- Main design features

- Supply ventilation device with air heating

- Supply ventilation schemes

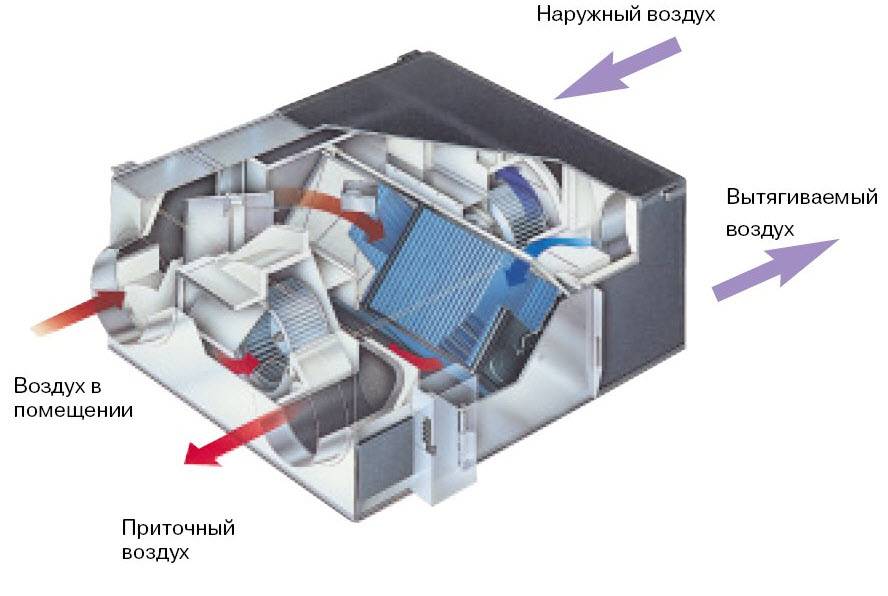

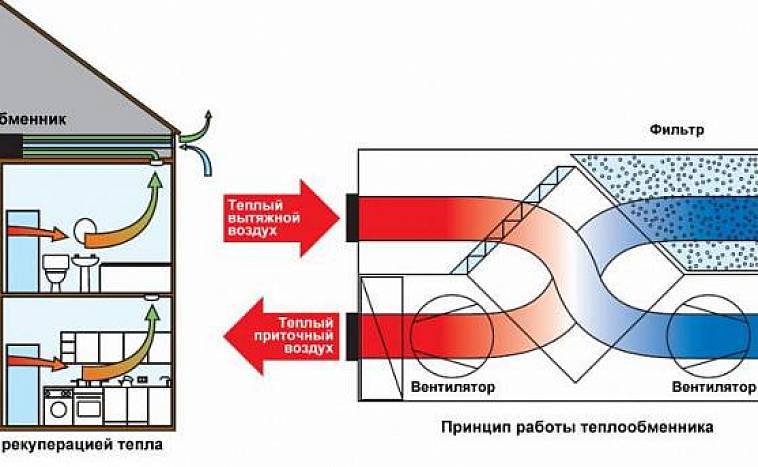

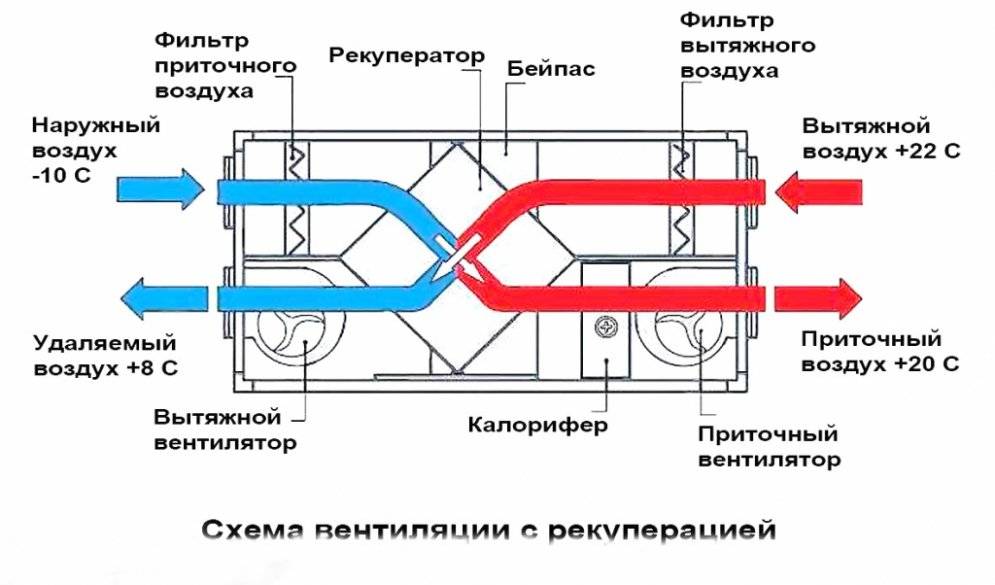

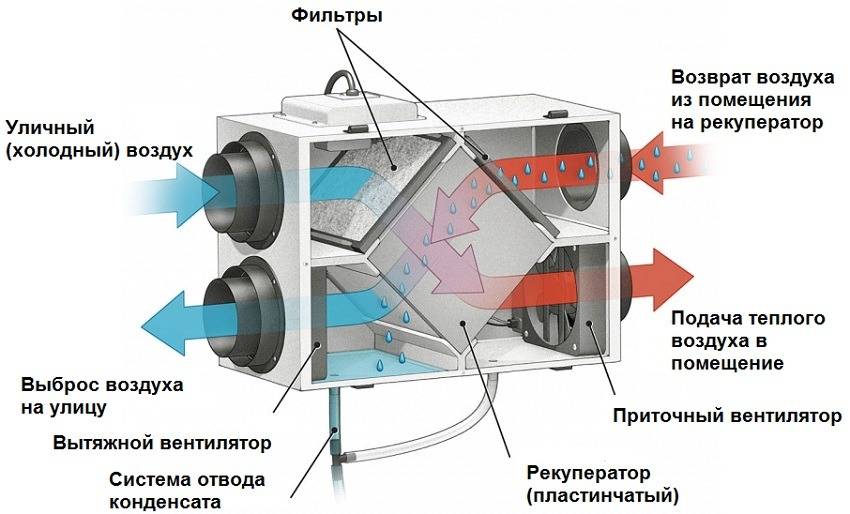

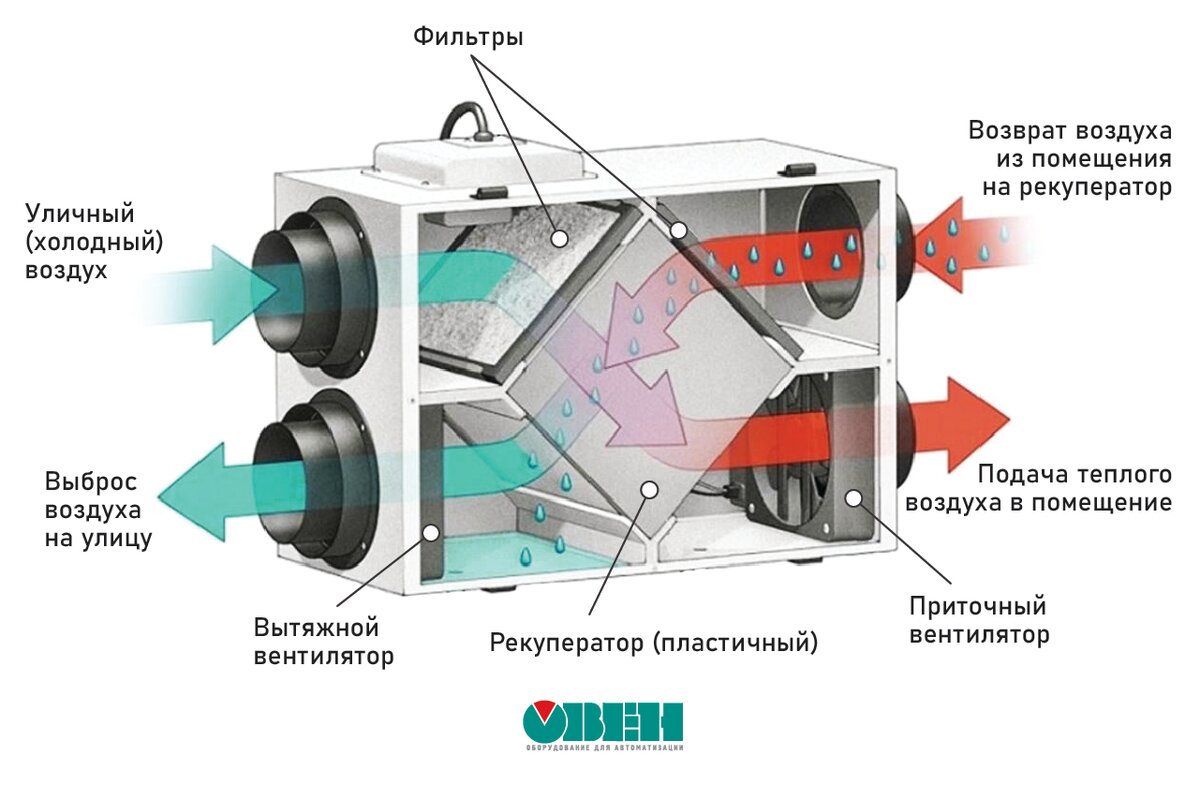

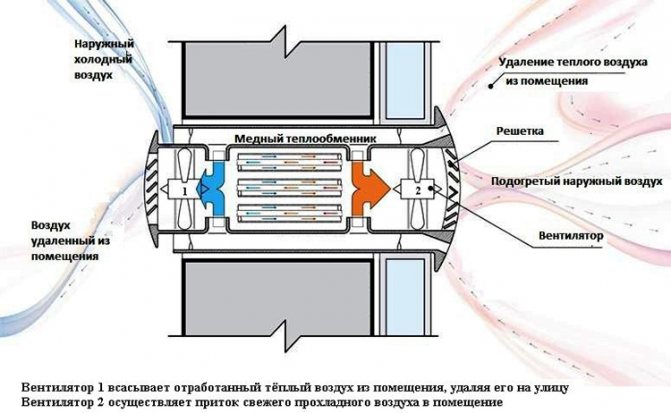

- Systems with recuperator

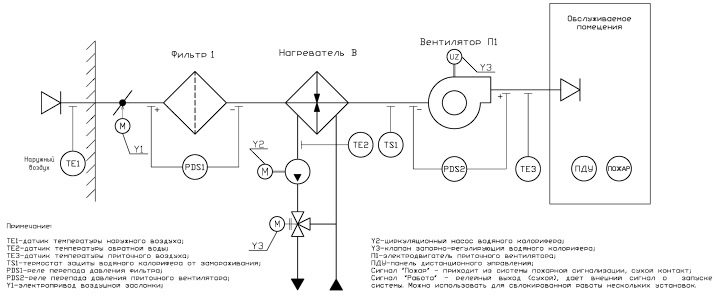

- Wiring diagram

