- Why can a well become clogged?

- Reason one. Sand got into the casing

- The second reason. Unused well silted up

- Necessary equipment for work

- Basic cleaning methods

- With the help of a bailer

- Deep Vibration Pump

- Using two pumps at the same time

- Compressor purge

- Water Hammer Technology

- Distinctive features of the method

- 2 A variety of wells - types and design

- First compressor cleaning immediately after drilling

- About method

- Flushing and pumping wells

Why can a well become clogged?

To understand the causes of the problem and choose the appropriate cleaning method, you need to familiarize yourself with the types of clogging.

Reason one. Sand got into the casing

This is a common problem in shallow sand wells with an aquifer located in a sand and gravel layer. If the well is properly equipped, sand will enter the casing in minimal volumes.

With a decrease in well productivity and the presence of grains of sand in the water, the problem may be:

- ingress of sand from the surface (due to leakage of the caisson, cap);

- broken tightness between casing elements;

- incorrectly selected filter (with too large cells);

- violation of the integrity of the filter.

It is impossible to eliminate leaks inside the well. Fine sand, constantly penetrating through the filter, is easily removed (especially since it is partially washed out when lifting). But when coarse sand enters, everything is somewhat more complicated, the well can simply “swim” over time

That is why it is necessary to choose a filter and mount casing elements with special attention.

The installation of a sand separator in the casing pipe significantly reduces the sanding of the filter and extends the service life of the well on the sand

The second reason. Unused well silted up

Over time, particles of rocks, rust, clay, and calcium deposits accumulate in the ground near the filter. With an excessive amount of them, the filter cells and pores in the aquifer are clogged, and therefore it will be more difficult for water to enter. The flow rate of the source decreases, it silts up to the complete disappearance of water. If the well is used regularly, then this process slows down and can take decades, and if not, then siltation may take one to two years.

In the case of timely cleaning of the well from sludge (that is, before the water disappears completely), the source can most likely acquire a “second life”. Water supply will be maintained in sufficient volumes for the residents of the house.

Water entering the well through the filter carries with it small particles of silt. There is silting of the soil near the filter. Calcium salts also accumulate in the suction zone if the water hardness is high.

Necessary equipment for work

The standard type of hydraulic drilling work is carried out by means of small-sized installations. For your own site, this is a wonderful solution and the best way to get water on your own.It is necessary to supply the working fluid to the wellbore with a significant pressure, and this requires a pump or motor pump for contaminated fluids.

Sometimes, to increase the breakdown force, shot or coarse sand is added to the working solution. For crushing large pebbles, which can be found in sandy layers, cone and cutter chisels are useful.

If during the drilling of wells or the construction of wells in neighboring areas there were boulders or large pebbles, the starting rod must be equipped with a reinforced drill bit. The tool must be fixed so that it does not interfere with the supply of water to the barrel

The most demanded by the consumer for the purposes of hydraulic drilling are special small-sized MBU units. This is a unit with a height of 3 m and a diameter of 1 m. This prefabricated structure includes:

- collapsible metal frame;

- drilling tool;

- winch;

- an engine that transmits force to the drill;

- swivel, part of the contour for sliding fastening of parts;

- water motor pump to provide pressure in the system;

- exploration or petal drill;

- drill rods for string formation;

- hoses for supplying water to the swivel from the motor pump;

- Control block.

Among the necessary equipment it is also desirable to have a current converter. It is necessary for the energy supply of the process to be stable. You also need a winch for lifting / lowering casing and stacking pipes. When choosing a motor pump, it is better to stop at a more powerful device, since large loads are expected. For hydro-drilling, you will also need such a plumbing tool as a pipe wrench, a manual clamp, and a transfer plug.

