- Types of heating systems for the home

- Project implementation procedure

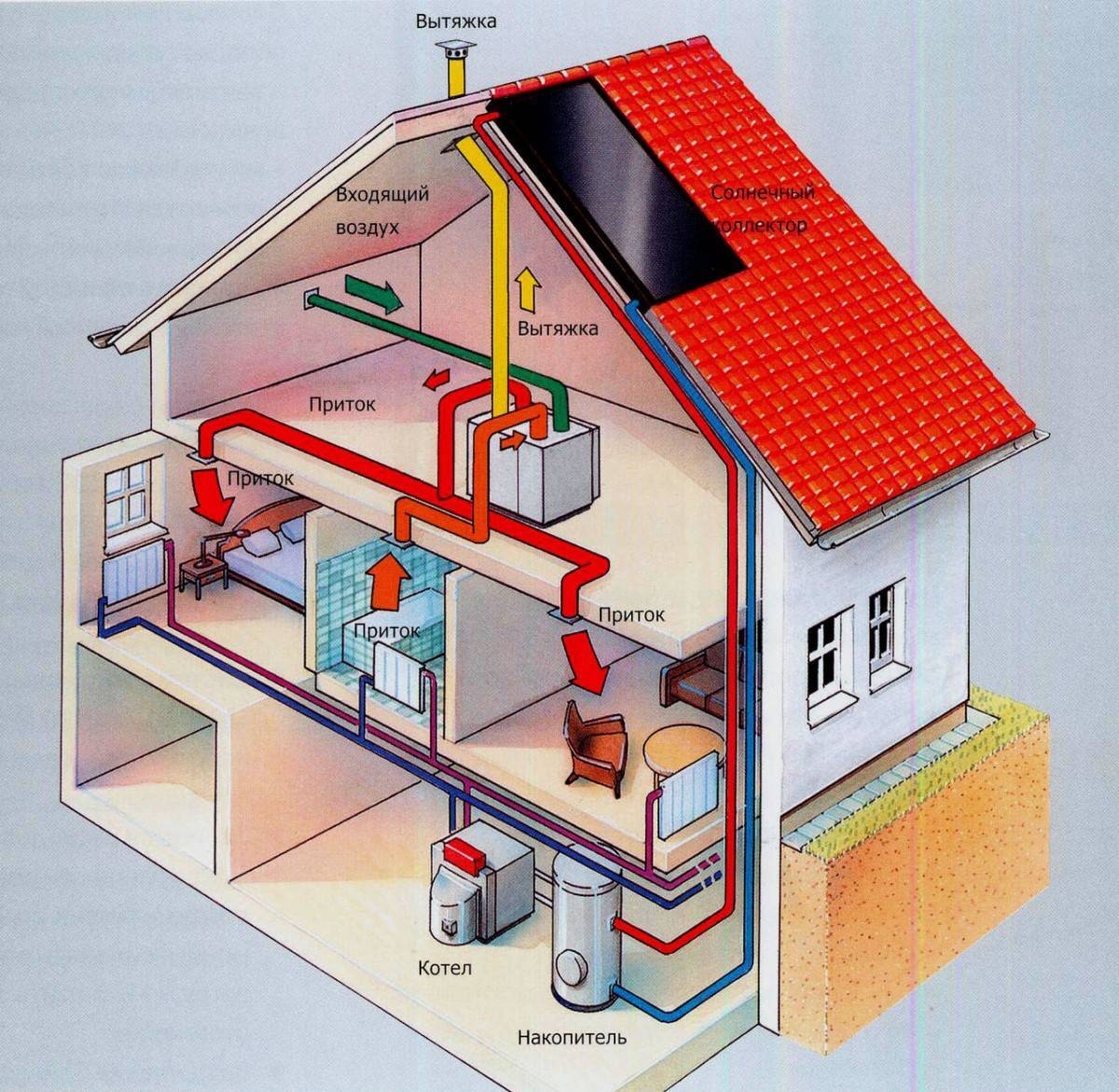

- Features of building air heating

- Heating boilers

- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- Classification of one-pipe heating systems

- Bottom and horizontal wiring of the system and its diagrams

- Heating appliances

- Varieties of alternative heating systems

- Use of diesel fuel

- Electric heating

- Use of solid fuels

- Heating using electrical equipment

- Installation of the cottage heating system

- Internal wiring

- Technical requirements

- Electric heating

- Alternative heating of a cottage or a private house based on biofuel

- Single pipe scheme

Types of heating systems for the home

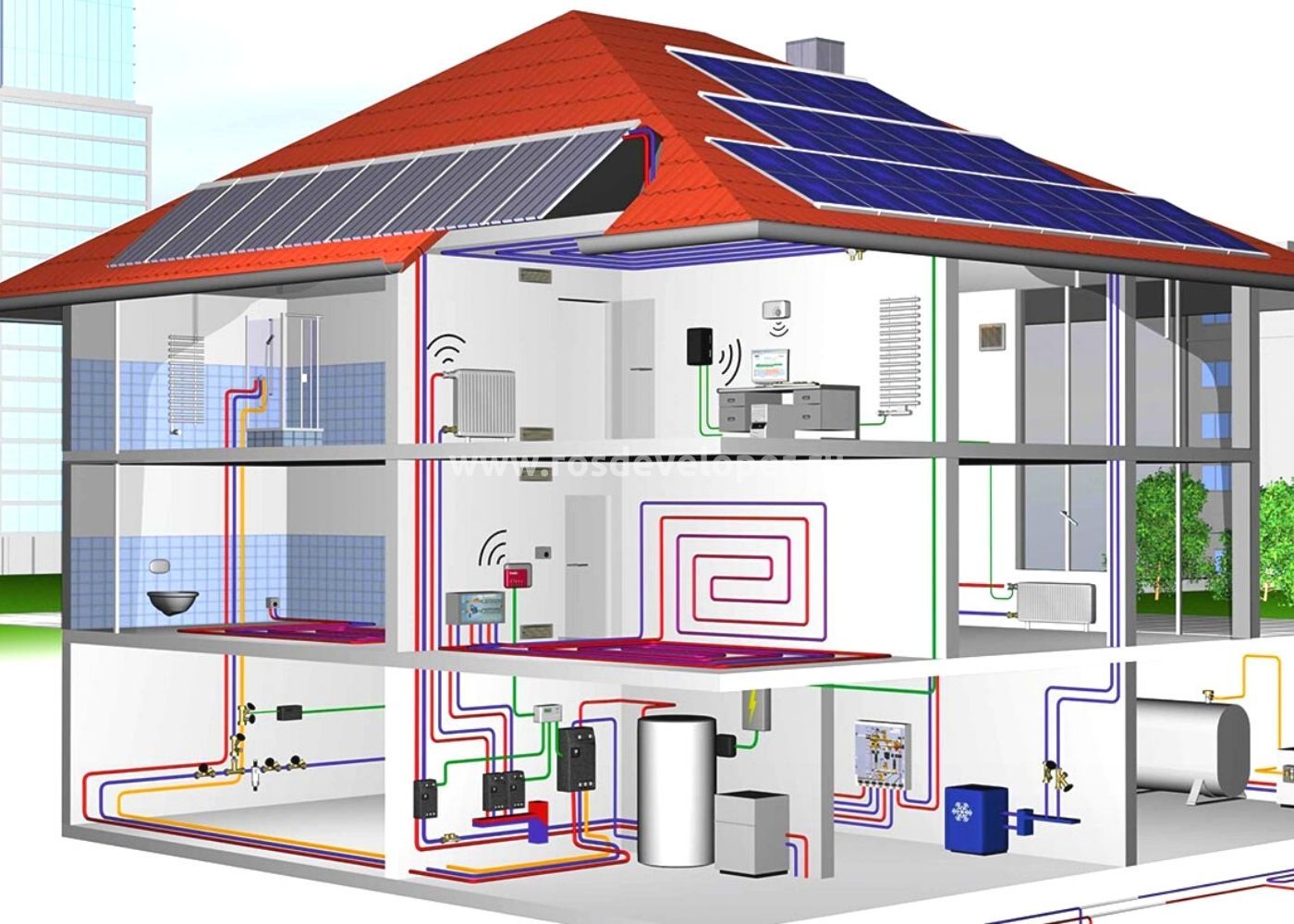

There are several options for equipment that is used to create a home heating system. They use different energy carriers and have different characteristics, cost and operating costs. There are such options for heating according to the energy carrier used:

- gas;

- electrical;

- on solid and liquid fuels;

