- Control mechanisms

- Why turn up the pressure

- Operating pressure in the heating system of an apartment building

- Types and their meanings

- Working pressure in the heating system of an apartment building: how to control?

- Pressure drops and its regulation

- Norm in an autonomous heating system

- Why does the pressure in the heating system drop, how to increase it

- Leak in the heating system

- Air out of the expansion tank, but no leaks

- Common Causes

- Peak values

- Heating system

- Why do you need an expansion tank

- Why does pressure decrease in a closed circuit?

- What is the danger of a pressure drop in a closed circuit

- How to slow down the pressure drop

- Where to put the expansion tank

- Control methods

- Reasons for the increase in power

- How to control the pressure in the system?

- If the pressure rises

- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- 4 The pressure in the heating system is growing - how to find out the cause

- Heating pressure regulation

- Pressure testing

- Cold

- Hot check

- Air test

- Conclusion

Control mechanisms

To prevent emergency situations in closed systems, relief and bypass valves are used.

Reset.Installed with access to the sewer for emergency descent of excess energy from the system, protecting it from destruction.

Photo 4. Relief valve for heating system. Used to drain excess coolant.

bypass. Installed with access to an alternative circuit. Regulates the differential pressure by sending excess water into it to eliminate the increase in the following sections of the main circuit.

Modern manufacturers of heating fittings produce "smart" fuses equipped with temperature sensors that respond not to an increase in pressure, but to the temperature of the coolant.

Reference. It is not uncommon for pressure relief valves to stick. Make sure that their design has a rod for manually retracting the spring.

Do not forget that any problem in the heating system of the house is fraught not only with loss of comfort and costs. Emergencies in the heating network threaten the safety of residents and the building. Therefore, care and competence are needed in the control of heating.

Why turn up the pressure

The pressure in the flow line is higher than in the return line. This difference characterizes the heating efficiency as follows:

- A small difference between the supply and return makes it clear that the coolant successfully overcomes all resistances and gives the calculated amount of energy to the premises.

- An increased pressure drop indicates increased section resistance, reduced flow velocity, and excessive cooling. That is, there is insufficient water consumption and heat transfer to the rooms.

To avoid a high drop on long heat supply branches with a large number of batteries equipped with thermostatic valves, an automatic flow controller is installed at the beginning of the main, as shown in the diagram.

So, excess pressure in a closed heating network is created for the following reasons:

- to ensure the forced movement of the coolant at the desired speed and flow rate;

- to monitor the state of the system on the pressure gauge and feed it or repair it in time;

- the coolant under pressure heats up faster, and in case of emergency overheating, it boils at a higher temperature.

We are interested in the item of the second list - the pressure gauge readings as a characteristic of the health and performance of the heating system. It is they who are of interest to homeowners and apartment owners who are engaged in self-maintenance of home communications and equipment.

Operating pressure in the heating system of an apartment building

This page contains information about operating pressure in the system heating of an apartment building: how to control the drop in pipes and batteries, as well as the maximum rate in an autonomous heating system.

For efficient operation of the heating system of a high-rise building, several parameters must comply with the norm at the same time.

The water pressure in the heating system of an apartment building is the main criterion by which they are equal, and on which all other nodes of this rather complex mechanism depend.

Types and their meanings

The working pressure in the heating system of an apartment building combines 3 types:

- Static pressure in the heating of apartment buildings shows how strongly or weakly the coolant presses from the inside on pipes and radiators. It depends on how high the equipment is.

- Dynamic is the pressure with which water moves through the system.

- The maximum pressure in the heating system of an apartment building (also called “permissible”) indicates what pressure is considered safe for the structure.

Since almost all multi-storey buildings use heating closed systems, then there are not so many indicators.

- for buildings up to 5 floors - 3-5 atmospheres;

- in nine-story houses - this is 5-7 atm;

- in skyscrapers from 10 floors - 7-10 atm;

For the heating main, which stretches from the boiler house to the heat consumption systems, the normal pressure is 12 atm.

