- Features of gas connections

- Prevention of cesspool subsidence

- Video - sealing and waterproofing the seams of the well

- Determine the type of offset - temporary or permanent

- How to make a cesspool with your own hands

- Step by step instructions, diagram

- Correct calculation of the volume of the pit

- Solving the problem with silting

- How long not to pump out a cesspool - simple tips

- Bottom silting

- What causes silting of the cesspool

- Biological preparations for cesspools

- Chemical preparations against siltation of the pit

- Signs of silting

- If drains freeze

- Determine the type of offset - temporary or permanent?

Features of gas connections

When connecting gas stoves, columns and other types of equipment, flexible connections are also used. Unlike models for water, they are yellow and are not tested for environmental safety. For fixing, end steel or aluminum fittings are used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

Holding "Santekhkomplekt" offers engineering equipment, fittings, plumbing and fixtures for its connection to communications.The assortment is represented by products and materials of well-known foreign and domestic manufacturers. Discounts apply for bulk purchases, and product quality is confirmed by standard certificates. For information support and assistance, a personal manager is assigned to each client. The ability to arrange delivery within Moscow and other regions of the Russian Federation allows you to quickly receive the purchased goods without any hassle.

Prevention of cesspool subsidence

In order to save yourself from the time-consuming, and sometimes expensive process of repairing the storage tank, it is better to immediately provide options for protection against displacement and subsidence of the structure.

For this you need:

- to equip an even, solid, stable base;

- fix the bottom or a concrete slab that acts as a bottom;

- fasten all the links together with metal brackets;

- to make reliable sealing of joints;

- fill the tank from the outside with a sand-gravel mixture with cement.

The larger the design, the higher the risk of ring displacement, so the protection measures must be more reliable.

When processing the joints between the rings, do not forget to seal the points of contact of the pipes with concrete links. The gaps in the holes are eliminated in the same way.

With high groundwater and loose sandy soil, we recommend installing a sealed container rather than a filter well.

The following article will acquaint you with the repair of a sewer well by installing a plastic insert, the contents of which we advise you to read.

Video - sealing and waterproofing the seams of the well

When installing new rings, try to connect them together in order to prevent possible shifts.The easiest way to do this is with an ordinary wire threaded through the shipping loops. Then the wire is twisted.

In your well, one of the rings may move relative to the others. You may be able to correct this shortcoming. To do this, you will have to dig in the well and, with an effort, restore the position of the rings relative to each other. In any case, after the repair associated with the movement of reinforced concrete rings relative to each other, you need to waterproof the seams of the well. After fixing the rings relative to each other, fill the free outer space with sand or soil.

Repairing a dry well

In a number of localities, the groundwater level has a pronounced long-term cycle. The duration of such a cycle can reach several tens of years, as a result of which, after a while, your well may suddenly become dry. An alarm signal can also be a decrease in the water level in the well. This issue is solved by deepening the well shaft, and the use of plastic rings to strengthen the walls will ensure the purity of the water in the well.

To deepen a dry well, the following activities are carried out:

- At the preparatory stage, we dismantle the well house and pump water out of it.

- We carry out a visual inspection of the state of the well well, if necessary, clean it and carry out disinfection measures.

- We completely remove the bottom filter of the old well.

- We lower the plastic ring to the cleaned bottom. We dig the soil under it and remove the earth from the well shaft.

- Under the influence of gravity, the ring will gradually lower.

- After sampling a sufficient amount of land, we install the entire shaft from plastic rings.

- If there are sufficiently strong walls of the well charge, formed from reinforced concrete rings, it can be limited to installing 1-2 articulated plastic rings. In order to prevent the ingress of dirt from the gap between the plastic and concrete rings, a concrete mixture is poured.

- A new bottom filter is filled at the bottom of the well, and the necessary infrastructure is mounted on top.

This is interesting: Is it possible to solder polyethylene pipes with polypropylene fittings - lay out the essence

Determine the type of offset - temporary or permanent

Due to improper installation of the rings, they can sag

One way or another, the well must be restored

It is important to find out the nature of the bias, how serious it is. The weakening of the bearing potential of the structure may be associated with hydrological changes in the soil, here restoration work will have to be approached with all scrupulousness

Problems are not excluded during some construction work carried out near the pit. If the structure is not fixed in advance with special brackets, its rupture and subsidence are inevitable. Of course, you need to stop the subsidence of the cesspool by any means.

