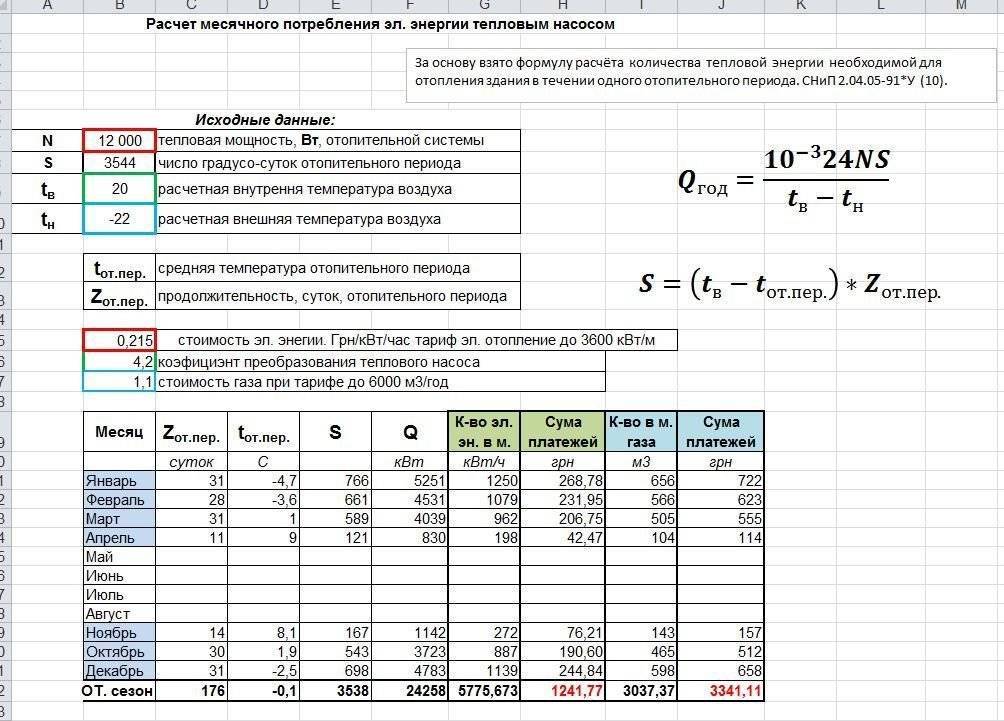

- Computing

- Pros and cons

- What increases gas consumption

- What affects gas consumption?

- Thermal loads of the facility

- Annual heat consumption

- Heat meters

- Vane meters

- Instruments with differential recorder

- Method of calculation for natural gas

- We calculate the gas consumption by heat loss

- Heat loss calculation example

- Boiler power calculation

- By quadrature

- Determine heat loss

- Area calculation technique

- We calculate how much gas a gas boiler consumes per hour, day and month

- Table of consumption of known models of boilers, according to their passport data

- Quick Calculator

- Gas Consumption Calculation Example

- Calculation of gas consumption for heating a house of 150 m2

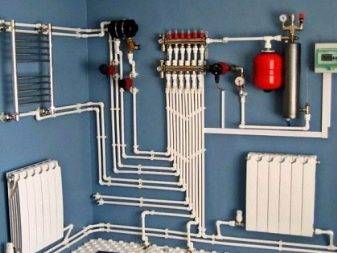

- Hydraulic calculation

Computing

It is practically impossible to calculate the exact value of heat loss by an arbitrary building. However, methods of approximate calculations have long been developed, which give fairly accurate average results within the limits of statistics. These calculation schemes are often referred to as aggregated indicator (measurement) calculations.

The building site must be designed in such a way that the energy required for cooling is kept to a minimum. While residential buildings may be excluded from structural cooling energy demand because internal heat loss is minimal, the situation in the non-residential sector is somewhat different.In such buildings, the internal thermal gains that are needed for mechanical cooling are caused by differential masonry to the overall thermal gain. The workplace also needs to provide a hygienic air flow, which is largely enforced and adjustable.

Along with the thermal power, it often becomes necessary to calculate the daily, hourly, annual consumption of thermal energy or the average power consumption. How to do it? Let's give some examples.

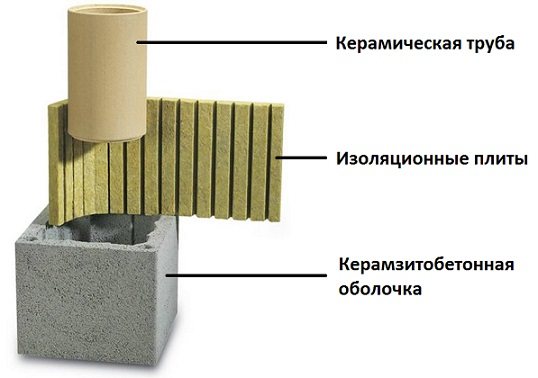

The hourly heat consumption for heating according to enlarged meters is calculated by the formula Qot \u003d q * a * k * (tin-tno) * V, where:

- Qot - the desired value for kilocalories.

