- In what cases is it necessary to restore a well

- The main causes of clogged water wells

- sanding

- Silting

- Preventive measures

- The task of pumping a well after drilling

- How to remove sand and dirt on your own

- Working with a vibration pump

- Surface water supply

- Dual pump operation

- How to use the bailer

- Chemical cleaning method

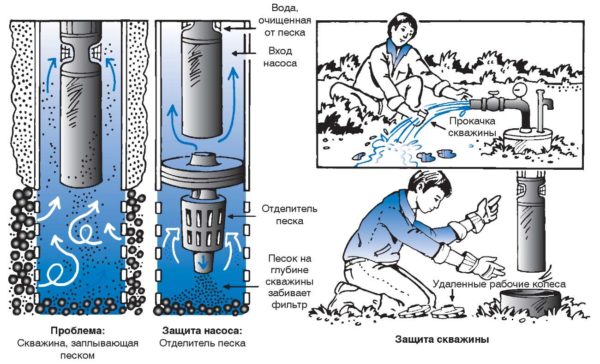

- Hydrocyclone

- Airlift

- Rinsing with gas-air mixture

- Extraction of sand with a bailer

- How to pump a well after drilling?

- Appointment of the buildup of the well after drilling

- Technology of well stimulation at the exhibition

- The process of building a well

- How to prevent clogging of the well?

- How to choose the right cleaning option

- Conclusions and useful video on the topic

In what cases is it necessary to restore a well

The decrease in the characteristics of the source can be caused by both improper operation of the well and natural causes. Let's consider what kind of troubles may lie in wait for the owners of wells during their operation, what are their causes, how to avoid or delay them.

The deterioration of water quality in the source can occur for the following reasons:

Contaminants got into the casing (working string) from the surface. This happens when storm or melt water penetrates into a caisson that is not sufficiently protected from the external environment or into an unequipped well.

Water can become cloudy from mechanical impurities, in which case it is enough to pump the source for several hours. Worse, if harmful microorganisms from the surface have penetrated into a clean underground environment. For example, iron oxide bacteria. They and other unwanted "guests" give the water a very unpleasant taste and smell. The infected source will have to be "treated". It helps to disinfect the well with the help of traditional antiseptics: potassium permanganate, hydrogen peroxide. They put the “medicine” in, wait for several hours, wash the well. After a couple of days, it becomes clear whether the desired result has been achieved. As a last resort, if repeated washings do not help, use products containing chlorine. There are also special preparations for disinfecting water pipes, but they are not cheap. At the end of the treatment, the well must be thoroughly washed out for several days.

As a result of corrosion of the steel casing, particles of rust and even soil get into the water if the connections have become loose. Water, as a rule, is transparent, but small solid particles come across in it. Installing a filter from mechanical impurities will help.

To make a more accurate "diagnosis", a laboratory analysis of water should be done. It will allow you to determine the nature of the measures for the "treatment" of the source, to choose the right filter system.

If the problem is not a decrease in the flow rate of the source, but a deterioration in water quality, start well resuscitation activities with a laboratory water analysis

A shallow well, arranged on a perch, can completely dry out during the dry season. After heavy rains or snowmelt, water will reappear.Well productivity "on sand" can also fall depending on the season, but not significantly. If a previously normally operating submersible pump began to “grab air” during long-term drawdown, or dry running protection is triggered, there is cause for concern. The well flow rate is falling and the regression is likely to continue. Up to the point that the source completely becomes unusable. The deterioration of well performance can occur for the following reasons:

Incorrect operation. The well must be pumped regularly. If no one lives in the house and does not constantly use the water supply, several hundred liters of water should be pumped out of it at least once a month. In the case when the source has been idle for many months, the soil in the water intake zone, as well as the filter, begins to clog with tiny particles, “silt up”. Calcium salts settle in hard water, the well is "calcified". Small particles, being motionless, accumulate and are compressed, forming rather solid layers. The pores in the soil and the holes in the filter are clogged, silt can accumulate in a rather thick, indelible sediment at the bottom of the casing. Water stops flowing into the column. For a year or two of insufficiently intensive use, the source can be spoiled. Silting and calcination also occurs naturally, even with proper well operation. But usually this process is lengthy, stretching for decades.

If the filter at the bottom is missing, poorly made or damaged, sand can enter the casing from below. Sand and dirt can also get inside due to leaks in the work string pipe connections resulting from corrosion.

