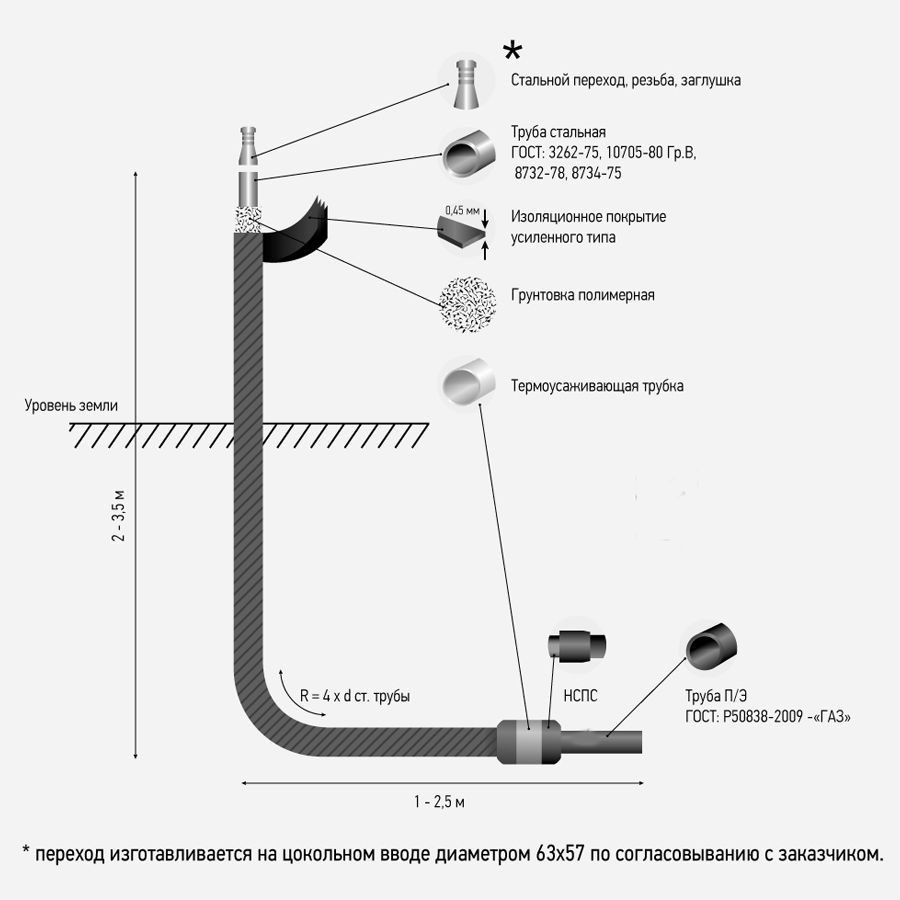

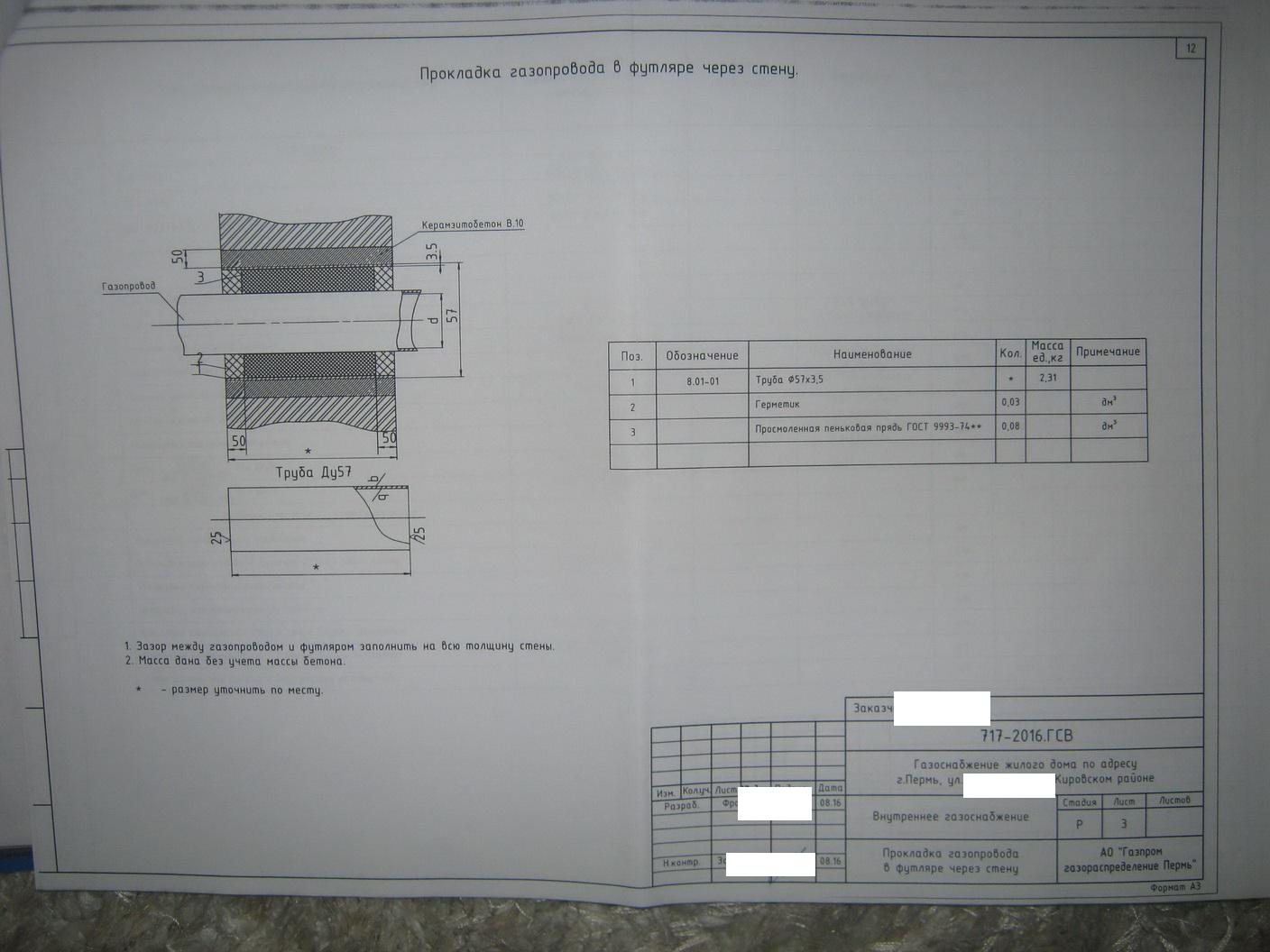

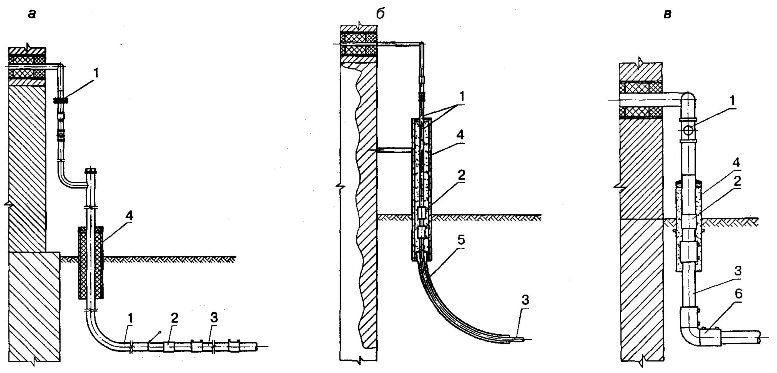

- Purpose of the protective case

- Making a case

- How can highways be laid

- Ventilation and security

- How is the distribution of gas pipes inside the house

- What can not be done with the internal wiring of gas pipes

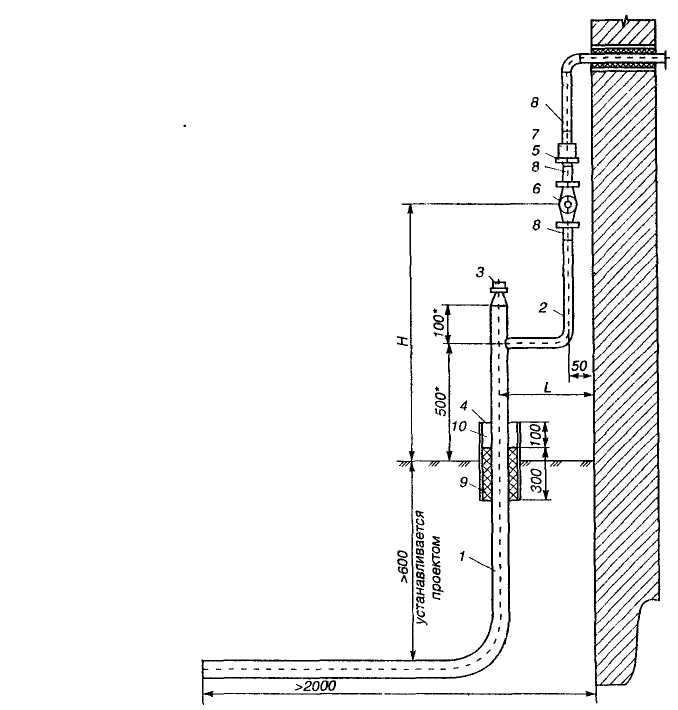

- Pipe transfer

- Issuance of a permit

- Preparing for the process

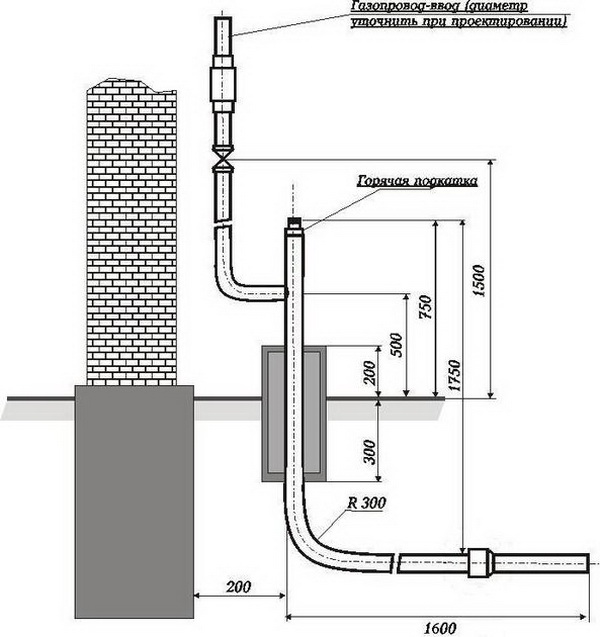

- Work order

- control tube

- Advantages of polyethylene gas communications

- In what cases is it not allowed to use polyethylene pipes?

- How to choose the type of gas pipeline

- Rules for assembling above-ground systems

- Additional norms

- Pipe Requirements

- Pipes and electric cable indoors

- Rules for the location of pipes on the site

- Pipe Laying Restrictions

- Gas pipeline security zone

- Installation of external gas pipelines: automated control systems

Purpose of the protective case

The use of the case is due not only to the protection of the gas pipeline itself from the effects of an aggressive environment and various damages, but also to ensure safety for others. Everyone knows that a gas leak is a very dangerous phenomenon, so additional protection, in this case, is not a luxury, but a necessary condition.