- q - specific heating value of the house in kcal / (m3 * C * hour). It is looked up in directories for each type of building.

Such drainage is also necessary during the summer period to cool down due to the removal of heat from outside air and the requirement for possible dehumidification. Shading in the form of overlays or horizontally dwelling elements is the method today, but the effect is limited to the time when the sun is high above the horizon. From this point of view, the most important method is to extinguish outdoor lifts, of course with regard to daylight.

Reducing the internal thermal benefits is somewhat problematic. This will also help reduce the need for artificial lighting. The performance of the personal computer is steadily increasing, but significant progress has been made in this area. The need for cooling is also represented by building structures capable of storing thermal energy. Such structures are especially heavy building structures such as.concrete floor or ceiling, which can also cause internal spur buildup, exterior walls or rooms.

- a - ventilation correction factor (usually equal to 1.05 - 1.1).

- k is the correction factor for the climatic zone (0.8 - 2.0 for different climatic zones).

- tvn - internal temperature in the room (+18 - +22 C).

- tno - street temperature.

- V is the volume of the building together with the enclosing structures.

To calculate the approximate annual heat consumption for heating in a building with a specific consumption of 125 kJ / (m2 * C * day) and an area of 100 m2, located in a climatic zone with a parameter GSOP = 6000, you just need to multiply 125 by 100 (house area ) and by 6000 (degree-days of the heating period). 125*100*6000=75000000 kJ or about 18 gigacalories or 20800 kilowatt-hours.

It is also advantageous to use special phase shift materials at the right temperature. For light residential buildings without cooling, where the storage capacity is minimal, there are problems with maintaining temperature conditions during the summer months.

In terms of air conditioner design, but also the need for cooling energy, it will be necessary to use accurate, affordable calculation methods. In this regard, a particularly clear design of heat sinks can be predicted. As already mentioned, the need for cooling energy will be minimal in zero buildings. Some buildings cannot be cooled without cooling, and providing optimal parameters for the thermal comfort of workers, especially in office buildings, is now the standard.

To recalculate the annual consumption into the average heat, it is enough to divide it by the length of the heating season in hours.If it lasts 200 days, the average heating power in the above case will be 20800/200/24=4.33 kW.

Pros and cons

To date, there is a huge amount of various equipment that, through gas, heats private houses, apartments and cottages. But also each of them has its own positive and negative characteristics.

So that you can determine the best option for yourself, we suggest considering a detailed description of the most popular types of heating.

- Main gas. The main disadvantage is the absence of this highway in the territory of a fairly large number of villages and villages in Russia. Because of this, in small villages, the option to heat a house with a gas boiler is impossible.

- Heating with electricity. To do this, you should buy equipment with a capacity of at least 10-15 kW, and not everyone can afford it. And also in the cold season, the wires are covered with ice, and until the repair teams resolve your situation, you will have to sit in the cold. Very often people complain that such brigades are in no hurry to come to small villages, because in times of bad weather, influential residents are in priority, and only then they.

- Installation of a container - a multi-liter tank - for storing refueling gas. This type of heating is quite expensive, the cost of which starts from 170 thousand rubles. In winter, there may be a problem with the approach of a tanker car, since snow is cleared on the territory of summer cottages only on the central streets, and if you don’t have one, then you will have to make the way for the transport yourself. If you do not clean it, then the cylinders will not be able to be filled, and you will not be able to heat the house.

- Pellet boiler.There are practically no disadvantages to this heating option, except for the cost, which will cost at least 200 thousand rubles.

- The boiler is solid fuel. This type of boilers use coal, firewood and the like as fuel. The only disadvantage of such boilers is that they often fail, and for the best possible work, you need to have a specialist who can fix problems immediately after they appear.

- Boilers are diesel. Diesel fuel today is pretty decent, so the maintenance of such a boiler will also be expensive. One of the negative aspects of a diesel boiler is considered to be a mandatory supply of fuel, which is enough in an amount of 150 to 200 liters.

What increases gas consumption

Gas consumption for heating, in addition to its type, depends on such factors:

- Climatic features of the area. The calculation is carried out for the lowest temperature indicators characteristic of these geographic coordinates;

- The area of the entire building, its number of storeys, the height of the rooms;

- Type and availability of insulation of the roof, walls, floor;

- Type of building (brick, wood, stone, etc.);

- Type of profile on the windows, the presence of double-glazed windows;

- Organization of ventilation;

- Power in the limit values of heating equipment.

Equally important is the year the house was built, the location of the heating radiators

What affects gas consumption?

