- Supply valve installation

- Video description

- Video description

- Window inlet valve

- Video description

- Briefly about the main

- Necessary tools and materials

- Varieties

- Folded

- slotted

- Overhead

- Installation instructions

- Installing an overhead vent valve

- Slit device installation

- PVC window installation process

- Valve installation and selection from A to Z

- Subtleties of choice

- Key Performance Indicators

- Mounting technology

- Air valve manufacturers

- The principle of operation of the ventilation of the apartment

- How measurements are taken

- Determining the width of the drainage

- Supply window valve-handle

- Do-it-yourself installation of a supply valve on a window

- Mounting

Supply valve installation

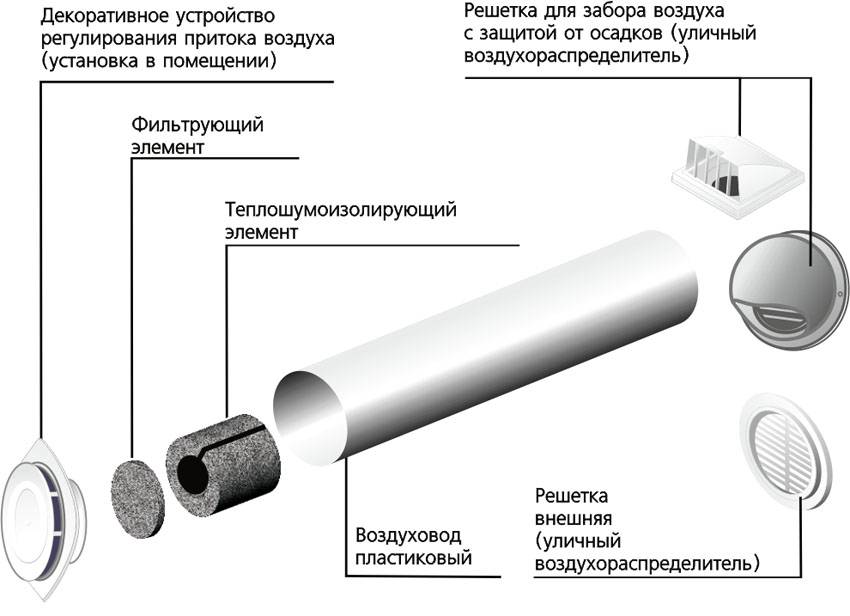

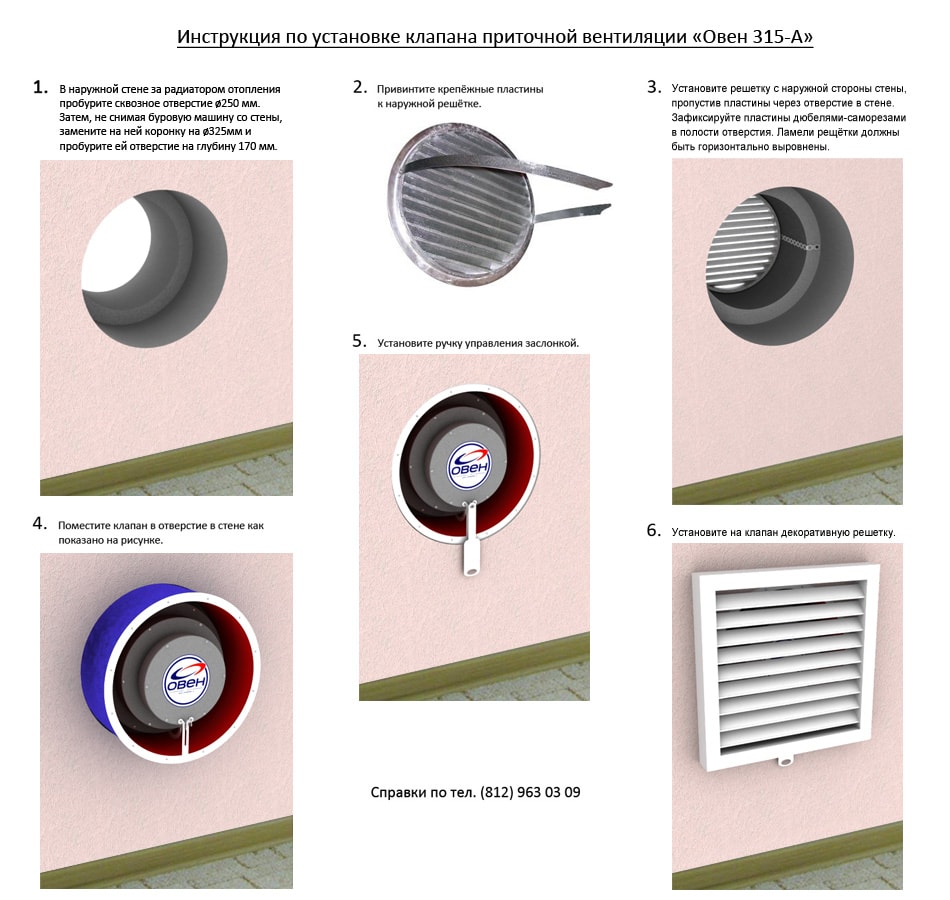

Installing the device is a dusty and noisy process, because you have to check the wall. This will require a diamond crown and a perforator. Masters use a special tool - a diamond drilling rig.

A hole drilled in the wall must be cleaned of dust, for which a vacuum cleaner is used. Then, a heat-insulating material is inserted into the hole. Usually for this today they use a shell made of mineral wool or polyurethane, which is sold in lengths of 1 m. It is simply cut to fit the width of the wall.

Next, the valve cylinder is inserted into the shell.From the outside, a decorative grille is attached to the wall with screws on plastic dowels. With inner cap with filter material.