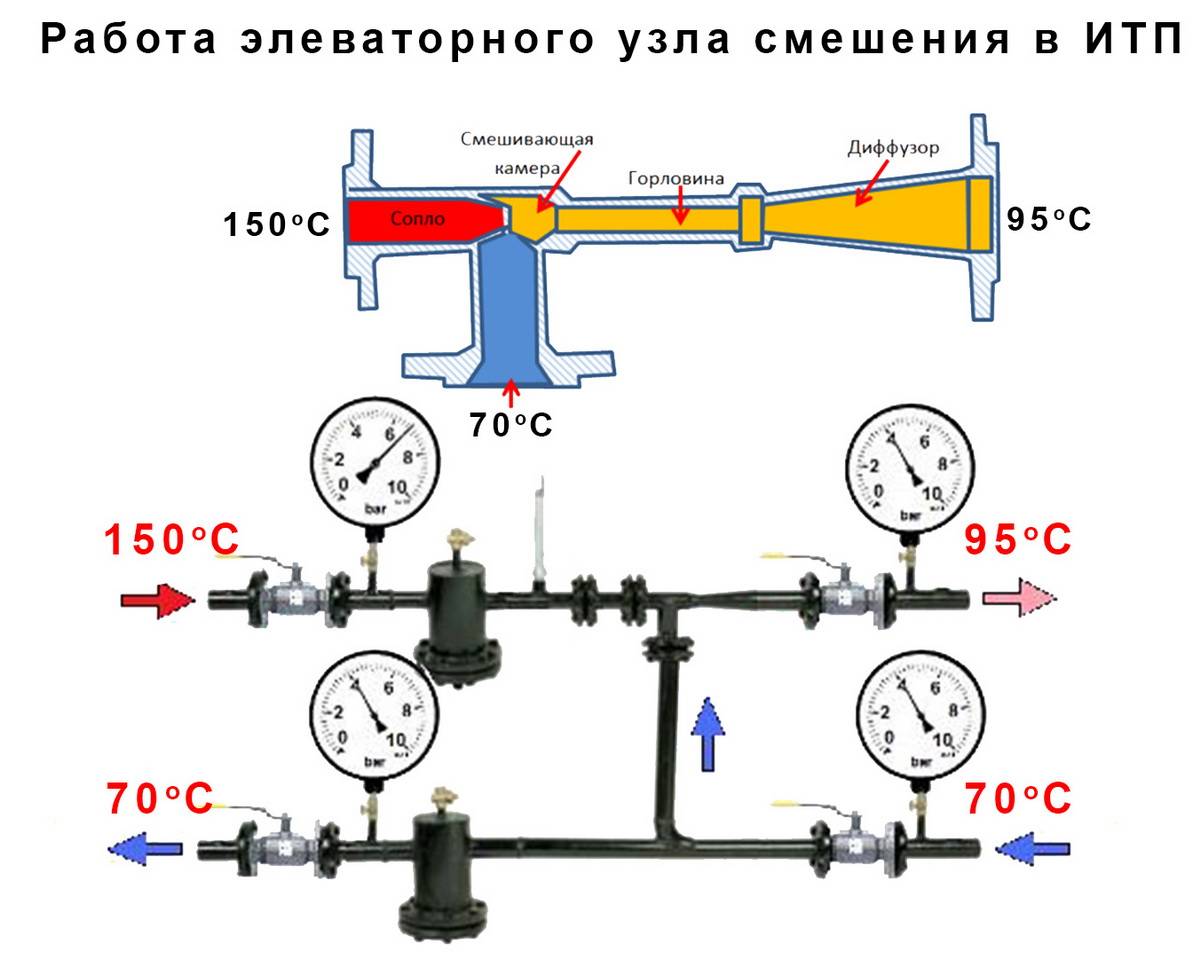

To equalize the pressure and ensure stable operation of the entire mechanism, a pressure regulator is used in the heating system of an apartment building. This balancing manual valve regulates the amount of heating medium with simple turns of the handle, each of which corresponds to a certain water flow. These data are indicated in the instructions attached to the regulator.

Working pressure in the heating system of an apartment building: how to control?