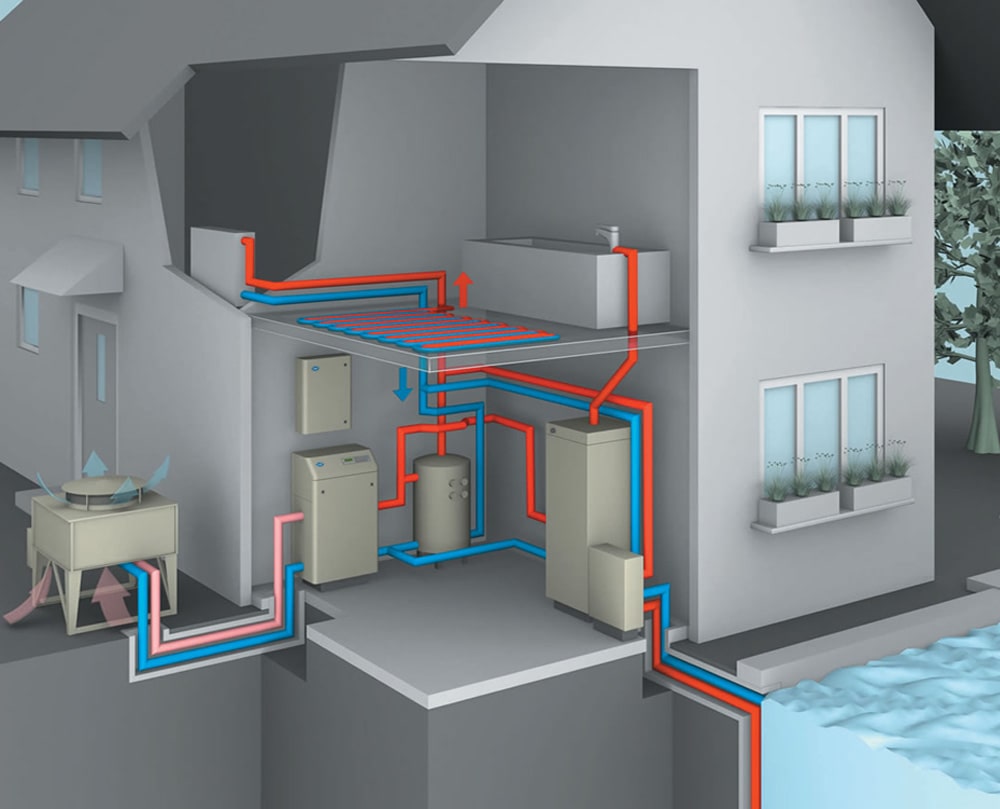

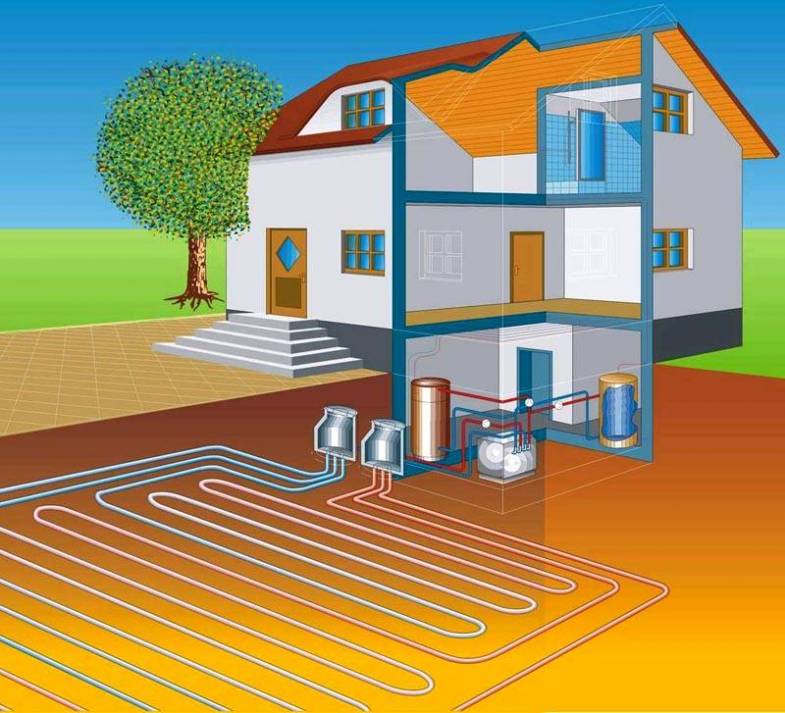

- heat pumps.

According to the scheme and layout of the equipment, the systems are divided into those that use a network with a coolant and separate ones.