Video description

The video shows how to properly install the ventilation inlet valve in the wall:

Since there are many varieties of valves on the market, the methods for installing them also vary, but the principle is the same. For example, there are devices in the cylinder of which a heat-insulating shell is installed. That is, they drill a wall along the diameter of a plastic pipe. The external decorative grille is not attached to the wall, but is inserted into the protruding end of the cylinder in the form of a cover. The same goes for the headline.

Video description

In the video, the specialist talks about the design of the flow valve, about the principle of its operation and installation method:

Window inlet valve

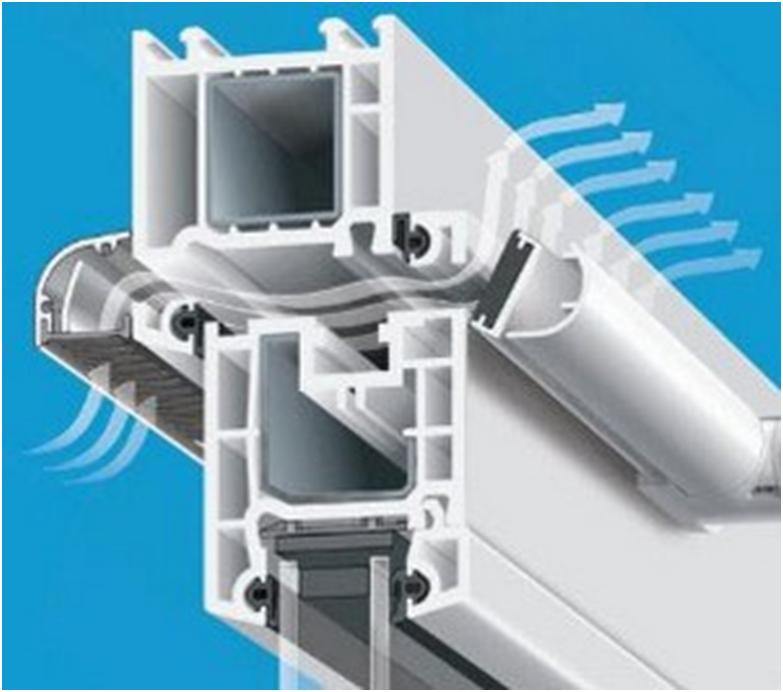

As promised above, we will give a little information about the ventilation valve for plastic windows. Let's start with the fact that the tightness of plastic windows has led to big problems. Many manufacturers immediately responded to the demands of consumers. So, various devices began to be inserted into the window frames, through which the air began to pass into the premises. For example:

- ventilated type profiles began to be used;

- limiters for opening frames and transoms were installed;

- seals were used with partial air permeability through them;

- glazing beads were mounted, in the design of which there was an opening valve.