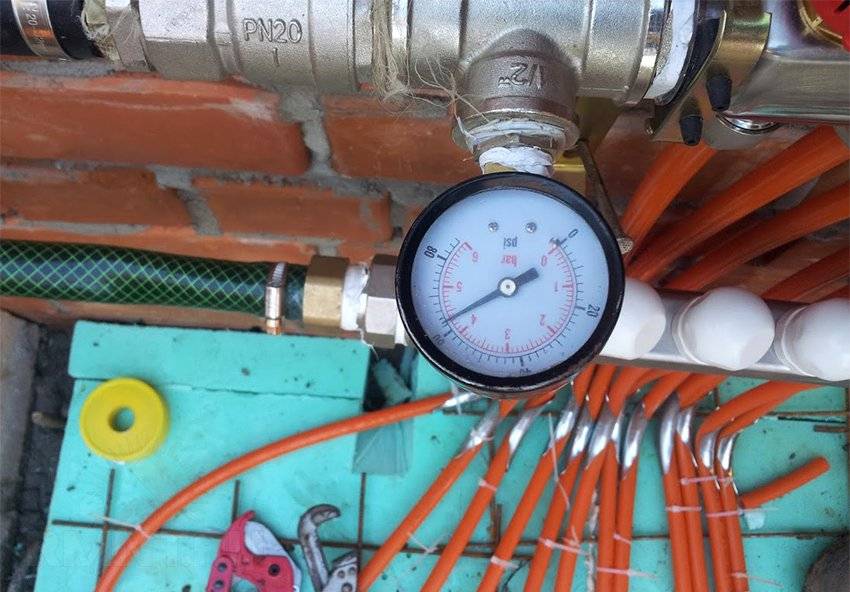

To know if the pressure in the heating pipes in an apartment building, there are special pressure gauges that can not only indicate deviations, even the smallest ones, but also block the operation of the system.

Since the pressure is different in different sections of the heating main, several such devices need to be installed.

Usually they are mounted:

- at the outlet and at the inlet of the heating boiler;

- on both sides of the circulation pump;

- on both sides of the filters;

- at points of the system located at different heights (maximum and minimum);

- close to collectors and system branches.

Pressure drops and its regulation

Jumps in the pressure of the coolant in the system are most often indicated with an increase in:

- for severe overheating of water;

- the cross section of the pipes does not correspond to the norm (less than required);

- clogging of pipes and deposits in heating appliances;

- presence of air pockets;

- pump performance is higher than required;

- any of its nodes are blocked in the system.

On downgrade:

- about the violation of the integrity of the system and the leakage of the coolant;

- breakdown or malfunction of the pump;

- may be caused by malfunctions in the operation of the safety unit or a rupture of the membrane in the expansion tank;

- coolant outflow from the heating medium to the carrier circuit;

- clogging of filters and pipes of the system.

Norm in an autonomous heating system

In the case when autonomous heating is installed in the apartment, the coolant is heated using a boiler, usually of low power. Since the pipeline in a separate apartment is small, it does not require numerous measuring instruments, and 1.5-2 atmospheres is considered normal pressure.

During start-up and testing of an autonomous system, it is filled with cold water, which, at a minimum pressure, gradually warms up, expands and reaches the norm. If suddenly in such a design the pressure in the batteries drops, then there is no need to panic, since the reason for this is most often their airiness. It is enough to free the circuit from excess air, fill it with coolant and the pressure itself will reach the norm.

To avoid emergency situations when the pressure in the heating batteries of an apartment building rises sharply by at least 3 atmospheres, you need to install either an expansion tank or a safety valve. If this is not done, the system may be depressurized and then it will have to be changed.

- carry out diagnostics;

- clean its elements;

- check the performance of measuring instruments.

2 thousand

1.4 thousand

6 min.

Why does the pressure in the heating system drop, how to increase it

The most common and commonplace cause of pressure drop is a power outage.

With frequent outages, it is solved by additionally installing an alternative source of electricity.

If the blackout occurs rarely and only in emergency situations, then the trouble that has arisen will be solved independently after it is turned on.

In the event of a power outage, it is recommended to check the pressure indicated by the sensor. Its normal value is considered to be 2 atm., At a higher value, there is a risk of depressurization of the heating structure. When water is supplied and the power is turned on, this value should be 1.5 atm.

Attention! Prolonged power outage can lead to defrosting of the heatsinks. This situation is dangerous due to costly repairs and replacement of a large amount of equipment.