In the case when the reason for the decline in the flow rate lies not in the disappearance of the aquifer, but in the contamination of the source, there is a chance that it will be possible to restore the well with your own hands.

The main causes of clogged water wells

The reasons for the appearance of pollution can be different: from improper installation of downhole equipment to the banal fall of pollution from the surface. There are only two types of pollution: sanding and silting.

And before starting work, it is important to understand where the pollution comes from, because the identified source of pollution is the beginning of the path to choosing the most effective way to flush the well.

sanding

A water well, designed and arranged in accordance with all the rules, helps to avoid unnecessary impurities and grains of sand getting into the casing. The opposite state of affairs can be caused by:

- Not tightness of the caisson or cap.

- Incorrect filter selection or damage.

- Often this is due to poor-quality welding of elements, breakdowns of a plastic pipe, or severe metal corrosion.

Sand in well water

Silting

The accumulation of tiny particles on the filter leads to clogging of the filter cells. This complicates the process of water penetration into the shaft of the working, the process of its "silting" begins. There may be a complete loss of water supply. By itself, this process is quite slow and in a source that is operated regularly, it can stretch for decades.

At the same time, improper well design and dirt ingress from the surface can lead to rapid silting even of a well that is constantly in operation.In the case when the well is not in operation, this process occurs much faster and it can take only a couple of years before the complete disappearance of the liquid. Timely treatment of the well and removal of silt before the water runs out completely can give the source a second wind.

Well pumping

Preventive measures

It is almost impossible to prevent silting or clogging of the well mine with sand, since subsoil sources always bring organic and inorganic fragments with them. But measures must be taken to reduce pollution.

First of all, secure the well from debris from outside. To do this, you need to close the exit of the mine, for example, with sheet metal, plastic and wooden covers. Such coatings are easy to make on your own, but you can find suitable items on sale.

It is possible to extend the life of a well by following a few simple rules of use:

- Carry out drilling in accordance with the technological rules, and at the end of it, immediately flush the shaft until the fluid is completely clear.

- Check if the casing is leaking and if the filter element is damaged.

- Clean the filter device regularly and replace it when worn.

- Protect the source from ingress of surface water and pollution by means of a caisson, head. It is possible to seal the top of the casing, but this is a temporary solution.

- Select the appropriate pressure equipment, taking into account the flow rate of the source. It is not recommended to use a vibration pump for pumping.In the process of vibration, mini-collapses of sand and organic compounds always occur. This technique is best used for cleaning.

The well must not be left without water intake. The ideal operating mode is the daily intake of several tens or hundreds of liters of liquid. It can be provided with permanent residence in the house. If for some reason this does not work out, it will be necessary to systematically take at least 100 liters of liquid at least once every two months.

The task of pumping a well after drilling

When the well is pumped after drilling, all particles and inclusions, even the smallest ones, are removed from the wellbore and from the nearby aquifer, and this is reflected in the fact that at the first stage of pumping, a very dirty liquid will flow from the well. However, in the future, as it is pumped, it will begin to brighten, and the more water is pumped out, the lighter the result will be.

Sometimes pumping requires really big efforts - so, if we talk about deep objects created in limestone or clay soil, then here it can take several weeks to pump, and only in this case it will be possible to get a quality result.

If we consider not too deep sandy wells, then pumping here usually takes about 12 hours. Long-term work on alumina is associated with the fact that in the process of drilling on such soils a clay solution is formed, which makes the water cloudy, and it is equally successfully formed both during drilling and during washing.

Clay breaks up into small particles, which are washed out with great difficulty, and therefore it takes a very long time to pump the well.Nevertheless, properly carried out pumping will allow you to end up with high-quality and clean water that will meet all the requirements, and this process will also allow you to operate the well for a long time.

Thus, in the case of water drilling there are no trifles, and each of the stages is significant. Understanding all aspects of such a craft can be difficult, and even professionals sometimes have difficulty with some things - for example, with access to new technologies and the study of the latest modern equipment.