Plastic window frame opening limiter

Window inlet valves have gained great popularity among consumers due to the high efficiency of air exchange. There are three types on the market:

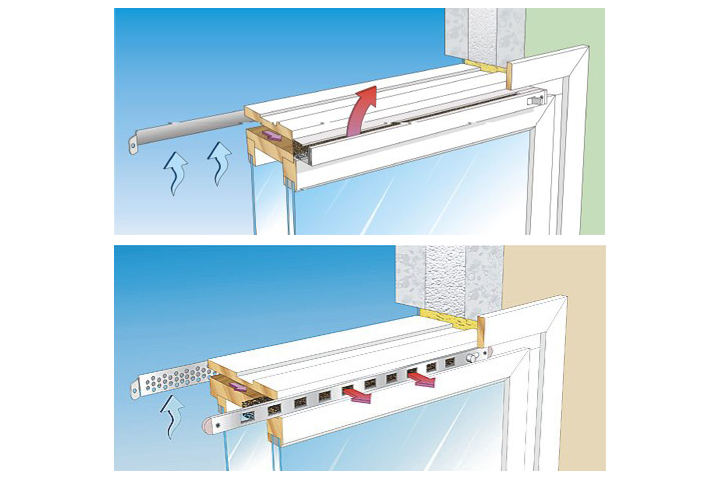

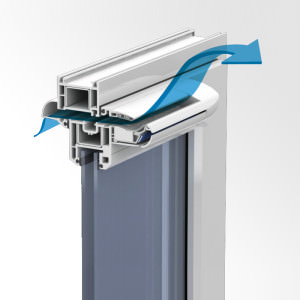

- Folded. This device crashes into the window frame.That is, installation can be carried out on an existing window structure without changing other parts or elements. This variety has one drawback - low productivity up to 5 m³ / h. But these are the cheapest valves.

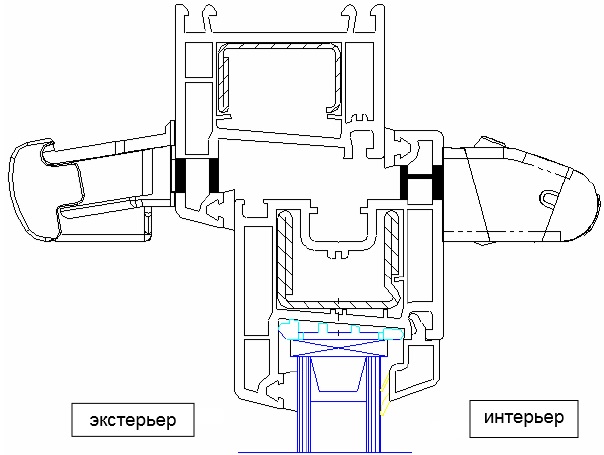

- Slotted. These models are installed in the gap between the frame and the sash. This is what complicates the installation process. Otherwise, the devices are better than folded ones due to more efficient air exchange - up to 20 m³ / h. The size of the inlets is limited only by the length of the gap.

- Overhead. These supply valves are installed on plastic windows during the installation of a double-glazed window. And this is a minus on the one hand. Another negative side is that the devices let a lot of noise through themselves, so they are not recommended to be installed in houses. But the devices have high performance - up to 100 m³ / h. They can be installed both in deaf and opening windows.

Video description

The video tells about the window supply, how the valve is installed in the window:

Briefly about the main

What is a supply air valve, the principle of its operation, for what purposes it is intended.

Advantages and disadvantages of the device, what you need to pay attention to when choosing it.

Installation technology, the nuances of the installation process.

Window supply: varieties, distinctive features, video - how to install the simplest valve on a plastic window.

Necessary tools and materials

Drilling a wall with your own hands will be difficult without special equipment

Of all the individual technological processes for assembling and installing the device, the most time-consuming is making a hole in the outer wall.

Since its thickness is usually 0.3-0.5 meters, it is recommended to use a powerful puncher or an electric jackhammer, especially for walls in prefabricated houses.

In general, you can independently assemble and install the valve yourself, for this you will need:

- perforator;

- drill;

- a set of long drills for concrete or stone;

- set of drills;

- knife;

- saw for metal;

- screwdriver;

- pliers.

The outer grille is attached to the wall with dowels and self-tapping screws. A sewer pipe in a hole in a panel or masonry requires reliable fixation; for this, mounting foam is used.

Varieties

There are three types of ventilation valves:

Folded

The principle of rebate ventilation

This is the simplest and most economical option. The influx of fresh air is carried out due to small cuts in the porch. This type practically retains sound insulation, but has a very small throughput, due to which the ventilation will be inferior.

Installation does not require dismantling of plastic windows. Valves of this type are mounted in already installed structures, which is their main advantage.

slotted

This type has a large capacity. Ventilation occurs due to the gap, which is 12–16 mm high and 170–400 mm wide. Outside, the hole is covered with a pass block, which prevents dust and insects from entering.

It is also mounted in installed plastic frames, but is more efficient than the rebate type.

Overhead

Provide the best ventilation, however, have some disadvantages.Firstly, they cannot be installed in a finished plastic structure, since it is necessary to prepare a place on the frame for it in advance. Secondly, they have poor sound and heat insulation.

