- When are they allowed to check?

- Air quality assessment

- Applied tools and equipment

- The act (protocol) of checking the effectiveness of ventilation in the house - a sample

- Optimization of ventilation in the apartment

- How much does a check cost?

- Traction test methods

- Who is responsible for checking chimneys and ventilation ducts

- Cleaning the air exchange network

- Ways to check ventilation

- Identification of ventilation design errors

- Why is it profitable to order a ventilation audit in IS Ecolife

- Passport of the ventilation system in the house

- Schemes of natural ventilation in the house, in the apartment

- Scheme of natural ventilation channels in a private house

- Schemes of natural ventilation channels in an apartment building

- Scheme of mechanical forced exhaust ventilation of an apartment building

- Correct connection of the kitchen hood to the ventilation duct

- The need for inspections

- Ventilation Check Frequency

- work log

- Measurement protocol (full)

- Protocol for ventilation passport

- Examples of ventilation test protocols

When are they allowed to check?

Employees of Rospotrebnadzor are required to notify you of the inspection at least 3 days before arrival.

Before starting the inspection, the inspector of Rospotrebnadzor is obliged to present an official certificate.An inspection can be carried out only after the presentation of an order to conduct an inspection (issued by the head / deputy head of the Rospotrebnadzor Department) and in the presence of the head of the organization. It is worth making sure that the verification is carried out by the person indicated in the documents.

Any violation of the inspection regulations can be considered a reason for going to court or to Rospotrebnadzor itself.

Air quality assessment

The composition of the air is determined by conducting aerosol and gas analysis in the workshops and premises of the enterprise where the production process takes place.

In addition, indoor and outdoor carbon dioxide concentrations are determined. Aerodynamic tests are also carried out.

In order to detect deviations in air quality from existing standards, it is necessary to take 5 samples at a specific workplace at different times of the work shift.

Aspirators and/or traction inducers are used to take each sample.

How often do you need to check?

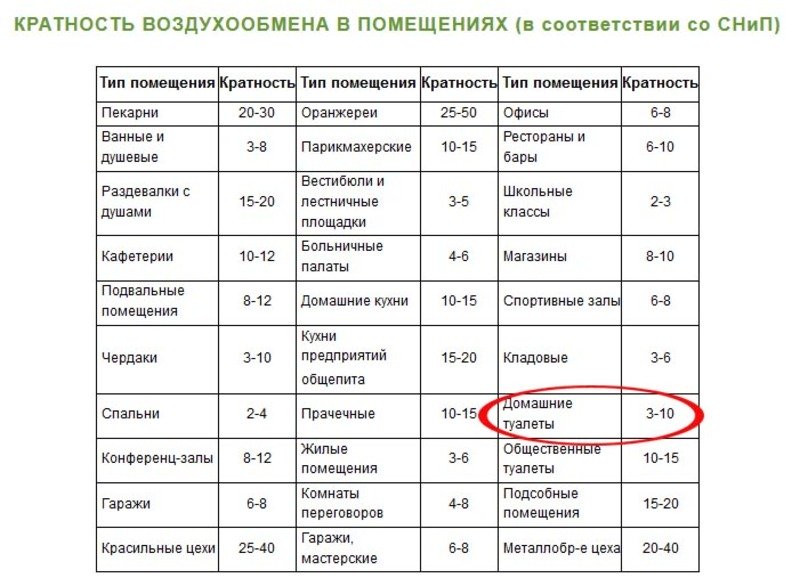

Mandatory checks of ventilation systems in the premises are carried out with the following minimum frequency:

- once every three years - natural or mechanical ventilation;

- once a year - supply and exhaust ventilation;

- 3 times a year - in residential and non-residential premises where gas equipment is installed;

- once a month - where combustible, explosive, radioactive, toxic substances of classes I-II are released.

When checking the ventilation system, instrumental and laboratory measurements are used.

If the efficiency is insufficient, the measurement results will be higher or lower than normal.

Applied tools and equipment

We offer to consider a set of cleaning equipment from the well-known Finnish manufacturer Pressovac:

- video camera for internal inspection of air ducts;

- brush machine with electric or pneumatic drive;

- vacuum installation;

- filter unit;

- compressor (used in conjunction with a pneumatic brush machine);

- spray bottle for ventilation system disinfection.

The brush device is a flexible shaft 6-40 meters long, connected to an electric motor or pneumatic drive. The rotating shaft is placed inside a strong shell, a brush of the required shape is fixed at the end.

