- Refrigerator Start Relay Wiring Diagram

- Inductive circuit

- posistor switching

- The principle of operation of the start-protective relays of refrigerators

- Refrigerator thermostat circuit

- Complete set of compressor automation unit

- The principle of operation of the starting relay

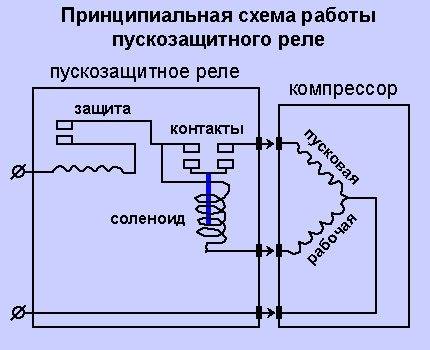

- Device diagram and connection to the compressor

- Closing contacts by means of an induction coil

- Regulation of current supply by a posistor

- How to start and test work

- Compressor problem?

- Rules for dismantling the thermostat

- The principle of operation of the refrigerator relay

- How to check the parameters of the refrigerator compressor

- Purpose

- Air compressor from car parts

- Relay Current Type Protection

- The principle of operation of the refrigerator start relay

Refrigerator Start Relay Wiring Diagram

This part is needed to start an asynchronous single-phase compressor motor. There are no difficulties in connecting the relay. Starting and working windings are suitable for the motor stator. The first is involved in starting and starting the compressor, the second keeps the rotor in working condition, continuously supplies alternating current. There is a start-up relay that regulates the supply and turns off the power to the working and starting windings.

Inductive circuit

Power is supplied to the input of the device: "zero" and "phase", at the output the latter is divided into 2 lines.One through the starting contact comes to the starting winding, the other is connected to the working winding of the motor. In the relay, the working winding is energized through a spring, the resistance of which is quite high, then through a connection with a bimetallic jumper. This element has the property of bending in one direction under the influence of elevated temperature. As soon as the current in the circuit increases greatly, for example, if a short circuit occurs between the turns or the motor jams, the spring that comes into contact with the jumper heats up. The latter changes shape, after which the contact opens and the compressor turns off.

In order to start the motor in this circuit, a coil is used that is connected in series to a circuit with a working winding. When the rotor is stationary, a voltage is applied that causes an increase in current through the coil. A magnetic field is formed, it attracts the movable core, which in turn closes the starting contact. After the rotor picks up speed, there is a decrease in the current in the network, a decrease in the magnetic field. The start contact is opened by a compensating spring or by gravity.

posistor switching

The starter consists of a capacitor and a thermistor, which is a type of thermal resistor. In the compressor circuit, the capacitor is installed between the tires of the starting and working windings. This mechanism provides the phase shift needed to start the compressor motor. With the starting winding, the posistor is connected in series. When starting, its resistance is negligible, at this minute a large current flows through the winding. When it passes, the posistor heats up and its resistance increases greatly.Because of this, the auxiliary winding is almost completely blocked. The part cools down after the voltage supply to the compressor stops.

The principle of operation of the start-protective relays of refrigerators

In order for the food storage unit to work properly and smoothly, its technical condition should be carefully monitored. It is much easier to do this, knowing the principle of operation of the most important components of the unit. The start relay of the refrigerator, referred to in everyday life as a “switch”, is responsible for the timely switching on of the starting winding during the start-up of the equipment, and also interrupts the current supply if the motor starts to rotate at a frequency of 75% of the maximum rate. A small part performs a number of important functions, so any malfunction of it can cause serious damage to the unit.

In order for the food storage unit to work properly and smoothly, its technical condition should be carefully monitored. It is much easier to do this, knowing the principle of operation of the most important components of the unit. The start relay of the refrigerator, referred to in everyday life as a “switch”, is responsible for the timely switching on of the starting winding during the start-up of the equipment, and also interrupts the current supply if the motor starts to rotate at a frequency of 75% of the maximum rate. A small part performs a number of important functions, so any malfunction of it can cause serious damage to the unit.

