they do not take into account any deviations. When determining the volume of water in a pipe with an online calculator, it is unlikely to make a mistake.

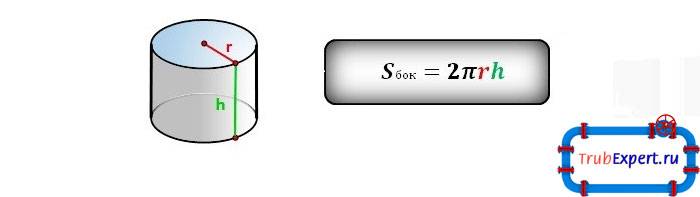

Pipe Surface Area Calculation

The pipe is a very long cylinder, and the surface area of the pipe is calculated as the area of the cylinder. For calculations, you will need a radius (internal or external - depends on which surface you need to calculate) and the length of the segment that you need.

The formula for calculating the side surface of the pipe

To find the lateral area of the cylinder, we multiply the radius and length, multiply the resulting value by two, and then by the number "Pi", we get the desired value. If desired, you can calculate the surface of one meter, it can then be multiplied by the desired length.

For example, let's calculate the outer surface of a piece of pipe 5 meters long, with a diameter of 12 cm. First, calculate the diameter: divide the diameter by 2, we get 6 cm. Now all values \u200b\u200bmust be reduced to one unit of measurement. Since the area is considered in square meters, we translate centimeters into meters. 6 cm = 0.06 m. Then we substitute everything into the formula: S = 2 * 3.14 * 0.06 * 5 = 1.884 m2. If you round up, you get 1.9 m2.

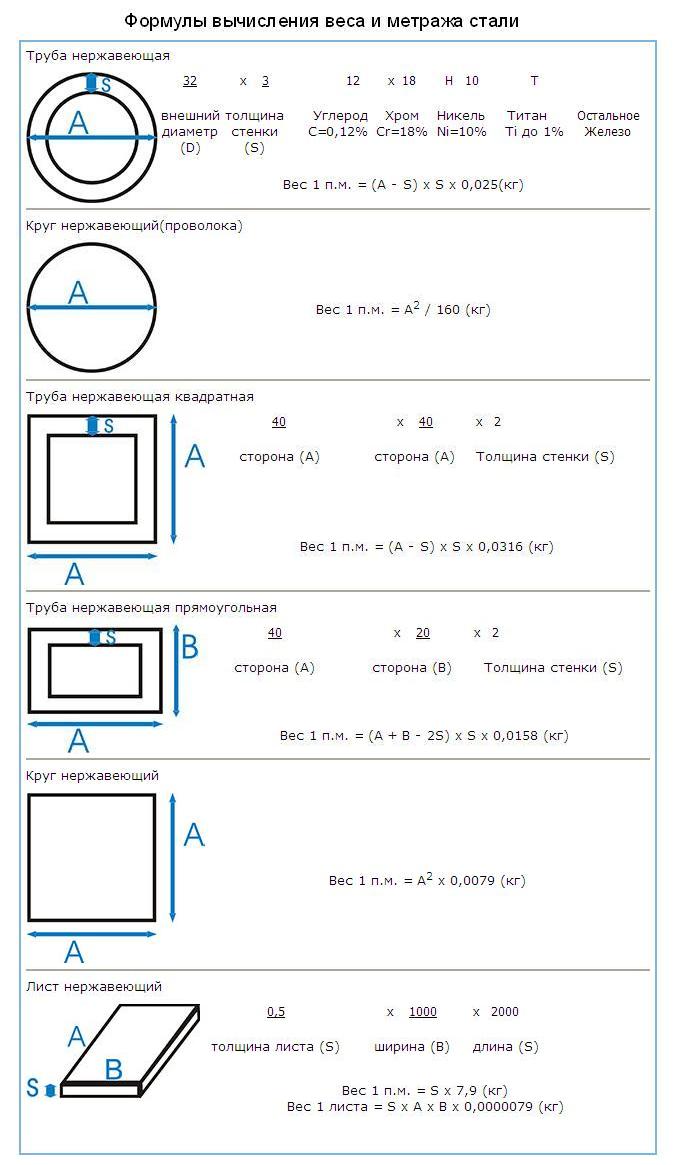

Calculation of the weight of a stainless pipe: sequence of actions and features

Pipes made of stainless steel differ from conventional steel products in that they are more resistant to adverse operating conditions. For example, they, unlike conventional steel pipes, have a high resistance to rusting.

