- The use of alloys of the tin-lead group

- Who and when is it better to use each of the solders

- Materials and tools

- Solders for aluminum brazing

- Fluxes for aluminum brazing

- Classification

- Features of the composition of food solders

- Varieties

- Areas of use

- Conclusion

- Solder classification

- Low temperature or soft solder

- High temperature or hard solder

- Soldering copper pipes

- Usage Tips

- View overview

- Low temperature

- high temperature

- Thermal additives (fluxes)

The use of alloys of the tin-lead group

These alloys include:

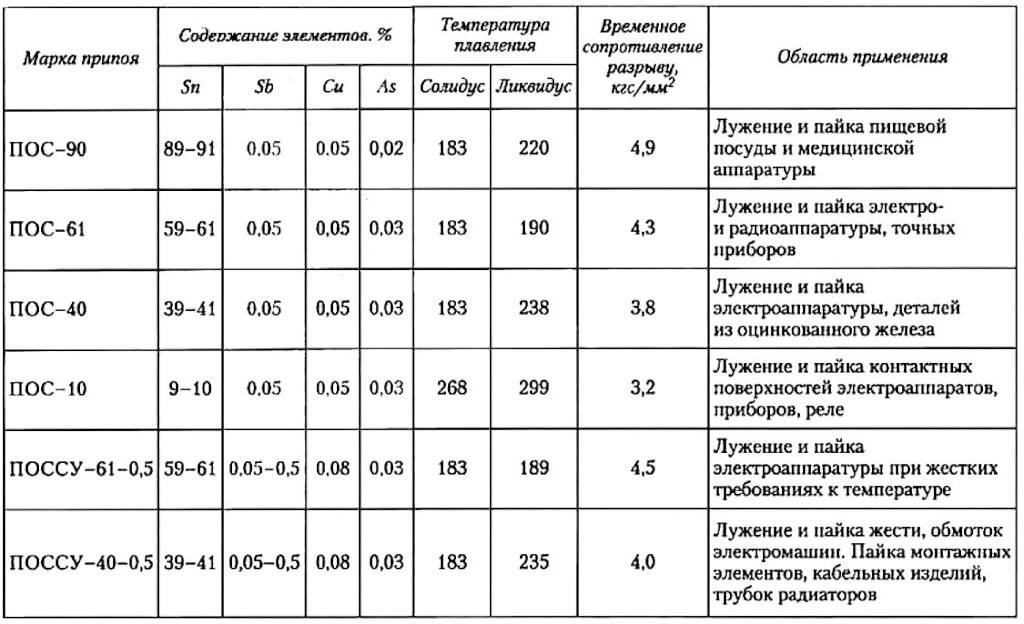

- POS-90 contains: Pb - 10%, Sn - 90%. Used to repair medical equipment and food utensils. There is not much toxic lead, since it cannot be in contact with food and water.

- POS-40: Pb - 60%, Sn - 40%. Mainly used for soldering electrical equipment and galvanized iron products, it is also used to repair radiators, brass and copper pipelines.

- POS-30: Sn - 30%, Pb - 70%. It is used in the cable industry, for soldering and tinning and zinc sheets.

- POS-61: Pb 39%, Sn 61%. As with POS-60. There isn't much difference.

