- Descaling without removing the heat exchanger from the boiler or column

- Which is better to take a scale filter for a column? - question in the comments

- Mechanical cleaning

- Why is it necessary to flush gas boilers?

- How to know that there is scale in the system

- The heat exchanger of the gas boiler is clogged with scale, what should I do?

- limescale

- Design features of heat exchangers

- Gas boiler cleaning options

- Manual cleaning

- Chemical cleaning

- Solutions for cleaning the heat exchanger

- Hydrodynamic cleaning

- Flushing of single-circuit and double-circuit gas boilers

- How to flush the heat exchanger of a double-circuit boiler

- How to flush the heat exchanger of a double-circuit boiler

- How to clean the heat exchanger?

- Flushing of a single-circuit and double-circuit gas boiler

- materials

- Steel

- cast iron

- Copper

- Aluminum

- Working with AOGV

Descaling without removing the heat exchanger from the boiler or column

The following video shows how to assemble the simplest device from improvised means to clean the heat exchanger without removing it from the boiler.

I would like to draw your attention to the following:

- The pump can be taken from any of the available ones, including from used equipment.

- Be sure to install a filter at the pump inlet or after the pump, at the water supply to the boiler.Otherwise, the dirt from the container with the solution will go back into the boiler and clog the filter and the flow sensor in the boiler.

- It is better to heat the solution up to 60 degrees. To do this, you can even turn on the boiler for a short time to heat hot water.

In this variant, the direction of movement of the cleaning solution should not be changed. It must match the direction of water movement during boiler operation.

You should be more careful in choosing the composition and concentration of the solution for descaling. Solutions can have a destructive effect on other parts of the boiler, including those made of various metals, plastics and rubber.

Which is better to take a scale filter for a column? - question in the comments

Water heater manufacturers prescribe that if the water hardness is higher than 20º F (where 1º F = 10 mg CaCO3 per 1 liter of water), then it is imperative to install a polyphosphate dispenser (filter) or similar water softening system.

I recommend reading the technical data sheet of the device when choosing. The technical passport must necessarily indicate in numerical format and with units of measurement the effectiveness of reducing the hardness of water after the filter. If there are only general words about the purpose, without numbers, then this is a hoax.

For example, there are devices on sale that are called something like this - electromagnetic scale converters. In the official document, in the technical data sheet of the device, there is no indicator of a decrease in water hardness after the device. Or another performance indicator that can be verified. The manufacturer does not promise or guarantee anything specific to the buyer. And this is no accident!

More articles on this topic:

⇆

Mechanical cleaning

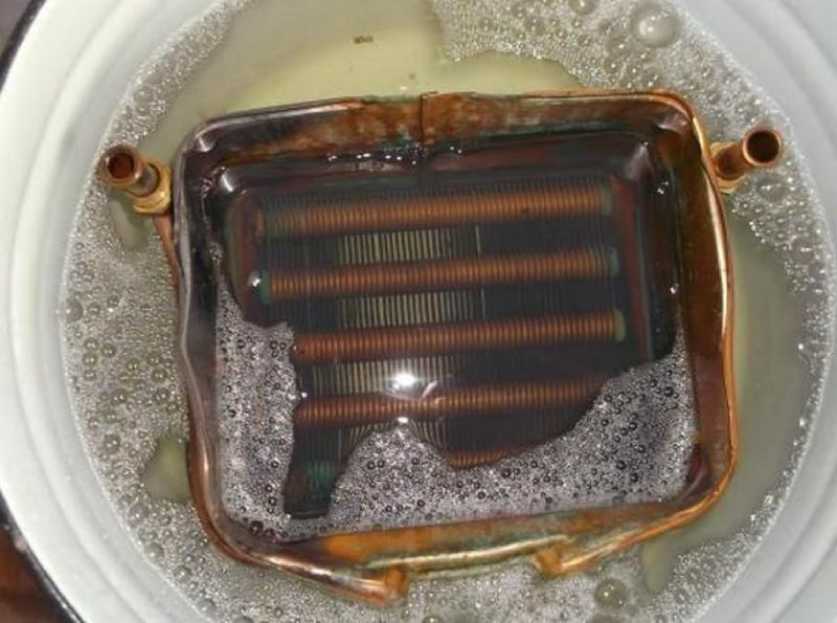

When choosing this option, it is worth remembering that the element itself in the boiler body takes up quite a lot of space. It is located in most cases above the combustion chamber. Getting to him is not easy. To gain access to the gas heat exchanger, it is necessary to dismantle the outer parts of the housing. To do this, disconnect the gas hoses and electrical cords, if any. Next, the element itself is directly disconnected from the pipes. Finally, at the last stage, the fasteners are removed.

After that, the part can be removed from the case and begin to clean it. Immediately after dismantling, you can see that the internal cavities of the device are literally clogged with various deposits. Often these are metal salts (sodium and calcium), as well as elements of the so-called ferric iron. They are cleaned with a metal tool - scrapers, pins are suitable

You need to work very carefully so as not to break the inner walls

The device itself can be soaked in a tub or basin. A solution of hydrochloric or sulfuric acid is added to the water. When deposits begin to soften under the action of acids, they can be removed mechanically. Experts recommend that at the end of the procedure, rinse the heat exchanger inside with water pressure. A mass of dirt will come out of the outlet. It is necessary to wait until clean water comes out of the heat exchanger. You can supplement this flush with light taps on the body.

Why is it necessary to flush gas boilers?

To understand the importance of grounding the boiler, you just need to look at the diagram of its structure. The device is attached to the wall or installed on the floor, both options do not contribute to electrical conductivity. The pipes are usually made up of non-conductive propylene

The pipes are usually made up of non-conductive propylene

The device is attached to the wall or installed on the floor, both options do not contribute to electrical conductivity. Pipes, as a rule, consist of propylene non-conductor.

It becomes clear that static electricity finds no other way out than a radiator in which water is concentrated.

As a result, being an excellent heat transfer agent, water also becomes an electrical conductor. With the onset of the winter period, the temperature of the equipment rises and the liquid is unable to discharge the current charge. As a result, the operation of the gas boiler becomes unsafe.

How to know that there is scale in the system

It is worth flushing the boilers as soon as there are signs of accumulation of salt deposits in the heating circuit and various types of boilers

However, for this it is important to understand what are the signs of scale accumulation.

You should pay attention to such points:

- when operating boiler equipment with the same level of intensity, the amount of fuel consumed has recently increased significantly;

- during the operation of the boiler, micro-ruptures and crackling can be heard;

- you have noticed a significant overheating of the heat exchanger - it does not have time to be cooled by the reverse flow of the coolant;

- heating radiators are unevenly heated;

- the circulation pump in the system is working with excessive load;

- in the presence of a double-circuit boiler, a weak pressure is observed in a tap with warm water;

- more time is required to heat the room under constant temperature conditions outside.

The heat exchanger of the gas boiler is clogged with scale, what should I do?

The most vulnerable part of any boiler, if it is not water, is the heat exchanger. This is where the water is heated.And if it is of poor quality, or does not soften, then sooner or later such a problem as flushing the boiler or its clogging will come. What problems can create a heat exchanger and, as a result, a boiler, low-quality water?

| Type of equipment | Effects |

| Gas boiler | Increased heating time Heating quality drops The heat exchanger may burn out Scale causes heat exchanger plates to stick together Scale from the heat exchanger enters the boiler Scale growths begin to be deposited wherever water comes into contact |

It is impossible to avoid lime scale if the household does not have the right softener installed. But what if the softener is not yet affordable? How to rinse the boiler from scale with your own hands? And will it give at least some effect, at least temporary?

When the heat exchanger is clogged with hard scale deposits, the problem can be solved in two ways:

- Washing the device with caustic cleaning agents;

- Having disassembled the device and soaking the particularly affected parts in caustic solutions;

- Having bought a softener, no longer remember this problem.

