- Materials, markings, dimensions

- What is indicated in the label

- Dimensions of check valves for water

- How to check

- Types of window ventilators

- Tips

- Supply and wall damper installation technology

- Determination of the optimal installation location

- Necessary tools and materials

- Work sequence

- Ventilators, breathers - supply valves with forced impulse

- Advantages and disadvantages of the ventilator, breather

- Supply valve device

- Kinds

- Varieties of supply valves

- 2 Functional purpose of the device

- Features of self-production

Materials, markings, dimensions

The check valve for water is made of stainless steel, brass, large sizes of cast iron. For household networks, they usually take brass - not too expensive and durable. Stainless steel is certainly better, but it is usually not the body that fails, but the locking element. That's his choice and should be approached carefully.

For plastic plumbing systems, check valves are made from the same material. They are polypropylene, plastic (for HDPE and PVD). The latter can be welded / glued or threaded. You can, of course, solder adapters to brass, put a brass valve, then again an adapter from brass to PPR or plastic. But such a node is more expensive.And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are non-return valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it's hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to work. Plastic wears out faster, but it does not wedge. In this regard, it is more reliable. No wonder some manufacturers of pumping stations put check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to "poison" and it is changed.

What is indicated in the label

A few words about the marking of the check valve. It states:

- Type of

- Conditional pass

- Nominal pressure

-

GOST according to which it is made. For Russia, this is GOST 27477-87, but not only domestic products are on the market.

Conditional pass is designated as DU or DN. When choosing this parameter, it is necessary to focus on other fittings or the diameter of the pipeline. They must match. For example, you will install a water check valve after a submersible pump, and a filter to it. All three components must have the same nominal size. For example, all should be written DN 32 or DN 32.

A few words about conditional pressure. This is the pressure in the system at which the valves remain operational. You need to take it exactly no less than your working pressure. In the case of apartments - no less than a test one. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. The pressure for your home can be obtained from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it indicates in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. Therefore, they are popular.

The opening pressure characterizes the “sensitivity” of the valve. For private networks, it rarely matters. Unless on the supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation

Do not forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of the check valve for water is calculated according to the nominal bore and they are released for everything - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are of the same size as all other shutoff valves: taps, valves, spurs, etc. Another "size" can be attributed conditional pressure. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Then there are the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And yet, please note that for different companies with the same conditional passage, the external dimensions of the device may differ. Length is clear

Here the chamber in which the locking plate is located can be larger or smaller. The chamber diameters also differ. But the difference in the area of the connecting thread can only be due to the wall thickness. For private houses, this is not so scary. Here the maximum working pressure is 4-6 atm. And for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. Air must not pass. Generally. No way. Also try pressing the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a non-return valve: blow into it and check for smoothness

Types of window ventilators

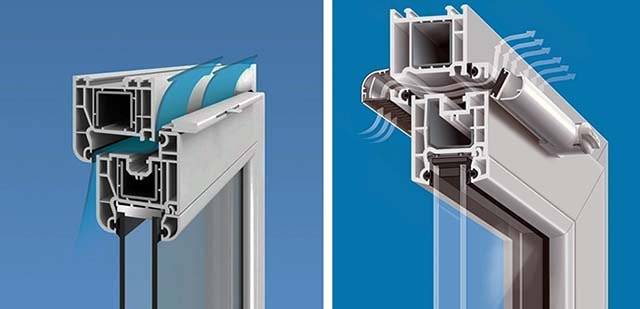

So you've decided to buy put ventilation valves on the windows. All these devices work on the same principle: under the influence of the hood, outside air enters the gap, enters the room and mixes with the upward flow from the heating radiator. According to the method of installation, ventilation valves are divided into 2 types:

- Overlays for opening windows. They are placed on the sash, a section of the standard rubber seal is cut out for air passage.

- Slotted (mortise) for deaf and hinged windows. Under these devices, a horizontal through slot is made in the frame.

Overhead (left) and slotted (right) vent valves

In the basic configuration, the overhead valve on the plastic window consists of the following parts:

- plastic case with adjustment knob in the form of a valve;

- external wind-shelter peak;

- special seal to replace the regular one;

- fastener elements.

Air-box dampers can be additionally equipped with a coarse filter of class G3 (80…90%), which simultaneously performs a noise-protective function. Horizontal or vertical installation is allowed, and the visor does not interfere with the installation of a window mosquito net from the outside.

Slotted built-in ventilators consist of the following elements:

- external visor;

- inner casing with grate and flow regulator;

- filter element G3;

- fixture.

Visors on VENTS dampers are equipped with an insect screen, the body is equipped with an adjustable swivel mechanism. It allows not only to regulate the amount of air, but also to direct the flow up / down.

Aereco brand supply valves are equipped with a special spacer to increase the air flow and a hygro-adjustable device. What it means: a damper is installed inside the case, whose position depends on the humidity in the room. As it increases, the polyamide moisture sensor opens the shutter, letting more air into the room. When the relative humidity drops, the damper closes automatically.

Regulation of the air flow direction in the VENTS damper

Tips

Evaluation of the performance range when choosing a valve should be based on the current pressure. It is not at all guaranteed that the passage of air through a valve designed for 15 cubic meters. m per hour at 10 Pa will be higher than through an apparatus designed for 12 m3 at 5 Pa. For stable operation of vent valves in the summer, it is required to use an artificial hood, supplemented with fans. Be sure to seal the entrance doors from the side of the street or entrance.The presence of other sources of cold air will devalue the entire system.

