- Calculation of boiler power and heat loss.

- Table 1. Heat-shielding properties of walls

- Table 2. Thermal costs of windows

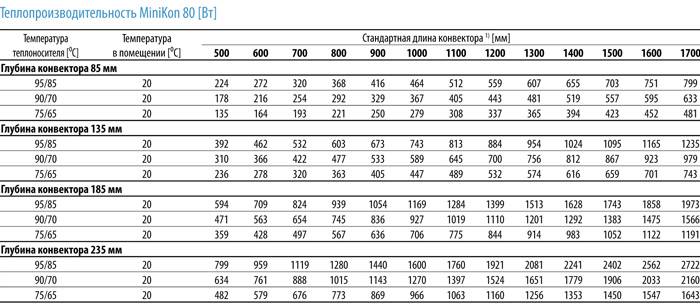

- Calculation of different types of radiators

- Features of functioning

- Combustion chamber type

- Heat exchanger material

- convection type

- Control automation

- Correct power calculation

- Varieties of convectors by installation method

- Different types of thermostats

- Calculation of the required convector power

- Calculation of the power of convectors by volume

- Climate zones are also important

- conclusions

- Selecting an installation site

- Calculations of electricity consumption by household appliances

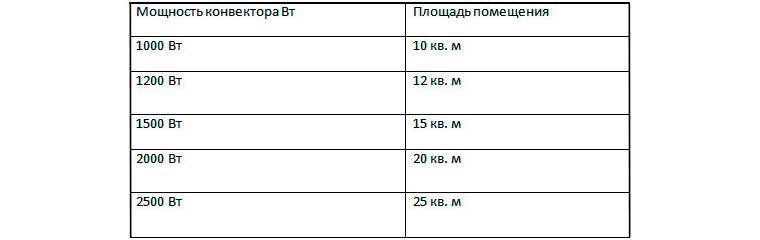

- Heating convector power table

- How to calculate and choose an electric convector

- We calculate the required power of the convector

- Choosing an electric convector according to functionality

- Does the electric convector dry the air

- What is better, an electric convector or a fan heater

- Oil radiator

Calculation of boiler power and heat loss.

Having collected all the necessary indicators, proceed to the calculation. The end result will indicate the amount of heat consumed and guide you in choosing a boiler. When calculating heat loss, 2 quantities are taken as the basis:

- Temperature difference outside and inside the building (ΔT);

- Heat-shielding properties of house objects (R);

To determine the heat consumption, let's get acquainted with the indicators of heat transfer resistance of some materials

Table 1. Heat-shielding properties of walls

| Wall material and thickness | Heat transfer resistance |

| Brick wall thickness of 3 bricks (79 centimeters) thickness 2.5 bricks (67 centimeters) thickness of 2 bricks (54 centimeters) thickness of 1 brick (25 centimeters) | 0.592 0.502 0.405 0.187 |

| Log cabin Ø 25 Ø 20 | 0.550 0.440 |

| Log cabin Thickness 20cm. Thickness 10cm. | 0.806 0.353 |

| frame wall (board + mineral wool + board) 20 cm. | 0.703 |

| Foam concrete wall 20cm 30cm | 0.476 0.709 |

| Plaster (2-3 cm) | 0.035 |

| Ceiling | 1.43 |

| wooden floors | 1.85 |

| Double wooden doors | 0.21 |

The data in the table are indicated with a temperature difference of 50 ° (in the street -30 °, and in the room + 20 °)