It is not necessary to bring the heat exchanger to such a state until it clogs! Therefore, each consumer, when installing a boiler room, must begin with an assessment of the condition of the water. But, if this factor is already missed? The consumer will know that the heat exchanger is clogged by several factors. The walls of the heat exchanger began to become very hot, the heating of water takes longer, scale particles began to fall into the water from the exchanger.

The girl independently rinses the boiler with her own hands

And this is the reason to sound the alarm! It's time for a flush. It can be capital, and can be preventive.In any case, without a softener, you will have to use both types of washes.

It is possible to wash the internal surfaces of the heat exchanger with special aggressive agents (such as anti-scale, for example, or sulfuric acid), but for this you need to know exactly in what proportions to dissolve it all, how long to keep it, and then how to remove adhering particles. Washes do not end with rinsing. If the case is running, then you will have to disassemble the heat exchanger and work mechanically - that is, scrape off the softened parts of the scale. But it is precisely in this that the disadvantages of flushing lie. They are very spoil the surface, which significantly reduces the life of any equipment.

How to flush the heat exchanger of a gas boiler? There are several simple remedies that are good as a preventive measure, and there are aggressive liquids that need to be applied according to the instructions and not often. Any housewife has vinegar and there is always citric acid in the house. Especially for those housewives who love to bake. Here they can be used for the simplest washing. It will be enough to dilute two tablespoons of flushing liquid per liter of water and hold the heat exchanger in this solution. And it is even better, of course, to drive such a solution through the device, at high temperatures. By analogy, vinegar works. Only for washing it is better to use essence, it is stronger than ordinary vinegar.

As for the purchase funds, there are a lot of them. It is easy to find them on the net, and learn how to use them. Effectiveness, of course, will have to be judged by trial and error. Everyone's water is different, and somewhere Antinakipin works better, and somewhere only a solution of hydrochloric acid can help. The situation is complicated by the ingress of dirt and dust into the heat exchanger.Which, in combination with scale, forms a poorly soluble plaque.

limescale

This is a consequence of working with water with a high threshold of calcification. A whitish deposit on the surface of the equipment is the most reliable sign of such water. But the fact that the water is not soft, the consumer will know only about a month later, when all the walls are covered with a coating. But this is only if you do not do a water test. Therefore, in order to avoid the formation of plaque, you need to start by checking the composition of the water. And it is best to put a softener if the analysis indicated that the hardness threshold was exceeded. You also need to understand that the design of the boiler will make its own adjustments to the flushing process. It is much more difficult to wash the heat exchanger of a wall-mounted boiler Baxi than a conventional floor boiler. Dismantling and assembly also takes a lot of time.

This is interesting: Gas boilers Proterm (Protherm) wall and floor - overview, model range, instructions, errors and malfunctions

Design features of heat exchangers

To properly flush the heat exchanger, you need to know its design. All information on your boiler can be found in the user manual.

Just in case, we recall that for organization of independent heating and hot water supply in apartments and private houses, gas boilers and water heaters with the following types of heat exchangers are mainly used:

- shell-and-tube;

- coaxial;

- lamellar.

In widely used shell-and-tube heat exchangers, water circulates through a tube that coils around the side walls of the shell in the form of a coil. Such a unit is soldered or welded, that is, non-separable.

The shell-and-tube heat exchanger is one of the most efficient and simple in design, it is easy to clean it from scale with your own hands

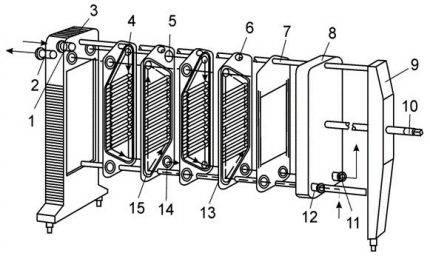

Plate-type heat exchangers are less common. Their main structural part is a metal package in which several plates are assembled.

For example, the heat exchangers of the Italian boilers Westen Zilmet and Baxi include from 10 to 16 plates. They give their heat to the water moving between them through the channels. Such a device must be disassembled before cleaning.