How to calculate the mass of a stainless steel part? Such an operation is not very difficult. To determine the specific gravity, it is necessary to multiply parameters such as material density and volume. In turn, in order to calculate the volume of the product, you will need to multiply the surface area of \u200b\u200bthe part by the wall thickness.

Consider how to determine the weight of a stainless steel pipe 57x57x3 mm, using an example. The calculation in this case includes 3 stages. The first formula will look like this:

S = B x L x 4

Stainless steel pipes are distinguished by the fact that they are more resistant to adverse operating conditions.

S is the area;

B - width of 1 wall;

L is the length of the product;

4 - the number of walls.

The finished equation with substituted values looks like this:

S = 57 x 6 x 4 = 1.368 m²

Using this method, you can determine the mass of various standard sizes (for example, the weight of pipes 108, 120 or 150 mm). After calculating the area of the stainless part, you can proceed to the next step.The second step takes into account the determination of the volume of the pipe. To do this, as mentioned above, it is necessary to multiply the surface area and wall thickness:

V = S x t

V = 1.368 x 3 = 4.104 m³

To determine the specific gravity of a stainless steel pipe, it is necessary to multiply parameters such as material density and volume

And, finally, after calculating the volume of the product, you can find its specific gravity. To do this, you need to multiply the fixed density of steel, equal to 7850 m³, by the volume of the part. Consider the equation:

m = V x 7850

m = 4.104 x 7850 = 3.2 kg

To determine the mass of a pipe made of stainless steel, there is another, simpler method. It is suitable for round parts. To make the calculation, you will need to subtract the wall thickness from the outer diameter. Then the resulting difference is multiplied by the thickness and a fixed number, which is 0.025 kg.

What are pipes for?

A preliminary detailed calculation of pipes allows you to find out how much material you need to take for the correct arrangement of the selected system and helps to avoid unnecessary spending on the purchase, transportation and subsequent installation of parts.

With the right approach, the finished pipeline will work clearly and reliably, and the coolant will move in it at the required speed, thus ensuring the most efficient operational return of the entire communication system.

Image gallery

Photo from

Pipe calculation is necessary for the competent design of heating systems, gas supply, sewerage, cold and hot water supply and budgeting for the upcoming work

It is especially important to accurately calculate the flow rate of the pipe for the construction of systems made of expensive materials: copper, galvanized steel or stainless steel.

Pipes are calculated to determine the volume of coolant flowing through the heating circuit. It should be enough to fully heat the object

Knowing the exact volume of the coolant is necessary for the selection of a circulation pump in forced heating circuits. The device must ensure the movement of the coolant at the standard speed

For a competent system design, you need to know exactly the planned performance characteristics. They are needed to select the optimal technology for connecting pipes, installing fittings and fittings.

It is necessary to foresee and calculate in advance options for compensating for thermal expansion, especially if pipelines are to be assembled from polymer pipes

Focusing on the volume of water consumed simultaneously by several water intake points, it is necessary to calculate and select a pipe, the throughput of which will provide consumers

In accordance with the volume of the medium transported through the pipeline, equipment is selected: boilers, water heaters, expansion tanks, shut-off valves, which must correspond to the operating pressure

Communication device in a country house

Copper pipe heating system

Bandwidth Calculation

Calculations for the selection of a circulation pump

The choice of the method of connecting pipes according to the load

Thermal expansion compensation

Calculation of the water supplied to the devices

Compliance of equipment and pipe dimensions

When preparing estimates, designers of plumbing systems recommend taking into account indicators such as:

- basic patency of the pipeline;

- level of potential heat loss;

- type, volume and thickness of the required insulation;

- the amount of material that protects pipes from corrosion and other negative external influences;

- the degree of smoothness or roughness of the inner surface of the pipe.

Based on these data, it will be much faster and easier to choose the appropriate type and order the right amount of pipe rolling.

This is interesting: How to clear a blockage in a sewer pipe - a selection of the best ways

You can record and print your results

Our calculator allows you to record the received calculations in a special field so that you can easily see your latest calculations. To do this, you need to click on the "Record" button, and the result of your calculations will appear in a special field.

Also, after you have calculated all the necessary data, you can click on the "Print" button and get a printout of the results in a convenient form.

You can compare prices for selected items from all suppliers.