The vacuum unit is a powerful fan with a capacity of up to 15,000 m³/h that sucks debris out of the channel. Then the flow is sent to the filter machine, where pollutant particles are trapped.

In addition to the main equipment, the kit includes accessories:

- brushes of various shapes and hardness;

- corrugated pipes connecting the units with air ducts;

- plugs for side outlets of ventilation ducts;

- vacuum discs used in round pipes;

- shaped elements and inspection hatches for additional inserts into the channels.

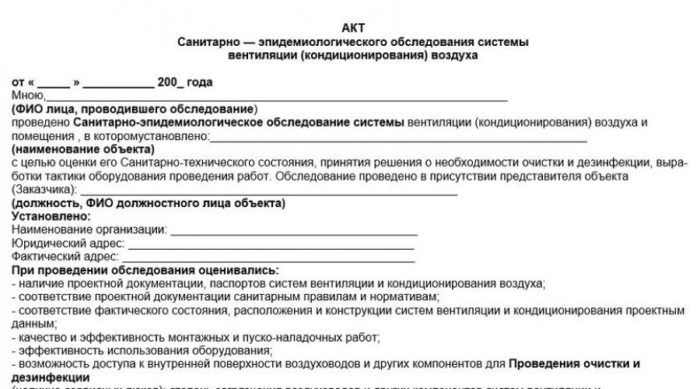

The act (protocol) of checking the effectiveness of ventilation in the house - a sample

Annex B (recommended). The structure of the technical report on the performance of work on testing and adjustment of ventilation and air conditioning systems:

3 Test results of ventilation systems and equipment (including description of test methods and sequence of measurements).

4 Sanitary and hygienic and/or technological conditions of the air environment of the premises (including the conditions for performing tests).

5 Conclusions and recommended actions (for the prevention of established equipment with indication of its features).

6 Drawings:

- plans of premises (workshop) with the application of ventilation systems;

— axonometric diagram of the air ducts of the system;

7 tables:

characteristics of ventilation equipment;

— meteorological condition of the air environment;

Note - If the amount of material entered into the table does not exceed five lines, then the material may be presented without the table.

8 Operating instructions based on the results of testing and adjustment of ventilation and air conditioning systems, including energy saving measures.

Optimization of ventilation in the apartment

To increase the air flow, install a supply valve on the wall

To increase the air flow, install a supply valve on the wall

Residents open vents to improve draft in the ventilation shaft, but such actions help to draw out heavily polluted air for a short period. For constant traction, it is difficult to keep the window sashes open, especially in winter. Some owners remove seals from windows, getting drafts and heat loss in return.

Manufacturers of plastic windows offer buyers the installation of special devices on the frame, which contribute to an organized flow of air, while the window still effectively protects from the cold.

Another method is to install a fan in the exhaust opening to activate the removal of air. At the same time, the influx of fresh flow from the street into the apartment remains relevant. Inlet ventilation valves are mounted in the outer wall of the building, they are also placed in window openings. Such devices come with natural and forced draft.

How much does a check cost?

The calculation of the cost of services for checking the operability of the ventilation system is carried out individually in each individual case.

The cost includes a number of factors, including the size of the system, the need for repairs, harmful production factors, the urgency of issuing an act, the frequency of inspections, etc.

If it is required to evaluate the operation of ventilation in buildings that are connected to gas supply, when calculating the cost of the check, methodological recommendations regarding the rules for calculating the cost are taken into account maintenance and repair of gas equipment that is used in private houses and apartments.

These recommendations have been approved by the Federal Antimonopoly Service.

The calculation of the cost is made within one business day.

Traction test methods

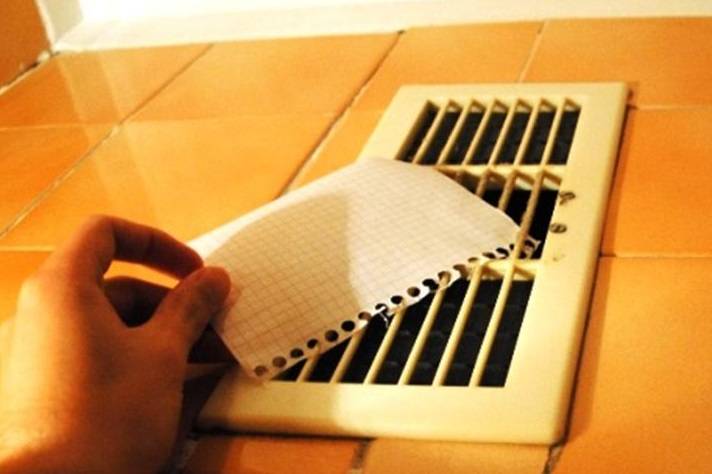

1. Sheet of paper. The easiest way.

Instruction:

- Cut off a strip from a newspaper or any other paper sheet of similar density. The width should be 2-3 cm, length - 15-20 cm.