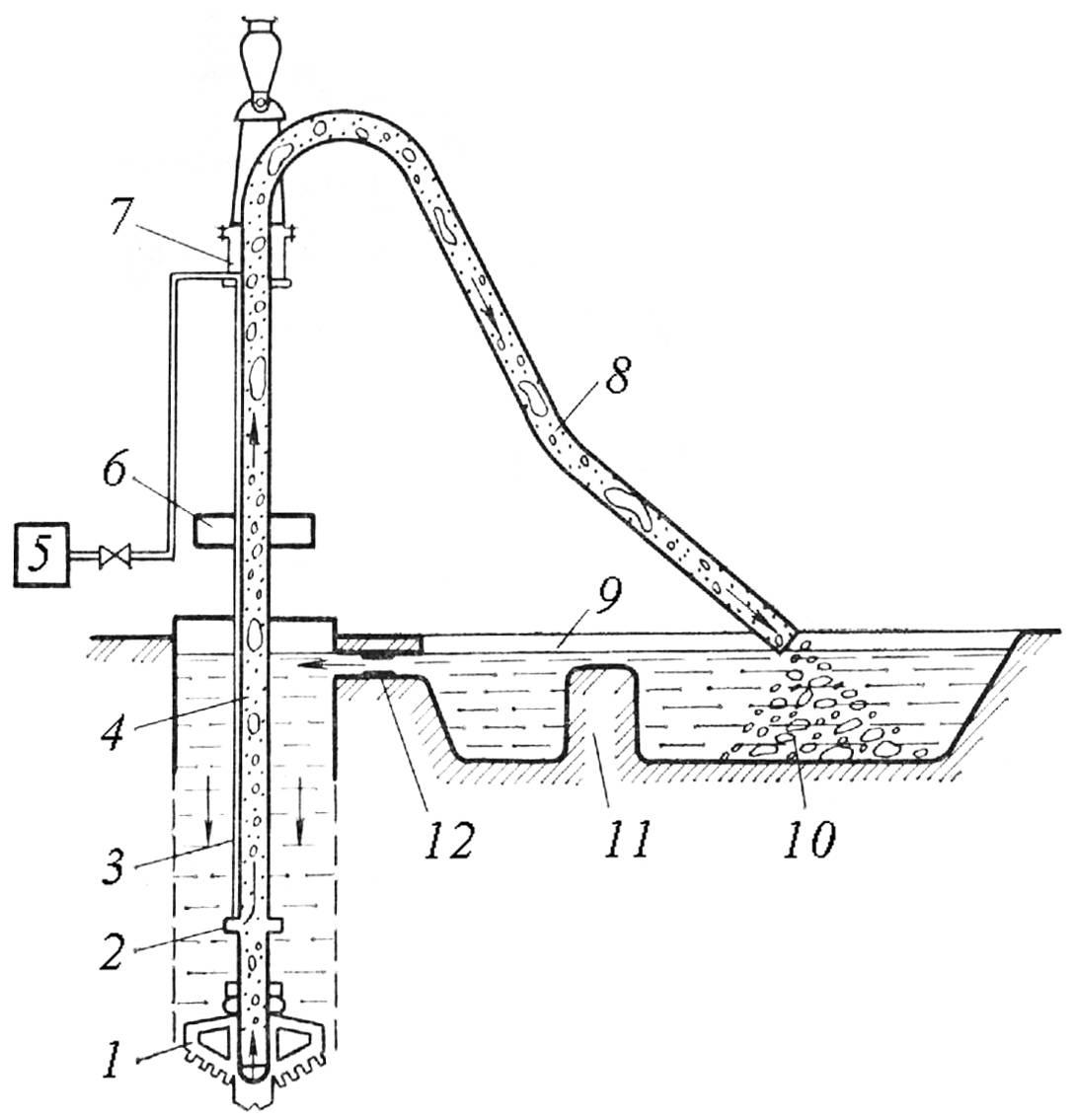

The hydraulic drilling process from the very beginning to the end of the work includes a constant circulation of the working fluid. With the help of a pump, an aqueous suspension with eroded soil leaves the well, enters directly into the pit, and, after the sedimentation of the suspension, is again fed into the well.

In addition to this procedure, it is possible to carry out hydraulic drilling of shallow wells for water without using a pit. This method does not require a recess for settling the working solution, saves time and makes it possible to drill a well even in garages and basements.

If there is an abandoned pond near the site, then you can also do without the installation of sumps - pits. There are no special requirements for the quality of water supplied to the well

For hydrodrilling, a motor pump is selected that is capable of pumping heavily polluted water. It is advisable to buy a unit with a head of 26 m, a pressure of 2.6 atm and a capacity of 20 m3 / h. More powerful pump guarantees faster, trouble-free drilling and better hole cleanout

For quality drilling, it is important that a good flow of water always comes from the well.

Basic cleaning methods

The methods described below will help clean the water intake in the country.

