- Operating recommendations

- How long is the power outage?

- TOP 5 Double Conversion Voltage Stabilizers

- Stihl IS550

- Stihl IS1500

- Stihl IS350

- Stihl IS1000

- Stihl IS3500

- What elements of the boiler depend on electricity?

- Choosing the type of stabilizer

- Different boilers - different consequences

- Shutdown process using the example of a Baxi boiler

- Determination of a suitable model of such an installation as a gas boiler without electricity

- General tips for choosing models

- "Pump Overrun"

- Pump overrun time

- Starting a wall-mounted gas boiler (video)

- Comments

- Can electricity be turned off in the winter due to accumulated debt?

- Protective gas cut-off devices

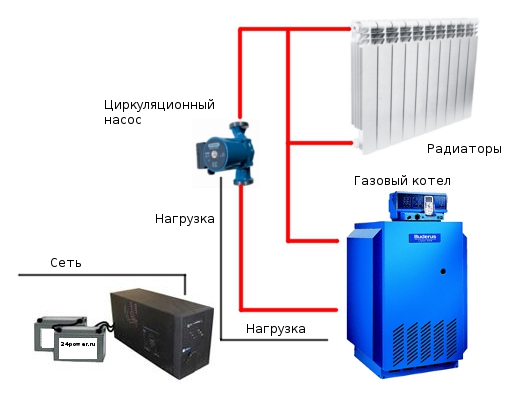

- UPS for a gas boiler and its power consumption

- How does a gas boiler work without electricity?

Operating recommendations

- In case of malfunctions of the gas valve, it is necessary to check it and adjust the settings. If the heat exchanger covers a large layer of scale, then this greatly reduces heat transfer and significantly increases fuel consumption. In such a situation, the boiler makes a crack or noise. This is due to the accumulation of salts, which slowly crumble from the surface over time, which is why noise is heard. You can remove them with the help of special reagents.

- Often you have to deal with too rapid wear of the nodes. The main reason for this is clocking. In this case, the gas boiler can automatically turn on and off. When the water in the circuit cools, a signal is received from the thermostat that the water has cooled, in this case the boiler turns on.

How to choose a gas boiler, see the following video.

How long is the power outage?

If you, having lived in a village for a year or two, have not experienced frequent and prolonged power outages, this does not mean at all that they will not happen.

No one is safe, and almost nowhere. Even in places close to large cities, there have been cases of week-long blackouts due to weather conditions.

Usually, the period for which the current is interrupted depends on its cause:

- Short-term shutdown for a period of half an hour to 2 hours due to a scheduled check of networks or exceeding the limit consumption.

- Liquidation of emergencies of a simple nature, connection of new subscribers - from 3 to 6 hours.

- Short circuits, PTS malfunction - 12-24 hours.

- Serious accidents associated with adverse weather conditions, the inability to quickly repair the line - from 1 to 3 days.

If the first 3 situations are quite tolerable in terms of time, then under the condition of poor thermal insulation of the house structure or the presence of residents who are contraindicated for coolness, the latter option is highly undesirable. In addition, even these terms cannot guarantee that even after their expiration, the supply of electricity will be resumed, it is better to play it safe.

Many people put an alternative source of heating, for example, a stove, a fireplace, and this, without a doubt, is a reasonable combination when someone is constantly at home and can control the heating, but it is much easier and even cheaper to install a backup power supply system.

TOP 5 Double Conversion Voltage Stabilizers

The most high-quality and reliable types of stabilizers include devices with double conversion. Consider the most notable models:

Stihl IS550

Low power voltage stabilizer (400 W), designed to work with one consumer. Compact, lightweight device. It is intended for hinged installation. The output is single-phase voltage, the error is only 2%.

Device parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 155x245x85 mm;

- weight - 2 kg.

Advantages:

- high stabilization accuracy, sh

- wide input voltage range,

- compactness and low weight.

Flaws:

- low power,

- too high price.

Stihl IS1500

Household voltage stabilizer with double conversion. Power is 1.12 kW. It is calculated on work with single-phase current with a frequency of 43-57 Hz.

Main parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 96%;

- dimensions - 313x186x89 mm;

- weight - 3 kg.

Advantages:

- compactness,

- attractive appearance,

- light weight.

Flaws:

noise from a running fan, for which there is no data on the service life in the passport.

Stihl IS350

300 watt dual voltage stabilizer. It has a high stabilization accuracy of 2%.

Device parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 155x245x85 mm;

- weight - 2 kg.

Advantages:

- compactness,

- small weight of the device,

- able to work with different sources,

- has high accuracy.

Flaws:

- low power,

- too high price of the device.

Stihl IS1000

Stabilizer with a power of 1 kW. Device with double voltage conversion, designed for wall mounting. Differs in compactness, small weight of the device does not create excess load on supporting structures.

Stabilizer Specifications:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 300x180x96 mm;

- weight - 3 kg.

Advantages:

- high speed,

- reliability,

- the input voltage range is very large, which gives no reason to worry about household appliances and electrical appliances.

Flaws:

- short power cord length

- little fan noise

- inconvenient location of plugs for consumers.

Stihl IS3500

2.75 kW double conversion stabilizer. It is calculated on hinged installation, possesses high accuracy of work (only 2% of an error).

Main parameters of the device:

- input voltage - 110-290 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 370x205x103 mm;

- weight - 5 kg.

Advantages:

- high accuracy,

- reliability,

- wide input voltage range.

Flaws:

- excessive noise from cooling,

- relatively high cost.

