- 8 Sawdust stove - nothing complicated and affordable

- How to make a long-burning solid fuel boiler with your own hands: drawings and diagrams

- Jet heating unit from a propane cylinder

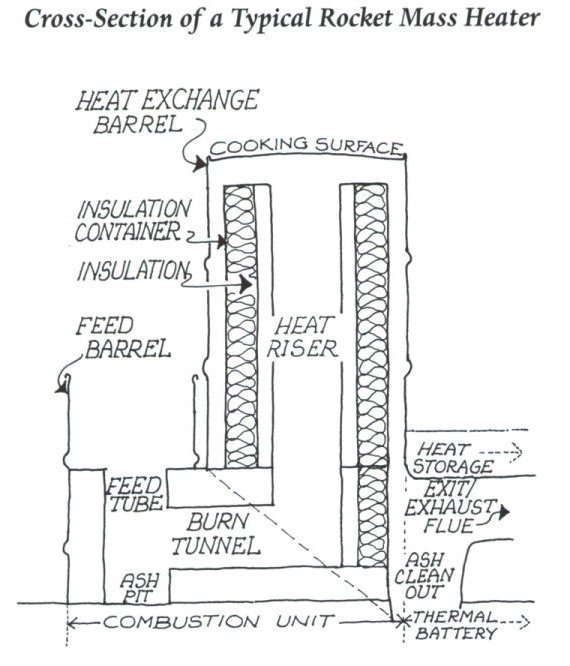

- Boiler unit

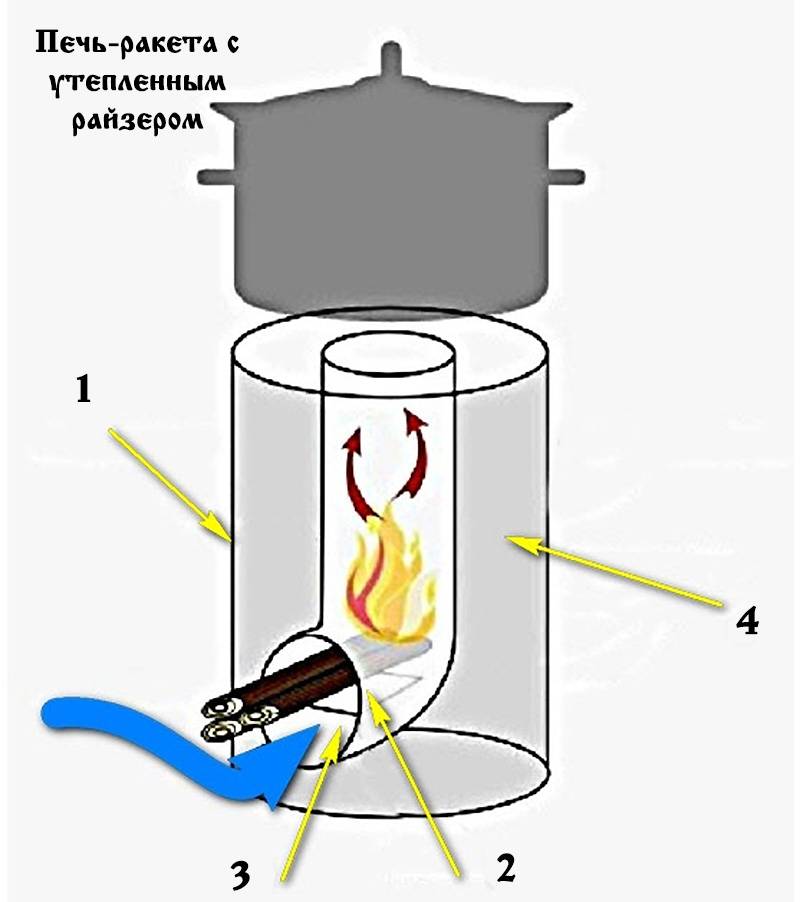

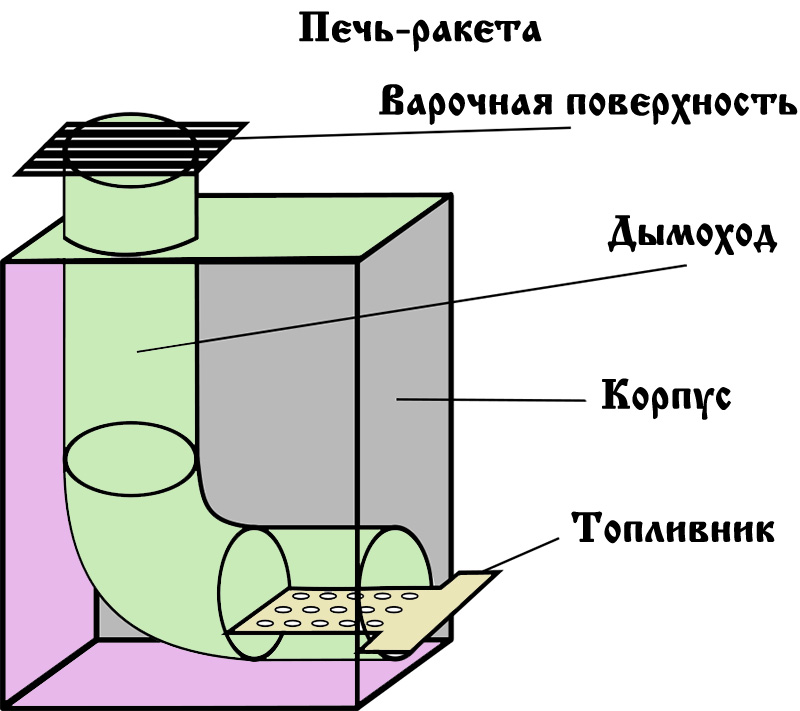

- What is a rocket stove?