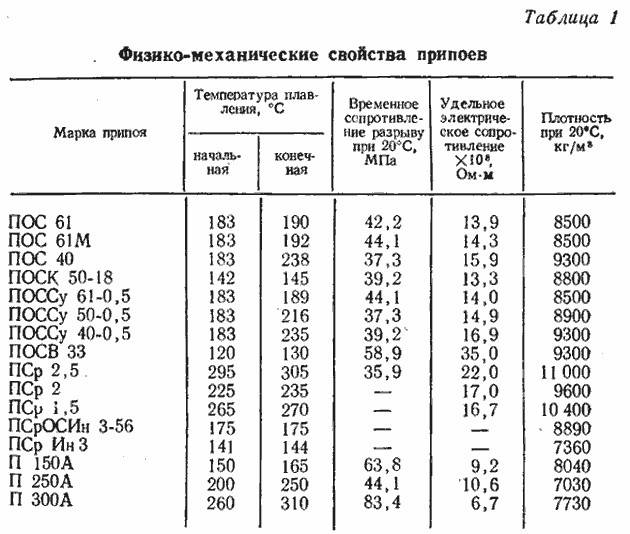

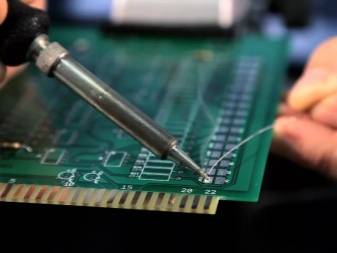

With the help of POS-61, tinning and soldering of printed circuit boards of radio equipment is carried out. It is the main material for assembling electronics.Melting begins at 183 °C, complete melting at 190 °C. You can solder with this solder using an ordinary soldering iron, without fear that the radio elements will overheat.

POS-30, POS-40, POS-90 are melted at 220–265 °C. For many electronic elements, this temperature is subcritical. It is better to assemble home-made electronic devices with POS-61, whose foreign counterpart can be considered Sn63Pb37 (where Sn is 63%, and Pb is 37%). Also, with its help, radio equipment and home-made electronics are soldered.

Solders are sold, as a rule, in tubes or coils of 10-100 g. The composition of the alloy can be read on the package, for example: Alloy 60/40 (“Alloy 60/40” - POS-60). It looks like a wire with a diameter of 0.25-3 mm.

It often contains a flux (FLUX) that fills the core of the wire. The content is indicated as a percentage and is 1−3.5%. Thanks to this form factor, there is no need to supply flux separately during operation.

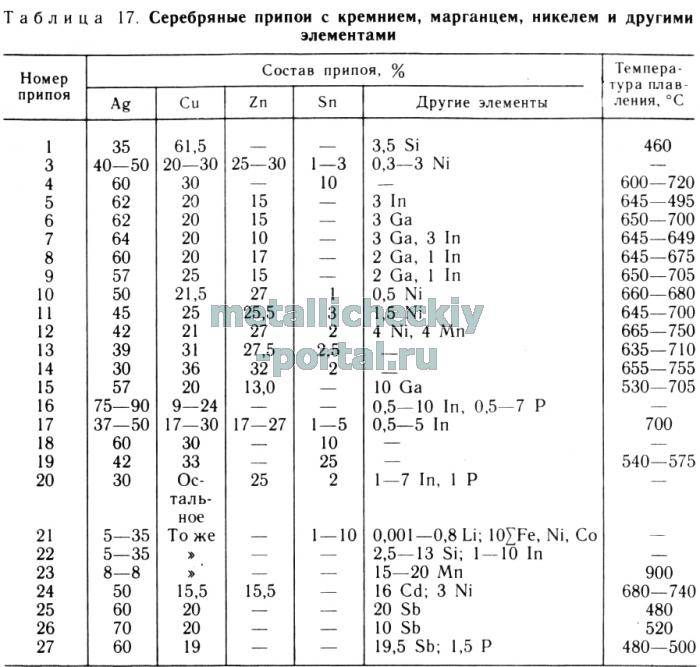

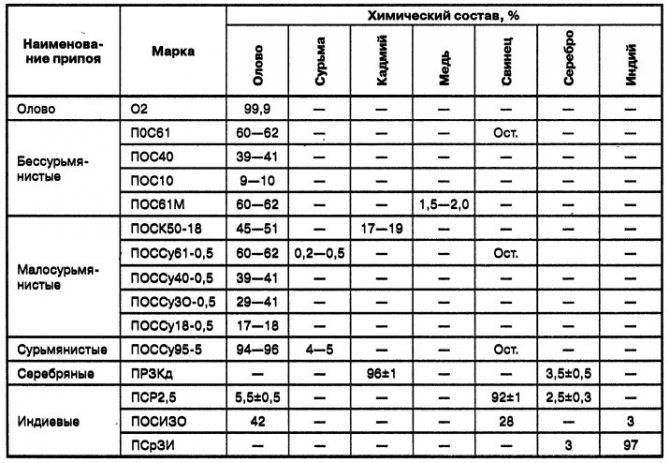

A variety of POS - POSSU is a tin-lead alloy with antimony, and is used in the automotive industry, in refrigeration equipment, for soldering elements of electrical equipment, windings of electrical machines, cable products and winding parts; suitable for soldering galvanized parts. In addition to lead and tin, the alloy contains 0.5–2% antimony.