To make the marking as accurate as possible, a contour template of the purchased valve is being prepared. According to this template, with the help of a marker, the top of the sash is shown. The line is used for perforation. The higher the valve installation point, the better and more reliable the system works (reduces the risk of cold air entering). According to the norms of SNiP, the minimum allowable height above the floor surface is 1500 mm.

How to mount the supply valve on a plastic window with your own hands, see the following video.

Supply and wall damper installation technology

The installation process of the device is quite simple, but specialized equipment is required for operation.

It is important to choose the right place for installation and follow the algorithm of actions

Determination of the optimal installation location

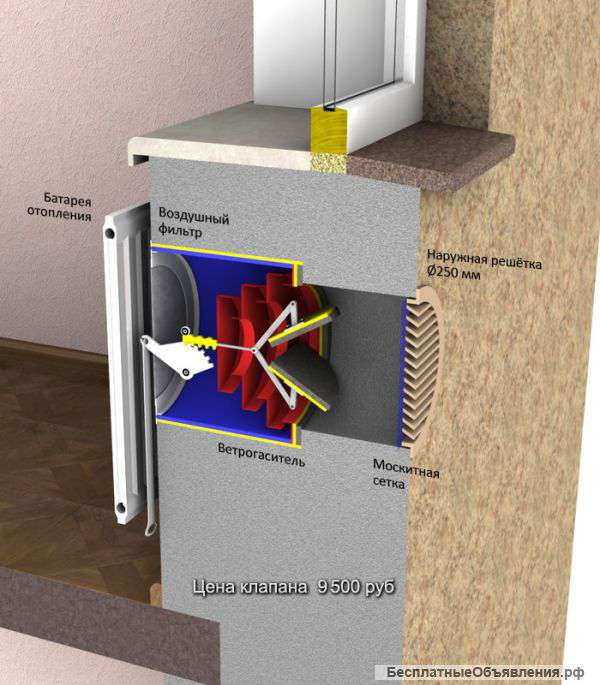

When choosing a room for installing a wall "supply", you should be guided by the following rules:

- Installation is preferably carried out in a load-bearing wall.

- In an apartment building, it is better to install the valve with the exit of the outer part to the balcony or loggia.

- It is undesirable to equip forced ventilation on the wall of the building facing the highway and the industrial zone.

It is not recommended to use the wall valve in rooms with a high degree of humidity - in winter there is a high risk of freezing of the device. As an option, you can use "supplies" with a heating function.

Having decided on the wall, it is necessary to choose the optimal place for inserting the valve.

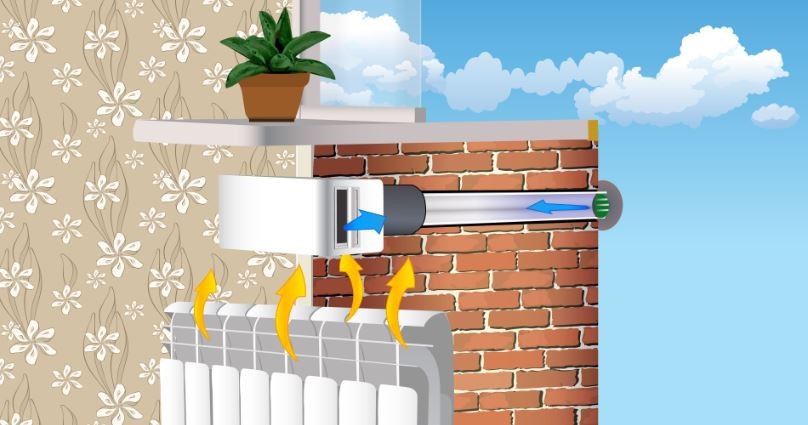

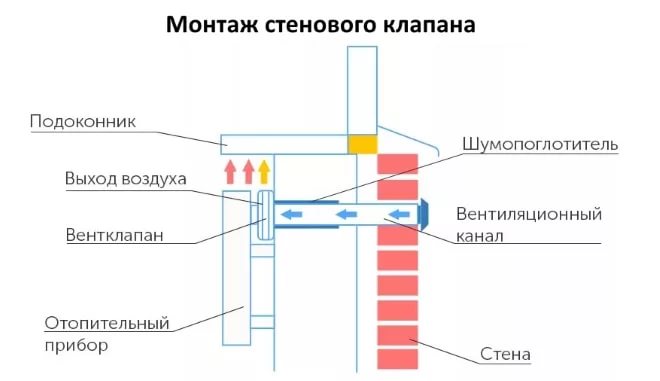

The most successful areas are:

- between the window sill and the batteries - the supply air is heated from the heating device and distributed throughout the house;

- at the top of the window opening (2-2.2 m) - air masses enter a warm environment, warm up to a comfortable temperature and fall down.

In both cases, the wall valve can be hidden behind a curtain.

When installing the ventilator at the top of the window, it is necessary to maintain a distance between the slope and the device of at least 30 cm - this will reduce the likelihood of freezing of the ventilation duct

Necessary tools and materials

To tie the supply valve into the wall you will need:

- a stationary drill or a powerful perforator with a diamond crown, the diameter of which should be slightly larger than the size of the duct;

- industrial or household vacuum cleaner - especially important if the installation is carried out in a "clean" area where the repair has already been completed;

- mounting foam;

- plaster mixture;

- construction knife;

- curly screwdriver;

- marking tools: measuring tape, building level, pencil.