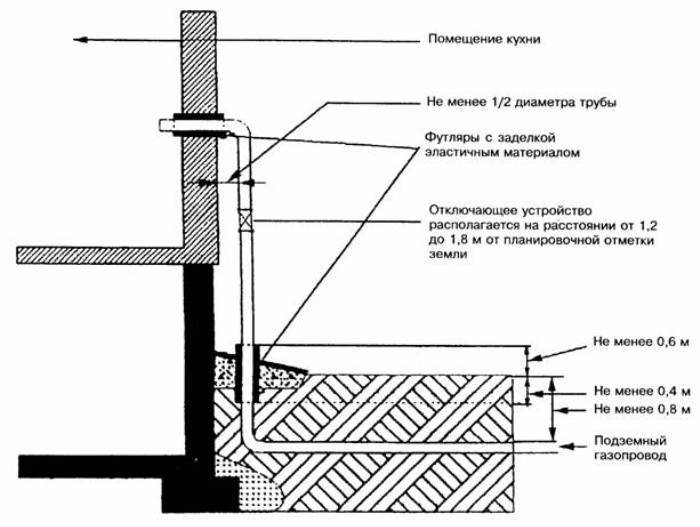

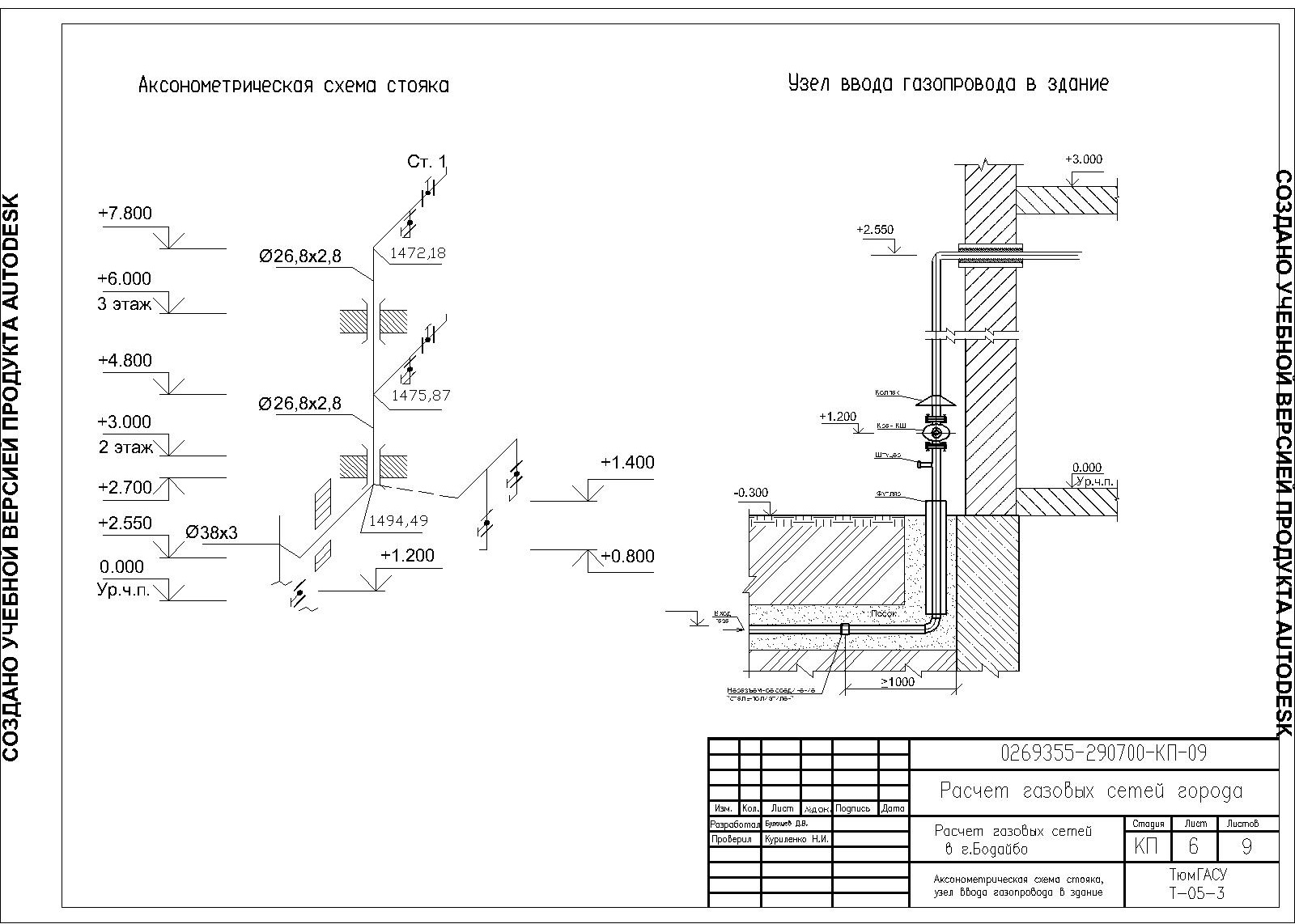

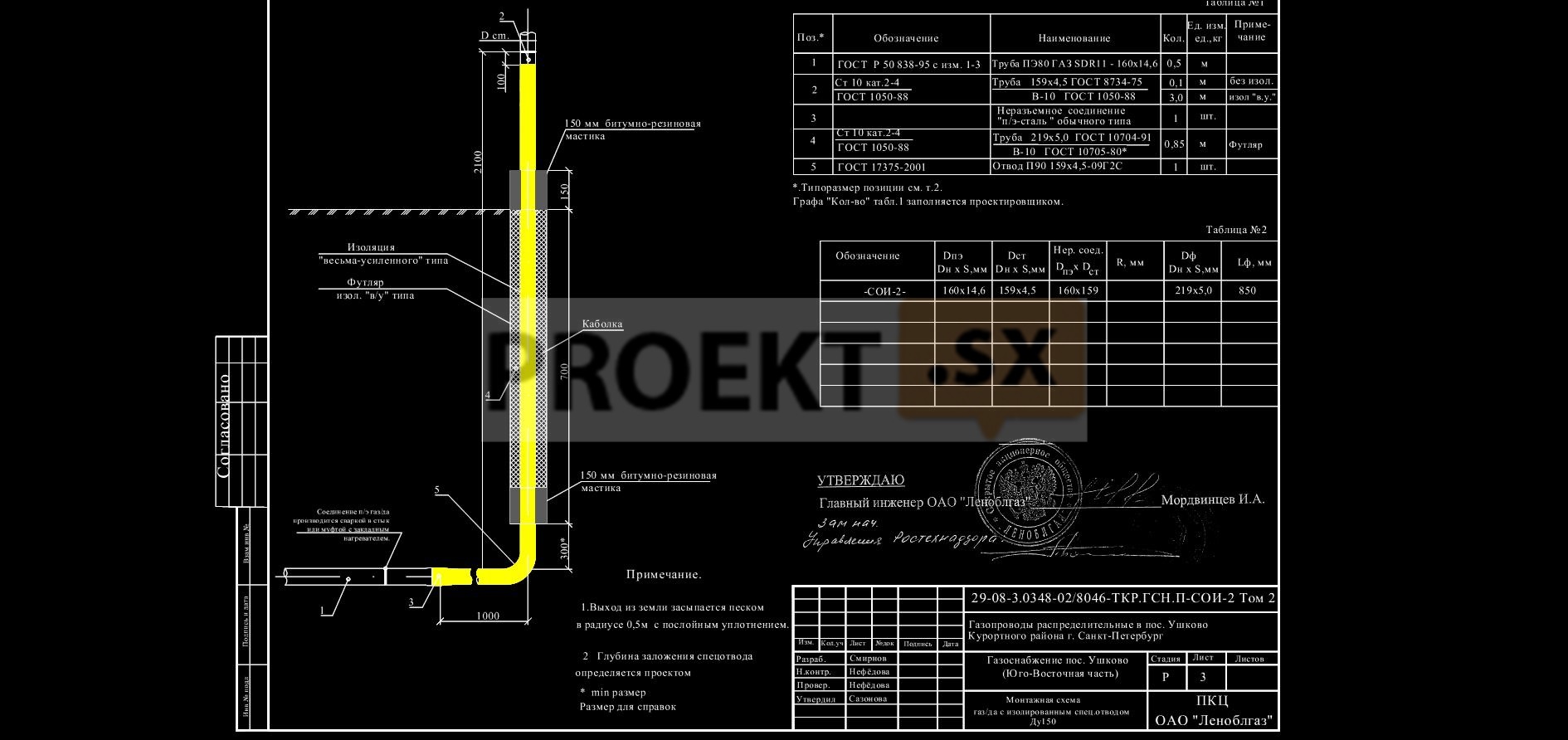

Pipe laying using a protective case is strictly regulated, in accordance with regulatory documents - SNiP 42-01 and SNiP 32-01.According to the requirements specified in the last document, not only the pipe laying process itself is regulated, but also the distance at which the ends of the protective case should be located.

In particular, if we are talking about railway tracks, then the protective case must pass through them and have a length of at least 50 meters from the exit. Such great importance is justified by the fact that natural gas is very explosive, and trains have a very high mass. As for roads, the cases should protrude from the exit 3.5 meters from them. In addition, there are precise instructions for the depth of laying the pipeline, which is about one and a half meters.

Making a case

In accordance with the same regulations, the cases must be made of steel pipes. The diameter may be different, because it all depends on the parameters of the diameter of the gas pipeline, but, in general, the diameter will not differ much, the spread will be within 10 cm.

How can highways be laid

It is allowed to pull the gas pipeline by underground or above-ground method. The latter technology is the most economical. The method of laying underground is considered safer. This is how gas pipelines are usually pulled through settlements. However, the implementation of this technique is more expensive. In maintenance, such a highway is also more costly.

Some sections of the network in large settlements can be laid above the ground. But they are almost never too long. Above-ground laying of the gas pipeline is also provided for on the territory of industrial enterprises.

Before starting the installation of the network, it is mandatory to draw up its scheme.The highway project, according to the regulations, must be carried out in a topographic plan.

Ventilation and security

When installing a geyser, a chimney must be used (read: “The nuances of installing chimneys for a geyser - expert advice”). A flexible corrugated aluminum pipe for these purposes is prohibited. Exhaust pipes for the column can only be steel or galvanized. A geyser, like any other heating device, is recommended to be equipped with fuses: they will cut off the gas supply in case of flame outage.

Features of arranging a gas pipeline in the kitchen from thin-walled metal pipes:

- Work begins with shutting off the gas supply valve.

- If the gas pipe in the kitchen needs to be relocated, the gas pipeline should be pre-purged to remove any remaining gas from the system.

- The gas pipe on the wall must be very well fixed. To do this, the product package includes clamps and brackets: they are used taking into account the diameter and length of the pipeline.

- When passing an electric cable near the gas pipeline, a distance of 25 cm should be observed between them. The gas system and the electrical switchboard should be 50 cm apart from each other.

- The gas-piped kitchen system should not be adjacent to cooling appliances such as a refrigerator or freezer. If you close the gas pipes with a refrigerator, its radiator will most likely overheat.

- When installing thin-walled gas pipes, heaters and a gas stove should be removed.

- It is forbidden to lay gas pipes in the kitchen on the floor surface, under the sink, near the dishwasher.

