- Technology

- Features for HDPE pipes

- Sewer laying

- Pipe selection

- Types of sewer pipes

- Possible sewer schemes

- Conditions for conducting according to regulatory documents

- What problems can arise during installation?

- auger drilling

- Puncture method

- Basic provisions of sanitary norms and rules

- Punching method

- Stages of a sewerage device in a private house

- Storm sewer - connection to the city storm network

- Installation of an autonomous storm sewer in a private house

- Conclusions and useful video on the topic

Technology

There are rules that must be followed at the facility when laying the pipeline in a trench:

- For lowering pipes into trenches, special pipe-laying cranes are used.

- During the procedure, the pipeline should not suffer from kinks, overvoltages or dents.

- The integrity of the insulating material must not be compromised.

- The pipeline must be completely adjacent to the bottom of the trench.

- The position of the pipeline must comply with the design documentation.

Before laying, a rejection is carried out: all pipes with defects cannot be laid in a trench. Prepare the base, if necessary - make the strengthening of the walls. With the help of a pipe-laying crane or manually, if the diameter allows, pipes are laid.Sometimes vertical shields, horizontal runs, and spacer frames are used.

Features for HDPE pipes

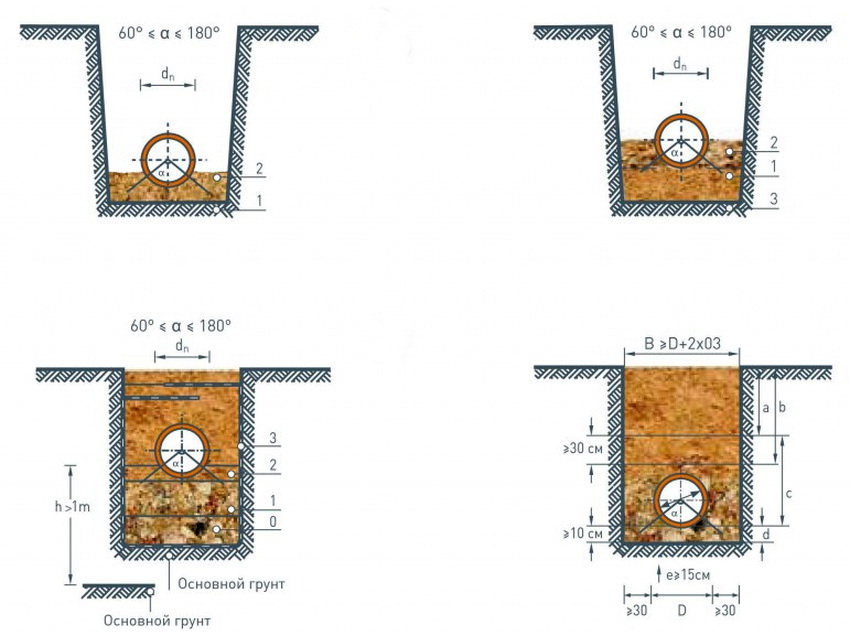

Under all polyethylene pipes at the bottom, a sand cushion should be organized. This is a mandatory requirement that must be observed by technology. The pillow should have a height of 10 to 15 cm. It is not compacted, but should be as flat as possible. If the bottom is flat and soft, then a pillow is not required.

The pipes are connected by butt welding. Before installation, the entire system is checked for leaks. The minimum laying depth must be at least 1 meter.

Sewer laying

Installation of external sewerage is regulated by SNiP and technological maps. The process of performed operations is reflected in the work production book. Records are made every working day with the obligatory reflection of the compliance of operations with the working project.

In the course of technological operations, the heating cable is installed inside the sewer. The work is carried out in accordance with the instructions for the installation and operation of the heating element.

Stages of work:

- A trench is being set up. A prerequisite is compliance with the necessary slope. The top point is at the exit from the building. The nearest, lower, is in the overflow well, at the junction with the main highway or at the local treatment plant.

- Overflow and manholes are mounted. The need is reflected in the project. The presence of structures is caused by:

- complex geology of the area with significant elevation changes;

- sewer line length;

- complicated design of external spillway systems.

The slope in the finished trench is checked.A gravel-sand cushion is being arranged - at this stage, errors that have arisen along the slope of the trench are corrected. A protective cover is mounted (if necessary).

External sewerage networks are being laid:

- pipes are assembled in a whip (determined by the conditions for the installation of sewer pipes);

- fittings are installed;

- the assembly of the highway as a whole is carried out.