Mounting the ventilator is a dusty and noisy job. Therefore, it is necessary to use personal protective equipment: gloves, goggles, construction earmuffs and a respirator with a dust filter.

To install a ventilation valve with a breather, a device with cleaning and heating of the air mass, you will need diamond drilling rig, because a conventional drill will not be able to drill a hole of sufficient diameter:

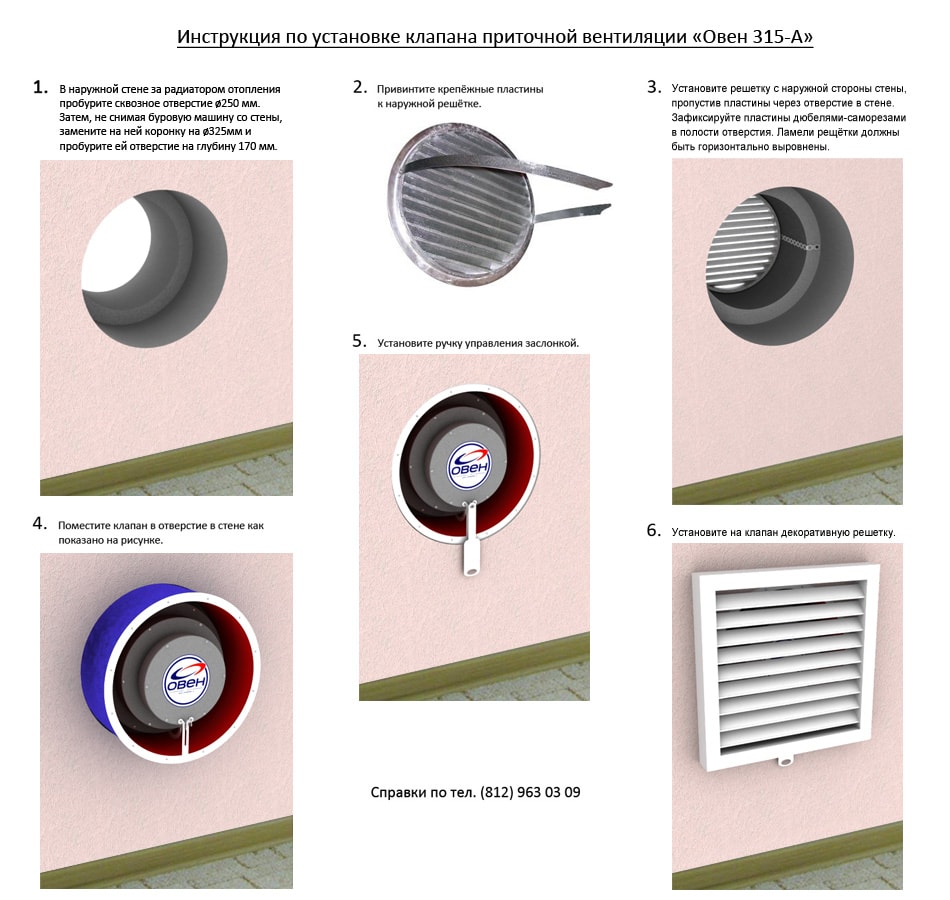

Work sequence

The entire technological process can be divided into several main stages.

Stage 1. Wall preparation. If the building is lined with hinged panels, then they must be temporarily dismantled. On the inner side of the wall, mark for drilling - attach the base of the valve and mark the contour with a pencil. It is advisable to organize the removal of dust.

Secure the plastic bag and plastic container with masking tape.Connect the hose of a vacuum cleaner to the “trap” from above - the dust generated during drilling will enter the garbage collector

