- Factors affecting the depth of sewerage

- The depth of soil freezing is a fundamental factor

- Relief features

- Laying a water pipeline

- Actual Methods

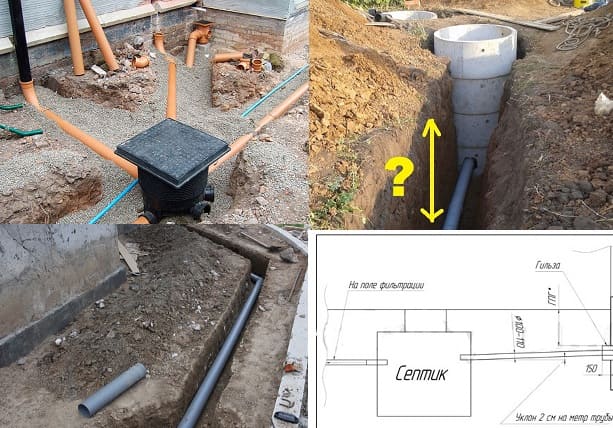

- Trench Development Rules

- Depth of laying and sewer slope

- What to do if it is not possible to lay pipes at the recommended depth?

- Do I need to insulate the pipeline?

- Sewerage scheme for a private house

- Factors that influence the choice of treatment facilities

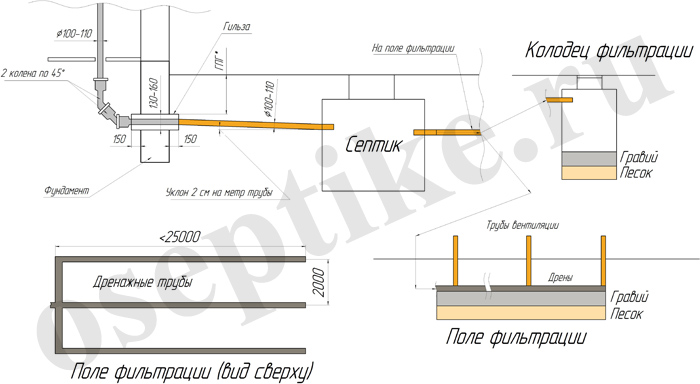

- Options for the device of the filtering part of the sewer in a private house

- Step by step procedure

- Rules for drawing up schemes and plans

- Installation of sewer pipes

- Selection of pipeline material

- Classification

- How to deal with insulation

- Installing filters

- We work with steel products

- About metal-plastic pipes

- Products with a polypropylene base

Factors affecting the depth of sewerage

The calculation of the depth of laying sewer pipes takes into account the following parameters:

- climate mark, which displays the power of annual soil freezing, this indicator is regulated by the normative act SNiP 2.01.01.82;

- technical properties of materials used in construction;

- specific features of the pipeline;

- the depth at which the sewer system is connected to a collector or septic tank;

- terrain;

- the maximum dynamic load acting on the sewer system (if the laying is carried out under the road).

The depth of soil freezing is a fundamental factor

Table of soil freezing depth for various regions of Russia

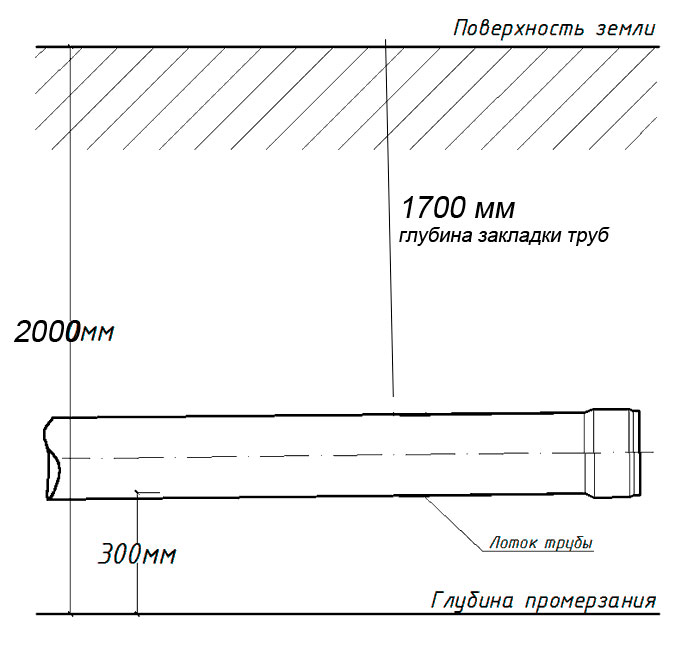

The design of sewer pipelines begins with determining the depth of freezing of the soil into which the sewer will be laid. The maximum depth, measured in standard units of measurement, below which moisture in the soil does not crystallize, is considered the mark of soil freezing. The depth of the sewer pipes depends on it.

Below the freezing mark, the soil does not freeze, its volume does not increase and, therefore, there is no effect on the pipeline laid in it. The depth of freezing for each region can be found in the collection of standards "Construction climatology", in the section of cartographic materials.

Insufficient deepening of the pipe can lead to the formation of an ice plug in it in winter and damage to the pipe

If for some reason it is not possible to access the collection, the local metrological service will help. Employees of the organization will tell you the value of the indicator, which was revealed as a result of many years of studying the properties of the soil. For example, studies have shown that in central Russia, the freezing depth is on average 1.4 m, in the North region - 1.8÷2.4 m, and on the Black Sea coast - 0.8 m.