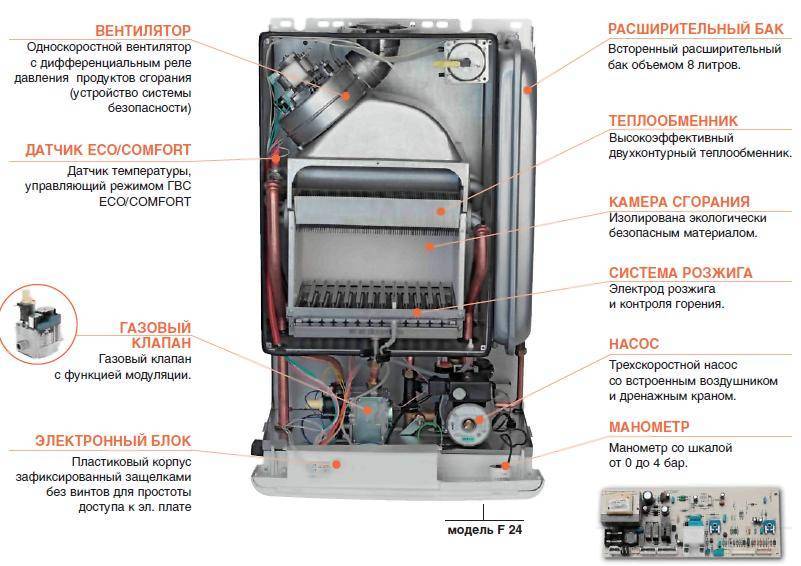

What elements of the boiler depend on electricity?

Stops in the power supply of houses not only in the outback, but also in cities occur quite often. They happen due to emergencies, planned repair and technical work, breakdowns on the line.And the most unpleasant thing is that when the electricity is turned off, the operation of the gas boiler is paralyzed if it is of a volatile type.

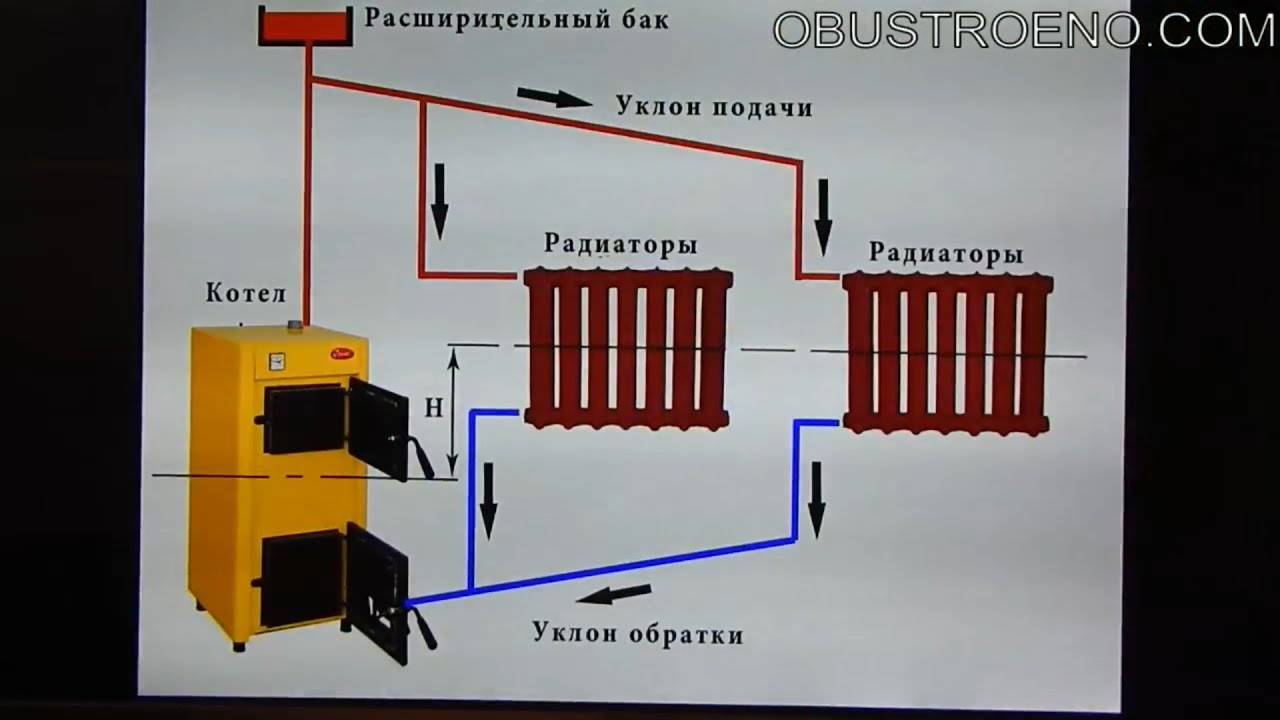

The non-volatile gas boiler continues to function normally, even if there is a power outage on the power line. The only exception is if a pump works in conjunction with it, and a system of gravitational circulation of the coolant is not provided.

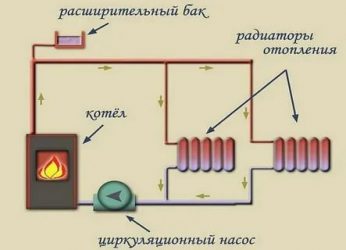

In a heating circuit with a boiler of the simplest type, the set of basic elements is approximately as follows:

- natural draft smoke exhaust system;

- heat exchanger;

- gas burner with nozzles for gas supply, which is located in the combustion chamber;

- gas supply and ignition unit;

- expansion tank;

- mechanical temperature sensor;

- control module, which includes the boiler ignition system (mechanical or piezo), temperature control;

- safety group (safety valve, pressure gauge, air vent).