As the table shows, POS-61-0.5 is most suitable for replacing POS-61, because the temperature of its complete melting is 189 ° C. There is also a completely lead-free solder, tin-antimony POS 95-5 (Sb 5%, Sn 95%) with a melting point of 234-240 ° C.

Who and when is it better to use each of the solders

A radio engineer uses a tubular element, the cavity of which is filled with rosin, when soldering is necessary:

- In the appliance, repair the electronic device.

- Small in volume areas, using tubes or reel equipment.

- At an industrial enterprise, in the presence of a coil, in compliance with all technological processes and properties of the soldered metal.

- With low melting points.

Soldering without internal fillers allows you to perform operations with different:

- Refractory metals.

- Temperature regimes of melting, depending on the composition of the alloy.

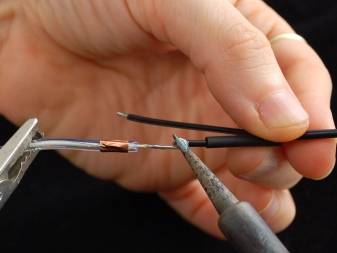

- Elements sensitive to overheating - fuses, transistors.

- Radio engineering products - wires, technical boards.

- Tin and join copper, bronze parts to obtain an airtight seam.

The master determines the scope of work and selects the substance that is suitable for specific work. It is good to attach radio components using wire with rosin. For joining elements made of bismuth or cadmium, it is better to choose separately solder and flux that meet the requirements of the alloys.

Materials and tools

To perform aluminum brazing, you should have a variety of materials and tools, which include heating tools, solders and fluxes.

Necessary materials and tools

Most often, an electric soldering iron is used as a heating tool. It can be considered a versatile tool that is easy to use at home. But it can only be used to repair small items, usually small-diameter tubes, wires and cables, and small electrical appliances. It can be used at home in a ventilated area, as it does not require special conditions and a lot of space.

When using burners, it is necessary to strictly control the supply of the flame, which must be characterized by maintaining the balance of gas and oxygen. When working, the flame should be bright blue. Any color changes may indicate an excess of oxygen.

Solders for aluminum brazing

Soldering aluminum with solder is a very difficult task. Therefore, the choice of solder is important for creating a quality seam and a strong connection. When using a conventional soldering iron, you need to select solder from a metal that has a low melting point. The most common alloys are:

- zinc-tin;

- bismuth-tin;

- copper-tin.

These species are very often called amateur radio.

They have a low melting point, which is very important for keeping aluminum in its original state without changing the structure and physical properties. The cost of such solders is low, so their purchase becomes affordable for home craftsmen.

Solders for aluminum

But their use has a number of disadvantages and a limited scope. So, the connection of objects with the help of such solder does not differ in high strength and reliability. Therefore, they are used almost exclusively in the repair of electrical equipment, including the connection of wires and cables.

When repairing large-sized aluminum objects with the help of such solders, the connection will quickly lose strength and collapse. In such cases, it is better to use refractory solder, which includes zinc and tin.

It is impossible to use such solder when working with a soldering iron, since their melting point is about 600 degrees. Therefore, to work with them, you need to have a gas burner.

It should be noted that when soldering with a gas burner, the metal of the workpiece does not melt, only the solder will melt.

Fluxes for aluminum brazing

When soldering aluminum, you need to use special fluxes, since not every flux is active in relation to aluminum. Substances based on ammonium fluoroborator and triethanolamine are considered to be the most suitable. Most special fluxes are marked with a special marking that indicates their use in aluminum brazing.

Fluxes for aluminum brazing

If it is necessary to work at high temperatures, attention should be paid to mixtures containing potassium chloride, which is half; potassium chloride; sodium fluorite and zinc chloride. This composition allows you to create the most optimal conditions for high-temperature work.

Classification

Solders are classified according to several main features. First of all, they are divided into soft and hard. Soft grades include those grades for which the melting point reaches 300 degrees Celsius. The maximum tensile strength in this case is 100 MPa, while the minimum is only 16 MPa. These include alloys of lead, tin, cadmium, zinc, antimony and other low-melting metals, including lead-free solders.

Solid grades include those grades whose melting point is above 300 degrees Celsius. This also increases the tensile strength, since the minimum value here is about 100 MPa, and the maximum value can reach 500 MPa.These are alloys of copper, zinc, nickel, silver and other metals that have a high melting point.

