- Types and forms

- Infrared gas heaters - pros and cons

- How to make a gas heater for a garage with your own hands

- Features and principle of operation of a gas infrared heater

- Varieties of industrial IR heaters

- Gas

- Electrical

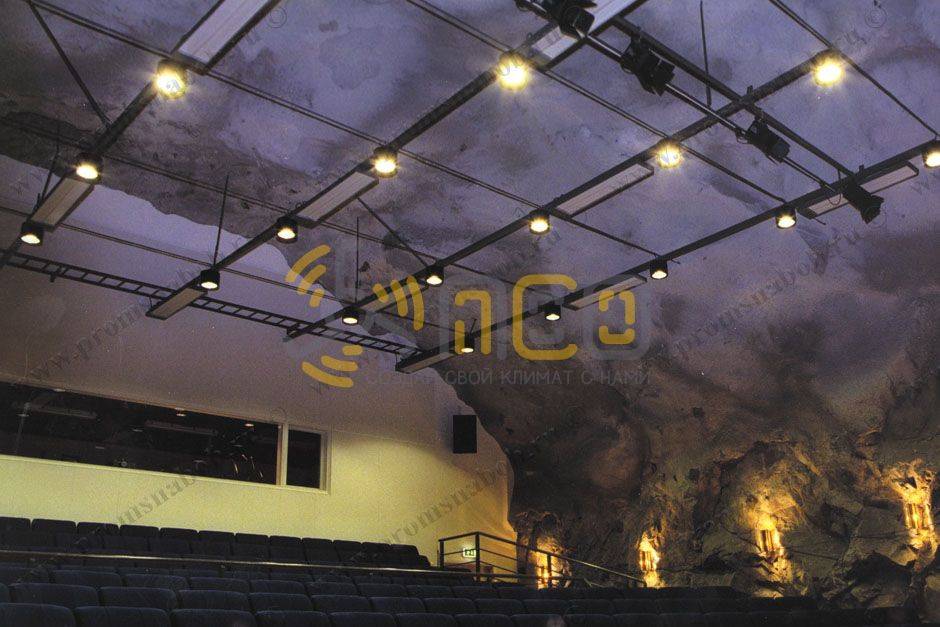

- Infrared heating systems system on infrared emitters

- Gas infrared space heaters

- Light gas heater

- Infrared gas heaters can be dark

- Energy saving

- How to choose a gas infrared ceramic heater

- How to choose an infrared heater for a summer residence

- How to choose an infrared gas heater for the garage

- Gas: dark, light emitters

- Operation of infrared heaters

- How it workscolor>

- Application featurescolor>

- Gas industrial infrared heaters

- Types of gas heaters from a cylinder

- Small-sized floor

- Built-in cylinder heaters

- Outdoor heaters

- Combined heaters

- Catalytic heaters

- Tent heaters

Types and forms

There are many types of gas infrared heaters. There are very simple, inexpensive, with little power. They are more suitable for camping life, for temporary use or as an option for emergency situations.There are more "civilized" ones that do not spoil the interior. They have more security systems, but the principle of operation remains the same.

Different types of gas infrared heaters and their prices

According to the area of \u200b\u200buse, they can be divided into several groups:

- for outdoor use;

- for premises.

Units for rooms are distinguished by the presence of a larger number of sensors that monitor the state of the air and the performance of the unit. Also in the heaters for rooms there is an automatic system with which you can adjust the temperature. The street usually has more power. There are gas infrared heaters for industrial premises - their power can be even greater than that of outdoor ones.

Outdoor options for gas infrared heaters can have a different shape

According to the installation method, you can find the following:

- nozzle for a gas cylinder;

- mobile (portable);

- ceiling;

- gas infrared fireplaces.

Of all, the most "civilized" look is infrared gas fireplaces. This is a fairly large case, which fits a standard gas cylinder of 27 liters. The total mass of the units is quite solid, so for ease of movement they are equipped with wheels.

The most civilized of gas infrared heaters

The cheapest ones are a cylinder attachment, a little more expensive are hiking ones, which are a small metal case with a ceramic heater. There are hiking options that are connected to the cylinder, there are options that are combined with fuel tanks. In any case, these are very inexpensive installations.