Fuel consumption is determined, firstly, by power - the more powerful the boiler, the more intensively gas is consumed. At the same time, it is difficult to influence this dependence from the outside.

Even if you turn down a 20kW unit to its minimum, it will still consume more fuel than its less powerful 10kW counterpart turned on at maximum.

This table shows the relationship between the heated area and the power of the gas boiler.The more powerful the boiler, the more expensive it is. But the larger the area of heated premises, the faster the boiler pays for itself.

Secondly, we take into account the type of boiler and the principle of its operation:

- open or closed combustion chamber;

- convection or condensation;

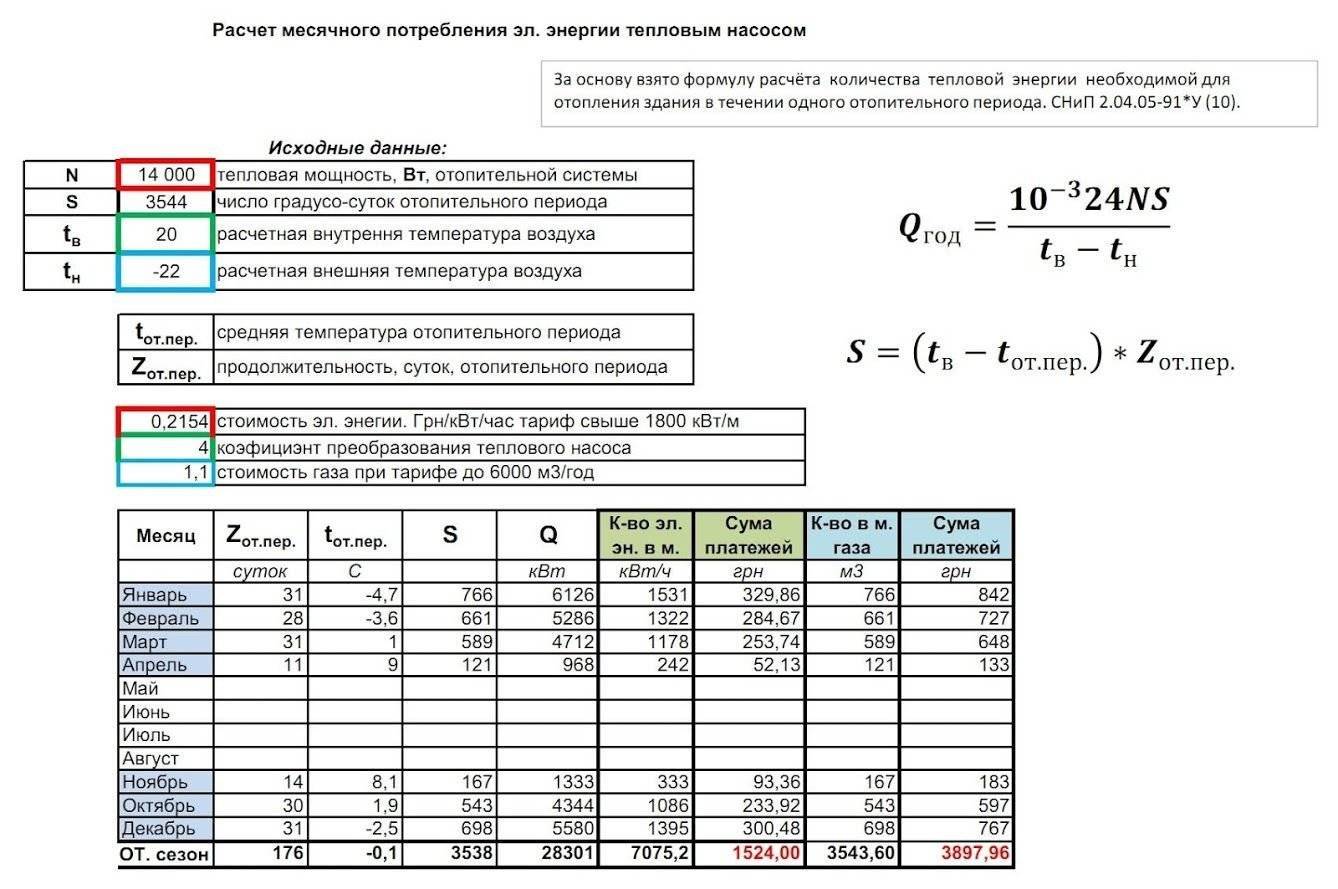

- conventional chimney or coaxial;

- one circuit or two circuits;

- availability of automatic sensors.

In a closed chamber, fuel is burned more economically than in an open chamber. The efficiency of the condensing unit due to the built-in additional heat exchanger for condensing the vapors present in the combustion product is increased to 98-100% compared to 90-92% efficiency of the convection unit.