Note: at the stage of assembling the line, it is necessary to install the heating cable inside the collector.

The final process is commissioning. Consists of two sub-stages:

- check with an open, not covered with soil trench;

- final measures with the assembled highway and a covered trench.

Before backfilling, visual control is carried out:

- connection points;

- the presence of sealing compounds and seals;

- compliance with the required slope of the sewer pipe;

- fixing (if necessary) the collector, the presence of unloading reference points;

- correct connection of electrical elements of the heating cable;

- no unnecessary bends and connections.

After backfilling the trench, test work is carried out, determined by the working draft. The simplest is pouring the finished line with water, measuring the incoming and outgoing flow by volume. The amount of incoming water can be fixed in the storage well of the septic tank. For an industrial drainage system, it is advisable to use special measuring equipment.

Advice. It is advisable to pour the system for private housing construction before the trench is closed, as it is easier to eliminate the identified shortcomings.

The test of external sewerage and the results are reflected in the relevant documents, after which an act of work performed is drawn up.How to fill out the document correctly is given in the corresponding SNiP 3.01.04–1987.

Registration of all documents, including the certificate of completion, is a permission to commission and operate outdoor water supply and sewerage networks.

Tell your friends about us:

Pipe selection

High loads act on the internal sewerage, while the external one is much stronger, therefore the requirements for tubular products for it are appropriate. Since sewer pipes are laid in deep pits, the pressure of the earth on them cannot be ignored. Moreover, when laying such products under the roadway, it is necessary to choose them with the highest strength class.

In order for the external sewage system to serve for a long time and efficiently, it is necessary to use pipes:

- Smooth polymer. They are often made of PVC, but there are also polypropylene products.

- Corrugated polymer. They are made of polyethylene, but there are many copies made of polypropylene.

- Cast iron.

Today, homeowners prefer polymer pipes. Moreover, where the load is especially high, it is recommended to use corrugated products. Most often, people choose products with a diameter of 110 mm. Remember that not only these materials will need to be bought, but also fittings.

Types of sewer pipes

The most commonly used in sewer systems are rigid and smooth pipes from polymers in orange or black, indicating the suitability of products for styling. The following types of pipes are also used for installation:

- Polymeric, smooth made of polypropylene or PVC;

- Corrugations made of polymers, polyethylene and polypropylene;

- Asbestos-cement;

- From concrete;

- Ceramic.

In places with significant external load, it is usually necessary to use corrugated pipes under roads or use steel pipes as a protective shell. Such cases must exceed the width of the carriageway by 150 mm each side. When installing the protection of the plastic pipe of the metal case, it is unfastened with the help of fixing rings, which excludes the possibility of contact between the sewer pipe and the protective one.

Possible sewer schemes

Depending on the number of residents, albeit temporary, the number of plumbing fixtures, the total number of drains, objects connected to the sewerage system, the schemes can be completely different.

- internal wiring;

- simple or branched pipeline;

- type of pit or septic tank.

Consider some of the most popular schemes.

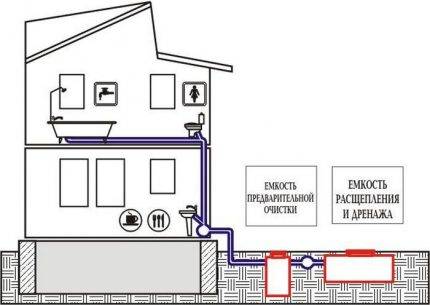

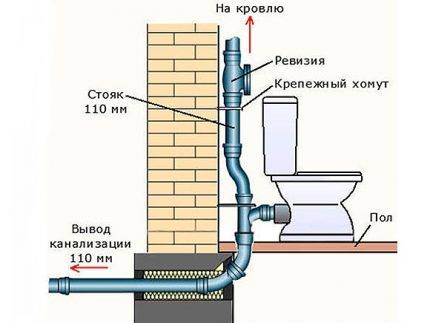

A modern dacha bears little resemblance to a utility room or barn. The owners of even modest country plots are trying to build solid, reliable, roomy housing, so a two-story building has long ceased to be a rarity. The optimal layout for two floors is shown in the diagram:

The toilet and bathroom are located on the second floor (sometimes it's just a modernized attic space), and the kitchen is downstairs. Pipes from plumbing lead to a riser located at the wall closest to the septic tank

The toilet and bathroom are located on the second floor (sometimes it's just a modernized attic space), and the kitchen is downstairs. Pipes from plumbing lead to a riser located at the wall closest to the septic tank

In small one-story houses, a toilet + sink set is usually installed. The shower, if present, is located on the street, not far from the garden area.