This type is best used in production shops.

Installation instructions

First, let's decide how many valves you need to put on the window in order to properly ventilate the room. If you rely on passport characteristics, then for air exchange in living rooms you will need at least 2 supply units, the same number in the kitchen.

Given the shortcomings of the supply window ventilation valves, we suggest that you first install 1 device in each room. Then we observe changes in the home microclimate and, if necessary, add 1 more valve each. The best option is 1 "inflow" for 1 window, no more.

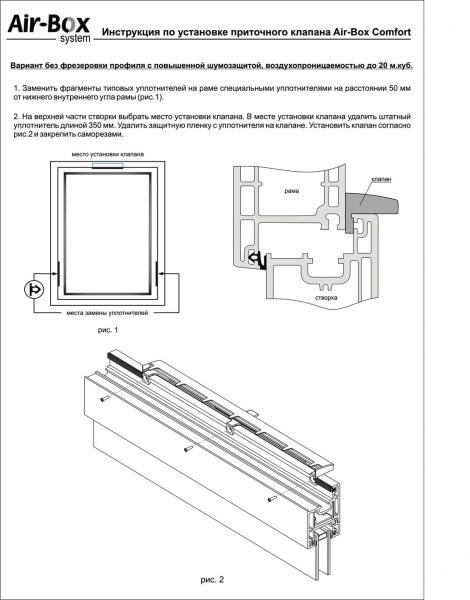

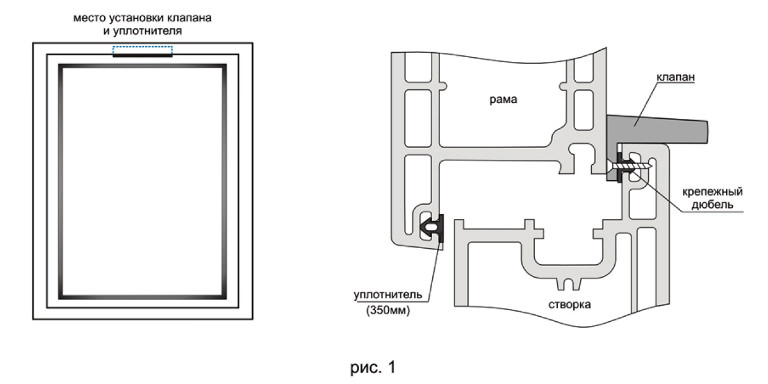

Installing an overhead vent valve

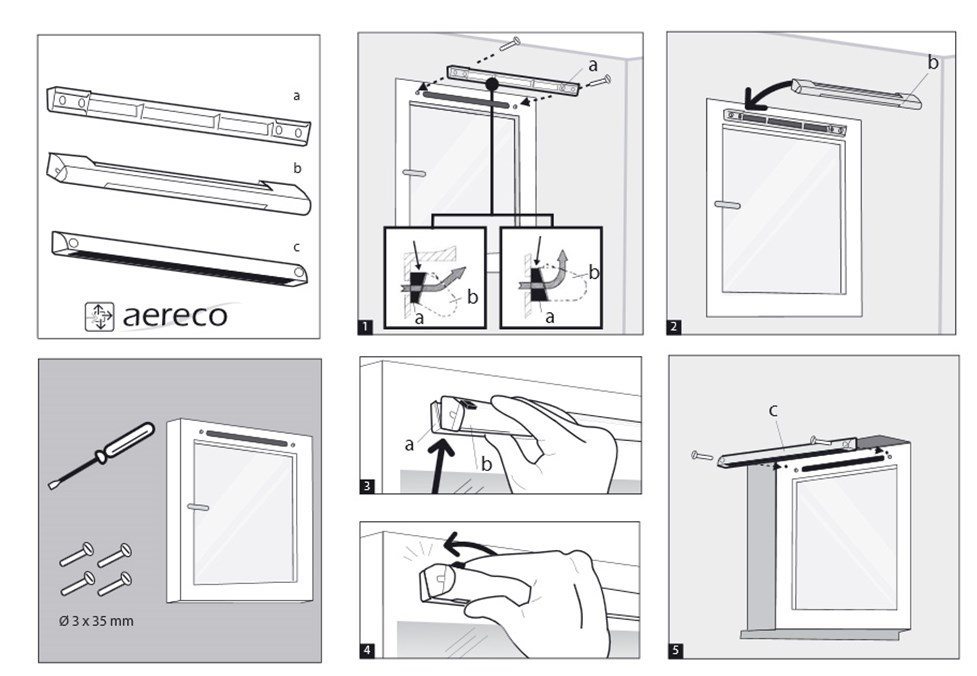

The device is mounted horizontally on the upper end of the opening sash or window. How it's done:

- Open the window, mark the location of the valve by attaching the body to the end.