To do this, you need to write down your calculations

Please note that in the field with the recorded results there are positions that are of interest to you. Next, click "Calculate the entire application online", and the system will transfer you to a page where the results of processing suppliers' prices will be shown

The range of water and gas pipes is often needed for online calculation of the weight of pipes of water and gas pipeline systems during construction, laying communications, laying water pipes, gas pipelines. A full range of pipes is used in the installation of heating systems and the execution of pipeline parts, in external drinking water supply networks.GOST 3262-62 for water and gas pipes allows the production of pipe products without threads at the ends or with threads, while the length of black pipes without threads ranges from 4 to 12 m, and black and galvanized pipes with threads - from 4 to 8 m. GOST 3262-75 pipes of increased manufacturing accuracy are used for parts of water and gas pipeline structures.

When welding pipelines, in the case when water and gas pipes are used, manual welding or a socket connection is used. Couplings are used for VGP pipes with normal wall thickness, welding is possible in all cases: light, conventional, reinforced VGP types. The range of steel pipes for water and gas pipelines of ordinary accuracy allows the manufacture of steel according to GOST 380 and GOST 1050 without standardizing mechanical properties and chemical composition. The most popular range of pipes is black pipe rolling, used for water pipes, gas pipelines and heating systems. High-precision VGP pipes are made from steels according to GOST 1050. The range of galvanized pipes is used for parts of water and gas pipeline structures with high requirements for durability and corrosion resistance.

Round pipe is a type of metal-roll assortment, which is produced by electric welding. The technology for the production of rolled pipes consists in the fact that steel sheet blanks from strips (steel sheet in rolls) go through the process of unwinding and straightening on rolls, cut to the size of a given length and width, after which the edges of the strips are processed by chamfering. Next, the strips are butt-welded, the sheet blanks are fed into the accumulator for supplying material to the forming mill, where they are profiled into a round pipe of the required diameter.The wall thickness of the pipe (thin-walled, thick-walled) depends on the thickness of the sheet strip. At the next stage, a longitudinal seam is welded (either in a straight line or in a spiral) by melting the edges of the metal with high-frequency currents, closing them into an integral connection to obtain solid metal over the entire cross section of a round pipe. At the final stage of the technological process, the burr is removed from the finished product and the electric-welded pipe is cooled, calibrated to comply with GOST diameters within tolerances and cut to the required length.

1 inch = 2.54 cm

Quarter of an inch - 8 mm; half an inch - 15 mm; three quarters of an inch - 20 mm; inch - 25 mm; an inch and a quarter - 32 mm; one and a half inches - 40 mm; two inches - 50 mm; two and a half inches - 65 mm; 4 inches - 100 mm.

This ratio between inches and millimeters greatly simplifies the selection of imported pipeline fittings for Ukrainian pipes, but it is important to understand here that such dimensions are also suitable for domestic bends, transitions, water taps, gas valves. Imported couplings, valves, bends, tees, spurs (and now imported stainless pipeline fittings are often used) have real inch dimensions, which are somewhat different from the connecting dimensions of VGP pipes

Steel Pipe Weight Table: Usage Tips

In this case, a special table can serve as a data source. Its choice is made depending on the type of product. In addition to GOSTs, schemes can also be found on many specialized sites.Today, on the Internet, you can easily find tables for determining the mass of parts made of different materials (for example, the weight of a cast-iron pipe is 100 mm).

Finding the mass in a tabular way requires compliance with two basic rules

First of all, it is very important not to make a mistake with the choice of the table. To do this, you need to check if the name matches state standard product material, the mass of which you want to determine

The second rule is that you should not completely rely on the data defined using the table. As a rule, the specific gravity of the pipe does not correspond to the actual one. Therefore, any calculation will only be approximate. For small parties, this difference is not a serious problem.

On the Internet, you can easily find tables for determining the mass of metal pipes

As an example, you can take a steel part with dimensions of 60x60x3. The weight of 1 meter of this type of pipe is 5.25 kg, based on a tabular calculation. This product belongs to the profile group and has walls equal in width. The actual weight of the product with these dimensions may vary. The maximum allowance in this case is 10% of the total mass (52.5 g).

The spreadsheet method is very good when you don't have time to do lengthy, complex calculations. However, it is always worth remembering the error that is present in this case.

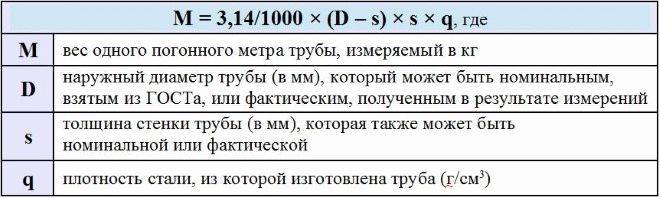

The simplest method for determining pipe weight

There is a simple technique that allows you to find out the weight of steel pipes by diameter. In addition to this parameter, information regarding the wall thickness will be required. In this case, the formula is used:

P \u003d πx (D - Sst) xSst xT, where

D is the outer diameter;

T is the density;

Sst. - wall thickness.

