- The act of checking the readiness of the technical condition and the serviceability of the fire-fighting equipment for operation in winter conditions 20______ 20______.

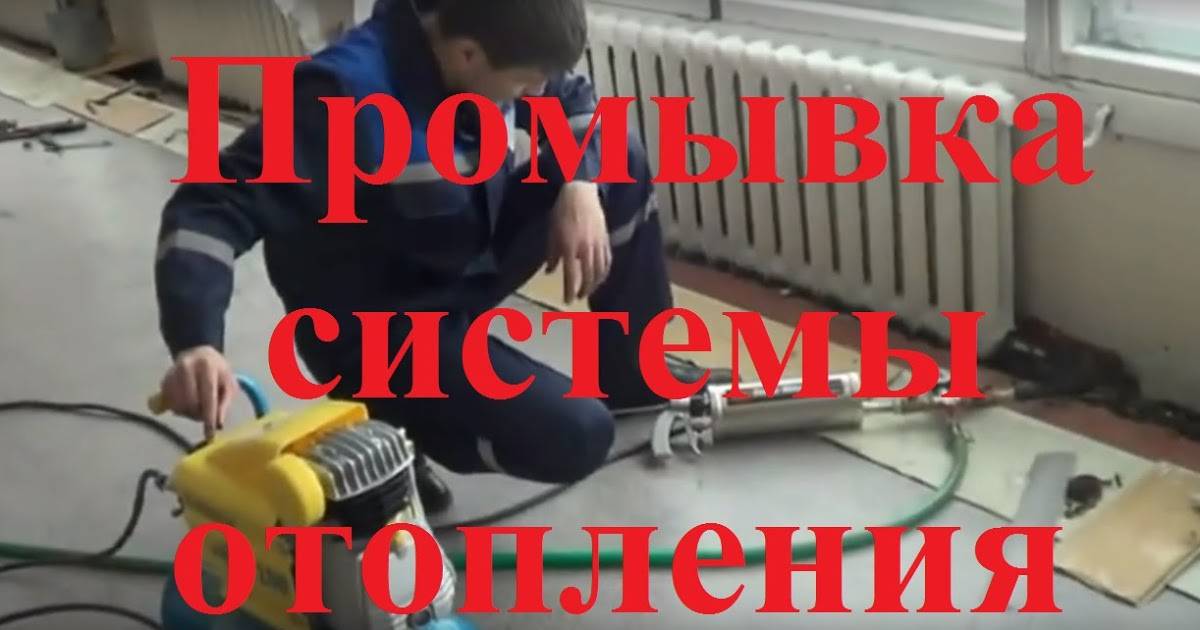

- The frequency of flushing the heating system

- The procedure for carrying out work on flushing heating

- Flushing step by step

- Chemical

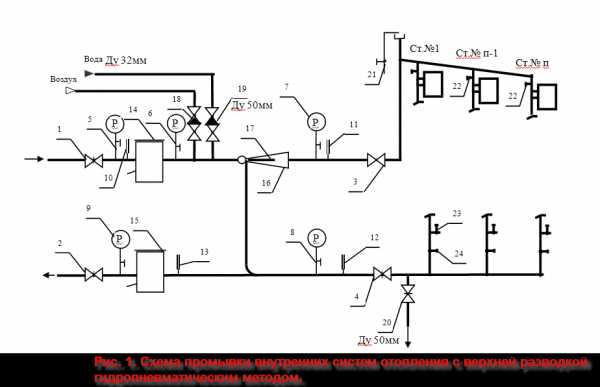

- hydropneumatic

- Hydrodynamic

- Pneumohydropulse

- Reasons for flushing the heating system

- Step-by-step instructions for an independent procedure for cleaning the coolant

- Various types of pollution

- The process of scale formation in the heating system

- Microbiological contamination

- Cleaning batteries with special equipment

- Pneumatic pistol "Typhoon"

- Installation ZEUS-24

- Apparatus Krot-Mini

- Radiator cleaning

- Washing with a special device

- Bath Rinse Algorithm

- Features of cleaning in a private house

- Features of flushing during the heating period

- Advantages and disadvantages

- Electropulse cleaning of the heating system: physics and nothing more

- How is electropulse cleaning performed?

