- Protection of hot water boilers against corrosion

- Sample projects

- Sample projects

- Water heating devices

- Underfloor heating construction

- Skirting and floor convectors

- Design calculations

- Tips

- Implemented remote control of the boiler room

- Radiator heating

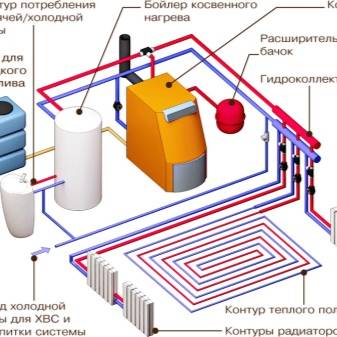

- Scheme of a thermal boiler house for a private house

- General Features

- Operating tips

- Operation and safety

- What is a schematic diagram of a boiler room

- Designing a boiler room in a private house: general provisions

- Warning SMS messages about emergencies and critical system parameters

- Automation of boiler equipment

- Good night program

- Hot water priority system

- Low temperature operating modes

- The principle of operation of the steam boiler

- The main mistakes in designing a heating circuit

- Separate building for the boiler room

- Operating rules

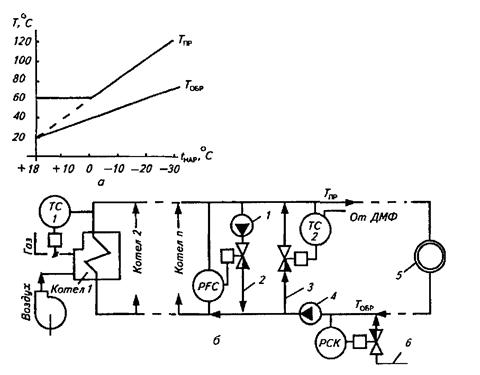

Protection of hot water boilers against corrosion

In conclusion, it should be noted that the hot water circuit of the boiler of the heating system is subject to greater corrosive loads than the home heating system itself. Flue gases can damage the heat exchanger through which heated water circulates.

Therefore, in order to level the effect of catalysts for corrosion processes, the coolant at the inlet to the boiler heat exchanger must be heated to 60-70 degrees Celsius.

True, this precautionary measure is justified only in the case of using steel heat exchangers made of structural steel. Copper or stainless steel heat exchangers do not suffer from corrosion

Published: 03.10.2014

Sample projects

Sample projects

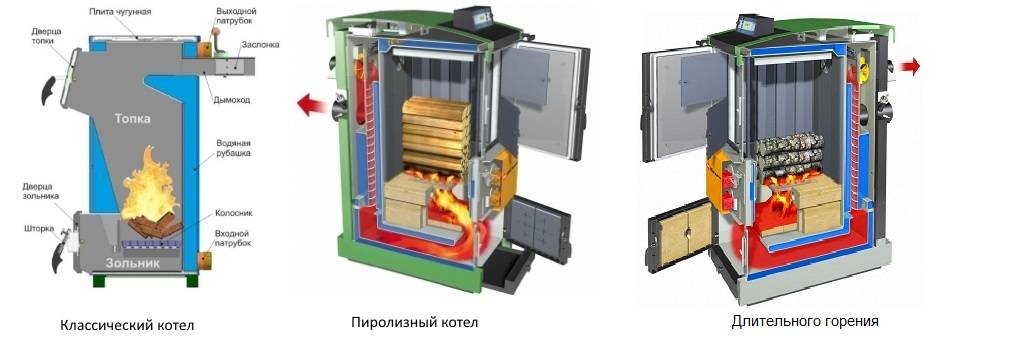

Boilers are very popular in our country and today they successfully heat both small private buildings and huge industrial facilities. These are municipal buildings, and various educational institutions - clinics, hospitals, schools, institutes and universities, kindergartens and schools, factories and plants, cafes and restaurants, shopping malls.

Typical design of a boiler house

In the construction of boiler houses, the moment of design is very important. Today there are standard projects that are allowed for construction.