This is interesting: Local sewerage for a country house - everything about the device and installation

How to make a cesspool with your own hands

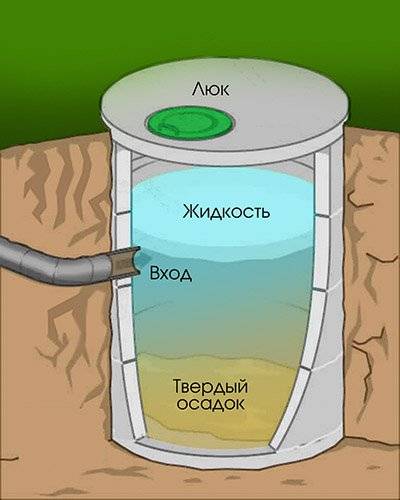

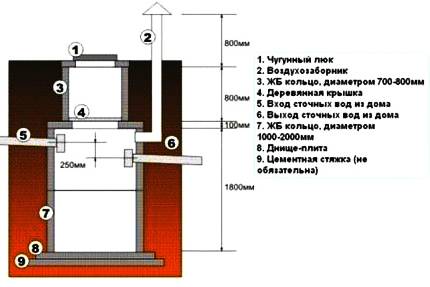

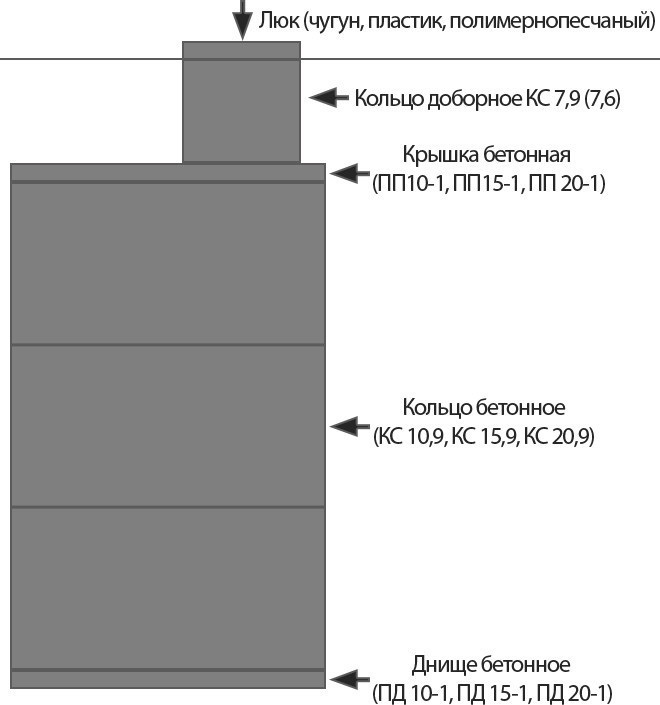

A bottomless drain pit in a private house with your own hands is an option that is convenient for summer cottages. It features a lightweight design. To strengthen the walls of the excavation dug under the pit, you can use gas silicate blocks, brick or concrete. The use of ready-made reinforced concrete rings speeds up the installation of the structure.

Step by step instructions, diagram

Work order:

- Preparation of the pit shaft. The optimal depth is 2-3 m, the width is equal to the diameter of the concrete ring + 80 cm.

- Installation and preliminary insulation of the pipeline.

- Pouring concrete screed along the perimeter of the pit. The central part of the mine is left free.

- With the help of a concrete crown, a series of holes with a diameter of 50 mm in increments of 10 cm is made in the lower reinforced concrete ring. This will allow the liquid fraction of wastewater to flow beyond the shaft.

- The lower perforated ring is installed on the pre-tamped bottom. The level is set. Then one or two whole ones are placed on top (depending on the height of the shaft).

- Backfilling of gravel, broken bricks and sand inside concrete rings to a height of 100 cm. This stage of work allows you to make a coarse filter.

- Waterproofing is lined around the perimeter of the pit, which will prevent groundwater from entering the pit.

- The pit is backfilled with the same materials that were used as a filter in the rings.

An example of a cesspool made of reinforced concrete rings

Correct calculation of the volume of the pit

The volume of the cesspool is determined by the number of adults and children living in the house. The following formula is used for the calculation: V = K x D x N, where:

V is the volume of the tank.

K is the number of adults living in the house. Per child - 0.5k.

D - Time interval between pit cleanings (usually 15-30 days).

N - The rate of water consumption per person (approximately 200 l / day)

Solving the problem with silting

Silting is a serious problem for both a permeable filter well and a sealed pit latrine. In the first case, the liquid part of the sediment will not be able to enter the soil due to the dense silt layer that covers the inner walls of the structure.In the second case, sewage will have to be pumped out more often, since deposits will reduce the volume of the tank.