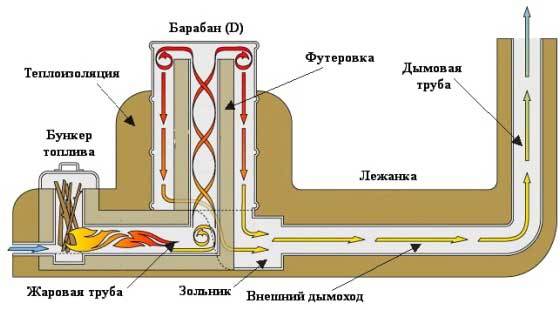

- Heating unit with bed

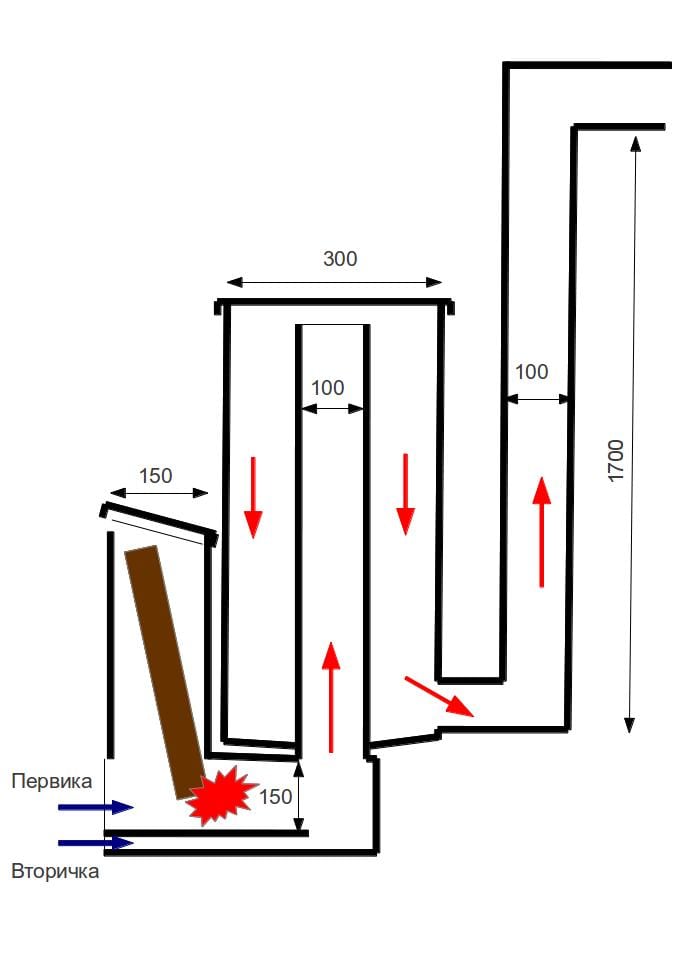

- Dimensions and proportions of the structure

- Lining Features

- How to make a DIY rocket stove

- Design of gas furnaces

- Stationary oven

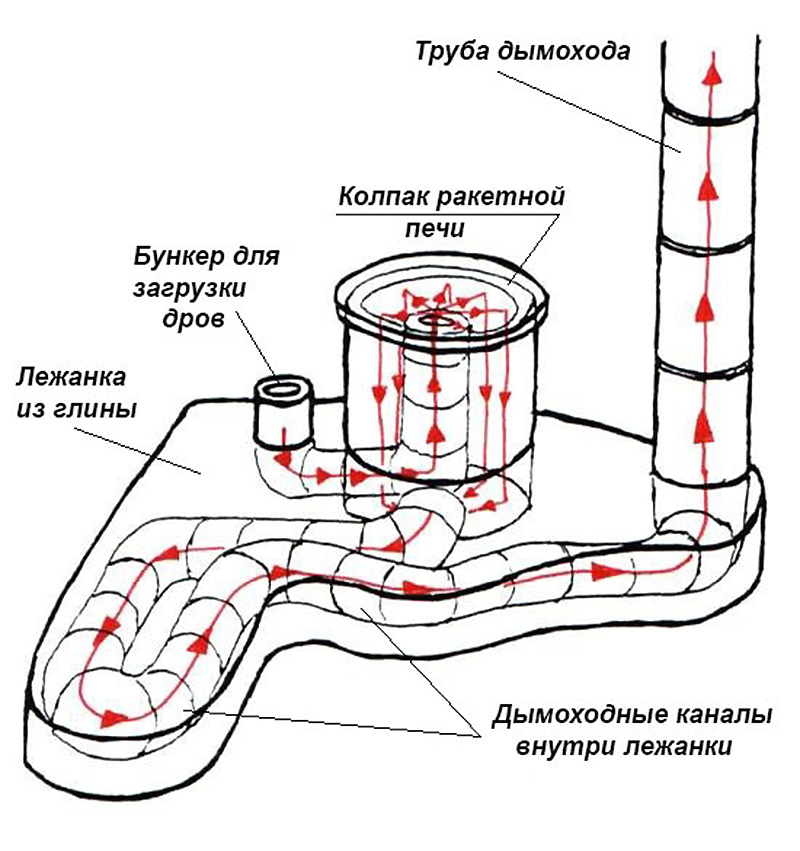

- Making a rocket stove with a bench

- Necessary materials

- Construction principles

- The kiln laying process

- Useful tips for making a TT boiler

- Design features of furnaces

- Types of stoves for different operating conditions

- Combined brick-metal barrel oven

- Device and principle of operation

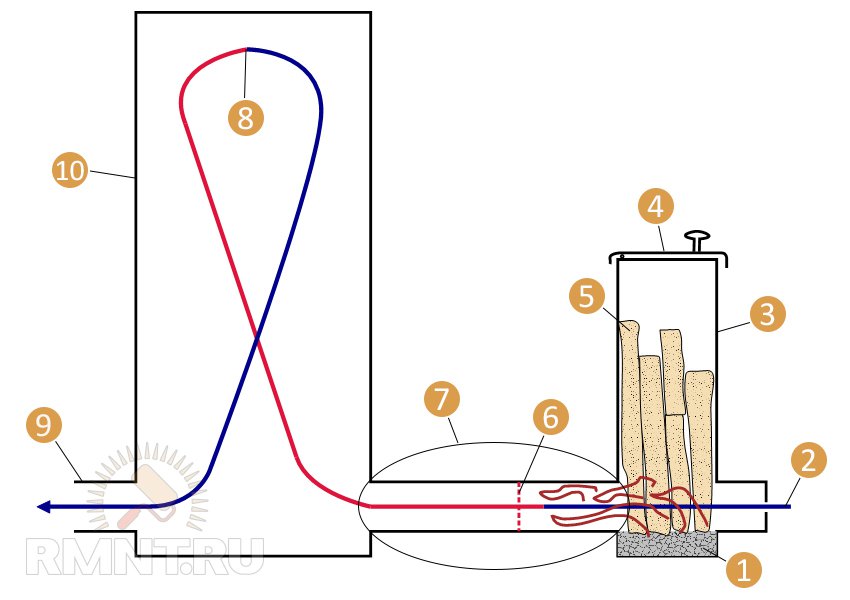

- Advanced Water Loop Rocket Furnace

8 Sawdust stove - nothing complicated and affordable

Such a device runs on the cheapest fuel, which burns well and gives a lot of heat energy. Often sawdust is simply thrown away or sold at a symbolic price. But they can burn only in special devices; in other types of furnaces, if they burn, it is bad. The design features provide for the possibility of strong compaction of the wood pulp so that no air remains between its particles.In this state, they will not burn out quickly, but smolder, giving off heat sufficient to heat one or two rooms.

The installation is going on the same principle as others with vertical loading. It is better to use cylindrical metal products, but if this is not possible, you can make a rectangular shape. Unlike a potbelly stove, where firewood is loaded from the side, we provide for loading sawdust from above. This one differs from other models by the presence of a conical tube. It is inserted in the middle of the air regulator - a circle with a hole inside the oven. The design is shown in the drawing.

We fill the sawdust inside and ram it as tightly as possible to prolong the burning process. We remove the pipe - it's easy because of its conical shape. The hole formed in its place will serve as a chimney and for supplying oxygen to support sawdust smoldering. From the side of the blower, we set fire to sawdust - the process has begun

It is important to properly adjust the chimney: excessive draft will draw heat out into the street, with weak combustion, smoke will penetrate into the room

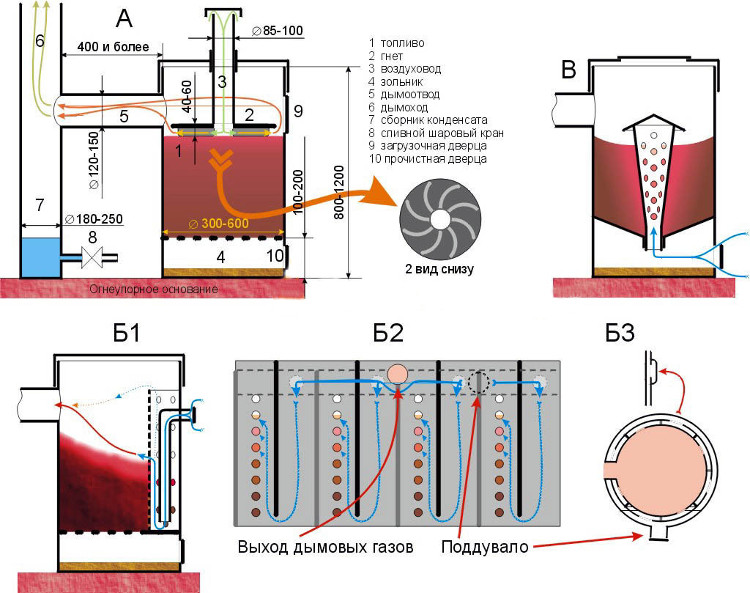

How to make a long-burning solid fuel boiler with your own hands: drawings and diagrams

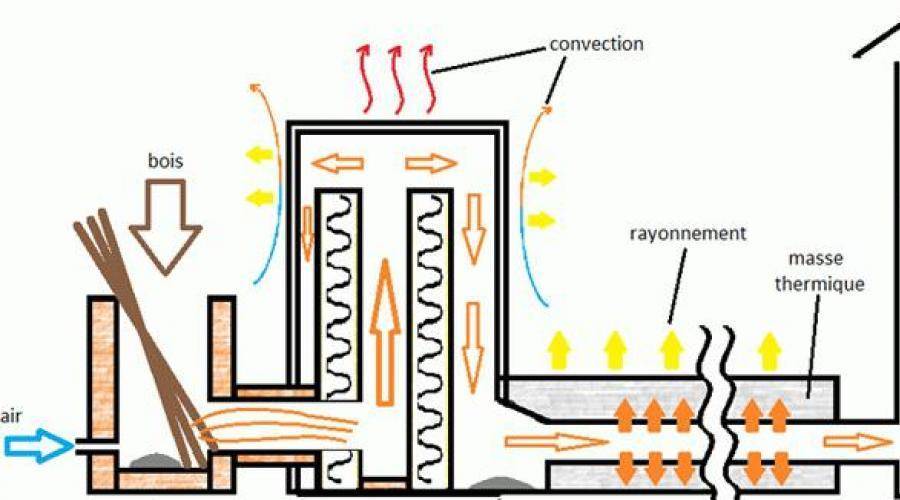

Before you start manufacturing the boiler, you need to decide on its design. Its choice depends on the purpose of the unit. If it is intended for heating a small utility room, garage or country house, then it is not necessary to make a water circuit in it. Heating of such a room will occur directly from the surface of the boiler, by convection of air masses in the room, as from a furnace. For greater efficiency, you can arrange forced air blowing of the unit with a fan.If there is a liquid heating system in the room, it is necessary to provide a device in the circuit boiler in the form of a coil from a pipe or other similar structure.