Any one consists of one or more boilers, burners, a boiler, an automatic control box with sensors, pumps, a gas pipe with valves and other elements and devices that will ensure the normal operation of the boiler room.

Each of these elements is necessary and important, and their quantity and quality depend on the type of boiler house and the manufacturer.

By type of fuel boiler rooms can be liquid fuel and solid fuel. In turn, these two types can be divided into many subspecies depending on the fuel used: diesel, coal, gas-oil, wood, etc.

There are even less powerful, but more functional boiler houses that operate on several types of fuel at the same time, while one of them will still be the main (dominant), and the other auxiliary.

Such boilers are called combined.

Liquid fuel plants

Liquid fuel boiler plants operate at large production facilities (for example, oil refineries), they use oil, fuel oil, diesel fuel, diesel fuel as fuel.

Solid fuel installations

Solid fuel boilers often work where it is difficult or almost impossible to use gas or liquid fuel - in remote areas of the country. As a rule, in private cottages, country houses, cottage villages. Branches and straw, firewood, coal, wood chips and other wood waste are used as fuel.

Gas boiler plants

Gas boilers are the most common type of boilers. They operate more often on natural gas, less often on liquefied hydrocarbons and associated petroleum gas. They are used for heating municipal buildings, apartment buildings, private residences and offices, warehouses and utility rooms, industrial facilities, old and new construction projects.

According to the type of execution, boiler rooms can also be roof-mounted, autonomous, stationary and mobile, block-modular and frame.

The execution of standard projects involves the maximum assembly of structures, and ease of installation and commissioning. This ensures short terms for the execution of all necessary documentation and the commissioning of the boiler house.

Water heating devices

As heating elements of the premises can be:

- traditional radiators installed under window openings and near cold walls, for example, on the north side of the building;

- pipe contours of floor heating, otherwise - warm floors;

- baseboard heaters;

- floor convectors.

Water radiator heating is the most reliable and cheapest option among those listed. It is quite possible to install and connect the batteries yourself, the main thing is to choose the right number of power sections. Disadvantages - weak heating of the lower zone of the room and the location of the devices in plain sight, which is not always consistent with the interior design.

All commercially available radiators are divided into 4 groups according to the material of manufacture:

- Aluminum - sectional and monolithic. In fact, they are cast from silumin - an alloy of aluminum with silicon, they are the most effective in terms of heating rate.

- Bimetallic. A complete analogue of aluminum batteries, only a frame made of steel pipes is provided inside. Scope of application - multi-apartment high-rise buildings with central heating, where the heat carrier is supplied with a pressure of over 10 bar.

- Steel panel. Relatively cheap monolithic type radiators made of stamped metal sheets plus additional fins.

- Pig-iron sectional. Heavy, heat-intensive and expensive devices with an original design. Due to the decent weight, some models are equipped with legs - it is unrealistic to hang such an "accordion" on the wall.

In terms of demand, the leading positions are occupied by steel appliances - they are inexpensive, and in terms of heat transfer, thin metal is not much inferior to silumin. Following are aluminum, bimetallic and cast iron heaters. Choose which ones you like best.

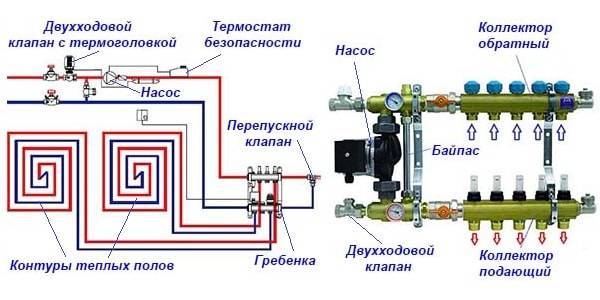

Underfloor heating construction

The floor heating system consists of the following elements:

- heating circuits made of metal-plastic or polyethylene pipes, filled with cement screed or laid between logs (in a wooden house);

- distribution manifold with flow meters and thermostatic valves to control the water flow in each loop;

- mixing unit - a circulation pump plus a valve (two- or three-way), maintaining the temperature of the coolant in the range of 35 ... 55 ° C.