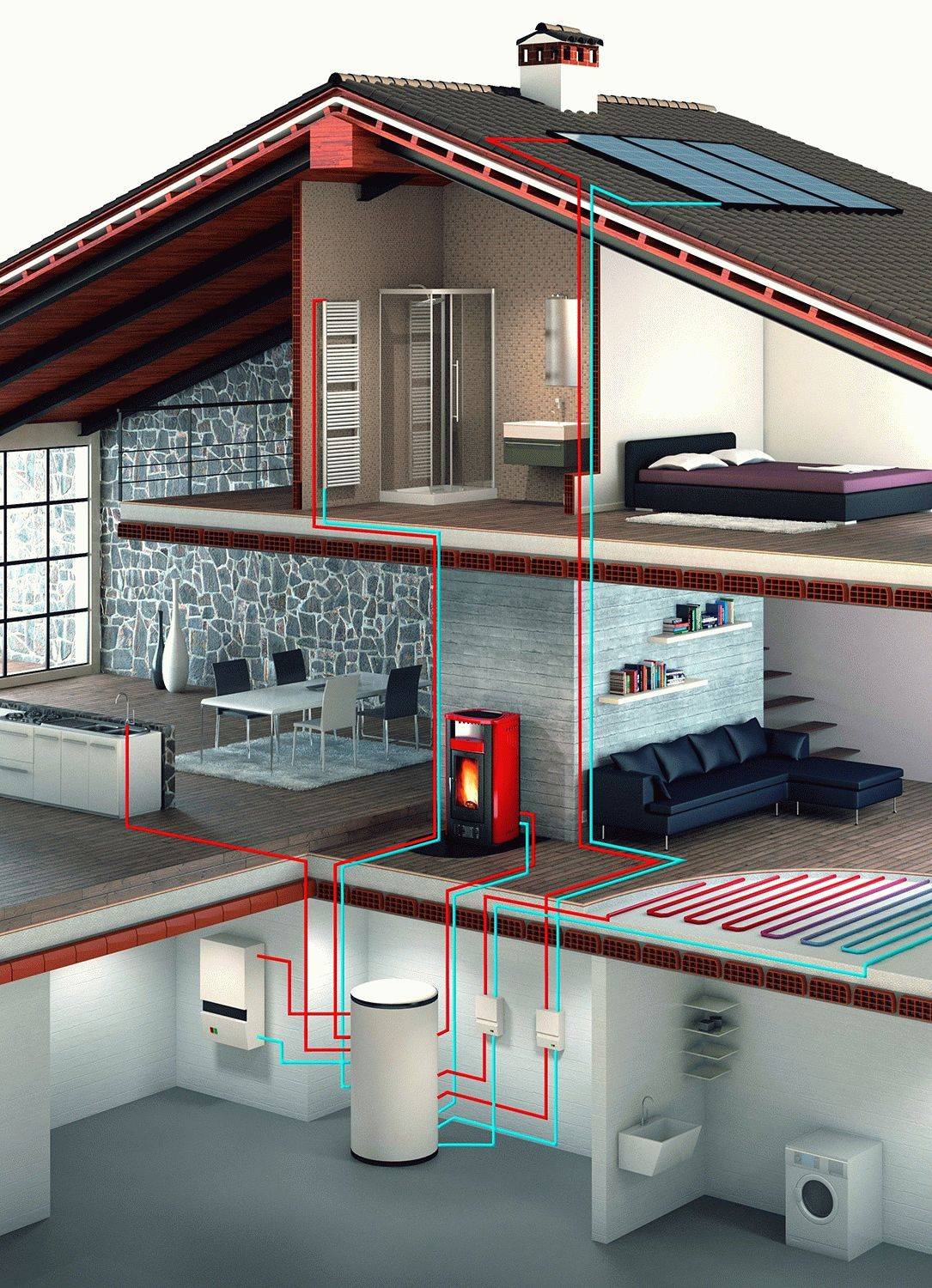

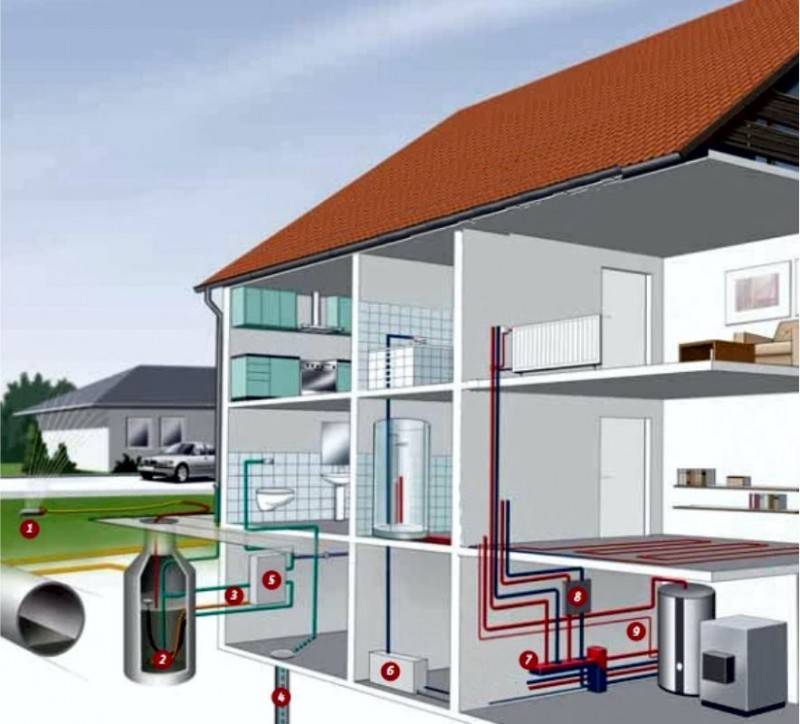

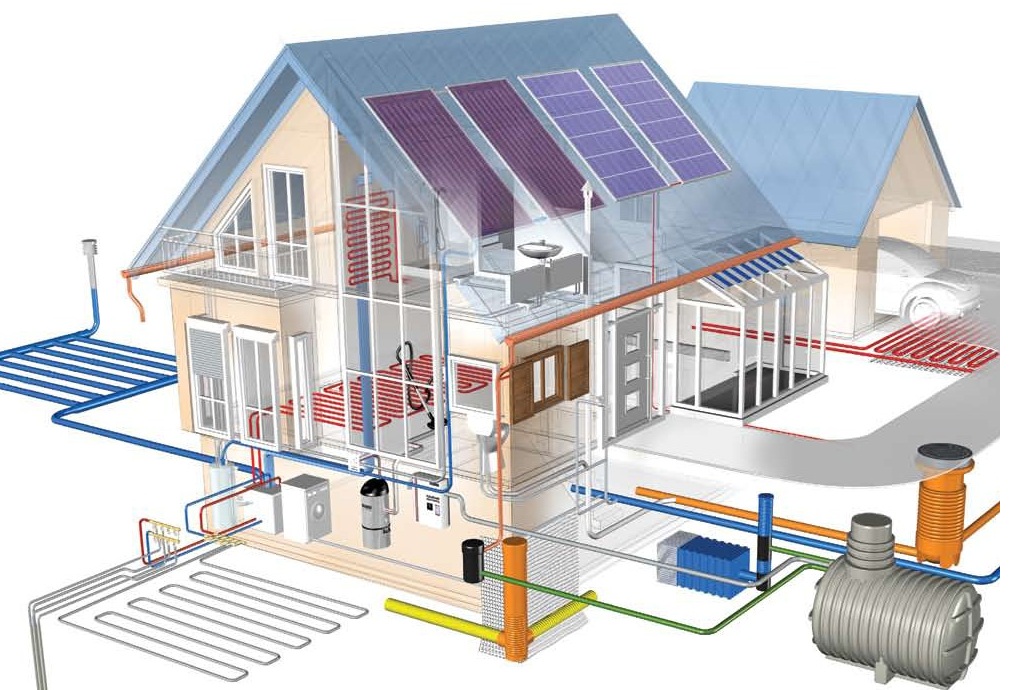

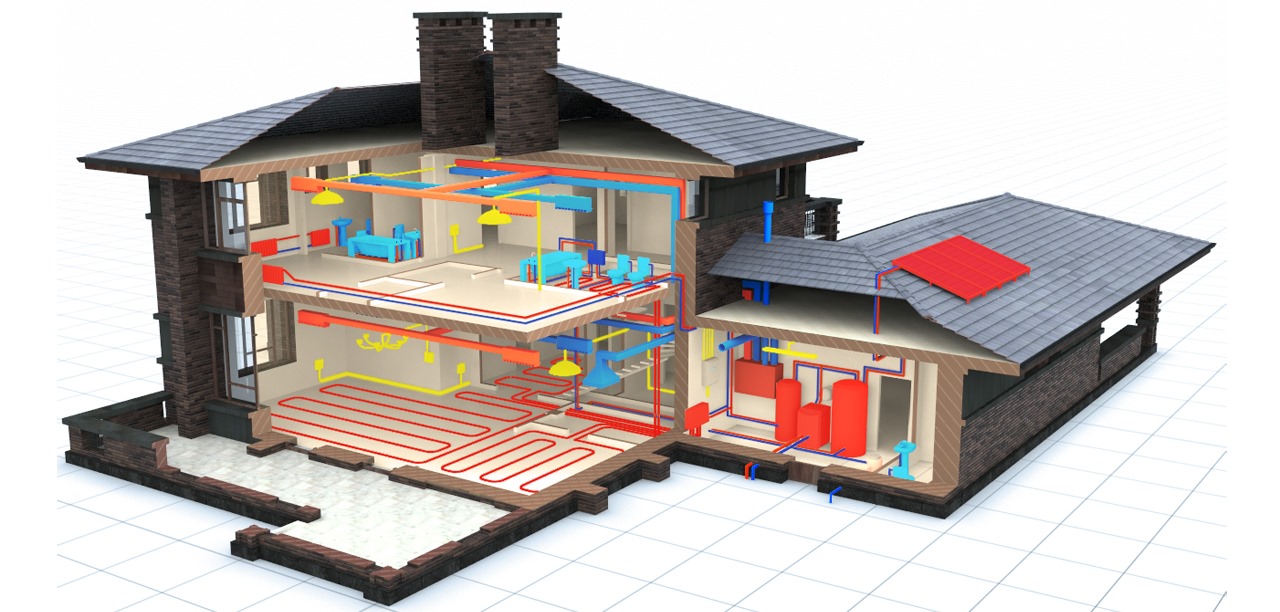

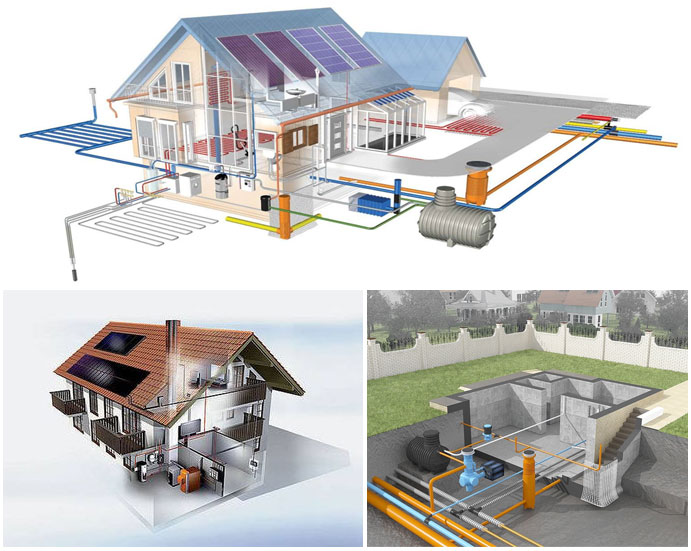

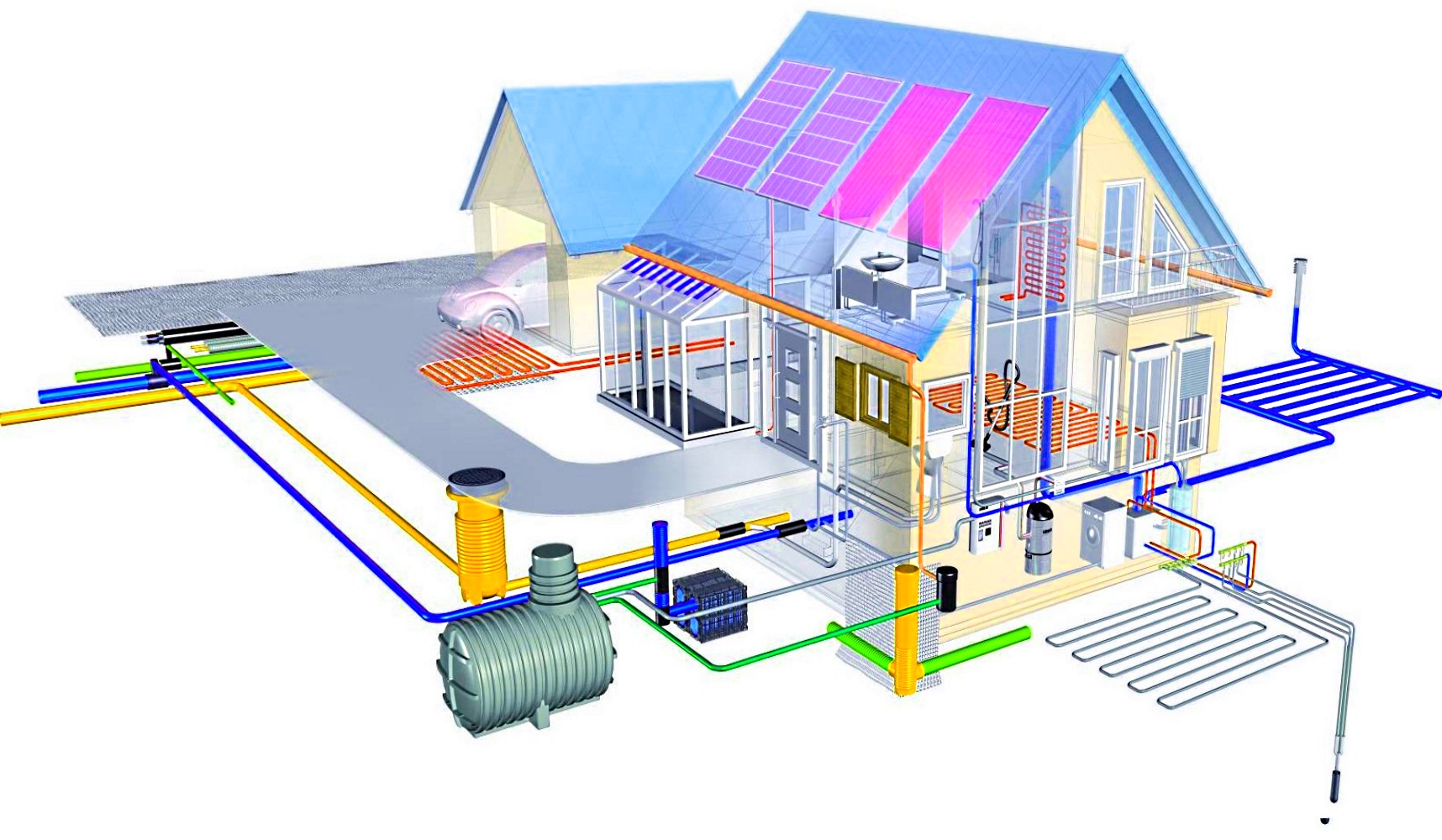

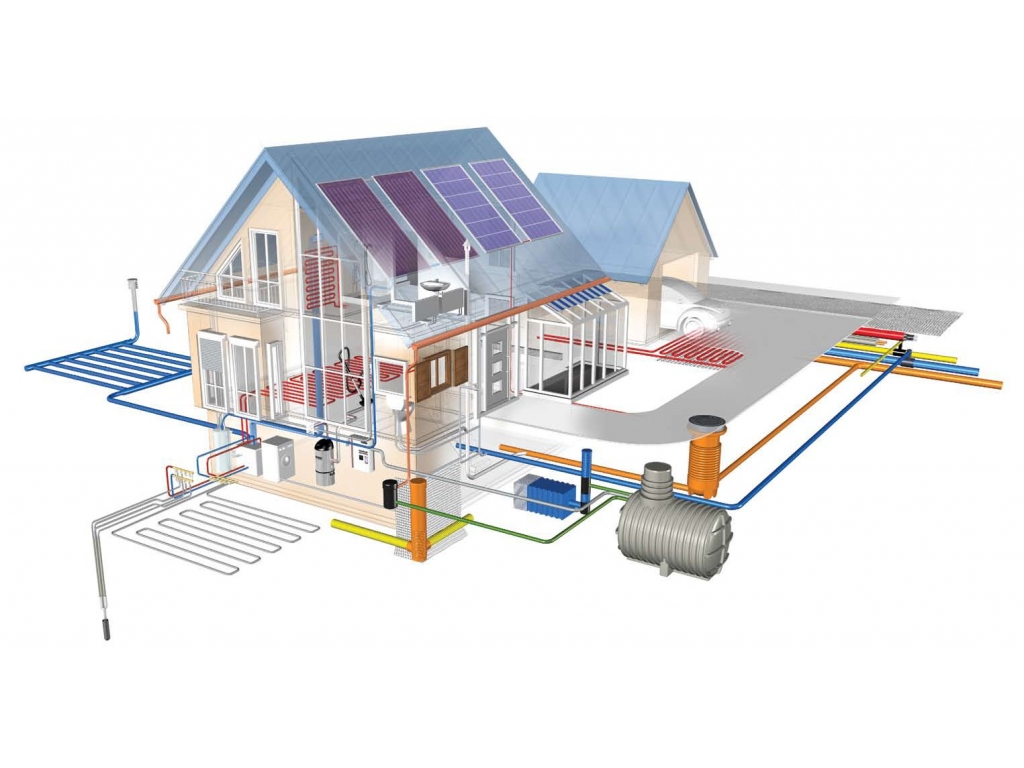

Water systems are the most common type of systems with a heat carrier network. A typical design of such a system includes:

- heat generator - gas, electric, solid fuel boiler or heat pump;

- network - a pipeline made of metal or plastic, through which heated water or antifreeze is delivered to heated rooms;

- heating devices - radiators or underfloor heating systems;

- automation and control valves.

In such a system, a gas boiler is more often used.

Separate heaters include gas and electric convectors, air conditioners with a heat pump function, fireplaces and stoves. What is the difference between each option and in what order is the calculation carried out?

Project implementation procedure

In order to make a high-quality home heating project and an accurate calculation of the heating system that will meet all the requirements, during work it is necessary to adhere to a certain order:

First, you need to form a technical task, which takes into account all the details and requirements for heating in the house

This is a very important stage and so that there are no misunderstandings in further work, it is very important to decide what exactly is meant.