Table 2. Thermal costs of windows

| window type | RT | q. Tue/ | Q. W |

| Conventional double glazed window | 0.37 | 135 | 216 |

| Double-glazed window (glass thickness 4 mm) 4-16-4 4-Ar16-4 4-16-4K 4-Ar16-4К | 0.32 0.34 0.53 0.59 | 156 147 94 85 | 250 235 151 136 |

| Double glazing 4-6-4-6-4 4-Ar6-4-Ar6-4 4-6-4-6-4K 4-Ar6-4-Ar6-4K 4-8-4-8-4 4-Ar8-4-Ar8-4 4-8-4-8-4K 4-Ar8-4-Ar8-4K 4-10-4-10-4 4-Ar10-4-Ar10-4 4-10-4-10-4K 4-Ar10-4-Ar10-4К 4-12-4-12-4 4-Ar12-4-Ar12-4 4-12-4-12-4K 4-Ar12-4-Ar12-4К 4-16-4-16-4 4-Ar16-4-Ar16-4 4-16-4-16-4K 4-Ar16-4-Ar16-4K | 0.42 0.44 0.53 0.60 0.45 0.47 0.55 0.67 0.47 0.49 0.58 0.65 0.49 0.52 0.61 0.68 0.52 0.55 0.65 0.72 | 119 114 94 83 111 106 91 81 106 102 86 77 102 96 82 73 96 91 77 69 | 190 182 151 133 178 170 146 131 170 163 138 123 163 154 131 117 154 146 123 111 |

RT is the heat transfer resistance;

- W / m ^ 2 - the amount of heat that is consumed per square meter. m. windows;

even numbers indicate airspace in mm;

Ar - the gap in the double-glazed window is filled with argon;

K - the window has an external thermal coating.

Having available standard data on the heat-shielding properties of materials, and having determined the temperature difference, it is easy to calculate heat losses. For example:

Outside - 20 ° C., and inside + 20 ° C. The walls are built of logs with a diameter of 25cm. In this case

R = 0.550 °С m2/W. Heat consumption will be equal to 40/0.550=73 W/m2

Now you can start choosing a heat source. There are several types of boilers:

- Electric boilers;

- gas boilers

- Solid and liquid fuel heaters

- Hybrid (electric and solid fuel)

Before you purchase a boiler, you should know how much power is required to maintain a favorable temperature in the house. There are two ways to determine this:

- Calculation of power by area of premises.

According to statistics, it is considered that 1 kW of heat energy is required to heat 10 m2. The formula is applicable when the ceiling height is not more than 2.8 m and the house is moderately insulated. Sum the area of all rooms.

We get that W = S × Wsp / 10, where W is the power of the heat generator, S is the total area of the building, and Wsp is the specific power, which is different in each climatic zone. In the southern regions it is 0.7-0.9 kW, in the central regions it is 1-1.5 kW, and in the north it is from 1.5 kW to 2 kW. Let's say a boiler in a house with an area of 150 sq.m, which is located in the middle latitudes, should have a power of 18-20 kW. If the ceilings are higher than the standard 2.7m, for example, 3m, in this case 3÷2.7×20=23 (round up)

- Calculation of power by the volume of premises.

This type of calculation can be done by adhering to building codes. In SNiP, the calculation of the heating power in the apartment is prescribed. For a brick house, 1 m3 accounts for 34 W, and in a panel house - 41 W. The volume of housing is determined by multiplying the area by the height of the ceiling. For example, the apartment area is 72 sq.m., and the ceiling height is 2.8 m. The volume will be 201.6 m3. So, for an apartment in a brick house, the boiler power will be 6.85 kW and 8.26 kW in a panel house. Editing is possible in the following cases:

- At 0.7, when there is an unheated apartment one floor above or below;

- At 0.9 if your apartment is on the first or last floor;

- Correction is made in the presence of one external wall at 1.1, two - at 1.2.

Calculation of different types of radiators

If you are going to install sectional radiators of a standard size (with an axial distance of 50 cm in height) and have already chosen the material, model and the desired size, there should be no difficulty in calculating their number. Most of the reputable companies that supply good heating equipment have the technical data of all modifications on their website, among which there is also thermal power. If not power is indicated, but the flow rate of the coolant, then it is easy to convert to power: the coolant flow rate of 1 l / min is approximately equal to the power of 1 kW (1000 W).

The axial distance of the radiator is determined by the height between the centers of the holes for supplying/removing the coolant

To make life easier for buyers, many sites install a specially designed calculator program. Then the calculation of sections of heating radiators comes down to entering data on your room in the appropriate fields. And at the output you have the finished result: the number of sections of this model in pieces.