- Bring the strip to the vent. The distance should be at least 5, but not more than 7 cm.

- Watch the "indicator": if the paper is attracted to the vent, but does not go completely into the hole, then the ventilation is functioning correctly.

2. Open fire. For the second method, you need a candle, a match or a lighter. Be careful if the house has gas appliances.

Subsequence:

- Light a match (candle, lighter).

- Bring to the vent so that the flame is at a distance of 6-7 cm.

- If the fire slightly (normally - no more than 45 degrees) deviates towards the mine - everything is in order, there are no problems with ventilation.

3. Anemometer.In order to check the ventilation in the apartment in the third way (which gives the most accurate result), you will need a special device - an anemometer, which measures the speed of the air flow in the ventilation duct.

Measurement technique:

- Bring the device to the outlet (the distance is indicated in the instructions, it may differ for different models).

- Fix the indicator (displayed).

- Calculate the volume of air passed by using the formula: Q = V*S*360. Air flow velocity (anemometer reading) - V, cross-sectional area of the vent in m2 - S.

Aneometer example

Aneometer example

Who is responsible for checking chimneys and ventilation ducts

So who does the maintenance of ventilation and smoke ducts? By law, only those organizations that meet certain requirements are entitled to this right. First of all, they must have a special license - a similar permit must be obtained from inspection organizations involved in the control of ventilation ducts and chimneys. Without it, not a single entrepreneur is worthy of trust, because it is more expensive for yourself to give the check into the hands of a non-professional.

It is worth talking in more detail about the licenses required by specialists. The first of these is a permit for the installation, maintenance and repair of smoke extraction and smoke ventilation systems. It gives the right to inspect ventilation ducts and chimneys. In order to also clean the smoke exhaust ducts, a second license is required - “Establishment, repair, cladding, thermal insulation and cleaning of stoves, fireplaces, other heat-producing installations and chimneys”. It will not be superfluous to make sure that employees have such permissions before entrusting them with their channels.

Good.Let's say that the executing company has already been selected, and the customer is completely confident in the quality of the services it provides. When is it worth calling its specialists for a periodic check? Of course, there are problems in the smoke and ventilation ducts, but calling people for nothing (and paying ridiculous money for it) is not worth it. The timing of the check must be chosen wisely.

As a rule, inspections of ventilation ducts are carried out on certain dates, for example, before the start of the heating season. After each repair or reconstruction, it is also necessary to check the chimneys and ventilation ducts.

Further terms depend on the material from which the channel is made. Brick products require inspection at least once every three months. Other materials allow you to forget about testing for a much longer period - systems are examined at least once a year.

Do not forget that the winter cold imposes additional requirements on the check: the problem is that during severe frosts, a dangerous amount of ice can accumulate on the heads of the outgoing channels. In order to avoid such troubles during severe cold weather, checks on the condition of hatches should be frequent up to once a month.

Cleaning the air exchange network

As already mentioned, clogging is one of the most common causes of system functionality failures. Dirt, dust and small debris, fat accumulated in the channels, clog the ventilation ducts, accumulating there, and prevent them from working normally.

In apartment buildings, it is unlikely that it will be easy to get access to the air exchange riser, however, it is quite possible to maintain the cleanliness and efficiency of the channel from the side of the apartment.In the first case, you will have to entrust the work to professionals of utility companies. In the second - you can do it on your own. To do this, you will need to remove the grate at the entrance to the channel, wash it, washing away all the dirt, dust and grease. The walls of the duct must also be cleaned with a scraper and vacuumed. At the end of the process, the channel should be wiped with a damp cloth. The cloth must not be wet.

Ways to check ventilation

The simplest method for studying the efficiency of air exchange is performed using a sheet of paper or newspaper. To do this, a strip 2-3 cm wide and 15-20 cm long is placed at a distance from the ventilation duct. If it rests on the grid without assistance, then the system is functioning normally. In the case of short-term sticking of the sheet ─ the air flow is weak and needs to be strengthened. The deviation of the paper from the lattice indicates the presence of reverse thrust.