- When carrying out repair work, it is advisable not to use sources of artificial light. The room must be constantly ventilated.

These standards can be followed during the operation of both ready-made gas systems, and during the installation or transfer of gas pipelines.

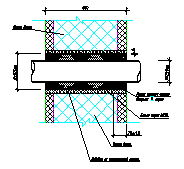

How is the distribution of gas pipes inside the house

In the design documentation, the gas pipeline route through the site must be laid in such a way that the pipe enters the wall of the non-residential premises. For this purpose, the boiler room is optimally suited. It is most convenient to carry out internal gas distribution from it.

In existing buildings, the rules allow the pipe to be laid through the living quarters. This applies to situations where the layout of the building does not allow you to choose another option. The gas pipeline, referred to in this case as transit, should not have shutoff valves and threaded connections. This requirement is quite logical. It is explained by the need to exclude gas leakage into living rooms.

To enter the gas pipeline into the house, a hole is drilled in the main wall and a steel sleeve (case) is placed in it. The gaps formed between the sleeve and the wall are sealed with an elastic material (rubber bushing or silicone). The ends of the sleeve must protrude from the wall at a distance of at least 3 cm. We note right away that it is forbidden to insert the pipe through the foundation, as well as lay it under it.

The main method of internal wiring is open. Of course, the appearance of the gas pipeline does not decorate the premises. However, this has to be accepted, since this requirement is dictated by security considerations.

The good news for owners who pay a lot of attention to the aesthetics of the interior is that the rules allow for hidden installation.It is performed in strobes (furrows) cut into the surface of the walls

They are covered with easily dismantled screens equipped with ventilation holes. Docking of pipe wiring (threaded and welded) laid inside the strobe is not allowed. All internal gas pipes, including those laid in a hidden way, must be painted with waterproof paints. At the points of connection of the pipe to gas equipment, the rules require the installation of shut-off valves.

Pipe connection method The main method of connecting pipe segments inside a building is electric welding. Threaded and flanged connections are allowed only for the installation of gas and metering devices, shut-off devices and pressure regulators. Regulations require that detachable connections be placed only in places where there is free access for their inspection and repair.

Pipe connection method The main method of connecting pipe segments inside a building is electric welding. Threaded and flanged connections are allowed only for the installation of gas and metering devices, shut-off devices and pressure regulators. Regulations require that detachable connections be placed only in places where there is free access for their inspection and repair.

What can not be done with the internal wiring of gas pipes

The prohibitions governing the installation operations look like this.

- Installation of gas wiring in ventilation shafts is not allowed.

- Thin-walled gas pipes should not cross door and window openings.

- The gas pipeline from the floor surface must be separated by at least 2 meters.