- How and how to flush radiators and heating system

- Mechanical flush

- Chemical Wash Method

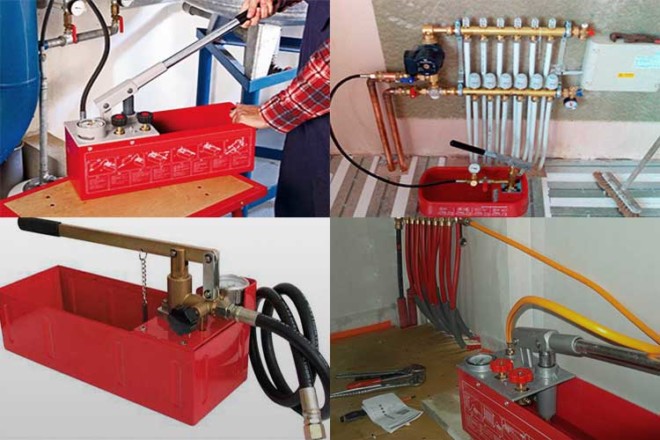

- Hydropneumatic flushing

- Pneumatic shock method

- biological flush

The act of checking the readiness of the technical condition and the serviceability of the fire-fighting equipment for operation in winter conditions 20______ 20______.

"____" _________________ 20____

| Address ______________________________________________________ Purpose of the object (residential, public, etc.) _________________________________________________ | ||

| Building ownership | ||

| (ZHSK, HOA, urban housing stock, etc.) | ||

| Floors _________________________________________________ Year of construction ______________ The main criteria for assessing the readiness of the technical condition and serviceability of the fire-fighting equipment of residential and public buildings for the new heating season: 1. Availability, maintenance and serviceability of primary fire extinguishing equipment: | ||

| 3. Availability, content internal fire water supply: | ||

| (available/absent, good/faulty) | ||

| 4. Availability, serviceability of automatic fire protection systems | ||

| (available/absent, serviceable/faulty) | ||

| 5. Availability, serviceability of means of warning people about a fire, control | ||

| fire evacuation: | ||

| (available/absent, serviceable/faulty) | ||

| (match/do not match) | ||

| 7. Carrying out fire retardant treatment of wooden structures of attic spaces (if any) after the expiration of the treatment (impregnation) and in case of loss of fire retardant properties of the compositions: | ||

| (passed/not passed, date of last processing) | ||

| 8. Operation of electrical networks, electrical installations and electrical products, as well as monitoring their technical condition in accordance with the requirements of regulatory documents on | ||

| power industry**: | ||

| (control is carried out / not carried out, meet the requirements / do not meet) | ||

| 9.Compliance with the legal instructions of the State Fire Commission on the elimination of violations of fire safety requirements in a timely manner: | ||

| (performed / not implemented, % of the fulfillment of prescription items) | ||

| Assessment by the responsible manager (owner of the building) of the readiness of the technical condition and serviceability of the fire-fighting equipment of residential and public buildings for a new heating | ||

| (done / not ready) | ||

| (Full name) of the responsible manager (owner of the building) | (signature) | |

* - for high-rise buildings (over 10 floors), an act of work performed and a copy from the register of maintenance work (MS) and scheduled preventive maintenance (SPM) are attached, indicating that maintenance has been carried out in accordance with the work schedule.

** - excerpt from the conclusion based on the results of measurements of insulation resistance and grounding of power and lighting electrical equipment with a defective statement attached.

preparation

and holding general meeting of shareholders 6) preliminary statement annual…

The frequency of flushing the heating system

According to SNiP, flushing the system is required annually. But there are different types of purges. Conventional hydraulic is carried out annually, with the addition of air - once every 2-3 years, and chemical - as needed, but not more than once every 5-7 years.

It is difficult to say to what extent the operating organizations adhere to such recommendations. But in individual systems, no one bothers to flush the heating system every two to three years. There is no need for annual processing. It is possible to drain a certain amount of coolant after the end of the season in order to assess its condition.If there are no “aromas” and precipitation, the time to flush the heating has not yet come.