Mobile infrared gas units

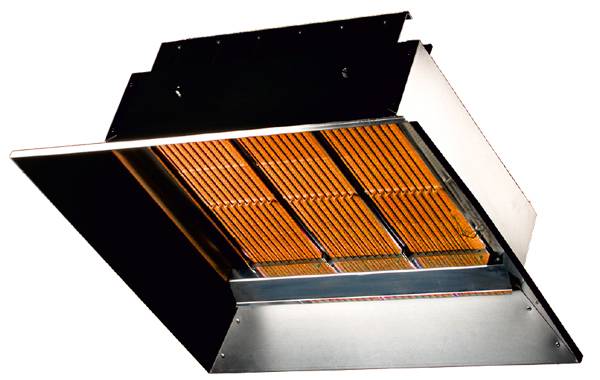

Ceiling options are more often used for industrial premises, heating of greenhouses, warehouses, etc. They are rarely used in everyday life, since it is not very convenient to pull the gas pipeline to this heater. Hidden laying is not possible, and pipes in living quarters are appropriate only in a loft style.

Ceiling - the best infrared gas heaters for a warehouse

If we talk about temporary space heating, you can use any mobile model. If they are needed as permanent heating or will be used frequently, it is better to choose models with air analyzers, flame control and other protective systems. These are more expensive models, but they guarantee safety.

Infrared gas heaters - pros and cons

Infrared gas heaters, like any heating equipment, have a number of advantages and disadvantages. First, we will look at their positive features and find out why they are so good:

Despite the variety of models of IR heaters, all of them can be installed both at home and on the street.

- autonomous operation - such devices operate only on gas and do not require connection to the electrical network (this applies to the vast majority of models);

- low noise level - despite the presence of burners, the noise level generated during the combustion of fuel remains extremely low;

- compact dimensions - due to their small dimensions, gas heaters are easily transferred from place to place without any effort;

- versatility in use - gas devices can be used to heat rooms and open areas;

- the ability to work in areas where there is no main gas pipeline - you can connect / install a cylinder and power the device from it;

- high degree of fire safety - despite the fact that this is gas equipment, it is safe. You can not be afraid of fires;

- no emission of toxic substances - during the combustion of gas, water vapor and carbon dioxide are formed;

- efficient heating of open areas - no other heating equipment is capable of this;

- fast warm-up - provided by efficient generation of infrared radiation.

For lovers of hiking and picnics, the fact that you can even cook food on IR heaters will be a definite plus.

Gas infrared heaters perfectly warm rooms and open areas, are easily connected to gas sources, do not require permits - you can purchase and use it without asking anyone for permission.

Some people use them not only for heating, but also for technical needs - for example, for drying any things and objects, as well as for eliminating frost and warming up rooms after a long period of inactivity in frosty conditions (relevant for summer cottages).

Next, we consider the disadvantages of gas infrared heaters:

the need for good ventilation - arises when using such devices indoors;

it is necessary to strictly follow the rules of operation - despite the fire safety, it is still necessary to comply with safety regulations and caution in use;

cannot be used where there is no gas - if bottled gas is not available in your area, the operation of heaters will become difficult. Say what you like, but electrification in our country is more common than gasification .. Despite the presence of certain disadvantages, home and street heaters continue to be in demand among consumers

Despite the presence of certain disadvantages, home and outdoor heaters continue to be in demand among consumers.

How to make a gas heater for a garage with your own hands

The price of a gas heater for a garage is not always acceptable, and in some cases you have to rely only on your own strength. Independent design of heaters has long been tested, and simple and understandable instructions have been compiled for craftsmen.

Homemade ceiling gas heater in the garage

Here are a few simple rules to keep in mind before you even get started:

The main requirement for both factory and home-made gas appliances is safety.

Give it as much attention as possible.

It is better to purchase ready-made (factory) elements that are responsible for supplying and shutting off gas, as they determine the safety of using the entire structure.

The simpler the mechanism of operation of the device, the better.

Pay attention to economy, otherwise the use of such a device may cost you dearly.

Use inexpensive, but high-quality components that will serve as a reliable basis.In order to make a high-quality heater with your own hands, you will need the following parts: a sheet of metal, scissors, rivets and a riveter for their installation, a fine metal mesh, a sieve and a gas cylinder

In addition, you can not do without a special burner equipped with a valve

In order to make a high-quality heater with your own hands, you will need the following parts: a sheet of metal, scissors, rivets and a riveter for their installation, a fine metal mesh, a sieve and a gas cylinder. In addition, you can not do without a special burner equipped with a valve.