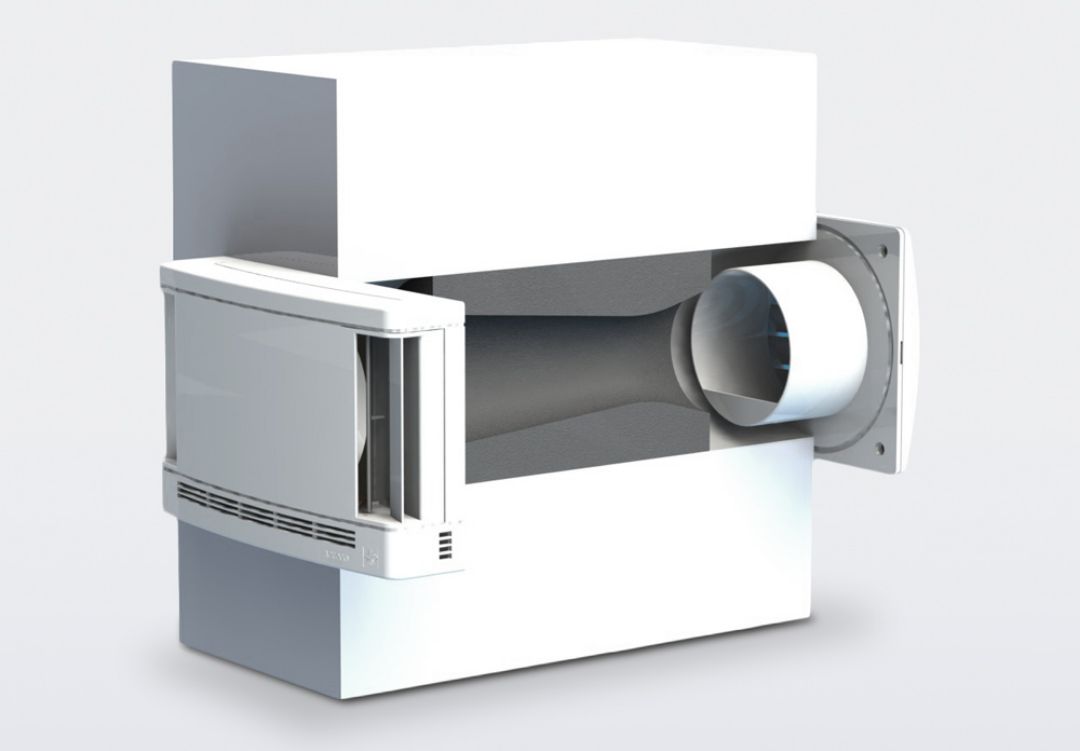

Stage 2. Drilling a hole. Using a diamond core bit or a drill, perform initial drilling to a depth of 7-10 cm. Remove broken fragments of concrete, knock out a notch in the center with a chisel for a more stable positioning of the drill. The entire channel must be made at a slight slope outward to prevent moisture from entering the room.

During drilling, the work area must be periodically moistened - this measure will reduce dust formation and protect the tool from overheating

Stage 3. Canal cleaning. Insert the vacuum cleaner hose into the cut groove and remove all dust from the hole.

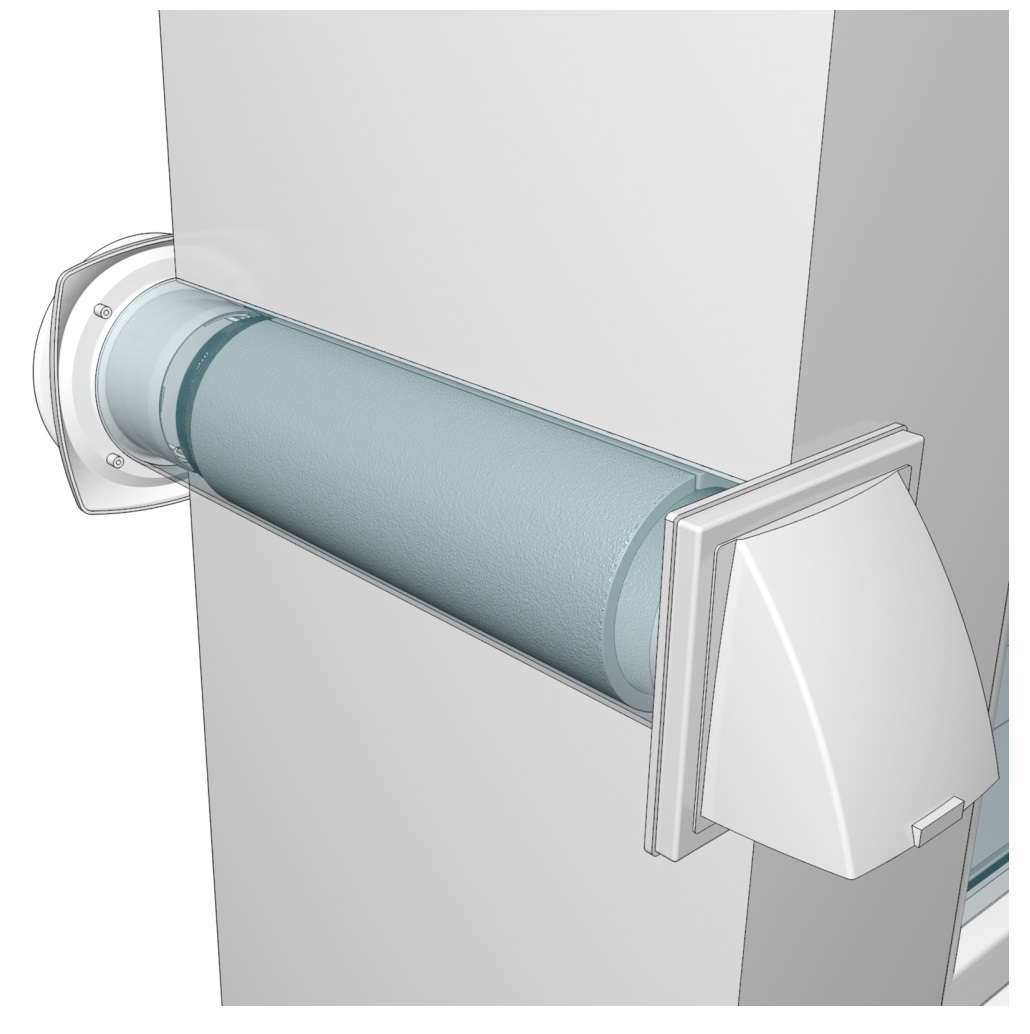

Stage 4. Installation of thermal insulation. To accommodate an additional layer of heat and sound insulation, it may be necessary to expand the hole. The exact dimensions of the channel depend on the type of insulation.

The optimal heat insulator for a wall valve is a foamed polymer material. It does not lose its qualities in conditions of high humidity

Stage 5. Installing the sleeve. Place the air duct tube into the channel with a heat-insulating casing, moving it outwards with screwing movements.