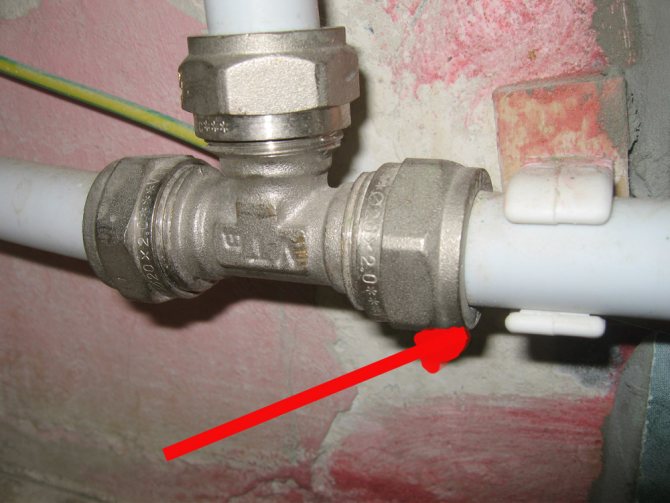

Leak in the heating system

An equally common problem is the appearance of a leak. It can manifest itself both in an open and in a hard-to-reach place. You can find it by the characteristic whistle that is created by the outgoing air, as well as by coating joints and other problem areas with soapy water.The presence of microcracks will be indicated by the appearance of soapy air bubbles.

Photo 1. Leak in heating pipe. Leakage can cause a drop in pressure.

A leak can occur inside a warm floor when the integrity of one of the branches is randomly violated. This cause of a pressure drop is easily detected by a wet spot on the floor covering or by the appearance of a small fountain of water. To eliminate this problem, you will need to disassemble part of the floor and install a special coupling in the place of failure. Such repairs require special skills and experience, which is why they are recommended to be performed only by professionals.

Air out of the expansion tank, but no leaks

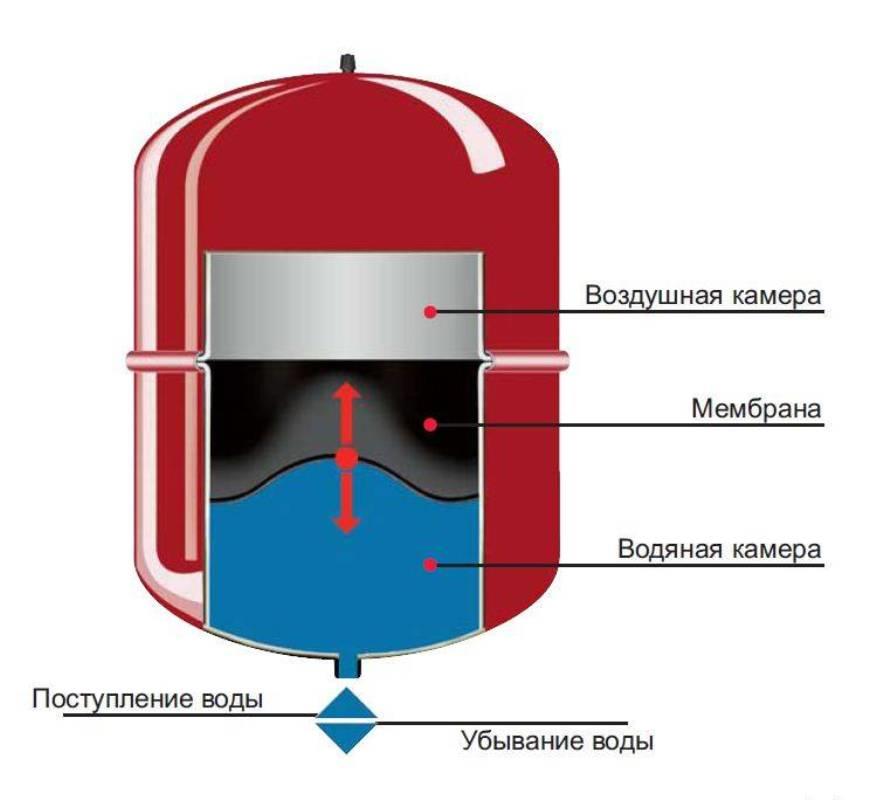

A few months after starting the heating system, the pressure may begin to decrease and the reason for this is the release of air from the expansion tank. In the upper part of this design there is a nipple through which the gradual bleeding of air is carried out. Its full release occurs only when the tank capacity is completely filled with coolant.

To normalize the indicators, measures are taken to reduce air ingress. This will require:

Competent creation of a heating scheme and the introduction of a heating system into operation according to it

The work must be carried out by a professional, paying attention to all connections and elements of the heating structure. Mistakes made at this stage require large financial costs and time.

Organization of testing of the system before its launch. To do this, with the help of a compressor, a pressure of 25% more than the optimum is supplied.If a sharp jump occurs within half an hour, this indicates a leak or a large amount of air.