First of all, you need to attach a heater to the burner. To do this, a sieve attached to a metal sheet is circled with a marker. After that, parallel and perpendicular to each other, you need to draw rectangular ears. In this case, one of them should be 2 times longer than the rest. Then, using scissors for metal, you need to cut out the resulting pattern.

Kovea Isopropane Gas Cylinder

After that, the elements must be fastened together: the burner is attached with bolts to a metal circle that has been cut out. The ears are wrapped in opposite directions, and a strainer is attached to them, which will act as a diffuser. This is a ready-made element of a homemade heater.

Next, you can proceed to the fastening of the metal mesh. For this purpose, it is necessary to once again draw a circle with ears on a metal sheet and then cut it out. Next, you need to fix the mesh, which is attached to the ears of each of the circles, forming a mesh cylinder.

When all the elements are ready, you can connect them together and connect the finished product to a power source.

Assembly steps for outdoor infrared heater Ballu BOGH-13

If you cannot afford to manufacture the device yourself, then the main thing you should focus on when choosing a gas infrared heater from a cylinder is customer reviews, as well as the technical specifications indicated by the manufacturer. Be sure to consider exactly where you plan to use it, as well as for what purpose. If you devote enough time to choosing the right model, then the purchased device will certainly meet all your expectations.

Features and principle of operation of a gas infrared heater

Heating equipment warms in two ways - thermal (infrared) radiation and by heating the air. The first method is involved in gas infrared heaters, which are actively used to heat open areas and premises for various purposes. They do not heat the air, but the surrounding objects, creating warm and comfortable conditions for a long stay of people.

Gas infrared heaters are most often used for heating outdoor areas, but nothing prevents them from being used for space heating. If you like to arrange evening gatherings with tea in the open air or on the veranda, then this unusual equipment will be a pleasant gift for you. It will create a warm zone in which adults and children will be comfortable.

Gas-powered infrared heating devices will become indispensable for heating areas with swimming pools, industrial premises, summer verandas, open areas of street cafes, sports grounds and residential premises.The powerful infrared radiation generated by these devices will allow you to quickly warm up the surrounding objects and warm people, consuming a minimum amount of gas fuel.

The device and principle of operation of a gas infrared heater.

How are gas infrared heaters arranged? Inside them we will find:

- burners with ignition system;

- emitters - they generate heat;

- control circuits - they regulate the gas supply.

The task of a gas infrared heater is to generate infrared radiation. For this, ceramic and metal elements are used here, heated under the influence of an open flame. When heated, they become a source of thermal radiation that heats the surrounding objects.

To form a certain zone of influence, some models are provided with reflectors that ensure the directionality of infrared thermal radiation.

The device evenly heats the surrounding objects at a distance of several meters from it.

The infrared radiation that occurs during operation warms up the surrounding objects, which is why they begin to give off heat. It is felt even at a distance of several meters, allowing you to heat large spaces. To increase efficiency, some models use additional fans that increase the intensity of flame burning.

Due to their design and principle of operation, such models are used for heating restaurant terraces, open courtyard areas, summer verandas, as well as residential and industrial buildings.

As already mentioned, heat is generated by burning gas - it is stored in built-in or plug-in cylinders.One filling, depending on the power of the burner and the capacity of the cylinder, can last for 10-15 hours of continuous operation. Due to the fact that gas combustion is carried out in an open form, heaters are installed only in well-ventilated places.

If you plan to heat the premises with such a device, do not forget to open the vents - the combustion products (there are not very many of them) should be freely removed outside by a natural draft.

Varieties of industrial IR heaters

Currently, gas and electric industrial infrared heaters are distinguished, which, in turn, are divided into several types, based on the type of fasteners:

- wall;

- floor;

- ceiling.

Wall-mounted models are designed for small-sized rooms, they are mounted on the wall, to a height of 2.5-3 meters.

Ceiling heaters are used to heat rooms, large in size. The power of such devices is high, they are mounted at a great height, on suspensions or torsos.

The IR heater is floor-mounted, it is not common, such a unit is a single stand with radiators attached to it. Scope of application - spot heating.

Gas

Such devices are highly economical. Under the condition of constant work, such devices fully pay off in 1-2 heating seasons.

Industrial-type infrared ceiling heaters operating on gas can be divided into two categories:

Light emitters - used to supply heat to industrial premises, where the ceiling height starts from 4 meters and above. Models are considered among the most effective.The principle of operation is based on the combustion of a mixture of gas and air in a special burner at a temperature of 800-1000°C. Combustion products are removed through the drainage channel.