How to remove sand and dirt on your own

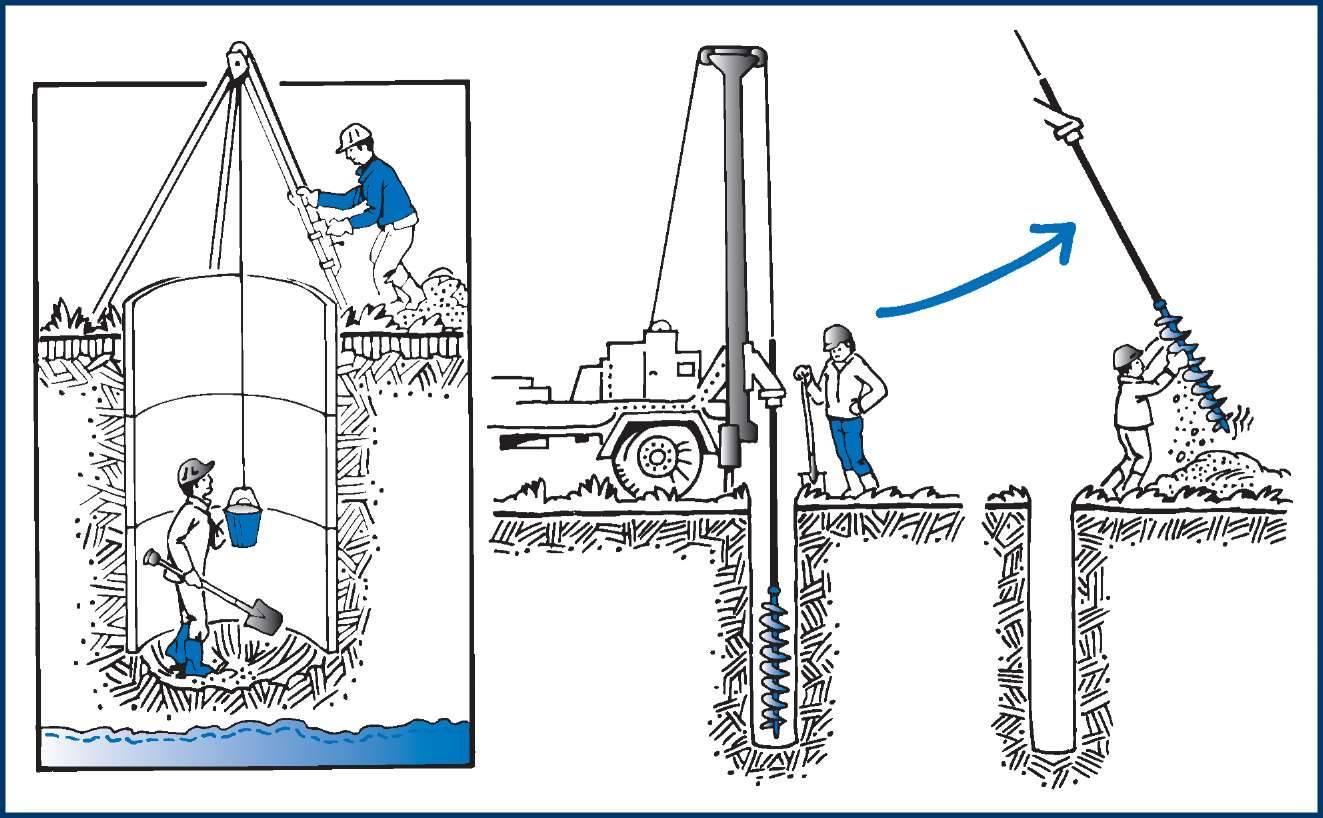

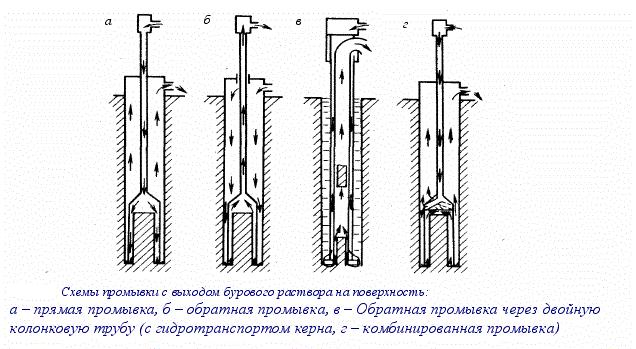

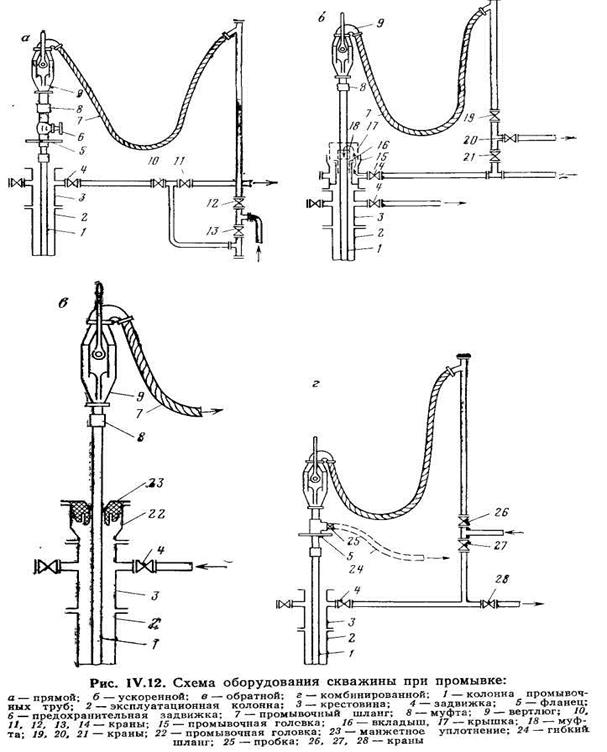

When sanding, one of the following methods is used:

| Technology | Equipment | How to use |

| Blowing | Compressor | After drilling for water |

| One vibration pump | Vibration pump | For cleaning wells with a depth of ≤ 10 m |

| Two pumps | Centrifugal and external pump | Purification of deep sources |

| Shock Rope Technology | Bailer, tripod and lift | Purification of heavily littered sources |

| bubbling | Compressor and motorized pump | Cleaning with the risk of damaging the filter and casing |

| pumping | Fire equipment | Quick Recovery |

Working with a vibration pump