The procedure for carrying out work on flushing heating

Firstly, there is a need to inspect the entire system and its individual parts. To do this, the butt joints of pipes, pipes with radiators, pipes with a boiler and a boiler, as well as pipes and instrumentation and automation are visually viewed. Joints are checked for water leakage. If any are found, then they must be repaired or replaced with new ones.

Secondly, before the start of the heating season, a test run of the system is carried out, during which the air accumulated inside the pipes and appliances is removed from it. For this, special air valves are used. Currently, experts recommend the installation of automatic air valves, which independently release air without human intervention until water flows out of the valve, after which the valve closes.

Thirdly, if a circulation pump is installed in the system, then it must be inspected, lubricated and turned on for testing.

Now you can start the process of flushing the heating. This is a serious operation, where you will have to accurately use the staging of the implementation.

- The water supply valve is closed, the electricity is turned off.

- Through the drain valve, which is installed on the boiler, water is drained into the sewer.

- To speed up the draining process, it is necessary to open the air valves on the heating radiators. Not all, but only those who are located above the rest. For example, on the second floor of the house.

- The water supply valve is opened, flushing is carried out until the water coming out of the drain valve is clear.

- Filling the system that starts with the boiler. For better operation of the heating system, it is necessary to add corrosion inhibitors to the water. To do this, the uppermost air valve is opened, through which inhibitors are added.

- Completeness of filling must be controlled by the level of water inside the safety tank. She should fill the tank only halfway. During operation, the water will heat up and expand in volume, which will lead to its pouring out of the system. Half the volume of the tank will be sufficient to prevent this trouble from occurring.

As you can see, the technology is quite simple, and you can safely do it yourself. But this is the easiest way that does not require the presence of special equipment, so it is not the most effective.

Flushing step by step

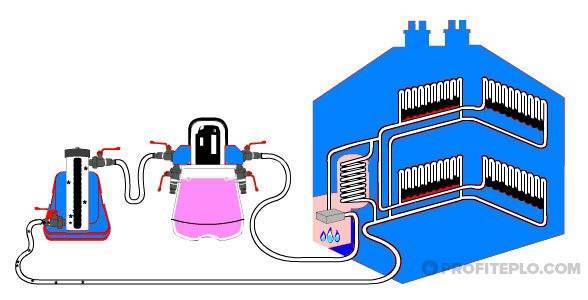

Chemical

The most effective and proven method is chemical. It is applied:

- when cleaning steel pipes of the gravity system;

- during the prevention of multi-storey buildings.

Chemical flushing is fairly easy to do. To begin with, the water is completely drained, and then a potent reagent is poured. A special pump circulates acid or alkali solutions through the pipes. It is not recommended to clean aluminum radiators with this method, since the reaction of this metal with a chemical agent reduces the strength of the product.

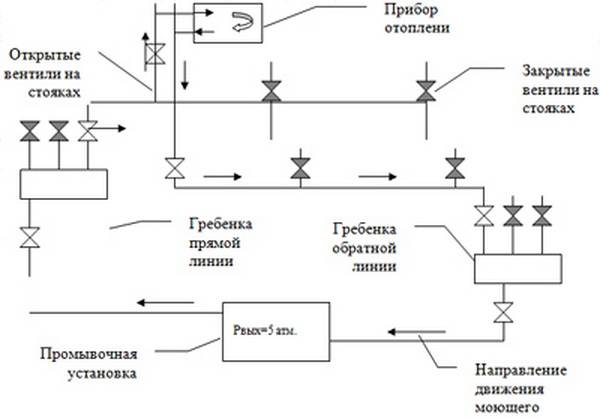

hydropneumatic

For hydropneumatic flushing, a compressor is required. The equipment is connected to a metering valve and supplies pressure from the supply to the return, and then vice versa. This technology shows a high performance result only when carried out correctly:

- You need to disconnect the radiator from the system.

- Drain the water.

- Clean the heating device, pipes.

- Assemble the system.