The mixing unit and the collector are connected to the boiler by two lines - supply and return. Water heated to 60 ... 80 degrees is mixed in portions with a valve into the circuits as the circulating coolant cools down.

Heated floors - the most comfortable and an economical method of heating, although the installation costs are 2-3 times higher than the installation of a radiator network. The optimal heating option is shown in the photo - floor water circuits + batteries regulated by thermal heads.

Warm floors at the installation stage - laying pipes on top of the insulation, fastening the damper strip for subsequent pouring with cement-sand mortar

Skirting and floor convectors

Both types of heaters are similar in the design of the water heat exchanger - a copper coil with thin plates - fins. In the floor version, the heating part is closed with a decorative casing that looks like a plinth; gaps are left at the top and bottom for the passage of air.

The heat exchanger of the floor convector is installed in a housing located below the level of the finished floor. Some models are equipped with low-noise fans that increase the performance of the heater. The coolant is supplied through pipes laid in a hidden way under the screed.

The described devices successfully fit into the design of the room, and underfloor convectors are indispensable near transparent outer walls made entirely of glass. But ordinary homeowners are in no hurry to purchase these appliances, because:

- copper-aluminum radiators of convectors - not a cheap pleasure;

- for full heating of a cottage located in the middle lane, you will have to install heaters around the perimeter of all rooms;

- floor heat exchangers without fans are inefficient;

- the same products with fans emit a quiet monotonous hum.

Baseboard heating device (pictured left) and underfloor convector (right)

