- Gasket replacement procedure

- Which is better: exchange or refueling?

- What problems can lie in wait when refueling

- Replacing the cylinder with a new one, repair

- Installation and connection

- Why are the cylinders covered with frost?

- Maintenance of gas sensors. Requirements for maintenance, repair, calibration of gas detectors (calibration of gas detectors, calibration of gas analyzers).

- Varieties of sealing gaskets

- Typical connection instructions

- Burner connection guide

- Types and arrangement of valves

- Service life of the gas supply

- Instructions for self-connection

- Step #1: Dismantling the old stove

- Step #2: Performing a Faucet Replacement

- Step #3: Connecting the Flexible Hose to the Stove

- Free replacement

- Who is eligible for the benefit

- Free connection procedure

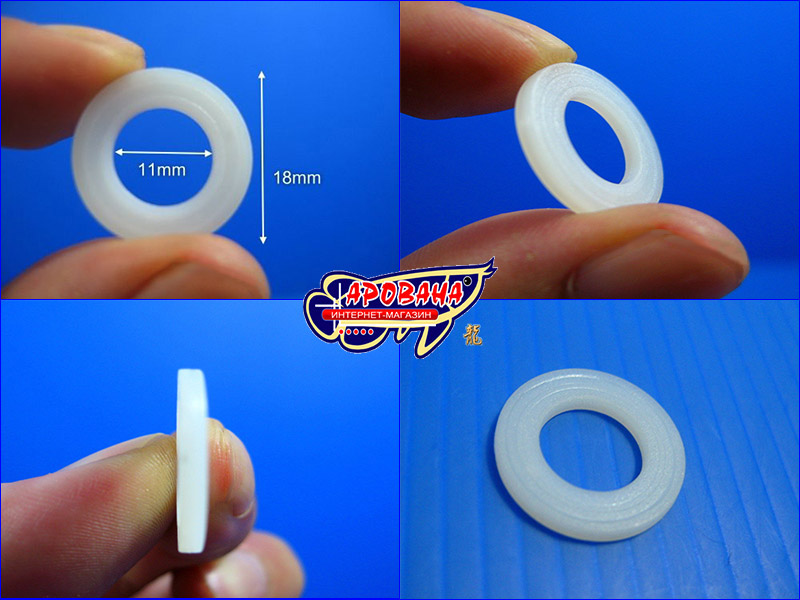

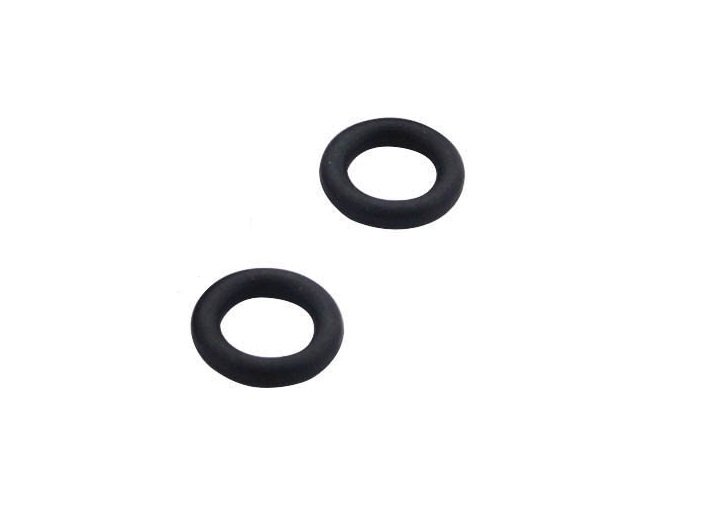

Gasket replacement procedure

The replacement of the O-ring on the body neck often coincides with the replacement of the valve. The gasket is updated if a problem is identified with it or the faucet.

Before connecting the gas cylinder to any gas-using device, worn parts should be replaced on the tanks: their appearance will be the best guide

The valve is replaced if:

- it is not possible to move the flywheel, it has become more difficult to scroll it;

- there is a deformation of the valve or its parts;

- there is a smell of gas in the room;

- scheduled technical inspection did not take place.