- Step-by-step instruction

- Schemes and pictures

- Calculations

- Mounting

- Types of systems

- Central and individual ventilation

- Active and passive ventilation

- By type of heating

- Other types

- Design features of the device

- Passive ventilation systems.

- On the wall

- Active ventilation systems

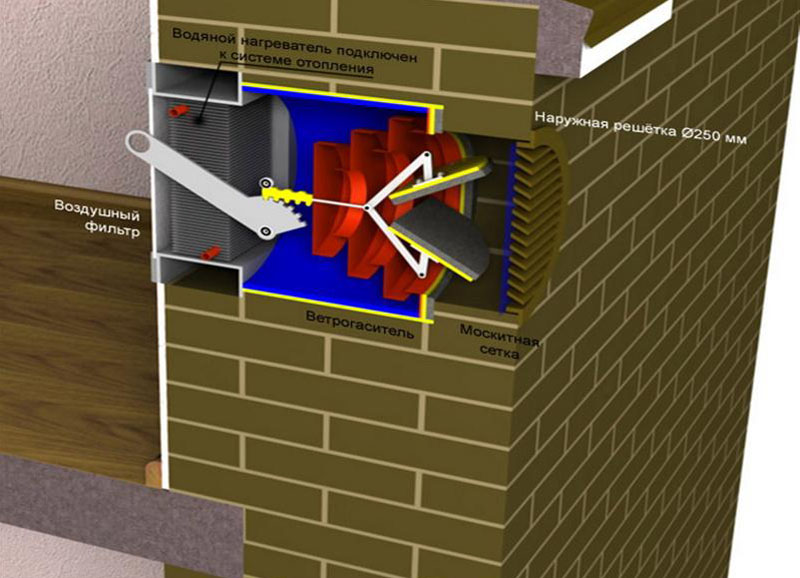

- Water heater

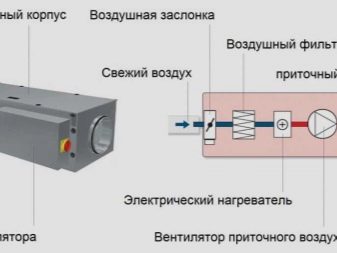

- Electric heater.