The process is easy to control by the appearance of the water, which should eventually become clean and transparent. After cleaning the group of risers, the heating switches to reset and the return line opens. Then the flush is repeated, only in the other direction.

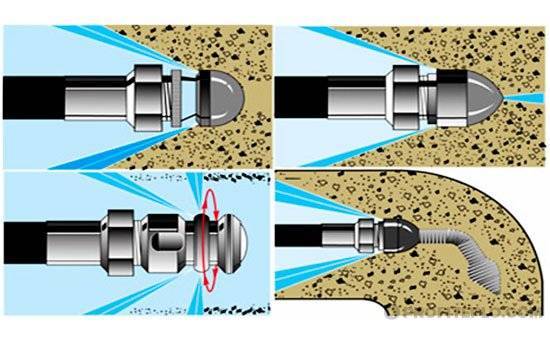

Hydrodynamic

The hydrodynamic method is based on the removal of deposits using special nozzles under high pressure. It differs from other methods in that it is absolutely environmentally friendly and is ideal for cast iron radiators. Under the influence of the installation, it is possible to clean the most clogged pipelines without violating the tightness and without harming the environment. Strong water pressure copes with almost all types of blockages.

Having hydrodynamic equipment, you can flush the system yourself:

- It is necessary to select a nozzle and set the working pressure. When doing this, make sure that excessively high pressure does not burst the pipes.

- Assemble the device and insert it into the pipeline.

- Start the car.

- When the hose has passed to its full depth, the equipment can be turned off.

After the manipulations, the system is well washed with water.

Pneumohydropulse

This washing is carried out with the help of an air gun by means of multiple impulses. During the process, cavitation bubbles are formed, due to which scale is easily separated from the pipe walls. Spot cleaning in this way can be done without removing the radiators. At the same time, various deposits from heating devices are completely removed. This procedure can be carried out during the heating period.

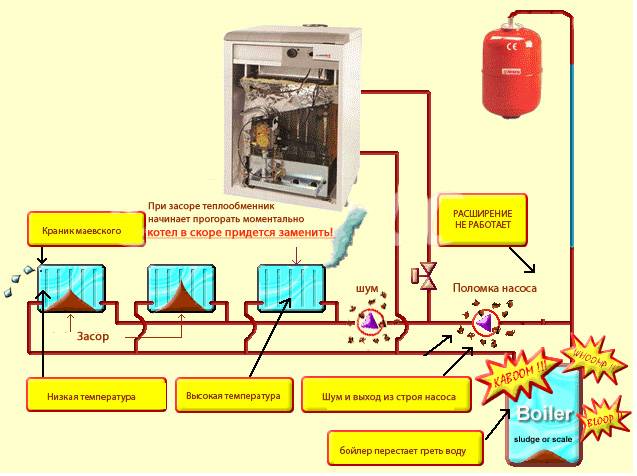

Reasons for flushing the heating system

The efficiency of space heating can decrease as a result of two inevitable processes, this problem is especially relevant for apartment buildings. The fact is that over time, deposits form in radiators and in pipelines that have a horizontal arrangement. The problem usually occurs in areas where the coolant moves slowly - in places of spills, in the supply to radiators and in these devices themselves.

But where do deposits come from and what are they? The coolant moving along the heating main carries rust particles, sand, scale formed during welding. CHP during the heating period heats large volumes of water used, and it is not possible to filter them ideally.

As soon as the gap in the pipe practically disappears, the circuit section may cease to function. Therefore, the owner of an apartment or house needs to know how to properly flush the heating system and how often. This measure should restore the efficiency of heat supply.