Scheme of a plate heat exchanger, which shows: nozzles for supplying the coolant and the heated medium (1, 2, 11, 12); fixed and movable plates (3, 8); channels through which the coolant moves (4, 14); small and large spacers (5, 13); heat transfer plate (6), upper and lower guides (7, 15); rear support and stud (9, 10)

The main element of a coaxial (bithermic) heat exchanger is two coaxial pipes. In the simplest version, it looks like a spiral with tightly fitting coils.

Double-circuit boilers are characterized by the presence of 2-3 heat exchangers. For example, the NEVALUX-8023 boiler is equipped with three heat exchangers, one of which is coaxial, but not of the spiral type, but with links connected in series.

Gas boiler cleaning options

There are several basic methods for cleaning gas boiler heat exchangers:

…

- manual;

- chemical;

- hydrodynamic.

Which method of them to apply depends on the degree of blockage. Let's take a closer look at each of these methods.

Manual cleaning

Not all users of gas boilers know how to clean the heat exchanger of a gas boiler themselves. Manual cleaning is the easiest way to do it yourself.There are two ways to execute this method:

- mechanical - with a brush and a brush;

- flushing with active solutions is a more efficient option, especially relevant for boilers with two circuits.

For heavy soiling, two methods of descaling are used - first rinsing, and then mechanical cleaning. This process is carried out in the following steps:

- turn off the gas and disconnect the unit from electricity;

- open the lid of the gas boiler;

- dismantle the heat exchanger;

- place it in an active substance, for example, a solution of hydrochloric acid;

- pull the heat exchanger out of the solution and clean the dirt with a brush or brush;

- rinse the element with water inside and out;

- dry and install the circuit back.

Chemical cleaning

Dry cleaning is distinguished by the use of a booster or its analogues, as well as aggressive chemicals. An important condition for chemical cleaning is to maintain a safe concentration of the substance so that it does not corrode the surface of the heat exchanger.

Dry cleaning is carried out using a booster, but many craftsmen create its cheap analogue with their own hands. To do this, take a container of 10 liters and attach two hoses and a pump to it.

Maintenance and repair of gas boilers

Do-it-yourself replacement of a heat exchanger in a gas boiler

If the scale layer is too large, you can use substances based on sulfuric or hydrochloric acid for cleaning. The simplest cleaning solution is made from citric acid: 200 grams of powder is diluted with 5 liters of water.

The chemical cleaning process is quite simple:

- the chemical solution is diluted in containers and poured into a booster;

- two hoses are connected to two pipes of the boiler - inlet and return;

- turn on the device and run the liquid through the heat exchanger several times.

Factory boosters have a heating function, which allows you to flush the circuits with greater efficiency.

After the procedure, it is necessary to drain the reagent and flush the system again with a neutralizing agent or clean water.

Of course, dry cleaning is more effective than manual cleaning, but the active substances contained in the solutions can lead to corrosion. Therefore, this method cannot be used often.

Solutions for cleaning the heat exchanger

Some owners of gas boilers on the forums are interested in how to flush a gas boiler from scale at home. Typically, the following products are used for dry cleaning:

Cleansing gel - it is considered the mildest remedy. After it, it is enough to rinse the heat exchanger with running water.

Despite the gentle effect, the gel copes well with scale and lime deposits.

Adipic acid - in order to flush the gas boiler heat exchanger with acid, it is important to dilute it with water in the correct proportion, otherwise the substance will damage the metal surface. Adipic acid well softens all deposits inside the heat exchanger

After flushing the system with this agent, the neutralizing liquid should be driven through it.

Sulfamic acid - well helps to cope with complex pollution. The substance is diluted with water and filled into a booster. After completion of the process, it is necessary to flush the heat exchanger with a neutralizing liquid.

Note! When performing dry cleaning, rubber gloves should be worn on the hands, and the body should be protected with overalls through which the acid solution cannot get on the skin

Hydrodynamic cleaning

This method of cleaning the heat exchanger is carried out only by specialists. It is unnecessary to disassemble the boiler and remove the heat exchanger for its implementation. The principle of hydrodynamic cleaning is as follows: the liquid is pumped into the system and driven under pressure several times. For greater efficiency, cleaning abrasives are added to the water. It turns out that due to the rapid movement of water, scale disappears and pollution is washed off.