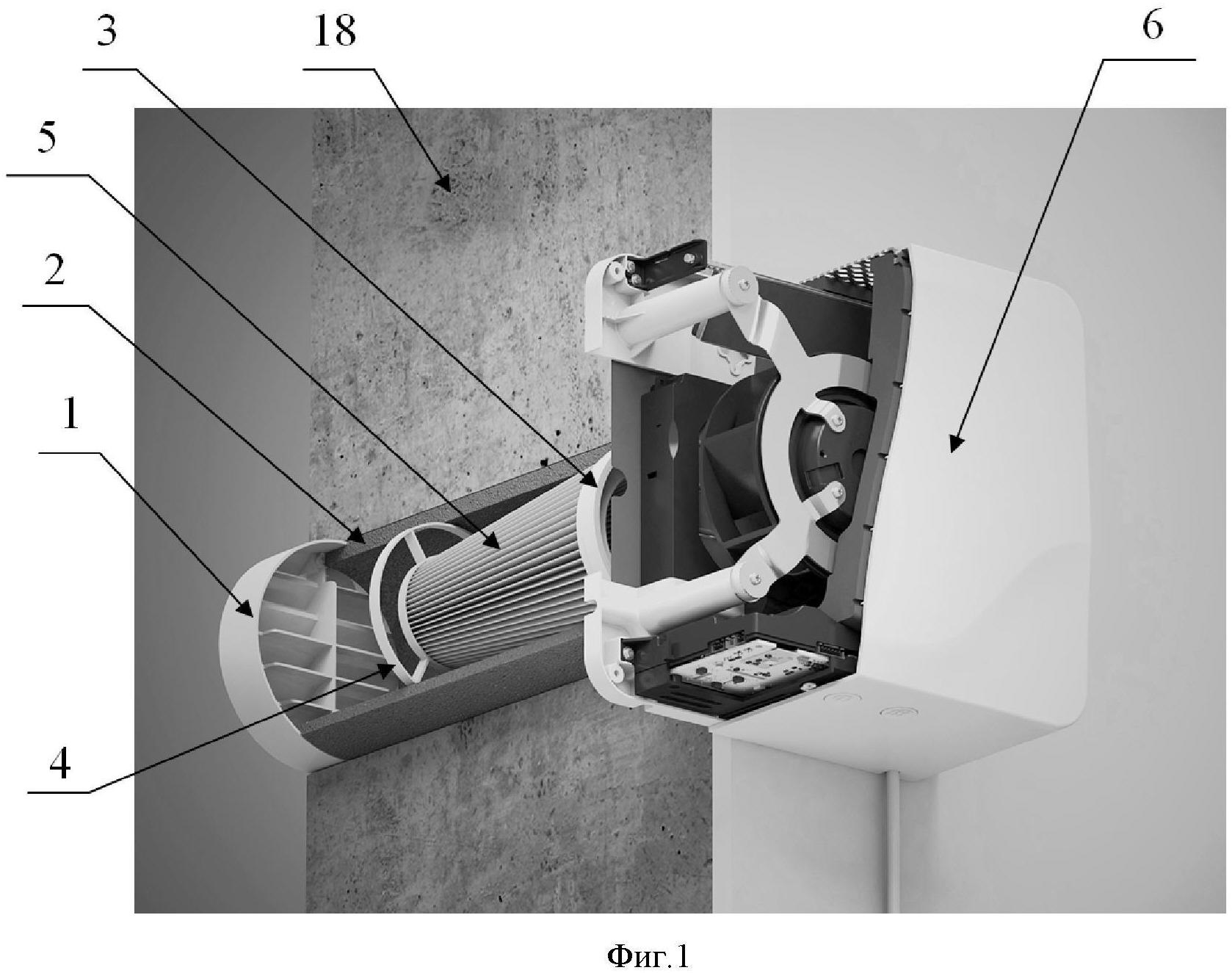

- breather

- The principle of operation of compact ventilation.

- Vehicle airflow

- Kinds

- water models

- Steam models

- Electrical Models

- Wiring diagram

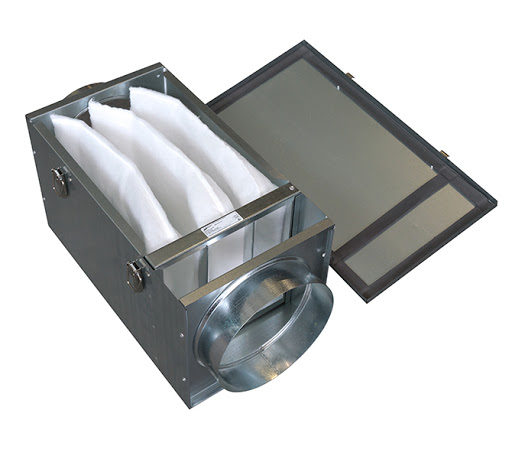

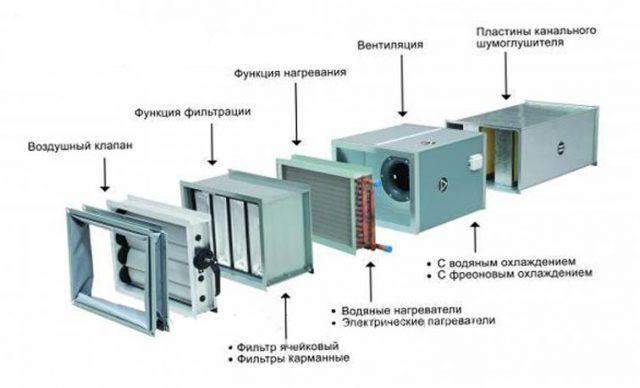

- Supply ventilation device

- How can you use a heater

- System features

Main design features

The system consists of several elements:

- Plastic grid. This decorative decoration of the structure filters out large debris that can enter along with air masses.

- valve or baffle. The function of the valve is to block the flow of air when the device is turned off.

- Filters. Filters trap fine debris and dust. These filters must be replaced every few months.

- The heating element is a heater (water or electric).

For small rooms or houses, it is better to use an electric heating element, and for large areas - water.

Supply ventilation device with air heating

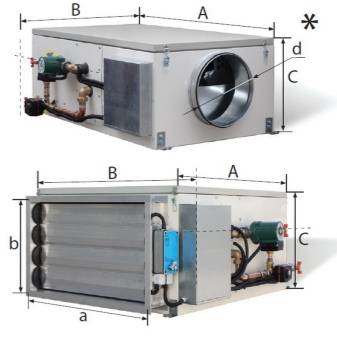

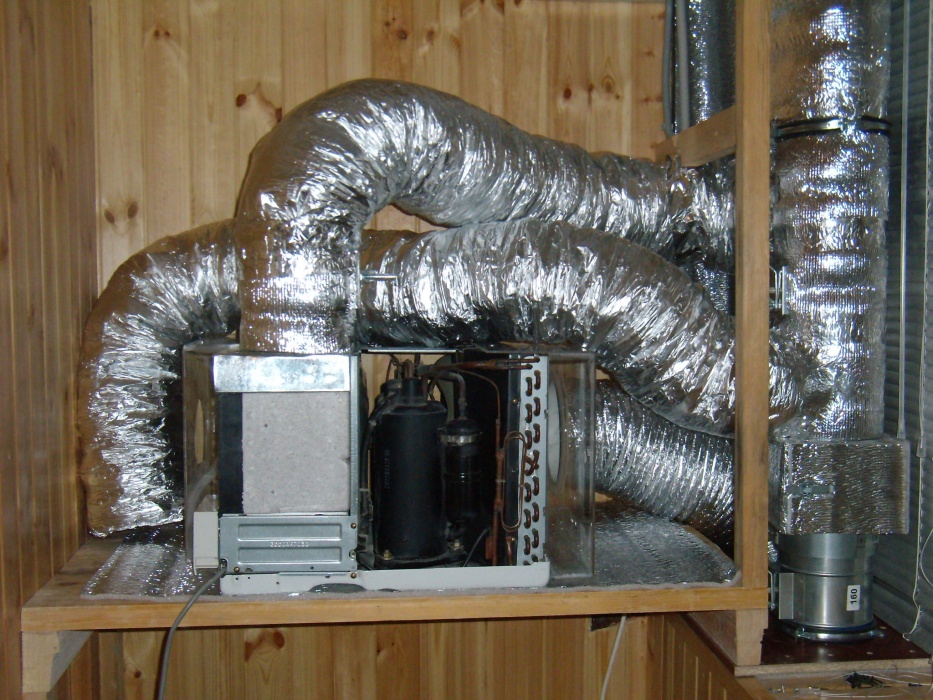

There are two types of units for forced ventilation:

- Monoblock - they are made up of one block, which is installed at the inlet of the duct. In such a block, without exception, all the necessary devices are located that provide high-quality and reliable service of the ventilation structure. This kind of device is often generally introduced into the wall or window frames. This method is considered the simplest and most inexpensive. But in practice, it is rather inefficient, since the placement of its intake fans does not make it possible to cover many areas of the building.