Gaskets change with the exact algorithm of actions. First, the balloon itself is carried as far as possible from the buildings. The valve flywheel is slowly unscrewed, after which the gas is released. The valve is carefully dismantled, smoothly and without damaging the body.

The condensate remaining in the bottle is poured out. Then simple technical steps remain: install a new gasket, another valve (if necessary). Finally, the tightness is checked.

Independent manipulations are prohibited by the rules, but in extreme cases and with skills, you can not wait for specialists. Some types of valves can be partially dismantled indoors and without venting gas, for example, to replace internal glands.

Cylinder parts may need to be replaced at least every two years, and there are limits on do-it-yourself and container storage conditions.

Replacing the gasket between the valve and the reducer will take less time. It will be enough to block the flywheel, disconnect the gearbox and install the seal between its nut and the valve fitting.

Some reducers do not work through a valve, but directly from the cylinder. In this case, it should be taken outside to release the gas.

Which is better: exchange or refueling?

There are two ways to get a cylinder of gas necessary for the operation of a gas boiler, stove, outdoor lighting lines, etc.: fill your container or exchange it for another one that has already been filled. In the first case, the cylinders are left at the station for 1-2 days, the consumer receives his full container.

In the second - a quick exchange of an empty container for a filled one. Consumers themselves can choose which way to use.The second method is faster, but you get someone else's equipment, perhaps not the newest. The cost depends on the type and volume of gases. Standard case: 200-300 rubles.

What problems can lie in wait when refueling

Nuances that are important to know about filling gas cylinders:

- Some Chinese cylinders have thin walls. They are not designed for heavy loads. It must be remembered that cheap equipment may not pay off due to high risk.

- Active gases are prone to ignition and explosions, so you need to carefully monitor the volume (85%) when filling with propane, oxygen, methane.

- For the use of household gas at low temperatures, it is better to use propane-butane winter mixtures, with the advantage of propane, since butane is of little use for winter operation.

In order to prevent the occurrence of the listed problems and risks associated with the replenishment of a liquefied explosive substance, it is necessary to think over the process in advance and provide for all the nuances.

A high-quality cylinder and compliance with the operating rules are a guarantee of safety

Refers to this characteristic should be with increased attention

Replacing the cylinder with a new one, repair

Sooner or later, the cylinder wears out, the valve may fail, the surface will begin to delaminate. In almost every city there is a point for replacing or repairing cylinders. You can give away the old and get a new product, with a surcharge of about 1500 rubles. This is a good alternative to buying new equipment.

If the valve needs to be repaired, it is repaired or completely replaced. The balloon itself can be sanded and painted. The cost of a new empty propane tank: from 2,500 to 600 rubles, depending on the manufacturer's materials.

It is more profitable to purchase large cylinders - a 50-liter capacity is enough for cooking on the stove for a small family for 2 months

Installation and connection

Often, gas hoses go on sale already with gaskets, but not in all cases. The user should connect the hose to the device and connect the device and the gas riser to each other, while using various components. The working angle must be correct and comply with the regulations.

In order to properly connect the coupling or sleeve with a tap at the junction of the gas pipe and the hose, it is worth performing a series of actions in turn.

- Shut off the gas supply.

- Leave the burners open to ensure complete burnout of the gas.

- Prepare several adjustable wrenches.

- Using the first wrench, it is necessary to support the valve located on the tube, and with the other, unscrew the nut on the flexible fixture.

- Screw the hose nut to the end on the coupling.

- Perform a thorough leak test. This is done by applying a soapy solution with a brush.

- After all the above actions, it is necessary to open the valve and check the operation for the absence of bubbles.

To install the clamps on the gas hoses, no special skills are required

It is important not to forget to follow these rules:

- maintain the correct distance between devices;

- using a screwdriver, it is necessary to fasten the clamps, while not overdoing it;

- insert a main element into each of the clamps;

- stretch the bolts through the holes, tighten the clamps, ensuring a tight fit.