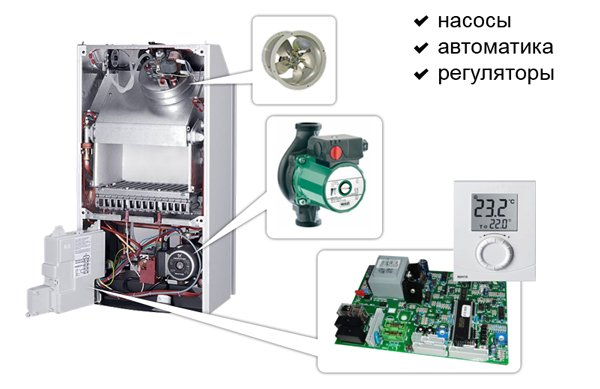

More complex in the device volatile devices

But is electricity really necessary and important for the operation of a gas boiler? Depending on the model and brand, in addition to the same basic set of elements, in some cases, electronic and automatic types, they may provide such functions as: Depending on the model and brand, in addition to the same basic set of elements, in some cases, electronic and automatic types, they may provide such functions as:

Depending on the model and brand, in addition to the same basic set of elements, in some cases, electronic and automatic types, they may provide such functions as:

- forced ventilation system;

- built-in circulation pump;

- electronic system control module;

- shut-off and control valves on the electric drive;

- various sensors - water flow, temperature, flame supply, water pressure in systems, manostat, emergency complexes;

- electric piezo ignition unit;

- automatic temperature controllers;

- warning and remote control system;

- display with the output of the current performance of the device

Units of this type are more reliable and much more convenient to operate, and besides, they are economical. Automation can be set on and off modes, reducing fuel consumption, creating a comfortable microclimate at home, not worrying about safety and performance.

The only negative is that after a power outage, a volatile gas boiler will not be able to fully work. It is difficult to say which functions will be completely absent, it depends on the model of the boiler. Some units have a combined control system - mechanical and electronic.

It is certain that forced ventilation, automatic adjustment of the flame supply to the burner, pump, display, electronic control module, in general, all devices operating on an electric drive and a constant current supply will not function.

But is it all that scary?

Choosing the type of stabilizer

Stabilizers differ in many ways. So, for example, the units can be located on the walls of the room (hinged) or on the floor (floor). The industry produces stabilizers operating on direct or alternating current, single-phase or three-phase.

The stabilizers use several ways to switch the windings, according to this principle, the units are usually subdivided: With a servo drive (electromechanical stabilizers), - a slider moves along the windings of the unit with the help of a servo drive. This type of stabilizer is made like a car transformer. Electromechanical stabilizers function thanks to built-in devices that ensure the operation of the transformer.

Schematic: servo stabilizer

The advantages of an electromechanical stabilizer include:

- gradual voltage regulation without the occurrence of phase disturbances and a decrease in the current sinusoid;

- small dimensions;

- high operability at various voltages, including the moments of occurrence of voltage surges from 100 to 120V.

Relay (electronic) - in this design, the windings are switched using a relay. At a low cost, such units have sufficient reliability and quality. The closed hermetic housing of the relay stabilizers prevents the penetration of dust and moisture into the structure.

Relay Voltage Stabilizer

The advantages of relay stabilizers are:

- relay stabilizers do not require maintenance;

- speed of reaction;

- high switching speed when the input signal changes;

- cost-effectiveness - the units have a low cost.

Attention! A significant disadvantage of electronic units is the stepwise regulation of the output voltage, which significantly reduces their use.

In the design of a triac voltage stabilizer, relays and triacs are used together. The advantages of this type of stabilizers are:

Triac voltage stabilizer

- triac voltage stabilizers do not contain parts in the design of the unit that wear out during mechanical operation, which distinguishes them from relay and electromechanical stabilizers;

- these units are highly durable and reliable;

- triac units are available in floor and wall versions;

- complete noiselessness of the unit;

- during short-term power outages, overloads, the triac stabilizer guarantees the uninterrupted operation of household appliances, including a gas boiler;

Scheme: operation of a triac voltage regulator

- the system is equipped with a built-in multi-level automatic protection, which provides load disconnection in case of overcurrent, protection against short circuits, protection against excessively high and low voltage;

- the service life of the device, set by the manufacturers, is up to 10 years.

Thyristor. Stabilizers of this design have thyristor switches, which, when turned on or off, can affect the sinusoidal shape of the current, causing it to be distorted. The algorithm for measuring the voltage by several tens of times and determining the moment when the thyristors are turned on is determined taking into account the algorithm for changing the voltage in a matter of fractions of a second. Turning the thyristors on or off is controlled by a processor built into the circuit.

Tristor voltage regulator

Thyristor stabilizers are not threatened with overload in case of emergency situations that have arisen on the power supply networks - the microcontroller immediately sends a command to turn off the stabilizer.

The advantages of thyristor stabilizers are:

- noiselessness during the operation of the current conversion unit;

- durability - the thyristor can work more than 1 billion times;

- during the operation of thyristors, an arc discharge is not formed;

- economy in energy consumption;

- small overall dimensions;

Schama: tristor voltage regulator

- lightning-fast speed and accuracy in leveling and normalizing voltage;

- operating range at voltage levels from 120 to 300 volts.

With an extensive list of advantages of a thyristor stabilizer, the unit is not without some disadvantages:

- stepwise current stabilization method;

- high cost - this is the most expensive stabilizer of all existing on the market today.

Different boilers - different consequences

Cooling down at home is not the main danger. Indeed, for a serious cooling of housing, 3-5 days are needed, depending on the quality of thermal insulation, the heated area, the temperature outside and other circumstances. Probably by this time electricity will appear. Except for major accidents.

Such shutdowns bring more harm to the boilers themselves. And that's not for everyone. Consider the consequences for different types of aggregates.

- Electrical. For them, a power outage is the least dangerous. They simply turn off, and after the resumption of power supply, they resume normal operation. There are usually no consequences.