Drains from the toilet enter the inner pipe, then go outside and move by gravity to the septic tank.

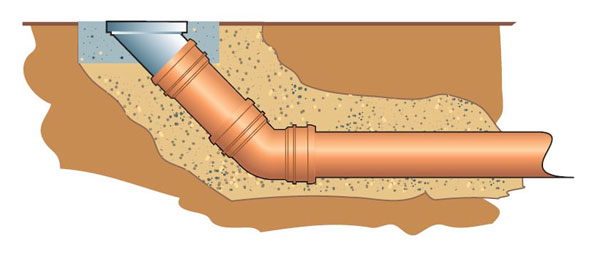

Scheme of the device of the riser and sleeve for the design of the transition of the pipe to the outside.The cross section of the line, as well as the riser, must be at least 100 mm, and the pipe fragment in the wall must be wrapped with a sheet of metal and thermal insulation

Scheme of the device of the riser and sleeve for the design of the transition of the pipe to the outside.The cross section of the line, as well as the riser, must be at least 100 mm, and the pipe fragment in the wall must be wrapped with a sheet of metal and thermal insulation

The cesspool is most often placed near the building, at a distance of 5-10 m. Less than 5 m is not recommended according to sanitary standards, more than 10 - difficulties may arise when laying the pipeline. As you know, to ensure the movement of effluents by gravity, it is necessary slope of sewer pipes - about 2 cm per 1 m of the line.

It turns out that the further the location of the pit, the deeper you have to dig. Too deeply buried container is inconvenient for maintenance.

Scheme of the location of the drain pit. This is the most popular option among summer residents, which is chosen because of its cheapness, simplicity of design and installation method.

Scheme of the location of the drain pit. This is the most popular option among summer residents, which is chosen because of its cheapness, simplicity of design and installation method.

Increasingly, instead of a cesspool, a two-chamber septic tank or cesspool is being built with overflow into a filter well. Vacuum cleaners will also have to be called, but much less frequently.

Diagram of a do-it-yourself two-chamber septic tank. The filter well receives partially clarified effluents and continues to purify them, transporting them through a sand and gravel filter into the ground

Diagram of a do-it-yourself two-chamber septic tank. The filter well receives partially clarified effluents and continues to purify them, transporting them through a sand and gravel filter into the ground

Common country sewerage schemes can be supplemented with branched internal or external wiring, connecting more waste disposal points, a more efficient septic tank, and a filtration field.

Conditions for conducting according to regulatory documents

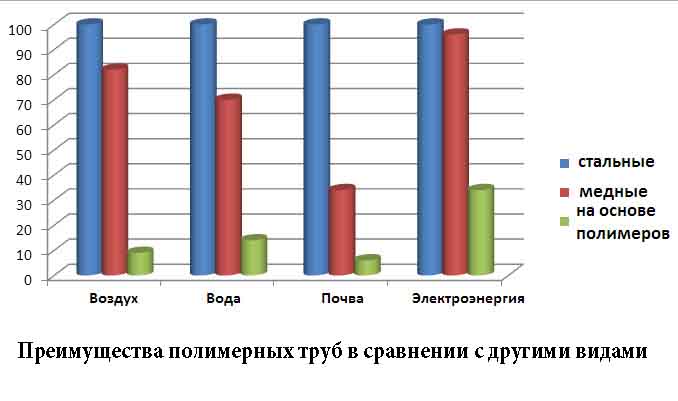

The laying of any pipeline, whether it be polypropylene or steel, is determined by the standards. It is SNiP that regulate many technical issues that allow you to perform all work efficiently, ensuring safety. For laying polypropylene pipes, the following requirements must be met:

Scheme of the advantages of polypropylene pipes over other materials

- Be sure to take into account the freezing point of the soil. Usually it is at a level of 1.4 meters, so if the pipeline is at a lower level, then in winter the water in it will simply freeze, and it will not be possible to use the pipe. Therefore, during installation, it is necessary to accurately calculate such moments, in the future it will only benefit.

- The laying of pipes largely depends on what buildings are located on the site, whether there are roads and highways nearby, laid communication and other engineering networks. If you are not sure where exactly you can lay the pipeline, it is better to contact specialized construction companies.

- When laying underground, we also take into account the features of the relief, soil, in some cases it is necessary to protect the pipe with the help of special casings.