Scheme for connecting a solid fuel boiler to a heating system

The choice of option also depends on the type of solid fuel that will need to be used. For heating with ordinary firewood, an increased volume of the furnace is required, and for the use of small fuel pellets, you can arrange a special container from which the pelleted fuel is automatically fed into the boiler. For the manufacture of long burning solid fuel boiler with your own hands, the drawing can be taken and universal. It is suitable for any type of solid fuel used.

Drawing of a solid fuel boiler for long burning with a power of 25/30/40 kW

We will tell you step by step how and from what parts it is possible to make a long-burning solid fuel heating boiler according to the proposed scheme:

- prepare a place where the future unit will be installed. The base on which it will stand must be even, strong, rigid and fireproof. A concrete foundation or a thick cast-iron or steel slab is best suited for this. The walls must also be upholstered with refractory material if they are wooden;

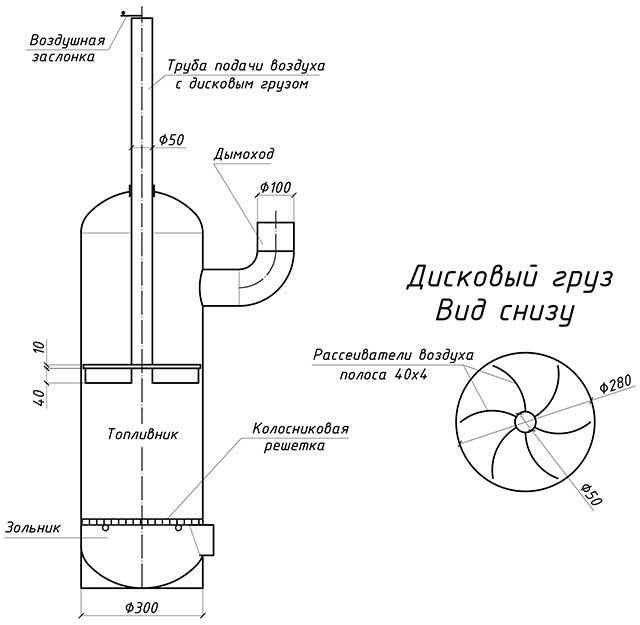

- we collect all the necessary material and tools: of which we need an apparatus for electric arc welding, a grinder and a tape measure. From materials: sheet 4 mm steel; 300 mm steel pipe with 3 mm walls, as well as other pipes 60 and 100 mm in diameter;

The structure and principle of operation of a solid fuel boiler

- in order to make a long-burning solid fuel boiler, you need to cut a piece 1 m long from a large 300 mm pipe.It can be a little less, if necessary;

- from a steel sheet we cut out the bottom along the diameter of the pipe and weld it, providing it with legs from a channel up to 10 cm long;

- the air distributor is made in the form of a circle made of steel sheet with a diameter 20 mm smaller than the pipe. An impeller from a corner with a shelf size of 50 mm is welded into the lower part of the circle. To do this, you can use a channel of the same size;

- from above, in the middle of the distributor, we weld a 60 - mm pipe, which should be higher than the boiler. In the middle of the distributor disk, we cut a hole through the pipe, so that there is a through tunnel. It is needed for air supply. A damper cuts into the upper part of the pipe, which will allow you to adjust the air supply;

Schematic representation of a solid fuel boiler device

- in the lowest part of the boiler we make a small door, equipped with a valve and hinges, leading to the ash pan for easy removal of ash. From above in the boiler we cut a hole for the chimney and weld a 100 mm pipe into this place. At first, it goes at a slight angle to the side and up by 40 cm, and then strictly vertically up. The passage of the chimney through the ceiling of the room must be protected according to fire safety rules;

- we finish the construction of a heating boiler for long-burning solid fuel by making the top cover. In its center there should be a hole for the air flow distributor pipe. The fit to the walls of the boiler must be very tight, excluding the ingress of air.

Drawing with dimensions for creating a solid fuel boiler with your own hands

Long Burning Boiler - Sectional View

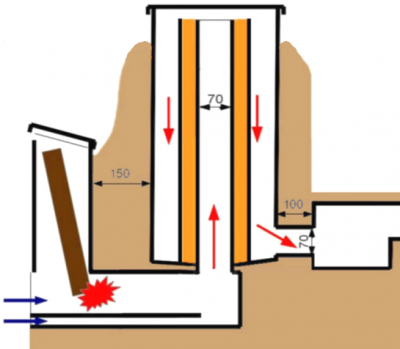

Jet heating unit from a propane cylinder

A gas cylinder rocket stove is an easy-to-make wood-burning stove that consumes fuel economically and heats the room efficiently.

It is used to assemble:

- empty propane tank (unit body);

- steel pipe with a diameter of 100 mm (for arranging a chimney and a vertical channel);

- profile steel pipe 150x150 mm (firebox and hopper are made);

- sheet steel 3 mm thick.

Making a furnace from a gas cylinder requires the use of a welding machine. If you plan to assemble such a rocket oven with your own hands, the drawings will help you accurately observe the optimal dimensions of all structural elements.

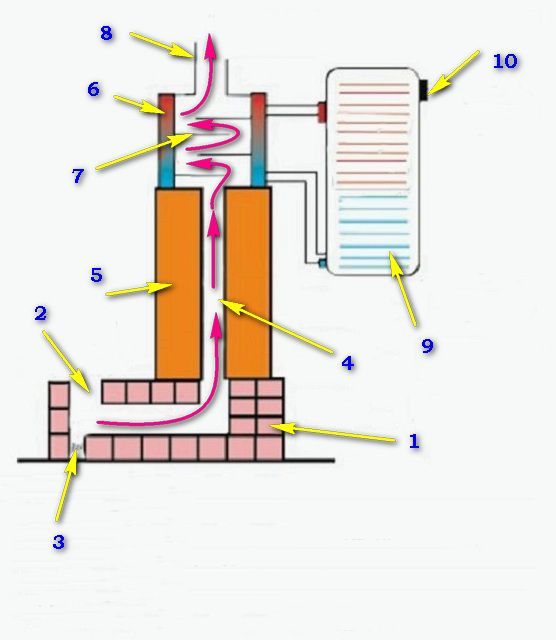

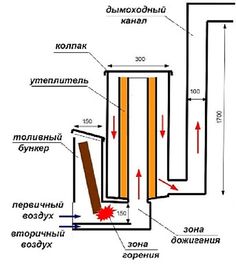

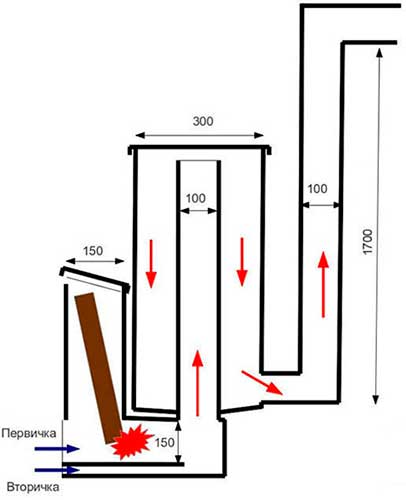

Scheme of the processes in the rocket furnace

Scheme of the processes in the rocket furnace

At the preliminary stage of work, a gas cylinder should be prepared - turn off the valve, fill the container to the top with water to ensure that gas vapors that can explode from a spark are removed from the container. Then the upper part is cut along the seam. In the lower part of the resulting cylinder, a hole is cut under the chimney, and in the bottom - under the combustion chamber with an attached firebox. The vertical channel is brought out through a hole in the bottom, a structure from a profile pipe is welded from the bottom side, according to the rocket drawing.

If you are installing a rocket furnace from a gas cylinder on your own, you should carefully consider the quality of the welds and check their tightness - air should not flow uncontrollably into the operating furnace. If everything is in order, you can install a chimney.

Such a furnace for the home is regulated in terms of power by the volume of fuel loading. The jet stove is put into operation by supplying air through the combustion chamber, this is regulated by the bunker cover. Further, secondary air is constantly supplied to the unit.This stove for heating explodes at the end of the combustion process, since it is impossible to shut off the supply of secondary air, and soot settles on the inner walls of the vertical channel. The cover of the casing is made removable so that it can be periodically removed.