However, with this method, it is important to correctly calculate the pressure force - if it is too large, a pipe break may occur. Therefore, hydrodynamic cleaning cannot be performed independently.

Is it necessary to conclude a contract for the maintenance of a gas boiler?

How to do it right gas boiler grounding? —

Flushing of single-circuit and double-circuit gas boilers

It is imperative to flush the heat exchanger, regardless of the type of boiler used. Internal deposits present in the device disrupt the circulation of fluid through the heating circuit, and in the case of double-circuit boilers, they also lead to problems in the water supply system. In addition, a contaminated heat exchanger collects substances that have a negative effect on the metal elements of the system.

The regularity of flushing is determined depending on the coolant with which the system is filled:

- If filtered water is used as a heat carrier, then cleaning is recommended at intervals of 4 years;

- When using antifreeze, flushing must be done every 2 years, and each time the coolant will need to be changed, since its characteristics decrease over time.

How to flush the heat exchanger of a double-circuit boiler

The method of descaling the DHW path depends on the type of heat exchanger installed in your heat generator. There are only two of them:

- bithermic, it combines the heating of the coolant and water for hot water supply;

- secondary heater in stainless steel.

It is better to clean units with a bithermic heater using a booster, since it can be quite difficult to remove such a unit. The hoses leading from the tank are connected instead of supplying cold water and exiting hot, after which the circulation pump and the boiler itself are started. The heating temperature should be limited to 50-55 degrees.

If a secondary heat exchanger is installed in a double-circuit boiler, in most cases it can be removed. Unscrew the front panel, release the control unit and move it aside. The plate heater for hot water is located at the bottom of the gas boiler and is fixed with 2 bolts. Unscrew them, disconnect the pipes and take out the heat exchanger. Next, immerse it in a saucepan with a solution of citric acid and boil on the stove, as detailed in the video:

How to flush the heat exchanger of a double-circuit boiler

The method of descaling the DHW path depends on the type of heat exchanger installed in your heat generator. There are only two of them:

- bithermic, it combines the heating of the coolant and water for hot water supply;

- secondary heater in stainless steel.

It is better to clean the units of the first type with the help of a booster, since it can be quite difficult to remove such a unit.The hoses leading from the tank are connected instead of supplying cold water and exiting hot, after which the circulation pump and the boiler itself are started. The heating temperature should be limited to 50-55 degrees.

If there is a secondary heat exchanger in the double-circuit boiler, the latter can in most cases be removed. To do this, the front panel is removed, and then the control unit is unscrewed and moved aside. The secondary heat exchanger is located at the bottom and is fixed with 2 bolts. After removing it, it is immersed in a saucepan with citric acid dissolved in water and boiled on a gas stove, which is described in detail in the video:

How to clean the heat exchanger?

Cleaning of the heat exchanger is carried out at the end of the heating season. To carry out the work, it is enough to have a standard set of tools available. Before starting work, it is necessary to disconnect the boiler unit from the gas network (main or local) and electricity.

Consider, how to clean a floor standing gas boiler :

- first of all, the burner is dismantled;

- it is required to disconnect all wires from the gas valve;

- a thermocouple is removed from the combustion chamber, which is connected to the gas valve by a capillary tube;

- the fuel supply pipe is disconnected;

- the bolts or nuts (4 pcs) are unscrewed, fixing the stove with the burner, the assembly assembly is taken out.