As a result, the result will be like this:

P \u003d 3.14x (0.168 - 0.008) x0.008x7850 \u003d 31.55 kg.

Using this formula, you can always find out how much pipe products weigh, having any size.

For example, one linear meter of a steel pipe with an outer diameter of 75.5 millimeters and a wall thickness of -4.5 millimeters will have a weight of:

P \u003d 3.14x (0.0755 - 0.0045) x0.0045x7850 ≈ 7.8 kg.

To find out whether the mass of rolled products is round or of another shape, it is necessary to multiply the resulting weight of one meter by the length of the product. Let's say that it is equal to 10 meters, then: 7.8x10 \u003d 78 kg.

But the final result will depend not on one steel grade, but also on the production technology. So the weight of an electric-welded pipe will not be the same as that of a seamless rolled product, provided that their main parameters match.

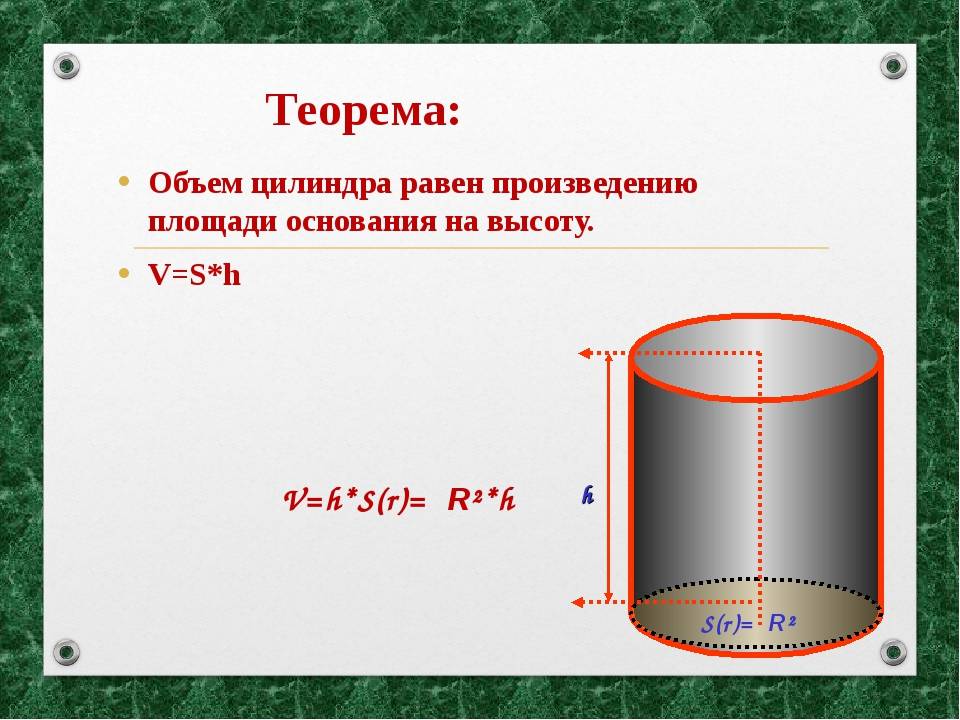

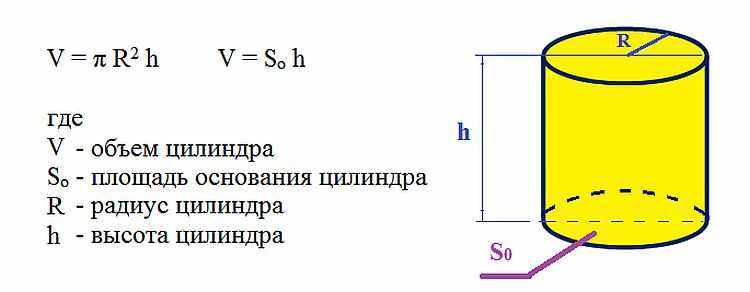

How to calculate the volume of water in a pipeline

When organizing a heating system, you may need such a parameter as the volume of water that will fit in the pipe. This is necessary when calculating the amount of coolant in the system. For this case, we need the formula for the volume of a cylinder.