One of the signs that silt is forming inside the cesspool is the appearance of a characteristic unpleasant odor - hydrogen sulfide vapor. When figuring out how to clean a silted cesspool, you must remember that in this case you need not just neutralize the waste or pump out the contents.

If the cesspool fills up too quickly or silts up frequently, consider upgrading it with an additional container and an overflow.

All plaque should be removed from the walls and bottom of the container. To do this, chemical agents or chemical cleaning methods are used, but a combination of these methods often turns out to be most effective. During mechanical cleaning, the bulk of the sewage is first pumped out. After that, using a hose, water must be supplied to the container under strong pressure.

The inner surface of the cesspool is treated with a jet in such a way as to break up the silty sediment and dismember it into separate small particles. Processing is carried out until the container is filled by about 25%. After that, the contents are pumped out with a pump or sludge pump, and then disposed of.

For chemical cleaning of a silted structure, chemical cleaners are used to dissolve solid inclusions - the nitrate oxidizers already described above. They usually cope with silty deposits as well. After some time, all or almost all of the contents will become liquid, it can be pumped out without problems.

After cleaning the absorption well, it is recommended to replace its filter bottom: remove the old backfill and fill the vacated space again with layers of sand, gravel and crushed stone

It is worth noting that the use of chemicals will cost significantly more than emptying by pumping, but this operation is easier to perform and takes less time. In the process of physical removal of sludge, you will have to put up with a lot of dirt, which usually accompanies this procedure.

In cesspools without a bottom, you will also have to clean or renew the sand and gravel filter, which is located below. The safest bet is to remove the entire contents of the filter and re-lay the clean components: a layer of sand, crushed stone and / or gravel about 40 centimeters thick.

To prevent silting of the cesspool, it is recommended to divert water from it to the filtration field. It is best to do it at the stage of creating a structure, but if you wish, you can perform this operation later. To do this, you need to install a horizontal sewer pipe at about half the height of the cesspool to drain liquid waste.

If the cesspool is silted up, it should be immediately pumped out and the walls cleaned using a scraper or chemicals, such as nitrate oxidizers.

For the device of the filtration field, it is necessary to excavate the soil to the level of laying the outlet pipe. A layer of agrofibre is laid down, and crushed stone is poured on top. A pipe coming out of the cesspool is laid on this “pillow”. The pipe must be perforated, you just need to make holes in it at an equal distance.

Another layer of crushed stone is poured on top of the pipe, and then again covered with agrofiber. It turns out that the pipe is surrounded on all sides by filter materials. This will ensure the rapid removal of liquid contents from the cesspool and its safe disposal in the ground.

How long not to pump out a cesspool - simple tips

If the silting of the cesspool is associated with washing, then, in this case, you can use special preparations. As part of such preparations there are special bacteria that will help to effectively process soap deposits, as a result of which water will begin to leave the cesspool into the ground.

By the way, at the expense of bacteria for septic tanks and pits, they show a fairly good result. If you regularly use them in your cesspool, then with its silting you can forget, once and for all.

Bacteria not only break down organic waste in the cesspool, but also allow you to get rid of the unpleasant odor. As a result of their use, the amount of waste will significantly decrease.

Below are tips on how long not to pump out the cesspool:

Pit dimensions. If you have to pump out the cesspool every year, then perhaps its volume is not enough for the whole house. There is only one way to solve the problem, once and for all - by increasing the volume of the cesspool. If the drain pit is made of concrete rings, then you need to add a few new ones.

It will also help to solve the problem of arranging drainage wells around the pit so that water passes well into the ground. Well, in extreme cases, when there is no way to modernize the old cesspool, then another one can be made nearby by connecting the old and new pits with an overflow (according to the principle of septic tank design).

Cesspool cleaning. Yes, this work is not pleasant, but sometimes the deposits on the walls of the pit are so large that it is simply impossible to do without mechanical cleaning.

Planting vegetation. I do not pump out the cesspool for a long time and my secret is simple.Several large trees grow near the pit, which suck out water well. Most plants are known to be very fond of water. For example, the same bird cherry, it is able to consume more than 100 liters of water in just one day.

When planning the construction of a cesspool, this fact can be adopted. And if there is a large plantation of trees nearby, then the pit can not be pumped out for ten or more years.

Bottom silting

- the occurrence of an unpleasant odor from the cesspool;

- silt can be seen with the naked eye when examining a septic tank.

The presence of the above problems indicates that the autonomous sewer needs thorough cleaning work. You can deal with silt deposits in different ways:

Manual cleaning. The available liquid is pumped out by a drainage pump or scooped out with buckets. The use of a fecal pump with the function of grinding dense masses can significantly facilitate the task. The mass of sludge is removed from the bottom manually, if its density is high, you can use metal brushes. The method is very economical in terms of costs, but rather complicated and time consuming.