The vibropump should be with a lower intake so that even large fractions of debris can be taken to the surface. The initial steps are lowering and raising the pump (3-7 times) to agitate and lift the mud into the water. The pump is attached at a level of 2-3 cm from the bottom. The bottom level is determined experimentally. The "Kid" type pump is designed for 30-40 minutes of continuous operation, after which it is lifted and cleaned of dirt. Find out how to lay a warm floor under quartzite tiles at this link.

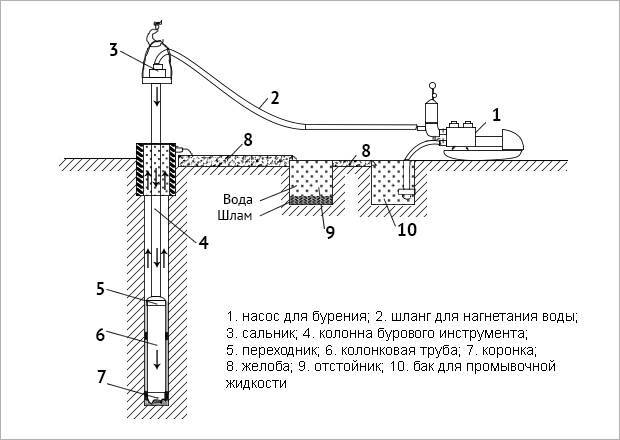

Surface water supply

If it is sandy, you can resort to short-term rental (from 60 to 180 minutes for a complete cleaning) of special fire equipment on a car chassis. If the well is concreted, then do not forget about heating the concrete in winter.

The principle of operation is as follows: the operator supplies a large volume of water to the casing pipe using a fire hose, and sandy dirty is pumped out through it.