There are recommendations to use a lit match or lighter to check the draft in the ventilation duct. However, this method is unsafe, and not only in houses with central gas supply. In clogged ventilation ducts, the decay process is often activated, resulting in the formation of combustible gas. Open fire can cause explosion and destruction.

A more accurate result is obtained by checking ventilation using a special device ─ anemometer, which shows the speed of air passage in the ventilation duct. Using the data obtained and special tables, as well as the cross-sectional area of \u200b\u200bthe vent, the volume of masses passing through it for an hour is determined.

According to the established standards for a bathroom, toilet and kitchen with an electric stove, this figure should be equal to 25, 25 and 60 m3 / h, respectively.

Identification of ventilation design errors

The audit helps to identify the initial errors that were made at the stage of designing and installing systems. This can be either an incorrectly calculated air exchange of a particular ventilation system, or an incorrect placement of air conditioning units.

Among the most common mistakes, one can also highlight the lack of valves for regulation indoor air flow, a lot of unforeseen turns of the air ducts, as a result of which the fan pressure is not enough to pump a given volume of air. In air conditioning systems, one has to deal with the excess of the length of the refrigerant route over the value limited by the manufacturer, inconsistent arrangement of air conditioner units and ventilation grilles, and other problems.

Conducting an audit helps to identify these errors with a view to their subsequent purposeful elimination.

Why is it profitable to order a ventilation audit in IS Ecolife

| VENTILATION SYSTEM FROM A TO Z We are focused on building the entire engineering infrastructure on a turnkey basis. Design, supply of equipment, installation and provision of services are carried out without the involvement of related contractors. High speed of work. Turning to us, you will save not only your money, but also time. | |

| REAL RESPONSIBILITY FOR THE RESULT IS Ecolife has a fully equipped production base, a staff of engineers and installers. We carry out all stages of work on our own, provide end-to-end quality control and are 100% responsible for the result.The company provides a guarantee for all work performed and is interested in long-term trouble-free operation of your equipment without downtime and emergency situations. | |

| ZERO PROBLEMS DURING INSPECTIONS We provide all the norms indicated in SanPin, SNiP, NPB, etc. You are protected from sudden orders and sanctions from supervisory authorities, save on fines and other fees. | |

| BEST PRICE We select decent equipment within even a small budget. You get equipment according to the principle "high quality - not necessarily expensive". The calculation of the estimate for services is made immediately after receiving the necessary information. Our principle is full transparency of the cost of work. The amount specified in the contract is a fixed price that will not be changed by us unless you yourself want to revise the estimate. For regular customers there are special discounts and delivery terms. | |

| CONVENIENCE 100% operation outsourced. You can outsource the maintenance of all engineering networks of the facility to one contractor - the company "Ecolife". We work officially under the contract and close all questions on the operation, both planned and urgent, and it is convenient for you to ask from one contractor. |

The Ecolife Engineering Systems Company is a team of experienced and licensed specialists in the installation and maintenance of all types of engineering systems with the subsequent execution of the entire package of documents.

• 5 years on the market of Moscow and the Moscow region

• 7 specialized licenses and certificates

• 40 employees, 4 service vehicles and 3 work crews for prompt execution of orders

• 2 sets of TV inspection and professional European equipment

• We will reduce your costs by 20%. The prices for our services are below the market average without any loss in the quality of work and service.

| Quality assurance |

| Installation of the ventilation system | Ventilation maintenance | Repair of the ventilation system | Installation of the air conditioning system |

Passport of the ventilation system in the house

Based on the results of the performed adjustment work, a passport of the ventilation system is compiled (at least two copies).

Sample Passport of the ventilation system of an apartment building (MKD)

A modern apartment building often consists of several sections (entrances), which can have different number of storeys, composition and area of apartments and non-residential premises, ventilation scheme. One passport is issued for several sections of the same type (entrances) of the house. The numbers of entrances and apartments in them are indicated in the heading of the passport.

For non-residential premises in the house (offices, shops, etc.), a separate ventilation system passport.

Sections of the passport "A. General information" and "B. Main technical characteristics” are filled in on the basis of information from the project and as-built working documentation.