- Mounting - these supply ventilation systems have sufficient power to cover high-rise buildings, large industrial premises, apartment buildings.

Supply ventilation schemes

The easiest type of installation:

- Air filter,

- blower fan,

- Heating element.

Standard scheme of supply and exhaust ventilation with heating

Standard scheme of supply and exhaust ventilation with heating

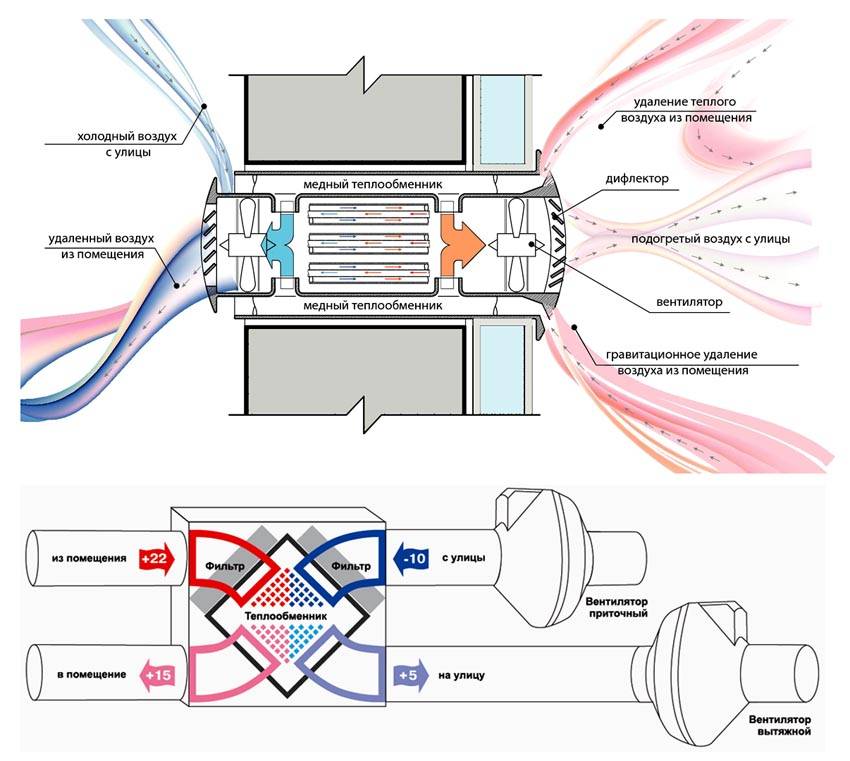

How to heat the supply air with a heat exchanger?

Recuperators are divided into 2 types:

- Rotary - work with the help of electricity. They have a cylindrical body in which a rotor element is mounted. It constantly rotates between the "incoming" and "exhaust" air valves. Quite a large piece. Efficiency - up to 87%.

- Lamellar. Such recuperators consist of combined plates. Supply and "exhaust" air move towards each other, through different valves.This prevents recirculation. Such recuperators are usually small in size.

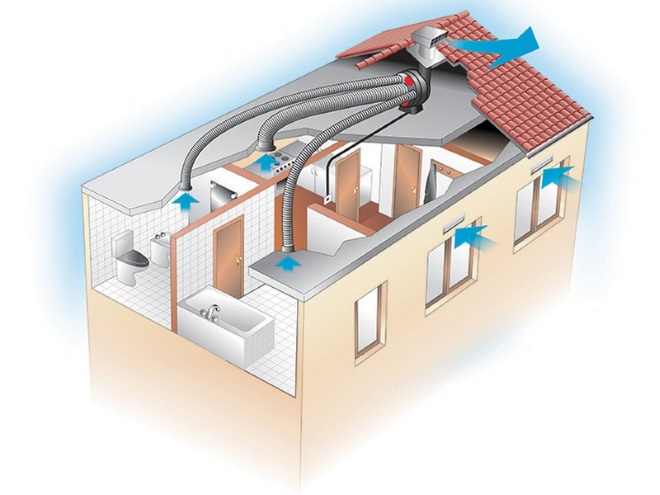

Systems with recuperator

Supply air can also be heated by a heat exchanger. These devices are divided into two types:

- Rotary recuperators - work at the expense of electricity. A rotary element is mounted inside the cylindrical body, which continuously rotates between the supply and exhaust air valves. The size of this type of heat exchanger is quite large. The efficiency reaches 87%.

- Plate heat exchangers consist of plates that are combined. Fresh air and "exhaust air" pass through separate channels towards each other. They do not mix, the cold supply air is heated by the warm outgoing wind flow. Such recuperators are compact.