To create a heating project, the contractor company offers the client to fill out a “Questionnaire”

Secondly, the design of heating in a private house requires the collection and formation of all the necessary data - the indicators necessary for work are taken. Be sure to keep in mind that there are no absolutely identical projects. Therefore, everything must be done precisely, taking into account this particular project, this building, without relying on examples.It happens that it means low-rise construction, which is being built according to standard standard projects, and, it would seem, the design of heating a country house can also be done according to the standard. But it must be borne in mind that each house is individual and it has its own requirements for the heating system.

Third, calculate the heat transfer. To do this, the master needs to carry out a calculation and determine how best to make the circuit so that it fully meets all the requirements. The main task is to find the solution and design the heating of the house, which will provide a comfortable atmosphere throughout the room.

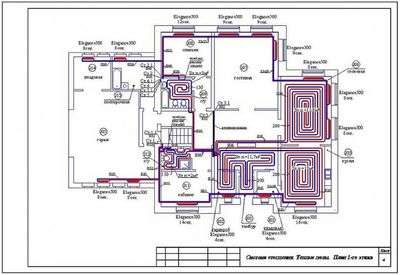

Fourth, complete the drawings. This is done only after all the above points are completed. It is necessary to make drawings taking into account GOST and other necessary documents.

Fifth, draw up and submit a project for a heating system for a country house. This is the final step in system design.