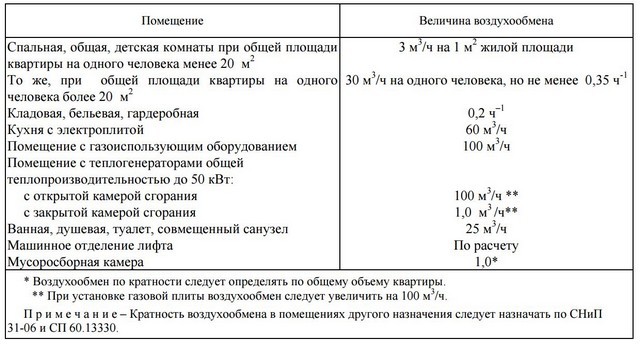

In table B.2.1, data on apartments of the same type in terms of area are recorded in one line. The minimum required air flow rates in the columns "Air movement" are taken from the project. Or define it yourself.

When independently determining the minimum required air flow, two conditions must be met:

-

- The total air flow through all ventilation channels from the premises of the apartment must be no less than the volume of air in the apartment (indicated in the column of the table). This will ensure that the air exchange rate in all rooms is at least 1 volume of the apartment per hour.

- At the same time, the flow rate specified in the norms for individual rooms with ventilation ducts - kitchens, bathrooms, etc. (see the table at the beginning of the article) must be ensured.

The simplified method proposed above for determining the minimum required air flow rates in the ventilation ducts is quite acceptable. Since, only the minimum values \u200b\u200bof these indicators are normalized. And the values themselves in operation change very much with changing weather conditions. It does not make sense to determine the minimum allowable air flow in the duct with high accuracy.

Attachments to the passport are:

-

- Protocols for measuring air flow in ventilation ducts.

- Schemes or photocopies of working drawings of plans (including a roof plan), sections, building facades with the tracing and arrangement of elements, units, ventilation chambers and deviations from the project, if any, occurred during construction, reconstruction or expansion;

- The list of requirements stipulated by the project to ensure the normal operation of the ventilation system.

After acceptance into operation or overhaul of the ventilation system as a whole or individual parts, the operation service employee must make changes to the copies of the passport. At the same time, data must be entered in the passport, taking into account changes in design decisions during major repairs or reconstruction.

Schemes of natural ventilation in the house, in the apartment

Natural ventilation (aeration): ventilation carried out under the influence of the difference in specific gravity (temperature) of the external and internal air, under the influence of wind or their combined action, as well as under the action of a complex of technical means that implement air exchange (clause 3.3 of GOST 34060-2017).

Deflector: a device installed with a specially shaped head that creates additional air pressure due to wind pressure (clause 3.9 of GOST 34060-2017).

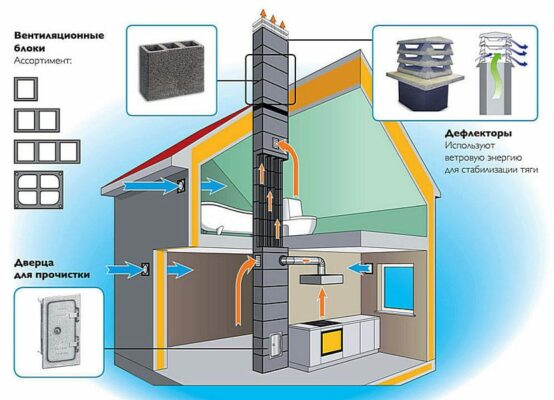

Scheme of natural ventilation channels in a private house

Scheme of natural ventilation in a private house up to 3 floors high. Outside air from the street is supplied to the house through supply valves in the walls or windows.

Scheme of natural ventilation in a private house up to 3 floors high. Outside air from the street is supplied to the house through supply valves in the walls or windows.

In a private house no higher than 3 floors, each channel of natural ventilation begins in a ventilated room and ends in a headroom above the roof.

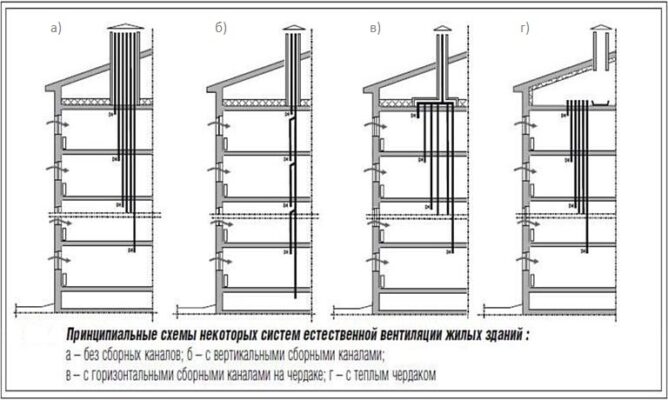

Schemes of natural ventilation channels in an apartment building

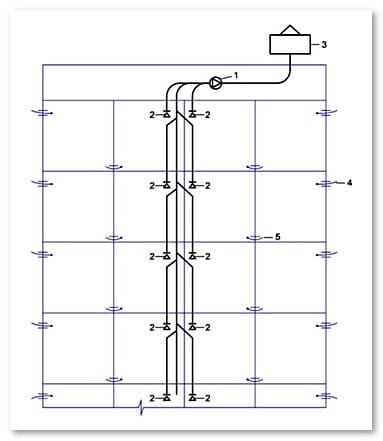

The figure shows options for the layout of natural ventilation channels in an apartment building.