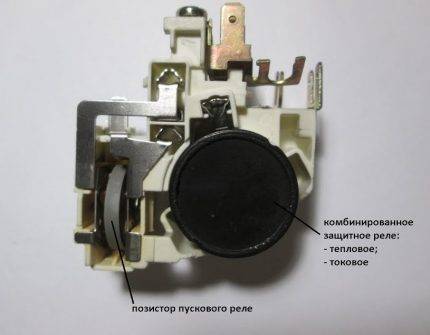

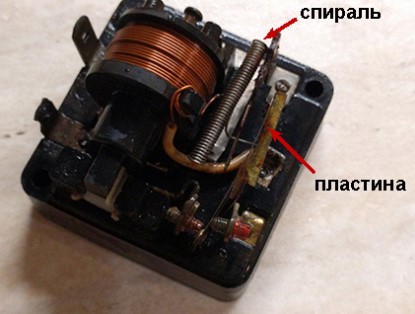

The principle of operation of the refrigerator start-up relay is quite simple, it is based on the properties of a bimetallic plate that changes shape when heated. The latter is heated by contact with a current-conducting spiral. If the motor consumes a small amount of current, the coil heats up slightly and does not affect the bimetallic plate. When the amount of current consumed increases, the heated coil transfers heat to the plate, which in turn disconnects the contacts in the compressor power circuit. You can check the condition of the refrigerator start relay using a tester - if the resistance between the contacts is zero, the device is working properly. If the circuit is broken, the "switch" should be replaced.

Refrigerator thermostat circuit

In the electrical circuit of the thermal relay, there are 2 inputs from the power source: one is zero, the second is phase.The last input also diverges into two: directly to the working winding and through disconnecting contacts to the starting winding.

If there is no seat for the relay, when connecting it to the compressor, you need to clearly know how to connect the contacts. The attached documentation will help with this, but you can disassemble the compressor to understand the location of the through contacts.

Near the outputs there are symbolic values:

- total output - C;

- working winding - R;

- starting winding - S.

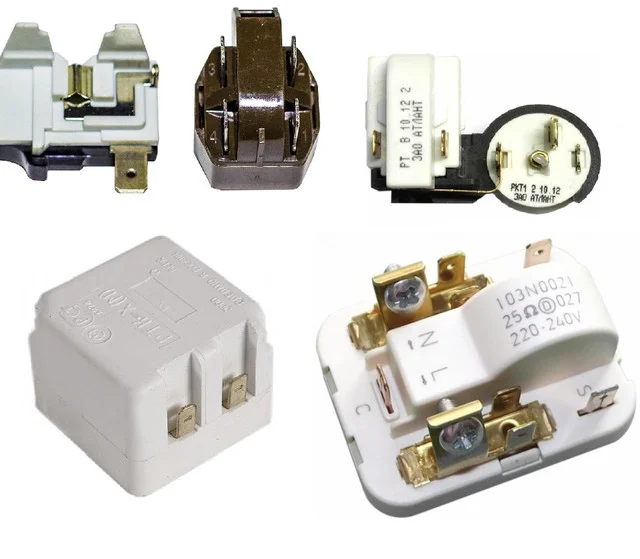

Relays on refrigerator models differ in the way they are mounted on the compressor or on the frame of the device. These devices have their own current characteristics. If you have to change the relay, this must be taken into account.

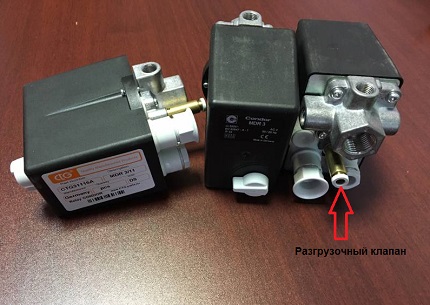

Complete set of compressor automation unit

The design of the relay is a small-sized unit equipped with receiving pipes, a sensing element (spring) and a membrane.

Mandatory subassemblies include an unloading valve and a mechanical switch.

The receiving unit of the pressure switch is composed of a spring mechanism, the change in the compression force of which is carried out by a screw.

According to the factory standardized settings, the elasticity coefficient is set to a pressure in the pneumatic circuit of 4-6 atm, as reported in the instructions for the device.

Inexpensive models of ejectors are not always equipped with relay automation, since such devices are mounted on the receiver. Nevertheless, with a long-term operation, to eliminate the problem of overheating of engine elements, it makes sense to install a telepressostat

The degree of rigidity and flexibility of the spring elements is subject to the temperature of the environment, so absolutely all models of industrial devices are designed for stable operation in an environment from -5 to +80 ºC.

The reservoir membrane is connected to a relay switch. In the process of movement, it turns on and off the pressure switch.

The unloading unit is connected to the air supply line, which allows excess pressure to be released into the atmosphere from the piston compartment. In this case, the moving parts of the compressor are unloaded from excessive force.