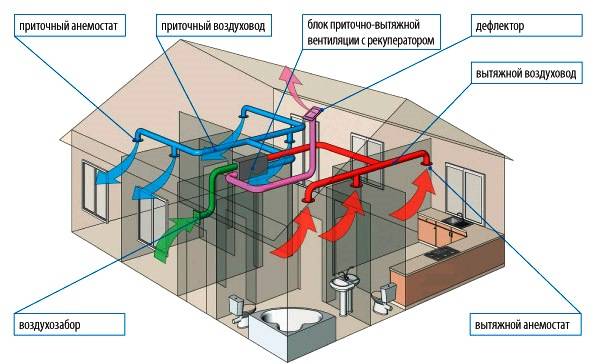

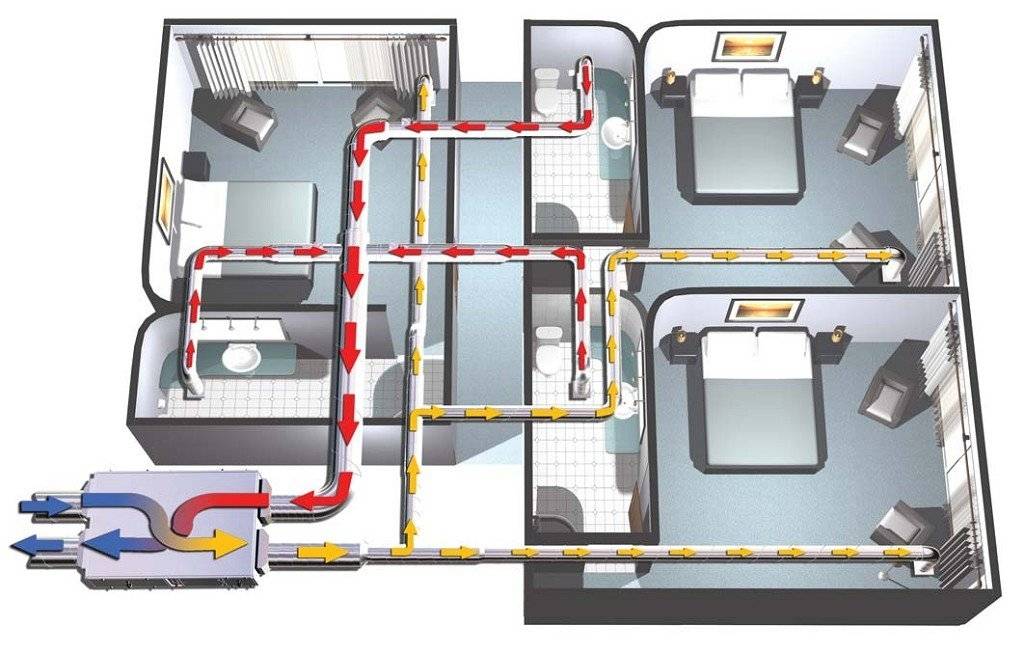

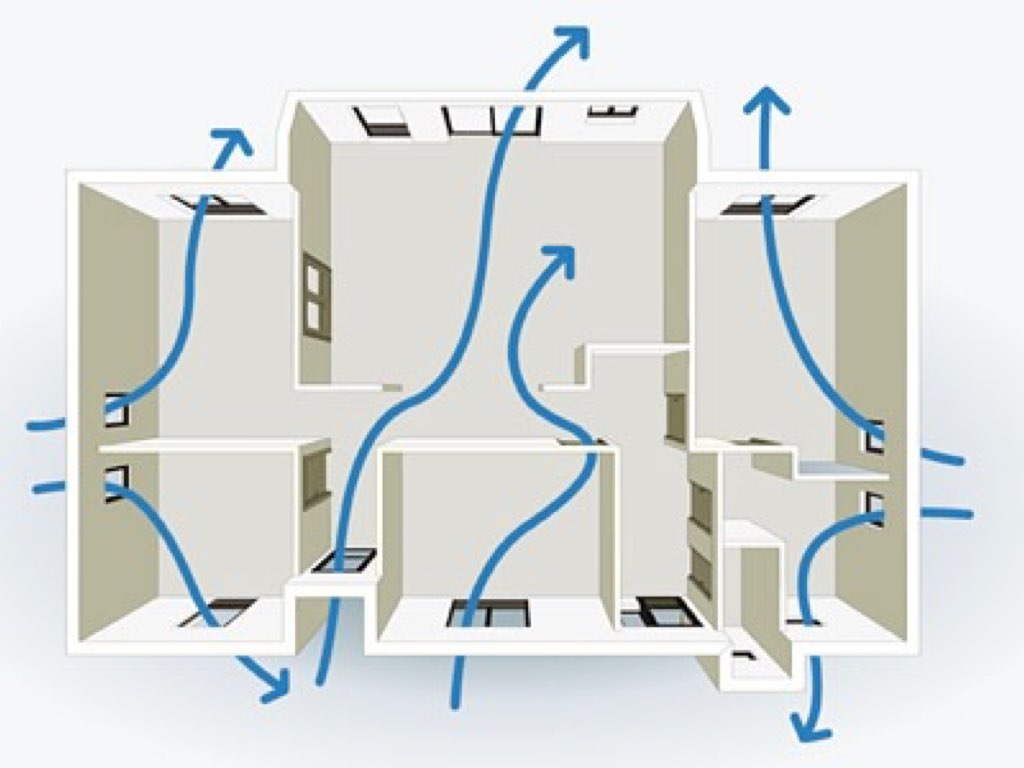

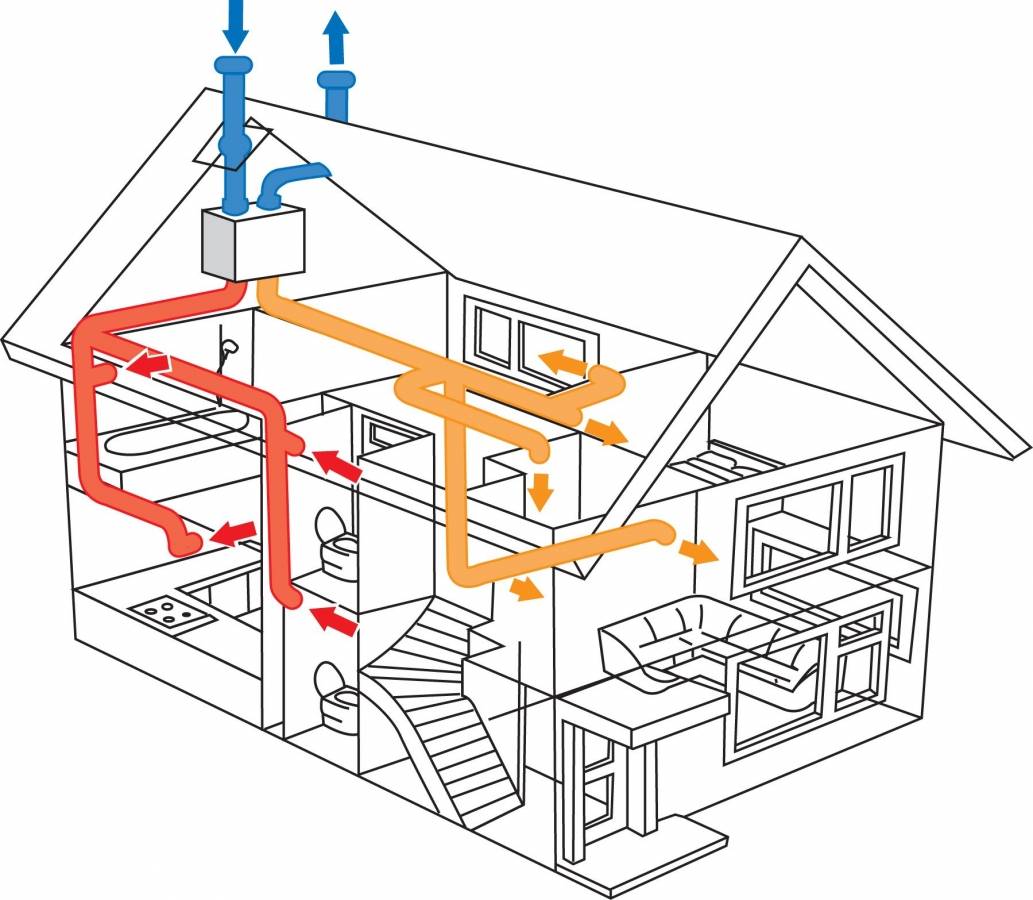

Wiring diagram

There are many schemes and methods for placing equipment and organizing air exchange. The choice of a specific scheme depends on the type of premises (apartment, private house, office), the dimensions of the system, its equipment (read about arranging ventilation in an apartment here).

For example, when organizing ventilation in a private house, the simplest scheme is often used with an air supply device in the corridor or hallway. In houses and apartments, the entrance hall communicates with almost all rooms, so heated purified air can be supplied to it, which will be distributed to all rooms.

Before you begin to develop or apply a scheme, you need to carefully calculate the air flow.