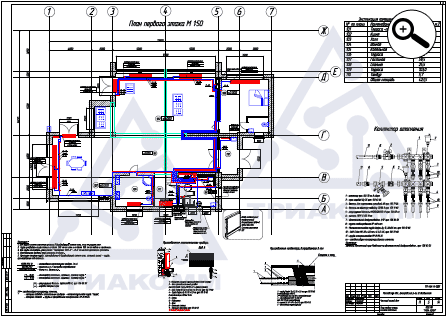

Design calculations

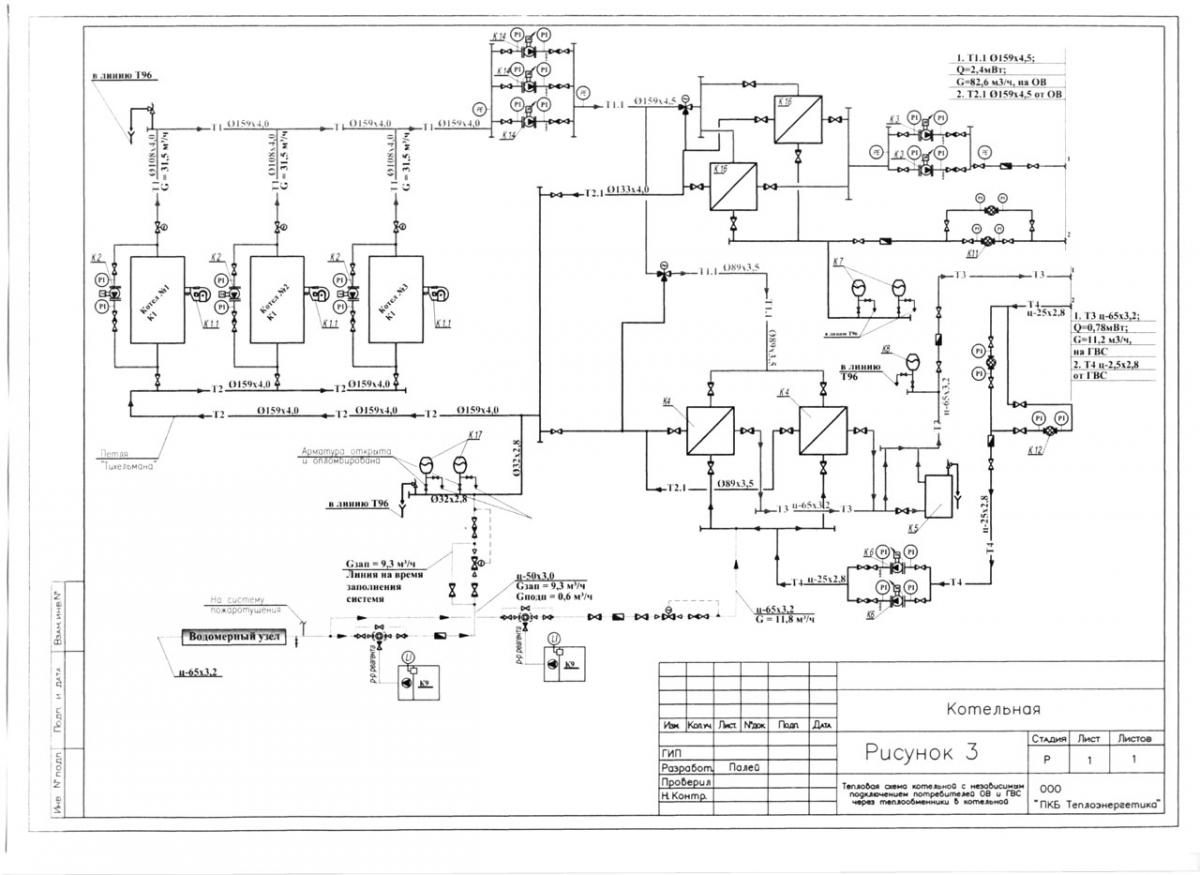

The first section of the explanatory note of the project presents the calculations of the main indicators for the heat supply system:

- The maximum heat consumption for heating the main house is 86,103 W.

- The maximum heat consumption for ventilation is 12,915 W.

- The maximum heat consumption for heating a small house is 6,415 W.

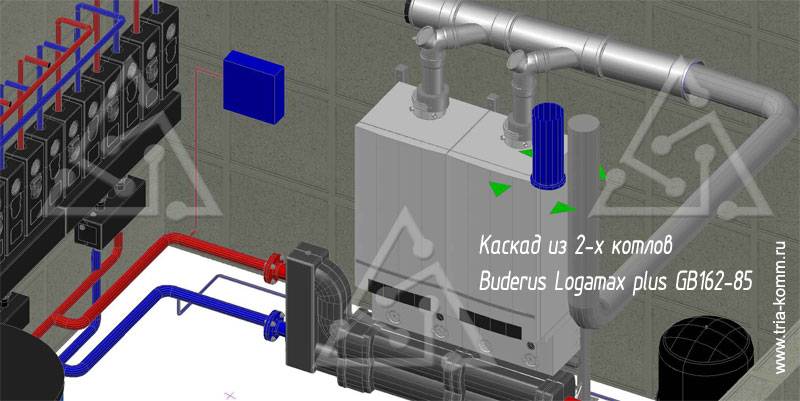

- The maximum second and hourly water consumption, on the basis of which the Buderus SU-500 series boiler was selected.

- Estimated capacity of the boiler house, taking into account 15% of the reserve, is 162 kW.

- Gas consumption for boilers and gas stoves.

Based on design calculations, two condensing wall-mounted gas boilers Buderus Logamax GB 162-85, connected in cascade, were provided as the main source of heat supply.

2 gas condensing boilers Buderus Logamax GB 162-85 provide a thermal output of the boiler room of 170 kW

2 gas condensing boilers Buderus Logamax GB 162-85 provide a thermal output of the boiler room of 170 kW

The calculation of indicators for the heat supply system in this boiler house project takes 4 sheets.