A feature of the construction of sewers is that, unlike water supply networks, the depth of sewer pipes is calculated by subtracting a certain distance from the soil freezing depth indicator, since sewer pipes transport effluents of positive temperature. The value by which the laying depth is reduced depends on the diameter of the sewer pipes:

- with a diameter of up to 0.5 m, it is 0.3 m. For example, in order to sewer into a house using pipes with a diameter of 0.4 m, in an area with a soil freezing depth of 1.6 m, it is necessary to lay pipes in the soil to a depth of 1, 30 m (1.60 - 0.30 = 1.30 m);

- with a larger diameter of pipes - 0.5 m. For example, to improve the same house, but using pipes with a diameter of 0.6 m, the required depth of laying sewer pipes will be 1.10 m (1.60 - 0.50 \u003d 1, 10 m).

Having completed the calculation of the sewer pipes, they begin to dig trenches into which the pipeline is then laid. It is possible to reduce excavation costs by making trenches as narrow as possible. Reducing the depth of the pipes is prohibited.

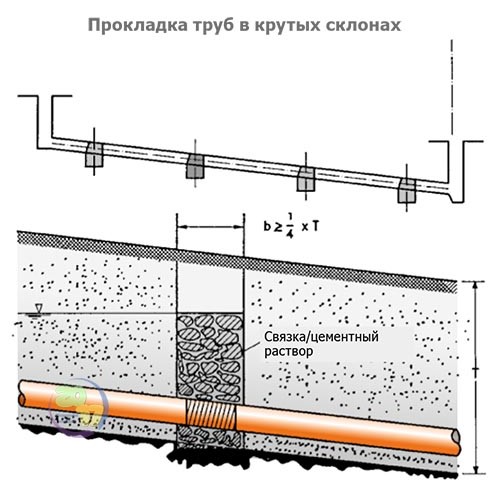

Relief features

The depth of laying sewer pipes will also greatly depend on the features of the terrain. When constructing a sewer on a relatively flat area, the depth will be the same along the entire length of the pipeline.

With difficult terrain, the sewer pipe at any point of the main line must be below the freezing level

But if the landscape has pronounced differences in height, the depth of the sewer pipe is calculated from the lowest point of the landscape on the site.In this case, the statement that the higher the pipes are laid in the ground, the lower the cost of materials and earthworks is not true, because the result will be a complex undulating construction of the main. For uneven terrain, it is advisable to build a direct sewer pipeline to a constant depth with a certain slope.

Pro tip: When the sewer system is laid in places where vehicles or people move, it is necessary to take into account the dynamic load on the polymer pipeline. In such areas, laying should be carried out in a closed way or reinforced polymer corrugated pipes should be used.

Laying a water pipeline

Actual Methods

Modern building technologies involve two main methods of underground laying of water pipes:

- Laying a water pipe in a trench. Along with this method, before the installation of the pipeline, the soil is excavated to the estimated depth, the base is prepared, and the walls of the trench are strengthened. Upon completion of the laying, backfilling is carried out, and the area above the territory of the work is ennobled;

- Trenchless plumbing. This method is more progressive and involves puncturing the soil between two technological wells, followed by laying a pipe into the resulting hole. Soil excavation, backfilling and landscaping work in this case are not required.

The open (trench) laying method allows you to cope with small amounts of work with your own hands using simple tools:

- shovels,

- scrap,

- perforator, etc.

It is well suited for suburban farms, since the soil is not covered with asphalt, development is rare, there are virtually no competitive communications and infrastructure, therefore, damage and subsequent restoration will be minimal.

Trenchless replacement of water pipes, as well as its laying, require special equipment and trained workers. The method is based on horizontal directional drilling or soil puncture using special tips and a jet of water under pressure.

Excellent for urban areas with dense buildings and developed infrastructure, where the open method is sometimes not available.