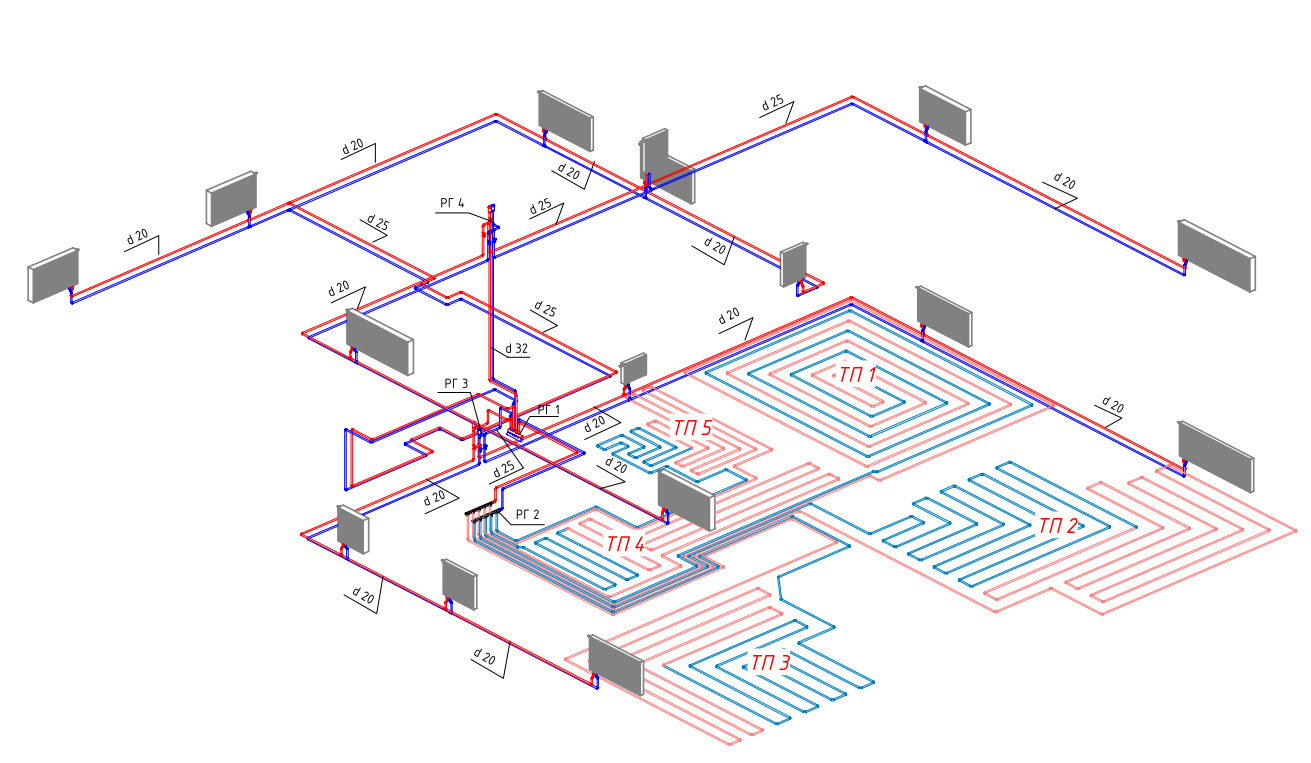

Drawing of the heating system of a private house

Features of building air heating

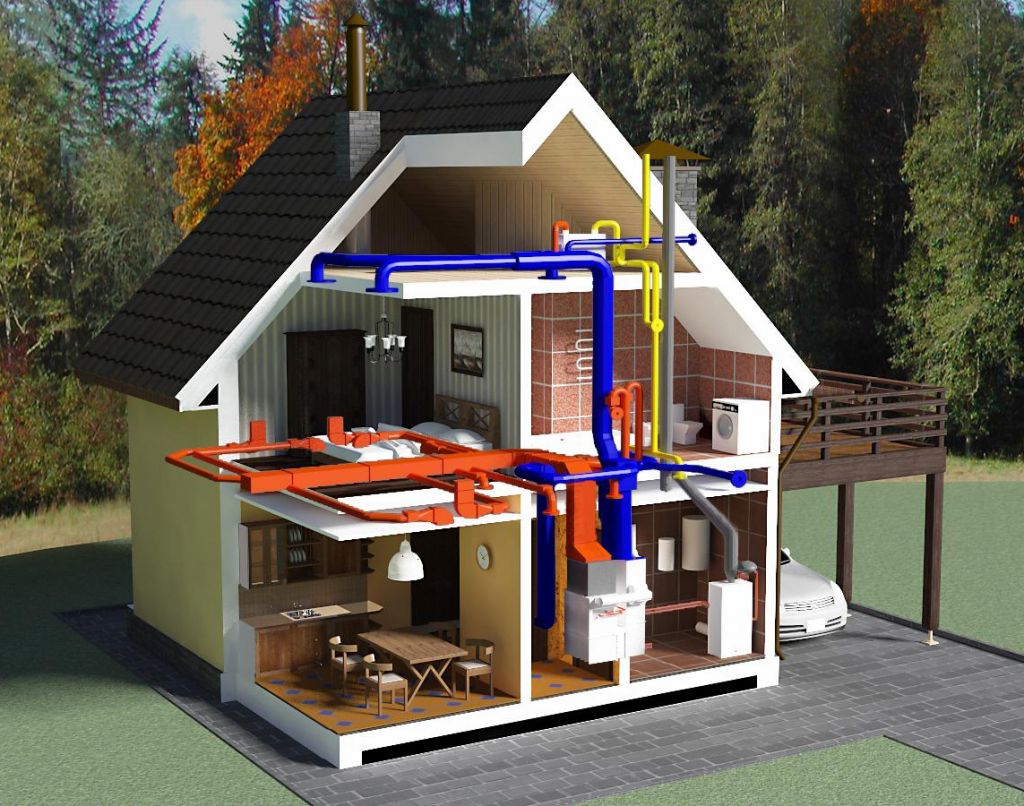

When planning to make an air heating system at home with their own hands, experts advise starting work with drawing up a project.

It is mandatory to calculate the required flow rate of warm air, the power of the heat generator, the parameters of the air channels, the volume of heat loss in different rooms.

Before you start installing air heating in a country house on your own, it is recommended to show the drawn up scheme to specialists who, if necessary, will make adjustments to the calculations made.

Video:

Having in hand a scheme that will allow you to assemble the air heating of a private house with your own hands, it remains to purchase the constituent elements.

First of all, this is a heat generator, which can be a wood-burning stove or a heating boiler - in the latter case, the fuel used will depend on the type of unit.

A modern boiler can be powered by an electrical network, run on liquefied or main gas, on diesel fuel.

Air ducts can be round and square, the former can have a diameter of 10 - 20 cm, the latter are made in the form of boxes from elements of 10x15 cm or 32x40 cm.

It is possible to give an aesthetic appearance to air networks and achieve unity with the design of the room thanks to decoration, for which drywall or other finishing material can be used.

To increase the efficiency of the system, you need to purchase a supply fan. The installation of an air heating system is possible using a climatic device, which in the warm season will be operated for the purpose of air conditioning and purification.

Video:

Depending on the scheme of air heating, the air conditioner can be mounted at the bottom or at the top of the room.

The installation of the supply fan is carried out under the combustion chamber of the heater, from where the warm air masses purified with its participation enter the heat exchanger.

After passing through the entire heating system, the cooled air is sent back to the heat exchanger.

When assembling air heating with your own hands, do not forget about safety rules. Here it is worth starting with the fact that the heater must be equipped with a security control system, have a fuel combustion control relay, and temperature sensors.

When designing air ducts, rigid elements are assembled using special clamps or using reinforced construction tape.

If an air conditioner is used in the air heating system, then the air ducts must be covered with a self-adhesive heat-insulating layer, which will prevent the formation of condensate.

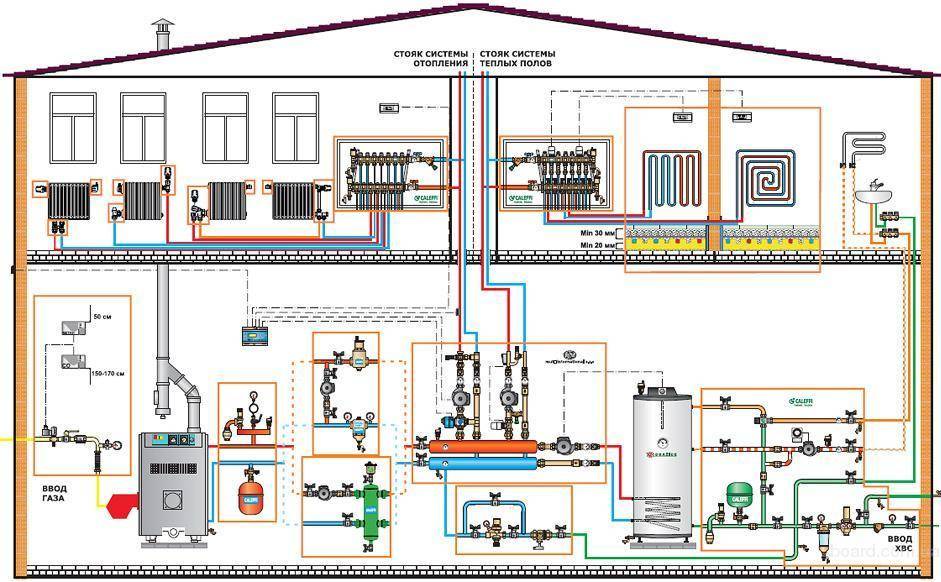

Heating boilers

At the heart of the heating structure is a heating unit, on which the source of energy received for heating depends.

To date, manufacturers offer consumers the following types of boilers:

- gas appliances. They are the most popular due to the low cost of operation and the presence of gas pipelines in many settlements.