- Cut and remove a section of the window seal on the sash, as shown in the photo below. Remove the same piece of rubber from the main frame opposite the valve.

- There is a groove on the window porch, insert 3 plastic clips under the screws into it. Of course, the fasteners must match the holes on the case.

- Remove the adhesive tape from the valve cover, screw it to the retainers with screws. Make sure the sash closes properly.

- Instead of sealing rubber cut from the main frame, you need to stick a special strip (comes with the ventilator).

On this, the installation of the invoice "inflow" is over.Do not rush to throw away the scraps of the regular seal, perhaps they will still come in handy. The installation process of the Air-box ventilation valve, see the video:

Slit device installation

To install a supply valve on a window without opening vents, you will have to remove the double-glazed window and mill the through slot. Hence the advice: if you do not have plumbing skills and do not have the right tool, it is better to call the installer. When installing the ventilator on a sash or balcony door, the double-glazed window does not need to be removed.

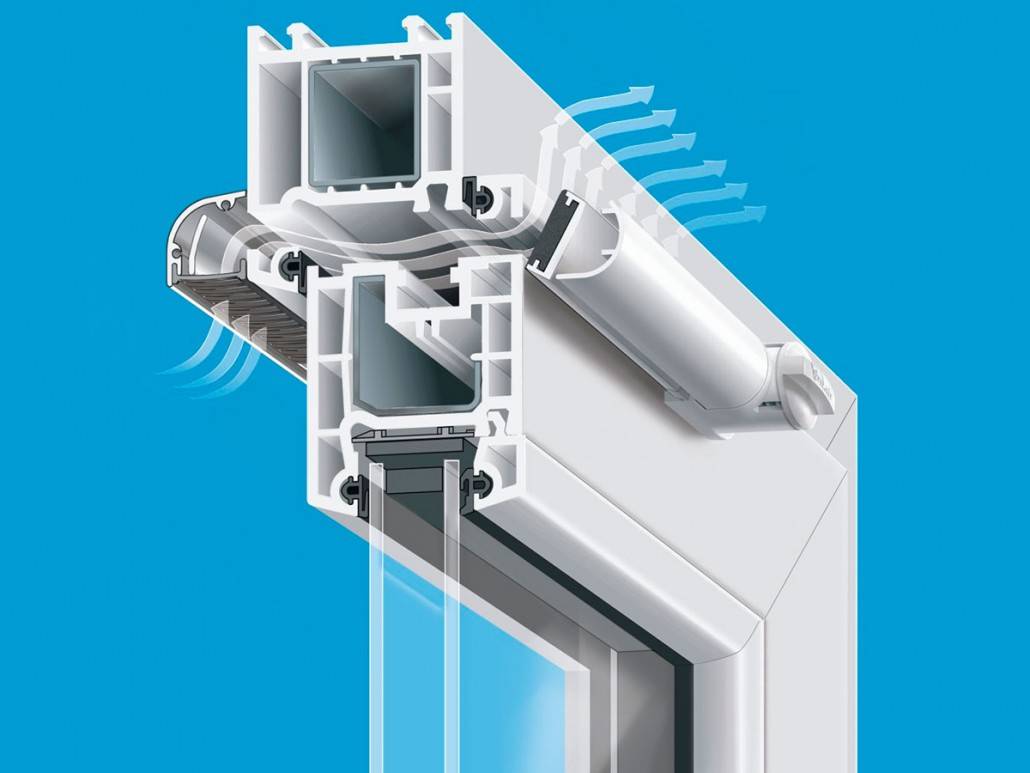

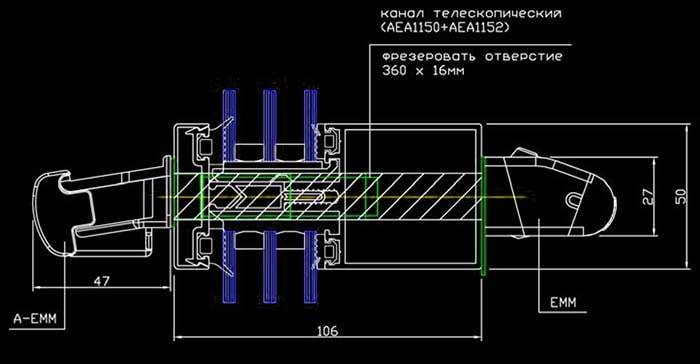

Installation drawing of the AERECO ventilation valve using a telescopic channel that is inserted inside the frame profile

How to install a slotted inlet valve:

- Determine the place of attachment of the inner part - at the top of the frame, in the middle of the window clearance. Do the markup. A slight offset is allowed towards the vertical profile, which is in the middle of the window.