The axial distance is determined between the centers of the holes for the coolant

But if you are just considering possible options for now, then it is worth considering that radiators of the same size made of different materials have different thermal output. The method for calculating the number of sections of bimetallic radiators is no different from the calculation of aluminum, steel or cast iron. Only the thermal power of one section can be different.

To make it easier to calculate, there are average data that you can navigate. For one section of the radiator with an axial distance of 50 cm, the following power values are accepted:

- aluminum - 190W

- bimetallic - 185W

- cast iron - 145W.

If you are still only figuring out which material to choose, you can use these data.For clarity, we present the simplest calculation of sections of bimetallic heating radiators, which takes into account only the area of \u200b\u200bthe room.

When determining the number of bimetal heaters of a standard size (center distance 50 cm), it is assumed that one section can heat 1.8 m 2 of area. Then for a room of 16m 2 you need: 16m 2 / 1.8m 2 \u003d 8.88 pieces. Rounding up - 9 sections are needed.

Similarly, we consider for cast-iron or steel bars. All you need is the rules:

- bimetallic radiator - 1.8m 2

- aluminum - 1.9-2.0m 2

- cast iron - 1.4-1.5m 2.

This data is for sections with a center distance of 50cm. Today, there are models on sale with very different heights: from 60cm to 20cm and even lower. Models 20cm and below are called curb. Naturally, their power differs from the specified standard, and if you plan to use "non-standard", you will have to make adjustments. Or look for passport data, or count yourself. We proceed from the fact that the heat transfer of a thermal device directly depends on its area. With a decrease in height, the area of \u200b\u200bthe device decreases, and, therefore, the power decreases proportionally. That is, you need to find the ratio of the heights of the selected radiator to the standard, and then use this coefficient to correct the result.

Calculation of cast iron radiators. It can be calculated by the area or volume of the room

For clarity, we will calculate aluminum radiators by area. The room is the same: 16m 2. We consider the number of sections of a standard size: 16m 2 / 2m 2 \u003d 8pcs. But we want to use small sections with a height of 40 cm.We find the ratio of radiators of the selected size to the standard ones: 50cm/40cm=1.25. And now we adjust the quantity: 8pcs * 1.25 = 10pcs.

Features of functioning

Bottled gas heaters can vary in many ways

It is necessary to pay attention to the characteristics of the equipment, which will allow you to choose the right heater for the features of a particular building and a private house

Main characteristics:

- Availability of automatic control.

- convention type.

- The presence or absence of a fan.

- Energy source used.

- type of combustion chamber.

- Installation power.

- heat exchanger material.

Depending on the version, these heaters can be floor-mounted or wall-mounted. Wall models are characterized by high efficiency and low weight. The power of wall convector heaters on liquefied gas can reach 10 kW, which allows them to heat large rooms. Floor-standing units can be equipped with a larger heat exchanger, but their performance usually does not exceed 5 kW.

When the operation of a propane boiler is already dangerous:

Combustion chamber type

The combustion chamber may be closed or open. In recent years, models with a closed combustion chamber have become the most popular, which ensures the highest possible efficiency and complete safety of equipment operation. Convectors with a closed combustion chamber can have a coaxial pipe instead of a classic chimney, which simultaneously takes fresh air from the street and effectively removes combustion products to the outside. The only drawback of convectors with a closed burner is their high cost.

Heat exchanger material

The material from which the heat exchanger is made will directly affect the durability, efficiency and reliability of the equipment. Today, convectors with heat exchangers made of cast iron and steel are on the market. The most durable, reliable and durable devices are those made with a cast-iron heat exchanger. With proper maintenance, they will last for 50 years. The disadvantage is the high cost of models with cast iron heat exchangers.

Some models of convectors will last you longer than others.

convection type

Depending on their type, thermal installations can use forced and natural convention. Heaters operating with natural convention make practically no noise, which allows them to be used in residential areas. The advantage of devices with forced convection is their improved performance and the ability to use such equipment to heat large rooms. Fuel consumption in a bottled gas convector can vary significantly depending on the power of the equipment and its type of convection.