Stage 6. Mounting the body and cover. Fasten the protective grille on the outer side of the wall. From the inside, apply markings for installing the case, drill holes, hammer in plastic dowels and fix the panel on the wall.

We also have a material that describes in more detail the process of installing an inlet wall valve.

After the housing is fixed, a damper is mounted that regulates the air flow and an anti-dust filter.The final stage - installing the cover

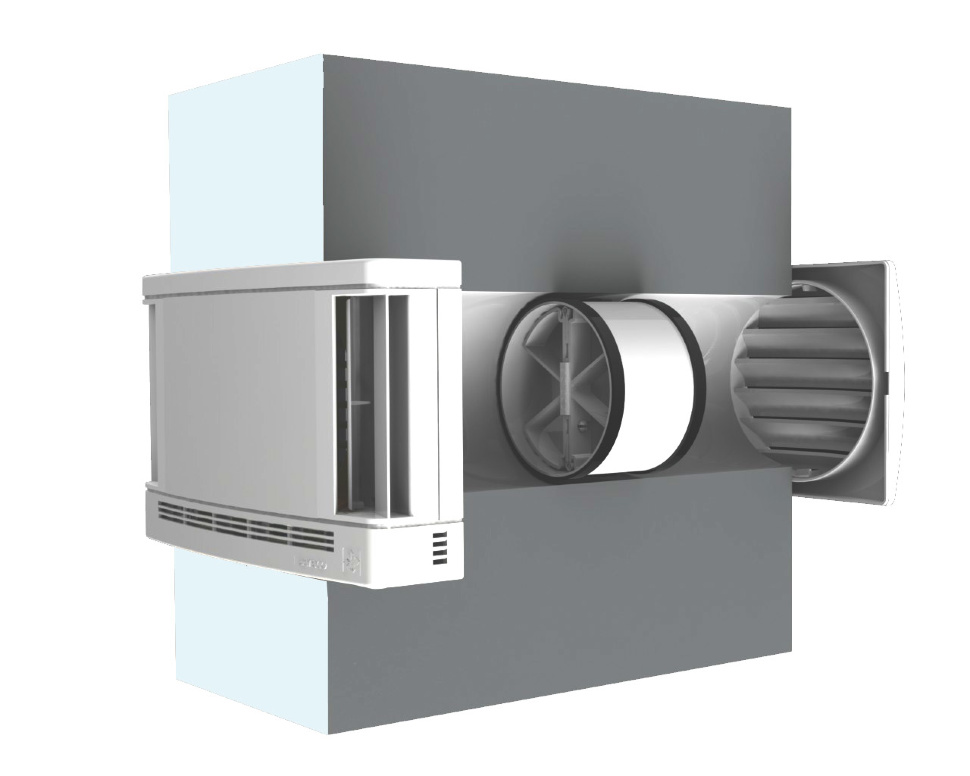

Ventilators, breathers - supply valves with forced impulse

The natural ventilation inlet valves described above should have a small aerodynamic resistance. Their throughput very much depends on climatic factors - outdoor temperature and wind pressure.

These features limit the throughput of the valves and do not allow equipping the valves with effective devices for supply air preparation.

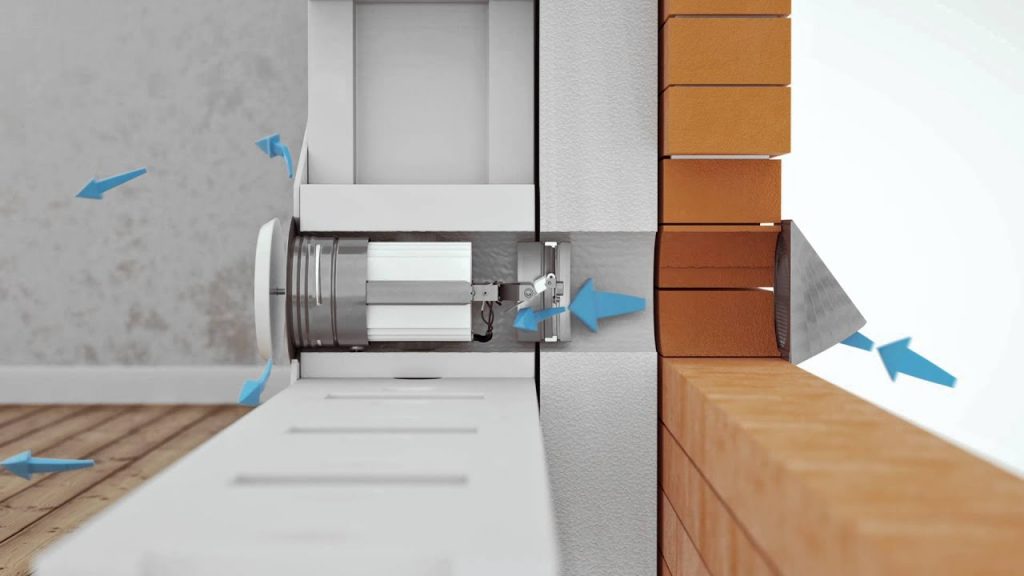

The same through channel in the wall, with a grill on the outside and heat and sound insulation inside. But indoors, an electrical appliance is mounted on the inside of the wall. The design and dimensions of ventilators from different manufacturers differ, but the principle of operation is the same. The air is taken from the street by a fan. Productivity depends on fan speed — 10-160 m3/h.