- The length of the flexible sections of the main line cannot be more than 3 meters with the obligatory provision of the maximum density of the joints.

- It is allowed to lay pipes in well-ventilated rooms, at least 2.2 meters high.

- In hard-to-reach places for inspection and repair, wiring is prohibited. An exception is easily dismantled wall sheathing structures.

- The ventilation of the kitchen, in which the gas pipes will be laid, cannot be combined with other living quarters.

- Finishing the ceiling and walls located near the gas pipe must be made of non-combustible materials.

- The fastening of the internal gas pipeline must be reliable. For this purpose, steel clips and clamps equipped with a rubber gasket should be used.

There are a number of requirements regarding the relative position of gas distribution and other utilities, household appliances and equipment. Let's list them:

- When laying in parallel, the distance between the gas pipe and the electric cable must be at least 25 cm. In case of their intersection, the gap must be at least 10 cm.

- The electrical distribution panel must be at least 50 cm away from the gas pipeline.

- A gap of at least 1 meter must be provided from the open busbar of the electrical wiring to the gas pipe.

- It is not recommended to place freezers and refrigerators in the immediate vicinity of the gas distribution. The pipe behind the refrigerator impairs the ventilation of its radiator grille. As a result, overheating and damage to the household appliance may occur.

- Do not install gas pipes behind the gas column, and also place them close to heating appliances and a gas stove.

- In the kitchen area, it is forbidden to lay a pipe line on the floor, under sinks and next to dishwashers.

Pipe transfer

The decision whether it is possible to cut or move the gas pipe in the kitchen will be up to the relevant services. You are only free to propose a redevelopment of the network and voice your own version. And professionals will tell you whether such changes are real, whether they will pose a threat to people's lives, and they will also tell you how much such an “upgrade” will cost you. Where to begin? Where to knock?

Any transfer of pipes must be coordinated with the relevant services.

Any transfer of pipes must be coordinated with the relevant services.

Issuance of a permit

Remember the step-by-step instructions for preparatory actions and coordination of plans for the transfer of gas pipes:

- Contacting the gas service according to the place of registration. It happens that you need to “knock” on some subsidiary structure of this organization: everything will be explained to you on the spot.

- Making an application. You will be provided with a sample appeal, on the basis of which you must write statements on your behalf on the topic of what changes you want to make (the statement serves as the basis for the master to visit you).

- Inspection of housing by a representative of the gas service. The master will listen to you, examine everything, check, make the correct calculations (subject to compliance with all standards). It is not a fact that at the same time the expert will reject your plan, it happens, especially with a diligent approach and the homeowner studying the norms, that the master does not have to correct anything.

- Drawing up a budget. This, in fact, is done by the office you contacted.

- Budget approval. When the plan is ready, it will be handed over to you so that you familiarize yourself with the documents and give your consent to carry out this kind of work.

- Payment. If the estimate suits you, you should pay for this service. If not, then do not worry, it can be improved, you just tell the master what you do not agree with, and he will find a compromise proposal.

Remember to install taps to turn off the gas if you want to change the stove

Remember to install taps to turn off the gas if you want to change the stove

Preparing for the process

If the estimate is agreed upon by you, then within up to 5 days (as a rule) a team will knock on your house, ready to move the pipes according to your wishes. Is it necessary to prepare for the arrival of the masters? If you want the work to be carried out quickly, efficiently, and your house is not damaged by the visit of workers, you should do the following:

- contact the craftsmen and find out if you need to provide any consumables (so as not to run after them during the work of the team, frantically looking for someone of your own who will look after the apartment, because strangers still work);

- free up space where it is planned to dismantle and install new pipes - workers should have unhindered access to the network;

- cover all kitchen surfaces, appliances and other valuable items, because craftsmen will cut, cook, dust and litter (it is better to use non-combustible coatings as a material, for example, tarpaulin, burlap);

- turn off the valve to stop the supply of blue fuel to the pipes.

Siphon connection simplifies the process of connecting elements

Work order

Of course, it will be interesting for you to know how to cut the gas pipe in the kitchen and install it, because for sure you will want to control the process, or even risk doing the entire block of work yourself (it's up to you to decide).

So, get acquainted with the process in stages:

- After shutting off the gas, blow through the pipes in order to remove all kinds of debris.

- Cut off the extra fragment of the system.

- Plug the hole that appears.

- Make a hole in another place - where you plan to connect a new network segment (a drill is acceptable).

- Weld the new structure to the gap.

- Weld other parts, if provided by the project.

- Install a faucet.

- Seal the joints with tow.

- Connect the device (stove, column).

- Check the quality of work (if the transfer will be carried out by the gas service, ask the master for a certificate of completion).

One last thing: if it is not possible to move the pipes, come up with a design to hide them.Now there are a lot of materials on this topic, so luck will certainly smile at you.

One last thing: if it is not possible to move the pipes, come up with a design to hide them.Now there are a lot of materials on this topic, so luck will certainly smile at you.

And the last thing: gas pipes in the kitchen are not a toy, treat all work related to blue fuel with seriousness and responsibility.

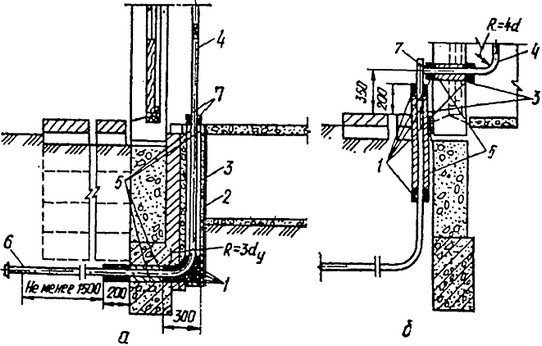

control tube

Control tubes the free end is lowered into the tank to different depths and ends at the levels corresponding to the controlled volumes. Shut-off needle valves are screwed onto the outer ends of the tubes, by opening which it is determined by the outgoing gas stream, what is going on - gas or liquid, waste. When opening the valves to check the level of liquefied gas, the service personnel must always put on gloves on their hands and be on the side of the outlet fitting of the valve in order to prevent the outgoing gas jet from falling on the operator, especially on open unprotected parts of his body. In cases where the evaporative capacity of the tanks is insufficient to supply consumers with gas, piping of the tanks with evaporator plants is used.

| Relief safety valve. |

Control tubes the free end is lowered into the tank at various depths up to the levels of controlled media.