Attention

If the calculation is done for private housing construction, then the air consumption for the operation of the boiler room is added to the result obtained by the standard formula.If the house has local exhaust devices (pipes, hoods), then the calculation will have to include their performance values.

Step-by-step instruction

Schemes and pictures

Before installation, the masters recommend making a sketch of the future ventilation system on paper. The drawing should be with all sizes and directions, so that it is more convenient to install the finished system and make calculations. Lattices and shutters are marked on the valves.

Any scheme takes into account:

- The air flow should go from clean to dirty rooms: from the bedroom, nursery, hallway to the kitchen and bathroom (how to install ventilation in the kitchen and bathroom?).

- A heated supply ventilation damper should be located in all rooms and premises that are not equipped with an exhaust hood (how to install an exhaust hood?).

- The exhaust ducts must be the same size everywhere, without expansion or contraction.

Scheme of heated ventilation ducts in a private house: Supply ventilation to the wall with heating and a supply valve in the section: A simple drawing of ventilation with check valves on the air ducts: A drawing of the location of the air ducts in the apartment:

Calculations

In order for the system to work properly, it is necessary to calculate its power as accurately as possible. To do this, you will need all the parameters of the room through which the flow will move. Take into account:

- number of floors in the house;

- area of rooms;

- space planning;

- the number of people living in the total area;

- the presence of household appliances (computers, televisions, machine tools).

The calculation of the ventilation system begins with the determination of the air capacity, measured in cubic meters per hour. For calculations, you need a plan of a house or apartment, where the rooms and their areas are indicated.

For each, the amount of air supplied is determined.

Important The calculation is usually carried out in accordance with the requirements of SNiP. For example:

For example:

- for residential premises where windows are not opened, the flow rate must be at least 60 m³ / h per person;

- for the bedroom - at least 30 m³ / h per person.

When calculating, only those people who are in the premises regularly (permanent residents or employees) are taken into account.

The next stage is the calculation of air exchange by multiplicity. This parameter shows how many times a complete change of air occurs in the room within one hour.

It is important to provide at least one air exchange

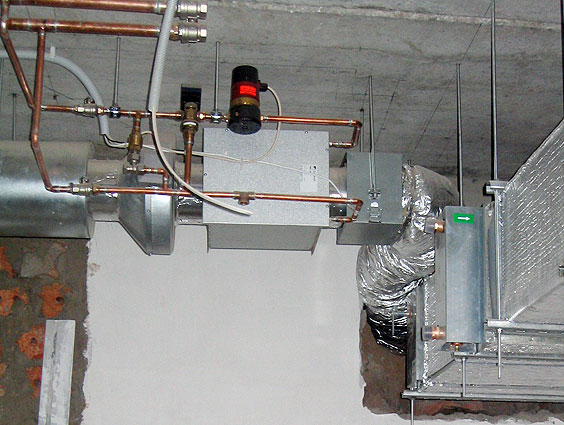

Mounting

The following tools are required for mounting the equipment:

- Perforator or diamond drill.

- Hammer or sledgehammer, screwdriver or screwdriver.

- Wrenches of different sizes and a ratchet wrench.

Stages:

- Prepare the plane for the through hole.

- Choose its dimensions, mark the space.

- Drill a through hole with a diamond drill or perforator. Prime the walls of the hole.

- Insert the air duct into the through hole. A case and a fan are mounted to it.

- After installing the air duct, fill all the cracks around the pipe with sealant.

- Lay channels for wiring to automate the operation of the device.

- Install all remaining parts: filters, noise absorbers, temperature sensors, grille.

- Check the system for functionality.

More details about the stages of installation of the ventilation structure in different types of premises, about the essential and significant nuances of the work on the installation of ventilation are described in a separate publication.

Supply ventilation with an air heating function can be done independently with your own hands, even if you have no experience with ventilation devices. The main thing is to act in stages, carefully prepare for work by drawing the necessary diagrams and making the right calculations.

Ventilation systems that provide the inflow and processing of air masses coming directly from the street, as a rule, are used exclusively in the economic and industrial sphere. For domestic conditions, such systems are not provided by default. This is one of the reasons that makes ordinary users think about putting together something similar for home use. But is it possible and how can this problem be solved?

By and large, almost everything is possible. However, there are always a number of nuances that should be considered. And we will talk about this in our article - we will consider what a do-it-yourself heated supply ventilation is and what main components it consists of. Let's discuss the issue of home "inflow" with heating from the point of view of possible solutions to this issue, supplementing the article with visual photos and thematic videos.

Types of systems

Heated ventilation can be of several types, they are classified according to different criteria: heating method, mounting location, design, etc.

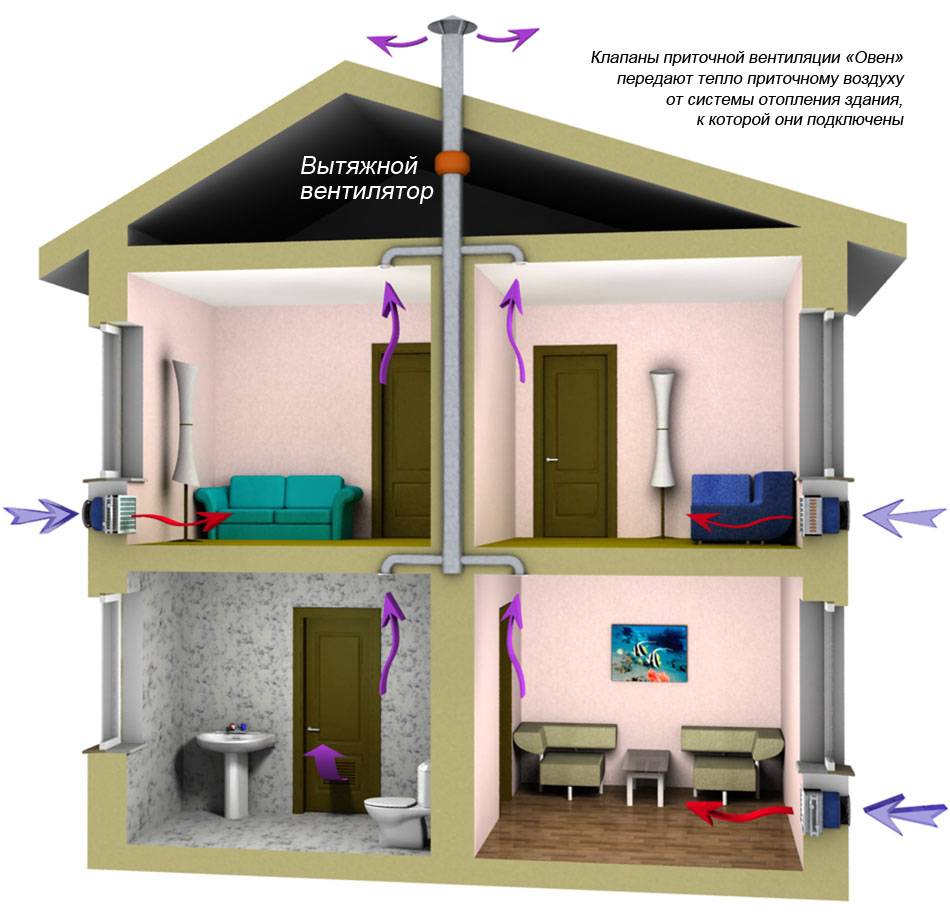

Central and individual ventilation

All types of ventilation can be divided into 2 main types: central and individual (compact or breather).