- Liquid fuel. Usually there are no special consequences for them either. When the light goes out, the fuel pump just stops working. Fuel is not supplied to the burner, its remains are used, after which the flame goes out. But in some situations, this leads to breakdowns of the heat exchanger. The reason is a strong overheating of the liquid in it. The situation is relatively rare, but it does occur.

- Gas. Here the consequences are more serious.The fact is that gas is supplied regardless of the availability of energy. Without electricity, automation does not work, but the fuel continues to go to the burner and burn. At the same time, circulation pumps, temperature sensors, and flame sensors also do not work. At this time, the liquid, when it enters the combustion chamber, heats up rapidly and can be brought to a boil. Starting reverse ignition without electricity is impossible, and therefore the gas that is supplied to the burner begins to gradually seep out - into the premises. These leaks can be quite copious. In ventilation boilers with closed chambers, gas leakage into the room is excluded. But here the gas goes into the chimney, which is also bad.

- Solid fuel. They are the most sensitive to blackouts. However, non-volatile units are most often used, for which the interruption of the supply of electricity does not play any role. Otherwise, the consequences are critical. The owner cannot extinguish the flame by cutting off the fuel supply, as in other boilers. Even if you close the shutter. Extinguishing a fire with water is prohibited. Consequence - at least the heat exchanger fails. But negative consequences can be for the entire system.

Shutdown process using the example of a Baxi boiler

Most modern Baxi gas installations are equipped with an electronic control system. The manufacturer's instructions describe the procedure for turning the boiler on / off, as well as descriptions of the failure codes issued by the unit and the measures that the user must perform.

The Baksi unit is stopped in the following cases:

- End of the heating season;

- emergency stop of the gas boiler;

- regime shutdown for maintenance and scheduled preventive repairs;

- shutdown of the unit for internal flushing of the heating circuit from scale formation;

- preventive cleaning of heating surfaces from soot deposits.

Cases of emergency shutdown of the boiler:

- the burner does not ignite or immediately goes out after ignition;

- clocking of the unit, frequent automatic shutdown / on;

- pops in the gas-air path;

- overheating of the main coolant in the circuit;

- low coolant temperature below 10C;

- noise during operation;

- failure of the automation system or its individual elements;

- water leaks into the unit;

- pressure drop in the gas pipeline;

- pressure drop in the network circuit;

- lack of drinking water;

- falling vacuum in the furnace;

- gas pollution in the room.

Noise during operation can cause the gas boiler to turn off

In order to turn off the boiler, perform the following operations:

- Close the gas cock, while turning off the fan is not necessary yet.

- Ventilate the furnace for 15 minutes.

- Stop the smoke exhauster and fan (if any).

- The coolant circulates until the network water is cooled below 30 C.

- Stop the circulation pump.

- Set the selector switch to position (0), thereby stopping the power supply to the device.

- Carry out conservation work in the winter. The water from the device is not drained, but antifreeze or propylene glycol with additives against calcium deposits is added.

More expensive models have a built-in multi-stage diagnostic system and effective safety automation, which will not only find an error in the operation of thermal and mechanical equipment, but will also independently stop the unit in accordance with regime procedures. These devices have one drawback - they are volatile and when the power is turned off, all "smart" protection systems will not work, so users need to be able to stop the boiler manually. In addition, to increase the reliability of such equipment, it is recommended to install backup power sources of low power, since all boiler electrical equipment is energy efficient and consumes extremely little energy for its own needs of safety automation and the operation of the circulation pump.

The operation of any gas boiler consists of several stages. For the user, the most important are the stages of its start and shutdown. These operations may seem difficult and incomprehensible to many. This is due to the features of the equipment used, as well as the necessary safety requirements. The article will consider two important procedures in stages using the example of the EuroSit 630 valve model and the start-up of a typical wall-mounted gas boiler.

Determination of a suitable model of such an installation as a gas boiler without electricity

The main guideline for determining a suitable model of such an installation as an autonomous gas boiler without electricity is the correspondence of its power for heating the required area, while this characteristic must also correspond to the load on the installation. more serious price category. This is explained by the increased quality, design and more advanced functionality of the device compared to domestic counterparts. At the same time, it is necessary to determine the manufacturer of the gas installation with special diligence, it is especially worth considering the presence of service centers of the company represented in the city or nearby, because the device requires maintenance and sometimes repair.

The following companies are among the most popular and high-quality manufacturers of gas autonomous boilers: the Italian manufacturers Alphatherm and Beretta - Italy, the Slovenian company Attack, Czech-made Protherm and Swiss-made Electrolux.

Although models from domestic manufacturers are more attractive in terms of price, their reliability does not always correspond to the level of foreign analogues. Although they have their own special advantage - the models are produced in all respects corresponding to the use of boilers under local temperature conditions.

It is better to give preference to a gas boiler with heat exchangers for the manufacture of which they used cast iron or steel, while special attention should be paid to the first version of the material.

In addition, after many years of using a gas boiler, the heat exchanger tends to corrode. At the same time, cast iron is more preferable than steel.Corrosion on this element of the device may occur as a result of a drop in temperature, which entails the formation of condensate. Corrosion processes in such cases are provoked by the released moisture.

In addition, the design of the heat exchanger provides for the presence of sections. If one of them is unsuitable, it is not advisable to change the entire heat exchanger, a replacement is enough. At these production stages, all kinds of impurities are added to cast iron, which significantly increase the strength characteristics of the boiler as a whole, which provides it with additional safety during transportation.

General tips for choosing models

Choice of Danko model boilers

The popularity rating of products of different brands and brands is the subject of a separate discussion. It is rather difficult to explain in a nutshell which floor-standing boiler of which manufacturer is better.

Therefore, it makes sense to voice the general selection rules that experts in boiler equipment recommend paying attention to.