- Screw the template to the frame with 2 screws. Mark with a core a row of holes Ø8…12 mm (the size depends on the valve model).

- Drill through holes in the profile with a long drill. Take your time, strictly maintain the drilling angle of 90 °, otherwise the exit holes will go awry. Better yet, use a special nozzle on the drill, which allows you to clearly observe a right angle.

- Using a hand tool, cut out a solid slot from a row of holes. Remove chips from inside the profile with a vacuum cleaner.

- Unscrew the template, install the inner valve body and the outer inlet hood.

Milling the clearance for a window valve is a rather time-consuming and accurate job. The gap should turn out to be even, damage to the metal-plastic profile should be minimal.How the ventilator is installed in the PVC window sash is shown in the next video:

PVC window installation process

First stage. Wooden wedges are installed, and around the entire perimeter. A window is installed on them in order to further facilitate the process of leveling the structure. Only then the window is attached to the wall. It is not worth removing the substrates, they will serve as auxiliary fasteners.

Installation of mounting wooden wedges under a double-glazed window

Second phase. Need a profile. If there is no support profile, then a gross violation of GOST standards is recorded. Profile-stand is intended:

- to improve resilience;

- to provide the possibility of installing a low tide with a window sill.

Third stage. The evenness of the installed window is specified in three planes. A mounting level with a plumb line is used. Bubble levels, which are used everywhere, are not suitable here, as they do not show accurate measurement results. The laser machine is ideal.

Fourth stage. The aligned window is fixed with anchors. For this purpose, a wall is drilled with a perforator through holes in the structure, which are prepared in advance. Drilling depth - 6-10 cm. Pre-fix the lower anchors. Further, the evenness of the package location is checked anew. If everything is in order, all other points are fixed.

Plastic windows are fixed with anchors

Fifth stage. When the final check is carried out, the final screed should be done. It is not worth applying special efforts, as excessive efforts can skew the structure.

Foaming a window opening

Valve installation and selection from A to Z

Despite the fact that manufacturers categorically advise against installing it yourself, there is nothing complicated about it and simple structures (for example, a slotted type) can be installed by yourself. Before this, it will be useful to familiarize yourself with the types of valves.

Subtleties of choice

As for wall structures, everything is more or less clear with them. A non-specialist will have much more problems when choosing the type of ventilation for a plastic window.

In general, supply ventilation valves for PVC windows can be divided into these types:

overhead - maximum (even redundant) performance. In addition, they are characterized by a high cost of installation work. The main disadvantage can be considered that they can only be installed when installing a new double-glazed window; installation on an already installed window is not possible.

Seam type

Purchased slotted valve

If the main criterion is to choose the simplicity of the work, the slot type can be considered the leader. Such supply ventilation valves for plastic windows work due to the fact that the standard seal is replaced with a narrower one, that is, a gap is formed through which fresh air enters the room.

Key Performance Indicators

It is also quite an important element when choosing.

It is necessary to take into account such parameters as:

- price - ideally, it should not exceed several thousand rubles;

- sound insulation - it should be approximately equal to the sound insulation of the window. You can focus on values of 30 - 35 dB;

- mode of adjustment - in principle, all ventilation devices should be equipped with a manual or even automatic adjustment system.But ultra-budget offers may not have such an option;

- installation method - you can immediately discard those options that require the replacement or dismantling of the old window unit. It will cost too much.

Mounting technology

From the point of view of the speed of work and the simplicity of the technology, a simple slotted valve can be considered the best choice. For its installation, it is not necessary to dismantle the window block, and all that is needed is to cut out a small part of the insulation.

Such ventilation valves for plastic windows are installed directly on the sash, thanks to which the frame remains intact. As for the productivity of such a solution, it can provide fresh air to the room within 6.0 m3 per hour. This is enough for any apartment.

To install, in addition to the valve itself, you will need a regular screwdriver, a sharp knife and a ruler.