Tips

Since every year developers present new requirements, it is unlikely to bypass the issue of designing a heating system. Many people prefer to leave such responsible work to specialists. In addition, if all the work is done by one organization, then the design, selection of materials, and installation work will please the developer with their quality. But you can do everything with your own hands.

First you need to develop several projects of the heating system. Then, having considered them, you need to make a choice. After that, it is necessary to develop an estimate and make a calculation. With the help of the heating project, installation schemes are made. In parallel, you need to make a list of the necessary components, as well as all equipment.

The design of the heating system should include the following documents:

- all initial data made in the form of a table;

- scheme sketches;

- agreement;

- specifications;

- equipment specifics;

- necessary materials;

- developed recommendations for piping heating;

- connection to electrical networks.

Having studied all the rules for designing a heating system, you can confidently proceed with installation work, without fear for the consequences. As can be seen from the above, you can carry out this procedure with your own hands. If you make all the calculations correctly and purchase the necessary devices, you will be able to successfully design a heating system and use it in the cold season.

You will learn more about designing a heating system in the next video.

Implemented remote control of the boiler room

Vitocom 100 Type LAN1 telecommunications interface from Viessmann is provided for remote control of the boiler room automation.With this module, you can implement the following functions:

- Setting of operating modes, setpoints and time programs for up to 3 heating circuits per heating system. Polling information about the installation.

- Display messages.

- Forwarding messages by e-mail to a personal computer, smartphone (requires the function of the e-mail client program).

- Forwarding messages via SMS to a mobile phone, smartphone or fax machine (via paid internet service Vitodata 100 Fault Management).

- Access to all heating circuits of the boiler plant.

- Setting of operating modes, setpoints, time programs and heating curves.

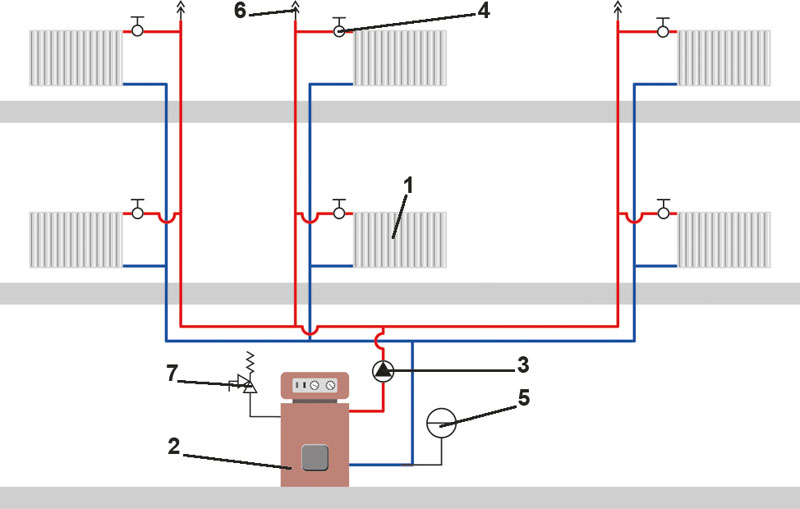

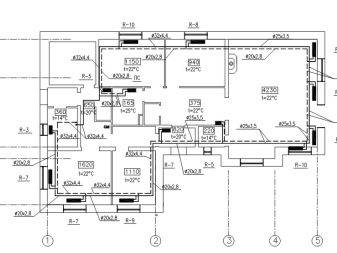

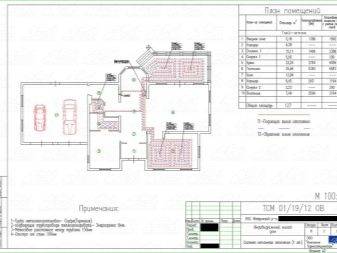

Radiator heating

The heating project reveals the main characteristics and features of creating a radiator heating system. In particular, the project indicates the type of wiring of the heating system, the type of heating devices and the method of their connection to the heating mains, the installation location of underfloor heating ducts, temperature control devices for rooms, and much more.