Control automation

The proposed gas convectors can be equipped with both the simplest automation, which includes only thermostats and control relays, and advanced logic, which ensures maximum automation of the equipment. Depending on the automation used, the cost of heating installations will differ.

Correct power calculation

Universal formula for calculation power is 1 kW thermal energy per 10 square meters of space. However, such calculations will be averaged and will not always allow you to choose the right converter for a particular room.It is necessary to take into account the features of the structure, the height of the ceilings, the presence or absence of windows, high-quality wall insulation, as well as the climate in the region.

When choosing a convector, you need to calculate its power

When choosing fully automated installations that have a forced convention, one can proceed from the calculation of 0.7 kW of thermal energy per 10 square meters of room area. They can be used as the main heating method only in small buildings. A propane gas convector will be an ideal solution for a wooden or brick cottage.

Varieties of convectors by installation method

Wall-mounted appliances have more power compared to other appliances. They do not take up floor space, so they are easy to use. The disadvantages of this placement option include the fact that warm air does not fall down, but tends to the ceiling, and the floor remains cold.

Floor-standing types of appliances, although they are produced with less power, but because of their location at the very surface of the floor, they heat the room much faster. Convenient is the ability to move to different points, which cannot be done with a permanently fixed wall electric convector.

The device of small-sized electric heating devices in floor niches significantly saves space in small rooms. In recent years, such placement is very popular, although it requires preliminary work.

Positive feedback won skirting types of convectors. which give a feeling of comfort to the feet. Their power is small, but to increase the flow of warm air, some users buy two or more devices, which equates to the energy consumption of a large device.

Different types of thermostats

The temperature controller is adjusted so that in the absence of residents in the house, the heating of the room occurs in a gentle mode and does not require excessive consumption of electrical energy. By time, you can set the mode when the inclusion occurs automatically with the return of the household.

Temperature regulators are mechanical and electronic. The first type significantly reduces the price of the device, but is not very convenient in terms of comfort. He cannot fully track the temperature regime, sometimes he allows, albeit minimal, but additional electricity overruns.

In addition, switching is accompanied by low sounds, which at night can cause trouble to a sleeping person.

Calculation of the required convector power

For a detailed calculation of thermal power, professional methods are used. They are based on the calculation of the amount of heat losses through the building envelope and the corresponding compensation for their thermal heating power. Methods are implemented both manually and in software format.

To calculate the thermal power of convectors, the integrated calculation method is also used (if you do not want to contact the designers). The power of convectors can be calculated according to the size of the heated area and the volume of the room.

The generalized standard for heating a built-in room with one outer wall, a ceiling height of up to 2.7 meters and a single-glazed window is 100 W of heat per square meter of heated area.

In the case of a corner location of the room and the presence of two external walls, a correction factor of 1.1 is applied, which increases the calculated heat output by 10%. With high-quality thermal insulation, triple window glazing, the design power is multiplied by a factor of 0.8.

Thus, the calculation of the thermal power of the convector is calculated by the area of the room - for heating a room of 20 sq.m with standard heat loss indicators, a device with a power of at least 2.0 kW is required. With the angular arrangement of this room, the power will be from 2.2 kW. In a well-insulated room of equal area, you can install a convector with a capacity of about 1.6 - 1.7 kW. These calculations are correct for rooms with a ceiling height of up to 2.7 meters.

In rooms with a higher ceiling height, the method of calculation by volume is used. The volume of the room is calculated (the product of the area and the height of the room), the calculated value is multiplied by a factor of 0.04. When multiplied, the heating power is obtained.

Using convectors in large rooms

Using convectors in large rooms

According to this method, a room with an area of 20 square meters and a height of 2.7 meters requires 2.16 kW of heat for heating, the same room with a ceiling height of three meters - 2.4 kW. With large volumes of rooms and a significant ceiling height, the calculated area power can increase up to 30%.