In houses above 5 floors, as a rule, a system of channels is used, pos. b) in the figure. This system has a common vertical channel that runs from bottom to top through all floors. On each floor, from the ventilation grilles of the premises, vertical channels depart - satellites, which are higher, at the level of the next floor, join the common collection channel. The length of the channel - the satellite must be at least 2 m.

Ventilation scheme of a high-rise building with a warm attic and satellite channels: 1 - exhaust fan; 2 - exhaust grille; 3 - deflector; 4 - warm attic; 5 - inflow; 6 - overflow

Ventilation scheme of a high-rise building with a warm attic and satellite channels: 1 - exhaust fan; 2 - exhaust grille; 3 - deflector; 4 - warm attic; 5 - inflow; 6 - overflow

In exhaust ventilation schemes with a horizontal collection channel - c), and with a warm attic - d), in high-rise buildings, a variant with a vertical collection channel and satellite channels from apartments is usually used.

In exhaust ventilation schemes with a horizontal collection duct and with a warm attic, on the last two floors, the length of the ventilation ducts is small and does not provide the necessary air flow. To eliminate this drawback, the project usually provides for the installation of exhaust fans in the channels of the upper floors. There are fans in the project, but, as a rule, they are not in the apartments.

Exhaust shaft from the "warm attic" pos. d), must have a height of at least 4.5 m from the top of the ceiling above the last residential floor. During the cold season, the air temperature in a warm attic should be at least 14 ° C.

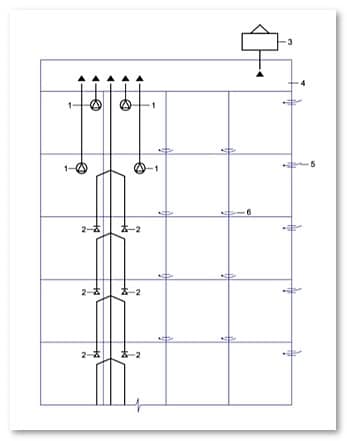

Scheme of mechanical forced exhaust ventilation of an apartment building

Scheme of the MKD exhaust ventilation system with mechanical exhaust: 1 - exhaust fan; 2 - exhaust grille; 3 - deflector; 4 - inflow; 5 - overflow

Scheme of the MKD exhaust ventilation system with mechanical exhaust: 1 - exhaust fan; 2 - exhaust grille; 3 - deflector; 4 - inflow; 5 - overflow

Compared to natural ventilation, mechanical exhaust ventilation in an apartment building has the following advantages:

-

- Provides a constant and stable air flow in the exhaust ducts of the apartments, independent of the outdoor temperature and other climatic conditions. It is known that in rooms with natural ventilation, with an increase in the temperature of the outside air (in summer), air exchange decreases up to its complete cessation. In winter, on the contrary, air exchange significantly exceeds the norm. And with excess air, heat also leaves.The energy consumption for the operation of the fan is compensated by the savings in thermal energy for heating.

- There is no need to install fans in the natural ventilation channels of apartments.

Correct connection of the kitchen hood to the ventilation duct

The kitchen hood is connected to the only ventilation duct in the kitchen through a tee on the duct. A non-return valve is installed behind the round ventilation grille. When the hood fan is turned on, the damper leaf blocks the passage of air through the ventilation grille.

The need for inspections

Constant monitoring and scheduled checks of the condition of the ventilation and air conditioning systems are necessary for the timely detection of technical problems, adjusting their functioning according to the required parameters, and for the planned replacement of consumables. Just like a complex system of ventilation ducts of an industrial building, a domestic air conditioner must be regularly and efficiently serviced. This is an essential condition for the operation of ventilation and air conditioning systems, since equipment failure or improper operation can endanger people's health and result in the loss of large amounts of money.