The polypropylene pipeline is laid subject to the following steps:

- First you have to prepare a trench for laying, which should be larger than the diameter of the pipe. So, for 110 mm pipes, you will need a trench with a width of 600 mm. The minimum distance between the pipe wall and the trench should be 20 cm. The depth should be 50 cm more.

- The bottom is sprinkled with sand with a cushion thickness of approximately 50-100 mm, after which the sand is compacted.

- The laying starts from the building; when installing sewer pipes, the socket should look at the end of the pipe that goes out;

- To connect the individual elements, a special lubricant is used.

- When laying sewers, it must be remembered that a slope of 2 cm must be observed for each m of the route.

- After laying the pipeline is covered with sand, it is compacted only from the sides.If necessary, before this, the pipe is wrapped with a heat-insulating layer;

- At the very end, polypropylene pipes are connected to a common highway, a treatment plant, and so on. This should be done using polypropylene solder.

What problems can arise during installation?

When laying polypropylene pipes underground, some problems may arise:

- the structure of the soil does not allow digging at the required depth;

- in winter, the soil freezes heavily, which can cause damage to pipes;

- there is a building on the site that cannot be bypassed.

In this case, there are several ways to solve these problems:

- If the soil is too loose or hard, it is recommended to make a puncture, in which a steel pipe is first laid, and a polypropylene pipeline is already inserted into its cavity.

- When the soil freezes, it is recommended to lay a heating cable throughout the entire route. This requires significant costs, the costs during the winter period may be higher than planned, but in any case, this option is cheaper than the constant repair of burst pipes.

- When there is a building or object on the route that cannot be damaged, it is recommended to perform trenchless laying methods, that is, a puncture. In this case, it is possible not only to lay the pipeline, but also to protect it with a steel casing. When laying such networks, it is necessary to carefully look at the layout of communications on the site so as not to damage the existing ones.

auger drilling

There is a method of laying pipelines using special equipment - auger drilling machines. In this case, drilling goes to the receiving pit from the working one. This means that no access to the surface is required. This method is suitable for laying pipelines in a closed way up to one hundred meters from steel, concrete or polymer pipes (100 - 1700 mm in diameter). It is highly accurate, the maximum deviation will not exceed 30mm. The pipeline itself will turn out to be smooth, without sagging. This method is often used when installing gravity sewers, when laying pipes under railway tracks or in the communications area of \u200b\u200bhouses.

Puncture method

The next way to lay the pipeline is a puncture. Carrying out work by this method is especially recommended when arranging sewerage or water supply systems in areas with clayey or loamy soil.

The method has length restrictions. For example, for pipes with a diameter of up to 0.6 m, the length of the corresponding tunnel can reach 60 m.

The puncture for laying the pipeline is carried out by compacting the soil along the edges, as a result of which the earth is not thrown to the surface, but remains in the work area.

The disadvantage is also associated with the compaction of the earth: a serious force (0.15 to 3 MN) is required to create sufficient radial pressure at the work site. This force is achieved through the use of winches, bulldozers, tractors and jacks, usually of the hydraulic type.

Of course, there is a way to overcome the increased resistance of the earth. For this at the end of the stretched pipe a cone is installed, the base of which protrudes 20 mm beyond the edges of the element (for large diameter pipes).If it is planned to lay a pipe of a small cross section, the earth is pierced directly by the pipe, and in the process a sealing core is formed.

The usual speed for performing work by the puncture method is 4-6 m / h. If, in addition to the technique, vibroimpulses are used (the technique is called vibropuncture), the speed increases to values of 20-40 m/h.

Another variation of the puncture is hydro-puncture. The technique is used when working in easily eroded soil. During the process, the soil in front of the pipe is eroded with a special nozzle, and the pipe is pushed into the resulting tunnel. Among the disadvantages of this method are quite significant deviations from the projected trajectory of the pipe and the need to free the path of movement from the resulting pulp. In this way, it is often pipe at the entrance to the site, as this is the best option in this case.

The work algorithm is as follows:

- At some distance from the beginning of the tunnel, a foundation pit is dug, and hydraulic jacks are placed on the frame in it. A pump is installed on top, supplying water to the jacks. The parameters of the jacks (the magnitude of the generated force and the length of the strokes of the rods or the pressure plate) must correspond to the characteristics of the soil, the pipes being laid, etc.