Filling the system with coolant must be done slowly and using cold water. Before this stage, the taps designed to drain the water should be opened. If possible, their radiators are also bled.

Photo 2. Pressure standards for different degrees of filling of the expansion tank in the heating system.

Common Causes

- The flow of water in those places where pipelines intersect.

- Corroded pipes.

- Permissible errors during installation and start-up of the heating system.

- Expansion tank membrane deformation.

- The appearance of microcracks on the heat exchanger.

- Violation of the automated operation of the boiler.

Peak values

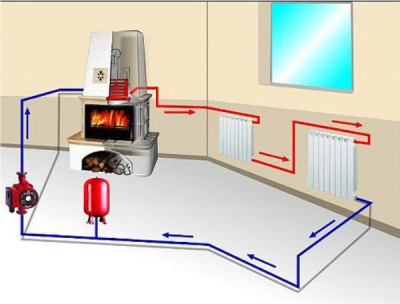

A closed-type heating system implies the movement of a coolant in a closed circuit that does not communicate with the external atmosphere. The tightness of the circuit is ensured by a membrane expansion tank. Unlike a traditional tank, it can be installed at any point in the system. For example, such tanks are present in many wall-mounted heating boilers.

Pressure of 100 atmospheres withstand monolithic bimetal radiators Rifar SUPREMO. A devastating indicator for them is the figure of 250 atmospheres.

Since the liquid in the pipes circulates in a closed volume, a certain pressure is created in the heating system. The norm for private houses with a height of 1-2 floors is 1.5-2 atmospheres. In large cottages, it may be higher. The upper limit is determined by the capabilities of the weakest node in the loop. In most cases, the weakest link is the boiler - it can withstand up to 3 atmospheres.Also on sale are less hardy models (1-2 atmospheres).

In high-rise buildings, peak rates are much higher. They reach up to 20 atmospheres and more. Water hammers also occur here - the pressure jumps to large values, which causes ruptures in pipelines and radiators. Therefore, in high-rise buildings, more durable and durable batteries are used that can withstand hydraulic shocks. Some of them are able to withstand pressure up to 100 atmospheres.

Heating system

Why do you need an expansion tank

The heating expansion tank contains the excess of the expanded coolant when it is heated. Without an expansion tank, the pressure can exceed the tensile strength of the pipe. The tank consists of a steel barrel and a rubber membrane that separates air from water.

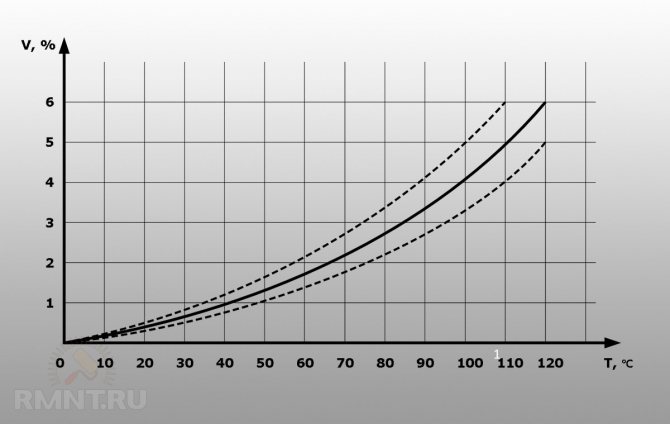

Air, unlike liquids, is highly compressible; with an increase in the volume of the coolant by 5%, the pressure in the circuit due to the air tank will increase slightly.

The volume of the tank is usually taken to be approximately equal to 10% of the total volume of the heating system. The price of this device is low, so the purchase will not be ruinous.

Proper installation of the tank - eyeliner up. Then no more air will get into it.

Why does pressure decrease in a closed circuit?

Why is it falling pressure in the heating system type?

After all, the water has nowhere to go!

- If there are automatic air vents in the system, the air dissolved in the water at the time of filling will exit through them.

Yes, it is a small part of the coolant volume; but after all, a large change in volume is not necessary for the pressure gauge to note the changes. - Plastic and metal-plastic pipes can be slightly deformed under the influence of pressure.In combination with high water temperature, this process will accelerate.

- In the heating system, the pressure drops when the temperature of the coolant drops. Thermal expansion, remember?