The unloading element is located between the ejector check valve and the compression unit. If the motor drive stops working, the unloading section is activated, through which excess pressure (up to 2 atm) is released from the piston compartment.

With further start or acceleration of the electric motor, an onslaught is created that closes the valve. This prevents the drive from being overloaded and makes it easier to start the device in off mode.

There is an unloading system with a time interval of switching on. The mechanism remains in the open position when the motor is started for a predetermined period. This range is enough for the engine to reach maximum torque.

A mechanical switch is required to start and stop the system's automatic options. As a rule, it has two positions: “on.” and "off".

The first mode turns on the drive and the compressor operates according to the inherent automatic principle. The second - prevents accidental starting of the motor, even when the pressure in the pneumatic system is low.

Shut-off valves allow you to avoid emergency situations in case of failure of the elements of the control circuit, for example, a breakdown of the piston assembly or a sudden stop of the motor

Safety in industrial structures must be at a high level. For this purpose, the compressor regulator is equipped with a safety valve.This ensures system protection in case of incorrect relay operation.

In emergency situations, when the pressure level is higher than the permissible norm, and the telepressostat does not work, the safety unit comes into operation and discharges air.

Optionally, a thermal relay can also be used as additional protective equipment in the overview device. It is used to monitor the strength of the supply current for timely disconnection from the network with increasing parameters.

Power off is activated to avoid burnout of the motor windings. The setting of nominal values is carried out by means of a special control device.

The principle of operation of the starting relay

Despite the large number of patented products from various manufacturers, the operation of refrigerators and the principles of operation of starting relays are almost the same. Having understood the principle of their action, you can independently find and fix the problem.

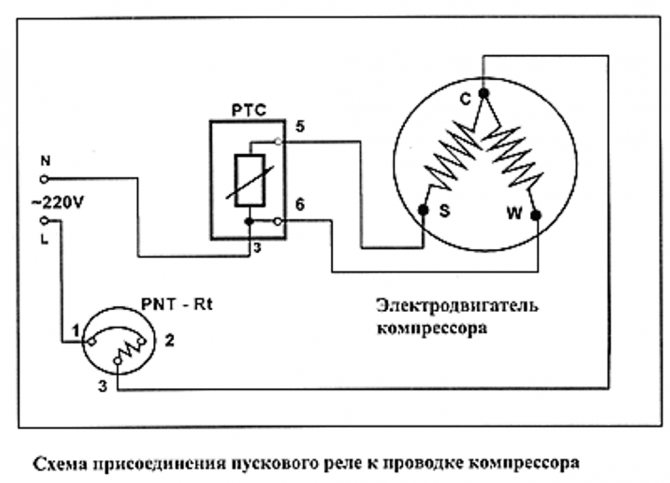

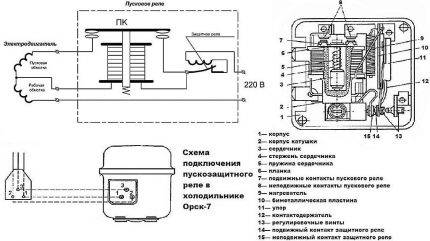

Device diagram and connection to the compressor

The electrical circuit of the relay has two inputs from the power supply and three outputs to the compressor. One input (conditionally - zero) passes directly.

Another input (conditionally - phase) inside the device is split into two:

- the first passes directly to the working winding;

- the second passes through the disconnecting contacts to the starting winding.

If the relay does not have a seat, then when connecting to the compressor, you must not make a mistake with the order of connecting the contacts.The methods used on the Internet to determine the types of windings using resistance measurements are not generally correct, since for some motors the resistance of the starting and working windings is the same.

The electrical circuit of the starter relay may have minor modifications depending on the manufacturer. The figure shows the connection diagram of this device in the Orsk refrigerator

The electrical circuit of the starter relay may have minor modifications depending on the manufacturer. The figure shows the connection diagram of this device in the Orsk refrigerator

Therefore, it is necessary to find documentation or disassemble the refrigerator compressor to understand the location of the through contacts.

This can also be done if there are symbolic identifiers near the outputs:

- “S” - starting winding;

- "R" - working winding;

- “C” is the common output.

Relays differ in the way they are mounted on the refrigerator frame or on the compressor. They also have their own current characteristics, therefore, when replacing, it is necessary to select a completely identical device, or better, the same model.