Dark emitters - the process of gas combustion is carried out at a temperature of 350-400 ° C. As a result, the metal tube, which acts as an emitter, does not glow red-hot, and this contributed to the name of the device.

When fastening dark-type heaters, it must be taken into account that the emitters have a larger mass than light-colored heaters.

For industrial premises, heaters of either a light or dark type are selected. The choice is influenced by the technical characteristics of the building itself (ceiling height, good air circulation), as well as the type of production activity.

Advantages of gas heaters:

- the possibility of local heating of premises;

- reduction of heat loss;

- payback comes very quickly;

- there is no need for any costs for the maintenance of the boiler room personnel.

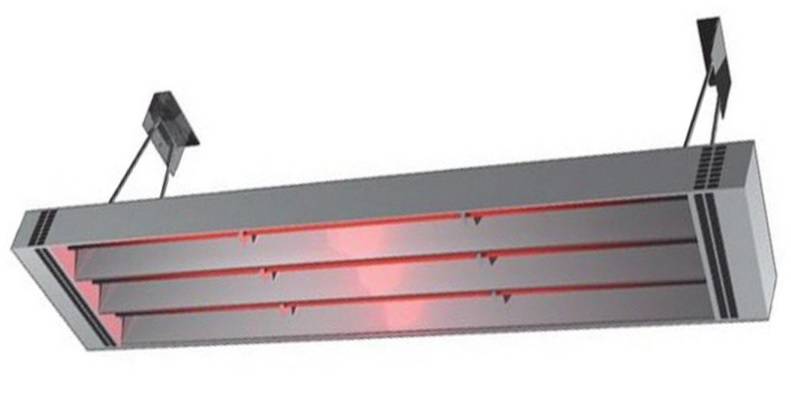

Electrical

Wall-mounted and floor-mounted units are used for local and general space heating inside and outside buildings. Depending on the principle of operation and design features, the following types of devices are distinguished:

- According to the type of mounting, electric infrared heaters are ceiling, floor, wall or universal, which can work anywhere with the same efficiency. Stationary and mobile installations are distinguished, which are very popular with construction teams.

- According to the principle of operation, emitters are distinguished that emit short and long infrared waves.Short-wave heaters are actively used for drying wood and equipment for painting booths.

Short infrared waves adversely affect human health. Therefore, installation in a room with a constant presence of people industrial electric short-wave infrared heaters is strictly prohibited.

Radiators that use long waves have a beneficial effect on people's health, so they are easily mounted in production workshops. Long-wave heaters act as the main source of heat in the winter.

Infrared heating systems system on infrared emitters

basis infrared heating system are infrared heaters. The principle of their operation is based on the fact that the energy of the burned gas or electricity is converted into the energy of thermal radiation.

Advantages: the ability to direct heat directly to the desired area and heat individual local areas in large volumes.

Disadvantages: if it is necessary to warm up the entire volume of air in the room, the efficiency of the devices is greatly reduced; radiating surfaces heated to high temperatures are located directly in the heated room, which can lead to a fire; emitters operating on natural gas require a complex and extensive gas supply system, which greatly increases the cost of the entire project; gas emitters burn out oxygen from the room, which leads to the need for ventilation; emitters powered by electricity consume a lot of electricity, which is uneconomical; possible deterioration of the well-being of personnel exposed to direct radiation.

Radiators are effective only when several local working areas need to be heated pointwise in a large volumetric room, the efficiency of their use for heating the entire volume of the room as a whole is extremely low.

Gas infrared space heaters

In this chapter, we will briefly analyze the principle of operation, the pros and cons of these devices. The principle of operation of this device is based on the operation of a gas burner. The gas, mixing with oxygen, burns in a closed chamber and heats a ceramic or metal plate up to 9000. The heated plates produce infrared radiation and the room is heated. Radiators are called thermal because of the sensation of heat. There are two main principles involved here:

- The level of heating of the surface of the plates affects the amount of radiation. This principle is called diffuse radiation. Plates - emitters can be heated by a stream of hot air or gas burners. Here, the gas burns in a closed chamber and does not come into direct contact with the infrared emitter.

- In the second method, the gas is completely burned on the ceramic grids, before passing through them. In this space, the burning gas is in contact with the emitter.

Gas heaters are divided into light and dark.