The ventilators for air purification are equipped with class G or F filters (coarse and fine filters). Some models are equipped with an electric air heating device.

Breathers are ventilators with extended functions. In the breather, unlike the ventilators, there is a highly efficient HEPA class H11 filter. In front of it is a fine filter of class F7, and after it a carbon adsorption-catalytic filter to purify the air from harmful gases.

Breathers, as a rule, have a microprocessor climate control system-control, LCD screen and remote control from the remote control.

Air filters in ventilators, breathers differ in cleaning class. The classes differ in the percentage of air purification and the type of pollutants for which the filter is designed.Dust, wool, plant pollen, bacteria, viruses - the sizes of these particles range from tens and hundreds of microns to fractions of a micron.

Coarse filters remove the largest particles from the air, fine filters - smaller particles, high-efficiency HEPA filters - the smallest particles of 0.01-0.1 microns, and carbon filters - molecules of harmful gases.

A ventilator with a fan increases the level of background noise in the apartment. But the uniform buzz of the device, as a rule, is perceived more easily than the "ragged" noise from the street.

Advantages and disadvantages of the ventilator, breather

Compared to the supply valve, ventilators, breathers provide:

- the influx of a sufficiently large amount of air into the house under any climatic conditions;

- the possibility of automatic and manual adjustment of performance in a wide range;

- deep purification of air from mechanical particles and some harmful gases;

- heating the air supplied to the house.

Among the disadvantages of installing a ventilator or breather in the house, it should be noted:

- rather high cost of installation and operation of devices;

- the need for regular maintenance - filter replacement;

- electricity consumption - especially large in the air heating mode;

- constant noise from the fan - the higher the speed of its rotation, the greater the noise level.

It is beneficial to use ventilators or breathers for ventilation if there is a need for good cleaning of the air supplied to the house. For example, in houses located near roads with heavy traffic. Or, if household members are allergic to particles contained in the street air.