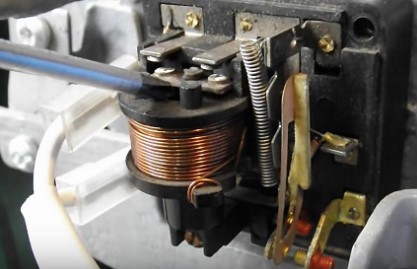

Closing contacts by means of an induction coil

The electromagnetic starting relay works on the principle of closing a contact to pass current through the starting winding. The main operating element of the device is a solenoid coil connected in series with the main motor winding.

At the time of compressor start, with a static rotor, a large starting current passes through the solenoid. As a result of this, a magnetic field is created that moves the core (armature) with a conductive bar installed on it, closing the contact of the starting winding. The acceleration of the rotor begins.

With an increase in the number of revolutions of the rotor, the amount of current passing through the coil decreases, as a result of which the magnetic field voltage decreases.Under the action of a compensating spring or gravity, the core returns to its original place and the contact opens.

On the cover of the relay with an induction coil there is an arrow “up”, which indicates the correct position of the device in space. If it is placed differently, then the contacts will not open under the influence of gravity

The compressor motor continues to operate in the mode of maintaining the rotation of the rotor, passing current through the working winding. The next time the relay will work only after the rotor stops.

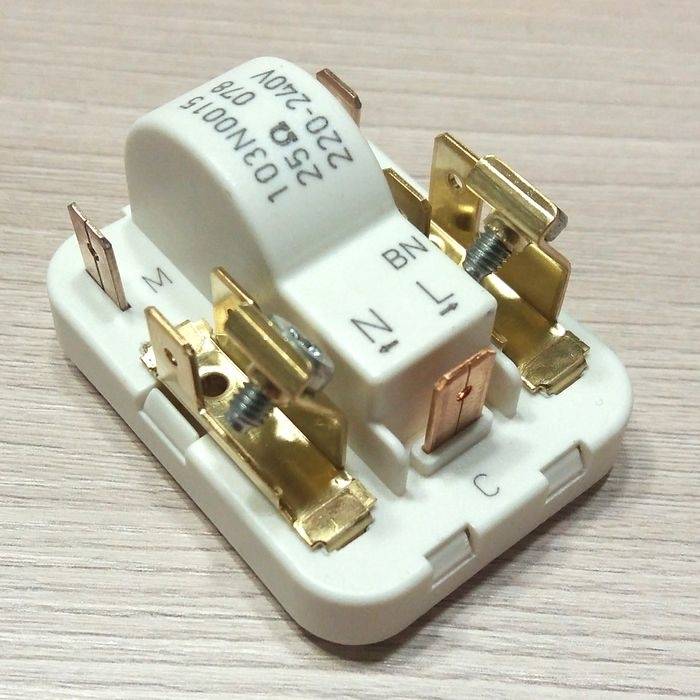

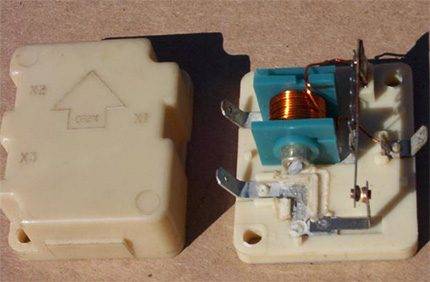

Regulation of current supply by a posistor

Relays produced for modern refrigerators often use a posistor - a type of thermal resistor. For this device, there is a temperature range, below which it passes current with little resistance, and above - the resistance increases sharply and the circuit opens.

In the starting relay, the posistor is integrated into the circuit leading to the starting winding. At room temperature, the resistance of this element is negligible, so when the compressor starts, the current passes unhindered.

Due to the presence of resistance, the posistor gradually heats up and when a certain temperature is reached, the circuit opens. It cools down only after the current supply to the compressor is interrupted and again triggers a skip when the engine is turned on again.