Brazing Solder

In addition, there is a division into what kind of base metal is contained in the composition of the filler material. It could be:

- Silver solder;

- Copper;

- Tin;

- Aluminum;

- Solder for soldering stainless steel.

It is also worth highlighting in a separate class fluxed grades, which contain flux, respectively, they do not require its additional use.

Delivery options include:

- Rods are small dense elements that are melted with a soldering iron;

- Wire - well suited for both gas soldering and a soldering iron;

- Tubular - made in the form of a tube, inside which the flux is often located;

- Sheets are thin sheets of alloy that are suitable for both flat surface soldering and other purposes.

There are different manufacturing techniques that also create different grades of solder solders. Among them are drawn, crushed, cast, pressed, sintered, stamped, amorphous and rolled.

Features of the composition of food solders

Tin is considered a safe alloy, so the bulk of all solders are made on its basis. The composition includes a limited number of elements, so there are few food varieties. Elements for "clean" solders:

- Copper, the content of which is within 10%, which does not increase toxicity.

- Zinc is also often used as a main or additional element.

- Bismuth. It is harmless, its content in a small amount is additive, and such solders are more used for medical purposes.

You can not use antimony in large quantities, cadmium is strictly prohibited, which has a high level of toxicity.

Solder food

The use of "pure" solders is also determined by the thickness of the parts to be joined and the allowable melting temperature for structures and products. For example, solder for food copper can be copper-silver, tin-zinc and tin-copper in terms of chemical properties, but the melting point of silver (670-800 ° C) and the use of a burner are not suitable for thin structures, as well as for metals with a melting point close to the melting point of the solder. That is why tin alloys are most common, which are able to combine various metals and "work" when heated to 250 ° C.

Varieties

Food grade solders are used in several types.

Silver. Modifications with the addition of nickel, copper, bismuth, manganese can be taken here. Their melting point is 670-800 degrees, which requires the use of a burner for heating. It is necessary to connect structures without applying loads or pressure on it.

Chrome-nickel. They provide high strength of the connection, but to increase the strength they can be additionally alloyed with calcium, sodium, nickel.

Copper-phosphorus. Low-melting (up to 450 ° C), needed to work with copper products. They form a strong connection, for interaction with which a burner of the appropriate power is required.

Tin. The most common are "soft" varieties with a melting point of 250 ° C. They may include the following elements: copper, zinc, bismuth. They are used for non-critical parts, as well as connected elements of thin section.For some products, special food solder may be required: for soldering a samovar, for example, pure tin or variants with its content of 90% are used. This is one of the most environmentally friendly brands of low melting solder.

The process of soldering food grade stainless steel and copper

Areas of use

The purpose depends on the metals used for the products themselves, their configuration and thickness. The main food metals are:

stainless steel

The method of its connection depends on the thickness of the sheet: if it is less than 3 mm and in the absence of requirements for the strength of the seam, tin alloys can be used. But silver solder is considered the best for soldering stainless steel food, especially if it includes a small amount of nickel. It has a similar color and corrosion resistance. In the second case, it is necessary to take into account the working conditions with stainless steel, as well as its physico-chemical composition, not each of which can be subjected to such high heat without consequences, which is necessary to melt hard solders. Complex are alloys with a nickel content of more than 25%, which begin to release carbides upon prolonged heating to + 500-700 ° C (corrosion resistance decreases).

For furnace soldering, silver-manganese or chromium-nickel varieties are used. Soldering is carried out using borax.

Copper with brass, stainless steel

Combining metals complicates soldering. The difference in melting temperatures and the properties of metals complicate the choice of solder, flux and, accordingly, technology. The use of a soldering iron is in most cases unprofitable due to the use of hard solders and / or large contact areas. Torch brazing is a good general technique as it will speed up the process by preventing the flux from oxidizing.For non-critical parts, brass solders are quite appropriate, for responsible ones, it is worth stopping at a more expensive and high-quality copper-phosphorus version.

Conclusion

For production scales, solder consumption rates for soldering according to GOST have been developed, without which the rational use of expensive materials is impossible. Performance evaluation was carried out on the basis of tabular data of material properties based on measurement and comparative calculations. Additional elements are also subject to rationing: fluxes, protective, oxidizing media, consumables for soldering.