Central ventilation is used when it is necessary to supply clean air to a large room. It has high performance.

It is used in industries, put on general house ventilation systems.The air is heated by a water or electric heater, less often a recuperator is used. Such equipment is expensive.

Breezers are used for individual ventilation. These are compact devices that are mounted in apartments and private houses. They are usually placed on the wall.

Installation is quick and takes less than an hour. You can put such equipment in any home. The device has many settings, a climate control function, a multi-stage cleaning system.

Active and passive ventilation

In this case, a division is used to control the supply of fresh air.

In passive structures, this possibility is absent. Air masses come from the difference in pressure between the room and the street.

The amount of air supplied depends on the speed of its movement, temperature difference and humidity level. Most often, the device is mounted on the wall, it is a small box.

Active ventilation systems allow you to control the air supply. Outwardly, they are similar to passive ones, but the control unit allows you to adjust not only the temperature, but also the intensity of the flow.

By type of heating

Supply ventilation may differ in the way the air is heated.

There are the following types of devices:

- with recovery. In this case, the incoming air is heated by the outgoing air. Used in passive ventilation systems. Suitable for regions with warm winters, as it is ineffective at large temperature differences;

- with water heating. In this case, central heating or a boiler is used for heating. Allows you to significantly save on electricity;

- electrical. In ventilation, a heating element is used, which is powered by electricity.It heats the passing air to the desired temperature.

Other types

Also, devices are divided according to the method of forcing air masses into natural and forced. In the second case, fans are used to supply them.

Devices are also divided by type of control. There are automatic devices that are controlled from the remote control or through the application on the smartphone. The second type is manual, the operation settings of which are set on a stationary control unit.

By design, monoblock and mounting are distinguished. The first ones consist of one block installed at the entrance to the ventilation duct. They are used when installing the inflow in the wall or in the window frame.

Devices have low productivity, suitable for small rooms. Mounting devices consist of many elements.

They are used in the arrangement of central ventilation. Their capacity is enough to supply fresh air to multi-storey buildings and production workshops.

Design features of the device

The main elements of supply ventilation

- Air intake grill. Acts as an aesthetic design, and a barrier that protects debris particles in the supply air masses.

- Supply ventilation valve. Its purpose is to block the passage of cold air from the outside in winter and hot air in summer. You can make it work automatically using an electric drive.

- Filters. Their purpose is to purify the incoming air. I need a replacement every 6 months.

- Water heater, electric heaters - designed to heat the incoming air masses.

- For rooms with a small area, it is recommended to use ventilation systems with electric heating elements, for large spaces - a water heater.

Elements of supply and exhaust ventilation

Additional elements

- Fans.

- Diffusers (contribute to the distribution of air masses).

- Noise suppressor.

- Recuperator.

The design of ventilation directly depends on the type and method of fixing the system. They are passive and active.

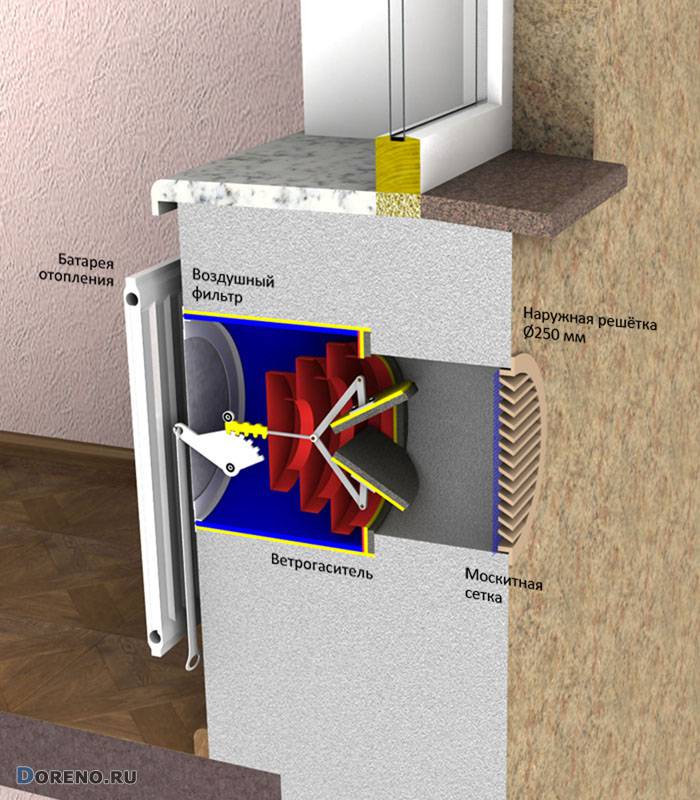

Passive ventilation systems.

Such a device is a supply ventilation valve. The scooping of street air masses occurs due to the pressure drop. In cold weather, the temperature difference contributes to the injection, in the warm period - the exhaust fan. The regulation of such ventilation can be automatic and manual.

Automated regulation directly depends on:

- the flow rate of air masses passing through the ventilation;

- air humidity in the space.

The disadvantage of the system is that in the winter season such ventilation is not effective for heating the house, since a large temperature difference is created.

On the wall

Refers to the passive type of supply ventilation. Such an installation has a compact box that is mounted on the wall. To control the heating, it is equipped with an LCD display and a control panel. The principle of operation is to recuperate internal and external air masses. To heat the room, this device is placed near the heating radiator.

Active ventilation systems

Since in such systems it is possible to regulate the intensity of fresh air supply, such ventilation for heating and space heating is more in demand.

According to the principle of heating, such a supply heater can be water and electric.

Water heater

Powered by heating system. The principle of operation of this ventilation system is to circulate air through a system of channels and tubes, inside which there is hot water or a special liquid. In this case, heating takes place in a heat exchanger built into the centralized heating system.

Electric heater.

The principle of operation of the system is to convert electrical energy into thermal energy using an electric heating element.

breather

This is a compact device, small size for forced ventilation, heated. To supply fresh air, this device is attached to the wall of the room.

Breather Tion o2

Breezer construction o2:

- Channel consisting of an air intake and an air duct. This is a sealed and insulated tube, due to which the device draws air from outside.

- Air retention valve. This element is an air gap. It is designed to prevent the outflow of warm air while the device is turned off.

- Filtration system. It consists of three filters, which are installed in a certain sequence. The first two filters clean the air flow from visible contaminants. The third filter - deep cleaning - from bacteria and allergens. It cleans the incoming air from various odors and exhaust gases.

- Fan for air supply from the street.

- Ceramic heater, which is equipped with climate control.Responsible for heating the inflow of air flows and automatic temperature control.

The principle of operation of compact ventilation.

- Masses of street air pass through the air intake, which is equipped with a closed-type plastic grille. Thus, the air masses are filtered from debris and insects.

- The air then passes through the duct into the body of the instrument. To protect the walls from freezing, it is made of a noise-heat-insulating plastic pipe. In this case, all joints are sealed.

- Then it is filtered from coarse and medium dust using special filters built into the device.

- After that, the air mass passes into the heater and warms up to the temperature set by the climate control. On such a device, you can set the desired temperature (up to + 25 ° C) and the system will maintain it automatically.