The work instructions will look something like this:

First you need to remove the section of insulation on the frame. Marking is carried out in order to determine where the valve will be located, then cuts are made on the seal to the full depth, and it is removed. In its place, the sealing material that comes with the kit is immediately glued;

Installation scheme

the supply ventilation valve for plastic windows itself will be installed on the frame, so the removal of the standard sealing material must be repeated for the frame;

- small plastic dowels are installed to which a valve will be attached to ventilate plastic windows. Since the length of the standard design is 350 mm, then 1 dowel is installed along the edges and 1 more - in the center of the free space;

- after that, the plastic strip is attached to the window sash with self-tapping screws.

Schematic representation of a window sash

At this point, the installation can be considered complete, you just need to check whether the work performed has affected the functionality of the window block. It should open / close without problems and be transferred to the ventilation mode.

Complete structure

In terms of functionality, a window with self-installed ventilation is no different from a window with a fresh air valve installed at the factory. And the cost is much better.

Ventilation is adjusted automatically by moving the lever left and right. In the extreme left position, the ventilation gap is completely closed; in the right position, it is completely open.

In the photo - air access to the room is blocked

Air valve manufacturers

Choosing a supply valve from a wide range of models is a rather difficult task. Today, there are about 10 companies operating in the market that have proven themselves in this area. Consider the most popular of them.

Company Rehau

The product line of the most famous company in Russia "Rehau". Valves of this company are distinguished by consistent quality and durability. Suitable for installation on any window structures.

One of offers on the market REHAU AirComfort

One of offers on the market REHAU AirComfort

A special mechanism ensures the supply of fresh air from the windows, depending on the wind pressure, opens and closes automatically.

Aereco Company

This French company is already 35 years old. Several types of valves have been developed, mounted both with the need for milling and without it. Convenient settings, support for automatic and manual modes will surely allow you to choose the appropriate option.

Window ventilation systems of domestic production Air-Box

The Russian company Mabitek decided to keep up with foreign colleagues and developed truly universal Air-Box window ventilation valves, which can be installed on window blocks of any design. Its undoubted advantage is the possibility of installing a window block in the rebate, which makes the valve invisible.

The standard version (Air-Box Standard) involves the installation of two parts of the valve: the lower outer one, which takes air from the street, and the upper one, which supplies fresh air to the room. The principle of operation of the valve is based on creating a vacuum in the room with the windows closed and the ventilation running, under the action of which the valve petals are opened and a constant air exchange of about 6 m³ / h is created.

Domestic developments are distinguished by durability, increased sound insulation and a fairly affordable price.

Domestic developments are distinguished by durability, increased sound insulation and a fairly affordable price.

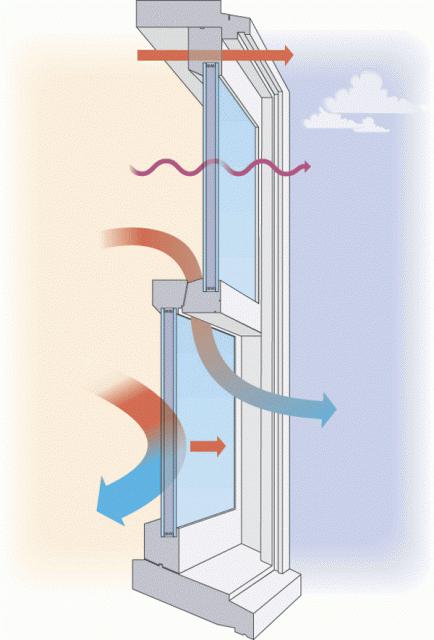

The principle of operation of the ventilation of the apartment

In multi-apartment residential buildings, natural supply and exhaust ventilation systems are installed. Their action is based on the creation of air draft due to the temperature difference in the street and in the room.

For the system to function, it must be:

- Draft in the ventilation shaft.

- Fresh air supply.

Ventilation shafts are located in the kitchen and bathrooms. It is through these rooms that the old air is removed from the apartment. In order not to create obstacles to the path of air masses, the doors to the rooms must be ajar or have ventilation grilles.

The exhaust air is replaced by fresh air. It enters the house through vents, transoms, leaks in door and window openings.

When installing sealed double-glazed windows in a house, one of the rules of the system operation is violated. To organize a constant air exchange, you have to keep the windows open. In winter, this significantly lowers the temperature in the house and creates discomfort.

How measurements are taken

Most apartments have openings without a quarter. The concept of "quarter" provides an internal frame. Its width is 6 cm. In other words, it is a quarter of a brick, which is why it is called so. Its purpose:

- prevent the window from falling out;

- reinforce the entire structure.

Correct window measurements ensure correct window installation

Let's say a quarter is missing. Then the frame is installed on the anchors. Next, you need to close the foam with flashings.