- Finally, minor leaks are easy to see only in centralized heating by rusty traces. The water in a closed circuit is not so rich in iron, and the pipes in a private house are most often not steel; therefore, it is almost impossible to see traces of small leaks if the water has time to evaporate.

What is the danger of a pressure drop in a closed circuit

Boiler failure. In older models without thermal control - up to the explosion. In modern older models, there is often automatic control of not only temperature, but also pressure: when it falls below the threshold value, the boiler reports a problem.

In any case, it is better to maintain the pressure in the circuit at about one and a half atmospheres.

Consequences of the explosion of the heating boiler.

How to slow down the pressure drop

In order not to feed the heating system over and over again every day, a simple measure will help: put a second larger expansion tank.

The internal volumes of several tanks are summarized; the greater the total amount of air in them, the smaller the pressure drop will cause a decrease in the volume of the coolant by, say, 10 milliliters per day.

Several expansion tanks can be connected in parallel.

Where to put the expansion tank

In general, there is no big difference for a membrane tank: it can be connected to any part of the circuit. Manufacturers, however, recommend connecting it where the water flow is as close to laminar as possible.If there is a heating circulation pump in the system, the tank can be mounted on a straight pipe section in front of it.

Control methods

To make the heating system correctly, to control the pressure level on your own, it is necessary to install control devices. These are pressure gauges with a Bredan tube, the calculation of the installation of which is carried out in accordance with regulatory documents. Their principle of operation is simple, they crash into the system with the help of three-way valves, which guarantees purging. If you choose such cranes for installation, then they can be installed without even turning off the entire system. It's more convenient and better.

The calculation of the choice of installation points includes the following key positions:

- before and after the heating boiler. If fireplace heating is used, then pressure gauges are not needed;

- before and after circulation pumps;

- at the exit from the heat generator;

- if a regulator is used, then the installation of pressure gauges before and after it must be included in the calculation;

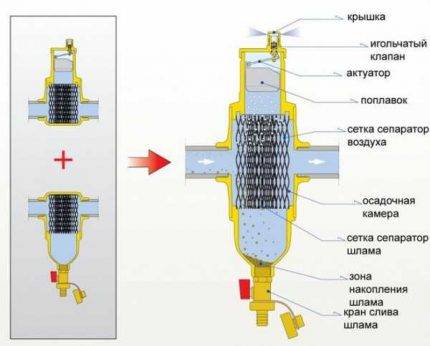

- in the presence of mud collectors, the pressure gauges include before and after them. This should also be included in the calculation of components for the heating system.

Reasons for the increase in power

An uncontrolled increase in pressure is an emergency.

May be due to:

- faulty automatic control of the fuel supply process;

- the boiler operates in manual high combustion mode and is not switched to medium or low combustion;

- battery tank malfunction;

- feed faucet failure.

The main reason is overheating of the coolant. What can be done?

- The operation of the boiler and automation should be checked. In manual mode, reduce the fuel supply.

- If the pressure gauge reading is critically high, drain some of the water until the reading drops into the working area. Next, check the readings.

- If there are no boiler malfunctions, check the condition of the storage tank. It accepts the volume of water that increases when heated. If the damping rubber cuff of the tank is damaged, or there is no air in the air chamber, it will completely fill with water. When heated, the coolant will have nowhere to be displaced, and the increase in water pressure will be significant.

Checking the tank is easy. You need to press the nipple in the valve to fill the tank with air. If there is no air hiss, then the cause is a loss of air pressure. If water appears, the membrane is damaged.

A dangerous increase in power can lead to the following consequences:

- damage to heating elements, up to rupture;

- overheating of water, when a crack appears in the boiler structure, instantaneous vaporization will occur, with the release of energy equal in power to an explosion;

- irreversible deformation of the elements of the boiler, heating and bringing them into an unusable state.

The most dangerous is the explosion of the boiler. At high pressure, water can be heated to a temperature of 140 C without boiling. When the slightest crack appears in the boiler heat exchanger jacket or even in the heating system next to the boiler, the pressure drops sharply.

Superheated water, with a sharp decrease in pressure, instantly boils with the formation of steam throughout the volume. The pressure instantly rises from vaporization, and this can lead to an explosion.

At high pressure and water temperature above 100 C, power must not be abruptly reduced near the boiler. Do not fill the firebox with water: cracks may appear from a strong temperature drop.

At high pressure and water temperature above 100 C, power must not be abruptly reduced near the boiler. Do not fill the firebox with water: cracks may appear from a strong temperature drop.