Light gas heater

Light gas heater

Light gas heater

The combustion temperature is more than 6000 and the combustion of the gas-air mixture occurs on a ceramic or metal mesh or plate - this is a light heater.

About 40% of the rays go to the light effect, they burn like lanterns. Only 60% goes into heat. Another disadvantage of this type is that the exhaust gases from the combustion of the mixture remain indoors.It is possible to use ventilation located in the upper part or by equipping local ventilation. All this reduces the level of heating of the room.

It consists of the following equipment:

- burners;

- plates made of ceramic or metal with holes;

- reflector;

- automatic control systems;

- mixing chamber;

- flame ignition systems;

Infrared gas heaters can be dark

Infrared gas heaters

Infrared gas heaters

When the heating temperature is less than 6000, the shape of the heating element in the form of a pipe is the main difference from the light heater.

But the most important advantage of the black type is the combustion of the gas mixture in a closed circuit. Additional ventilation is not required.

Consists:

- heat reflector;

- ceramic pipe, on the surface of which infrared radiation occurs;

- automatic control unit;

- reduction device;

- gas-burner;

- gas ignition device;

- smoke exhaust fan.

It is important. Before purchasing equipment, it is necessary to calculate the power of the infrared heater by the area of the room

100 W of heater power is required per 1 m2.

When using gas infrared heaters, certain safety conditions must be strictly applied:

- Power calculation before purchase.

- It is installed only in industrial facilities or in rooms with natural ventilation.

- Additional and sufficient air ventilation system.

- The distance to combustible materials must comply with established fire safety standards.

- An infrared gas heater for an industrial type room is the best and most profitable solution to the problem of heating.

Energy saving

Due to the aggravated economic situation in the country, relevant for all enterprises, they began to pay more money to pay receipts for the use of electricity and gas. Industrial organizations suffer great damage due to improper distribution of heating devices on their territory. Often, heat is distributed unevenly, which is why where it should be warm, it is actually cold and vice versa. As a result, financial losses do not justify themselves in any way, and it is necessary to look for solutions to this problem. One of them is the replacement of old heating systems with infrared heaters.

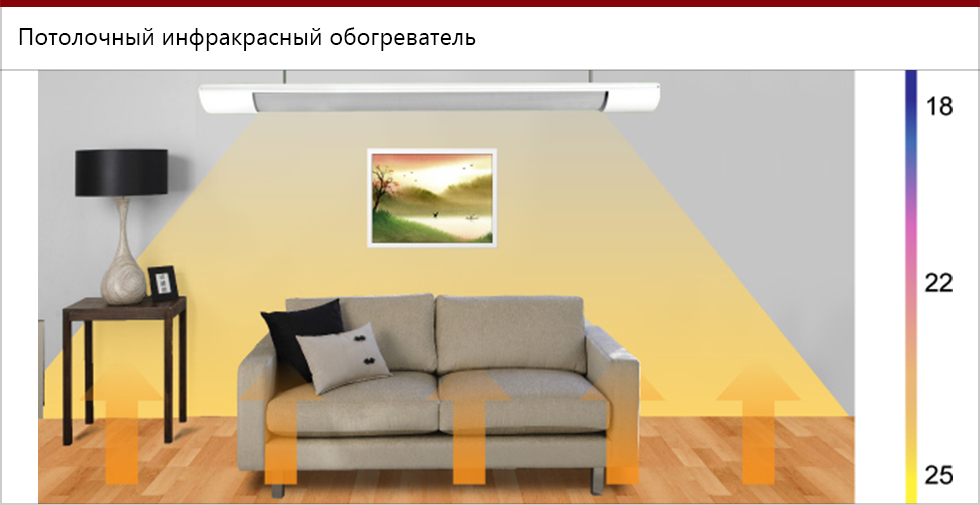

Temperature distribution under the appliance IR 4.5-6 kW

How to choose a gas infrared ceramic heater

Before you buy a gas infrared heater for a summer residence or at home, you need to familiarize yourself with a number of characteristics that determine the purpose of this device. Depending on the power, as well as design features, each of the options is most suitable for specific operating conditions.

The main guideline when choosing infrared gas heaters is their safety, so here you should exercise maximum caution and care. A mandatory requirement for the purchased model is a built-in automatic shutdown system, which is triggered when the product rolls over or is strongly tilted.

Today, such a security measure is considered mandatory.