With a coaxial chimney, the efficiency value also increases - cold air from the street is heated by a heated exhaust pipe. Because of the second circuit, there is, of course, an increase in gas consumption, but in this case the gas boiler also serves not one, but two systems - heating and hot water supply.

Automatic sensors are a useful thing, they catch the outside temperature and adjust the boiler to the optimal mode.

Thirdly, we look at the technical condition of the equipment and the quality of the gas itself. Scale and scale on the walls of the heat exchanger significantly reduce heat transfer, and it is necessary to compensate for its lack by increasing power.

Alas, the gas can also be with water and other impurities, but instead of making claims to suppliers, we switch the power regulator a few divisions towards the maximum mark.

One of the modern highly economical models is the floor Baxi brand gas condensing boiler Power with a capacity of 160 kW. Such a boiler heats 1600 sq. m area, i.e. large house with several floors.At the same time, according to passport data, it consumes 16.35 cubic meters of natural gas. m per hour and has an efficiency of 108%

And, fourthly, the area of heated premises, the natural loss of heat, the duration of the heating season, weather patterns. The more spacious the area, the higher the ceilings, the more floors, the more fuel will be required to heat such a room.

We take into account some heat leakage through windows, doors, walls, roofs. It doesn’t happen year after year, there are warm winters and bitter frosts - you can’t predict the weather, but the cubic meters of gas used for heating depend directly on it.

Thermal loads of the facility

The calculation of thermal loads is carried out in the following sequence.

- 1. The total volume of buildings according to the external measurement: V=40000 m3.

- 2. The calculated internal temperature of heated buildings is: tvr = +18 C - for administrative buildings.

- 3. Estimated heat consumption for heating buildings:

4. Heat consumption for heating at any outdoor temperature is determined by the formula:

where: tvr is the temperature of the internal air, C; tn is the outside air temperature, C; tn0 is the coldest outdoor temperature during the heating period, C.

- 5. At the outside air temperature tн = 0С, we get:

- 6. At the outside air temperature tн= tнв = -2С, we get:

- 7. At the average outdoor air temperature for the heating period (at tn = tnsr.o = +3.2С) we get:

- 8. At the outside air temperature tн = +8С we get:

- 9. At the outside air temperature tн = -17С, we get:

10. Estimated heat consumption for ventilation:

,

where: qv is the specific heat consumption for ventilation, W/(m3 K), we accept qv = 0.21- for administrative buildings.

11. At any outdoor temperature, the heat consumption for ventilation is determined by the formula:

- 12.At the average outdoor air temperature for the heating period (at tn = tnsr.o = +3.2С) we get:

- 13. At outdoor air temperature = = 0С, we get:

- 14. At outdoor air temperature = = + 8C, we get:

- 15. At outdoor temperature ==-14C, we get:

- 16. At the outside air temperature tн = -17С, we get:

17. Average hourly heat consumption for hot water supply, kW:

where: m is the number of personnel, people; q - hot water consumption per employee per day, l/day (q = 120 l/day); c is the heat capacity of water, kJ/kg (c = 4.19 kJ/kg); tg is the temperature of hot water supply, C (tg = 60C); ti is the temperature of cold tap water in winter txz and summer tchl periods, С (txz = 5С, tхl = 15С);

- the average hourly heat consumption for hot water supply in winter will be:

— average hourly heat consumption for hot water supply in summer:

- 18. The results obtained are summarized in Table 2.2.

- 19. Based on the data obtained, we build the total hourly schedule of heat consumption for heating, ventilation and hot water supply of the facility:

; ; ; ;

20. On the basis of the obtained total hourly schedule of heat consumption, we build an annual schedule for the duration of the heat load.

Table 2.2 Dependence of heat consumption on outdoor temperature

| Heat consumption | tnm= -17С | tno \u003d -14С | tnv=-2C | tn= 0С | tav.o \u003d + 3.2С | tnc = +8C |

| , MW | 0,91 | 0,832 | 0,52 | 0,468 | 0,385 | 0,26 |

| , MW | 0,294 | 0,269 | 0,168 | 0,151 | 0,124 | 0,084 |

| , MW | 0,21 | 0,21 | 0,21 | 0,21 | 0,21 | 0,21 |

| , MW | 1,414 | 1,311 | 0,898 | 0,829 | 0,719 | 0,554 |

| 1,094 | 1,000 | 0,625 | 0,563 | 0,463 | 0,313 |

Annual heat consumption

To determine the heat consumption and its distribution by season (winter, summer), equipment operation modes and repair schedules, it is necessary to know the annual fuel consumption.

1. The annual heat consumption for heating and ventilation is calculated by the formula:

,

where: - average total heat consumption for heating during the heating period; — average total consumption heat for ventilation for the heating period, MW; - duration of the heating period.