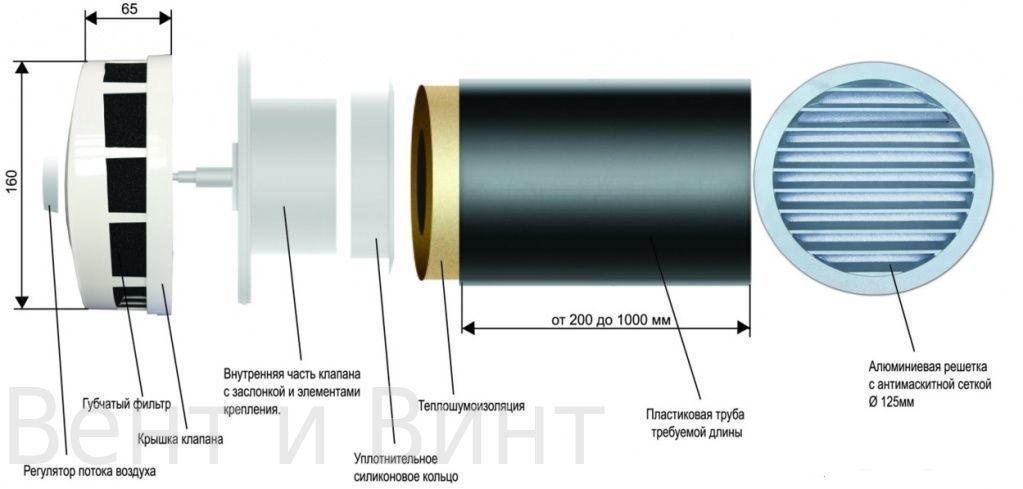

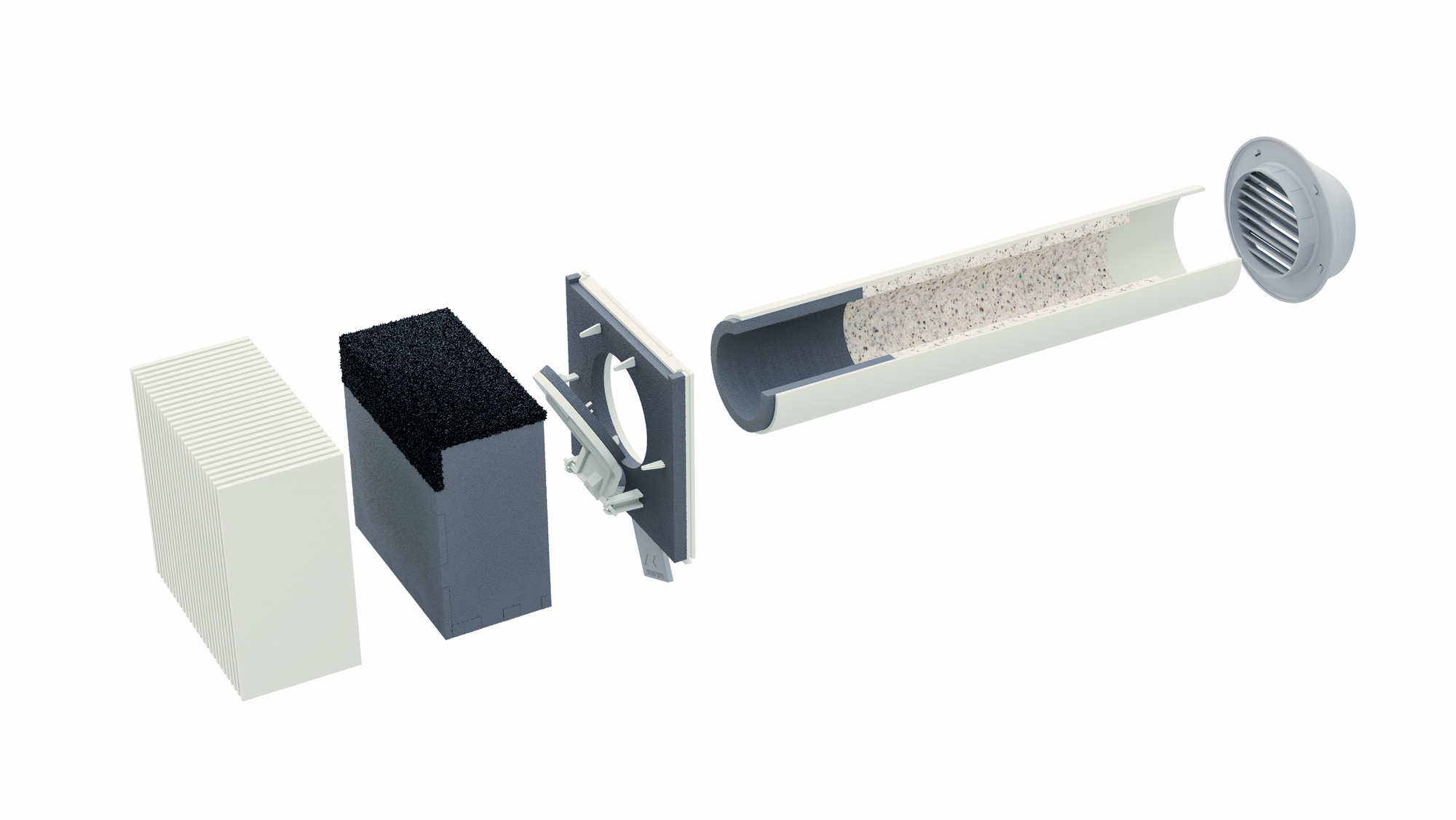

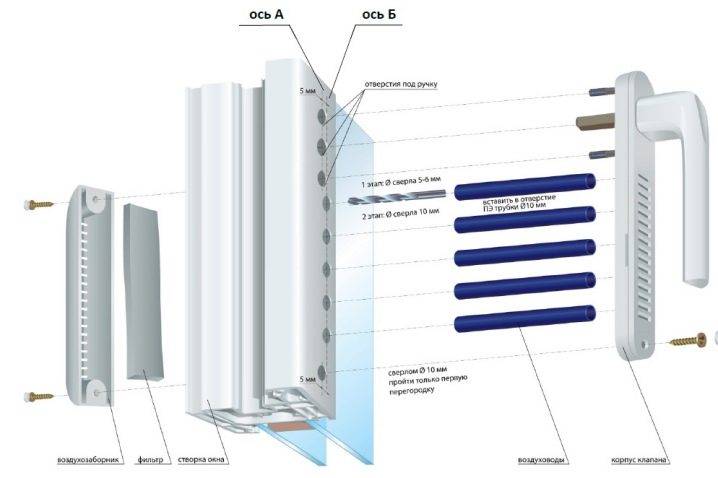

Supply valve device

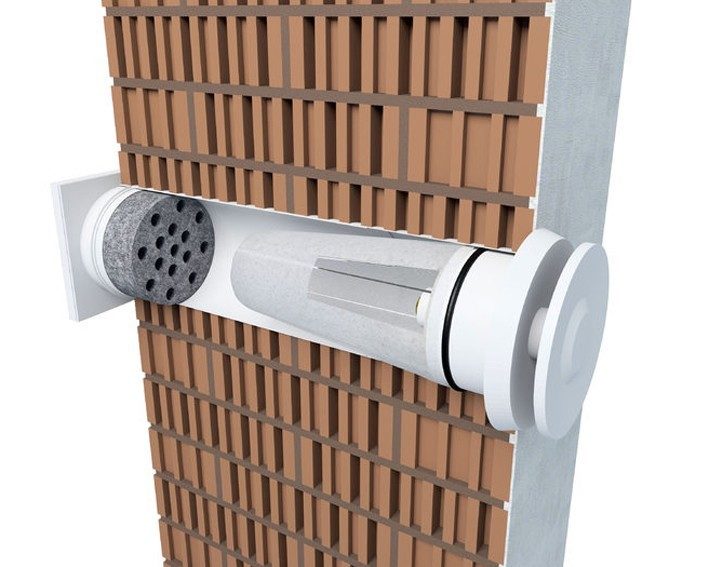

Structurally, the inlet valve is a plastic pipe with a standard inner surface diameter of 131.8 mm. The models are different in length - from 20 cm to 220 cm. It all depends on the thickness of the wall. During the purchase, a calculation is always made with a margin, and it is easy to cut off the excess part.

The scheme of the supply valve, which is mounted in the wall, is shown in the figure.

The valve consists of several components:

- In the room, only the outer part of the device, which calls the head, will be visible. It is made of white plastic and can have a square or rounded shape.

- There is always an adjustment knob in the head, with which the device is completely closed (for example, in cold weather) or opened to the desired width.