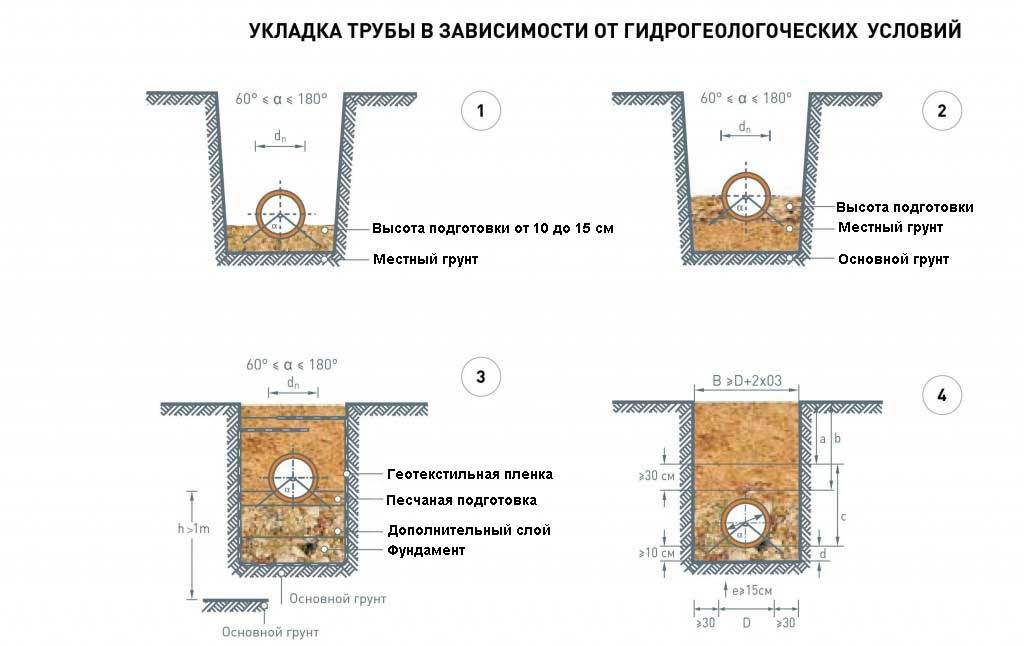

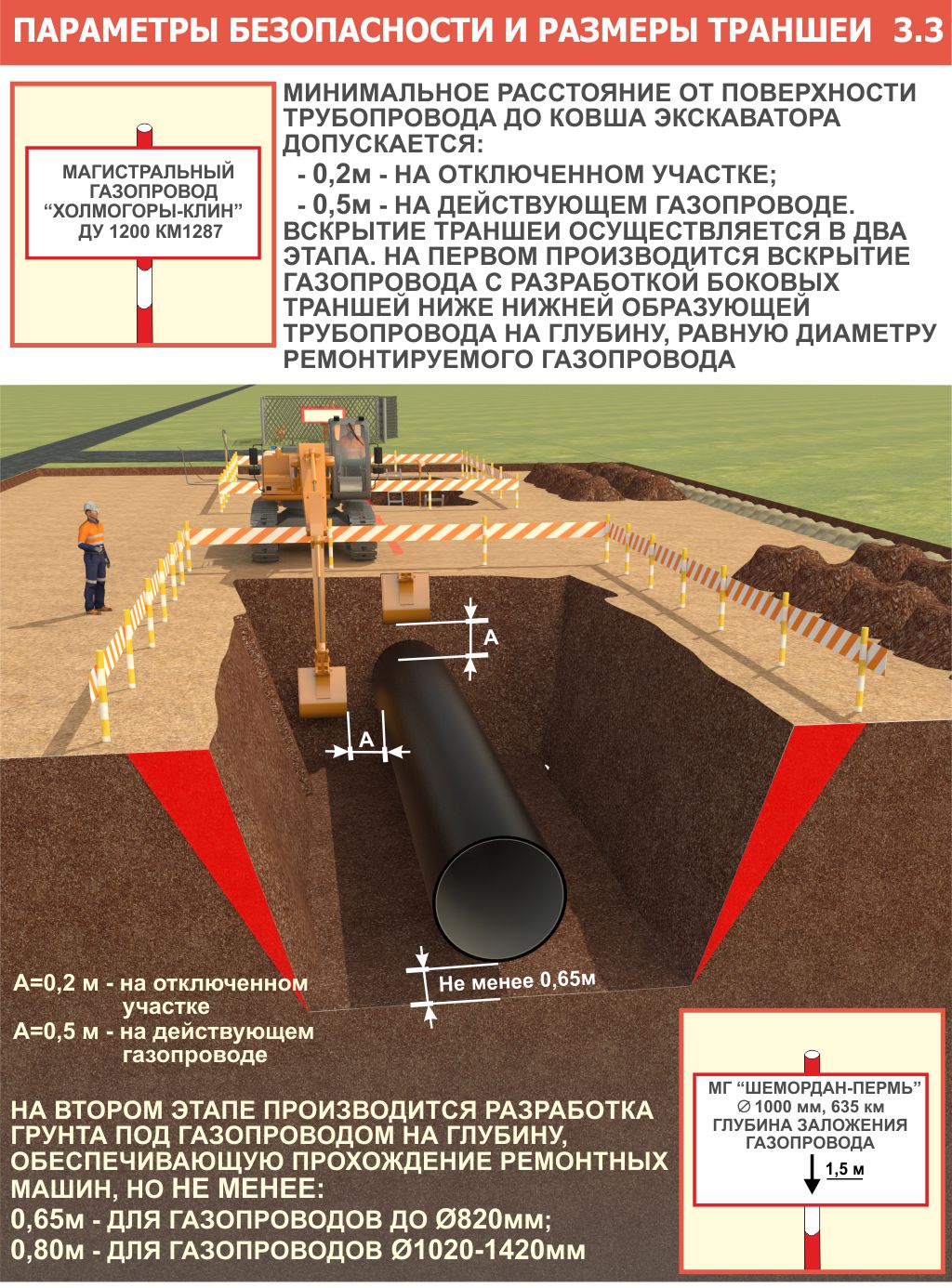

Trench Development Rules

So, for work outside the city, it is possible to use the open method of laying pipes. So we need a trench.

In order to build it correctly, you will need instructions, where we have collected the basic requirements and the necessary clarifications on a number of issues:

- It is necessary to lay a ditch along the slightest straight path. If this is unrealistic, it is divided into straight segments with turns of 90?, other angles of turns are acceptable from time to time;

- The depth of the trench is a very important feature. In accordance with SNiP, the minimum laying depth, taking into account probable dynamic loads, must be at least one meter, but the climatic conditions of our country impose a different restriction: the ditch should be approximately 30 cm deeper than the freezing depth of the soil in your region (for the middle lane - approximately 2 - 3 m, for the southern regions - 1.2 - 1.3 m);