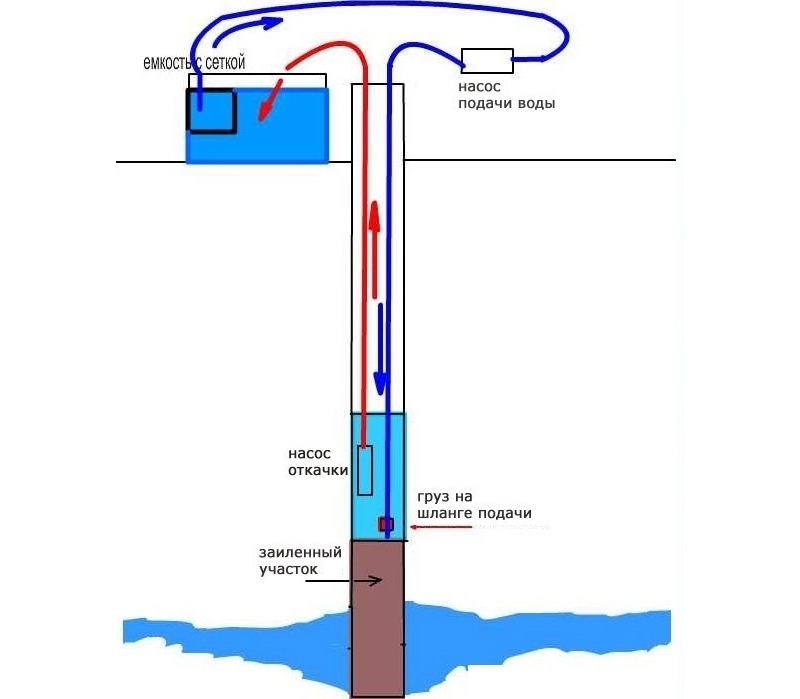

Dual pump operation

This method involves the use of two pumps - a powerful one for supplying water to a well under high pressure, and a drainage one for pumping out suspension. Both pumps turn on and run synchronously. The supply hose is weighted with any load so that it floats, and lowered by 25-30 cm from the beginning of the silting level. At a distance of 30-40 cm from the bottom, a water intake hose is fixed, after which both pumps are started. The incoming flow will wash away the dirt, and the drainage pump will bring it to the surface. Read about wall panels for interior decoration here.

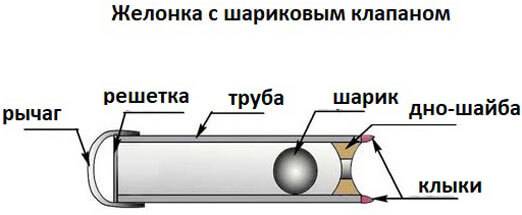

How to use the bailer

A bailer is a piece of iron pipe with teeth and flaps. The bailer is dropped into the hole from a height of 60-80 cm, and under its mass, sand and silt fall into the open cavity. When the bailer is removed, the blades slam shut. After removing the main mass of contaminants, water is supplied to the well under pressure, which will wash out the residual sand around the filter. Dirty is constantly pumped out until a clean liquid appears. Read about PVC lining for indoor and outdoor use in this material.

Chemical cleaning method

Cleaning with strong chemicals - weak acid solutions and food solvents:

- Orthophosphoric acid.

- Household plumbing products, such as Sanoks.

- Hydrochloric acid. It must not be used for cleaning galvanized pipes.

Hydrocyclone

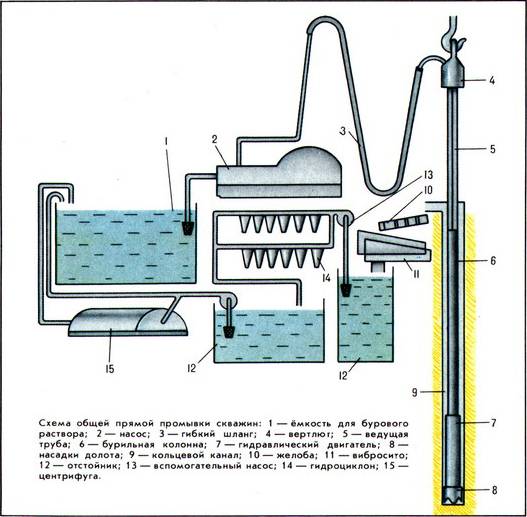

This is a hydromechanical device for separating substances by mass. Structurally, GCs are pressure (closed type) and non-pressure - open. The liquid suspension enters the pipe at a pressure of 5-15 bar and is given a vortex rotation. Heavy fractions of alluvial sand and gravel are thrown by centrifugal forces to the walls of the device, while 2 cyclones work - external and internal. Heavy fractions go down, light particles rise up to the central pipe. This article will tell you about foam rubber insulation for windows.