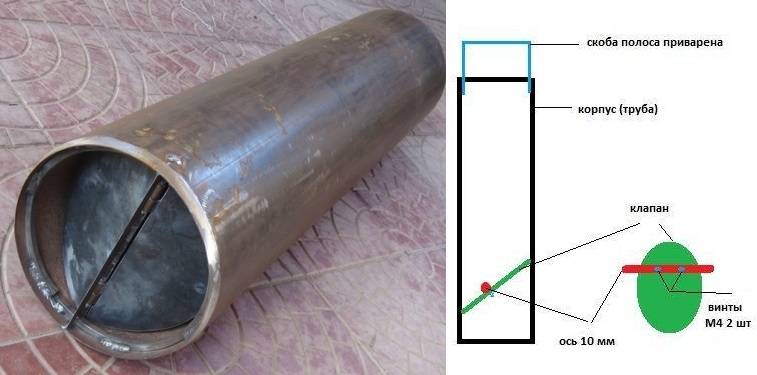

With the help of a bailer

A reliable, but time-consuming method is cleaning with a bailer. With this device, which perfectly cleans the mine from silt, sand and rust, it is possible to restore a practically idle well and return it to its original state. The method is good in that it is economical, simple and does not involve highly specialized equipment.

The bailer is a simple device that helps to clean the well from sand and silt with your own hands

The bailer is a simple device that helps to clean the well from sand and silt with your own hands

How does he work? The bailer is an ordinary pipe about 1-2 m long.At the bottom, a valve is made in it, and pointed teeth are welded for efficiency. The upper opening of the pipe is closed with a mesh and rings are welded on which a cable or rope will be attached in the future. After the device is ready, it is abruptly thrown from a height into the mine. The teeth loosen sediments on the bottom, the bailer valve opens, silt, clay and sand fill its interior, the valve closes, and the trapped contents remain inside the pipe. The bailer is lifted up, where it is freed from pollution. The cycle is repeated over and over until the well is completely clean. This simple device can be made independently from household improvised materials or bought in a store.

Deep Vibration Pump

To clean this way, you will need a vibrating deep-well pump, a narrow metal tube or a piece of fittings. A tube or armature is needed to loosen the bottom sediments.

The vibration pump allows you to quickly and inexpensively get rid of sand and other contaminants.

The vibration pump allows you to quickly and inexpensively get rid of sand and other contaminants.

The principle of operation is as follows: fittings tied on a thin cable are lowered into the shaft. Up and down translational movements of the reinforcement loosen the deposits at the bottom and mix them with water. After that, the pump is lowered into the well and the turbid water is pumped up until it goes clear. The cycle is repeated several times until the well is completely clean.

Using two pumps at the same time

The cleaning method with the help of two pumps is effective. For this, a barrel with water with a volume of 150-300 liters, a hose, one deep pump and the second one are used for delivery.

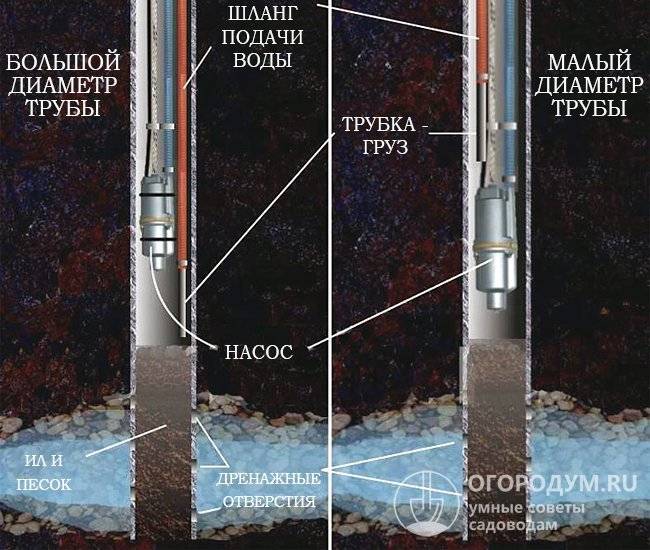

Two-pump flushing technology depends on casing diameter

Two-pump flushing technology depends on casing diameter

The injection pump is located on the surface and, through a hose, supplies water from the tank under pressure downwards, washing away deposits at the bottom. The deep pump is installed 10 cm above the sediment level. To do this, it is lowered all the way to the bottom of the well, then raised to the desired height and fixed. As soon as the water reaches the level of automatic operation, the deep pump gradually pumps out the water along with the deposits. Due to the fact that the water pressure is small, the two-pump method is longer in time than the previous one, but it allows you to operate equipment with lower loads.

With the help of a pump, cleaning can be carried out independently

With the help of a pump, cleaning can be carried out independently

Compressor purge

This is a simple and economical way to quickly and efficiently remove deposits from the bottom of the structure. You will need a compressor and an air hose with a plastic tube.