Solder classification

Solders

- by the chemical composition of the alloy, for example, phosphorus solder;

- by the height of the melting temperature;

It would be logical to consider the types of solders in terms of the physical properties of the resulting solder composition. The main factor is the characteristics of the metal and alloy - the companion.

According to this criterion, the species differ as follows:

Low temperature or soft solder

Only 450 ° C - this is the maximum allowable level for the melting point in this form. This feature affects the strength of the joint, but not in the most critical way: it is slightly lower than that of hard solders.

Within this species there are also subspecies based on the chemical composition:

- lead and lead-free;

- lead-tin alloys;

- special purpose and with easy melting.

Solder for soldering copper.

Tin-copper solders are 97% tin and only 3% copper. This is a very popular mixture, and it is quite inexpensive.

Tin-silver solders are stronger than the previous ones in their properties; these are the most popular mixtures for soldering heating systems. Their share composition is almost the same: 95% - tin and 5% - silver.

The marking of compositions for soldering is simple and clear. Take, for example, the brands POS-18, POS-30 and so on. The numbers indicate the percentage of tin in the mixture. POS-61 mixture is the most suitable option for working with copper and brass, and POS-30 is more versatile: in addition to copper and brass, it is suitable for soldering steel alloys and iron.

High temperature or hard solder

It is clear that here the level of melting temperature is much higher, which sometimes reaches 800°C. This gives more strength to the seams, it is higher than when using "soft" solders.

According to the chemical composition, hard alloys are divided into:

- copper-zinc;

- copper-phosphorus solders;

- pure copper, no impurities.

This is necessary because of the risk of damage to the structure of the part due to the base metal in copper, for example, tubes with thin walls.

Solid grades are used where stronger connections are needed. They include hard soldering alloys of the brands BCuP, Bag, etc. The quality and reliability of the connection depends on the fractional composition of different elements.

Hard solders are divided into:

- refractory

- fusible

Copper-zinc alloys are quite rare, they are perfectly replaced by other mixtures containing bronze, brass or zinc.

Varieties of copper fittings.

Copper-phosphorus solder has the same properties and functions as the expensive version of the pure silver mixture for soldering workpieces made of bronze, brass, etc.

The markings here are slightly different: PMC-36, where the letter "P" stands for "solder", "MC" - the words "copper-zinc", and the number 36 - the percentage of copper in this composition.

According to the criteria of versatility and economic availability, in the first place, of course, are copper-phosphorus solders. They are used in a variety of types of work, although they have a certain disadvantage. This is insufficient bond strength at low temperatures.

The strongest and most durable joints are obtained using special multi-component mixtures. The same strength is given by copper-zinc solders. The most common composition is as follows: 92% copper, 2% silver, 6% phosphorus.

It should be noted that even small deviations from technology standards can lead to serious situations up to accidents.