Control tubes are more effective on a gas pipeline that is above the groundwater level. In some cases, devices are installed that block the path of gas to the danger zone in case of leaks and facilitate the possibility of its detection. The loosened strip of earth provides the exit of gas to the outside when it spreads from the place of leakage towards basements and buildings.To control leaks and vent gas in the desired direction, in some cases, permanently open drains are arranged, similar to control tubes.

control tube is a U-shaped tube filled with soda lime and calcium chloride in approximately equal amounts. The layers of calcium chloride and soda lime should be separated at the bottom with a small piece of cotton wool (Fig. 45), and at the top they should not reach 6 mm to the side discharge tubes; from above they are covered with pieces of cotton wool; the tube is closed with stoppers and filled with Mendeleev putty. Rubber tubes are also put on the side tubes, closed with scraps of a glass rod.

| Main characteristics of safety relief valves. |

control tube (Fig. VI-33) is made of a steel pipe with a diameter of 2, the lower end of which is welded to a casing made of sheet steel 2–3 mm thick and 350 mm wide, bent in the form of a semicircle and usually placed above the gas pipeline joint. The space between the casing and the gas pipeline is filled with a layer of crushed stone or gravel. The upper end of the control tube is supplied with a plug, brought to the surface of the earth and protected by a kb-ver.

| control tube device. |

Control tubes are of great importance for proper operational supervision; they are the main device that makes it possible to check the density of the gas pipeline from the surface of the earth.

Control tubes only conditionally can be attributed to devices that protect underground gas networks from damage.Their main task is not to protect, but to create conditions that allow timely detection of a gas leak from a pipe, taking urgent measures to protect the gas pipeline from further damage, as well as to eliminate the possible consequences of a leak.

Control tubes are installed along the gas pipeline route at certain distances, as well as over such points of the gas pipeline, for which it is desirable to carry out systematic operational supervision.

| Control device Installation for suction-tubing of gas from the soil. |

Control tubes are of great importance for proper operational supervision; they are the main device that makes it possible to check the density of the gas pipeline from the surface of the earth.

Control tubes are brought to the surface of the earth under the carpet in accordance with the requirements of 2 - 1 - 5 of these Rules.

| Tank head. |

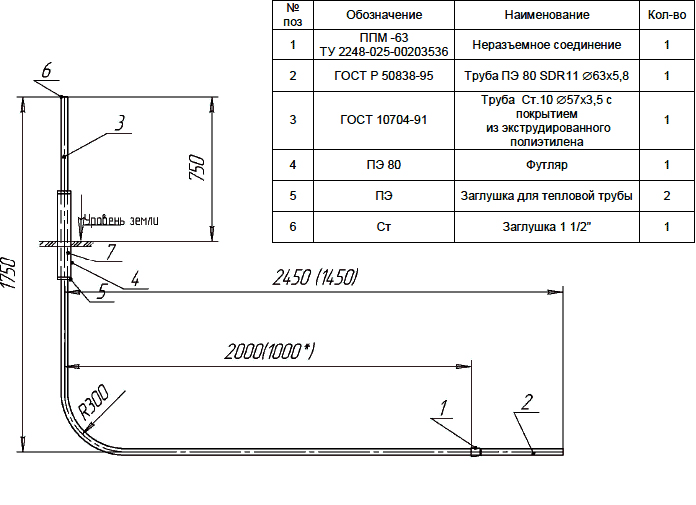

Advantages of polyethylene gas communications

Polymer pipes have an undeniable advantage over similar steel products, because:

- They are absolutely not subject to corrosion under the influence of an aggressive environment. This provides a lower cost estimate for the construction, maintenance and repair of the gas pipeline.

- The polymer is very easy to process (cut and weld) if necessary to fit the pipe.

- The manufacturing technology of polyethylene pipes makes it possible to make their inner walls absolutely smooth, which significantly increases the throughput of the gas pipeline.

- During the operation of such pipes, there is no decrease in their throughput due to clogging of the walls with various substances, since they are very smooth and elastic.

- The polymer from which the pipes are made is not able to react chemically with any other chemicals. Therefore, the pipeline does not require additional protection.

- Polyethylene is not a conductor of electricity. That is why pipes made from it are not afraid of the occurrence of stray currents in them, which could lead to an accident as a result of a gas explosion. That is, when using polyethylene pipes for laying underground gas communications, it is not necessary to place them in an expensive steel case, which would require an increase in the cost of construction.

- Polyethylene pipes have excellent flexibility, which is very good when laying gas pipelines using the horizontal directional drilling method, when the well has sharp enough turns to bypass various obstacles. For example, the maximum bending radius of such a pipe can reach a value equal to 10 times its outer diameter. This allows you to significantly reduce the cost of purchasing connecting elements.

- The polymer has a weight that is significantly lower (7 times!) The weight of a similar pipe made of steel. This property greatly facilitates the laying of the gas pipeline, which significantly reduces the cost of its construction.

- Polyethylene pipes have excellent resistance to temperature extremes, which increases the reliability of gas communications. Manufacturers guarantee that a gas pipeline made of polyethylene pipes will last 50 years or more without degrading its original performance (this is almost three times longer than the warranty period of steel gas pipes).

However, despite all the advantages of polymer pipes, there are a number of restrictions that do not allow the construction of gas pipelines using them.

In what cases is it not allowed to use polyethylene pipes?

There are a number of conditions that limit the use of polymer pipes in the construction of underground gas pipelines. It is forbidden to use polyethylene pipes:

- If soil freezing is possible in the conditions of the given area, as a result of which the temperature of the pipe wall may drop below -15 ° C (this is possible at an ambient temperature below -45 ° C).

- If the flow of liquefied petroleum gas through them is provided.

- In the area where earthquakes are observed, the magnitude of which exceeds 7 points, if it is impossible to provide ultrasonic inspection of the integrity of the welds.

- When arranging gas pipelines of ground (aerial), external and internal types, as well as when laying pipes inside tunnels, channels and collectors.

- When the gas pipeline passes over various obstacles, both natural and artificial (for example, over roads or railways).

Now, having some knowledge on choosing the type of gas pipeline and the rules for laying it, you can begin to go through all the stages of building gas communications in your area.