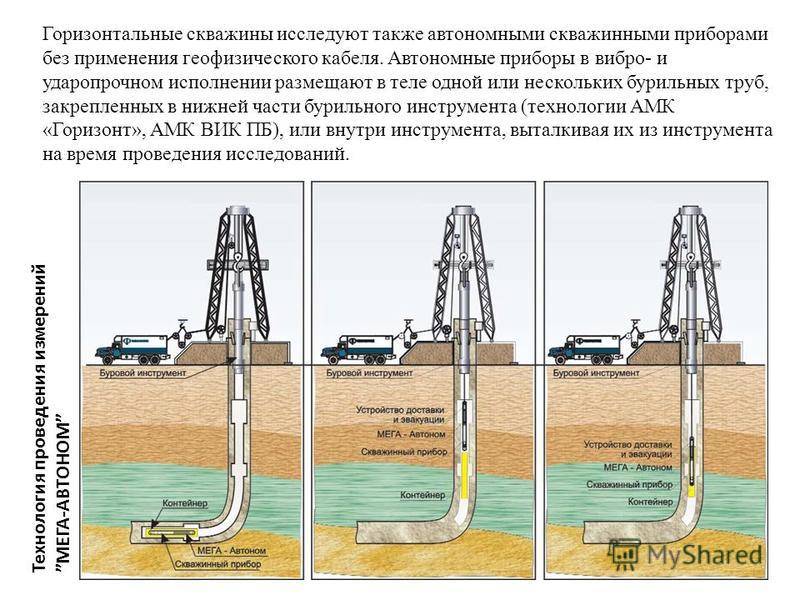

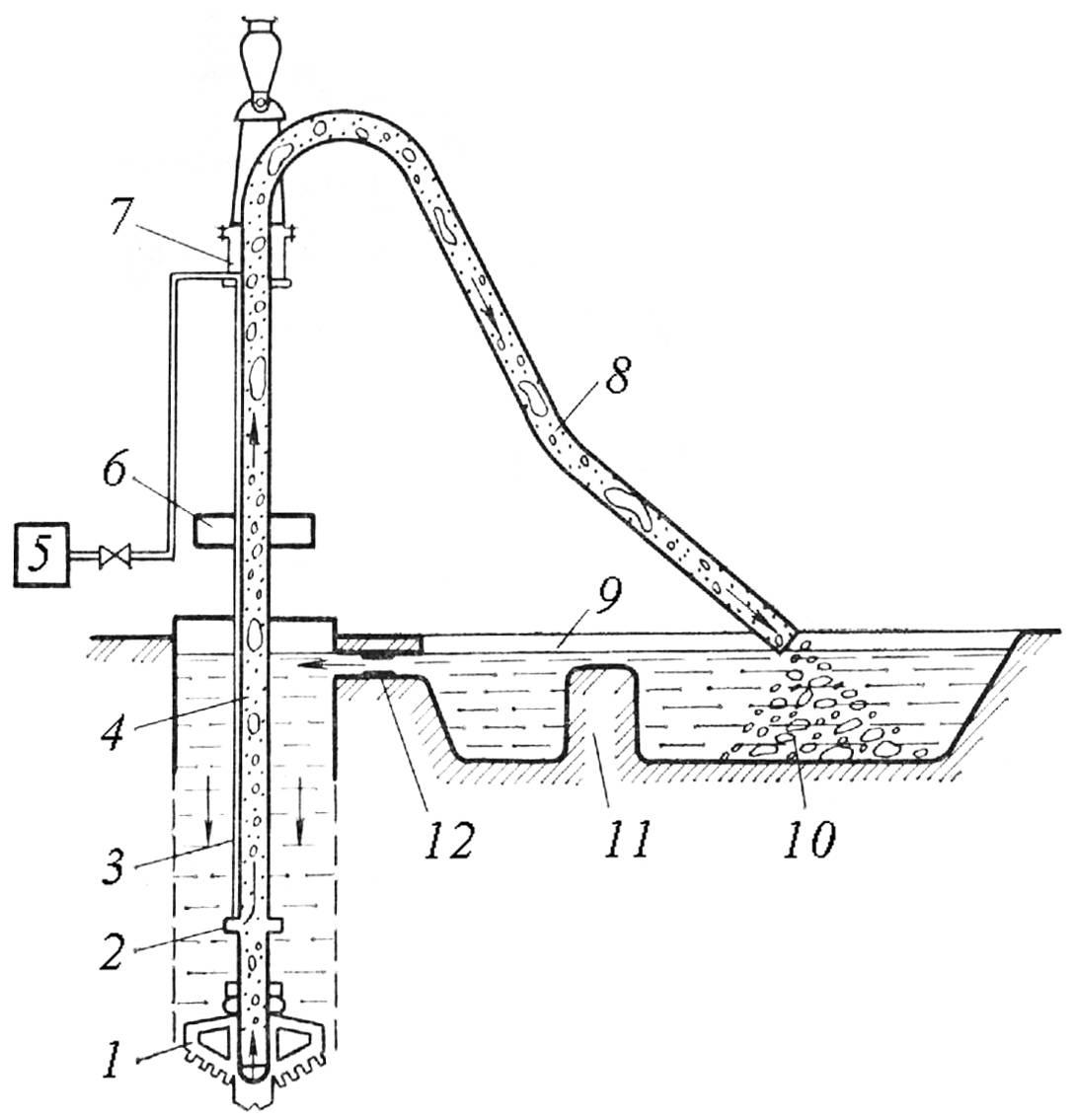

Airlift

Airlift (airlift) - a device that uses compressed air to pump out dirty. Applicable at any depth. Structurally, this is a suction device, a mixer, a mixture supply pipe, an air separator and a pipe line for compressed air. A pumping pipe is lowered into the well, a pipe with compressed air is connected to it below, the resulting mixture rises up into a special device for separating air, water and solid particles.

Rinsing with gas-air mixture

To work, you need to rent an air compressor and a surface pump. Lower the hose from the motor pump to the bottom. Insert a special atomizer with a hose connected to the supercharger into the layer of sand at the bottom of the source. Cover the head of the column with a nozzle to drain water into the sump. Turn on both units. Air bubbles will capture the grains of sand and lift them to the surface, and then into the sump. In the tank, the water will clear, and the pump will send it back to the barrel.

This method allows you to remove all the sand from the bottom, but the process can take several days or even weeks.

Extraction of sand with a bailer

The technology of cleaning the source with a bailer is effective when it is required to remove a large amount of pebbles, sand and compacted fine-grained deposits from the casing. But it is practically useless when you need to clean the filter and the soil adjacent to it.

The bailer consists of a piece of steel pipe 1 - 1.5 meters long, on one side of which there is a valve, and on the other - a lever-eye for the cable. The valve is a heavy steel ball held by a washer attached to the threads.

Often this method is used when cleaning artesian wells. It is desirable to completely pump out water from the casing string. With a sharp movement, the bailer is lowered to the bottom of the source. When it hits the sand, the valve opens and a certain amount of sand enters the device.

Raising the projectile to the surface, the dirt is shaken out of it. This process is repeated several times. You can work the bailer by hand, but it's hard work, even if you work together. To raise and lower the projectile and steel cable, it is better to use a tripod equipped with a winch or pulley.

You can buy a bailer of a specific diameter in a specialized company, make it yourself or rent it

In the process of its application, care must be taken when the projectile approaches the filter, since there is a possibility of damage to the fine mesh. The remains of sediments at the very bottom are best removed in another way that does not have shock effects.