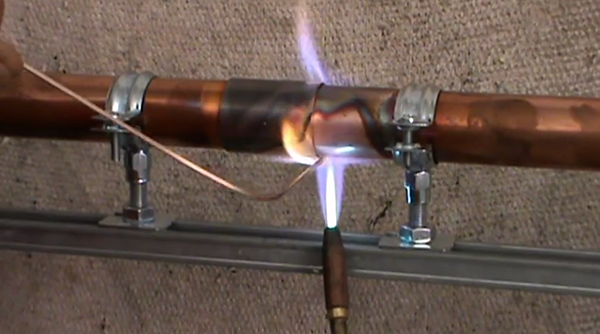

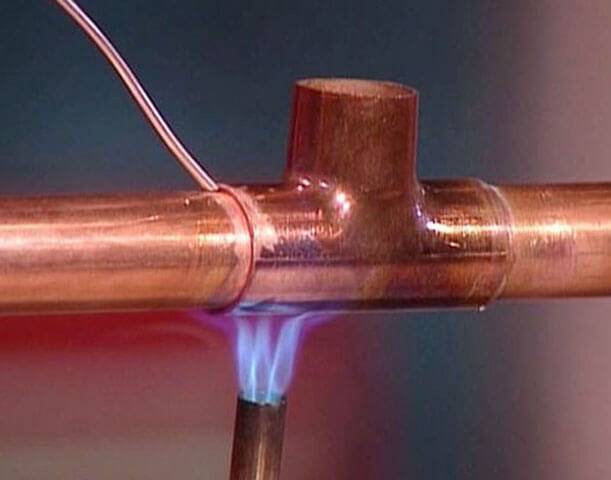

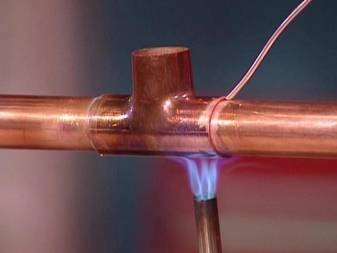

Soldering copper pipes

Due to the fact that copper is slightly susceptible to corrosive processes, it can be easily soldered. Tin, silver, other alloys and metals are best in contact with it during the docking process.

Capillary soldering is used to connect copper products. It is based on the ability of a liquid to move through narrow channels due to adhesion, including against the direction of gravity. Due to the phenomenon of capillarity, the solder is able to evenly fill the gaps, regardless of how the pipes are located.

The soldering process in this case can occur using light, medium - and high-melting solders. Due to the first type, low-temperature soldering is performed, and the other two - high-temperature soldering. The choice of solder is based on the conditions in which the finished pipeline will be operated.

The fusible type, also called soft solder for soldering copper pipes, belongs to tin and alloys with it: tin-copper, tin-silver, tin-copper-silver. Solders are of the same type, the main component of which is lead, but they are toxic and for this reason they cannot be used when laying pipelines for supplying drinking water.

Usage Tips

The correct choice of solder makes it possible to join copper pipes into a single system without much effort and time. The butt joint, as a rule, comes out reliable and even, it is able to provide sealing in pipelines of any type of configuration. A carefully executed seam completely eliminates the occurrence of leaks of substances that circulate through the pipeline system. A well-made solder joint with the right solder can last for years without requiring close attention or regular special maintenance.

When making joints with high-temperature solder, a situation often arises when a flux is required. This component is necessary to prepare the area for soldering to prevent oxidative copper processes that destroy the butt joint. Metaboric acid, sodium tetraborate, boron oxide are used as a flux. Potassium and calcium fluoride components are often added to these components.

For soldering copper, compositions with hydrofluoric and boric acids are often used, potassium hydroxide is added to them. The cheapest flux for soldering copper is ordinary borax. Flux is a powder of a fine fraction or a composition of small pieces. Experienced craftsmen dip the solder wire in flux powder for the convenience of performing work.Sometimes solder is ground together with flux until a homogeneous powder is obtained, but this is rarely done, since the process is labor-intensive.

To start soldering copper pipes, you will need the following tools:

- solder composition for copper;

- flux;

- gas burner or soldering iron;

- cutting device for cutting the pipe blank into separate parts of the desired size;

- beveler and metal brush - they will help remove metal burrs that may occur when cutting the pipe.

Before starting work, you need to cut the pipe and process it so that there are no burrs on it, if this is not done, the butt coupling of two parts will not work out the required strength. The inner side of the pipe is brushed for metal. This treatment increases the throughput of the pipeline system. The next step in the process of making a butt joint is that the working surface of the pipes at the joint is cleaned. Cleaning is carried out with a flux, which allows you to remove the oxide film and thereby reduce the degree of surface tension in the material, as well as increase adhesion.

Some technologies for the soldering process provide for preheating of the parts to be joined. For this purpose, a gas burner with a directed flame exit is used. To perform large volumes of work, you can use a gas cylinder with a propane-butane mixture.

In the process of soldering copper parts, various situations may arise, help to cope with them advice from experienced craftsmen.

In the process of cutting blanks from a pipe, defects often appear in the form of dents on its walls, this circumstance is the reason for the poor quality of the butt joint. When cutting, it is necessary to avoid deformation of the pipe and not to solder over its defects.

For better adhesion, it is necessary to degrease the surfaces of the joined pipe sections, since any, even the most subtle contamination will lead to a decrease in the quality of the butt joint.

In order for the seam to turn out to be even and strong, it is necessary to correctly select the gap within which the soldering will be performed. If the pipe section is in the range of 10-110 mm, then the gap value is chosen in the range from 7 to 50 mm.

Before making a butt joint, it is best to warm up the workpieces properly. If the heating is insufficient, then the butt joint can be destroyed even with small loads.