It is necessary to take measures to reduce the temperature and smoothly reduce the pressure by draining the coolant in small portions at a far point from the boiler.

If the water temperature is below 95 C, corrected for the error of the thermometer, then the pressure is reduced by the discharge of part of the water from the system. In this case, vaporization will not occur.

How to control the pressure in the system?

To control at various points in the heating system, pressure gauges are inserted, and (as mentioned above) they record excess pressure. As a rule, these are deformation devices with a Bredan tube. In the event that it is necessary to take into account that the pressure gauge must work not only for visual control, but also in the automation system, electrocontact or other types of sensors are used.

The tie-in points are defined by regulatory documents, but even if you have installed a small boiler for heating a private house that is not controlled by GosTekhnadzor, it is still advisable to use these rules, since they highlight the most important heating system points for pressure control.

It is imperative to embed pressure gauges through three-way valves, which ensure their purge, reset to zero and replacement without stopping all heating.

The control points are:

- Before and after the heating boiler;

- Before and after the circulation pumps;

- Output of heat networks from a heat generating plant (boiler house);

- Entering heating into the building;

- If a heating regulator is used, then the pressure gauges cut in before and after it;

- In the presence of mud collectors or filters, it is advisable to insert pressure gauges before and after them. Thus, it is easy to control their clogging, taking into account the fact that a serviceable element almost does not create a drop.

System with installed pressure gauges

A symptom of malfunctions or improper operation of the heating system is pressure surges. What do they stand for?

If the pressure rises

This situation is less common, but still possible. Its most likely cause is that there is no movement of water along the circuit. To diagnose, do the following:

- And again we remember about the regulator - in 75% of cases the problem is in it. To reduce the temperature in the network, it can cut off the coolant supply from the boiler room. If it works for one or two houses, then it is possible that the devices of all consumers worked at the same time and stopped the flow.

It is necessary to investigate the settings and adjust them so that the regulator does not give an order to completely close the valves, its inertia will increase, but such situations will be excluded;

Perhaps the system is under constant replenishment (malfunction of automation or someone's negligence). As the simplest calculation shows, the more coolant in a limited volume, the higher the pressure. In this case, it is enough to shut off the power line or set up automation;

If, however, everything is in order with the control devices or the heating system does not turn them on at all, we again take into account, first of all, the human factor - perhaps somewhere along the course of the coolant a tap or valve is closed;

The least likely situation is when an air lock interferes with the movement of the coolant - it is necessary to detect and remove it. May also be clogged in the direction of the coolant filter or sump;

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? It directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare hand pump for filling the heating system.It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes.However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When pressure drops in the line tap water pressure will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

4 The pressure in the heating system is growing - how to find out the cause

By checking the pressure gauges from time to time, you may notice that the pressure inside the system is increasing. This can happen for several reasons:

- you raised the temperature of the coolant, and it expanded,

- the movement of the coolant has stopped for some reason,

- on any section of the circuit, the valve (valve) is closed,

- mechanical clogging of the system or air lock,

- additional water constantly enters the boiler due to a loosely closed tap,

- during installation, the requirements for pipe diameters were not met (larger at the outlet and smaller at the inlet to the heat exchanger),

- excessive power or flaws in the operation of the pump. Its failure is fraught with a water hammer that is detrimental to the circuit.

Accordingly, it is necessary to find out which of the listed reasons led to the violation of the working norm and eliminate it. But it happens that the system worked successfully for months and suddenly there was a sharp jump, and the pressure gauge needle went into the red, emergency zone. This situation can be provoked by the boiling of the coolant in the boiler tank, so you need to reduce the fuel supply as quickly as possible.

Modern devices for individual heating are equipped with a mandatory expansion tank. It is a hermetic block of two compartments with a rubber partition inside. A heated coolant enters one chamber, air remains in the second. In cases where the water overheats and the pressure begins to rise, the partition of the expansion tank moves, increasing the volume of the water chamber, and compensates for the difference.

In the event of boiling or a critical surge in the boiler, mandatory safety relief valves are provided. They can be located in the expansion tank or on the pipeline immediately at the outlet of the boiler. In an emergency, part of the coolant from the system is poured out through this valve, saving the circuit from destruction.

In well-designed systems, there are also bypass valves, which, in the event of a blockage or other mechanical blockage of the main circuit, open and let the coolant into the small circuit. This safety system protects the equipment from overheating and damage.