2. Annual heat consumption for hot water supply:

where: - average total heat consumption for hot water supply, W; - the duration of the hot water supply system and the duration of the heating period, h (usually h); - coefficient of reduction of the hourly consumption of hot water for hot water supply in the summer; - respectively, the temperature of hot water and cold tap water in winter and summer, C.

3. Annual heat consumption for heat loads of heating, ventilation, hot water supply and technological load of enterprises according to the formula:

,

where: - annual heat consumption for heating, MW; — annual heat consumption for ventilation, MW; — annual heat consumption for hot water supply, MW; — annual heat consumption for technological needs, MW.

MWh/year.

Heat meters

Now let's find out what information is needed in order to calculate the heating. It is easy to guess what this information is.

1. The temperature of the working fluid at the outlet / inlet of a particular section of the line.

2. The flow rate of the working fluid that passes through the heating devices.

The flow rate is determined through the use of thermal metering devices, that is, meters. These can be of two types, let's get acquainted with them.

Vane meters

Such devices are intended not only for heating systems, but also for hot water supply. Their only difference from those meters that are used for cold water is the material from which the impeller is made - in this case it is more resistant to elevated temperatures.

As for the mechanism of work, it is almost the same:

- due to the circulation of the working fluid, the impeller begins to rotate;

- the rotation of the impeller is transferred to the accounting mechanism;

- the transfer is carried out without direct interaction, but with the help of a permanent magnet.

Despite the fact that the design of such counters is extremely simple, their response threshold is quite low, moreover, there is reliable protection against distortion of readings: the slightest attempt to brake the impeller by means of an external magnetic field is stopped thanks to the antimagnetic screen.

Instruments with differential recorder

Such devices operate on the basis of Bernoulli's law, which states that the speed of movement gas or liquid flow inversely proportional to its static motion. But how is this hydrodynamic property applicable to the calculation of the flow rate of the working fluid? Very simple - you just need to block her path with a retaining washer. In this case, the rate of pressure drop on this washer will be inversely proportional to the speed of the moving flow. And if the pressure is recorded by two sensors at once, then you can easily determine the flow rate, and in real time.

Note! The design of the counter implies the presence of electronics. The overwhelming majority of such modern models provide not only dry information (temperature of the working fluid, its consumption), but also determine the actual use of thermal energy. The control module here is equipped with a port for connecting to a PC and can be configured manually

The control module here is equipped with a port for connecting to a PC and can be configured manually.

Many readers will probably have a logical question: what if we are not talking about a closed heating system, but about an open one, in which selection for hot water supply is possible? How, in this case, to calculate Gcal for heating? The answer is quite obvious: here pressure sensors (as well as retaining washers) are placed simultaneously on both the supply and the “return”. And the difference in the flow rate of the working fluid will indicate the amount of heated water that was used for domestic needs.

Method of calculation for natural gas

The approximate gas consumption for heating is calculated based on half the capacity of the installed boiler. The thing is that when determining the power of a gas boiler, the lowest temperature is laid. This is understandable - even when it is very cold outside, the house should be warm.

You can calculate the gas consumption for heating yourself

But it is completely wrong to calculate the gas consumption for heating according to this maximum figure - after all, in general, the temperature is much higher, which means that much less fuel is burned. Therefore, it is customary to consider the average fuel consumption for heating - about 50% of the heat loss or boiler power.

We calculate the gas consumption by heat loss

If there is no boiler yet, and you estimate the cost of heating in different ways, you can calculate from the total heat loss of the building. They are most likely familiar to you. The methodology here is as follows: they take 50% of the total heat loss, add 10% to provide hot water supply and 10% to heat outflow during ventilation. As a result, we get the average consumption in kilowatts per hour.

Then you can find out the fuel consumption per day (multiply by 24 hours), per month (by 30 days), if desired - for the entire heating season (multiply by the number of months during which the heating works). All these figures can be converted into cubic meters (knowing the specific heat of combustion of gas), and then multiply cubic meters by the price of gas and, thus, find out the cost of heating.