The formula for calculating the volume of water in a pipe

There are two ways: first calculate the cross-sectional area (described above) and multiply it by the length of the pipeline. If you count everything according to the formula, you will need the inner radius and the total length of the pipeline. Let's calculate how much water will fit in a system of 32 mm pipes 30 meters long.

First, let's convert millimeters to meters: 32 mm = 0.032 m, find the radius (halve) - 0.016 m. Substitute in the formula V = 3.14 * 0.0162 * 30 m = 0.0241 m3. It turned out = a little more than two hundredths of a cubic meter. But we are used to measuring the volume of the system in liters. To convert cubic meters to liters, you need to multiply the resulting figure by 1000. It turns out 24.1 liters.

Methods for calculating specific gravity

- length;

- height, width or diameter;

- wall thickness.

Therefore, it is indicated as the mass of the volume (in m2) of a profile or cylindrical shape filled with homogeneous steel with the required density (in kg / m3). The length of the pipe when determining its specific gravity is one meter. For steel pipe, in any calculations, the density of the composition from which it is made is constantly taken as 7850 kg / m. cube To determine the weight of one meter of steel pipe (specific gravity), choose one of the following methods:

- according to calculation formulas;

- using tables where the required data are indicated for standard sizes of rolled tubular products.

In any case, the data obtained are only a theoretical calculation. This is due to the following reasons:

- in calculations, it is often necessary to round the calculated values;

- in the calculations, the shape of the pipe is assumed to be geometrically correct, that is, metal sagging at the welding joint, rounding in the corners (for profiled steel), reduction or excess of dimensions relative to the standard ones within the permissible GOST are not taken into account;

- the density of different steel grades differs from 7850 kg/m. cube and for many alloys, the difference is quite significant when determining the weight of a large number of tubular products.

With the help of special tables, the most approximate theoretical indicator of the specific weight of pipe rolling is determined, since complex mathematical formulas were used in their compilation, which took into account the production technology and geometry of the products as much as possible. To use this calculation option, first, according to the available data on pipe rolling, its type is determined. After that, they find in the reference literature a table corresponding to this metal-roll or GOST for this assortment.

The tabular version of the calculation is good because it does not require any calculations, which eliminates the possibility of making a mathematical error in the calculations. But this method implies the availability of special literature. The most universal option is the use of mathematical formulas. This method can be used in any conditions, even, so to speak, "field", far from the possibilities and benefits of civilization.

Determination of the specific gravity of the pipe by the formulas

As mentioned above, the calculation is based on determining the volume of raw materials used to produce one meter of pipe. Then this value must be multiplied by the density of the composition (in the case of steel, by 7850 kg / m3). The desired volume is determined in this way:

- Calculate the volume of a part of a pipe one meter long according to its external dimensions. Why determine the cross-sectional area of \u200b\u200bthe pipe, which is multiplied by the length, in our case by 1 meter.

- Calculate the volume of the hollow part of the pipe 1 meter long. Why first determine the dimensions of the cavity (for a round product, the inner diameter is calculated by subtracting double the wall thickness from the outer diameter, and for profiled pipe-rolling, the height and width of the inner diameter are determined, subtracting double the thickness from the outer dimensions). After, according to the results obtained, a calculation is made similar to that indicated in the first paragraph.

- At the end, the second result is subtracted from the first result, this is the volume of the pipe.

All calculations are made only after the conversion of the initial indicators into kilograms and meters. The determination of the volume of a round and cylindrical section of pipes occurs according to the following formula:

V = RxRx3.14xL, where:

- V is the volume;

- R is the radius;

- L is the length.

Another simple formula, but for steel round pipes:

Weight = 3.14x(D - T)xTxLxP, where:

- D is the outer diameter;

- T is the wall thickness;

- L - length;

- P is the density of steel.

data must be converted to millimeters

Specific gravity = (A–T)xTx0.0316

For rectangular pipes:

Specific gravity = (A+B–2xT)xTx0.0158

That is, to determine the exact weight of the material, you can use special tables, which indicate the mass of pipes, taking into account the cross section, diameter and other indicators. If this table is not at hand, then you can always use a special calculator, where to calculate the required values, you just need to enter the necessary data, such as wall thickness and section type of the structure. How to determine the specific gravity, everyone chooses for himself.