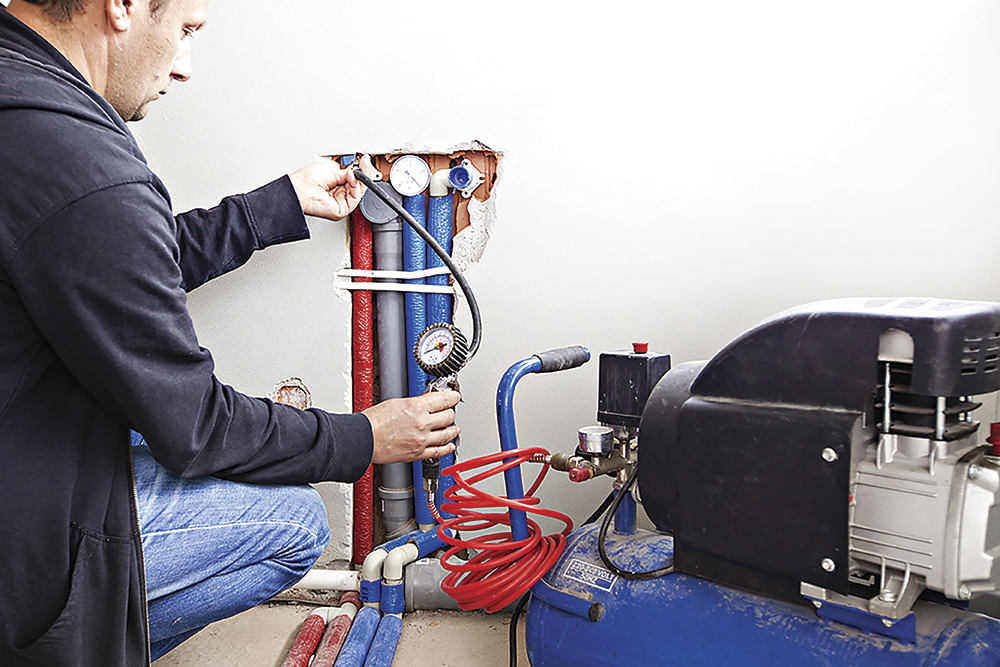

Step-by-step instructions for an independent procedure for cleaning the coolant

It is possible to clean the artificial heating system of a building without a third-party organization. This will require a pneumatic diaphragm pump capable of raising pressure above 6 atmospheres. Before starting the operation, it is necessary to close all the valves, unscrew the end caps of the radiators with a wrench.

Algorithm:

- Close the resource drain valve.

- Connect the diaphragm pump to the valve located after the stop valves.

- Discard the used coolant.

- Turn on the diaphragm pump, raise the pressure to 6 at.

- Open the system valve.

- Turn off all house heating risers in turn. No more than 10 apartment highways should be closed for one run.

After the operation, through the return line, you need to connect the pump to the carrier inlet to the building. However, before this, it is necessary to drain the heating. After high-quality processing of the contour, the water should come out clear.

Various types of pollution

The term "sludge" is often used to describe all the various contaminants in a central heating system. Different types of contaminants can be caused in different ways, and in some cases require special methods to remove them.

Sludge is typically a mixture of corrosion caused by products such as rust or magnetite (magnetite is black magnetic corrosion caused by a product derived from steel when corroded in an oxygen environment), scale from hard water, and particulate matter that enters into the system until it is filled with water. Silt can also include microbiological formations - fungus, etc.

The process of scale formation in the heating system

When the water is heated, insoluble calcium carbonate is formed, which can then turn from suspension into deposits on the internal surfaces of the system (this is often referred to as "limescale").

Scale most often forms in the boiler heat exchanger, and can also accumulate in other parts of the system, often in places where water circulates more slowly.

Under normal operating conditions, non-bicarbonate or "permanent" hardness salts, such as calcium sulfate, remain in the heat transfer fluid, but at higher heat exchanger surface temperatures, their solubility rapidly decreases and scale can form.

The likelihood of scale formation is greatest in those regions where water hardness and its bicarbonate alkalinity are high. Scale formation will be most pronounced if there is a high rate of water loss from the heating circuit, requiring frequent additions of fresh water to the system.

Scale in the heat exchanger will have a negative effect on the heat transfer efficiency of the boiler. Scale also affects the noise of the heater. Sooner or later you will have to think about flushing the heating system

Microbiological contamination

Microbiological organisms range from simple bacteria to fungal and yeast spores. All this can cause problems in the operation of the central heating system.