The gas hose fitting diameter 9 mm must have a 3/8″ thread, while the nut must be made of steel.The best would be to install a fitting that is made of brass.

Why are the cylinders covered with frost?

Here you can also debunk one of the most common misconceptions. It is generally accepted that if such a device "freezes", then it becomes covered with frost. Some even argue that it is necessary to insulate such equipment with blankets, old coats and other improvised devices. So, the frost will disappear faster if the gas container is left as it is, without helping it to “thaw” with warm clothes.

The bottom of the gas cylinder, which is covered with frost

The appearance of frost can be explained by a number of physical processes that occur inside the structure when it is connected to furnaces or burners. At such moments, active fuel consumption is observed, therefore, large volumes of gas liquid turn into a vapor fraction. And such a phenomenon is always accompanied by a large consumption of heat, it is for this reason that the surface of the cylinder becomes much colder than the temperature in the surrounding space. Moisture in the air space begins to appear in the form of condensate on the walls of the installation, subsequently turning into frost. This is a completely natural phenomenon, with which nothing needs to be done.

Moreover, all attempts to use artificial "insulation" violate safety regulations during operation, and also affect the deterioration of the device's heat exchange with the environment and affect on gas supply conditions. If your burner did not please with a grandiose flame, then after your “maneuvers” with a blanket, it may stop working altogether.

Do not insulate gas cylinders with anything!

In general, when connecting gas devices with high power, you need to be aware that the gas cylinder has limitations in terms of recoil speed. This means that the liquid fuel is converted into the steam stage gradually. For example, a 50 liter tank can provide about 500 grams of gas in 60 minutes. This is equivalent to a power of 6-7 kW. In the cold season, this figure is halved if the equipment is located outside. In summer, the situation is reversed: the maximum flow rate increases.

In any case, it can be concluded that frost is evidence that the cylinder cannot cope with high fuel consumption. This can cause a temporary drop in gas pressure and equipment failure. If this happens, it is better to stop consumption and wait until a sufficient vapor head has formed.

Maintenance of gas sensors. Requirements for maintenance, repair, calibration of gas detectors (calibration of gas detectors, calibration of gas analyzers).

• Servicing and repair of control devices are carried out in the manner and within the timeframe stipulated by the manufacturer's technical documentation for these devices.

• Testing and verification of devices must be carried out according to the manufacturer's methodology.

• Once a year, it is necessary to carry out state verification of gas detectors, gas analyzers, detectors with control mixtures at the response levels. This includes verification of the carbon monoxide sensor and verification of the methane sensor.

• Repair and maintenance of control devices must be carried out by trained personnel who have been certified by the qualification commission of a specialized organization or manufacturer.Participation of a representative of the body of Rostekhnadzor of Russia in the work of the commission for attestation of the named personnel is not necessary.

• At the end of the service life of the device (sensor) for monitoring gas content, its diagnostics are carried out in order to determine the possibility of further operation or replacement.

• Boiler-house personnel must verify the operability of control devices with a note in the logbook every shift.

Many enterprises operating fuel-using thermal equipment, already at the design stage, require the presence in the workshop of a sufficient number of signaling devices for CO and CH4 to guarantee the safety of the units and maintenance personnel.

Gas detector, gas alarm, gas analyzer, toxic gas alarm, combustible gas alarm, maintenance of gas sensors.

It is likely that you have come across government control over gas appliances. Perhaps you are an entrepreneur, and even the most insignificant aspects related to expenses matter to you? We believe that a very small number of the population knows the rules for calibrating gas analyzers, and meanwhile, an unsuccessfully chosen device will eventually cost tens of thousands of overpayments.

We tried to gather all the useful information together. We are talking about all the key points: norms, frequency, stages of verification. You will thoroughly approach the choice of a gas analyzer if you read the material presented by us.

Gas analyzers are subject to government regulation, as they provide security at facilities from various fields of human activity. This concerns, first of all, the verifications that are performed to make sure that the metrological characteristics are met.Let's figure out together how verification activities are carried out.