You can find out if there is a quarter in a simple way. It is enough to visually determine whether the outer and inner frame widths differ. If they are different, then a quarter is provided initially.

First action. Determine the width of the opening, that is, the distance between the slopes. To clarify the result, the plaster is removed.

Second action. Measure height. This is the size from the window sill to the slope from above.

To accurately determine the width of the window, take the width of the opening and subtract the value of the installation gap in double size from this indicator. And the height is determined in this way: they take the height of the opening and subtract two mounting gaps from it, and, in order to obtain the final result, subtract the height of the profile for the stand.

How to take measurements of a plastic window

Next, they check how symmetrical the opening is, rectilinear. Help with the definition:

- plumb;

- level.

Any of the irregularities and defects must certainly be reflected in the drawing.

Determining the width of the drainage

To do this, take the indicator of the existing ebb and add 5 cm, this additive is intended for bending. In addition, you have to take into account the width:

- insulation;

- subsequent cladding, if the facade will subsequently be specially veneered.

Supply window valve-handle

The ventilation valve for plastic windows is installed instead of the standard handle. Many PVC window owners do not want to install ventilation inlet valves that protrude beyond the sash. For them, a convenient solution has been created that allows you to ventilate the room without disturbing the appearance.

Benefits of window ventilation in the form of a handle valve:

The ventilation valve is located in the place where condensation normally appears on the plastic window.

The valve creates a natural movement of air, especially important in the cold season;

The combination of a handle valve and an exhaust ventilation system creates a healthy microclimate in the premises, removes excess moisture;

The supply ventilation valve in the form of a handle for plastic windows is a straight-through design. According to the laws of physics, penetrating into a warm room, cold air does not create condensation.

That is, the valve will not freeze in winter;

The valve is equipped with an air filter that does not let dust into the room. The filter is changed once every six months.

There are still few reviews on the supply ventilation valve in the form of a handle, because this is a novelty. But the principle of its operation is similar to the well-established ventilation devices for metal-plastic windows. This design is also suitable as a ventilation valve for aluminum windows.

Installing a valve for ventilating a plastic window with your own hands is not difficult. The kit includes detailed instructions and a diagram of the location of the holes in the air chambers of the sash. All fasteners are included.

Do-it-yourself installation of a supply valve on a window

The supply air valve on the plastic window can be installed independently. A home master with experience will spend no more than an hour on this.

You will need the following tools:

- ruler;

- screwdriver or screwdriver;

- sharp knife;

- valve.

Do-it-yourself supply valve for plastic windows is installed on the window flap. First you need to make a markup in the middle of the upper part of the sash using a ruler. The order of work depends on the design of the valve. So in some cases, to equip a window with ventilation, you only need to replace the sealant section with the one included in the kit. For other models, you will have to make a gap in the profile. When choosing a ventilation valve for aluminum windows, it is preferable to stop at the first option, since it is difficult to cut the supply slot accurately at home.

Step-by-step instructions on how to install a supply valve for window ventilation in the video:

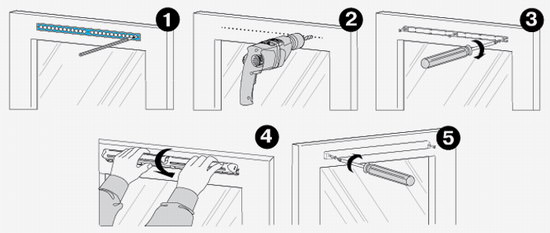

Mounting

Installation scheme

Virtually all companies that sell valves offer their installation services. Their cost is low, but the amount of work is small. We suggest that you read the instructions for self-assembly. For example, we will tell you how to install a slot-type ventilation device.

Required materials and tools:

- construction knife;

- screwdriver;

- ruler;

- valve;

- seal and plugs;

Walkthrough:

- Remove all unnecessary from the windowsill.

- Open window.

- On the upper sealing rubber, measure the length of the purchased valve.

- Using a knife, make two cuts and remove the intermediate piece.

- Replace it with a new sealing rubber.

- Measure the distance from the edge of the window to the beginning of the new seal.

- Set aside the same distance on the upper sash of an open window and make an incision in the seal.

- Measure the length of the future valve on the flap and make a second incision.

- Remove the intermediate piece.

- Instead of the old seal, install three plugs with the wide side up. They should move freely on the side of the window.

- Install the plugs at a distance corresponding to the valve mounts.

- Peel off a strip of double-sided tape on the valve and stick it to the window, pressing it firmly against the installed plugs.

- Screw the screws into the fasteners.

- Glue shorter seals between the fasteners.