Ventilation Check Frequency

the first step in checking ventilation is inspection

the first step in checking ventilation is inspection

Instrumental verification of the effectiveness of ventilation systems and shafts is carried out:

- in rooms with the release of combustible, explosive, radioactive or toxic substances of classes I-II - 1 time in 30 days;

- in rooms with supply and exhaust systems - 1 time in 12 months;

- in rooms with a natural or mechanical general exchange system - 1 time in 36 months.

Checking the efficiency of ventilation systems is a combination of instrumental and laboratory measurements.

Checking the effectiveness of ventilation is carried out by measuring:

- speed of air movement in ventilation ducts and air ducts;

- air exchange rate (calculated)

A set of verification measures:

- Checking the natural ventilation system. It is carried out when the building is put into operation. The results are entered into the act of the primary examination;

- Checking the artificial ventilation system. The condition and performance of all components of supply, mixed or exhaust ventilation are checked. The data are recorded in the protocol of laboratory measurements. The client receives a ventilation passport and a conclusion on compliance or non-compliance with design standards.

Most often, the energy efficiency of a ventilation system is tested in two stages. At the first stage, the most noticeable shortcomings are found:

- damage to flexible elements;

- leakage of buildings and air ducts;

- insufficient number of drive belts;

- fan imbalance.

In some cases (if the client cannot eliminate the shortcomings in a short time), the check is implemented in one stage. Then all defects are recorded directly in the protocol for measuring the efficiency of the ventilation system.

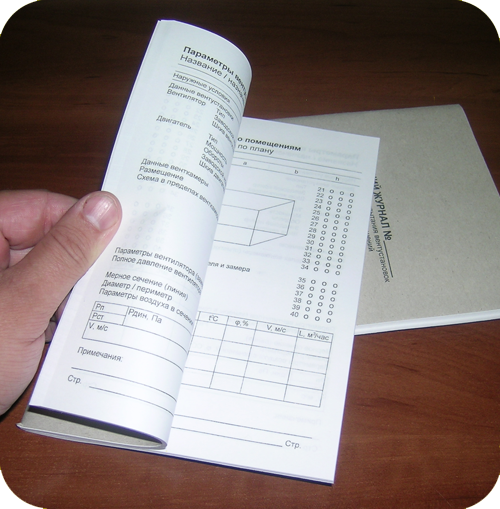

work log

After reaching the required parameter of work, according to the last measurement, a

measurement protocol.