Purging is an economical and fast way to remove deposits

Purging is an economical and fast way to remove deposits

The cleaning technology is as follows: the hose is connected to the compressor and, from the side where the tube is, is lowered into the well. After turning on the compressor, air begins to flow into the mine at a pressure of 10-15 atmospheres. The high pressure created by the air pushes water and sand to the surface.

Water Hammer Technology

If silt and sand are removed from the pipe, it is pumped and washed, but there is still no water or its pressure is very small, then most likely a plug of silt deposits has formed. To eliminate it, you need to use the method of water hammer.

Water hammer is an effective method for removing sludge plugs

Water hammer is an effective method for removing sludge plugs

You will need a punching pipe with a diameter slightly smaller than that of the steel casing pipe of the well, that is, freely penetrating inside.One end of the punching pipe is completely welded, and at the other end rings are made for which a rope or cable will be attached. The well is filled with water so that the level of the water column is about 5-6 meters, and phosphoric acid is added. The punching pipe is thrown down to hit the water and transfer its momentum to the water column, then it is raised again. The process is repeated several times over an hour.

Distinctive features of the method

The use of wells as an autonomous source of drinking water is quite an old and proven method. Along with traditional, sometimes expensive technologies, the hydrodrilling method can be deservedly called economical and versatile.

Popular drilling methods wells are discussed in our other article.

This fairly simple way to drill a well has some nuances, ignoring which can nullify all your efforts. Its essence lies in an integrated approach.

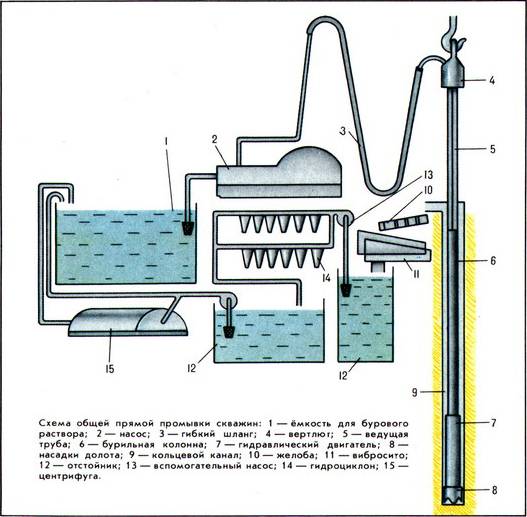

from A specific feature of hydraulic drilling is that the destroyed rock is removed not with a drilling tool, but with a pressure jet of water. Simultaneously with the drilling process, the working is flushed, which reduces the stages of work before putting it into operation drilling tool Water from the mine is drained through a hose into a sump. After settling in a container and settling to the bottom of the soil particles, the water is used again. A high drilling rig is not needed for hydraulic drilling. A mini machine is quite suitable, because.there is no need to extract from the bore of the drill string. In self-made machines, water is supplied to the drill through the cavity of the rod column. A weighty disadvantage of hydraulic drilling is the dirt and slush that accompanies the work. In order not to dilute it, you should prepare a couple of containers for water or dig deepenings. Water should be supplied to the pit with good pressure, therefore, before starting drilling, you should stock up on sufficiently powerful equipment. workHomemade drilling rigPerceptible disadvantages of hydrodrillingEquipment for water injection

Two main processes are combined here - this is the direct destruction of rocks by a drilling tool and the washing out of drilled soil fragments with a working fluid. That is, the rock is affected by the drill and water pressure.

The load required for immersion in the ground is given by the weight of the drill rod string and special drilling equipment that pumps flushing fluid into the body of the well being formed.

The washing solution is a mixture of the smallest particles of clay and water. Close it in a consistency slightly thicker than pure water. A motor-pump takes the drilling fluid from the pit and sends it under pressure to the wellbore.

The simplicity of the hydraulic drilling method, the availability of technology and the speed of execution have made it so popular among independent owners of suburban areas.

Water in the hydrodrilling scheme performs several functions simultaneously:

washes out drilled particles of destroyed soil;

brings the dump to the surface along with the current;

cools the working surfaces of the drilling tool;

when moving, it grinds the inner surface of the well;

strengthens the walls of the well that are not fixed by casing, reducing the risk of collapse and filling with a moldboard.

As the drill string is deepened, it is increased with rods - sections of the VGP pipe 1.2 - 1.5 m long, Ø 50 - 80 mm. The number of extended rods depends on the depth of the water carrier. It can be determined in advance during the farrowing of neighbors in order to mark the water mirror in their wells or wells.