Calculation of the power of convectors by volume

You already know how to calculate the power of a convector, taking into account the area of \u200b\u200bthe premises. But some experts believe that it is best to calculate by their volume. For this, a formula is used, according to which for 1 cu. m volume requires 40 W of heat

. The main advantage of this formula is that it is the most accurate, as it fully takes into account the height of the ceilings.

The process of calculating the power of convectors by volume is carried out as follows:

- We take a tape measure and measure the room;

- We calculate the volume of the room by multiplying the obtained values by each other;

- We multiply the volume by 0.04 (40 W per 1 cubic meter);

- We get the recommended thermal power.

A more illustrative example - let's try to calculate the power of convectors for a room 3 m long, 2.5 m wide and 2.7 m high. Its volume is 20.25 cubic meters. m, therefore, the power of the convector heaters used should be 0.81 kW (feel free to buy a 1 kW model). If we make similar calculations for the area, then the recommended figure will be 0.75 kW.

As in the case of calculating the power of convectors by area, it is necessary to take into account in the calculations possible heat losses that may be present in any premises.

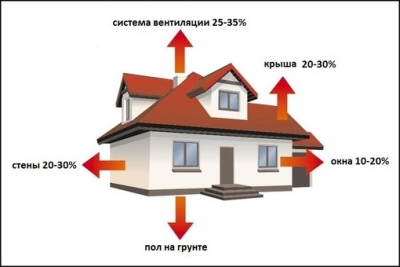

Our houses lose a lot of heat energy. In order not to overpay for electricity, just get rid of heat loss.

Making calculations by area or volume, and completely ignoring heat losses, you risk getting an inefficient heating system - it will be cool in the rooms. The worst thing is if severe frosts hit in winter, which are not very typical for the area - if the calculations were made incorrectly, the convectors will not cope

Next, we will tell you how to reduce heat loss. To reduce them by 10-15% will help the banal lining of homeownership with an additional layer of brick and thermal insulation.Yes, the costs can be large, but you must remember that when using electric convectors, the cost of lighting can be gigantic - this is associated with large heat losses.

(in fact, you heat the air "outside").

You also need to work on windows:

- Single glazing requires a 10% power increase;

- Double windows do not lead to any heat loss (already a plus);

- Triple windows save up to 10%.

Theoretically, triple pane windows can lead to substantial savings, but there are other factors to consider.

In the process of warming, it is necessary to work in the attic. The thing is that the presence of an unheated attic entails losses. Therefore, you need to lay a layer of effective thermal insulation on it - it is not very expensive, but you can save up to 10% of thermal energy. By the way, an indicator of 10%, based on the area of \u200b\u200bthe house of 100 square meters. m, this is approximately 24 kW of heat per day - equivalent to cash costs of 100 rubles / day or 3000 rubles / month (approximately).

Climate zones are also important

Climatic zones also have their own coefficients:

- the middle lane of Russia has a coefficient of 1.00, so it is not used;

- northern and eastern regions: 1.6;

- southern bands: 0.7-0.9 (minimum and average annual temperatures in the region are taken into account).

This coefficient must be multiplied by the total thermal power, and the result obtained should be divided by the heat transfer of one part.

conclusions

Thus, the calculation of heating by area is not particularly difficult. It is enough to sit for a while, figure it out and calmly calculate.With it, each owner of an apartment or house can easily determine the size of the radiator that should be installed in a room, kitchen, bathroom or anywhere else.

If you doubt your abilities and knowledge, entrust the installation of the system to professionals. It is better to pay once to professionals than to do it wrong, dismantle and re-start work. Or do nothing at all.

Selecting an installation site

Rather, the question is not like this: which of the convectors is suitable for fulfilling your wishes. If you want to bring the appearance of the room closer to the standard, you can hang rectangular wall convectors under the windows. A little more attention is drawn to models that can be installed under the ceiling, but they are inaccessible to children and pets - they will not be able to burn themselves or "adjust" in their own way. The mounting method is the same here - on brackets fixed on the wall. Only the shape of the brackets differs.

You can choose any place for installing an electric convector. It is only desirable that it is not covered by furniture.