In the choice, a serious role is played by where exactly the heater is planned to be placed. So, for residential premises, it is necessary to have a special sensor that will indicate the level of carbon dioxide in the room.Indeed, in the process of combustion, carbon dioxide is released, which can accumulate. In large quantities, it is unsafe for both health and human life.

Ceramic heating element of a gas heater

In the presence of a special sensor, the level of carbon dioxide in the room is regulated as follows: the device regularly takes a sample, determining the current level. At the same time, he compares it with a given boundary. If the current level has reached the limit, the device switches off automatically.

How to choose an infrared heater for a summer residence

In order to buy a gas infrared ceramic heater, you need to focus on the mode in which it is planned to use it. Perhaps you will turn it on periodically when you come to the country for a few days. If long-term operation is planned, then the efficiency of the device will play a significant role, because its long-term use will entail certain costs.

When choosing an infrared heater for a summer residence, be sure to pay attention to the power of the device. There is a simple rule to be considered here: the more powerful the device, the less mobile it is.

And, accordingly, vice versa. A simple and lightweight device will never be able to produce the same power as a massive bulky heater.

The choice in this case is not affected by the total area of \u200b\u200bthe room. After all, such devices do not heat the entire room, so its size does not matter. Think in advance where you will install the heater, and what area it will need to heat.

Portable gas heater Kovea Cupid Heater KH-1203

The appearance of the device will also play a big role, because everyone wants the heater to naturally fit into the environment and not create visual discomfort. Despite all its advantages, an infrared heater still cannot be considered a full-fledged heating device when it comes to permanent residence in the house. Its use is fully justified as an alternative for short periods of time, or as an additional source of heat.

How to choose an infrared gas heater for the garage

Buying a gas heater for a garage is one of the most difficult tasks. After all, initially this room is filled with a large amount of combustible substances, which, in combination with such equipment, create a fire hazard. Therefore, more stringent requirements are imposed on the safety of gas equipment.

Gas heater is perfect as a source of heat for the garage

According to the type of construction, portable models are considered the most suitable for a garage, since, if necessary, you can change the direction of the heat flow. Optimum in a room of this type may be the use of a ceiling gas infrared heater.

Gas: dark, light emitters

Among gas equipment that emits infrared heat, heaters are divided into the following two types according to the intensity method:

- Light emitters. The main feature is the bright reddish-orange color of the heating devices in the state of their incandescence. Variations of this class are able to glow their metal tubes (heating elements) to a bright intense color-light, while not overheating.

- Dark emitters.The main difference is the muted color of hot heating devices - metal tubes. They do not heat up to red, therefore it is conventionally customary to call them "dark" heaters.

Light infrared heaters are used to heat the space in a room with a floor-to-ceiling height of at least 4 meters. Their productivity is always higher than instances with a lower heating intensity. Such devices should be installed from a simple calculation: for every 20 cubic meters. m. it is required to supply one heater with a power of 1 kW. If we take into account large areas of premises, then for every 100 sq. m. space will need one device, the power of which is 5 kW.

Dark ones are designed to heat the space in a room with an installation height of 3-3.5 m. The gas is burned in this case at temperatures from 350 to 400 degrees Celsius. These installations are much heavier in weight than light-type equipment. Therefore, this factor should always be taken into account during installation. To select this or that equipment, you need to look at the height of the ceilings in the room, the type of activity of the enterprise and the existing ventilation.

Operation of infrared heaters

Operation of infrared heaters - the order of operation of heat-generating devices that convert the consumed energy into heat, which is transferred to objects through infrared radiation.color>

Principle of operationcolor>

The principles of operation of infrared heaters differ significantly from any other types of heating devices.Its functioning is associated with the formation of thermal energy in a wide spectrum of infrared radiation. Moreover, the maximum value of the radiation intensity in this spectrum falls on a wavelength proportional to the heating temperature of the radiating body. Thermal energy is delivered to the required place by electromagnetic waves at a speed of about 300,000 km / s.

In this respect, infrared heating differs from other types in that the delivery of infrared heat

occurs almost immediately after turning on the heater. And, conversely, the effect of heat rays ceases when turned off. There is no fundamental difference: turn on or off the light source or the heat source in the room.

The work of infrared heaters is based on the fact that infrared radiation heats primarily objects that are in its path. Air directly practically does not receive heat from the infrared beam, it passes it through itself. Objects, gradually heated by convection, transfer heat to the air. With this method of heating, objects located in the zone of functioning of infrared radiation will always be 2 - 3 ° C warmer than air.