The estimated depth of the future well is divided by the length of one rod to calculate how many pieces need to be prepared for work. On both ends of each rod, it is necessary to make a thread for making up the working string.

One side must be equipped with a coupling, which is desirable to be welded to the rod so that it does not unscrew in the barrel.

Hydrodrilling technology allows arrange a source of industrial water in the country without the involvement of a drilling crew

In practice, hydrodrilling in its pure form is rarely used, because a large pressure of water is needed. It is also difficult to drill dense clay layers. More often produce hydrodrilling with a burner.

This method is somewhat similar to rotary drilling, but without a rotor. For better centering of the well and easy overcoming of tight areas, a petal or cone-shaped drill is used.

Hydrodrilling is not suitable for driving through rocky and semi-rocky soils. If sedimentary rocks in the drilling region are crushed stone, pebbles, sands with a large inclusion of boulders, this method will also have to be abandoned.

It is technically impossible to wash and lift heavy stones and fragments of heavy rocks from the well with water.

The addition of an abrasive to the working fluid increases the rate of penetration by increasing the destructive effect

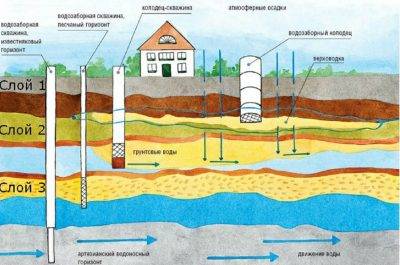

2 A variety of wells - types and design

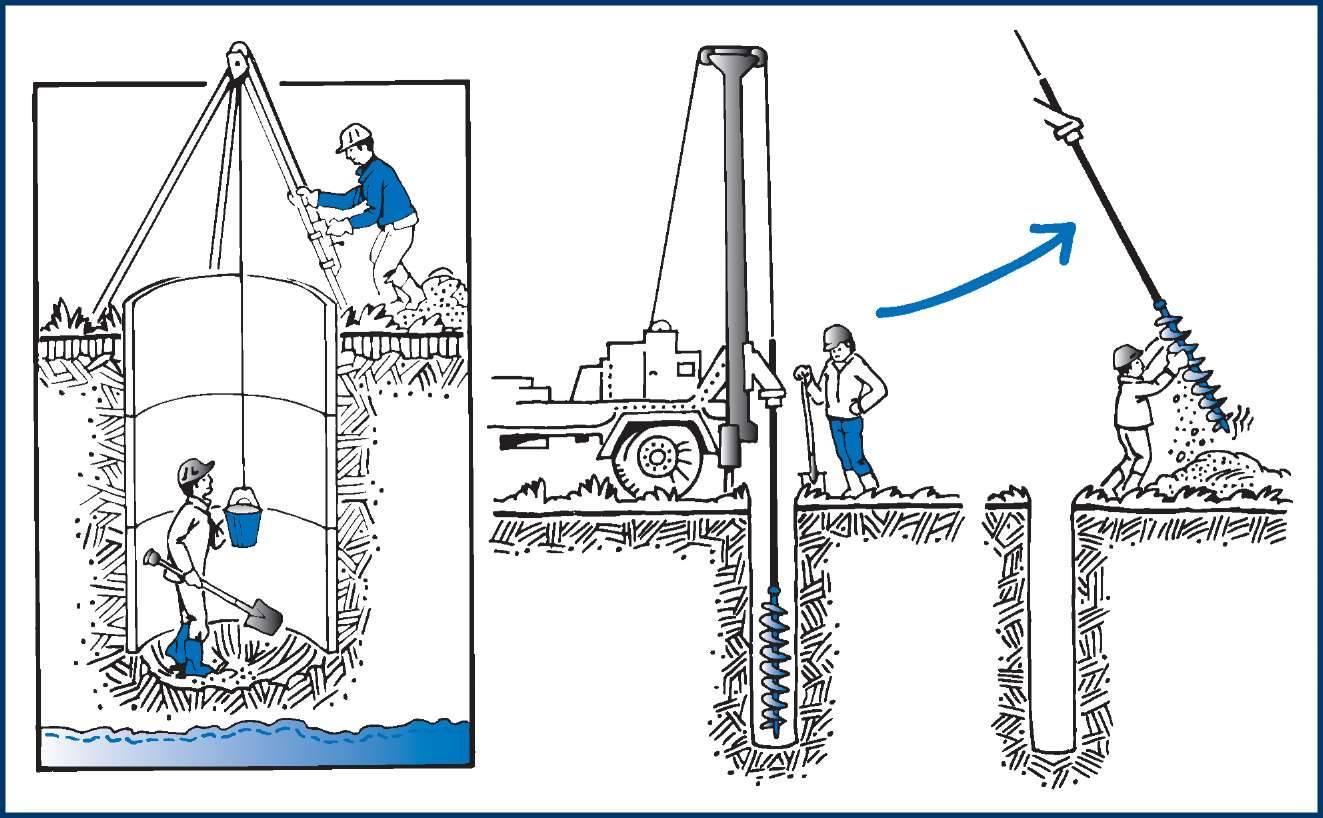

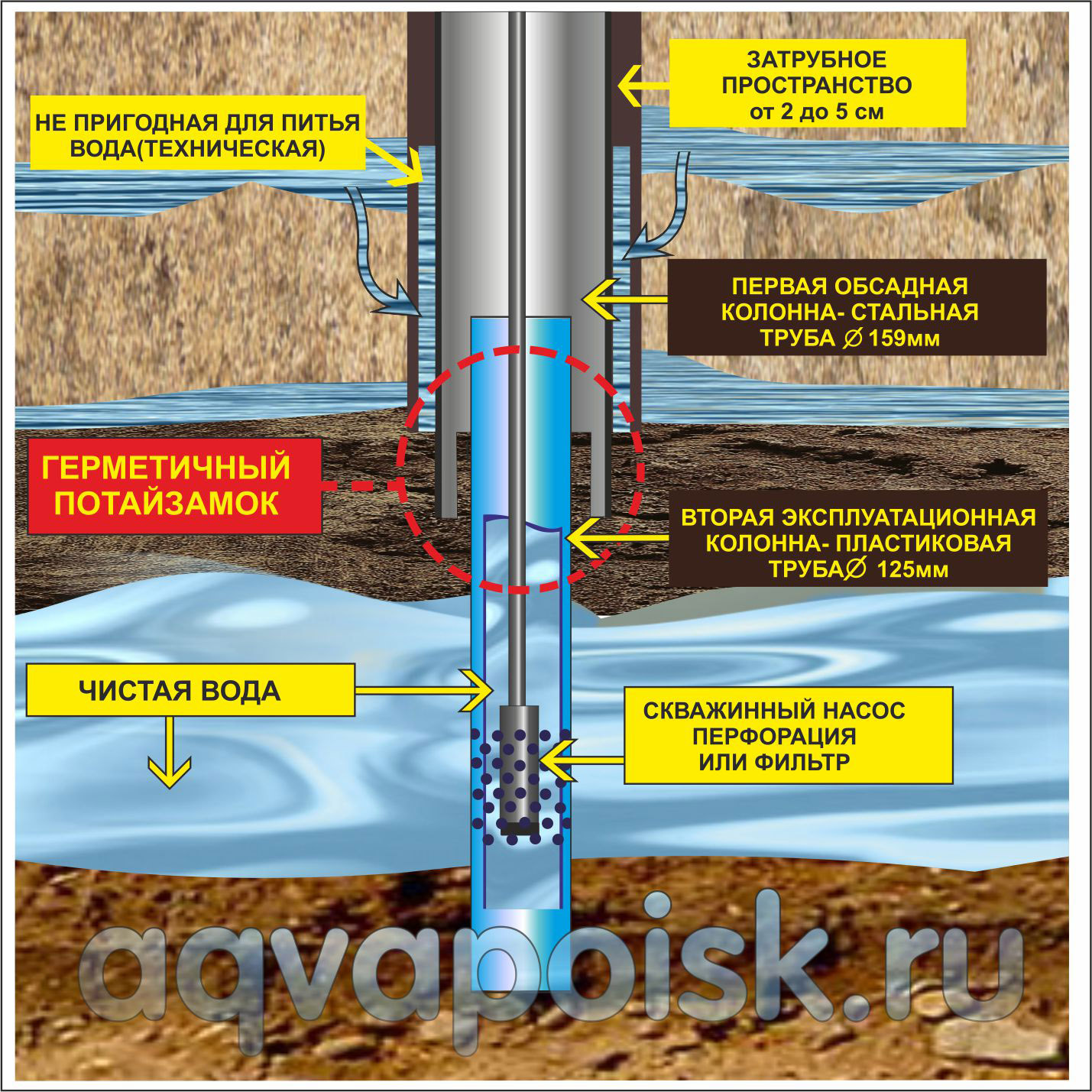

The well can be punched with a drilling tool with a pipe rod or using a wireline. A narrow hole is formed in which a pipe casing is placed to protect the walls from spilling. It can be installed tightly or with a gap that is covered with clay. The bottom of the trunk is made in several versions: open, muffled or narrowed, which is called the face. A device is installed at the bottom of the trunk that takes water. At the top of the well - the head, install external equipment.