The most likely site for microbiological growth is in the expansion tank of an open vented system. Here, the temperature conditions are more favorable for the growth of bacteria, since there is contact with air. Aerobic bacteria, fungus and mucus that have formed in the tank can enter the make-up water system and gradually clog the heating circuit with sludge. Such debris can cause clogging of the heating system, and can lead to fouling of the boiler heat exchanger.

Underfloor heating and other systems that operate at lower temperatures (typically below 60°C) may also be susceptible to microbiological contamination. Although it happens that even a high temperature in the boiler heat exchanger may not be enough to destroy all microorganisms.

Anaerobic bacteria can thrive in both open and closed systems contaminated with corrosion and other debris – under sediments where temperatures can be cooler and oxygen is absent.This can lead to microbiological corrosion of both steel components of the heating system and components made of non-ferrous metals. The heating will need to be flushed again.

Cleaning batteries with special equipment

Cleaning cast-iron batteries without removing them from their place can be carried out using special equipment. The following complex equipment is designed for domestic needs:

- pneumatic gun "Typhoon";

- device for electrohydropulse impact ZEVS-24;

- apparatus for cleaning Mole-Mini.

Pneumatic pistol "Typhoon"

Flushing the battery with a Typhoon air gun

The equipment is compact and easy to handle. It is used to perform a point impact on blockages in water and sewer pipes with a diameter of up to 150 mm. The essence of the process is a hydraulic ram to remove hardened deposits from the walls of the equipment and adjacent risers with a shock wave at a speed of 1.5 km / h, which extends to a distance of 60 meters.

Pneumatic gun "Typhoon" in operation

Such cleaning of the heating system allows you to cleanly remove contaminants that are not amenable to conventional hydraulic flushing.

"Typhoon" is indispensable as a plumber's tool for cleaning blockages in various hard-to-reach places. Depending on the configuration and weight, the device has 6 modifications and the following indicators:

- cleaning inner diameter up to 150 mm;

- the maximum firing range to the object of influence is 60 m;

- special valve design for kinetic ramming;

- manometer on the body;

- Possibility of manual loading.

Complex flushing of heating batteries

As a rule, "Typhoon" is used in combination with an automatic installation ZEUS-24 and a device for cleaning hard-to-reach objects Krot-Mini.

Installation ZEUS-24

ZEUS-24 has small dimensions and sufficient power to destroy hardened heating devices, internal and external water supply and sewerage networks that have firmly adhered to the inner walls. The essence of its work is based on electrohydropulse impact on solid pollution in pipes with a diameter of 7 to 150 mm. The electric discharge created by the device leads to the appearance of a shock wave and powerful hydrodynamic flows that act on hardened blockages, scale and deposits.

The procedure for hydropneumatic flushing of heating radiators (batteries)

- destruction of blockages of any strength;

- safety of the cleaned equipment;

- cleaning of hard-to-reach bent and spiral pipes;

- wear resistance of manufacturing materials;

- safety switch on the plug.

Apparatus Krot-Mini

The device has the following advantages:

- the ability to work with various drums and spirals with a diameter of 6 to 13 mm;

- easy procedure for replacing the drum;

- to facilitate work, the distribution pipe is located inside the drum;

- automatic feed of the spiral;

- strong and flexible helix of hardened steel cable wrapped with hardened steel wire;

- high torque allows you to remove persistent dirt;

- standard equipment consists of 4 different nozzles that allow you to perform a complete cleaning of pipes and removal of foreign objects;

- for use in wet rooms, the device is equipped with an RCD.

Flushing of heating batteries with the Krot-Mini device

How to provide warmth and comfort in your home depends on the choice and preferences of everyone. Can extend the life of old equipment or replace it with a new, more modern one.

Radiator cleaning

Imagine what the cleaning procedure will look like under different conditions.

Washing with a special device

For quick and efficient cleaning of radiators "on the spot" there are special devices for flushing them. Of course, having such a device for infrequent cleaning of a home battery is, in fact, a luxury.

The device works from the mains - with a powerful jet it drives water into the radiator, which, with its pressure, removes scale, rust, grease, and various chemical deposits. But if you don’t have this device, you can replace it by cleaning the radiator in the bath.