How to choose the type of gas pipeline

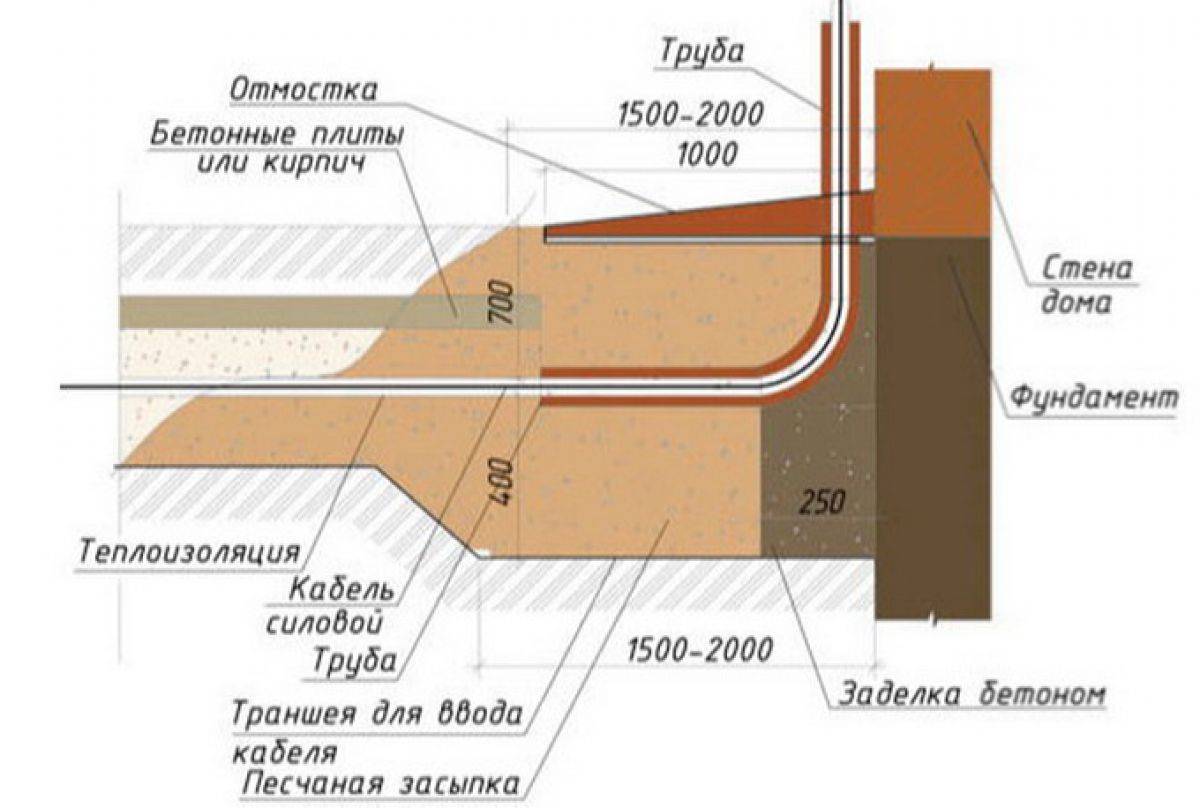

There are two types of individual gas pipeline: aboveground and underground route. In each option, the gas pipeline is connected in its own way, the distribution of gas throughout the house, premises and floors is carried out in the same way: it is only necessary to comply with the requirements and norms of snip.The cost of work depends on the chosen gas connection: underground gas pipes in a private house, the installation standards of which are described in the above snips, are much more expensive to lay due to the large volume of earthworks - by about 50-60%. However, this solution is considered more reliable due to the following points:

- The underground gas route is more protected from the environment - temperature extremes, moisture and wind, and it is almost impossible to mechanically damage such a pipeline, which, due to the combination of conditions, makes the life of gas pipes much longer than with ground installation.

Underground gas pipeline

Underground gas pipeline

- The advantage of an onshore gas pipeline is its low cost. In addition, the composition of the soil at the gas pipeline site may be such that the metal in the ground will quickly rust and collapse, which will not happen when pipes are laid on the surface. And the last advantage: with a long length of gas pipes, it is cheaper to stretch them through the air, rather than dig trenches for them, insulate and protect them from aggressive influences.

Above ground transportation of gas through pipes

Rules for assembling above-ground systems

The requirements for laying gas pipelines of this type are as follows:

- above the ground, the gas pipeline should be located at least 2.2 m in places where people pass, 5 m - above roads, 7.1 m - above tram tracks, 7.3 m - in places where trolleybuses travel;

- the distance between the fixed supports of the line should be equal to a maximum of 100 m with a pipe diameter of up to 30 cm, 200 m - up to 60 cm, 300 m - over 60 cm;

- steel gas pipes intended for laying above ground must have a wall thickness of at least 2 mm.

Gas distribution pipelines in small settlements are often laid on supports.The distance between the latter directly depends on the diameter of the pipes. So, for Du-20, this figure will be 2.5 m, Du-50 - 3.5 m, Du-100 - 7 m, etc.

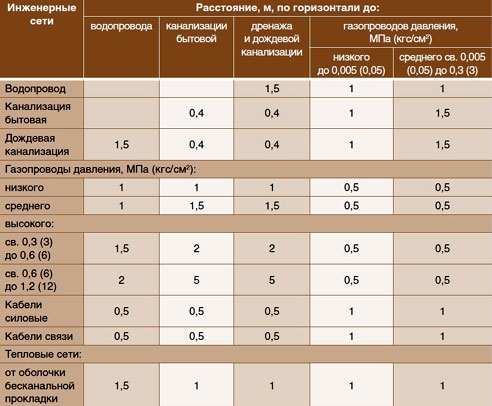

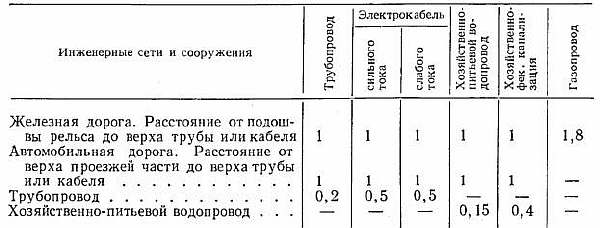

Additional norms

The adopted resolutions took care of all the norms of distances from the gas pipeline to communications. There are reference tables in the PUE standards and the minimum distance provided for gas pipes in main pipelines, residential and industrial buildings.

Power cable

Power cable

Everything that concerns specific cases that can constitute an increased danger - from a huge overpass to an electrical outlet dangerously close to a thin gas pipe connected to a cooking stove - depends on the type of cable and voltage, pressure of gas and its type. If in doubt, it is always better to play it safe and check your calculations with a specialist than to endanger the world around you.