How to pump a well after drilling?

Well construction work requires certain knowledge and qualifications, but the question is: “How to pump the well after drilling?” - not only specialists can decide.

Appointment of the buildup of the well after drilling

Swinging is a special process designed to clean the well from the soil after it has been drilled. If this process is not carried out, then soon the well will silt up to such an extent that it will interfere with its work. This is a natural process that will happen over time. Therefore, well maintenance and cleaning should be done regularly.

The smallest grains of sand that are not captured by filters are present in any aquifer. Grains of sand or other small particles, when they enter the well, accumulate over time and occupy its area, which significantly impairs productivity.

With a properly performed buildup, all small elements rise from the well and the nearby water layer. In this case, the liquid supplied from the well will be cloudy, which is a confirmation of the effectiveness of the work performed. Gradually, the water will become more and more pure.

Before swinging the well after drilling, it is necessary to make sure that the equipment is properly set up and the power supply is available, as this process can take up to 12 hours in sandy soil.

As for wells drilled in limestone or clay soil, their buildup can take from several weeks to several months.

Technology of well stimulation at the exhibition

This process, in fact, is a simple pumping of water. However, there are several points that require attention from those who produce it.First of all, this is a competent choice of a pump that can build up.

At the same time, you should not choose expensive powerful models. It is better to opt for a simple submersible pump. In the process of buildup, it can even fail several times, since it is rather difficult to pump a turbid suspension, but at the same time it will be able to complete the task.

It is worth paying attention to the height of the pump before starting work. It should not be too close to the water surface

Otherwise, he will not be able to capture fine particles from the bottom of the well, and his work will be useless. Burying the apparatus is also not worth it due to the fact that it itself can become clogged with silt and stop functioning. A "buried" pump is also difficult to remove to the surface for cleaning.