Varieties of sealing gaskets

On the modern market, you can purchase a gasket for a heating radiator of absolutely any kind - made of cast iron, aluminum or bimetal.

Depending on the material of manufacture, the following types of products are distinguished:

- Silicone gaskets . Such products are resistant to high temperatures of the coolant and well compensate for the thermal expansion of the metal. Such gaskets are used, as a rule, in autonomous heating systems with low operating pressure.

- Paronite products . They are made from pressed rubber with the inclusion of asbestos and a special powder. Such gaskets are used in radiators connected to a centralized heating system, where the temperature of the coolant can rise to 90-100 ℃. Paronite gaskets are suitable for cast iron radiators, as well as for aluminum and bimetallic products.

- Fluoroplastic gaskets . Produce this kind of products from heat-resistant plastic. They are intended for installation on bimetallic and aluminum radiators, and without pre-lubrication. They are distinguished by high temperature resistance, resistance to aggressive factors and pressure drops.

- Cardboard spacers impregnated with oil paint for durability are used for aluminum and bimetal radiators in autonomous heating systems. The production of products is regulated by GOST No. 9347-74.

Typical connection instructions

Ideally, it is better to invite a specialist to install gas and gas-electric stoves, but if you are still determined to make the connection yourself, then the installation instructions will help.Following it in detail and carefully observing the mandatory points, it is quite possible to cope with this task yourself.

The standard sequence of actions is as follows:

- Release the "object" from packaging materials and all accessories (tray, tray, dividers, etc.), leaving only the protective film, which must be removed after all repairs are completed.

- Install the stove in the intended place, maintaining the distance from the wall, prescribed in the attached documentation.

- With the help of a level and adjustable feet, the work surface is leveled horizontally.

- The flexible hose is connected to the gas pipeline. To do this, the threaded connection is wrapped with a sealant (FUM tape) and tightened with an appropriate key.

Then the gas hose is similarly connected to the device, using a sealant and tightening the lock nut with two open-end wrenches. It often happens that the thread at the exit of the plate has a pitch of 3/8 ′, then an adapter is installed that comes with the device.

- The last item is to check both connections for tightness, which is carried out using a soap solution. At the same time, thick foam is abundantly applied to the joints (with a brush or by hand) and the gas supply valve is opened at the descent. If bubbles appear at the joint, the valve is closed and the defective joint is redone. If the surface remains level, then there is no gas leakage, which means that the new plate is installed correctly.

- At the end, the operability of the burners and the oven is checked.

A video will help you more clearly understand how to properly install a gas stove yourself.

Burner connection guide

Gas cylinders in everyday life are usually used for cooking. But nothing prevents you from connecting a torch for soldering copper pipes to them. A similar tool is used for roofing, singeing animals during slaughter at home, etc.

The reducer for the burner should not be selected as an ordinary household one for a stove, but a special one for welding machines. From the first pressure will be too small

The reducer for the burner should not be selected as an ordinary household one for a stove, but a special one for welding machines. From the first pressure will be too small

Before connecting a burner to a gas cylinder, you should carefully examine it and the hose to it. Balloon gas in the tank is under pressure of 15–16 atm. If the burner and outlet are not designed for such parameters, then an adjustable propane reducer will have to be connected. Without it, according to the rules of TB, it is impossible.

If the gas reducer is not connected at all, the gas will be consumed too much. Of course, you can adjust its supply with a valve on the cylinder, but it is difficult to talk about any safety of work in this situation.

Types and arrangement of valves

The threads of valves for gas cylinders are standardized, but they themselves can have a variety of designs. The choice of valve model is influenced by the type of stored chemical, the production features of operation and the amount of money. Before buying new equipment, you should familiarize yourself with the options for the execution and internal arrangement of the valves.

The design features of gas cylinder valves are not due to the whims of engineers, but to safety considerations.