In this typical heating project, the radiator heating system has the following characteristics and features:

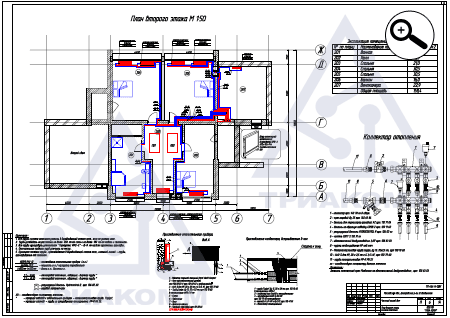

In addition to the above general data, the heating project includes detailed drawings of the radiator heating system on the plans of each floor. In our case, we provide drawings of the heating system on the plans of the first and second floors.

The project of the heating system on the plan of the first floor of the house (the illustration can be enlarged)

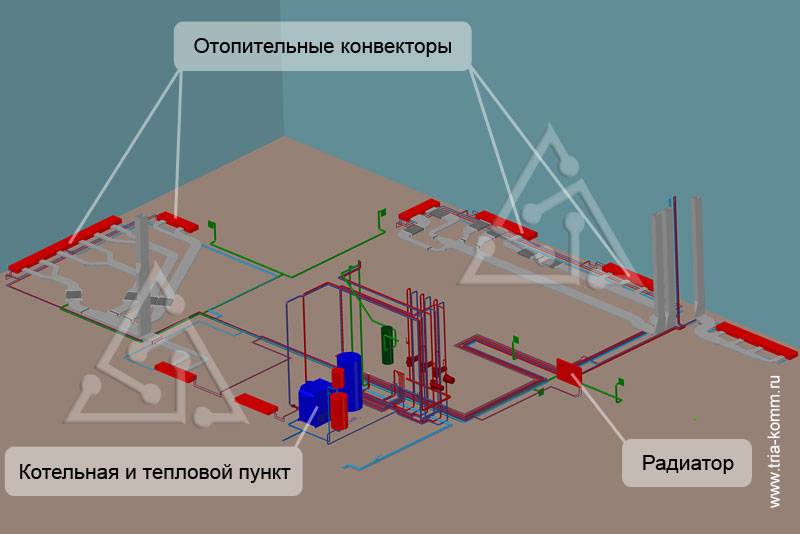

External view of the heating system on the 1st floor

External view of the heating system on the 1st floor

The project of the heating system on the plan of the second floor of the house (the illustration can be enlarged)