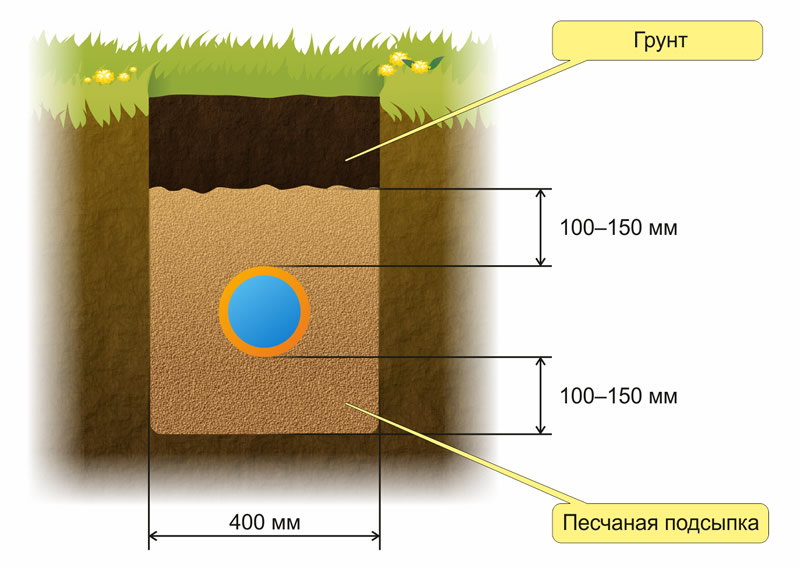

- The width of the trench when laying a water pipe according to SNiP should not be less than 70 cm.But in practice, such strict standards are used during experimental work, and in the garden it is possible to be guided by the diameter of the pipe and the convenience of work. In most cases, they dig to the width of a shovel - 45 - 50 cm;

- When laying water pipes, it is necessary to carry out a slope of 0.002 - 0.005 towards the well if there is a drain valve in it to empty the system in case of repair or conservation for the winter;

- Water supply and sewerage in one trench do not fit in accordance with all norms and rules. But this requirement is quite often ignored when using plastic pipes in protective sleeves. We would not advise doing so;

- It is possible to lay the cable and the water supply in the same trench in compliance with the following conditions: the cable (up to 35 kV) is laid in a plastic pipe above the water supply, the distance between them is not less than 25 cm, above the cable is not less than a meter of soil;

- The bottom of the trench must be tight and compacted, it is necessary that the pipe lies on the ground with the body fully attached.

In addition to the above rules, you will need a number of tips. So, in the northern regions and in the middle lane, it is better to cover the pipe with a layer of foam or mineral wool. Extreme frosts happen from time to time, and this measure can protect you from an accident.

When backfilling a ditch, especially at the initial stage (the first 25 - 30 cm), throw the earth carefully into the corner of the trench. Avoid packed clods, bricks, stones and other heavy debris, otherwise the pipe may be damaged.

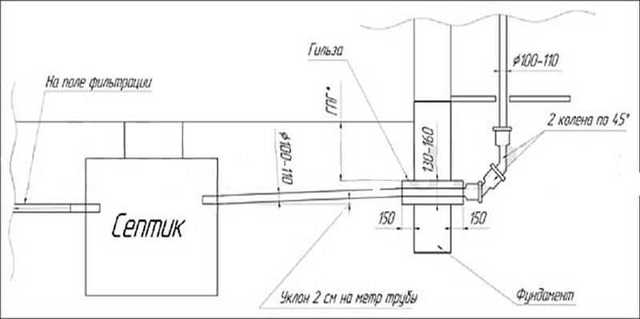

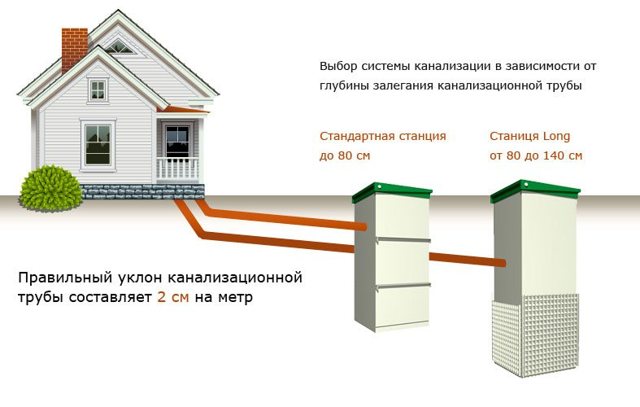

Depth of laying and sewer slope

As mentioned above, in order for the sewer system to work correctly, not only the depth of the sewer pipe is important, but also the calculation of its slope.

According to the SNiP technology, when arranging a gravity sewer, it is necessary to comply with the requirements for the mandatory slope of the pipe. It is he who contributes to the gravity passage of drains, and also prevents clogging of the sewer. The degree of slope of the pipeline depends on its diameter:

- if the diameter of the plastic pipe of the outer part of the sewer system does not exceed 5 cm, the slope of the line must correspond to 3 cm per linear meter;

- for a collector whose diameter is in the range of 5 to 10 cm, the slope of the pipeline can be reduced to 2 cm per 1 meter;

- if the pipe diameter exceeds 10 cm, the slope can be reduced to 1 cm per 1 linear meter.

Everyone decides which sewer pipe to lay, however, in order to avoid blockages and to ensure the free passage of drains, it is most optimal to use pipes with a diameter of 10 cm for the outer part of the sewer.

We have already talked about the basic rules for calculating the depth to which you need to bury the sewer. However, according to the rules of SNiP, sewerage installation depends not only on climatic conditions and what material you have chosen, but also on other buildings and communications and on vehicles.

- pipe laying at the exit from the foundation should be carried out at a depth of at least 50 cm from the soil surface;

- if any section of the pipe is planned to be laid under the road along which vehicles run, it is correct to bury the sewer in such a place to a depth of 0.7 to 1 meter;

- sewerage should be laid at a distance of at least 0.4 meters from other communication pipes.

It is desirable to dig a trench for laying a sewer in such a way as to avoid turns and bends as much as possible, since in such places the patency of the drains will be significantly complicated, which may lead to the frequent need to clean the pipes. If, for some reason, it is not possible to dig a trench in a straight line, it is better to equip manholes in such places, allowing you to freely get to the pipeline.

What to do if it is not possible to lay pipes at the recommended depth?

If for some reason it is not possible to dig a trench according to the rules of SNiP, the sewer can be laid at a shallower depth, or even on the surface of the soil. However, in such cases, it will be necessary to solve the problem of how to prevent freezing of the sewer.