If you want the heaters not to be visible, you will have to choose between skirting models and floor models. There is a big difference in installation: the skirting boards were simply installed and plugged into the network, and under the floor ones you will have to make special recesses in the floor - their top panel should be on the same level with the finished floor. In general, you won’t install them without a major overhaul.

These are floor mounted convectors. They are also electric.

Calculations of electricity consumption by household appliances

Before finding out how much electricity a heater consumes, consider the consumption of other household appliances.All devices that require electrical energy to operate consume this energy in accordance with their power. However, not all such devices work in the same way and, accordingly, the consumption of electricity is not the same. Appliances such as an electric kettle, TV, various types of lighting devices, when turned on, begin to consume the maximum amount of energy. This amount of energy is indicated in the technical characteristics of each device and is called - power.

Let's say a kettle with a power of 2000 W was turned on to heat water and worked for 10 minutes. Then we divide 2000 W by 60 minutes (1 hour) and get 33.33 W - this is how much the kettle consumes in one minute of operation. In our case, the kettle worked for 10 minutes. Then we multiply 33.33 W by 10 minutes and get the power that the kettle has consumed during its operation, i.e. 333.3 W, and it is for this consumed power that you will have to pay.

The operation of the refrigerator, electric stove and electric convector is somewhat different.

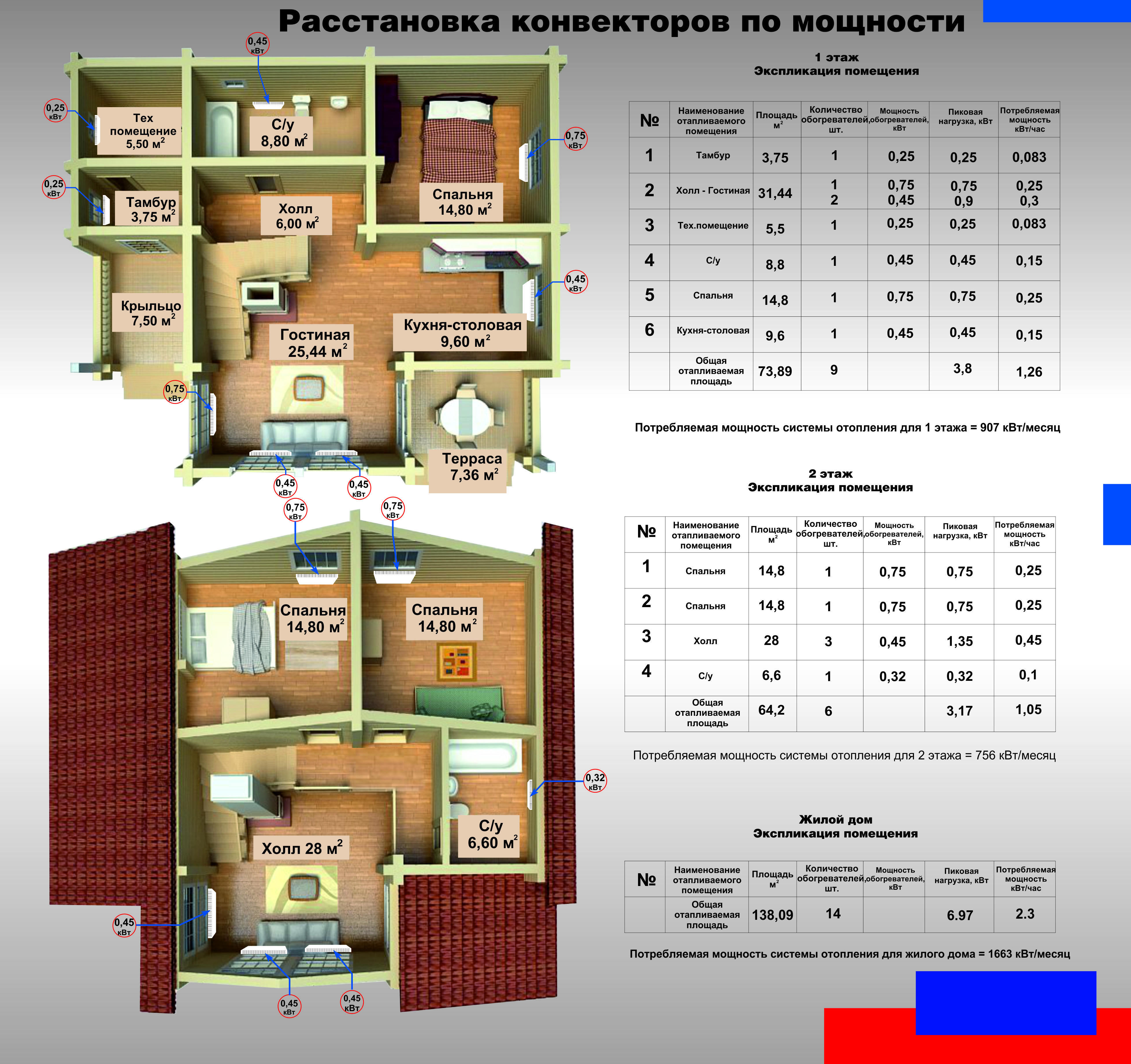

Heating convector power table

This section of the article provides a table for selecting the capacities of convectors depending on the area of the heated room and volume.