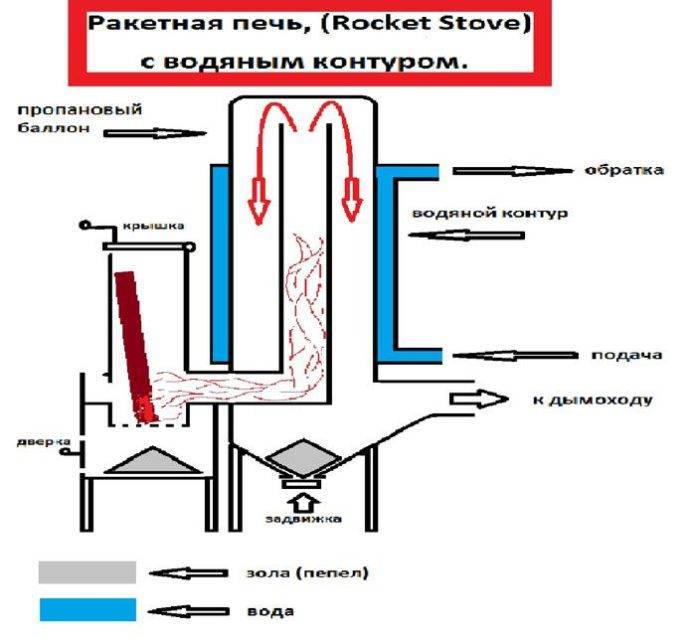

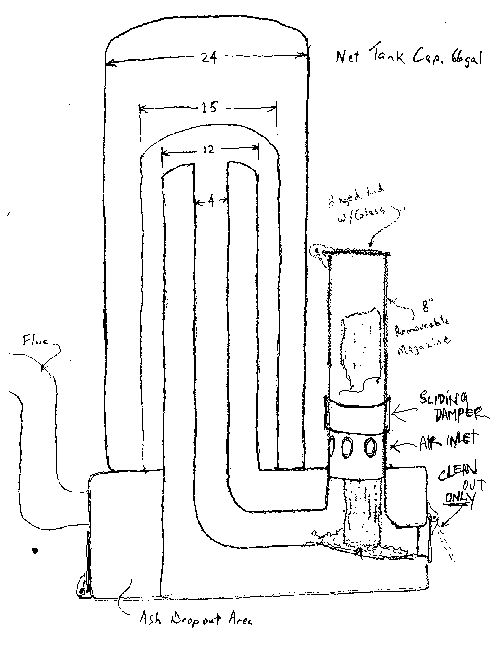

Boiler unit

A long-burning boiler can be obtained by installing a water circuit on the chimney of a stove made from a gas cylinder or other materials, but according to the same scheme indicated above. However, water heating in the circuit of such a unit will be inefficient, since the main part of the thermal energy is transferred to the room air and to the containers on the hob.

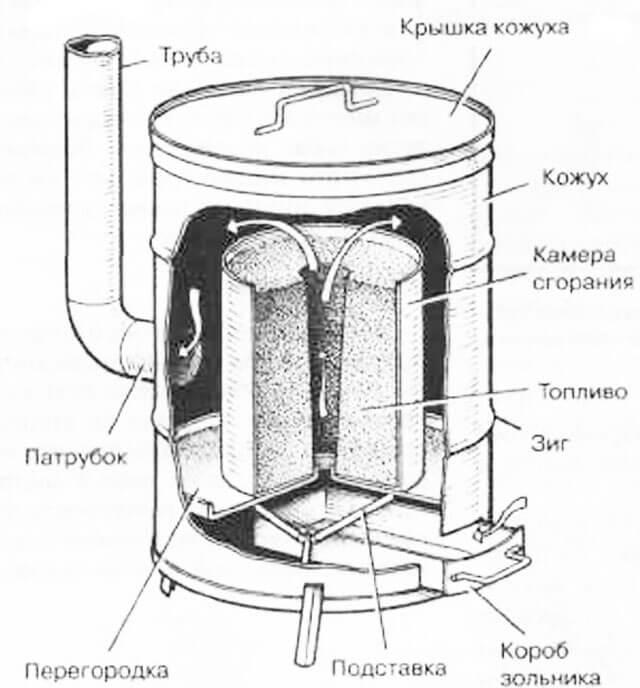

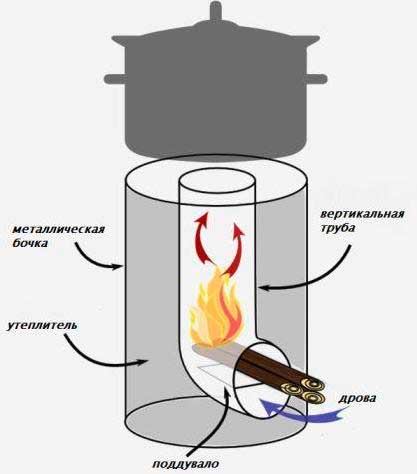

An effective version of a rocket furnace from a metal barrel

An effective version of a rocket furnace from a metal barrel

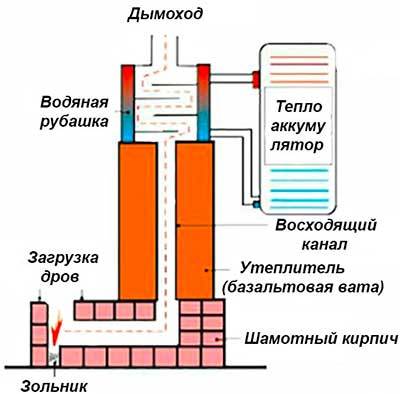

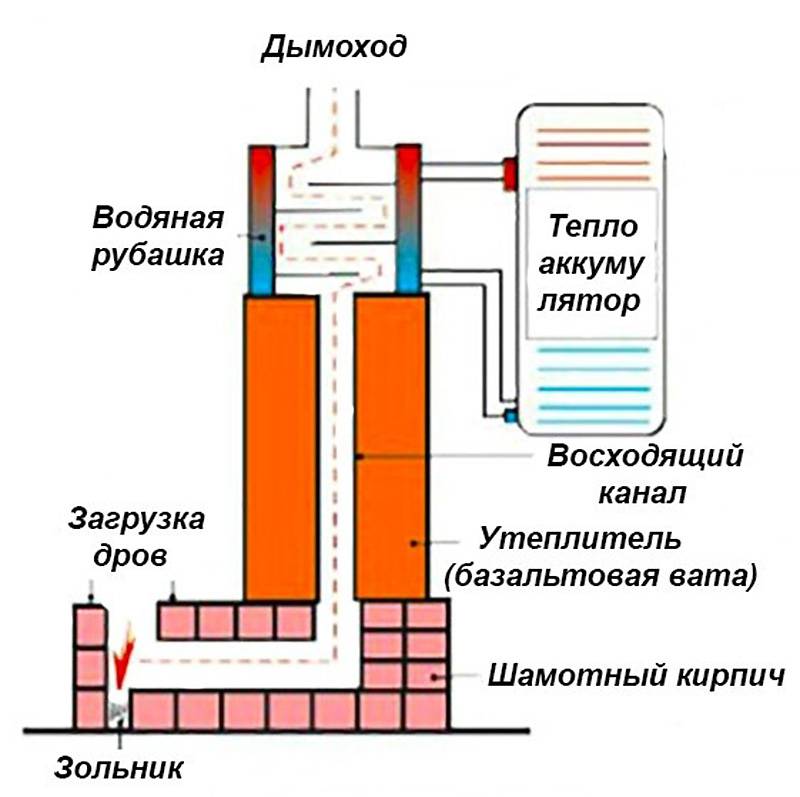

If you want to create a rocket boiler for water heating with high efficiency, you will have to sacrifice the cooking function. Bake do-it-yourself rocket according to the drawing below, can be mounted in a short time.

This will require:

- fireclay bricks and refractory masonry composition (for mounting the base of the stove with a firebox);

- steel pipe with a diameter of 70 mm (for a vertical channel);

- steel barrel (for casing);

- refractory heat insulator;

- sheet steel 3 mm thick and a metal barrel (or pipe) of a smaller diameter than the casing (for arranging a water jacket and smoke channels for heating the water circuit);

- steel pipe with a diameter of 100 mm for the chimney;

- container, pipes and connecting pipes for arranging a heat accumulator.