To do this, you need to use additional methods of insulation:

- mineral wool;

- foamed polyethylene;

- Styrofoam;

- expanded clay;

- winding the pipe with an electric cable.

After the sewer is insulated, it can be left on the surface or hidden in a shallow trench.

Which of the insulation methods to choose is up to you, however, we add that the winding of an electric cable can save sewers from freezing even in the most severe conditions.

Do I need to insulate the pipeline?

The outer part of the sewer line in most cases is laid by a hidden method and is underground.

In warm climates, natural shelter is used. The pipeline is located below the freezing level of the soil, the entire system is simply covered with earth, which serves as a natural insulation.

But in the main part of the Russian territories, this method of insulation is not suitable.For trouble-free operation of drain communications in winter, when laying main sewer lines at a depth of more than 70 cm, care must be taken to insulate the outer part of the sewer.

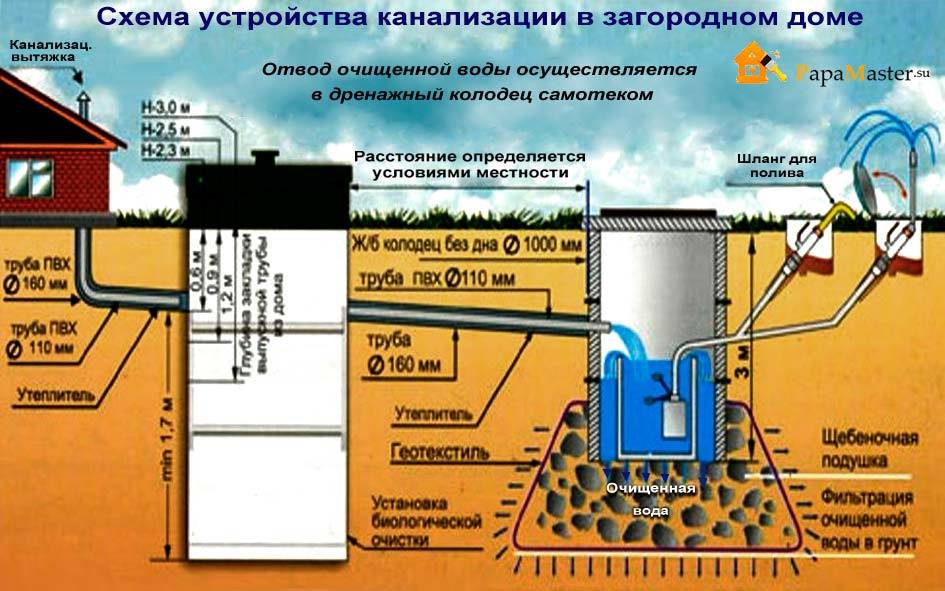

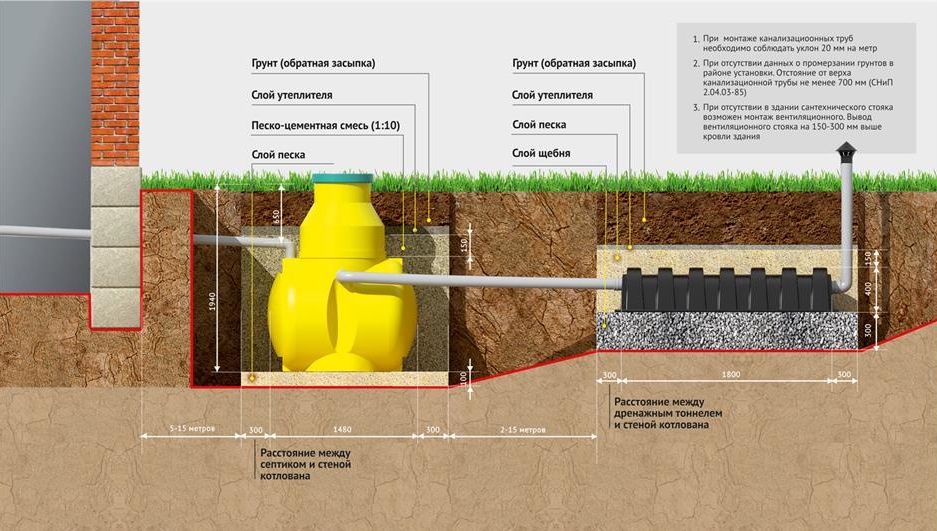

Sewerage scheme for a private house

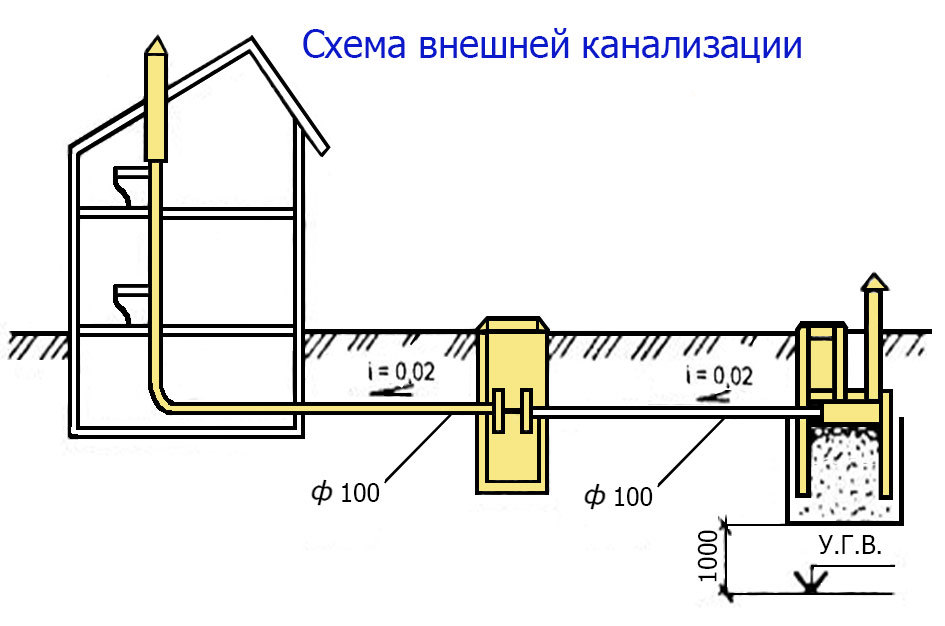

The riser is a vertical channel made of plastic or cast iron. Its design does not depend on the type of building and its parameters. She is always the same. On the sides make inputs for plumbing fixtures. From below, through the basement, the vertical pipeline is connected to the treatment plant installed on the site. Their composition depends on many factors.

Factors that influence the choice of treatment facilities

- Waste water volume.

- The nature of the pollution.

- Mode of residence (permanent or temporary).

- Soil type.

- Features of the terrain.

- The level of occurrence of groundwater (GWL).

- Depth of ground freezing.

- local government requirements.

To determine the composition of prefabricated elements, you need to think about their design, reliability, features of operation and costs.

At the beginning, mechanical filtration from suspended particles is carried out. For this, gratings, sieves, grease traps are used, followed by pits, septic tanks and settling tanks. Then the sewage, free from suspensions, is subjected to biological treatment. It allows you to get rid of organic contaminants due to their decomposition with the help of natural microorganisms. They "eat" about a quarter of the organic matter and decompose almost the entire remaining part with the formation of water, gases and solid sediment.The released gases (carbon dioxide, nitrogen, hydrogen sulfide, ammonia, methane, hydrogen) not only give rise to odors known to everyone, but are also explosive. Therefore, devices and structures must be provided with reliable ventilation and located as far as possible from residential buildings.