| Home | |

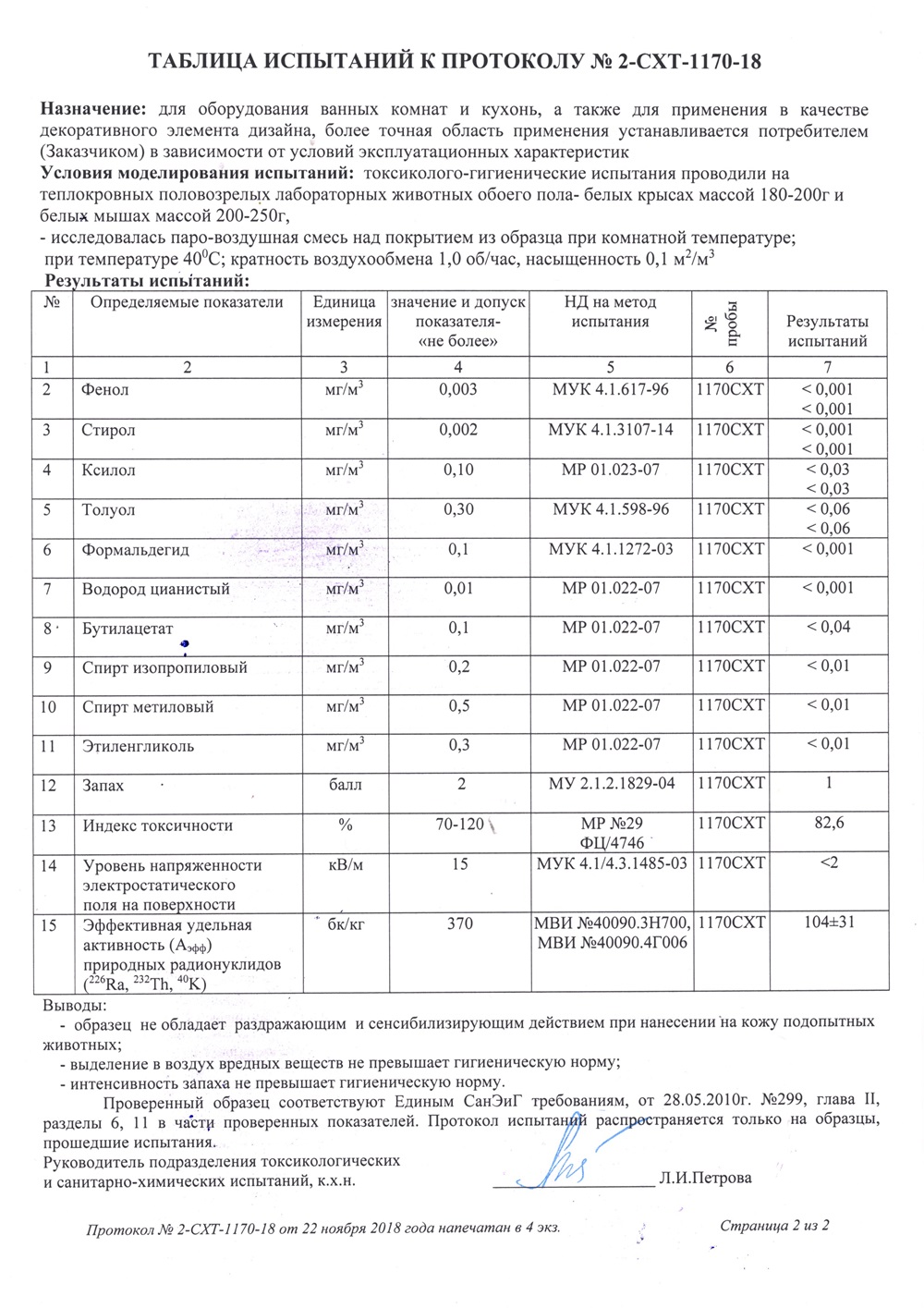

Measurement protocol (full)

The full protocol contains all the required information so that each

could take the primary data, and, repeating the calculation, get the final one.

The protocol reflects the error, or, as they say now, the uncertainty

measurements.

I cannot say that we fully follow this practice: full protocol

too big. We try to place the protocol on one sheet, so

include only the main sections:

- Object identification.

- Identification of the place of work.

- Measurement technique.

- Information about measuring instruments (devices, verification certificates).

- Link to the work log with the primary measurement data.

- External conditions for the measurement.

- Measured parameters (if required, with an error).

- Comparison with standards.

- Notes (if required).

- Conclusion (if possible).

It is the protocol that is the basis for paying for the corresponding measurement.

Already from the protocol, the parameters are rewritten into the passport. And when I see a passport

without a protocol, at least one, one would like to ask where the numbers come from?

Upon completion of the adjustment (by air) in full, the customer can receive:

- Fan aerodynamic test protocol (flow rate, pressure

at the fan). - Protocols of aerodynamic tests of the network (flow rate, pressure according to sections

networks). - Protocols of aerodynamic tests of air distributors (flow rate,

sometimes other parameters)

| Home | |

Protocol for ventilation passport

We attach the test report of the fan to the passport, protocols

tests of air distributors to the table of air exchange rate. Protocols

we provide network measurements on request, as there are many of them.

I must make a reservation that due to the inconsistency of regulatory documentation

according to the requirements of the inspections, it is necessary to give the protocols inaccurate names

type: Protocol (or even Act) of aerodynamic efficiency tests

ventilation.

Protocol attached to the passport:

In this example, it is accidentally seen that the standard (project) coincided with the fact

deviation 0%. This is completely uncharacteristic, no more than 1% of all protocols.

The presence of the protocol immediately shows what has been achieved by the commissioning organization

level.

Compared to normal laboratory practice, the setup feature is

the fact that the protocol does not draw up any measurement, but the final one, therefore

in the commissioning literature, the protocols are called "Results", for example:

- The results of tests of suction suction of a closed type.

- Local suction test results.

- Cyclone test results, etc.

The work log records records for all measurements, not just

by final.

June 28, 2011

| Home | |

Examples of ventilation test protocols

There are recommendations on the design and completion of protocols, but normative

there are no samples: each normal laboratory develops its own forms,

and approves them for his work.

Portrait orientation is more convenient for me and for the protocol to fit on one sheet,

from two sides. In this case, you do not need a header with a number and quantity

pages.

Below I have made examples of the design of the most popular protocols: aerodynamic

tests, network measurements, supports for smoke ventilation.

The qualification of the performer is shown not by the form, but by the content.

February 11, 2018

| Home | |