- Electrical units. Heating with their use is expensive.

- Solid fuel appliances. Popular in those regions where there are problems with gas supply and electricity. You need a constant supply of coal or firewood for several gas stations a day.

- Liquid fuel heating units. For their functioning, they use fuel oil, solarium, which are inexpensive. But in this case, there are problems: air pollution by mining products and the need to equip a storage facility for liquid fuel.

- Waste oil devices. Also a cheap source of energy, but now the market for such fuel is not established.

- Underfloor heating system. It helps to solve problems with heating, but its cost cannot be called cheap.

You have to pay for heating system projects for a private house, because they are not given away for free. This is quite a serious job that requires high qualifications.

Before proceeding with the design, the following information will be required from the property owner:

- floor plan of a country house;

- choice of piping options - open or hidden, single or double-circuit.Perhaps in some rooms there is no need for heating, because, for example, a fireplace is used in the living room;

- already completed measures for the insulation of the building;

- the place where it is planned to install the boiler and the area of \u200b\u200bthe room for its placement.

In a word, all the preferences and wishes of the owners of country houses are reflected in the document, which is called the "Terms of Reference". For the customer, it is desirable to record all relationships with design and contracting organizations on paper, drawing them up accordingly.

It is the internal and external layout of the construction of the house that determines the features of the future heating system in it. The fact is that the design of heat supply for a country wooden cottage or a brick building will have significant differences. The heat carrier is usually water heated to a certain temperature by a boiler running on electricity (natural gas, coal, liquid fuel, etc.). The coolant circulates through pipes laid inside the building.

An example of a heating project for a private house consists of the following steps:

- development of a preliminary sketch;

- economic justification and necessary calculations;

- development of a scheme for the installation of pipes and heating radiators;

- creation of a working project. This will avoid many mistakes that novice builders make during the installation process.

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system.It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

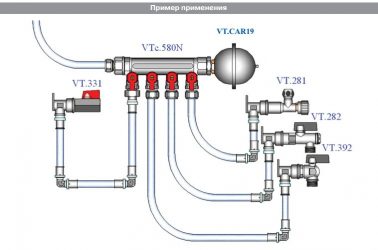

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes.However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Classification of one-pipe heating systems

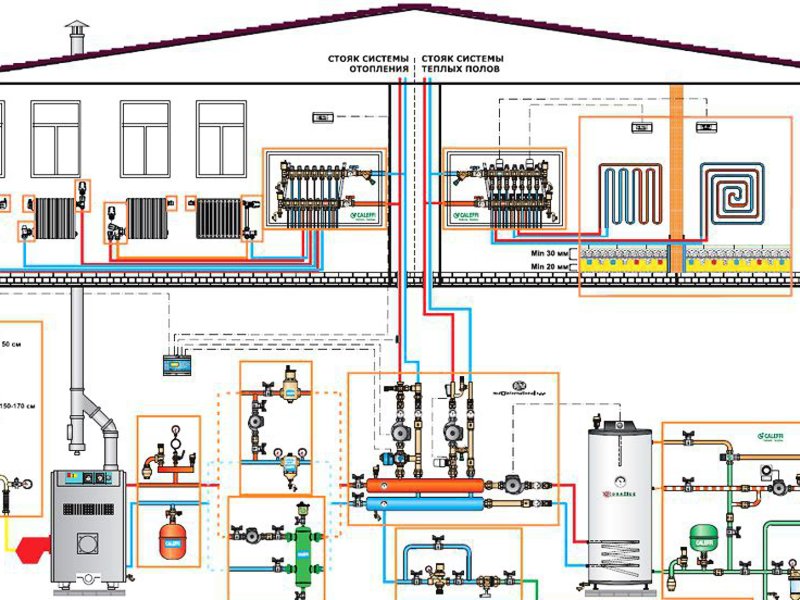

In this type of heating, there is no separation into return and supply pipelines, since the coolant, after leaving the boiler, goes through one ring, after which it returns to the boiler again. Radiators in this case have a serial arrangement. The coolant enters each of these radiators in turn, first into the first, then into the second, and so on. However, the temperature of the coolant will decrease, and the last heater in the system will have a temperature lower than the first one.

The classification of single-pipe heating systems looks like this, each type has its own schemes:

- closed heating systems that do not communicate with air.They differ in excess pressure, the air can only be discharged manually by means of special valves or automatic air valves. Such heating systems can work with circular pumps. Such heating may also have a lower wiring and a corresponding circuit;

- open heating systems that communicate with the atmosphere using an expansion tank to release excess air. In this case, the ring with the coolant should be placed above the level of the heating devices, otherwise air will collect in them and the water circulation will be disturbed;

- horizontal - in such systems, the coolant pipes are placed horizontally. This is great for private one-story houses or apartments where there is an autonomous heating system. Single-pipe type of heating with lower wiring and the corresponding scheme is the best option;

- vertical - the coolant pipes in this case are placed in a vertical plane. Such a heating system is best suited for private residential buildings, consisting of two to four floors.

Bottom and horizontal wiring of the system and its diagrams

The circulation of the coolant in the horizontal piping scheme is provided by a pump. And the supply pipes are placed above or below the floor. A horizontal line with a lower wiring should be laid with a slight slope from the boiler, while the radiators must be placed all on the same level.

In houses with two floors, such a wiring diagram has two risers - supply and return, while the vertical circuit allows for more. During forced circulation of the heating agent using a pump, the temperature in the room rises much faster.Therefore, to install such a heating system, it is necessary to use pipes with a smaller diameter than in cases of natural movement of the coolant.

On the pipes that enter the floors, you need to install valves that will regulate the supply of hot water to each floor.

Consider some wiring diagrams for a single-pipe heating system:

- vertical feed scheme - can have natural or forced circulation. In the absence of a pump, the coolant circulates by means of a change in density during the cooling down of the heat exchange. From the boiler, water rises to the main line of the upper floors, then it is distributed through the risers to the radiators and cools in them, after which it returns to the boiler again;

- diagram of a single-pipe vertical system with bottom wiring. In the scheme with the lower wiring, the return and supply lines go below the heating devices, and the pipeline is laid in the basement. The coolant is supplied through the drain, passes through the radiator and returns down to the basement through the downcomer. With this method of wiring, heat loss will be much less than when the pipes are in the attic. Yes, and it will be very simple to maintain the heating system with this wiring diagram;

- scheme of a single-pipe system with an upper wiring. The supply pipeline in this wiring diagram is located above the radiators. The supply line runs under the ceiling or through the attic. Through this line, the risers go down and radiators are attached to them one by one. The return line goes either along the floor, or under it, or through the basement. Such a wiring diagram is suitable in the case of natural circulation of the coolant.

Remember that if you do not want to raise the threshold of the doors in order to lay the supply pipe, you can smoothly lower it under the door on a small piece of land while maintaining the general slope.

Heating appliances

The last, but no less important step in the selection of the system is the choice of heating devices. Modern manufacturers than just do not lure potential customers. This is the price, design and a wide range of choices.

Radiators are:

- cast iron,

- aluminum,

- steel,

- bimetallic.

Be sure to check with the seller for certificates for their products. Often on the forums you can read about buying low-quality devices. Correctly calculate the number of sections for the device or their marking will help in the design organization. I advise you not to save on this calculation.

I often have to recalculate devices that are selected “by eye”. Calculation and adjustment of the existing scheme are more expensive, to say nothing of spending money on dismantling equipment. And I'm not even talking about the need for repairs after installing new equipment.

If you are planning an automated regulation of the system, then pay attention to heating devices with built-in thermostatic valves. This will help reduce costs a little.

Smart heating not only saves money, but also takes care of maintaining the temperature at a given level.