Pumping sewage with the help of a sewage machine. Calling in specialized equipment will greatly facilitate cleaning. It is recommended to perform a double pumping - for the first time, the effluents accumulated in the pit are removed. Sludge masses are filled with clean water, softened and also removed. The method is quite working, but the regular call of the sewers will cost you a lot of money.

Chemical cleaning. Effectively fights hard deposits

It is important to remember that leaving "chemistry" in the pit is not safe for the environment.Substances can enter the soil, causing subsequent problems with growing horticultural crops in the garden; or reach sources of water, then it will become unfit for drinking and watering. Therefore, chemically treated effluents are subject to pumping, after which the septic tank will become safe again and will perform its functions more intensively.

Therefore, chemically treated effluents are subject to pumping, after which the septic tank will become safe again and will perform its functions more intensively.

The use of biologically active substances for the decomposition of sludge masses. Both liquid forms and powdered forms are commercially available, which must be dissolved in water and brought into the sewer. The bacteria and microorganisms contained in such products can soften the sludge crust, reduce its amount and, with regular use, remove unpleasant odors. There is an important nuance - microorganisms are effective only at temperatures above +5 degrees, which means that other methods will have to be used to clean the sludge in the cold season. Another feature is that bacteria colonies work only when a certain concentration is reached. You will have to periodically add biological products to the drain.

What causes silting of the cesspool

Over time on the walls cesspool formed a thick layer of silt. Silt prevents the normal passage of water from the pit into the ground, which causes a problem with the frequent pumping of the cesspool.

The second reason why water does not go into the soil is the washing of the cesspool. All those detergents that are used for washing accumulate on the walls of the pit, and also prevent the normal passage of drains.

Well, the third problem, it is associated with fatty deposits, which also prevent the soil from absorbing wastewater normally.

All of the above problems can be easily dealt with. For example, a grease trap installed under the sink will trap grease and prevent it from accumulating on sewer pipes and cesspool walls.

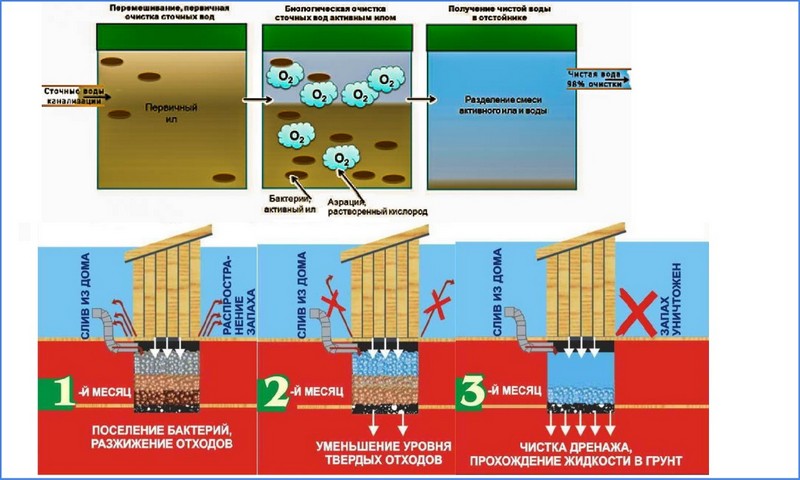

Biological preparations for cesspools

The presence of special bacteria in the tank can significantly increase the efficiency of the sewer, as well as reduce the rate of its filling. Usually these are specially selected complexes of anaerobic (i.e., able to exist without oxygen) microorganisms. These bacteria are able to process effluents, decomposing them into more or less pure water and neutral sludge.

Such biological treatment of wastewater significantly reduces the risk of soil contamination. If the degree of purification is high enough, water can even be used for irrigation, and the resulting sludge can be used as fertilizer.

In practice, after biological treatment, the amount of liquid in wastewater increases, it is disposed of faster into the ground, and sludge accumulates more slowly than when using a cesspool without bacteria.

Such preparations are sold in the form of concentrated liquids, granules, powders, tablets, etc. The packaging contains detailed instructions, which must be followed. Powder and granular preparations usually need to be pre-diluted in a small amount of water, and the concentrates are immediately sent to the sewer.

In this case, attention should be paid to the list of chemicals that have a detrimental effect on these microorganisms. Such substances, such as chlorine, are found in various household chemicals.

Owners of automatic washing machines should pay special attention to what gets into the sewer.