The power of the boiler must comply with the existing operational requirements. If a double-circuit boiler is selected, the calculated indicators are multiplied by one and a half. It makes no sense to choose models with a flow-through method of supplying hot water for a family with more than three people. It is better to immediately buy a floor installation with a storage tank. The power of boilers with a storage boiler is calculated on a separate scale.

"Pump Overrun"

After the heating of water in the boiler is stopped, the burner is turned off. If at this moment the boiler pump is also switched off, then due to the high inertia, the temperature of the heat exchanger may rise above the permissible level, which may lead to the operation of the thermal protection (safety valve). To prevent this, the “pump overrun” function is designed.

In some boilers, this function also works before the burner is turned on in order to equalize the temperature of the coolant, preventing clocking.

Pump overrun time

The pump overrun is set as standard to 4 minutes after the end of the heating demand. If desired, this parameter can be changed by specialists up to 20 minutes, depending on the brand and model of the boiler.

Starting a wall-mounted gas boiler (video)

Switching off occurs by pressing the corresponding button on the control panel and closing the tap on the gas pipeline.

Comments

0 Mikhail 02/14/2018 06:15 If you start the boiler correctly from the very beginning, you can really be calm for a long time. For example, I have removed the air from the batteries, but not from the circulation pump. I had to come back to it later. You always need a competent specialist. Quote

0 Oleg 02/12/2018 06:23 I still do not advise you to keep any electrical wiring and fire near gas boilers. All cylinders, one way or another, pass a little gas, the whole thing can end badly. And so for 4 years we have been heating our house with a gas boiler, it is much more convenient than with the same coal and firewood.

Quote

0 Olya 02/11/2018 21:03 Each boiler has its own characteristics, everything is detailed in the instructions for it, so first of all you need to read it. I've never had any problems turning on the gas boiler.

Quote

0 Inna 01/25/2018 06:30 After the main switching on of the boiler, you need to be near it for half an hour. Well, just in case, to make sure that the unit is working and will work properly. The first minutes are especially important. Sometimes during the first five the boiler may go out. This speaks of its inadequacy.

Quote

0 Zhenya 01/23/2018 06:22 Installation of the boiler, no matter what you think, this is really a serious moment, if you do not know how to install, it is better to contact a specialist, and, accordingly, to the gas service! There are many nuances in the installation that must be carried out from A to Z.

Quote

Refresh list of comments RSS feed of this entry's comments

Can electricity be turned off in the winter due to accumulated debt?

In this case, the consumer must be notified in writing at least 10 days before the expected date of introduction of the restriction (power outage).

All reasons for which the supply of electricity is interrupted, not counting the termination of the contract between the supplier and the consumer, can be divided into two groups: technical and economic.

I live in the Crimea, in Feodosia. When you dial a number, the phone immediately turns off. A question: A transit riser (MKD) passes through the apartment. The apartments have individual heating. The first floor is a branch of the State Treasury, which, in the process of uncoordinated repairs, flooded our 3rd and 2nd floors with Twice-cold and four days later with hot water. The downstairs neighbor was persuaded to make me the defendant. Who is the owner of the transit pipe?