Instagram @kopaemkolodec_dmd

Instagram @vis_stroi_service

There are several ways to organize a horizontal filtering part located underground.

Options for the device of the filtering part of the sewer in a private house

- The central system - the sewer pipe of the site is brought to a common channel. All houses in the district or village are connected to it.

- Accumulative - they dig a pit on the territory and equip a cesspool. If the GWL is less than 2 m or the cesspool is located near the house, the pit must be waterproofed. The walls and bottom are made of reinforced concrete rings, bricks, plastic and metal. Waste is removed by a sewage machine.

- Draining septic tank - instead of the bottom, a drainage pillow is poured. Purified water seeps through it and goes into the ground.

- Filters - use from one to four containers.

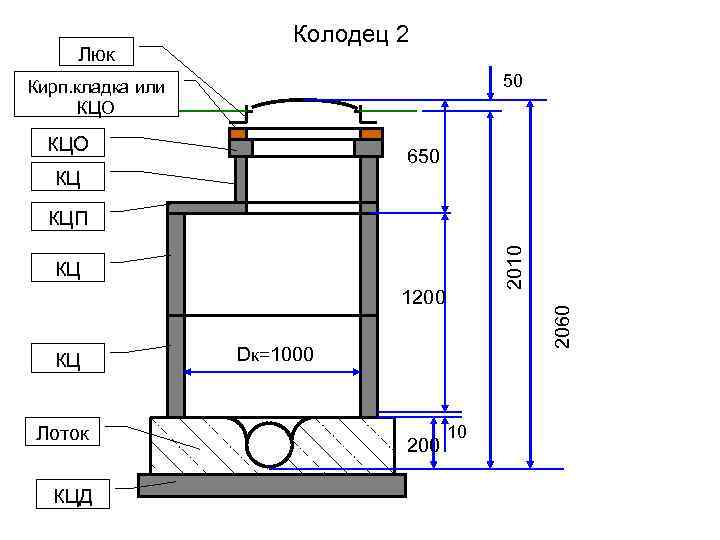

Consider the organization and installation of a vertical pipeline and underground sedimentation tanks in more detail. Let's start with the vertical part.

Step by step procedure

To dig a trench for any type of pipeline, use the general plan of action:

- Produce markup. To do this, use pegs and lace. The stakes are inserted into the ground along the entire length of the trenches, guided by the scheme. Then a string is pulled between the stakes, which will mark the width of the trench.

- Begin to develop the soil. If it is manual digging, use bayonet and shovel shovels. If semi-mechanized - use a walk-behind tractor and a motor drill.

Fully mechanized digging involves the use of bulldozers, tractors or a bar mechanism.

- Strengthening the walls. If the trench is too deep and the soil is crumbly, the walls and slopes of the ditch are strengthened. This is necessary for the safe conduct of work at the facility in order to avoid the collapse of the earth.

After digging the trench, its bottom is rammed with special tools. This is a vibrating hammer or home-made devices for tamping the soil.

Rules for drawing up schemes and plans

To draw up a plan or diagram of a trench, followed by the laying of pipelines, the following rules are followed:

- Make a drawing while maintaining scaling.

- The drawing indicates the layout of the trench, as well as the pipes in it.

- Be sure to indicate the presence of intersections with communications on the site.

- If a certain area already exists, but is covered, it is also depicted on the plan.

- The pipeline itself is drawn with the image of joints, adapters, corners.

- The diagram shows the place where the soil will be dumped.