| Heated area, sq.m, room height - up to 2.7 meters | Thermal power of the convector, kW | Heat output of the convector (ceiling height -2.8 m) | Heat output of the convector (ceiling height -2.9 m) | Heat output of the convector (ceiling height -3.0 m) |

| 1 | 2 | 3 | 4 | 6 |

| 10 | 1,0 | 1,12 | 1,16 | 1,2 |

| 15 | 1,5 | 1,68 | 1,74 | 1,8 |

| 20 | 2,0 | 2,24 | 2,32 | 2,4 |

| 25 | 2,5 | 2,8 | 2,9 | 3 |

| 30 | 3,0 | 3,36 | 3,48 | 3,6 |

From the table below, you can choose a convector according to the heated area. Heights are given in 4 versions - standard (up to 2.7 meters), 2.8, 2.9 and 3.0 meters.With an angular configuration of the premises, a multiplying factor of 1.1 must be applied to the selected value, while in construction with high-quality thermal insulation - a reducing factor of 0.8. With a ceiling height of more than three meters, the calculation is carried out according to the above method (by volume using a coefficient of 0.04).

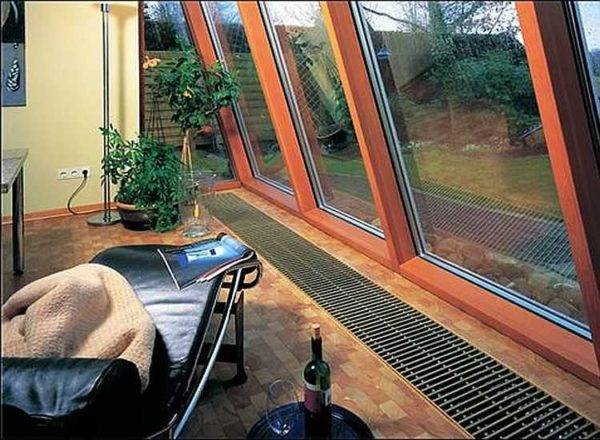

After calculating the thermal power selection of heating convectors - quantity, geometric dimensions and method of installation. When selecting devices in rooms of a large area and volume, it is necessary to take into account the characteristics and power of each individual convector. It is necessary to be guided by the principle of increased power of the convector installed in the zone of blocking the maximum heat losses. That is, a device installed along a full profile glass showcase should have a higher thermal performance than a convector placed near a small window or external wall.

How to calculate and choose an electric convector

We calculate the required power of the convector

- Calculation of the power of the convector according to the area of the room. Provided that the room is well insulated and has a ceiling height of no more than 2.7 m, for every 10 m² of heated area, 1 kW of thermal energy will be sufficient. For a bathroom of 6 m², one heater per 1 kW should be enough. Bedroom 20 m² - convector with a capacity of 2 kW.