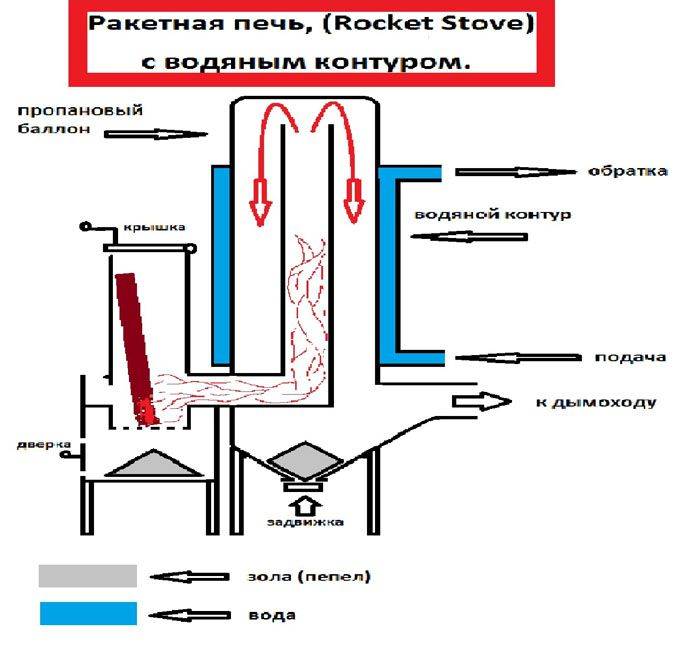

A rocket furnace with a water circuit is characterized by the fact that the thermal insulation of the vertical channel provides an optimal mode for burning pyrolysis gases, while all the heated air enters the "coil" with a water jacket and gives off the main part of the thermal energy there, heating the coolant.

Rocket stove with water circuit

Rocket stove with water circuit

The heat accumulator will continue to supply the heated coolant to the heating circuit even after the furnace itself has cooled down. The water tank is provided with a thick layer of insulation.

What is a rocket stove?

A rather interesting option for any room is a do-it-yourself rocket stove. Its design is original, and it is suitable for a private home.

, and for a bath, as well as for other types of structures

When creating it with a contour, expensive materials are not required, the dimensions are selected depending on the dimensions of the heated room, however, it is important to make the correct drawing in advance

to get an efficient and durable device. If the correct and up-to-date scheme is applied, then you can make high-quality water heating in the room with your own hands

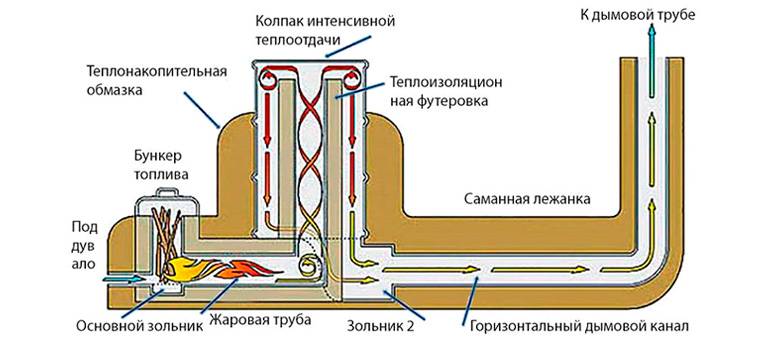

Heating unit with bed

A rocket stove with a bench is a device that can create a comfortable environment in one room. Such a unit cannot be used to heat several rooms, not to mention the whole house.

The arrangement of such a long-burning unit with your own hands requires accurate calculations - its power and the maximum allowable length of the hog on which the stove bench is arranged depend on the size of the stove body

It is also important to choose the right cross-section of pipes for mounting the structure.Errors will result in the fact that the jet furnace will quickly become tightly overgrown with soot or will roar loudly during operation due to turbulence of gas flows

The design of the oven with a stove bench

The design of the oven with a stove bench

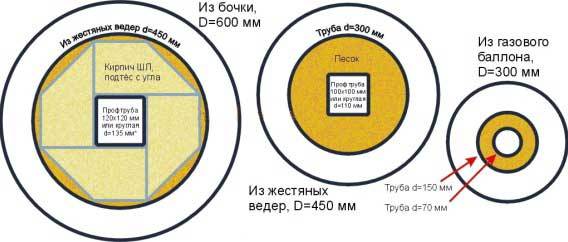

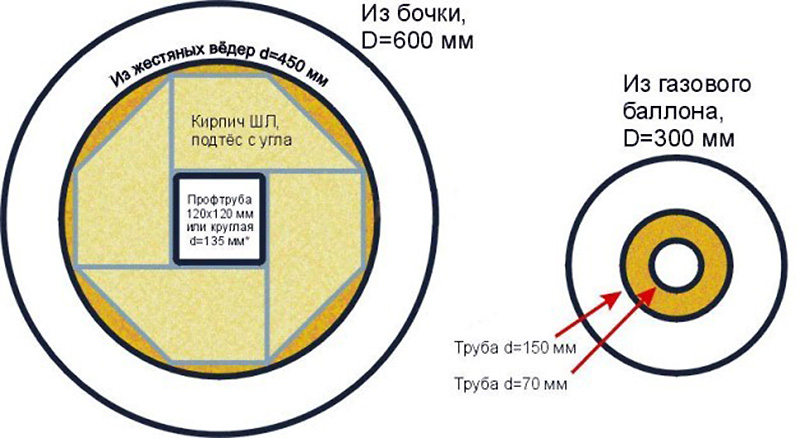

Dimensions and proportions of the structure

To build a do-it-yourself rocket stove, detailed drawings must be prepared, indicating the dimensions of all elements. At the stage of project preparation, calculations are made based on the base values to which all the others are tied.

The basic calculated values are:

- D is the diameter of the drum (furnace body);

- S is the area of the inner cross section of the drum.

Calculations of the design parameters are carried out taking into account that:

- The drum height (H) is between 1.5 and 2 D.

- The drum is coated with 2/3 N (if it is planned to cut it curly, then 2/3 of the height should be the average).

- The thickness of the coating layer on the drum is 1/3 D.

- The area of the internal cross-section of the vertical channel (riser) is 4.5-6.5% of S, the optimal value is in the range of 5-6%.

- The height of the vertical channel is as high as the furnace design allows, but the gap between the upper edge of the riser and the drum cover must be at least 70 mm for normal flue gas circulation.

- The length of the flame pipe (fire pipe) must be equal to the height of the vertical channel.

- The cross-sectional area of the igniter is equal to the corresponding indicator of the riser. Moreover, it is recommended to use a square-section profile pipe for the fire pipeline, in this case the furnace works more stable.

- The cross-sectional area of the blower is ½ of the cross-sectional area of the furnace and riser. For stability and smooth adjustment of the furnace mode, a rectangular profile pipe with an aspect ratio of 2: 1 is used, which is laid flat.

- The volume of the secondary ash pan depends on the volume of the drum minus the volume of the riser. For a barrel stove - 5%, for a gas cylinder stove - 10%. For intermediate volume tanks, it is calculated according to linear interpolation.

- The cross-sectional area of the external chimney is 1.5-2 S.

- The adobe cushion under the external chimney should be 50-70 mm thick - if the channel is made of a round pipe, the count is from the bottom point. The thickness of the pillow under the chimney is halved if the bench is mounted on wooden floors.

- The thickness of the coating layer of the bench above the chimney channel is 0.25 D if the drum from the barrel is 600 mm, and 0.5 D if the drum from the cylinder is 300 mm. If the coating layer is reduced, the structure will cool down faster after heating.

- The height of the outer chimney must be at least 4 meters.

- The length of the flue, on which the length of the bed depends: for a stove from a barrel - up to 6 m, for a stove from a cylinder - up to 4 m.

A long-burning rocket furnace made from a 600 mm diameter barrel reaches a power of about 25 kW, and a heating rocket made from a 300 mm cylinder reaches up to 15 kW. It is possible to regulate the power only due to the volume of fuel loading; such a stove does not have air regulation, since an additional flow violates the furnace mode and provokes the release of gases into the room. By changing the position of the blower door, it is not the power that is regulated, but the operating mode of the furnace.

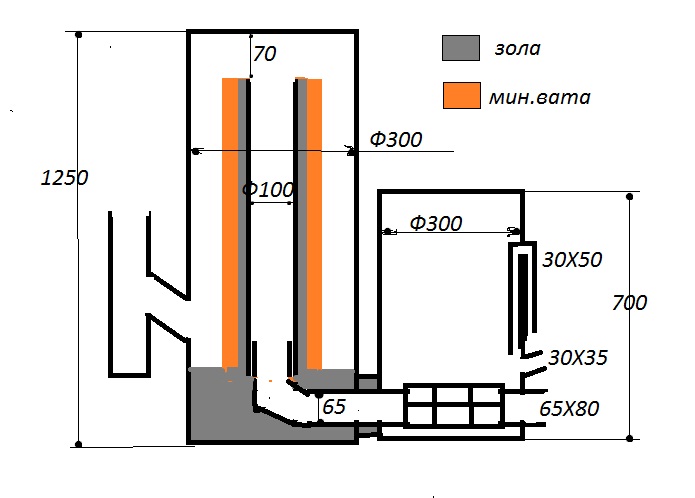

Lining Features

The quality of the thermal insulation of the riser directly affects the efficiency of the heating unit. Light fireclay bricks SHL and river sand mixed with alumina are available for lining in our area.An external metal casing should be provided for the lining, otherwise the materials will quickly absorb carbon deposits and the furnace will roar during operation. The end face of the lining is tightly covered with furnace clay.