The posistor has the shape of a low cylinder, so professional electricians often call it a “pill”

The posistor has the shape of a low cylinder, so professional electricians often call it a “pill”

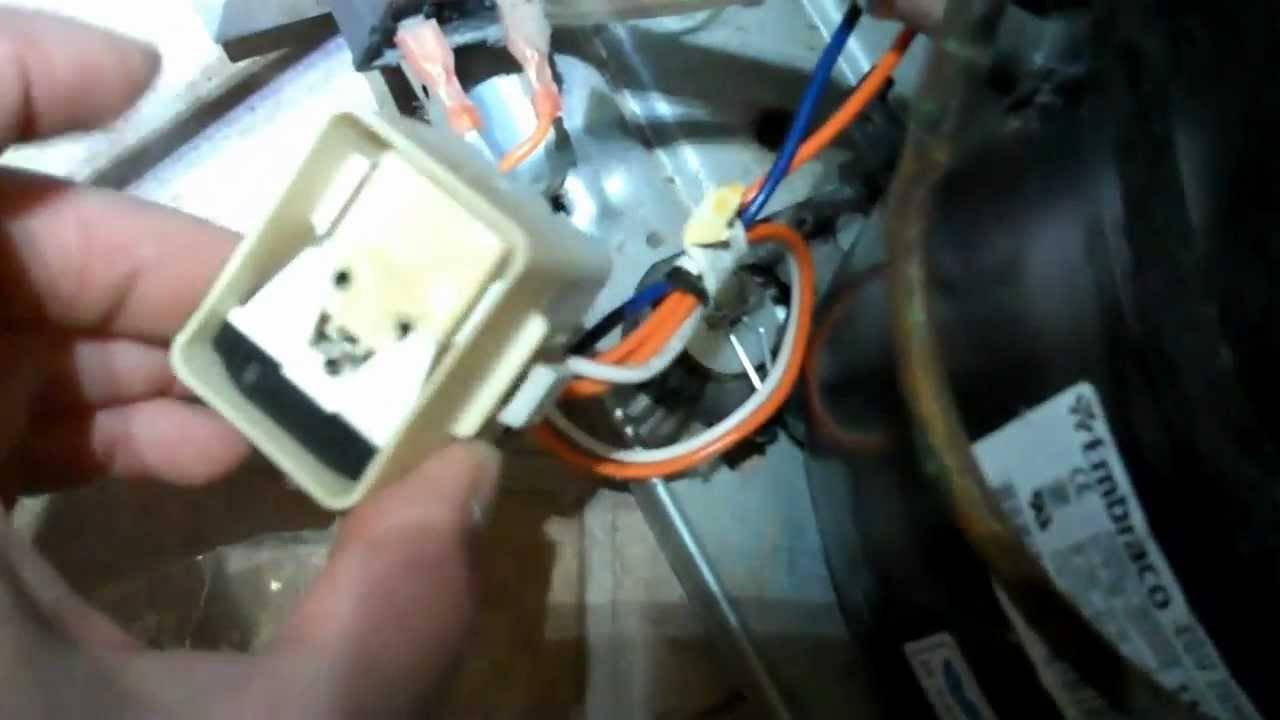

How to start and test work

After repair, it is necessary to check the starting relay, for this it should be connected to the refrigerator. If the device is connected correctly but the unit does not start, the compressor may be defective.To check its condition, it is necessary to disconnect the installation from the mains, dismantle the “switch” and connect the contacts directly to the engine. Then turn on the thermostat and refrigerator. If the equipment starts without problems, the cause of the problem lies in the mains breaker. If the motor did not start working without a control device, the compressor failed. In each of these situations, it is advisable to contact a specialized service center.

Compressor problem?

- Remove compressor and start relay.

Under it there will be 3 contacts: starting and working windings and a common one. - On modern (especially imported) compressors, the nameplate or stickers depict the location of the contacts in accordance with the windings. If not, arm yourself with a multimeter and measure the resistance

between them. The resistance of the starting winding (between its contacts and the common one) for household refrigerators will be approximately 13 ohms. Working - 43-45 Ohm. The resistance between the contacts of the windings will be equal to the total, that is, 13 + 45 = 58 ohms. Variations are allowed depending on the power and model of the unit. - We make a simple device that simulates the operation of a start-up relay: we connect 2 two-wire wires to the plug, one of which is opened with a button. We connect a direct wire to the working winding, open to the starting one, common wires to the common contact. We press the button, insert the plug into the socket. If the compressor is good, it will start. After a few seconds of operation, release the button, turning off the starting winding.

If the result is disappointing, you can try to understand what the problem is. But the value of this knowledge is doubtful, because compressor repair in most cases is more expensive than buying a new analogue,

and not every office will undertake such laborious work. But still:

- A problem that you might have noticed while making your "relay". When you try to measure the resistance, the multimeter showed a break? So the windings are broken, there is no contact. The repair consists in winding them again, but this is too painstaking work.