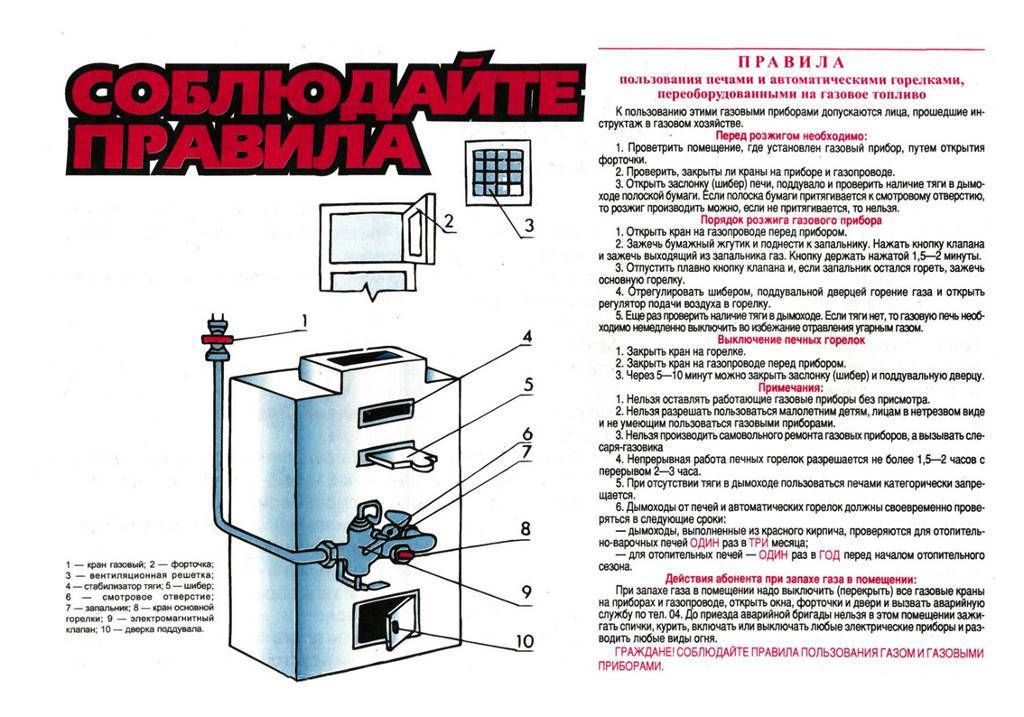

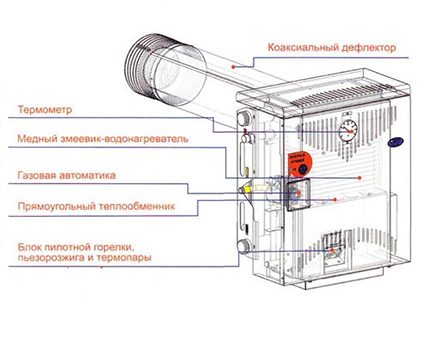

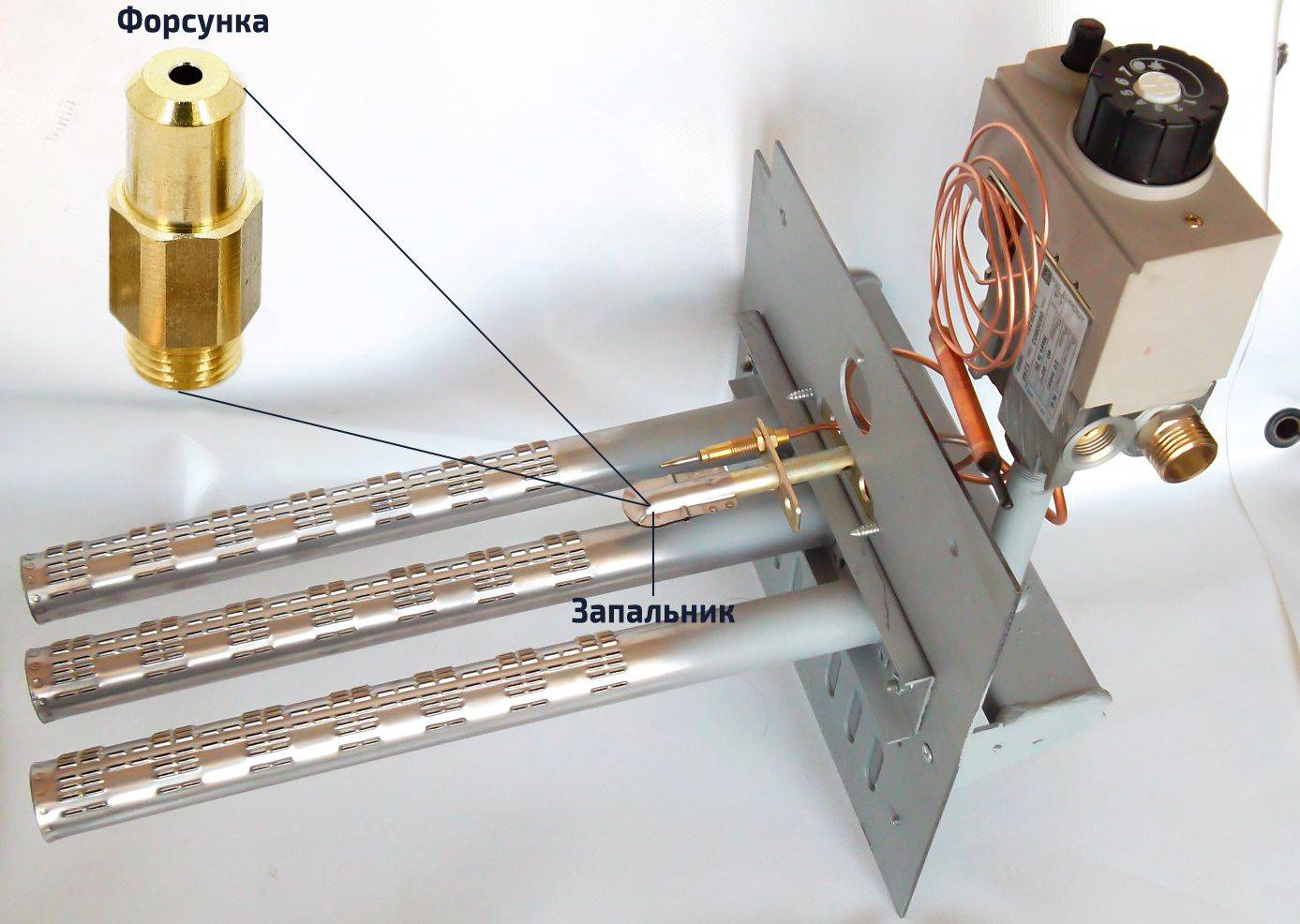

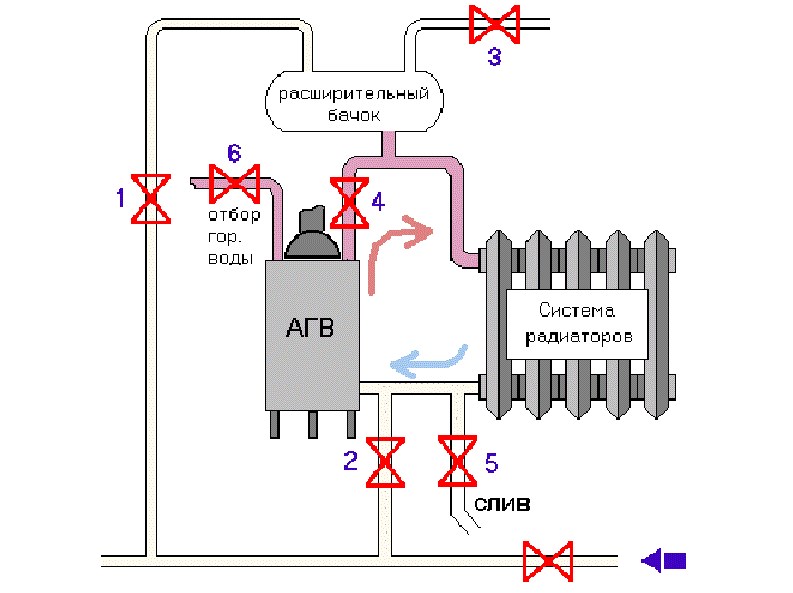

Protective gas cut-off devices

As part of gas boiler automation as a fast-acting shut-off system, a shut-off valve, popularly called simply a shut-off valve, is often used. Unlike other shut-off valves, the valve has automatic operation.