When applying flux, care must be taken to ensure that it evenly covers the entire work surface.

In places where the flux does not hit, the butt joint will collapse.

When working with a soldering iron or a gas burner, it is important to follow the technology. If the joint area is overheated, then not only the flux, but also the solder will lose their properties.

In the next video, you will find TOP 4 solders for soldering copper pipes of refrigerators.

View overview

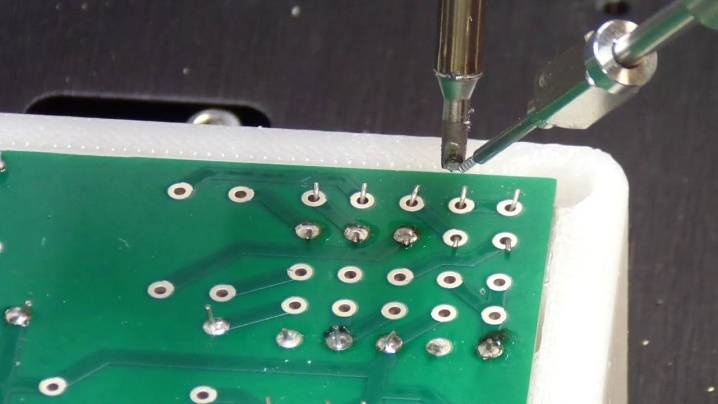

Selective soldering allows you to form reliable joints on the pins of the pin components of radio electronics. This technology is different from the traditional solder wave connection. Soldering is performed at single points of processed boards. Tight mounting, the location of the pins under the case, the small spacing cease to be a serious problem.The main processes and steps, however, are the same as in the classical technique.

The term "curvilinear soldering" refers primarily to the connection of suspended ceilings. With strict adherence to technology, it is possible to achieve an almost invisible seam.

A curved joint, however, is very difficult to create and very expensive to work with.

Low temperature

This type of work became very popular in the second half of the 20th century. Its distribution is associated with the emergence of the radio-electronic industry and especially computer engineering. Only manipulations at a relatively low temperature make it possible to ensure the safety of thin electronic circuit boards and individual microcircuits. But do not assume that soft soldering is possible only in well-equipped industries with sophisticated equipment. There are separate options available to almost any radio amateur.

The role of the solder is not the main one, but only the strengthening of the joints being created. Soft solders can also be used in current-carrying joints. A variety of metals can be soldered with such compositions, but you will have to carefully consider the preparation parameters.

high temperature

This term refers to compounds obtained at a temperature not lower than 450 degrees. The high temperature solder joint is tighter. But it must be taken into account that this results in significant changes in the structure of the material. Many problems arise in the high-temperature soldering of cast iron. In some cases, heating occurs up to 1000 degrees and even higher, but such a need rarely arises.

Thermal additives (fluxes)

Most often, brass solders are used when it is necessary to articulate products made from the same material.

Most often, brass solders are used when it is necessary to articulate products made from the same material.

Since brass (an alloy of zinc and copper in a ratio of two to three) belongs to the category of refractory solders, when working with it it is impossible to do without special additives - fluxes.

A competent choice of active materials when working with brass products not only allows you to get a fairly strong connection, but also greatly simplifies the workflow itself.

Among other things, the solder joints obtained when working with flux have a completely finished and aesthetic appearance and do not need additional editing.

To obtain the desired result, the usual compositions based on alcohol and rosin are not suitable, through which it is not possible to dissolve the film of oxides that is always present on brass products.

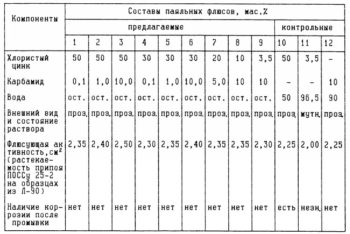

That is why, when soldering brass, more active types of flux additives prepared on the basis of zinc chloride should be used. The list of existing modifications of zinc chloride fluxes and their areas of application can be found in the corresponding table.

The most common names of flux components also include such well-known active additives as borax and its derivatives (potassium fluoroborate, for example).

When working with borax and other fluxes, the content of active components in the soldering zone should not exceed 5 percent, which is quite enough for good fluidity of brass solder and high-quality filling of existing gaps.