Proper lining

Proper lining

When using hewn fireclay bricks, the remaining cavities are filled with sand. If only sand is used for lining, it is sifted from large debris and covered in layers - each approximately 1/7 of the pipe height. Each layer is compacted tightly and sprinkled with water to form a crust. The backfill must be dried for a week, and then cover the end with a layer of oven clay. Then the construction of a rocket furnace with their own hands continues according to the drawings.

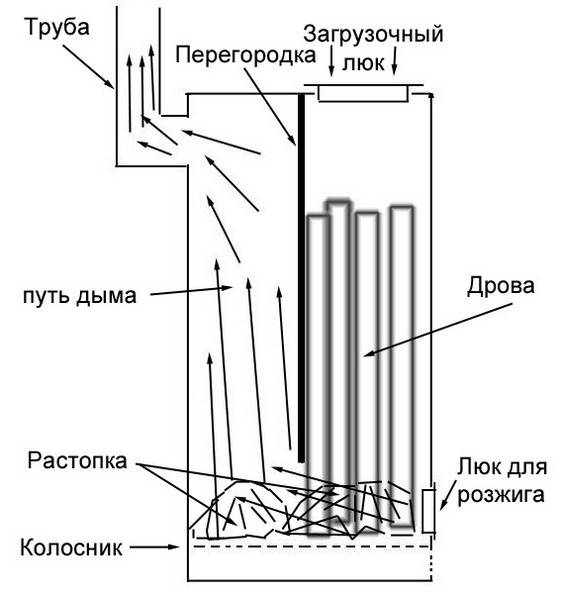

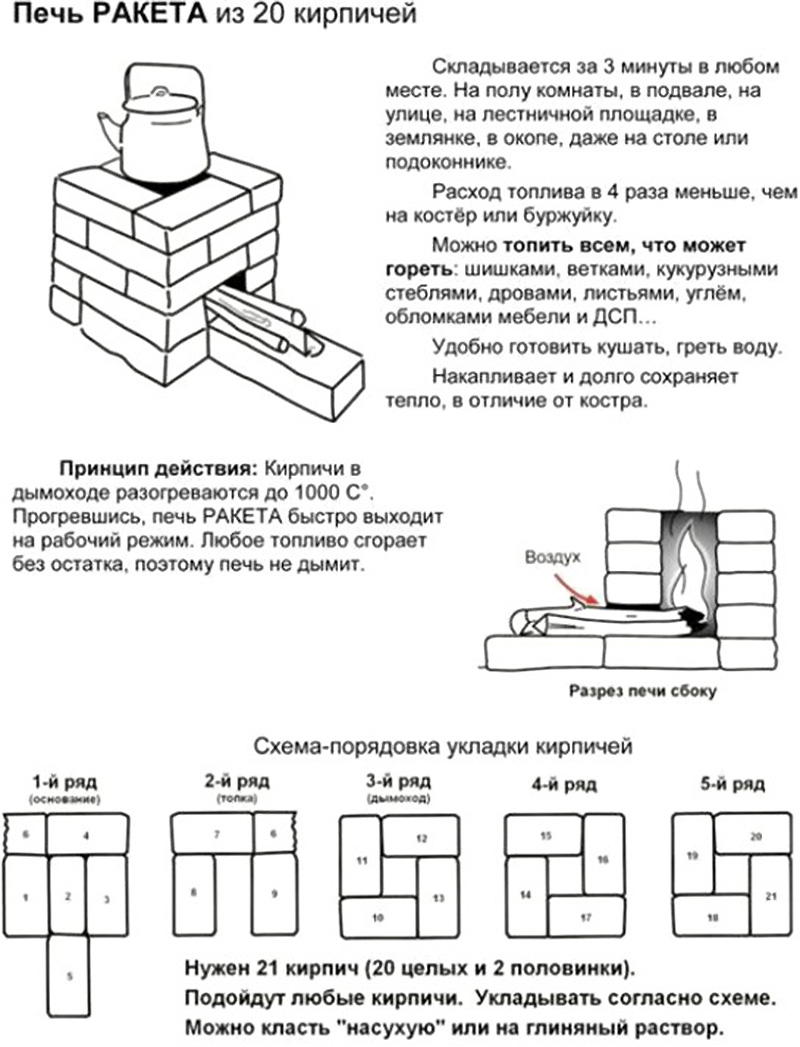

How to make a DIY rocket stove

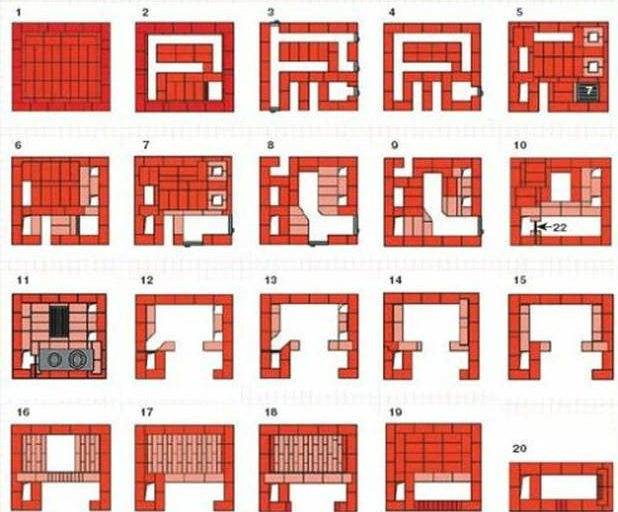

Let's start with the simplest brick sample designed for cooking. Such a stove can be quickly folded in your yard without clay mortar, and disassembled after use. It is also possible to assemble a stationary version - for those who like to cook on an open fire. The picture below shows a drawing of the stove, or rather, its ordering. There are only five rows here.

The first row is the base, which includes six bricks. The second row forms the firebox, and the next three rows form the riser chimney. In the first and second rows, halves of bricks are used so that the stove is rectangular, without protruding elements.

Immediately after assembly, you can start kindling - cook any dishes on the fire in cast-iron cauldrons and pans, heat kettles and pots of water.

A sheet metal oven can be both a camping and a stationary option. We have already given her drawing in the previous sections of our review. It can be used for cooking in any conditions.

Design of gas furnaces

The device of gas stoves is similar to wood stoves, but has some differences in the properties of the fuel. The gas furnace has a body, a fuse (to stop the supply of fuel in case of attenuation), a thermostat, a sealed gas chamber, a chimney. The difference lies in the fact that the fuel supply is carried out through a gas pipeline.

Gas cylinders are placed in an unusual container in accordance with all safety regulations. As experience shows, a gas cartridge of 5 cubic meters will be able to warm up a room up to two hundred square meters during the 1st heating season. It is worth emphasizing that propane has a higher heat transfer property if it is associated with natural gas. Such furnaces will be able to have different power, the calculation of which depends on the volume of the bath.

You should know that there are two hundred and fifty two kilocalories of heat per 0.4 cubic meters. Based on this, it may be easy to calculate how much gas you need. Gas sauna stoves do not require repeated heating, so they should be turned off during use. Such furnaces work according to a very easy principle - the air space is mixed with gas even before it enters the furnace. A separate part of the air passes into the furnace.

You have the ability to regulate the amount of air supplied to the gas sauna stove with the help of the lower door, which, in addition, allows you to clean the burner. Using a special flexible hose, gas is supplied to the burner (or a cylinder is used).