- After heating, the air passes through a two-stage filtration from fine dust, odors, gases and allergens, enters the fan and is discharged into the room.

Such supply ventilation can be controlled remotely using the remote control.

The bottom device is mounted within one hour.

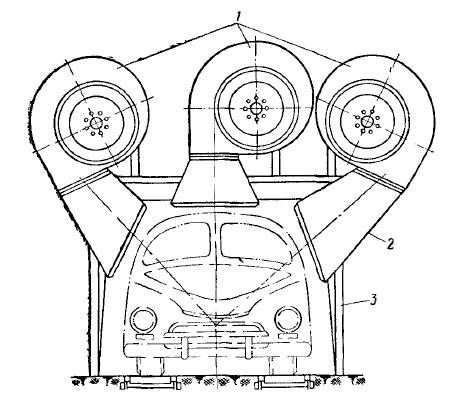

Vehicle airflow

To speed up the drying of cars, blowing with cold or heated air is used.

After washing, cold air is blown with the help of a powerful blower installation of fans of the "Sirocco" type, forcing air into the air distribution pipes with slotted nozzles at an angle of 60 ° to the surface being blown.

The installation for blowing air after washing cars consists of three fans 1 of the EVR-6 brand, driven by electric motors with a power of 20 kW. To direct the air jet, each fan is equipped with a figured nozzle 2 of a rectangular shape.The unit is mounted on frame 3 and enclosed in a casing.

The disadvantage of drying with cold air is a significant consumption of electricity (the power of the electric motors of the fans reaches 60 kW). However, the use of warm air due to its low thermal conductivity (250 times less than the thermal conductivity of iron) is also not effective enough due to the too low heat utilization factor.

A promising method of drying a car can be considered the use of lamps with infrared rays, as well as thermoradiation drying with dark infrared radiation panels with high efficiency. and little heat loss.

Kinds

Heaters for supply ventilation are classified according to the type of heat source and are water, steam and electric.

water models

They are used in all types of ventilation systems and can have two- and three-row versions. The devices are installed in the ventilation systems of rooms with an area exceeding 150 square meters. This type of heaters is absolutely fireproof and the least energy-consuming, which is due to the possibility of using water from the heating system as a coolant.

The principle of operation of water heaters is as follows: outdoor air is taken through the air intake grilles and fed through the air duct to the coarse filters. There, the air masses are cleaned of dust, insects and small mechanical debris, and enter the heater. A copper heat exchanger is installed in the heater body, consisting of links arranged in a checkerboard pattern and equipped with aluminum plates. The plates significantly increase the heat transfer of the copper coil, which significantly increases the efficiency of the device.The coolant flowing through the coil can be water, antifreeze, or a water-glycol solution.

Cold air flows passing through the heat exchanger take heat from metal surfaces and transfer it to the room. The use of water heaters allows heating air flows up to 100 degrees, which provides ample opportunities for their use in sports facilities, shopping centers, underground parking lots, warehouses and greenhouses.

Along with obvious advantages, water models have a number of disadvantages. The disadvantages of the devices include the risk of water freezing in pipes with a sharp drop in temperature, and the inability to use heating in the summer, when the heating system is not functioning.

Steam models

They are installed at the enterprises of the industrial sector, where it is possible to produce a large amount of steam for technical needs. Such air heaters are not used in domestic supply ventilation systems. Steam acts as the heat carrier of these installations, which explains the instantaneous heating of the passing flows and the high efficiency of steam heaters.

To prevent this from happening, all heat exchangers are subjected to a tightness test during the production process. Tests are carried out with jets of cold air supplied at a pressure of 30 bar. In this case, the heat exchanger is placed in a tank with warm water.

Electrical Models

They are the simplest type of heaters, and are installed in ventilation systems serving small spaces.Unlike heaters of water and steam types, the electric heater does not involve the arrangement of additional communications. To connect them, it is enough to have a 220 V socket nearby. The principle of operation of electric heaters does not differ from the principle of operation of other heaters and consists in heating the air masses passing through the heating elements.

Even with a slight decrease in this indicator, the electric heating element overheats and breaks. More expensive models are equipped with bimetallic thermal switches that turn off the element in case of obvious overheating.

The advantages of electric heaters are simple installation, no need for plumbing, and independence from the heating season. The disadvantages include high energy consumption and inappropriate installation in powerful ventilation systems serving large spaces.

Wiring diagram

There are many schemes and methods for placing equipment and organizing air exchange. The choice of a specific scheme depends on the type of premises (apartment, private house, office), the dimensions of the system, its equipment (read about arranging ventilation in an apartment here).

There are many schemes and methods for placing equipment and organizing air exchange. The choice of a specific scheme depends on the type of premises (apartment, private house, office), the dimensions of the system, its equipment (read about arranging ventilation in an apartment here).

For example, when organizing ventilation in a private house, the simplest scheme is often used with an air supply device in the corridor or hallway. In houses and apartments, the entrance hall communicates with almost all rooms, so heated purified air can be supplied to it, which will be distributed to all rooms.

Before you begin to develop or apply a scheme, you need to carefully calculate the air flow.

Attention

If the calculation is done for private housing construction, then the air consumption for the operation of the boiler room is added to the result obtained by the standard formula. If the house has local exhaust devices (pipes, hoods), then the calculation will have to include their performance values.

Supply ventilation device

Ventilation is a way to ventilate an enclosed space that helps:

- fill the room with fresh air;

- create a special microclimate;

- prevent the appearance of mold, fungus on the walls and ceiling.

- temperature control;

- adjustment of air supply power, etc.

Ventilation devices are compact and fit into a residential interior. Heated ventilation devices consist of a heating element, a filter grill that cleans the incoming air masses from debris, dirt, dust, and additional elements that not all systems are equipped with (humidifiers, antibacterial filters).

Attention

A high-quality ventilation system regularly fills the room with fresh, warm, purified, humidified air

How can you use a heater

The main purpose of a fan heater is to heat air masses. For more intensive circulation of flows - the fan pumps air forcibly. This makes this device versatile.

Fan heater operation options:

- This appliance can be used as the main source of heat supply to a room that does not have central heating.

- The fan heater can complement the main heating system.

- For heating construction sites and workers on them.

- For fast heating of air in a small room.

- The fan heater can be used as an ordinary fan: in winter - for heating, in summer - for cooling the air.

- For ventilation and heating of closed premises.

System features

The most important advantage of a mechanical system is the control of air supply and flow rate. Moreover, for the operation of a mechanical system in a private house, huge ventilation shafts are not needed - a small hole in the wall or door is enough.

Example: Passive (natural system) fills the room at a rate of 1-3 cubic meters per hour. To pump 300 cubic meters per hour, a pipe with a diameter of 35-37 cm is required. The mechanical system pumps 5 times faster, and for the same volume, a pipe diameter of 20 cm is sufficient.

Since there is not always a place for a large hood, and it will look ugly, it is the mechanics that can create the necessary conditions with an almost imperceptible system.

Ventilation in a private house is as follows:

- The air exchange is calculated.

- Air duct sections are selected.

- The type of ventilation is selected.

Based on these points, a diagram is drawn up with the location of ventilation elements and duct points.