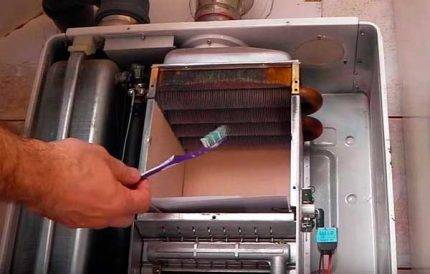

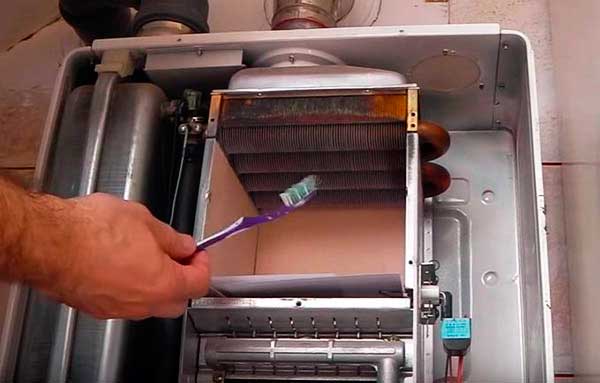

It is convenient to clean the burner of a gas boiler with an old toothbrush. Soot must also be removed from the flame control sensor, igniter, piezoelectric device for automatic ignition.

To get to the boiler heat exchanger, remove the top cover of the unit, disconnect the draft sensor and the chimney, remove the insulation, dismantle the casing fasteners and the casing itself.Having gained access to the heat exchanger, it is necessary to remove the turbulators from it.

A soft metal brush is suitable for cleaning the turbulators, and the heat exchanger itself is freed from soot deposits with a miniature scraper made of thin metal. A brush with a long handle is also used. First of all, the smoke pipes are cleaned and swept, then the soot that has fallen on the bottom should be removed.

Cleaning the wall-mounted boiler is done with a toothbrush

Cleaning the wall-mounted boiler is done with a toothbrush

Cleaning the wall-mounted heat generator. After turning off the gas supply, it is necessary to dismantle the front panel of the boiler. Then the front cover is unscrewed, which closes the combustion chamber. It is recommended to cover the nozzles with a sheet of thick paper so that the burner does not become clogged with falling soot. Do-it-yourself cleaning of the heat exchanger of a double-circuit boiler is carried out using an old toothbrush or a brush with metal bristles. After the cleaning is completed, it is necessary to sweep the heat exchanger with a brush and carefully remove the paper with the collected soot. How the procedure is performed, see the video below.

Flushing of a single-circuit and double-circuit gas boiler

Flushing the gas boiler heat exchanger is necessary to remove internal deposits that can disrupt the normal circulation of the coolant in the heating system and cause problems with the supply of hot water to the local DHW system. Substances that destroy the metal may also be present in the deposits.

How often this measure is required depends on the type of coolant. If purified water circulates in the system, it is enough to do prophylaxis every four years, removing deposits.The system with antifreeze should be flushed every two years and the coolant should be changed regularly - under the influence of high temperatures, it changes properties over time and can become dangerous for the metal elements of the system.

materials

Modern heat exchangers are made from various materials. It is on this parameter that many qualities of these parts depend, as well as their pros and cons. Let us consider in more detail what heat exchangers for gas boilers are usually made of.

Steel

Most often, heat exchangers made of steel are found in gas heating equipment. Their prevalence is explained by the democratic cost of steel and the ease of its processing. Steel parts have their own distinctive characteristics, for example, such a heat exchanger turns out to be quite plastic. In addition, these options have a long service life, which attracts many consumers.

It should be noted that the plasticity of steel specimens plays one of the most important roles when it comes to the contact of the exchanger with high temperatures. Thanks to this characteristic, cracks do not form on the constituent elements of the boiler when a serious thermal stress forms in the inner part of the metal next to the burner.

However, steel options have one serious drawback - they are prone to corrosion. Of course, the appearance of rust shortens the life of the exchanger. In addition, it must be taken into account that defects of this kind can appear both on the inner and on the outer half of the device.

Another disadvantage of steel exchangers is their large size and weight.In addition, with such parts, gas consumption will increase. This is because most modern manufacturers strive to achieve a high level of inertia and expand the volume of the internal cavities of the heat exchanger.

cast iron

The second most popular heat exchanger is rightfully recognized as a cast iron heat exchanger. A similar model differs from steel in that, in contact with a liquid, it does not become susceptible to corrosion. Thanks to this distinctive feature, we can safely talk about the durability of cast iron options.