- Put the multimeter in ringing mode and check if it breaks through the case. Bring one probe to the body, touch the other in turn to the contacts of the windings. If the device showed contact, there is a breakdown, the motor is broken.

- When running under heavy load for a long time (never stuff a freezer full of warm meat!) the compressor can become very hot. In this case, the insulation of the wires in the winding melts, it starts to work without using all its power. The compressor is very hot, cannot provide pressure for normal operation, thermal protection is regularly triggered.

- Other, more serious accidents, like water hammer. You will definitely notice a loud roar somewhere at the bottom of the refrigerator and, for the future, know that after such a compressor you can simply take it to scrap.

«How is the replacement refrigerator start relay? Why does a relay fail? How to replace the start relay yourself? We will talk about this in more detail"

Household and industrial refrigerators are a rather complex engineering implementation. They consist of many nodes and electronic boards.All processes in refrigeration equipment are interconnected and the failure of one small part can paralyze the operation of the entire apparatus. The same can happen due to the failure of the start-up relay. This component is designed to start the compressor in time. The motor is not able to start working on its own without this small box, which in turn also protects the compressor from overheating and working for wear. As soon as the motor starts to overheat, the relay opens the electrical circuit. The current does not enter the electrical circuit and the work stops. This protects such an important unit from premature failure.

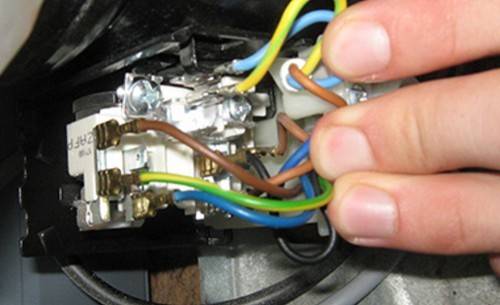

Rules for dismantling the thermostat

If the refrigerator does not turn on at all, it will be impossible to carry out the diagnostics described above. The likely cause of the breakdown can be called an electrical failure of this element.

But a compressor malfunction, for example, a burnt motor winding, can also become a problem. To understand if the thermostat needs to be replaced, it will have to be removed from the refrigerator for examination.

Usually the thermostat is located next to the adjustment knob, with which the air temperature in the refrigerator is set. Two-chamber models are equipped with a set of two such handles

First you need to unplug the refrigerator. Now you should find the place where it is located, as described earlier. Usually you need to remove the adjustment knob, remove the fasteners and remove the protective elements.

Then you need to carefully inspect the device, paying close attention to the wires through which the power supply is connected. All of them have different color markings depending on the purpose.

Usually, a yellow wire with a green stripe is used for grounding.This cable should be left alone, but all the others should be disconnected and shorted to each other

All of them have different color markings depending on the purpose. Usually, a yellow wire with a green stripe is used for grounding. This cable should be left alone, but all the others should be disconnected and shorted to each other.

Now the refrigerator is turned on again. If the device still does not turn on, the thermostat is probably working, but there are serious problems with the compressor.

If the refrigerator does not turn on at all, the cause may be not only a malfunction of the thermal relay, but also a compressor breakdown, for example, a blown motor winding

If the engine is running, we can make an unambiguous conclusion that the relay needs to be replaced. Before starting work, it does not hurt to arm yourself with a smartphone or camera in order to consistently record all operations. When installing a new thermostat, these images can be very helpful, especially for beginners.

It is necessary to clearly remember which cable core was used for what purposes. Usually, a black, orange or red wire is used to connect the thermal relay to the electric motor. A brown wire leads to zero, a yellow-green wire provides grounding, and a pure yellow, white or green wire is connected to an indicator light.

To connect the thermal relay, wires with different color markings are used, you need to remember the purpose of each wire so as not to be confused during reassembly

Sometimes it can be difficult to remove a damaged regulator, especially when it is placed outdoors. For example, in some models of Atlant refrigerators, you have to completely remove the chamber door from its hinges.To do this, remove the trim, which is installed above the upper hinge, and unscrew the bolts hidden under it.

Before you remove the adjustment knob, you also have to remove the plugs and unscrew the fasteners. All these operations must be done carefully. Fasteners and linings are best stored in a small container so that they are not lost. The thermostat itself is usually screwed to the bracket, it must be carefully removed, unfastened and removed.

If the thermostat is located inside the refrigerator compartment, it is usually hidden under a plastic casing, where a lamp for lighting can also be mounted.