Gas valve model VB-2. This valve model has positively proved itself in Soviet times. For decades, it has been used in everyday life and industry, bringing a minimum of problems.

The choice of metal for the manufacture of the valve body is determined by the type of gases contained in the cylinder. There are the following types of stopcocks, depending on the type of stored chemicals:

- Acetylene. The body of such cylinders is painted white. Special valves are used in cylinders with acetylene, chlorine, ammonia and other aggressive substances.

- Oxygen. The cylinders are painted blue and are designed to store oxygen, argon, hydrogen, nitrogen, carbon dioxide and other inert gases.

- Propane-butane. They are painted red and are intended for the storage of substances corresponding to the name and other gaseous hydrocarbons. The most common valve type model for such a cylinder is VB-2.

Valves for acetylene cylinders are not made of brass because the substances contained in them can react chemically with copper. Usually, for the manufacture of valves of this type, carbon or alloy steel is used.

The lower fitting of the valve is used to connect to the gas cylinder, the upper one is for fastening the flywheel, and the side one is for connecting communications for gas outlet and injection. The device of the crane for a gas cylinder is quite simple. Shut-off valves usually consist of the following common elements:

- Brass or steel body.

- Stuffing box valve or handwheel attached to the body with a union nut.

- Internal locking mechanism with valve and stem.

- Sealing gaskets.

- Plug for outlet.

You can consider in more detail the arrangement of valves on gas cylinders of each type in the presented images.

Image gallery

Photo from

Draining poisonous gases through a safety valve can be harmful to health even in open spaces.

Acetylene valves use a maximum of seals so that poisonous gases do not get outside

Seals on propane tanks are simple, so they must withstand a maximum pressure of only 16 atmospheres.

Worn valves can let a small amount of gas through, which can lead to unpredictable consequences in enclosed spaces. To prevent such situations, a plug is used on the side fitting, which serves to additionally seal the cylinder during transportation and long-term storage.

The direction of the threads on the outlets depends on the chemicals contained in the cylinders: the right one is used for non-flammable gases (oxygen, nitrogen, argon, etc.), and the left one is used for combustible gases (hydrogen, acetylene, propane, etc.)

The principle of operation of the assembled gas valve is unremarkable. To supply gas and shut it off, simply turn the handwheel slowly in the appropriate direction.

Service life of the gas supply

After installing the hose, you should clarify the duration of its service life and remember the date of installation. The product, depending on the type, is designed for a period of 5 to 15 years.

It is important not to forget to replace it in time

p, blockquote 39,0,0,0,0 —> p, blockquote 40,0,0,0,1 —>

Guaranteed service life is indicated in the product passport and in the certificate of conformity.

- rubber hoses (with and without sheath) - 5 year warranty, service life up to 10 years;

- PVC eyeliner - 12 years warranty, lasts up to 20 years;

- bellows gas hose - 15 years warranty, does not require replacement up to 30 years.

The gas heating boiler is connected to the main line using a flexible hose.

The choice and installation of a hose for the boiler is a very responsible matter, because we are talking about gas.

The result of incorrect connection to the gas pipeline may be an explosion.

For domestic gas supply, flexible gas hoses specially designed for this purpose are used. The use of water hoses for this purpose is strictly prohibited.

Instructions for self-connection

Payment for the services of a gasman for installation work is not too high, but many home craftsmen prefer to do everything on their own. This is a feasible occupation that requires the purchase of components and theoretical knowledge.

And to connect, you will need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver to tighten the clamp, if required;

- seals (thread loctite 55, linen, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2';

- brush and soap solution, which will be required to control the progress of work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary cover against a gas leak. The narrowed edge of the plug must be adjusted to the opening of the supply pipe. If during the extraction process, a homemade part gets stuck, it can be easily removed with a corkscrew.

Step #1: Dismantling the old stove

Closing the crane on the descent is a top priority to ensure the safety of the work performed. Next, you need to unscrew the lock nut located on the outlet and remove the coupling.If the coupling and locknut of the old plate were previously painted, this will greatly complicate the process of their dismantling.