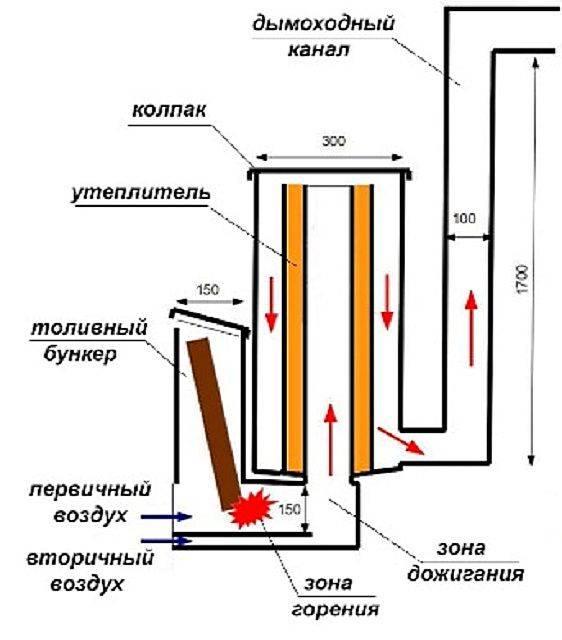

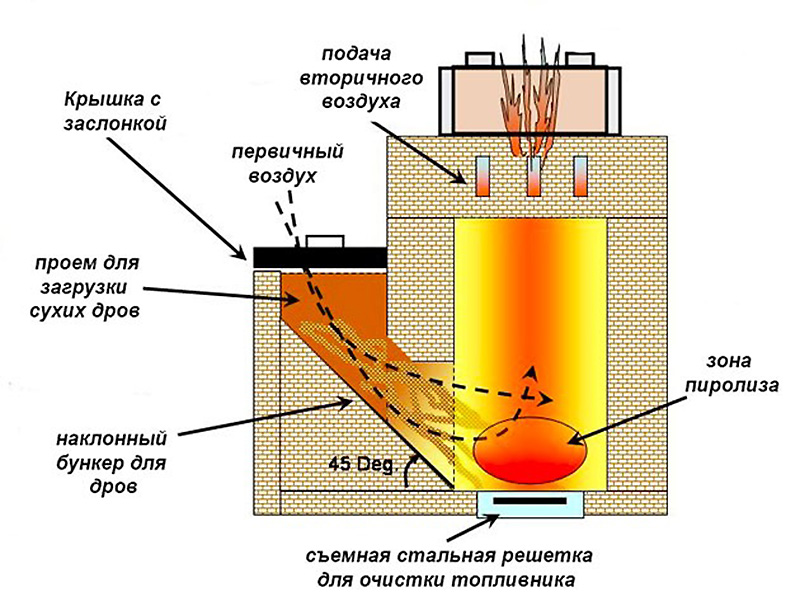

Stationary oven

Stationary models have a cap to keep the heat in the room longer. In such a stove, fuel combustion occurs according to a different scenario.The beginning of the process of burning wood is the same - the air supply is limited. This causes the release of pyrolysis gases, which are afterburned in the lower section of the vertical pipe or duct, where the secondary air is supplied separately.

The hot gas, once at the top, begins to cool and descends into the free inter-chamber volume, and then into the chimney. It happens like this:

- Gravitational forces cause the colder, and therefore heavier, burnt gases to rush down, where they enter the chimney.

- This is facilitated by the constantly maintained pressure from the firewood and the consistently high temperature of the gases.

- Natural draft in the chimney.

All this creates effective conditions for the combustion of firewood and it becomes possible to attach a smoke channel with arbitrary geometry to the "rocket". Basically, long and complex chimneys are needed in order to better heat the room.

The main disadvantage of all solid fuel stoves is the inability to keep most of the heat in the house. But the positive qualities make it possible to neutralize the negative points - the high rate of gas outlet allows you to organize complex vertical or horizontal chimneys with several channels. The implementation of this principle in practice is the Russian stove. In a jet furnace with a horizontal multi-channel chimney, it is also possible to equip a warm bench, as shown in the diagram below.

A jet rocket stove is a variant of home heating, which is cheaper only for nothing. A person familiar with the basics of construction can fold a combined brick oven in a design suitable for any home interior.The main task of ennobling the appearance will be decorating the iron cap and the lid of the firebox - everything else will not be visible.

Making a rocket stove with a bench

The dimensions of its main parts will be as follows:

- stoves - 505 x 1620 x 580 millimeters;

- beds - 1905 x 755 x 6200 millimeters (plus 120 millimeters for the headrest);

- compartments for the firebox - 390 x 250 x 400 millimeters.

Necessary materials

Such a rocket oven will require:

- 435 pieces of red brick;

- for smoke protection - one furnace door (250 x 120 millimeters);

- one blower and one cleaning door (140 x 140 millimeters each);

- asbestos sheet (thickness - 2.5–3 mm) for laying between bricks and elements and metal elements;

- stove for cooking (505 x 580 millimeters);

- chimney pipe (outlet - 90 degrees, diameter - 150 millimeters);

- rear shelf - metal panel (370 x 365 millimeters);

- heat-resistant mixture or sand and clay for mortar.

Regarding the last point, it must be indicated that for every hundred bricks laid flat with a seam width of five millimeters, two dozen liters of mortar will be required.

Construction principles

Missile top loading oven structurally simple. It is reliable and effective in everyday use. The main thing is to qualitatively and competently perform its laying. If you don’t have experience working as a stove-maker or bricklayer, but you want to fold the device yourself, practice first. Lay it dry to begin with, without using mortar. So you can fill your hand and figure out how the bricks are arranged in each row.

To ensure equal joint widths, prepare plastic or wood shims for masonry.They are placed before laying the next row on the previous one. They are removed without problems - as soon as the solution seizes.

Provide a solid, level base for the jet stove masonry.

After all, although it is compact and not too heavy, it will not stand on the floor, lined with thin slats.

And even on a durable wooden coating, it is necessary, after laying, to fix a material that is resistant to heat. Asbestos works great. Thickness - five millimeters.

The kiln laying process

The first row of bricks is laid flat. The connections of the entire three sections of the structure should be visible. It is desirable to round or cut off the corners along the facade for beauty.

Second row:

it is important to lay internal channels for the removal of smoke. Gases heated in the furnace and giving off their heat to the stove will go along them;

they connect with the chamber, which is already formed at this stage;

the first brick, which will divide a pair of channels under the stove bench, is cut obliquely;

combustion products that have not burned out completely will collect in this corner;

opposite the bevel, a door is installed that opens for cleaning;

here it is also necessary to install doors for cleaning and blowing chambers

With their help, it will be possible to restore order in the channels and the ash chamber;

they are fixed with a wire twisted on the ears of cast iron elements.

Scheme of laying the furnace

The third row of the rocket oven is similar to the previous one - adjusted for laying in a dressing. On the fourth row, the channels passing in the couch are covered with a continuous brick layer. Leave a hole for the firebox. A channel is formed that heats the stove and discharges combustion products into the chimney. Overlap the rotary channel running horizontally.

In the sixth row, a headrest for a stove bench, part of the stove for the stove and channels for removing smoke are laid out.In the seventh, the headrest is completed and the base rises under the slab. In three more - a design with a triple of channels is laid out.

In subsequent rows, a hole is formed for the chimney pipe, the base for the stove. A metal plate is laid on top. It is separated from the couch by a wall. At the end, a pipe is installed and brought outside to remove smoke from the jet furnace.

Useful tips for making a TT boiler

-

If you want to make a TT boiler universal in terms of the use of raw materials, then use a pipe made of heat-resistant alloy steel for the combustion chamber.

You can significantly reduce the cost of building a unit if you take a seamless steel pipe of grade 20.

- Before installing the boiler in the place determined for this unit, carry out the first kindling on the street, equipping the boiler with a temporary chimney. So you will be convinced of the reliability of the design and see if the case is assembled correctly.

- If you use a gas cylinder as the main chamber, then keep in mind that such a unit will provide you with combustion for 10-12 hours due to the small amount of fuel being put in. So the small volume of the propane tank will decrease after cutting off the lid and ash pan. To increase the volume and ensure a longer burning time, two cylinders must be used. Then the volume of the combustion chamber will definitely be enough to heat a large room, and there will be no need to lay firewood every 4-5 hours.

-

In order for the ash pan door to close tightly, preventing air from entering, it must be well sealed. To do this, lay an asbestos cord around the perimeter of the door.

If you will make an additional door in the boiler, which allows you to “reload” the fuel without removing the cover, it must also be tightly sealed with an asbestos cord.

For the operation of a TT boiler, the diagram of which we attach below, any solid fuel is suitable:

- hard and brown coal;

- anthracite;

- firewood;

- wood pellets;

- briquettes;

- sawdust;

- shale with peat.

There are no special instructions for the quality of fuel - any will do. But keep in mind that with a high moisture content of the fuel, the boiler will not give a high efficiency.

Design features of furnaces

A long-burning stove is convenient because it can burn on one load of firewood several times longer than traditional stoves and fireplaces. This is directly related to its design features - it is endowed with a large firebox, and some of them burn wood under certain conditions, with minimal access of oxygen to the combustion chamber and subsequent combustion of pyrolysis gases.

Sealing the seams will exclude the possibility of ingress of combustion products into the heated room.

Long-burning stoves are endowed with large fireboxes - a large amount of firewood and other types of warm fuel are placed here. Due to this, the frequency of approaches for laying fuel is reduced. Classic stoves and boilers with miniature combustion chambers require new portions every 2-3 hours. In the daytime, this can still be put up with, but at night a person wants to sleep, and not bother with laying firewood.