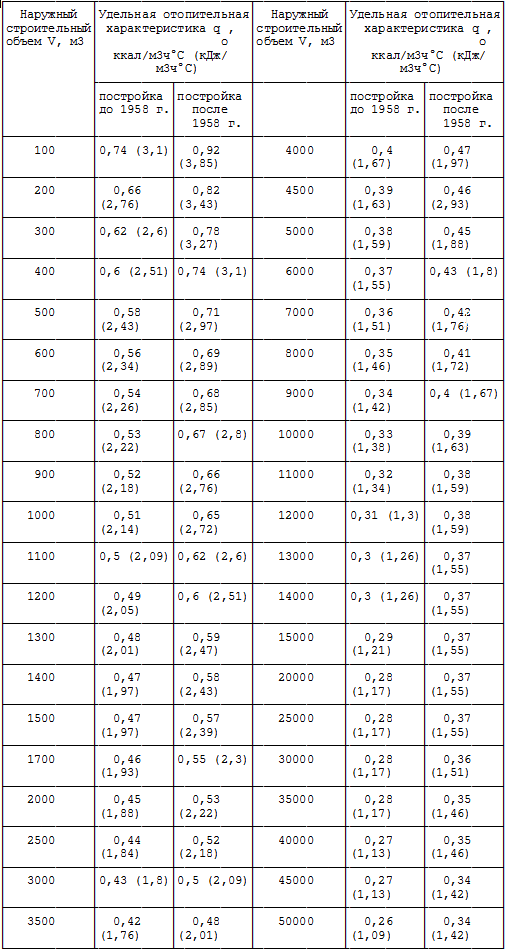

| The name of the crowd | unit of measurement | Specific heat of combustion in kcal | Specific heating value in kW | Specific calorific value in MJ |

|---|---|---|---|---|

| Natural gas | 1 m 3 | 8000 kcal | 9.2 kW | 33.5 MJ |

| Liquefied gas | 1 kg | 10800 kcal | 12.5 kW | 45.2 MJ |

| Hard coal (W=10%) | 1 kg | 6450 kcal | 7.5 kW | 27 MJ |

| wood pellet | 1 kg | 4100 kcal | 4.7 kW | 17.17 MJ |

| Dried wood (W=20%) | 1 kg | 3400 kcal | 3.9 kW | 14.24 MJ |

Heat loss calculation example

Let the heat loss of the house be 16 kW / h. Let's start counting:

- average heat demand per hour - 8 kW / h + 1.6 kW / h + 1.6 kW / h = 11.2 kW / h;

- per day - 11.2 kW * 24 hours = 268.8 kW;

-

per month - 268.8 kW * 30 days = 8064 kW.

Convert to cubic meters. If we use natural gas, we divide the gas consumption for heating per hour: 11.2 kW / h / 9.3 kW = 1.2 m3 / h. In calculations, the figure 9.3 kW is the specific heat capacity of natural gas combustion (available in the table).

Since the boiler has not 100% efficiency, but 88-92%, you will have to make more adjustments for this - add about 10% of the figure obtained. In total, we get the gas consumption for heating per hour - 1.32 cubic meters per hour. You can then calculate:

- consumption per day: 1.32 m3 * 24 hours = 28.8 m3/day

- demand per month: 28.8 m3 / day * 30 days = 864 m3 / month.

The average consumption for the heating season depends on its duration - we multiply it by the number of months that the heating season lasts.

This calculation is approximate. In some month, gas consumption will be much less, in the coldest - more, but on average the figure will be about the same.

Boiler power calculation

Calculations will be a little easier if there is a calculated boiler capacity - all the necessary reserves (for hot water supply and ventilation) are already taken into account. Therefore, we simply take 50% of the calculated capacity and then calculate the consumption per day, month, per season.

For example, the design capacity of the boiler is 24 kW. To calculate the gas consumption for heating, we take half: 12 k / W. This will be the average need for heat per hour. To determine the fuel consumption per hour, we divide by the calorific value, we get 12 kW / h / 9.3 k / W = 1.3 m3. Further, everything is considered as in the example above:

- per day: 12 kW / h * 24 hours = 288 kW in terms of the amount of gas - 1.3 m3 * 24 = 31.2 m3

-

per month: 288 kW * 30 days = 8640 m3, consumption in cubic meters 31.2 m3 * 30 = 936 m3.

Next, we add 10% for the imperfection of the boiler, we get that for this case the flow rate will be slightly more than 1000 cubic meters per month (1029.3 cubic meters). As you can see, in this case everything is even simpler - fewer numbers, but the principle is the same.

By quadrature

Even more approximate calculations can be obtained by the quadrature of the house. There are two ways:

- It can be calculated according to SNiP standards - for heating one square meter in Central Russia, an average of 80 W / m2 is required. This figure can be applied if your house is built according to all requirements and has good insulation.

- You can estimate according to the average data:

- with good house insulation, 2.5-3 cubic meters / m2 are required;

-

with average insulation, gas consumption is 4-5 cubic meters / m2.

Each owner can assess the degree of insulation of his house, respectively, you can estimate what gas consumption will be in this case. For example, for a house of 100 sq. m. with average insulation, 400-500 cubic meters of gas will be required for heating, 600-750 cubic meters per month for a house of 150 square meters, 800-100 cubic meters of blue fuel for heating a house of 200 m2. All this is very approximate, but the figures are based on many factual data.

Determine heat loss

The heat loss of a building can be calculated separately for each room that has an external part in contact with the environment. Then the received data are summarized. For a private house, it is more convenient to determine the heat loss of the entire building as a whole, considering the heat loss separately through the walls, roof, and floor surface.