In practice, when self-drilling, several types of wells are used, different in design. To arrange Abyssinian wells - simple water intake structures, use a well-needle. A drilling tool is a single unit of connected parts: rods, casing and drill. No other tools are required. The passage is performed by impact, the drilling tool is not removed after the end of the work, but remains in the well. In an hour they pass up to three meters, the greatest depth known from practice is 45 m.

There is little water in the well-needle, but in summer the debit is quite stable. This is perhaps the only type of wells that do not depend on the regularity of use - there is always water. But the unpredictable also happens to them: water disappears for no apparent reason, although cases of service have been known for over a century. It is possible to arrange a well-needle if the rock is loose and homogeneous.It is permissible to use pipes with a maximum diameter of 120 mm, which allows the installation of a submersible pump.

Imperfect wells are represented by the majority of self-made water intakes. The well hangs in the reservoir, its capabilities are not fully utilized. The debit is small, the water quality increases if the well is shut off at the bottom point. You can increase the debit and quality by further deepening, but the result is not guaranteed. Even in thick layers, when deepening into it more than 1.5 m, debit stabilization is observed, further deepening has almost no effect on the result.

A perfect well produces water more than others with excellent quality. The drill passes the entire aquifer until the casing rests on the underlying one. It is almost impossible to make a perfect well without experience: when drilling, surprises happen with bad consequences:

- casing can go into the next layer behind the aquifer, if it is plastic;

- you can continue to drill and go through the underlying layer without feeling its beginning, the water will go down from the aquifer;

- an improperly arranged perfect well can harm the local ecology.

First compressor cleaning immediately after drilling

As soon as the well is drilled, it must immediately be cleaned, because not only water will flow into the pipes from the aquifer, but also all the debris that is in it. Installed filters cannot trap the smallest particles, from which the water becomes cloudy and unsuitable for drinking. Depending on the depth of the well, the flushing process after drilling can take from 10 hours to several weeks.

If drilling was carried out by specialists, then they flush the system using a flushing unit.If you drilled the well yourself, you will also have to clean it of dirt yourself. To do this, you will need a compressor with a capacity of at least 12 atm and several pipes that must be connected to each other and inserted into the well so that they reach the bottom. In this case, the diameter of the pipes must be smaller than the diameter of the well so that there is an empty space between them.

The compressor forces air into the well at high pressure, so dirty water can fly out at high speed and splatter everything around

Let's consider step by step how to clean the well yourself using a compressor:

We insert pipes into the well. It is desirable to strengthen the top with a rope, because under high water pressure the structure can bulge upward. We put a vacuum adapter on the pipe, fixing it with self-tapping screws. We pump up the compressor to maximum pressure. We put the compressor hose on the adapter. pumping.

Air under pressure will push dirty water through the annulus. Therefore, do not be surprised if everything around is filled with mud.

If air does not achieve clean water, repeat the procedure, replacing the air purge with a water purge, using the same piping system with an adapter. To do this, find some large barrel, put it next to the compressor and fill it with water.

Using a water compressor, drive this water at maximum pressure into the well. But be careful, because heaps of dirt pushed out by this water will fly at you. Clean the well until the tank is dry.Then, flushing should be repeated until dirt is no longer ejected from the annulus.

With the help of blowing and flushing, the well is cleaned of silt or sand. But salt deposits on the filter cannot be knocked out in this way.

4

Bailer - an elementary device for extracting sand

If the farm does not have a vibration pump, it is possible to clean a well up to 30 m deep in another way, involving the use of a device called a bailer. It is a one and a half meter piece of metal pipe with an eye lever on one side and a valve on the second.

Bailers are sold in hardware stores. If desired, they are easy to make with your own hands. The function of the valve in such designs is performed by a heavy steel ball. He is held by the puck. It is fixed with a threaded connection. The eyelet lever allows you to attach a cable to the fixture.