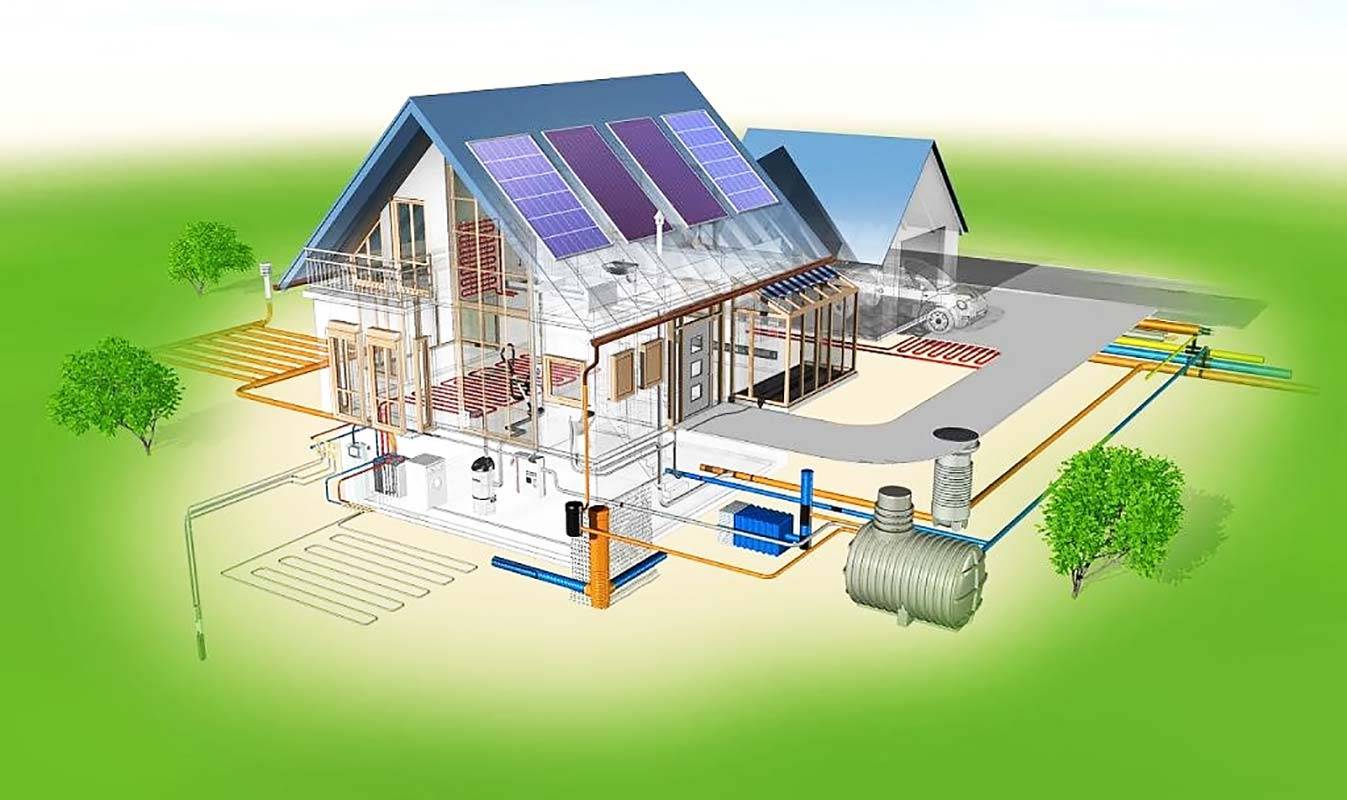

Varieties of alternative heating systems

An alternative to gas heating is, as a rule, automated heat supply systems that use modern technologies and the latest developments in practice.

These systems are an ideal solution for owners of private and country houses, especially those located at a distance from the places where the gas pipeline network is laid.

Alternative heating can have the following varieties:

- Diesel.

- Electrical.

- Solid fuel (coal, briquette, firewood, etc.).

- Natural renewable sources (wind energy, earth heat, solar energy, etc.).

Which of the above options is the most optimal for use in a country private house? To answer this question, consider the advantages and disadvantages of each of them in terms of efficiency and cost-effectiveness.

Use of diesel fuel

One of the main advantages of using diesel fuel for heating a private house is the relatively low cost of installing a thermal installation that generates thermal energy.

Any other types of heating, the principle of which is based on the combustion of fuel with the subsequent release of heat, require much more installation costs than oil-fired boilers.

The main disadvantages of this system include the high cost of operation and the need for regular maintenance and monitoring of the system.

Electric heating

Electric heating is a good alternative to gas heating in a country or private residential building.

This system is characterized by ease of installation and operation, a high level of automation that ensures reliable and high-quality operation of the entire system.

Electric heating can be adjusted for each room individually. Click to enlarge.

In addition, electric-powered heating systems differ in almost the maximum value of the efficiency factor (about 100%).

The list of numerous advantages can be supplemented by the small overall dimensions of heating systems and the possibility of their installation in almost any room.

Electric heating can be adjusted for each room individually.

The disadvantages of the system include the high cost of electrical energy, the dependence of stable operation on the availability of current and the quality of the electrical network.

Use of solid fuels

The most balanced alternative to gas heating is solid fuel boilers.

These devices combine the relatively high availability of solid fuel, low installation cost and sufficiently high efficiency (the efficiency factor can reach 85% - 95%).

The performance of solid fuel boilers is ensured by their periodic "refueling", which must be done manually 3-4 times a day.

The structural reliability of these boilers should also be noted. The main disadvantages of a solid fuel heating system are associated with the need to harvest, dry and organize the storage of firewood (coal, briquettes, etc.).

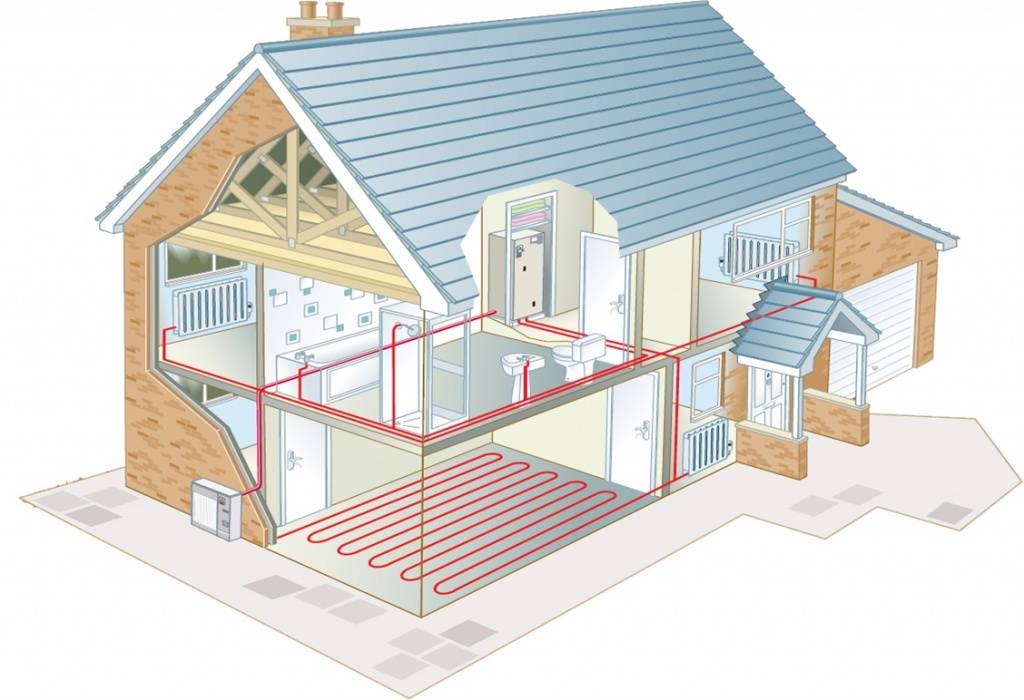

Heating using electrical equipment

The simplest and most inexpensive is electric heating without the use of a network of pipelines with a coolant. It does not require complex installation work and the purchase of expensive equipment. In this scheme, single heating devices connected to the electrical network are used:

- electric convectors;

- infrared heaters;

- fan heaters.

The design of such a system is similar to any other. First of all, the required power for each room is calculated. Then, according to the required parameters, devices of a given power are selected. Most often, electric convectors are used, since they are not inexpensive enough and allow you to get a convenient and unpretentious heating system.

The selected convector, or any other device, is placed in the same way as radiators for water systems. The best option is to mount them under the window and near the outer wall.

More economical and comfortable are electric floor heating systems (TP). Their positive characteristics are the same as those of a water heated floor - a more comfortable distribution of heat and less waste of energy resources.

Electric underfloor heating is of the following types:

- heating cable;

- heating mat;

- infrared film.

The calculation of TP is carried out in the same way as for single heating devices. After calculating the required power, proceed to the choice of equipment:

- if it is planned to use electric convectors, then they are determined with their type, method of regulation, installation site;

- when using a warm floor, determine the type of heating element, the place of installation.

The warm floor is planned in such a way that there is no overall furniture or other equipment above the cable or film. This must be done in order to prevent inefficient use of energy.

The project for heating a private house with electricity should also include checking the ability of the electrical network to operate at a given load.If necessary, install a separate wiring for heating devices with their own shield and control and regulation devices.

Installation of the cottage heating system

After the arrangement of the boiler room, according to the heating scheme of the cottage, radiators are mounted. The main parameters by which consumers choose radiators are dimensions, power and the material from which they are made.