Its main purpose is to supply gas to the burner with the required pressure at a given power and completely cut off the fuel supply in the event of a malfunction.This process is carried out at the expense of control devices with built-in sensors.

Automation differs in the type of ignition - piezo ignition and electric ignition are distinguished.

Piezo ignition is when the start is done manually by pressing a button. It controls the operation of the flame - a thermocouple, which is heated by an igniter and generating direct current, ensures the open state of the valve.

As soon as, for some reason, the pilot burner stops supplying an open flame, the solenoid valve closes and the gas flow stops. Piezo ignition is a volatile element of automation.

The electric ignition unit is connected to the power supply. The start is made from an electric spark in automatic mode. This system is volatile and when the current is turned off, the valve of the device shuts off the gas supply.

It looks like this. The differential relay has two contacts. During normal operation of the heater, one block is closed. When there is any change in the operation of the boiler, for example, a power outage, the second block is activated, and the first one opens. The relay moves, the membrane bends and the gas supply is cut off.

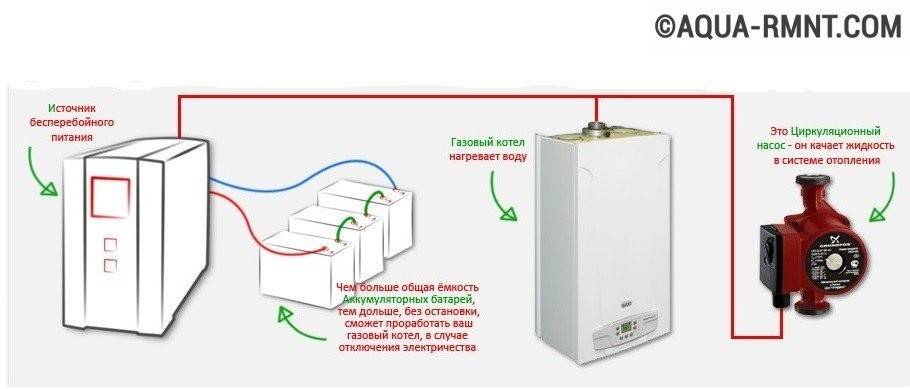

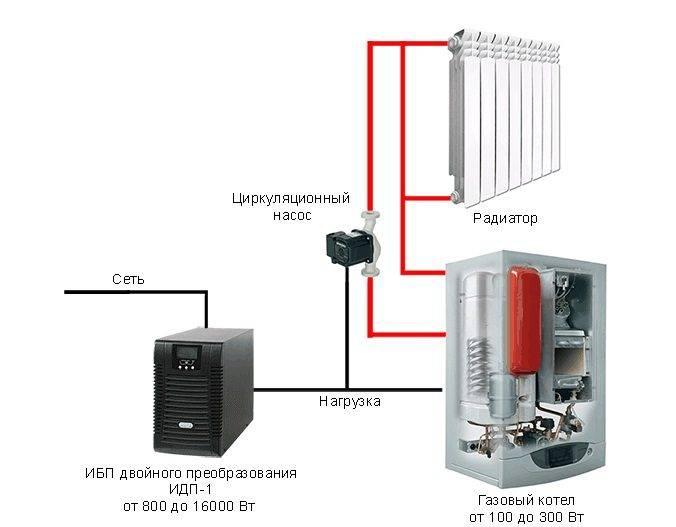

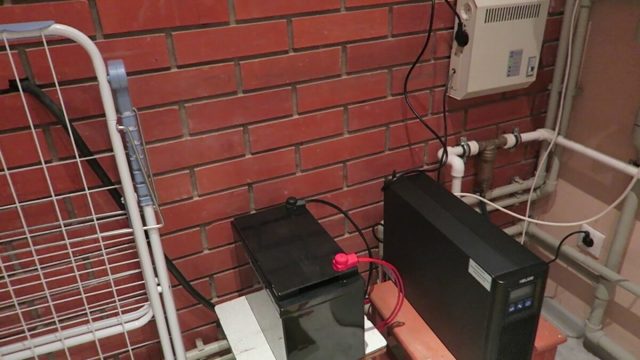

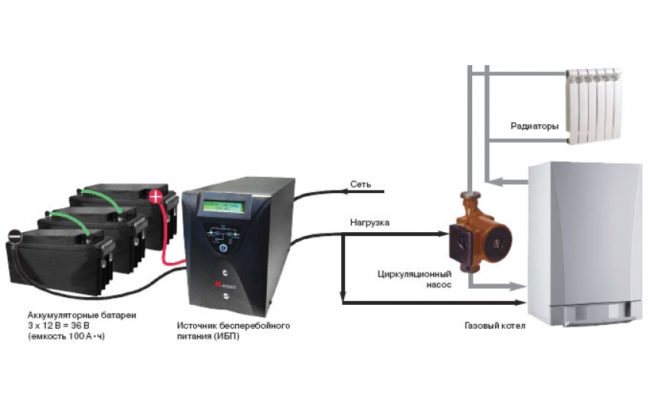

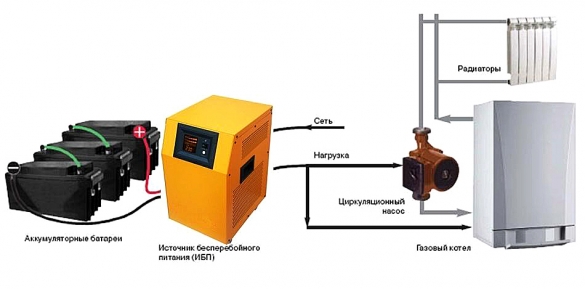

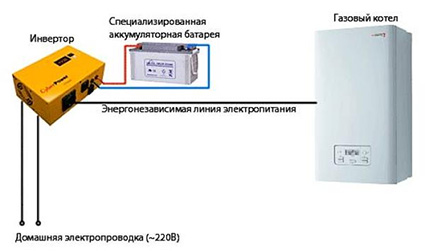

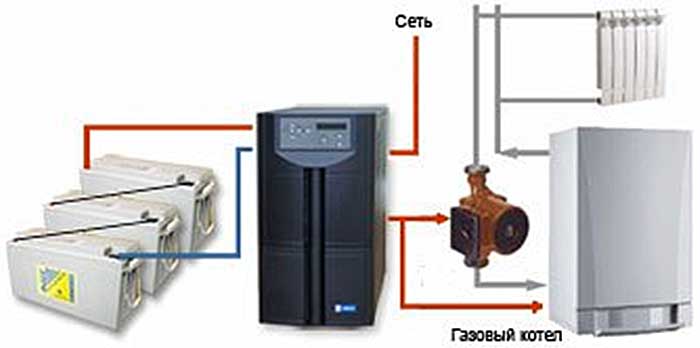

UPS for a gas boiler and its power consumption

If electricity is lost in the network, the gas unit will switch to an emergency worker, which threatens to break expensive components. And in such situations, the UPS will come to the rescue (uninterruptible).

How long a gas boiler can work in the absence of electricity in the network depends on the capacity of the battery pack. Choose either a UPS with a built-in battery, or a UPS with the ability to connect the required number of battery sections to it

How long a gas boiler can work in the absence of electricity in the network depends on the capacity of the battery pack. Choose either a UPS with a built-in battery, or a UPS with the ability to connect the required number of battery sections to it

Type "line-interactive" - the most popular UPS, according to numerous customer reviews. They include a voltage stabilizer, which is able to respond to voltage fluctuations in the network within 10%, if this value is exceeded, a transition to battery power follows.

Type "off-line" - these are uninterruptible power supplies without a voltage stabilizer. They help out in case of a sudden power outage, but do not protect against fluctuations in the mains voltage.

Type "on-line" - the most advanced UPS. They smoothly switch from mains power to battery power and vice versa. The only drawback is that not everyone can afford their price.

At the time of starting a gas boiler, electricity consumption increases by at least two, or even three to four times. Even if this is a short-term moment lasting a second or two, we still take the UPS for a gas heating boiler to the maximum and with a power reserve. For a gas boiler with an electric power of 100 W, you need a UPS with a power of at least 300 W (with a margin of up to 450-500 W).

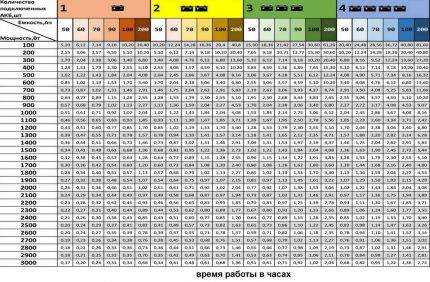