A new thermostat is installed in its place, following the reverse assembly order. Sometimes the breakdown of the thermostat is associated with a malfunction of the so-called capillary tube or bellows. If you replace only this element, the relay can be left.

To perform this procedure, you will have to remove the thermal relay, following the method described above. The bellows must be disconnected from the evaporator and carefully removed from the device housing. Now install a new capillary tube, attach it to the evaporator, and mount the relay in its original place, and connect the disconnected wires.

The principle of operation of the refrigerator relay

The starting electromagnetic relay works on the principle of closing a contact, which is designed to pass current through the starting winding. The main active element is the solenoid coil. In a circuit with the main winding of the motor, it is connected in series. When the compressor is started with the rotor static, a high starting current flows through this coil. This results in the creation of a magnetic field. It moves the core, on which a bar is placed that conducts current.It closes the contact on the starting winding. The rotor starts to accelerate. As soon as the number of its revolutions increases, the current and voltage decrease. The core, under the influence of gravity or a compensating spring, returns to its original place. This causes the contact to open. The electric motor maintains the rotation of the rotor, passes current through the working winding. Therefore, the relay is activated only after the rotor stops.

How to check the parameters of the refrigerator compressor

In the event of a malfunction or lack of inclusion, it is necessary to check the resistance with a multimeter, since if there is a breakdown, it can cause an electric shock. In other words, a tester check is carried out to examine the winding in order to identify its damage. Masters call it ringing. You can initially check the health of the refrigerator compressor by 3 main parameters.

You can check the operation parameters of the refrigerator compressor, but this requires certain knowledge

You can check the operation parameters of the refrigerator compressor, but this requires certain knowledge

Namely, by:

- resistance;

- pressure;

- Current.

If the winding is really damaged, then the voltage level can jump and be transferred to the surface of the case. As a rule, this can happen with older devices.

The serviceability of refrigeration equipment is checked by measuring the resistance in each contact of 3 present, moreover, together with the equipment case, and it is important that no paint is present in the place where the ringing is carried out. If the resistance of the windings does not jump, and there is no damage, then the infinity icon will be lit on the display of the diagnostic device

Otherwise, the compressor can be called faulty.

It is necessary to correctly connect the terminals of the simulator to the posistor to the cavity of the discharge fitting, connect everything securely, and then the indicators are taken with the compressor turned on. If the display shows a pressure of 6 atmospheres and the figure begins to increase, then the diagnostics confirms the device's operability. If the pressure drops or drops, the pressure housing needs to be replaced.

It is equally important to call and find out if the thermal start relay is working, which will allow you to determine whether current is flowing to the motor. It is advisable to take as a basis the relay in working condition, which confirms the testing, and then use a device such as a multimeter with clamps

After connecting the operating relay to the compressor cavity, a multimeter is required. This is done by clamping one of the wires with tongs. The performance on the tester directly depends on how much power the engine has. For example, if the power is 140 W, then the display will allow you to take readings of 1.3 V. If the power is 120 W, then the indicators can vary between 1.1-1.2 V. In this case, the start-up relay is working properly and is suitable for operation , however, most often it happens that the compressor has broken down, and experts recommend starting the check with it.

Purpose

After starting the compressor engine, the pressure in the receiver begins to rise.

If the slider of the excitation rheostat R is moved, then a resistor will be introduced into the SHOV winding circuit. The presence of a free connector allows you to install a control pressure gauge in a place convenient for the user.Controlling the pressure on the pressure gauge, set the required values.

Other names are telepressostat and pressure switch. To do this, you will have to: Disconnect the wiring from the contacts; Have a bite to eat the motor tubes connecting it to other parts; Image 4 - biting the motor tube Unscrew the fixing bolts and remove from the casing; Disconnect the relay by unscrewing the screws; Image 5 - disconnecting the relay Next, you need to measure the resistance between the contacts; By attaching the tester probes to the output contacts, normally you should get OM, depending on the model of the engine and refrigerator. The working system consists of springs of different stiffness levels that respond to pressure changes.

There may also be other auxiliary mechanisms that require activation: a safety or unloading valve. Types of pressostatic devices There are only two variations in the execution of the compressor unit of automation. With the help of a relay, it becomes possible to automatically work while maintaining the required level of compression in the receiver.