Internal wiring

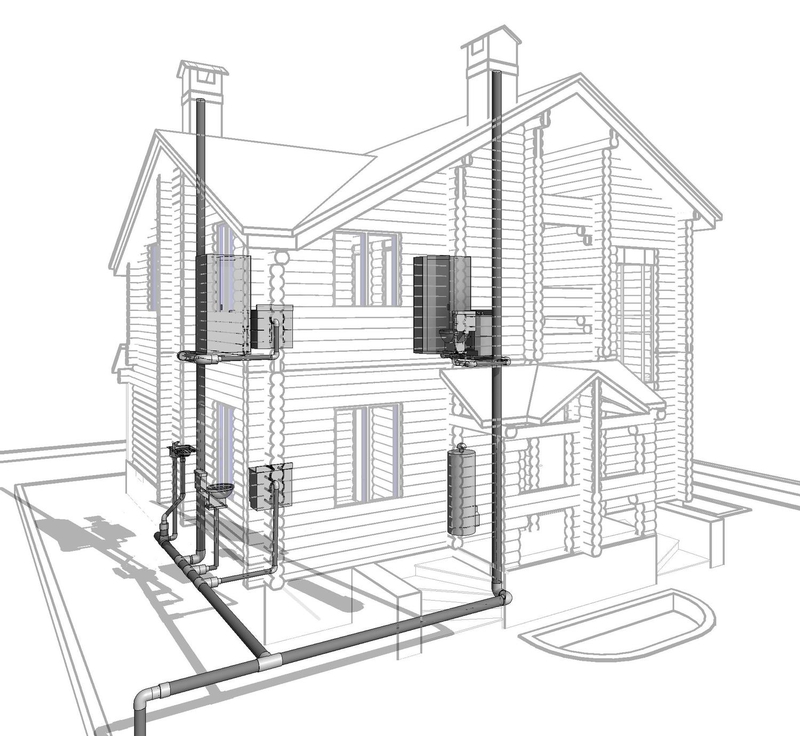

When installing the cottage heating system, special attention should be paid to the material of the pipes. To date, there are several types of pipes that are traditionally used in heating systems.

Let's take a closer look at these types.

- Steel pipes. Durable, resistant to pressure drops, but difficult to install and subject to corrosion. Over the years, a layer of rust settles on the inner walls, which can impede the flow of water.

- Metal pipes. Strong, flexible and easy to install. It is convenient to use with complex geometry of the heating system. But they also have a number of weak points: they are destroyed by mechanical impact and ultraviolet radiation, as well as flammable.

- Propylene pipes. The most popular material, which is undoubtedly related to the price of such pipes. They are the most economical compared to pipes of their other materials. They have only one drawback - good flammability. Otherwise, it is an ideal material for heating pipes. They do not rust, do not crack, are easily welded with the help of special “irons”, and are durable in use.

- Stainless steel pipes. They are usually used in non-residential premises: basements, laundries, billiard rooms. They have good heat dissipation, and so high that they can heat the room without installing radiators. Variety - corrugated stainless steel pipes.In addition to those listed, they have another advantage: they easily “bypass” corners and turns without additional joints.

Technical requirements

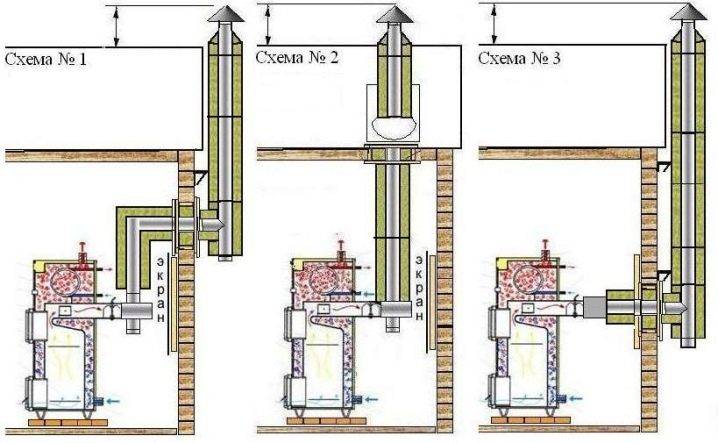

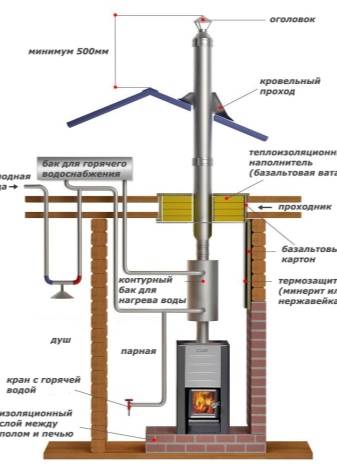

Designing modern heating systems is a responsible process. In such a scheme, an important role is played by the chimney. It is used to ensure that all combustion products go outside.

There are some requirements for chimneys:

- Joints and joints must be treated with fire-resistant materials.

- The chimney must be gas-tight.

- Its size must correspond to the power of the heat generator.

- The cross section of the chimney can be determined in accordance with the standards in the list of acts SNiP 41-01-2003 "Heating, ventilation, air conditioning", as well as SP 7.13130.2013 "Heating, ventilation, air conditioning".

- The length and diameter of the chimney itself must fully comply with the recommendations of the boiler manufacturers.

- It must be placed vertically.

- Above the roof, the chimney can protrude no more than 50 centimeters. If the distance between the ridge and the pipe is less than three meters, the pipe may be located on the same level as the ridge.

- It also needs to be protected from various atmospheric precipitation with the help of nozzles, for example, umbrellas or deflectors.

- Laying a chimney through living quarters is not permitted.

Various materials are used for the manufacture of chimneys. They can be brick, or metal, less often - ceramic. If brick is used, then the design takes place even before the house is built. Nowadays, stainless steel chimneys are most often used, as this is a fairly durable material.It is for this reason that a ceramic pipe is least likely to be installed, since it is quite fragile.

Electric heating

The first option that comes to mind when gas heating is not possible is electric heating.

With him, things are much simpler: since there is no risk of an explosion, the number of permits for installation is narrowing. There are 3 common methods of electrical heating:

- beam (heating panels, carbon heaters);

- convective (oil radiators, convectors);

- thermal fans.

The advantages of electric heating include:

- uncomplicated installation;

- there is no need for regular inspection, inspection as needed is sufficient;

- low costs for the purchase of equipment;

- high reliability;

- there are no harmful emissions.

The disadvantages are the following:

- on average, operation lasts no more than 8 years;

- huge level of electricity consumption;

- closure instability.

If power outages are not uncommon in your area, electric heating is best avoided. The disadvantage of high cash costs is compensated by special night rates.

Another important point regarding electric heating: so that heat does not seep through the walls, roof and windows, a country house must be well insulated. Then the approximate energy consumption will be 1 kW per 10 m².

Alternative heating of a cottage or a private house based on biofuel

Biogas can be obtained from biomass, which includes various organic wastes - plants, manure, sewage. The main process for producing biogas is decomposition by bacteria.Houses with one floor will be most efficiently heated by means of logs, chips from wood pellets, pressed waste from the woodworking industry. In order for the fuel to enter the boiler, today fully automated options for heating a country house are used. If you install a boiler that runs on fuel such as wood or logs, then it must be loaded manually.

Pellet boiler with hopper

Pellet boiler with hopper

The implementation of such a heating system can be in several versions, but what they will have in common is the automatic fuel supply. This makes it possible for no person to be near the boiler. Such a system allows you to maintain exactly those temperature indicators that were set by the residents of the house.

Single pipe scheme

It consists of a chain of radiators connected in series to each other. The coolant, having the desired temperature, supplies heat directly to the heating system from the riser. It moves from one radiator to another, transferring part of the heat to them on an ongoing basis. Therefore, heating after installing such a circuit will not be uniform.

If a single-pipe heating scheme with an upper wiring is selected, then the main pipe is laid along the entire perimeter of the heating system. In addition, it should be higher than windows and appliances. Batteries in this case have a connection at the top, which does not look very attractive. It is also worth noting that they are equipped both at the inlet and outlet with special shut-off valves. On one of the sides there can be a thermostatic head.

If the circuit has a bottom wiring, then the piping line will run below all heating devices.This design is more often chosen for modern houses, because it looks more attractive. But there is a peculiarity here: a Mayevsky crane must be installed on each battery. They are placed in order to remove excess air from the battery located at the top.

The one-pipe scheme has several advantages:

- ease of design and installation;

- significant savings on the process itself and on the materials used.

There are also disadvantages:

- complex temperature control,

- direct dependence of the operation of each battery on the state of the entire system;

- the difficulty of disconnecting the battery from the general system (in order not to stop the operation of the system as a whole, it is necessary to lay a bypass under each of them, that is, a bypass pipe supplemented with valves).