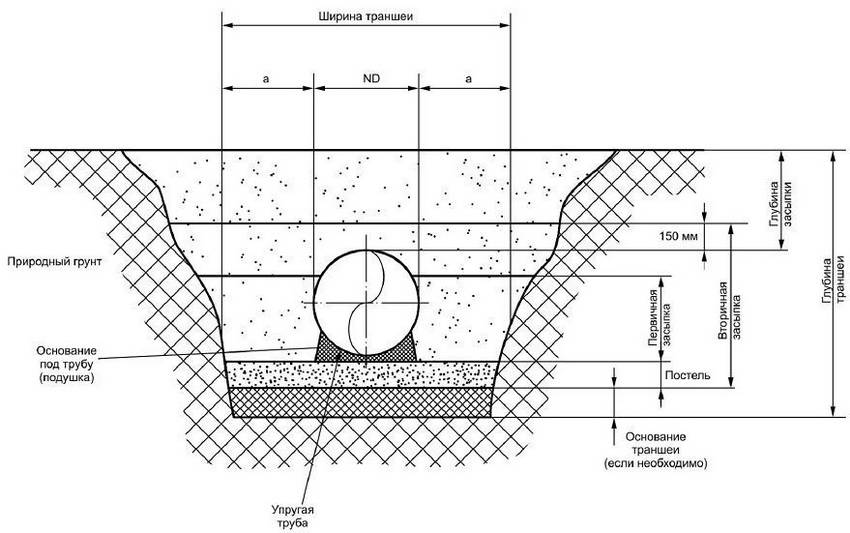

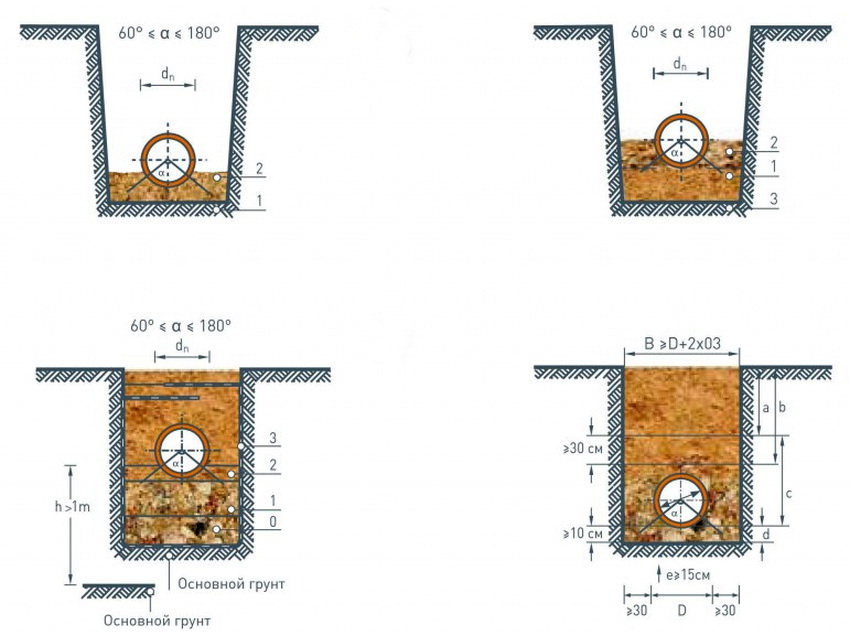

Additionally, you can draw up a diagram of the trench in the section. It indicates its width and depth. Also in this scheme, the depth of the sand cushion is indicated, if necessary, the primary and secondary backfill, as well as the pipe itself, while maintaining the scale of its diameter.

In the general scheme, trees are marked on the site, which are located nearby. If the foundation of the house is located nearby, it must be indicated on the plan. Read more in this article.

- Download pipeline diagram

- Download the pipeline laying plan

Installation of sewer pipes

When the laying level of the sewer pipeline is set, you can proceed to installation. The task itself is simple, but rather time-consuming, requiring precision.

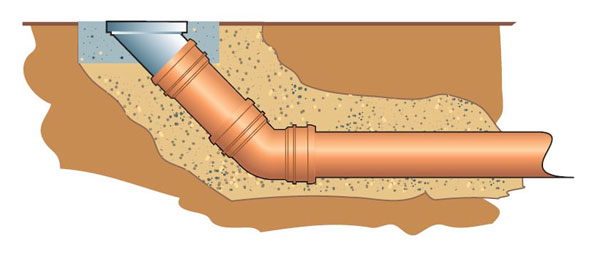

First you need to dig a recess of the desired size. As mentioned above, it can be made narrower, but not too much so that it is convenient to lay sewer pipes in a private house in the future. The bottom of the pit must be covered with a pillow of sand and clay. This is done for thermal insulation and depreciation of the pipeline.

If necessary, it will be possible to additionally insulate the structure using appropriate materials. Insulation of sewer pipes in the ground is required, for example, if it is impossible to dig a trench of the required depth. In this case, mineral wool or similar materials are perfect for insulating the heat pipe.

Free cavities must also be filled with sand and clay. It is forbidden to use the old soil for burying the pipe. For this task, again, a mixture of sand and clay is needed. When the pipe is completely covered, you need to tamp the top layer. This will avoid deformation of the pipeline during operation.

As mentioned earlier, manholes should be placed at the turn points of the highway. They are used to eliminate blockages, as well as monitor the condition of the sewer pipeline. For arranging the walls of manholes, it is recommended to take reinforced concrete rings, and broken bricks are also suitable for this task. Their dimensions depend on the level of placement of the sewerage system.

A correctly determined depth of sewer pipes in a private house, as well as compliance with all regulations, can guarantee the maximum service life of a sewer pipeline in a private house. This approach will avoid any problems during operation, domestic wastewater will be discharged without difficulty.