Bath Rinse Algorithm

How to flush the batteries in the apartment without being able to pull them out into the street? The instruction will consist of the following blocks:

- Hot water inlet. You will need to use a hose, a shower, a watering can, a kettle with a narrow spout, or an ordinary funnel to pour hot water into the radiator. Open both plugs so that dirty water can flow freely from them. After there is enough liquid in the battery, shake it and pour out all the contents. The action should be repeated until large pieces of dirt fly out of the cleaned radiator. It is worth noting that the procedure is difficult to perform alone - the weight of the battery is significant even for a brave athlete. Therefore, 1-2 assistants in this matter are vital for you.

Filling with cleaning agent. The second step is to pour the substance you have already chosen for flushing into the radiator, diluting it with water

Now it is important to put plugs on all the holes in the battery so that the “useful liquid” does not leak out of it. Depending on the drug, it is left to "sour" for a period of 2 hours.

As soon as the time of action of the active component has come to an end, it is necessary to shake the radiator again. You can knock on its various parts with a wooden, plastic, rubber mallet

This will help to further remove rust and other contaminants from its internal parts.

You can knock on its various parts with a wooden, plastic, rubber mallet. This will help to further remove rust and other contaminants from its internal parts.

Now it is important to thoroughly wash the cleaning agent. Therefore, it is necessary to clean until the foam stops coming out, the smell stops being felt, or the rest of the characteristic features of its presence appear in a different way. If you do not flush the radiator to the end, then the active components of the product will continue to act, destroying the metal from the inside, which will cause leakage and failure of the battery.

If you do not flush the radiator to the end, then the active components of the product will continue to act, destroying the metal from the inside, which will cause leakage and failure of the battery.

The videos in this article will show you how to follow the instructions visually.

Features of cleaning in a private house

Flushing batteries in your homes is even more important than in apartments. This is due to a number of features of heating:

- The coolant is water from a well, a well, or even a reservoir. Hence, there is more coarse dirt stuck in the radiator than in the water circulating through the mains of urban heating systems. Therefore, the need for cleaning arises much more often.

- Not only the radiator is washed (purged), but also the heating main. After all, all the debris stuck in it will invariably fall into the cleaned battery.

- In case of urgent need, you can clean the radiator during the heating season. In a different state of affairs during the cold period, it makes no sense to turn off the heating system for cleaning.

Features of flushing during the heating period

If you decide to clean the battery in the cold season, then pay attention to the following:

- The method of cleaning, as well as detergents, are the same.

- It is possible to flush the radiators (in a private house) without removing them and without draining the water from the heating boiler:

- Turn off the steam line completely while cleaning.

- Perform a purge.

- Put all the valves back, then let the water through the heating circuit.

- Feed it until absolutely clean water flows out of the pipeline.

The measures taken will clean not only the radiator, but the entire heat pipeline in general.

Thus, it is possible to clean the radiator without removing it only in your own home. Residents of apartments to clean the battery from the inside will have to remove it. An exception for those who have a special apparatus for cleaning batteries.

Advantages and disadvantages

From the end of the 18th century, when Bonnemann proposed the prototype of modern heating systems, to the present day, the world industry offers various means for the effective cleaning of pipelines and radiators. The industrial era has significantly changed approaches to the cleaning process. Manual work and labor-intensive operations have sunk into oblivion - flushing pumps have entered the service of specialists.

For two and a half centuries, history has offered various ways to remove scale. But today the equipment of the following principles of operation is considered effective:

- Unit for flushing the system with chemical reagents.

- flushing pump for descaling pneumohydraulic method.

- Hydro-pneumatic devices for cleaning pipes and radiators.

Experts believe that the ideal methodology does not exist, since each method has unique advantages and disadvantages. For example, chemical cleaning is considered low-cost, so it is used most often. But an aggressive solution is not suitable for aluminum radiators, and spent reagents need to be carefully disposed of.