How to calculate pipe weight

Before ordering stainless steel, the consumer often needs to know in advance how much the entire batch of goods will weigh, for example, to organize delivery or to design future structures. Moreover, the greatest number of questions arises regarding stainless pipes of various sections. It is not necessary to look for product samples and weigh them separately - you can make all the calculations without leaving your desktop. There are several options for solving the problem:

- use the weight calculator on our website or on the manufacturer's website,

- find special tables (they are only suitable for standard products),

- apply the formula for calculating the theoretical weight of one linear meter.

In any case, you need to decide on the following points:

- what grade of steel the products are made of,

- pipe outer diameter,

- wall thickness,

- configuration (round, square, rectangular).

Pipe, as a molded product, has a constant section, so using the formula for theoretical weight, we essentially determine the cross section (actually, the volume of material per meter of pipe), and then multiply it by the density of a particular grade of stainless steel.

The weight formula for a round pipe is as follows: m \u003d π * (d - e) * e * r π is a constant value equal to 3.142, d is the outer diameter, e is the wall thickness, r is the steel density.

For example, let's determine the mass of a running meter of a round pipe made of AISI 304 steel, with a diameter of 32 mm, with a wall of 2 mm. Note that the specific gravity (density) of stainless steel of this grade is 7.9 g/cm3. m \u003d 3.142 * (32 - 2) * 2 * 790 kg / m3 \u003d 188.5 mm2 * 7.9 g / cm3

Now let's convert square millimeters to centimeters 188.5: 1000 = 0.1885 cm2 and finish the calculations. m = 0.1885 * 7.9 = 1.489 kg

To calculate the mass of a rectangular or square pipe, it is necessary to unfold the section (determine its length), then, multiplying this figure by the wall thickness (e), we get the cross-sectional area, which we multiply by the steel density (r). You can use the following formulas: m (square pipe) = 4a * e * r where a is the length of the side in millimeters. m (for rectangular pipes) = (2a + 2b) * e * r where a and b are the sides of the rectangle in millimeters.

How to calculate pipe weight A detailed methodology for calculating the weight of a stainless steel pipe with a description of the nuances and formula.

Determination of the diameter of the pipe material

To clarify the diameter of the pipe used in the process of repair and installation work, first measure its circumference. An ordinary sewing centimeter tape is suitable for this.If it is not at hand, the pipe is simply wrapped with a dense thread, rope or twine, and then the fragment is applied to the ruler and its length is found out.

The outer diameter of the pipe can be measured with the most ordinary tape measure or stationery ruler. However, these methods are appropriate where minimal requirements are imposed on the accuracy of the parameters. For more accurate calculations (up to tenths of a millimeter), it is better to use a caliper. True, this measurement option is relevant only for products with a small cross section.

For the purpose of subsequent accurate calculations, an elementary mathematical formula for determining the circumference is used:

L=πD

(L - indicates the length of the outer circumference of the circle; π - is a constant number "pi", having the same value in all cases - 3.14 (for the most accurate calculations, up to eight digits after the decimal point are taken into account); D - symbolizes the diameter of the circle circle). To correctly calculate the outer diameter, the equation is converted into the formula D \u003d L / π and all the necessary calculations are made

To correctly calculate the outer diameter, the equation is converted into the formula D \u003d L / π and all necessary calculations are made.

Accurate data on the inner and outer diameter of the pipe allow you to calculate in detail the actual throughput of the pipeline, its strength and resistance to operational loads

To determine the size of the inner diameter of the circle, first of all, the wall thickness of the pipe material is measured, and then this value, multiplied by 2, is subtracted from the number that determines the outer diameter of the product.

Measurement of parameters in difficult conditions

If the pipe to be measured is difficult to access, use the copy method and apply a suitable measuring tool or an object with already known parameters, for example, a matchbox, to the part.

Then the required area is photographed and all other calculations are performed, focusing on the picture. The obtained values are then converted into real parameters of pipe rolling, taking into account the scale of the survey.

The nuances of measuring the diameter of pipes for a heating system

In the process of arranging the heating complex, the diameter of the pipes is determined as correctly and accurately as possible. The subsequent efficiency of the entire system and its ability to produce the required amount of heating will depend on the correctness of these data.

The pipe material intended for arranging the heating system must clearly correspond to the declared diameter. Too narrow fittings will not withstand the active circulation of the heating element and will quickly wear out, and excessively wide fittings will lose heat and will not be able to properly heat the room

Pipes installed for heating residential or industrial premises are subject to special requirements. They are expected to have high operational stability and the ability to withstand coolant pressure.

When using elements of an inappropriate diameter, this task becomes extremely difficult. As a result, significant heat loss occurs, and it becomes cold and uncomfortable in an apartment, house, office or workshop.