If all the instructions are followed exactly, then you will not have to replenish the colony of bacteria in the cesspool. They reproduce and maintain the required number. If the unpleasant odor from the cesspool has become stronger or has changed in the direction of deterioration, this may indicate that a significant part of the microorganisms have died, it is necessary to restore the colony.

The methods for cleaning cesspools are discussed in detail in the following article, which we recommend that you read.

Chemical preparations against siltation of the pit

In the fight against poor outflow of water from the septic tank, chemicals can also be used.

In the fight against poor outflow of water from the septic tank, chemical preparations can also be used. Formaldehydes, nitrate oxidizing agents and ammonium compounds are used as the basis for such agents. All of them quite effectively dissolve silt and fatty deposits on the walls of the septic tank. But there are a number of features on the use of chemicals for cleaning the pit:

- So, formaldehyde agents kill the soil for at least 7-10 years. That is, even a weed will not grow near the septic tank during this period. Therefore, formaldehyde preparations are used extremely rarely.

- Ammonium-based preparations work only at positive temperatures. But they effectively eliminate unpleasant odors from the septic tank, dissolve all silt and greasy deposits on the walls and bottom of the tank.

- The best option of chemicals in the fight against poor water outflow are products based on a nitrate oxidizer.The sludge dissolved with the help of such a product can be used to fertilize the garden and garden.

Important: it is recommended to work with chemicals in a protective respirator and rubber gloves

Signs of silting

The most striking sign of siltation of the bottom of the cesspool is a decrease in the volume of the reservoir. Subsequently, the filling rate of the waste tank increases, and there is a need for frequent pumping. The second "symptom" is the accumulation of body fat on the walls. They also reduce the volume of runoff and interfere with the normal settling of the waste.

Sewer tank silting

Sewer tank silting

Other signs of silting:

- The presence of a sharp, unpleasant odor. Naturally, a certain stench will come from the cesspool, but if it manifests itself especially brightly, then it is urgent to eliminate silt deposits. Such a stench signals about the slow processes of decay;

-

A layer of silt is visible from the inspection hatch. This is a clear sign indicating the need for immediate cleaning of the pit.

If drains freeze

Rarely in winter, owners of country houses are faced with the problem of freezing waste in the sewer. Basically, this situation occurs due to improper thermal insulation, there may also be comments regarding incorrectly performed installation work. Sometimes, even with the correct algorithm for performing work, the sewer can freeze.

The most effective way to defrost the pit is its heating with the help of conductors. For these purposes, you need to prepare:

- copper wire that can withstand a load of 2 kW;

- metal pin, the length of which should be approximately 20 cm;

- also, for the convenience of work, a hook may be needed.

If freezing of the entire cesspool is observed, then it is advisable to use this defrosting method: a strong metal pin is hammered in the center of the pit, to which a wire with a stripped end is subsequently attached. With the help of a hook put on the second end of the wire, it is thrown over the element connected to the current source. Defrosting a cesspool usually takes several hours, sometimes it takes several days. Everything will depend on the degree of freezing and the amount of waste.

At the end of defrosting, the wire is first de-energized, only then it is disconnected from the pin

In the process of work, it is important to consider and apply safety rules

If only the pipe leading the wastewater to the pit freezes, then it is advisable to act according to a different method. It is necessary to strip such a piece of copper wire that it is quite enough to wind a frozen pipe. The second free end will need to be brought to the outlet phase.

In winter, sewer pipes can freeze, they must be thawed

Using this defrosting method, the sewer pipe can still function after a few hours.

You can use another way to defrost sewer pipes, which is to supply hot water, but this is not always possible and not everyone has it.

To defrost plastic pipes, you can use specialized machines that are designed to supply high current through the ice. As a result, frozen water melts very quickly. Not every owner of a country house has such equipment, so it is better to use the services of specialists.

If there is an urgent need to do the work yourself, you can try to defrost the sewer using a welding machine, while its contacts should be in water or ice, and the opposite side is connected to a frozen pipe.

Determine the type of offset - temporary or permanent?

The process of subsidence of reinforced concrete rings can be temporary. At the same time, the sagging walls of the structure freeze at a new level, leaning on a strong layer of soil, after which their movement is no longer observed. In this case, the structure is built up with an additional ring made to order, or the resulting gap is laid with red brick.

The problem of the incessant "drowning" of rings is much more difficult to solve. At the same time, more serious measures must be taken to stop this process. To establish the true cause of what is happening is within the power of specialists. Often it is not possible to completely eliminate the causes of subsidence of the structure, it is only possible to fix the existing position of the concrete rings and stop their further displacement.