- This is followed by layers of thermal insulation that do not allow the valve to freeze in winter, and a filter for sifting dust and small particles of street air.

- Then comes the actual valve (plastic pipe), which ends with a metal grill with a mesh that acts as the first barrier to air from outside.

Kinds

A wide variety of plastic windows, the specifics of individual buildings and localities, the peculiarities of climatic conditions and the use of ventilation systems lead to a significant range of valves. To adjust the air flow in a number of models, a manual technique is used. Depending on the intention of the designers, sometimes you can use laces (in the same way as for controlling the blinds)

This is important because the valve itself is often placed quite high. There are versions that are equipped with electric motors.

Typically, the leftmost placement of the regulator opens the ventilation duct by 100%.Accordingly, the right position corresponds to its complete closure. Difficulties can be associated with the selection of a suitable intermediate mode, it is very difficult to choose it without the help of professionals. Automated systems can be quite expensive, but the fees are completely reasonable. Saving thermal energy during the cold period compensates for all investments.

The automatic type of ventilation allows you to track whether there are people in the room, and the intensity of ventilation is adjusted accordingly. Such adjustment is carried out by sensors, depending on the type of their adjustment takes place according to indicators of humidity or atmospheric pressure. The system that measures the pressure is equipped with a curtain with a top suspension. This curtain goes up or down according to the pressure of the air flow, that is, there is no need to use a barometer. Pressure gauges are often made from nylon tapes.

The bottom line is that nylon shrinks under the action of moisture, and therefore the passage of air systematically increases. Speaking about the division of valves, it should be noted that they belong to one of three groups:

- slotted;

- overhead;

- folded category.

Slotted products are able to maintain an optimal supply of fresh air. It goes through a channel 17-40 cm wide and 1.2-1.6 cm high. To prevent the penetration of harmful insects and dust particles, an inlet cover is used. It is able to additionally stop the ingress of rainwater into the house. The opening on the reverse side of the hood (inside the building) is equipped with a control system.

Slotted valves can be installed in the upper parts of the leaves or in horizontal dividing profiles. The advantage of such products is increased throughput and ease of fixing. If we talk about the rebate type of the exhaust system, which is placed on PVC windows, its important advantages are cheapness and simplicity. For the passage of air, narrow cuts of small size are used, made in the vestibule. The rebate block differs in the increased noise-protective characteristics.

In addition, such structures are mounted very easily. A serious weakness is insufficient air passage. Therefore, folded equipment in rooms of a large area is not used. If they try to put it there, it will only create a lot of problems. The overhead climate apparatus, according to the developers (and according to consumer estimates), is distinguished by the highest throughput.

There is another option for a constructive solution - a supply valve in the form of a handle. This option eliminates the violation of the design concept of the window. It provides a natural mode of air penetration, which is extremely valuable in the off-season and in the cold season. Combining the valve with an exhaust device allows you to stabilize the microclimate. Valves in the form of a handle belong to the direct-flow format, and therefore the appearance of condensate in the room is excluded.

Varieties of supply valves

Wall valves do not differ in great variety, since the principle of their operation is the same regardless of the specific model: cold air is forced into the room due to its greater density.

The shape of the valves can be distinguished:

- round (most);

- with a rectangular chamber.

By equipping the device are:

- with heat / sound insulation;

- without them.

By appointment are:

- standard models - designed specifically for apartments (standard diameter 131.8 mm);

- industrial valves (for industrial premises, swimming pools, baths, etc.).

Also, devices are classified depending on whether additional installations can be mounted to them or blocked completely or partially. An important group of valves is with a forced (automatic) ventilation system.

2 Functional purpose of the device

Most owners of houses and apartments ask themselves questions - what is forced ventilation, does she need within the living space in general, and how to make it with your own hands? We have already considered what a tributary is. The main purpose of the system is to provide people, plants and animals with the necessary amount of fresh air, as well as to prevent the likelihood of mold formation.

Supply ventilation systems fill the space with oxygen, which is vital for the human body. On average, 1 adult needs about 30 m3 of fresh air every hour. Excessive stuffiness can contribute to the formation of wet condensation on window frames, slopes, and there it is not far from mold and fungus.

The solution to the problem is more than simple - install an inlet valve into the wall and fill the room with oxygen. If the pressure difference between the inner and outer space does not exceed 10 Pa, the supply ventilation sends up to 30 m3 of air every hour. In accordance with sanitary standards, this is the volume required for one person.

For those who still doubt the purchase and installation of this device, we recommend watching the video below.

Features of self-production

Given the low cost of check valves, self-manufacturing of the device is relevant only when using a ventilation grill or air duct with non-standard geometric parameters. In this case, it is often cheaper and faster to make a valve for it than to make the transition to a standard shape and size.

The easiest way is to make a diaphragm or single-leaf valve yourself. A rigid material is used as a sash, such as a plastic or metal plate.

Particular attention should be paid to the following points:

tight fit of the plate to the walls of the valve body or the fixing protrusion to prevent the formation of a gap and the passage of air;

elimination of plate knocking, which is especially important in the case of frequent changes in the direction of air movement.

For the diaphragm valve, you can use a sheet of thick paper or lavsan film, with a larger diameter than the vent hole. With a strong reverse thrust, in order to avoid deformation of the membrane material, it is necessary to install a grid on which it will rest.

Lavsan film is suitable as a membrane. It does not lose its properties under the influence of moisture, as well as with repeated bending.