The effect of infrared heaters lies in the fact that the thermal energy generated by them is used by 90% to heat objects and only 10% is directly absorbed by the air mass, so they have a high efficiency. All other types of heaters spend the bulk of the energy consumed on air heating, and all other objects are heated only from it.Due to the fact that the infrared beam is almost not absorbed by the air and does not reduce the oxygen content in it, comfortable conditions are created for a person to stay. At the same time, he does not experience such sensations as a lack of oxygen, headache, general malaise and fatigue, which are inherent in staying in a room heated by convection heaters.

Application featurescolor>

This type of heaters is widely used in the creation of local zones.

heating of workplaces at industrial enterprises and is the only way to heat a person in rooms with large ceilings and heat losses.

The use of infrared heaters makes it possible to create a local heating zone with a spot diameter approximately equal to (2 * h), that is, equal to two heights of the emitter suspension. At the same time, the heat transfer area is much larger than that of conventional heaters, which means that the heating time is reduced. Reducing the operating time of the heater leads to energy savings. Therefore, infrared heaters are by far the most efficient electric heaters that allow you to save electricity by about 50% of the calculated power.

They have found wide application in heating houses, cottages, garages, industrial premises, etc.

Gas industrial infrared heaters

Working in the market of thermal equipment for more than 7 years, the Aerostandard company is professionally engaged in the supply of industrial gas infrared heaters throughout Russia.

In recent years, the high efficiency of gas infrared equipment, its quick payback, inexpensive maintenance and ease of operation are already known to many, especially large enterprises with large production areas, which require a large amount of resources to heat.

That is why our company devotes a lot of time to studying new products that appear on the gas infrared heating equipment market, then carefully studies them, and only after being convinced of the high quality of the equipment, it purchases and supplies it to the Russian market.

By presenting only high-quality equipment on the market, Aerostandard has earned the trust of many large enterprises, which have become regular customers.

Types of gas heaters from a cylinder

We will talk about all these gas infrared heaters, and not only, below.

There are many types of gas infrared heaters. Most often, the differences are in appearance, but there are differences in the functionality of the equipment. We will consider the following types of devices in our review:

- small-sized floor, with connected cylinders;

- models with built-in cylinders;

- outdoor devices for open areas;

- devices for tents;

- combined models;

- catalytic heaters.

Small-sized floor

Small-sized gas ceramic bottled gas heaters are designed for use in a variety of conditions. They are used for heating open areas and well-ventilated areas. Cylinders are connected to them through reducers or through a special valve (for small capacity cylinders that are sold in tourist shops).For ease of use, the devices are equipped with metal legs.

Certain types of small-sized models resemble the most common miniature gas stoves. It can be used for both heating and cooking.

Built-in cylinder heaters

Gas heaters on bottled gas with built-in cylinders are heating equipment, made in a neat case. Burners, automation systems and gas cylinders with a capacity of up to 27 liters are located inside the buildings. Such models can be used for heating rooms and open areas. Their main advantages are neat execution and compactness.

Outdoor heaters

Street heaters are somewhat reminiscent of gas street lamps. They have a circular directional zone, allowing you to effectively heat open areas and verandas. They are powered by plug-in or built-in gas cylinders. The built-in cylinders are located on the legs-supports, and the connected ones are connected through reducers.

The most compact models with plug-in cylinders can be used as outdoor heaters. They differ in the directed heating zone.

Combined heaters

Combined gas cylinder heaters can be used for heating open areas, semi-enclosed verandas and terraces, as well as ventilated rooms. They heat not only due to infrared radiation, but also due to convection. To implement the dual principle of operation, they are equipped with special burners.

Catalytic heaters

Catalytic gas infrared heaters warm the premises due to the oxidative reaction.Gas fuel does not burn here, but is oxidized in the presence of catalysts with the release of a large amount of heat. They spend a minimum amount of oxygen and emit a minimum of products of their activity. Such devices can be used in any conditions, both outdoors and indoors.

Tent heaters

Tent gas heaters, powered by gas cylinders, are designed specifically for tourists. They are small in size and are focused on creating comfortable conditions in tents. The power supply of such devices is carried out from compact cylinders of small capacity. Due to the small capacity and minimal consumption, one bottle will last for 2-3 nights (sometimes more).

This is interesting: A new generation of energy-saving ceramic heaters for the home - the price of the model