- number of windows. The principle of operation of the devices is associated with the use of convection, which in a certain way makes its own adjustments to the choice of heaters. The total heat energy required to heat the room should be divided by the number of window openings.So, for a room of 20 m² and having two windows, you will need to install 2 heaters of 1 kW each.

- Presence of heat loss. The technical characteristics of electric convectors, given in the instruction manual of the device, in particular, the coefficient of heated area, are taken taking into account the absence of significant heat losses in the room. If there is an uninsulated basement, walls of the house, you should choose a heater with a sufficient power reserve.

Choosing an electric convector according to functionality

What do manufacturers offer?

- Mechanical thermostat. Almost every device is equipped with a mechanical or electronic thermostat. The mechanics do not withstand loads well, cannot accurately regulate the temperature regime. It is strongly not recommended to leave the electric convector unattended. If overheated, the mechanical control unit may fail, resulting in a fire hazard.

- Electronic thermostat - maintains the set temperature with a minimum error of no more than 1/10 degree. Comes with a timer and temperature sensor. The use of an electronic thermostat reduces energy consumption. Wall-mounted energy-saving electric heating convectors with an electronic thermostat are recommended to be used as the main source of heating. The control unit has several degrees of protection that ensure the safety of operation.

- A programmable thermostat is a control unit installed in premium class heaters. Typically, such modifications are equipped with a remote control and can even be connected to a GSM notification system. Programming of modes of operation is provided.Installed from 2-4 ready-made programs, and it is also possible to set an individual heating mode. The heater is switched on with the control panel.

- Additional functions. Climatic equipment from well-known manufacturers often has built-in modules that affect the quality of operation. Models with a humidifier are popular. Premium class heaters automatically monitor and maintain the required humidity in the room.

Does the electric convector dry the air

When using a fan, there is a slight decrease in moisture. This is especially noticeable if the heaters are operated continuously. Compared to heat guns, the convector does not dry the air at all.

As an additional measure to maintain a healthy microclimate, it makes sense to put an air humidifier complete with an ionizer, or purchase a heater modification with a built-in device of this type. The control system itself will automatically monitor the humidity level and maintain it at the proper level.

What is better, an electric convector or a fan heater

Unlike a fan heater, convectors operate in a safer mode. Thanks to this, you can even hang electric convectors on a wooden wall. The surface temperature of the housing rarely exceeds 60°C.

Of course, you should follow the rules for installing electric convectors in a wooden house:

- The electric wire is laid over wooden surfaces in a special refractory corrugation.

- Thermal insulation with a foil coating is placed under the heater mounted on the wall.

- Floor electric heating convectors for a wooden cottage are installed in such a way that the nearest wall is at least 0.5 m. There is no need to lay non-combustible material under the heater.

Type

Oil radiator

One of the most popular household heaters. They have a power of 1.0 to 2.5 kW and are used in apartments, offices, and cottages.

| Principle of operation | Inside a sealed metal case filled with mineral oil, there is an electric coil. When heated, it transfers its heat to the oil, and it, in turn, to the metal case, and then to the air. Its outer surface consists of several sections (ribs) - the greater their number, the greater the heat transfer, with equal powers. The heater maintains the set temperature in the room and automatically turns off in case of overheating. As soon as the temperature starts to drop, it turns on. |

| Advantages | Low heating temperature of the case (about 60 ° C), due to which oxygen is not “burned” fireproof, silent due to the thermostat and timer, some models do not require shutdown, high mobility (the presence of wheels makes it easy to move them from room to room) |

| Flaws | Relatively long heating of the room (however, they retain heat longer), the surface temperature of the radiator does not allow you to freely touch it (which is extremely dangerous if there are children in the room), relatively large dimensions |

| conclusions | Oil radiators are ideal for heating apartments. Silence, efficiency and safety are very important here. One heater is enough to heat a hall or bedroom.Oil-filled radiators are equipped with wheels and can be easily moved from room to room. For the summer, the oil cooler can simply be taken out to the barn or put in the pantry. |