- Equipped with a special tip and a transfer ramrod connecting it to the jack plate, a pipe is immersed in the pit. The ramrod can be larger or smaller in diameter than the pipe, respectively, it is attached either outside or inside. The first section of the pipe, on which the ramrod is put on, should be 6-7 m long.

- The first puncture is carried out using only one ramrod fixed directly on the pressure plate.After that, a steel rod with a radius of 25 mm is inserted into the holes of the ramrod, then the cycle of work is repeated.

- If during the laying process a movable stop is used, which tightens the jack during the reverse passage of the rods, a ramrod is not required. In this case, the jack moves along with the slab behind the pipe being laid until it is completely buried in the ground, then returns to its place. A new element is welded to the end of the pipe, and the process is repeated until the required length of the pipeline is increased.

Basic provisions of sanitary norms and rules

In 1985, Sanitary Norms and Rules were approved, according to which sewer systems should be installed.

The same document provides guidance on nuances of installation work. In particular, it contains information regarding the depth of the pipeline and other important points.

When work is carried out in areas with increased load exerted on the soil surface (for example, under the roadway), the products should be laid deeper, sometimes at around 9 meters.

The document regulates how installation of sewer pipes in trenches:

- In a place where it is planned to lay a sewerage outlet from a private household, it is imperative to compact the earth. This will prevent erosion of the engineering structure by groundwater during heavy precipitation.

- The laying of the external pipeline is considered to be correctly performed if the slope of the main line is created, which should be from 1 to 2 centimeters per linear meter.This requirement must be observed because there is no pressure pressure in domestic sewer structures.

The technology for laying sewer pipes in a trench provides that in your own house in a place where the pipeline bends sharply, you need to equip a special well.

This allows you to make the repair work easier and in the shortest possible time to change the section of the highway that has become unusable.

A similar layer should be covered with a sewer line from above. The use of backfill will simplify access to the pipeline if repairs are necessary.

Experts also recommend installing manholes in areas where there are significant differences in the depth of pipe laying. If the length of the network is large, several of them should be installed, observing a gap of about 25 meters.

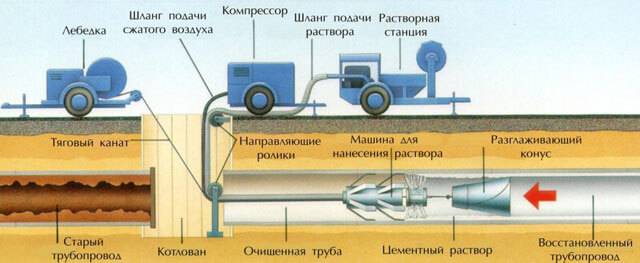

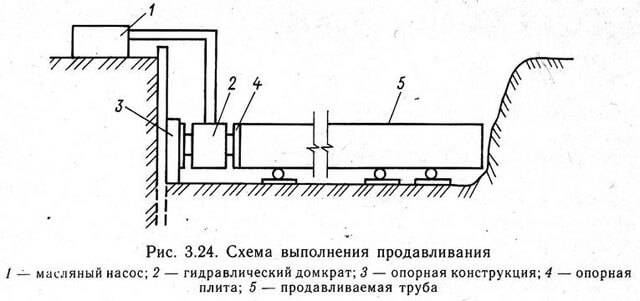

Punching method

Another way of laying the pipeline is the punching method. With this method, the pipe, as with piercing, is pressed into the ground, but with an open end, and after the work is done, the pipe is cleaned - manually or using appropriate equipment.

This method allows you to pull pipelines from steel pipes with a diameter of up to 2 m.

To carry out punching along the circumference of the pipes, hydraulic jacks are attached. Such fastening ensures normal operation in soils of any group, pipe pulling length up to 100 m and product diameter up to 1.72 m.

Work order:

- Hydraulic jacks are installed in the created pit.

- The first element of the future pipeline is installed on the guide, fixed on the jack plate, while the end of the pipe is free.

- The pipe pushed by the jacks is inserted into the ground, as a result of which an earth plug is formed in it. During the return movement of the pipe, this plug is first removed using long-handled shovels, then short-handled shovels and pneumatic percussion devices.

- After cleaning the pipe, the first pressure pipe is placed in the space between the pressure plate of the jack and the pipe being wired. In total, there are three such nozzles, the length of the first corresponds to the length of the pitch of the jack rods, the second is twice as long, the third is three times as long. When the gap between the pipe and the jack plate reaches a value four times the step of the rod, the first and third nozzles are installed, five times the second and third.