Sometimes this procedure cannot be performed, then you will need to cut the eyeliner with a grinder.

The dismantling of the gas stove is carried out after disconnecting from the pipe-conductor of the gas main. Difficulties encountered with unscrewing the locknut on a metal pipe are solved by trimming the liner

In the process of unscrewing the drive located in the lowering tap, it is necessary to hold the tap itself with a key. It will not have to be removed if the crane is not planned to be replaced. When it is planned to postpone the installation of the plate, an additional plug is installed on the descent.

Step #2: Performing a Faucet Replacement

There are situations when the wall is located very close to the crane and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue to do the work.

It is necessary to prepare a piece of rags sufficient to completely cover the pipe after dismantling the old faucet. The next will be its tearing without full untwisting. And you will also need to prepare the selected type of sealant. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the faucet, the outlet from the pipe is tightly fixed with a finger, and then with a wet rag. The main actions are aimed at the maximum elimination of gas exit from the pipe. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the sealant, the thread on the descent must be thoroughly cleaned. Further, its winding is carried out directly.This process ensures a secure and airtight fixation of the new faucet, which is then tightly twisted. The last step is to install the previously removed handle on the faucet.

With the help of soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work has been carried out correctly, the installation of the gas hose can be continued.

If the gas equipment is connected to the main for the first time, it will be necessary to call the gas master. In his presence, a control check of the equipment for gas leakage with the valve open is carried out. In the event that the gas service employee did not find any violations, he must enter the established stove brand in the register.

Step #3: Connecting the Flexible Hose to the Stove

Using a sealant, the external thread of the hose fitting is wrapped around. After that, it must be screwed into the faucet on the branch pipe. The connection of the flexible hose to the manifold is carried out at the finishing stage.

Next, the stage of test opening the faucet on the descent for gas leakage is mandatory. Using soap foam, the docking points are processed with a brush. If foaming occurs when the gas valve is opened, the work must be redone.

It is necessary to check the thread located on the plate manifold. Quite often it is 3/8′. In this case, you will need to install a 1/2 ′ adapter, with a seal

If the work on replacing the gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will release too much soot, which likes to settle on furniture and utensils in the kitchen.

Free replacement

Public utilities in some regions allow certain categories of citizens to replace outdated and faulty gas equipment without paying a penny for it. The rules of procedure will need to be clarified in advance with the city gas service.

Who is eligible for the benefit

Only certain categories of citizens can use the service of free replacement of the plate. Relief is available in the following cases:

- apartment owners receive subsidies from housing and communal services, are veterans of the Second World War, have the titles of heroes of the USSR, socialist labor, the Russian Federation, or have received the Order of Glory;

- the existing gas equipment is the property of the state, regardless of whether the apartment is municipal or owned by the tenant;

- persons who received it by the right of the queue for housing are settled in the apartment;

- in a family that needs to replace the stove, or for a single person, the income is less than 1.15 of the subsistence level;

- single pensioners or families of pensioners who have reached retirement age and do not receive additional social assistance to pay for housing and communal services and housing.

Installation of a stove for pensioners

In practice, there are very few such persons, and it is possible to carry out a substitution on a benefit only if there is a package of documents confirming the right to receive such a service.

Free connection procedure

To replace the gas stove free of charge, you will need to provide an act of technical inspection of the equipment. One copy remains in the gas service. The second is received by the applicant, who transfers the document to the ZhSK or DEZ. The survey is carried out by employees of the organization that controls the operation of gas appliances.

The paper indicates the period of operation, existing defects and malfunctions.Based on the opinion received and the application for replacement, beneficiaries can receive a new gas stove free of charge. Additionally, the host provides an identity card.

Retirees will also need:

- pensioner's ID;

- if necessary, a certificate in form 9 on registration at the place of residence.

Citizens with an income level below 1.15 of the subsistence level are preparing to submit:

- income statements of their personal and other family members for the last 3 months;

- if necessary, a certificate in form 9 on permanent registration at the place of residence.