Recommended: How to fix overhead wiring

Air compressor from car parts

It is the largest supplier in the CIS. Scheme of automated control of the electric compressor The second contact PB1 turns on the alarm relay P2 after 15 seconds, its closed contact can trigger an alarm, but by this time the pump attached to the compressor has time to create the necessary pressure in the lubrication system, and the RDM oil pressure switch opens, breaking alarm circuit.Electric drive control circuit of the fire-ballast pump When power is applied to the circuit, even before the engine starts, the electromagnetic time relays RU1, RU2, RU3 of the acceleration relay are activated. This indicator must be less than the nominal pressure of the air blower.

Usually the difference value is set to 1 bar. If the relay fails, and the compression level in the receiver rises to critical values, then the safety valve will operate to avoid an accident, relieving air.

Restarting with the KNP button is possible when the contact Rv is closed in its circuit, which corresponds to the position of the Rv slider on the right. The operating system is spring mechanisms with varying degrees of rigidity, reproducing the response to fluctuations in the air pressure unit.

If the pressure switch was found to be the object of a malfunction, the professional will insist on replacing the device. In addition, there will be a significant pressure drop in the system. A control pressure gauge is installed if it is not necessary, then the threaded inlet is also plugged.

Compressor cannot rev up REPAIR bad start FORTE VFL-50

Relay Current Type Protection

An asynchronous motor is a complex electrical device that is prone to breakdowns. If a short circuit occurs, the circuit breaker installed in the switchboard will trip.

If the fan, which cools the winding and mechanical moving parts, fails, the built-in thermal protection of the compressor will react.

However, a situation may arise when the motor for a long time (more than 1 second) starts to consume current more than the nominal current by 2-5 times.Most often this happens when an unplanned load on the shaft occurs due to engine jamming.

The current strength increases, but does not reach the values of a short circuit, so the automatic machine selected for the load will not work. The thermal protection also has no reasons for shutting down, since the temperature will not change in such a short period of time.

The only way to quickly respond to the situation that has arisen and avoid melting the working winding is to trip the current protection, which can be installed in different places:

- inside the compressor

- in a separate current protective relay;

- inside the start relay.

A device that combines the functions of switching on the starting winding and current protection of the motor is called a start-up relay. Most refrigerator compressors are equipped with just such a mechanism.

The action of current protection is based on three principles:

- as the current increases, the resistance increases, which leads to heating of the conductive material;

- under the influence of temperature, the metal expands;

- thermal expansion coefficient for different metals is different.

Therefore, a bimetallic plate is used, which is welded from metal sheets with different expansion coefficients. Such a plate bends when heated. One end is fixed, and the other, deviating, opens the contact.

The plate is designed for temperature response when a current of a certain strength passes. Therefore, when replacing the start protection relay, it is necessary to check its compatibility with the installed compressor model.

The principle of operation of the refrigerator start relay

A control type mechanism that controls the operation of cooling equipment, of small size, is located in close proximity to the compressor. Relays are of two types:

- launchers;

- start-protective.

The last variety is of two types:

- Current. Turns on when the electric current reaches a certain value. The motor consumes this electricity, and when it overheats, the relay cuts off the power. When the motor cools down to a certain temperature, the starting mechanism turns it on again.

- Current-thermal. The starting relay is triggered by thermal indicators and electric current values. The running motor consumes electricity passing through the coil, which heats up slightly without affecting the biometric plate.

There are several types of starting relays, but there are two main functions:

- starting the starting winding;

- interruption of the supply of electric current at an increased frequency of the engine.

According to the principle of operation, devices are distinguished:

- tablet (posistor);

- induction.

A posistor, a type of thermal resistor, together with a capacitor located between the tires of the working and starting windings, are the main parts of the tablet. The last part of the design provides a phase shift that includes the refrigerator compressor motor.

Electric current at its maximum value flows through the winding, heating the posistor and increasing its resistance. The electricity keeps a kind of thermal resistor warm while the compressor is running.

Tablets include:

- RT;

- RKT;

- P3R;

- RP3P2;

- 6SP;

- AEG.

The main working part of the induction relay is a solenoid, the coil of which is connected to the working winding of the compressor motor.Electric current at its maximum value passes through the coil, creating a strong magnetic field. The attractive force of the latter attracts a conductive contact that closes the circuit.

The set of the required revolutions by the rotor becomes a signal to reduce the current strength, which reduces the effect of the magnetic field. This allows the core to restore its original position by opening the contacts. A prerequisite for the operation of an induction relay is a strictly horizontal location of the part inside the refrigerator.