After the first section of the pipeline is completely laid, the second and subsequent sections are mounted in a similar way.

Stages of a sewerage device in a private house

If you would like to independently install the sewerage system in a private house by connecting to the central system, then the following steps should be taken:

- you need to use the services of a surveyor to draw up a situational plan for your site, including a plan for the house itself and marking the path along which the sewer line will be laid;

- file an application with the relevant organization for the development of technical conditions for wastewater disposal at your site;

- these technical specifications should be transferred to the design specialists who will develop a project for entry into the central sewerage system.The finished project must be submitted for approval to the architect and to the water utility service;

- the architect must issue a permit for the work to be carried out by a specific organization;

- it is also necessary to obtain the consent of your neighbors to carry out work near their homes to connect to the central sewer;

- if the destruction of the road surface is envisaged in the course of work (in the event the route passes through it), then it is necessary to obtain the appropriate permits from the traffic police, as well as from the road maintenance service;

- before putting the line into operation, it is necessary to warn the operating service of the water utility;

- upon completion of the sewerage installation, the operating organization must accept the finished project and sign an agreement with you regulating the acceptance of wastewater from you.

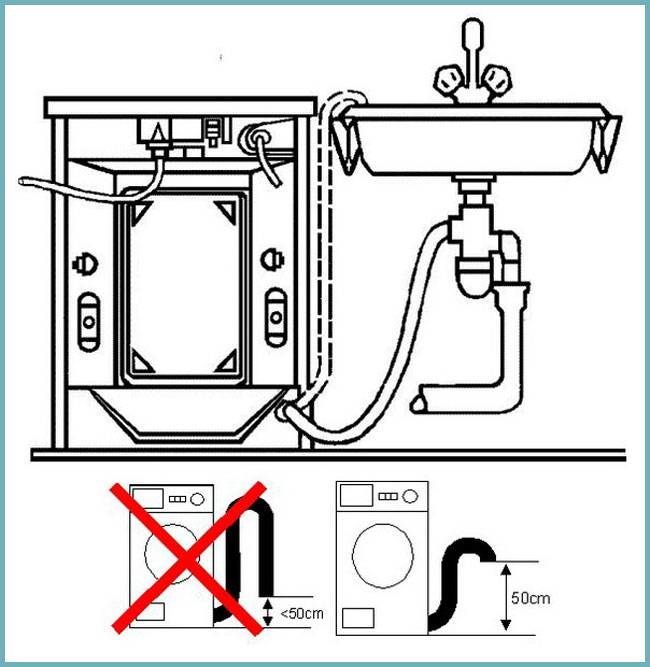

At laying sewer pipes remember that the pipe must run at a depth of 1200mm from at home, and the slope should be approximately 5 mm per linear meter.

Storm sewer - connection to the city storm network

Many owners of private cottages would like to divert rainwater from their plots together with domestic wastewater. Technically, this is completely simple, but directing rainwater into sewer wells is strictly prohibited.

This method can easily lead to the overflow of the well, due to which a large amount of sewage will come out. Therefore, in order to free the site from accumulated rainwater, it is necessary to carry out not only the installation of sewage in a private house, but also the connection to the central or city storm sewer.Since storm sewers have a much greater capacity, then rainwater flows will not create an excessive load for it. The rainwater pipe can lead directly to the collector.

Keep in mind that during heavy rains, water can go back through the sewer, so when connecting to the central storm sewer system, you must also install a return valve.

Installation of an autonomous storm sewer in a private house

The most practical way is to arrange a special pit with a reservoir for rainwater runoff in the area. A similar system can also be used as a local sewer for a summer residence. The reservoir is located in the soil, and therefore there is a natural cooling that prevents the growth of bacteria. Then a drain is laid, through which rainwater from the roof will enter the reservoir. It is also advisable to install a special grate that will work as a filter and keep leaves, branches and other debris out of the tank.

The water accumulated in the tank can then be used, for example, for irrigation.

Conclusions and useful video on the topic

To better imagine the process of organizing a sewer system, we suggest watching helpful videos.

Secrets of laying outdoor pipes:

DIY internal wiring overview:

Important points when building a cesspool:

As you can see, certain engineering knowledge and skills are required to install an autonomous sewage system at your dacha. If in doubt, it is better to seek help from specialists: there are many companies that successfully deal with the design and installation of local sewer systems.

Do you have experience with sewerage in the country? Please share good advice with our readers, tell us what you need to pay attention to when arranging an autonomous system - the feedback form is located under the article