As for the capacity of the battery, then, for example, one battery with a capacity of 50 Ah is enough for a power consumption of 100 Tue for 4-5 hours work. To ensure 9-10 hours of operation, you need to have two such batteries, etc.

This table shows the autonomy of the gas boiler in hours, depending on the electricity consumption of the gas boiler (electrical power in W), battery capacity (capacity, Ah) and the number of batteries connected at the same time (one, two, three or four)

This table shows the autonomy of the gas boiler in hours, depending on the electricity consumption of the gas boiler (electrical power in W), battery capacity (capacity, Ah) and the number of batteries connected at the same time (one, two, three or four)

And finally, will the UPS consume electricity for its needs? It all depends on efficiency.If we take efficiency = 80%, then for our 300 W UPS, the consumption together with the load will be:

300 W / 0.8 \u003d 375 W, where 300 W is the load, the remaining 75 W is consumption by the UPS itself.

The above calculation example is conditional and applicable for simple uninterruptible power supplies, namely for the moment when the mains voltage surges become above a certain level - more than 10%. When the mains is standard 220 V, the UPS does not consume almost anything.

Detailed calculations for calculating the power of the UPS, the capacity of the batteries and the additional costs of electricity in connection with the installation of a UPS in the heating network are best left to an electrician.

How does a gas boiler work without electricity?

The principle of operation of all models, the operation of which does not depend on electricity, is the same. The gas boiler is connected to a gas distribution line. Through it, the blue fuel enters the burner, where it lights up with the help of a piezo ignition and burns out, releasing a large amount of heat. This heat enters the heat exchanger that heats the coolant and hot water if a double-circuit gas heating boiler is used. Or all the heat is spent on heating water for heating when single-circuit installations are operated.

In addition to piezo ignition, other options for turning on the burner can be used in non-volatile boilers. Sometimes uninterruptible power supplies in the form of conventional batteries or generators running on liquid fuel are mounted in boilers.

Models with piezo ignition are gradually fading into the background. After all, its presence implies a constant burning of the wick, which means that there is a constant consumption of fuel. Due to the regular increase in prices for it, the operation of such models does not allow saving.

Almost all modern manufacturers offer a range of non-volatile boilers powered by batteries. Such a compromise solution made it possible to use all the innovative technologies that exist today - complex automation with thermostats, pressure indicators and a multi-stage security system.

The only drawback of this choice is the need to constantly change uninterruptible power supplies. Batteries should always be at hand, otherwise, when their charge runs out, the boiler will stand up and will not be able to work. In winter, this situation can lead to rather disastrous results.

Models where the starting element is a generator running on liquid fuel have the same advantages and disadvantages as models running on battery-type batteries.