It should be noted that the calculation of heat losses at home is a rather complicated process that requires special knowledge. A less accurate, but at the same time quite reliable result can be obtained on the basis of an online heat loss calculator.

When choosing an online calculator, it is better to give preference to models that take into account all possible options for heat loss. Here is their list:

outer wall surface

Having decided to use the calculator, you need to know the geometric dimensions of the building, the characteristics of the materials from which the house is made, as well as their thickness. The presence of a heat-insulating layer and its thickness are taken into account separately.

Based on the listed initial data, the online calculator gives the total heat loss value at home. To determine how accurate the results obtained can be by dividing the result obtained by the total volume of the building and thus obtaining specific heat losses, the value of which should be in the range from 30 to 100 W.

If the numbers obtained using the online calculator go far beyond the specified values, it can be assumed that an error has crept into the calculation. Most often, the cause of errors in calculations is a mismatch in the dimensions of the quantities used in the calculation.

An important fact: the online calculator data is relevant only for houses and buildings with high-quality windows and a well-functioning ventilation system, in which there is no place for drafts and other heat losses.

To reduce heat loss, you can perform additional thermal insulation of the building, as well as use the heating of the air entering the room.

Area calculation technique

There are two ways to calculate natural gas consumption based on the total area of \u200b\u200bthe house, but the results will be very inaccurate.

According to SNiP, the rate of gas consumption for heating a private house located in the middle lane is calculated based on 80 watts of thermal energy per 1 m2. However, this value is acceptable only if the house has high-quality insulation and is built in accordance with all building codes.

The second method involves the use of statistical research data:

- if the house is well insulated, 2.5-3 m3 / m2 is required to heat it;

- a room with an average level of insulation will consume 4-5 m3 of gas per 1 m2.

Thus, the owner of the house, knowing the level of insulation of its walls and ceilings, will be able to roughly estimate how much gas will be used to heat it. So, for heating a house with an average level of insulation with an area of 100 m2, approximately 400-500 m3 of natural gas will be required monthly. If the area of the house is 150 m2, 600-750 m3 of gas will have to be burned to heat it.But a house with an area of 200 m2 will require about 800-1000 m3 of natural gas per month. It should be noted that these figures are rather average, although they are obtained on the basis of actual data.

We calculate how much gas a gas boiler consumes per hour, day and month

In the design of individual heating systems for private houses, 2 main indicators are used: the total area of \u200b\u200bthe house and the power of the heating equipment. With simple averaged calculations, it is considered that for heating every 10 m2 of area, 1 kW of thermal power + 15-20% of the power reserve is sufficient.

How to calculate the required boiler outputIndividual calculation, formula and correction factors

It is known that the calorific value of natural gas is 9.3-10 kW per m3, hence it follows that about 0.1-0.108 m3 of natural gas is needed per 1 kW of thermal power of a gas boiler. At the time of writing, the cost of 1 m3 of main gas in the Moscow region is 5.6 rubles / m3 or 0.52-0.56 rubles for each kW of boiler heat output.

But this method can be used if the passport data of the boiler are unknown, because the characteristics of almost any boiler indicate the gas consumption during its continuous operation at maximum power.

For example, the well-known floor-standing single-circuit gas boiler Protherm Volk 16 KSO (16 kW power), running on natural gas, consumes 1.9 m3 / hour.

- Per day - 24 (hours) * 1.9 (m3 / hour) = 45.6 m3. In value terms - 45.5 (m3) * 5.6 (tariff for MO, rubles) = 254.8 rubles / day.

- Per month - 30 (days) * 45.6 (daily consumption, m3) = 1,368 m3. In value terms - 1,368 (cubic meters) * 5.6 (tariff, rubles) = 7,660.8 rubles / month.

- For the heating season (suppose, from October 15 to March 31) - 136 (days) * 45.6 (m3) = 6,201.6 cubic meters. In value terms - 6,201.6 * 5.6 = 34,728.9 rubles / season.

That is, in practice, depending on the conditions and heating mode, the same Protherm Volk 16 KSO consumes 700-950 cubic meters of gas per month, which is about 3,920-5,320 rubles / month. It is impossible to accurately determine the gas consumption by the calculation method!

To obtain accurate values, metering devices (gas meters) are used, because the gas consumption in gas heating boilers depends on the correctly selected power of the heating equipment and the technology of the model, the temperature preferred by the owner, the arrangement of the heating system, the average temperature in the region for the heating season, and many other factors , individual for each private house.