The flushing pump of the hydro-pneumatic impact type, due to the kinetic impact at a speed of 1500 m / s, perfectly copes with scale and mud blockages. And, nevertheless, the device will not be able to clean the system, which has a length of more than 60m. Specialists use similar units to clean the heating system of a cottage and risers in an apartment building.

Electropulse cleaning of the heating system: physics and nothing more

To clean the system with electrical impulses, you will need a special device that will generate them. A regular coaxial cable is connected to it. At its opposite end, a charge is formed, which forms a discharge that contributes to the separation of scale and salts from the walls of radiators and heating pipes.

The impulses from this device do an excellent job with scale inside the pipes.

The impulses from this device do an excellent job with scale inside the pipes.

How is electropulse cleaning performed?

For such cleaning, no action is required on the heating system.All that is needed is to connect the coaxial cable to the radiator and turn on the device for a certain time (depending on the model). After the end of the cycle, it is only necessary to completely flush the heating circuit, removing the exfoliated scale from it.

This method has no effect on the pipes and radiators themselves, which is also important. In addition, the dismantling of radiators is not required, and the exfoliated slag can be safely poured into the sewer without fear for the environment.

It is best to get rid of blockages in the initial stage.

It is best to get rid of blockages in the initial stage.

How and how to flush radiators and heating system

The process of cleaning the heating system at home is not complicated, any owner can cope with it.

There are several ways to clean the heating network in a private house with your own hands:

- mechanical washing;

- dry cleaning;

- hydropneumatic washing;

- method of pneumohydraulic impact;

- biological washing.

Mechanical flush

This method of flushing heating systems requires a complete disassembly of all communications - before cleaning the elements, you will have to remove every detail of the system. The complexity of the method lies in cleaning the internal surfaces of pipes and batteries from scale and rust manually using metal brushes. Nowadays, it is practically not used, as it requires a significant investment of time and effort.

Chemical Wash Method

Cleaning the system requires connecting a pump with a container filled with chemicals. The detergent dissolves and exfoliates contaminants adhering to the pipe walls.

For chemical cleaning, two types of liquids are used - acid or alkaline, depending on the material from which the pipes and batteries are made, as well as the type of deposits.Chemistry is recommended to flush the heating system also in cases where it is too difficult to remove the elements of the system.

Alkaline or acid based flushing fluid should not be used on aluminum batteries due to the fact that the metal reacts with chemical compounds. It is also forbidden to clean depressurized systems, since the chemical flushing agent is toxic and can be harmful to health.. For the same reason, used liquids cannot be drained into the sewer, and work should be done with rubber gloves and a respirator.

After chemical cleaning, all contaminants will be completely removed, the service life of the system is extended.

Hydropneumatic flushing

This method consists in treating the internal surfaces of batteries and pipes with a flow of a mixture of air and water supplied under high pressure. Flushing the heating system in this way is highly efficient, but its use requires special equipment.

Hydropneumatic cleaning has proven itself when working with old-type cast-iron radiators, still Soviet-made. Cleaning with water and air does not impose any strict requirements on the elements of the heating system, as a chemical method, that is, it is equally suitable for all types of materials and pipes. Despite the high cost compared to the chemical method, it is completely safe and more effective.

It is recommended to treat batteries before cleaning with a special composition that softens the crust of contaminants.

Pneumatic shock method

This method is the fastest (takes no more than an hour), convenient, since it is not necessary to dismantle the elements of the system, but requires the use of special equipment.

Special equipment is attached to the ends of the heating communications - a pneumatic gun, with the help of which a pneumatic-hydraulic impulse is supplied to the pipeline, which peels off contaminants adhering to the walls of pipes and batteries.

Despite the serious and frighteningly complex name, flushing pipes in this way is absolutely safe, since a force of no more than 2% of the pulse power is applied to the walls, and the main blow falls on pollution.

biological flush

At its core, this method is very similar to the chemical method, only high-tech solvents and wedging biological products are used instead of dangerous reagents. Under their influence, the crystalline bonds of pollutants are destroyed, corrosive and organic deposits are cleaned off.

The flushing biomaterial is produced on a water basis, and their use allows you to completely clean the heating network in an apartment building and in an individual dwelling.