Selection of pipeline material

If you don’t know which products are better to use in order to lay sewers in the ground, then you should know that until recently cast-iron products were used, but they have given way to more durable, corrosion-resistant polymer elements. In addition, when answering the question of which pipelines are best used for arranging sewers, it is worth considering the weight of the product. So, cast iron pipes are very heavy, which makes their installation difficult. Lightweight plastic has an undeniable advantage over cast iron.

Products made of polymeric materials have the following advantages:

- Resistant to aggressive chemicals.

- Have corrosion resistance.

- Easily and quickly mounted.

- They have a small specific gravity.

- Ideally smooth surface inside reduces the likelihood of blockages.

If you are still in doubt about which pipes to lay for underground sewerage, you should familiarize yourself with the additional characteristics of plastic:

- Products made of polymers do not conduct electricity. This is true not only for outdoor installation, but also for installation in a house where there are many household electrical appliances.

- The material is non-toxic.

- Acceptable price. This fact often has a significant impact on which pipes to use for sewerage.

- Pipes can be easily and quickly connected using sockets, welding or fittings in a line of various configurations. However, for this you need to know the rules for performing work and installation technology.

- If such pipes are laid in a bathroom or bathroom, they will not spoil the appearance of the room, since they have a decent appearance that does not change over the years of operation.

Classification

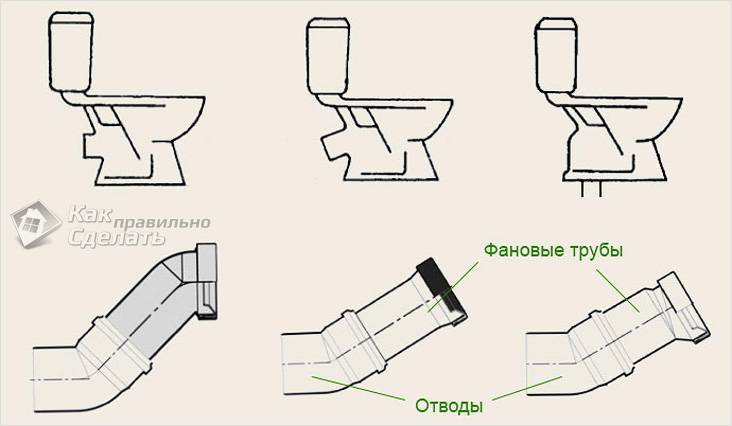

Laying sewer pipes inside the house is usually carried out using gray products. External networks are laid using orange polymer pipelines.

In this case, two types of pipes can be used:

- Smooth polyethylene and polypropylene pipes of orange color are suitable for arranging autonomous sewage systems of a cottage or a private house. These pipes should be chosen if the underground sewerage is laid at a shallow depth (up to 3 m), and the pipes themselves will not be subjected to significant loads, for example, from cars moving on the surface.

- Corrugated two-layer products made of PP and PE should be used if the nets need to be laid at a considerable depth (from 2 to 20 m), as well as under pedestrian and motor roads.

How to deal with insulation

For this, for example, special cases are used. The existing water supply is laid inside another pipe, with a small diameter. This contributes to the formation of an air cushion between the walls of different products. This keeps the heat in the water.

Or the pipeline is simply poured using polystyrene concrete or foam concrete. This is a monolithic layer, with a base in the form of concrete with a low weight and a porous structure.

Plumbing is sometimes wrapped with insulation. Or heating cable. The latter is laid both inside and outside the structure. Laying is recommended in two available ways:

- Two lines parallel to each other.

- Spiral around the plumbing.

Not every system is designed in such a way that it builds pressure without problems. But this method of protection is able to boast of efficiency.

When high pressure is maintained inside, the liquid does not freeze. Even if there is no physical thermal insulation.

When installing external non-pressure types of sewage, the so-called socket connection is used. The main thing is the absence of pollution on the plastic, then the connections will acquire high tightness. Silicone or liquid soap lubricates parts that require connection.

Sealant treatment will provide additional protection during work such as laying water pipes from polypropylene pipes in the ground.

Only compliance with all requirements and technologies will allow you to get a water supply system that will function for a long time. And it will help reduce operating costs.

Installing filters

If there is no scale or sand in the water, then elements such as fittings on toilet bowls, automatic washing machines, and ceramic faucets live much longer.

Do not give preference to filters that are disassembled manually. Inside such structures are rubber seals, whose durability leaves much to be desired.

The preparation process depends on which type of pipes you have chosen. If it is galvanized, then we use a grinder to cut the blanks of the sizes we need with our own hands. You can also do this with a hacksaw.

It is more convenient to cut metal-plastic or polypropylene products immediately in place. Even small misses in size will not be terrible.

When connecting, preference is given to two methods.For example, through a collector, which plays the role of wiring for individual devices, when each of them has its own fittings. Or through a simple tee.

We work with steel products

With the appropriate tools at hand, such as welding, for example, it is used to connect a metal structure.

It is easy to use for welding threads. Or bends that were bent on a special machine, the so-called pipe bender.

You can use dies or holders and do the work manually. Threaded connections are made in the same way as in the case of valves.

About metal-plastic pipes

In this case, the connection is made using fittings, which are supplied with union nuts. After cutting off the pipe section, proceed to chamfering from the inside with a knife. The union nut is put on the pipe together with the split ring.

Watch the video

We place the fitting from the fitting inside the pipe

The main thing is to act carefully, otherwise the rings with sealing characteristics will shift. The nut is tightened just as carefully, without sudden movements.

Products with a polypropylene base

To do the job, it will be enough to purchase an inexpensive soldering iron. Heat is applied to the inner fitting surface by selecting the desired nozzle.

We do the same with the end where the polypropylene pipe is located. We insert one part into another, wait until everything cools down.