Pipe Requirements

The "blue fuel" in underground systems can be supplied through steel or polyethylene lines. The advantage of the latter is corrosion resistance and relatively low cost. However, the standards do not always allow the use of polyethylene pipes for the transportation of "blue fuel". For example, laying underground gas pipelines using such material is impossible:

- on the territory of settlements with gas pressure over 0.3 MPa;

- outside the territory of settlements at a pressure of more than 0.6 MPa;

- for the liquid phase of SGU;

- at a temperature of the pipeline wall below 15 degrees.

Strength factor of pipes used for laying gas external networks, must be at least 2.

Pipes steel gas pipeline can be both seamless, and welded. For an underground system, similar lines with a wall thickness of at least 3 mm can be used. It is allowed to use both straight-seam pipes and those with a spiral seam for gas transportation.

Pipes and electric cable indoors

In PUE-7, adopted by the Ministry of Energy, there is a special subsection that details all the distances and essential gaps between electrical outlets, switches, cables and pipes for gas wires, the diameter of which starts from a certain value.

Norms of distance from engineering networks according to SNiP

Norms of distance from engineering networks according to SNiP

The support of the 0.4 kV overhead line can be installed at a distance of 2 m from the fence or fence. The location of the facade of the building is provided for by the relevant SNiP, and inside the adjoining space, every centimeter can be important.

The conditions to which wires and cables are limited depend on multiple factors:

- the environ- ment intended for laying (dry, wet areas, premises of all kinds or installations mounted outside);

- different types of electrical wires: single-core or two-core, protected and unprotected, cables in a metal sheath or in an insulating layer of another type;

- the voltage to which this type of wiring is oriented is 220 or 380 V or its other values;

- laying in the form of an overhead line vertically or horizontally;

- in a private building or a public building, in industrial buildings;

- in the form of special wires with a carrying cable, for which cables with different numbers of cores and variable types of insulating sheath can also be used.

Table of distances to structures according to regulations

Table of distances to structures according to regulations

All this is indicated in the PUE as vital criteria for the safety of people, buildings and structures. Therefore, during installation, variable placement is used - in niches or in special gates, and as an additional protective measure, an insulating layer of common building materials classified as fireproof in the PUE is used.

When building a house, when they simply conduct light, there are special insulation standards, but they are designed for cases where there are frankly combustible materials near the wire or power cable. Then the insulation layer cannot be less than 10 cm.

Table of distances from engineering networks in accordance with the norms of SNiP (SP)

In PUE-6, the distance between gas pipes and any type of cable depends on the type of fuel. If the gas is explosive and poses an increased threat, then the usual distance in the light of 50 mm is doubled - up to 100 mm. On both sides of the electrical wiring there must be protection against mechanical influence on the cable, it is made on both sides of the pipe for the passage of gas.

When laying an industrial parallel of pipes with a relatively neutral gas and an electric cable, a clearance of 100 mm can be left. But the power line and the gas pipeline pipe cannot approach more than 40 mm.

High pressure gas pipeline

High pressure gas pipeline

This is not all, but only the most general conditions. When laying a cable in private construction, it is better to immediately calculate the layout and consult with a professional electrician. This is especially true in rooms where heat-water pipes are provided at the same time, passing with gas or electric pipes at the intersection.

Metal and steel are not suitable for this purpose, especially in damp and cramped rooms or in outdoor installations.

Gas pipeline near the city

Gas pipeline near the city

Rules for the location of pipes on the site

The laying of gas systems on the land plot can be carried out:

- in the ground. The internal gas pipeline allows you to save the usable space of the site and "hide" the main communications;

- along the surface. Outdoor piping will cost less, but pipes running through the site limit space.

During the construction of any type of pipeline, it is required to follow the rules for laying pipes, which are established by SNIP 42-01-2002.

Pipe Laying Restrictions

At what distance from the gas pipe should the foundation of the house be located? The distance from the house to the pipeline depends on the parameters of the communication system, in particular pressure:

- a line with low pressure (not more than 0.05 kgf / cm²), which is typical for pipelines supplying fuel to private consumers, should be located at least 2 m;

- a pipeline with average pressure indicators (from 0.05 kgf / cm² to 3.0 kgf / cm²) used for laying central systems can be located at a distance of 4 m;

- a high-pressure pipeline system (up to 6.0 kgf/cm²), which provides gas to enterprises and economic complexes, can only pass at a distance of 7 m or more.

Varieties of gas pipelines by pressure

The outdoor piping must not pass:

- at a distance of less than 50 cm from window and door openings;

- at a distance of less than 20 cm to the roof of the room;

Distances to other communications (water supply, sewerage, and so on) are presented in the following table.

The location of single pipes relative to other communications

Gas pipeline security zone

In addition to the rules for the location of pipes, when laying a gas pipeline, the presence of a security zone should also be taken into account.

Under the security zone of the gas pipeline system is meant the distance between the communication pipe and two conditional lines running parallel on one side and the other.

Depending on the pressure in the gas supply line, the size of the security zone is:

- for low pressure pipelines - 2 m;

- for lines with an average pressure value - 4 m;

- for pipes with high pressure - 7 m.

The special zone of the gas supply system can be increased:

- for pipelines made of polyethylene pipes (up to 3 m);

- for highways laid in permafrost conditions (up to 10 m);

- for systems laid under water (up to 100 m);

- for routes laid in the forest belt (up to 3 m).

The size of the buffer zone is indicated on the information plate installed on the pipeline.

Presence and size of the buffer zone

Within the security zone it is prohibited:

- construction of any structures;

- arrangement of cesspools;

- arrangement of places for storage of toxic and chemically active compounds;

- installation of fences and other barriers. The minimum distance from the fence is determined by the size of the protected area;

- kindle a fire;

- cultivate the soil to a depth of more than 30 cm (for underground utilities).

Installation of external gas pipelines: automated control systems

Such equipment is designed to ensure the highest performance of highways. Automated control systems (APCS RG) have a centralized structure. Their main elements are:

- controlled points (CP) installed on external highways;

- central control room (upper level).

- gas distribution systems (lower level).

The central control room includes several workplaces, united with the help of computer networks. Gas pipeline automated control systems are used:

- for the purpose of operational control of distribution;

- monitoring the condition of the equipment;

- accounting for the flow and flow of gas.