Technologies and rules for well swaying after drilling are covered at many forums and congresses, including at the largest industry exhibition "Neftegaz", which will be held at the Central Exhibition Complex "Expocentre". Among other topics, it also covers this issue, as well as new technologies related to it.

Research carried out by industry experts in this area provides, first of all, an increase in the efficiency of the buildup process, as well as its acceleration.

Exhibition "Neftegaz" in the Central Exhibition Complex "Expocentre" – a great opportunity to evaluate the latest developments in this area, as well as get acquainted with samples of modern equipment designed for well stimulation.

The process of building a well

Well cleaning after drilling takes place in several stages.

- Choice of location.As far as possible from the future well, with the installation of treatment facilities-barrels.

- Hanging the pump on a cable and lowering it into the well. 70–80 cm above the bottom, so that all particles of sand and clay can be captured, preventing them from settling to the bottom.

- Turning on the pump and actually cleaning the source. During the procedure, the mechanism will have to be removed and cleaned several times.

As soon as clear water begins to flow from the cleaning barrels, the procedure for rocking the well after drilling can be considered completed.

Pumping a well after drilling is a simple task. If you set yourself the goal of ensuring that only clean water comes from a new source, choose the right tools and be patient while removing drilling products from the reservoir, this procedure will be relatively easy. This is within the power of the owner of the future well and without the help of professionals.

How to prevent clogging of the well?

There are no "eternal" wells for water supply. Unfortunately, sooner or later, the owner of an individual water source will run into problems. It’s bad if the aquifer has dried up, you have to drill again or deepen the existing development. This is difficult and very costly.

It is another matter if a clogging of the well has happened - it is easier and cheaper to prevent than to “treat”.

Extending the service life of the source contributes to the observance of several rules of operation:

- Strictly adhere to the chosen drilling technology. Carefully monitor the tightness of the casing and the integrity of the filter.

- Immediately after completion of drilling operations, flush the source until clean water appears.

- Protect the well from the penetration of surface water and pollution by installing a caisson, head.As a temporary solution, simply seal the top of the casing.

- Prior to the start of operation, it is correct to select and install a submersible pump at the required height, always taking into account the flow rate of the well.

- It is advisable not to use a vibration pump to supply water. Vibrating in the casing, it, depending on the type of soil, to a greater or lesser extent provokes the penetration of sand into the well or contributes to siltation of the adjacent soil. A cheap and simple vibrator can be used for a short time; a centrifugal pump is needed for permanent operation.

- The well should not stand idle without parsing water. The ideal mode of operation is the daily pumping of several tens or hundreds of liters of water. It is provided if people permanently live in the house. If this is not possible, you should regularly, at least once every 2 months, pump out at least 100 liters of water from the well.

The implementation of these recommendations, of course, will not allow to avoid clogging of the well in the future. However, it will delay this trouble by providing the maximum possible resource for effective operation for this source.

The correct arrangement of the well is the key to its longevity. It is necessary to install a special head on the casing pipe, which seals it and serves for reliable installation of equipment

How to choose the right cleaning option

It can be difficult even for a specialist to determine exactly why the well flow rate has fallen. As a rule, pollution is complex. If the pump "drives" sand with water, this does not mean that the soil is not silted.

When cleaning the well with your own hands, you should be patient. It may be necessary to apply successively several methods and try hard before a satisfactory result is obtained.

We recommend starting with the simplest: pumping with a vibration pump. If pumping did not help, proceed to flushing. We start with flushing if the source is almost dry. To scoop out sand, if there is a lot of it at the bottom, a bailer will help.

But it cannot be used for plastic casing, only for steel. For polymer barrels, we use only bubbling. If there is neither sand nor water in the steel casing, we turn to the water hammer technology.

This, of course, if the aquifer itself has not dried up. Renting a washing machine, of course, costs a penny, but the cleaning efficiency is noticeably higher than when using artisanal methods.

Conclusions and useful video on the topic

Flushing the well with a pump:

What does the process of flushing a well with one pump look like and why it is necessary to take care of the organization of water disposal:

As you can see, flushing a well after drilling is completed is a necessary measure that you cannot do without if you want to get clean water.

Flushing can be done in several ways: one or two pumps or an airlift. The manual method of cleaning with a bailer for primary washing is not advisable due to its low efficiency.

Have something to add, or have questions about the topic? Share your well flushing experience with readers, please leave comments on the publication. The contact form is in the bottom block.