However, we must not forget that cast iron exchangers require regular care and attention. In addition, these options are distinguished by their fragility. If scale accumulates on the cast iron heat exchanger, the heating in the system may become uneven, which will lead to cracking of the exchanger. In order to extend the life of this element, it is necessary to carry out periodic flushing. In most cases, if running water is used, then washing is done once a year. If antifreeze is used as a heat carrier, then such work will need to be carried out every 2 years.

Copper

Copper specimens are practical and durable. They have more pros than cons. The following characteristic features inherent in such exchangers should be highlighted:

- copper parts are lightweight;

- differ in small dimensions;

- are not covered with destructive rust;

- they need very little fuel to warm up well.

Thanks to these advantages, the copper heat exchanger is recognized as one of the most popular. However, it is expensive, so they do not buy it so often. In addition, such elements become less strong and reliable under heating conditions.Copper heat exchangers burn out very quickly, after which they fail.

Aluminum

In many branded models of gas boilers, aluminum heat exchangers are present. This material is distinguished by high plasticity, so exchangers of any shape and complexity are obtained from it. In addition, it is necessary to take into account the fact that the level of thermal conductivity of aluminum is 9 times higher than that of another popular raw material - stainless steel. Heat exchangers made of aluminum have a very modest weight. Thanks to such positive characteristics, we can safely talk about the practicality of such components, as well as their reliability and functionality.

Such devices are also good because they usually do not have vulnerabilities. For example, in stainless steel structures there are welding seams, kinks and other similar areas. They are very vulnerable, so they endure significant loads during the operation of the equipment. In aluminum versions, there are simply no such problems. Aluminum parts have strong chemical resistance, which is excellent for condensation.

Working with AOGV

It starts when the gas supply is blocked - the corresponding valve closes. And this is a general principle for such work with any boilers and columns.

How to clean the burner of a gas boiler AOGV? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the following two models.

First. AOGV 11.6-3. It is a reliable and practical device.

But after a certain operational period, it is thoroughly cleaned. The process goes like this:

Removing the burner block

To do this, the pallet of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples.

Carefully unscrew the nuts located on the fittings of the automation mechanism.

The paronite gasket on the main gas pipe is removed and its condition is studied. If it is damaged, it needs to be replaced.

The designated pallet is taken out through the groove, which is as close as possible to the tubes

Along with it, the casing is also pulled out. Fixing the lower part of the pallet, direct it towards yourself and remove the remaining holders (two pieces) from engagement.

This whole knot falls to the floor.

The main burner is being studied and cleaned. The igniter nozzle is examined.

The wick and thermocouple are unscrewed.

A box-shaped casing is separated from the pilot burner. This clears the way to the nozzle. If it is brass and there is a coating on it, it can be removed with fine-grained sandpaper.

Nozzle cleaning. For this, a thin copper wire and a blowing method under strong pressure are used. The second action is carried out by a special pump from the side where the tube is connected to the tee.

The same sandpaper very carefully cleans the bend of the thermocouple tube.

After this work, all the details are assembled in the reverse algorithm. Gently, avoiding distortions, lift this block as a whole. The burner must be inside the housing, and the igniter and thermocouple must not touch the flange of the casing.

From the side of the tubes, the entire assembly should be pushed towards itself with a slight downward slope. The opposite side of the pallet should rise.

Then feed it forward and synchronously put on a pair of distant holds. They should be on the flanging of the casing. The near hook is a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise movement. The gas pipe must be positioned only under its branch pipe of the automation unit.

Next, it is tested how well the gaskets fit, and all tubes return to their places. The wrench tightens the nuts on two tubes: igniter and gas.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut is finger-tight.

The final stage is to check the tightness of all connections for potential leakage. In their absence, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened tighter.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the kit stretch outward, move out to the side towards the user. If there is difficulty with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Burner disassembly. To do this, the studs are unscrewed 4 pieces on both sides.

- The slotted plates are removed from the top of the burners, then the springs. Every detail is thoroughly cleaned.

- Assemble all elements in reverse order.

After reassembly, a tightness test is arranged, it is studied how tightly the burners adjoin the body.