Table of consumption of known models of boilers, according to their passport data

| Model | power, kWt | Max consumption of natural gas, cubic meters m/hour |

| Lemax Premium-10 | 10 | 0,6 |

| ATON Atmo 10EBM | 10 | 1,2 |

| Baxi SLIM 1.150i 3E | 15 | 1,74 |

| Protherm Bear 20 PLO | 17 | 2 |

| De Dietrich DTG X 23 N | 23 | 3,15 |

| Bosch Gas 2500 F 30 | 26 | 2,85 |

| Viessmann Vitogas 100-F 29 | 29 | 3,39 |

| Navien GST 35KN | 35 | 4 |

| Vaillant ecoVIT VKK INT 366/4 | 34 | 3,7 |

| Buderus Logano G234-60 | 60 | 6,57 |

Quick Calculator

Recall that the calculator uses the same principles as in the example above, the actual consumption data depends on the model and operating conditions of the heating equipment and can only be 50-80% of the data calculated with the condition that the boiler operates continuously and at full capacity .

Gas Consumption Calculation Example

According to the regulatory data obtained as a result of the practical use of heating systems, in our country, about 1 kilowatt of energy is required to heat 10 square meters of a living space.Based on this, a room of 150 sq. m. can heat a boiler with a power of 15 kW.

Next, the calculation of gas consumption for heating per month is performed:

15 kW * 30 days * 24 hours a day. It turns out 10,800 kW / h. This figure is not absolute. For example, the boiler does not work constantly at full capacity. Moreover, when the temperature rises outside the window, sometimes you even have to turn off the heating. The average value in this case can be considered acceptable.

That is, 10,800 / 2 = 5,400 kWh. This is the rate of gas consumption for heating, which is quite enough to ensure a comfortable temperature in the house for one month. Taking into account the fact that the heating season lasts about 7 months, the required amount of gas for the heating season is calculated:

7 * 5400 = 37,800 kWh. Considering that a cubic meter of gas produces 10 kW / h of thermal energy, we get - 37,800 / 10 = 3,780 cubic meters. gas.

For comparison - 10 kW / h (according to statistics) can be obtained from burning 2.5 kg of oak firewood with a moisture content of not more than 20%. The rate of firewood consumption in the above example will be 37,800 / 10 * 2.5 = 9,450 kg. And pine will need even more.

Calculation of gas consumption for heating a house of 150 m2

When arranging the heating system and choosing an energy carrier, it is important to find out the future gas consumption for heating a house of 150 m2 or another area. Indeed, in recent years, a clear upward trend in natural gas prices has been established, the last rise in price by about 8.5% occurred recently, on July 1, 2016

This led to a direct increase in heating costs in apartments and cottages with individual heat sources using natural gas.That is why developers and homeowners who are just choosing a gas boiler for themselves should calculate heating costs in advance.

Hydraulic calculation

So, we have decided on heat losses, the power of the heating unit has been selected, it remains only to determine the volume of the required coolant, and, accordingly, the dimensions, as well as the materials of the pipes, radiators and valves used.

First of all, we determine the volume of water inside the heating system. This will require three indicators:

- The total power of the heating system.

- Temperature difference at the outlet and inlet to the heating boiler.

- Heat capacity of water. This indicator is standard and equal to 4.19 kJ.

Hydraulic calculation of the heating system

The formula is as follows - the first indicator is divided by the last two. By the way, this type of calculation can be used for any section of the heating system.

Here it is important to break the line into parts so that in each the speed of the coolant is the same. Therefore, experts recommend making a breakdown from one shut-off valve to another, from one heating radiator to another. Now we turn to the calculation of the pressure loss of the coolant, which depend on the friction inside the pipe system

For this, only two quantities are used, which are multiplied together in the formula. These are the length of the main section and specific friction losses

Now we turn to the calculation of the pressure loss of the coolant, which depends on the friction inside the pipe system. For this, only two quantities are used, which are multiplied together in the formula. These are the length of the main section and specific friction losses.

But the pressure loss in the valves is calculated using a completely different formula. It takes into account indicators such as:

- Heat carrier density.

- His speed in the system.

- The total indicator of all coefficients that are present in this element.

In order for all three indicators, which are derived by formulas, to approach standard values, it is necessary to choose the right pipe diameters. For comparison, we will give an example of several types of pipes, so that it is clear how their diameter affects heat transfer.

- Metal-plastic pipe with a diameter of 16 mm. Its thermal power varies in the range of 2.8-4.5 kW. The difference in the indicator depends on the temperature of the coolant. But keep in mind that this is a range where the minimum and maximum values are set.

- The same pipe with a diameter of 32 mm. In this case, the power varies between 13-21 kW.

- Polypropylene pipe. Diameter 20 mm - power range 4-7 kW.

- The same pipe with a diameter of 32 mm - 10-18 kW.

And the last is the definition of a circulation pump. In order for the coolant to be evenly distributed throughout the heating system, it is necessary that its speed be not less than 0.25 m / s and not more than 1.5 m / s. In this case, the pressure should not be higher than 20 MPa. If the coolant velocity is higher than the maximum proposed value, then the pipe system will work with noise. If the speed is less, then airing of the circuit may occur.