Additionally, you need to prepare a tripod, on top of which there is a block. Work on cleaning the well with a bailer is carried out by two people. The process implementation algorithm is given below:

A deep pump is drawn from the source. All foreign objects are removed from the pipe, water is pumped out. The bailer is fixed on a strong rope or cable and drops sharply into the well. Sand particles begin to move and enter the bailer through the intake valve, which is opened by a steel ball.

Then the pipe is lifted up. At the same time, the ball clogs it, preventing the “captured” contaminants from falling out back. On the surface of the earth, the bailer is freed from sand particles and again lowered into the well.This operation is repeated several times.

The described technique is ideal for cleaning the casing from small compacted deposits and pebbles, large volumes of sand. But it is not suitable for removing silt from the well. The method described in the next section helps to cope with such sediment.

About method

This method is suitable for different types of soil:

- Sandy;

- sandy loam;

- loamy;

- Clayey.

This method is not suitable for rocky soil, since its principle is to soften the rock with water pumped into the drilling zone using a pump, which greatly facilitates the process. Waste water enters the pit next to the installation, and from there it returns to the well through hoses. Thus, the whirlpool has a closed system and a lot of liquid is not required.

Hydro-drilling of wells is carried out by a small-sized drilling rig (MBU), which is a collapsible mobile structure of compact size and light weight. It consists of a bed, which is equipped with:

- A reversible motor with a gearbox (2.2 kW) that creates torque and transmits it to the drilling tool.

- Drill rods and drills.

- A manual winch that raises and lowers the equipment when building up the working string with rods.

- Motor pump (not included).

- Swivel - one of the contour elements with a sliding type of fastening.

- Hoses for water supply.

- A petal or exploration drill in the shape of a cone, which is used to penetrate compacted soils and center the equipment.

- Control unit with frequency converter.

The presence of rods and drills of different diameters allows drilling wells of different depths and diameters.The maximum depth that can be passed with the MBU is 50 meters.

Water well drilling technology consists of several stages. A frame is mounted on the site, an engine, a swivel and a winch are attached to it. Then the first elbow of the rod is assembled with a head in the lower end, pulled up to the swivel with a winch and fixed in this knot. The elements of the drill rod are mounted on a conical or trapezoidal lock. Drilling tip - petals or chisel.

Now we need to prepare the drilling fluid. Near the installation, a pit is made for water or drilling fluid in the form of a thick suspension, for which clay is added to the water. Such a solution is poorly absorbed by the soil.

The intake hose of the motor pump is also lowered here, and the pressure hose is connected to the swivel. Thus, a constant flow of water into the shaft is ensured, which cools the drill head, grinds the walls of the well and softens the rock in the drilling zone. Sometimes an abrasive (such as quartz sand) is added to the solution for greater efficiency.

The torque of the drill rod is transmitted by a motor, below which the swivel is located. Drilling fluid is supplied to it and poured into the rod. The loosened rock is washed to the surface. Waste water is reused many times as it flows back into the pit. The technical fluid will also prevent water release from the pressure horizon, as back pressure will be created in the well.

As the well passes, additional rods are set until the aquifer is opened. After drilling is completed, a filter with casing pipes is inserted into the well, which are threaded and extended until the filter enters the aquifer.Then a cable with a submersible pump with a hose and an electric drive is lowered. Water is pumped until transparent. The adapter connects the source to the water supply.

This is interesting: Purification of water from a well - we learn from all sides

Flushing and pumping wells

Cleaning, flushing and pumping wells are different concepts. Flushing is performed by the drilling crew immediately after drilling and casing the well with pipes. Flushing is also used in case of well silting after a long downtime.

Flushing is the release of the internal space of the casing pipes and the annulus of the well from the drilling fluid after drilling or accumulated sludge after the downtime of the well.

When flushing inside the casing of pipes, a fire hose is lowered and water is supplied under pressure. This water rises along the wellbore, pushing the entire drilling fluid in front of it, washing it out. After the inside of the string is washed, a special cap with a fire hose screwed to it is put on the head of the casing string of pipes, and again water is supplied under pressure. By pressurizing the casing pipe, the water looks for a way out and finds it in the filter part of the casing string. Now the water rises through the annulus, flushing it. Now, after the entire pipe and wellbore are washed, the drilling crew made a test pumping out and showed that there is water in the well with a sufficient flow rate, they start pumping the well with a pump.

Pumping is mainly needed for wells drilled in sandy soils and clay.The purpose of pumping a well is to completely clean the aquifer from the remnants of the drilling fluid carried along the aquifer during drilling and the opening of aquifers smeared during drilling if the aquifer is on clay.