Worst of all, if everyone works during the day - there is simply no one to put logs in the oven. During this time, the temperature in the heated rooms will become quite low, so the evening will have to be devoted not to rest, but to kindling in order to create comfortable conditions.However, at night you will have to do the same thing as during the day - to throw more and more portions of logs into the insatiable firebox of a wood-burning stove.

The principle of operation of a long-burning furnace depends on its design:

- Units with a large firebox - their long work is due to the use of large combustion chambers, where a lot of firewood is loaded;

- Pyrolysis units - here solid fuel is burned with a minimum amount of oxygen and forms pyrolysis gas;

- Units without pyrolysis, but with a limitation in the intensity of combustion, are “boubafonya” furnaces from a barrel, which have a simple but very original device.

The furnaces themselves can be made from a variety of materials - stone, refractory bricks or metal.

The key to a longer burning of your stove is the use of normal firewood, and not rotten logs with a low calorific value. Beech, oak, hornbeam and some varieties of fruit trees burn the longest.

Types of stoves for different operating conditions

A rocket stove with a water circuit, brick or metal, can replace the boiler. The heat exchanger here is arranged in the upper part of the flame tube in the form of a surrounding water jacket. Jumpers are located inside the jacket for more efficient heat removal to the coolant. The design is extremely simple, it can heat households up to several tens of square meters.

A rocket stove for a garage can be made from an old pot-bellied gas bottle or barrel. To do this, two holes are made in the selected container - one in the top cover, and the other on the side surface. An L-shaped pipe is inserted inside.With little experience with a welding machine, all work will take you a maximum of half an hour.

You can also make an oven of the above-described rocket type from pieces of a square and metal pipe according to the drawing.

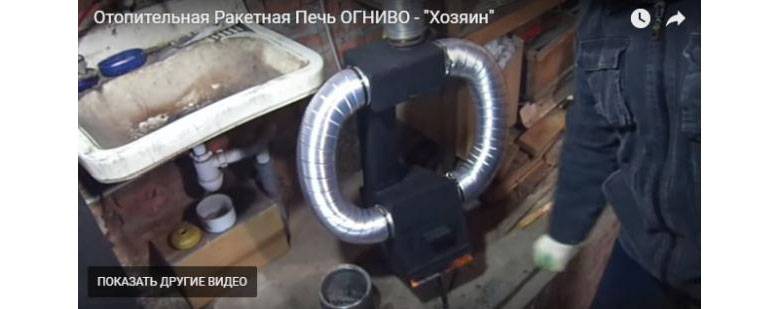

Also, for heating the garage, the heating rocket stove "Ognivo - Boss" is suitable. This is a shop model made of corrugated aluminum pipe and ordinary sheet iron. It works in much the same way and allows you to warm a garage up to 30 square meters. m.

There are no drawings of her in the public domain yet, so you can try to assemble the Flint stove with your own hands based on her photograph. It can also be purchased from the manufacturer's website.

We have already said that a long-burning rocket stove with a water circuit will be required to heat large households. A small household from one room can be heated with a simpler stove with a stove bench - this way you save space on furniture. It consists of the following nodes:

- Firebox with vertical loading - logs are placed in it;

- Afterburner - a horizontal section in front of the riser (flame tube), pyrolysis combustion takes place here;

- Riser with a hob - a vertical section with a metal case that gives off heat to the room;

- Horizontal channels - they heat the stove bench, after which the combustion products are sent to the chimney.

A rocket stove for heating a house from one room is coated with clay to make a flat and comfortable bed - here you can lay a mattress or a small blanket.

For field use, the simplest rocket-type furnaces made of metal pipes are used.They are compact, easy to kindle and extinguish, cool quickly and allow you to quickly cook dinner in the open air. The main thing is not to overdo it with the amount of fuel loaded, so as not to burn the food with a high-temperature flame.

Combined brick-metal barrel oven

It is stationary, because the structure cannot be moved. A fuel chamber and a chimney are laid out of fireclay bricks, valves and doors are made of metal. The brick gives off heat very slowly, so the room will be warmed for a long time.

High efficiency is not the strong point of such models, but good heat transfer can be achieved by adjusting the air supply to the chamber, without trying to enter the combustion mode, in which the stove begins to “roar” and “buzz”.

In order to somehow minimize heat losses during the operation of this simplest design, many craftsmen build a water circuit into the oven and connect a hot water tank. Also, the construction of a stove bench with a multi-channel horizontal chimney contributes to the preservation of heat in the room. Negative qualities of "rocket" models that cannot be minimized or removed:

- It is necessary to constantly monitor and adjust the thrust - there are no automation devices.

- Every 2-3 hours you need to load a new portion of firewood.

- The iron cap heats up to dangerous temperatures.

The simplest and cheapest option is the Robinson model, which is shown in the drawing below. For its manufacture, you need trimming pipes or a rectangular profile box, metal corners for legs, a welding machine. Its dimensions are selected based on the dimensions of the blanks. The main thing is to adhere to the principle of action, not size.

For a home-made design, gas cylinders or barrels of 200 liters are often taken - thick walls and a suitable size are the best fit for what was intended. Both those and others are used to make the outer case, and the internal elements are made from pipes of a smaller diameter or are brought out with bricks - halves, quarters or whole.

There is no general formula for calculating heat transfer for all models of a rocket stove, so the option of using ready-made calculations based on the principle of similarity of circuits is quite suitable. The main thing is that the size of the future "rocket" should at least approximately correspond to the volume of the heated room. For example, a gas cylinder will do for a garage, a two-hundred-liter barrel for a country house. An approximate selection of internal elements is shown in the diagram below.

Device and principle of operation

Rocket furnaces have practically nothing to do with the design of rocket engines or jet turbines. On the contrary, they are extremely simple structurally, in contrast to the above devices. The similarity is noticeable only in a quietly noisy flame and high combustion temperature - all this is observed after the stove enters the operating mode.

Consider the device of rocket furnaces - they consist of the following elements:

- Firebox - a vertical or horizontal area in which firewood burns;

- Combustion chamber (it is also a flame tube, riser) - here the process of fuel combustion takes place with the release of a large amount of heat;

- Blower - necessary for the correct operation of the stove and starting the process of burning pyrolysis gases;

- Thermal insulation - envelops the vertical part, forming a drum together with the body;

- Bed - used for its intended purpose;

- Chimney - removes combustion products into the atmosphere, creating traction;

- The support under ware - provides unhindered exit of heat.

Depending on the type of rocket furnace, certain elements may be missing.

Rocket furnaces with vertical furnaces (fuel bunkers) and blowers have the greatest efficiency and convenience - large volumes of fuel are placed here, which ensures long-term combustion.

The most important part of the rocket furnace is the vertical drum. It is in it that the highest temperature is observed, since flames break out here.

In order for it to start working, it must be thoroughly warmed up. Without this, the combustion process will be weak. To warm up, paper, cardboard, small chips or thin branches are placed in the firebox. As soon as the system warms up, the flame in the drum will begin to burn out with a buzz, which is a sign that the operating mode has been reached.

A rocket (jet) stove without a blower burns wood in a direct way. It is simpler, but less efficient. The blower model supplies secondary air to the base of the riser, which causes intense combustion of combustible pyrolysis gases. This increases the efficiency of the unit.

Fireboxes in rocket furnaces are located horizontally or vertically (at any angle). Horizontal fireboxes are not very convenient, since the firewood in them has to be moved to the burning zone manually, independently. Vertical combustion chambers are more convenient - we load fuel into them and go about our business. As the logs burn, they will fall down, independently moving towards the combustion zone.

Advanced Water Loop Rocket Furnace

A long-burning cauldron can be obtained by equipping a furnace with a water jacket. Water heating may not be efficient enough.The fact is that the bulk of the warm air enters the room and containers on the hobs. To create a rocket cauldron, it is necessary to give up the possibility of cooking on a stove.

Materials required for equipping a stove with a water circuit:

- fireclay bricks and masonry mortar;

- Steel pipe (diameter 7 cm);

- Barrel or cylinder;

- insulation;

- Sheet steel and a barrel of a smaller diameter than for the hull to create a water jacket;

- Chimney (diameter 10 cm);

- Details for the heat accumulator (tank, pipes, connecting pipe).

A characteristic feature of rocket furnaces with a water circuit is that the insulation of the vertical part ensures the combustion of pyrolysis gases. In this case, warm air is sent to the coil with a water circuit and gives off heat to the stove. Even when all the fuel has burned out, warm air will still be supplied to the heating circuit.