Do I need to explain how important it is to monitor the health of these elements of the system. In case of small volume or violation pressure inside the expansion tank, as well as coolant leaks through microcracks, even significant pressure drops in the system are possible

Heating pressure regulation

Installing a professional device to control the pressure of liquid in pipes implies its further maintenance and adjustment.

The pressure gauge dial has several measuring zones:

- white - speaks of the fall of the onslaught of water;

- green, that the pressure is normal;

- red - increased number of atmospheres.

The path of warmth.

With a low supply of hot carrier, you need to open the valve, and after balancing - close it. If the pressure is increased, the relief valve opens. Under it you need to substitute an empty container to dump water. However, the above measures are not complete with frequent drops, the latter must be sought in the design of the heating circuit itself.

The algorithm for examining the central heating scheme of a high-rise building is as follows:

- before the start of the season, the line is checked with cold water for tightness;

- if within 30 min. the onslaught fell by 0.06 mPa, or the next two hours - 0.02, you should look for a rush of the circuit;

- in the absence of malfunctions, the circuit is filled with a hot resource, creating the maximum static pressure in the central heating.

To check the plastic wiring, the pressure is increased one and a half times higher than the working one and kept for 30 minutes, after which it is halved. If the indicators have not changed in the next 90 minutes, then the circuit is in good condition.

Pressure testing

The procedure for checking the heating system, before commissioning or during the off-season, is carried out by the masters of energy enterprises. The mechanism is filled with coolant and pressed under pressure close to critical.

The main purpose of the operation is to test all structural elements to identify and eliminate possible problems, determine the heating potential of the building and check the efficiency of heat transfer. Heating structures are tested by hydrostatic (water) and manometric (air) methods.

Important! When pressure testing the heating structure, gusts of old worn pipes and radiator smudges most often occur.

Cold

Cold hydrostatic testing takes place in stages:

water supply to system components;

- removal of air by opening air collectors and taps;

- closing the air collectors after filling the heating system with water;

- increasing the pressure level to the test one;

- exposure of the heating structure for a certain time under test pressure;

- draining.

Cold tests are considered the safest. But they are produced only in the warm season at a positive temperature in the rooms of the house in order to avoid possible "defrosting" of pipes. The pressure test water temperature must be above 5 °C.

For water heating structures during hydrostatic checks, the test pressure is approximately 1.5 MPa, but should be more than 0.2 MPa at the lowest point. The expansion tank and boilers are separated from the structure for testing. It is required that the pressure drop during testing be below 0.02 MPa for 5 minutes. Identified shortcomings that do not interfere with the course of hydrostatic testing are fixed and later eliminated.

Hot check

Approbation of the circuit using hot water is carried out closer to the heating season. The coolant is supplied with a pressure higher than the working one.

This testing is a control before cold weather and often allows you to identify critical violations in the efficiency of the equipment.

Hot testing must be carried out without fail.

Thanks to such testing, the probability of an accident for each individual house is reduced.

Air test

When testing the heating mechanism by manometric tests, you can not be afraid of flooding and "defrosting". But when testing a pipeline with compressed air, there is a risk of destruction of various elements. Therefore, in order to preserve the life and health of people, access to the premises in which the inspection is carried out should be limited.

Manometric tests of the heating structure are carried out by filling it with compressed air at the required test pressure. After appropriate measurements, the pressure is reduced to atmospheric.

Using air, heating circuits are checked not for strength, but for tightness. Initially, a pressure of 0.15 MPa is applied and a search for hearing damage is performed. Then check for 5 minutes with a pressure of 0.1 MPa. The pressure during the test should not fall below 0.01 MPa.

Photo 2. The process of checking heating with a pressure gauge. The system is filled with compressed air through batteries and measurements are taken.

Conclusion

As you can see, the importance of pressure in district heating networks is somewhat exaggerated. Even if the owner of the apartment is aware that he should have 0.7 MPa in the pipes, but this does little for him

In addition to the correct selection of radiators and pipes for replacing highways.

In a private house, the picture is different: the pressure gauge readings, and even a puddle near the safety valve, serve as an indicator of minor or significant malfunctions.These things need to be monitored and reacted in time by replenishing the system in order to raise the pressure to normal. Do not forget about the expansion tank - pump up the air chamber in time and monitor the integrity of the membrane.