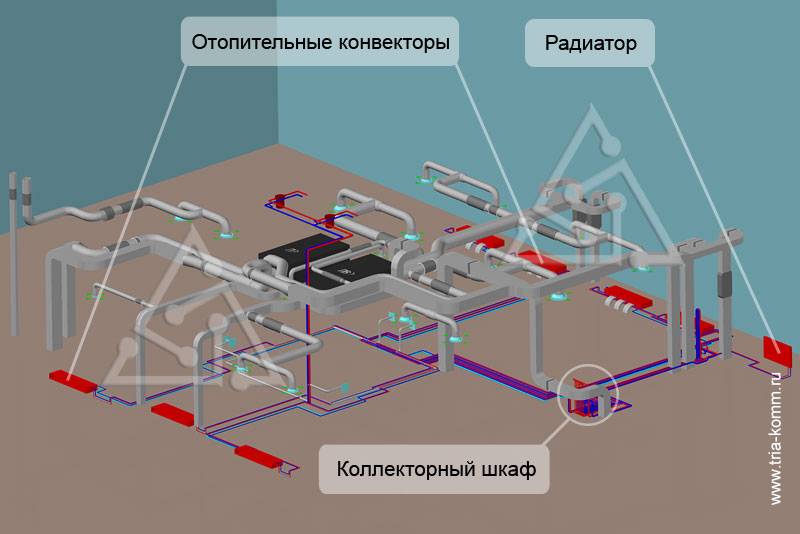

External view of the heating system on the 2nd floor

External view of the heating system on the 2nd floor

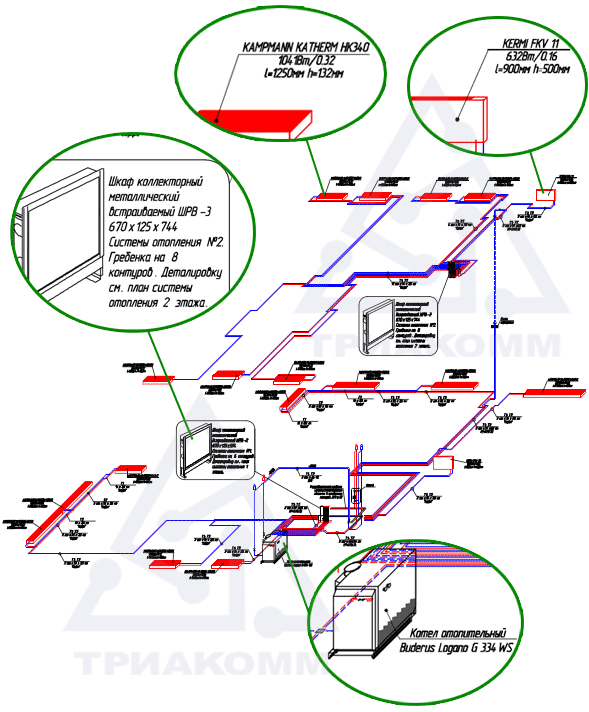

In addition to floor plans, the project contains a diagram of the heating system, which most clearly represents the entire heating system as a whole.

The diagram of the heating system more clearly shows the elements of the project

The diagram of the heating system more clearly shows the elements of the project

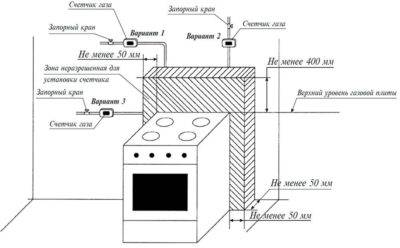

Scheme of a thermal boiler house for a private house

There are two options: floor and wall. The latter are most often installed in the kitchen, as well as in the corridor, because they do not take up much space, although they include many components. The main disadvantage is weak power, but for a small volume it will be enough. So, in order to assemble a boiler room on your own, you can be guided by the following steps:

- First you need to lay the chimney, sewerage, electrical wiring and the main system.

- Next, finish with non-combustible materials, respectively, taking into account all the requirements of SNiP.

- Install and conduct a boiler, boiler in the place of your choice and do not forget about the expansion tank.

General Features

In the room where the unit is located, it is necessary to have a window or door that opens outwards.

Despite the importance of the area, it is permissible to build space with boilers in an amount of more than 2 units.

Compliance with fire safety requirements is mandatory. This also applies to the use of various materials. For example, when finishing, you need to use plaster or tiles - they will be non-combustible elements.

In addition, the similarity of ventilation, chimney and equipment must certainly be

Because it is very important that the movement of air masses is at least three times a day.

Operating tips

In the process of using the device, it is necessary to properly mount it and interact with it, observing special measures.Otherwise, there is a high risk of serious problems, namely a fire or even an explosion. The points listed below are just what is needed to ensure safety during operation.

- As already mentioned in the article, the presence of a window is mandatory - natural ventilation airflow inside the room.

- For maintenance of a special service, the distance at which the boiler and furniture should be located (more than 0.7 meters wide) should be taken into account.

If you use a floor device for work, then you should attach a substrate made of strong and also non-combustible material to it.

Operation and safety

Since the gas system is not safe, in case of any deviations from the norm, it is necessary to turn off the equipment and contact the company involved in its repair and maintenance. The fuel supply must be stopped immediately in several cases. These include:

- the smell of gas;

- overheating of the coolant;

- power outage;

- triggering an alarm;

- violation of the integrity of the pipeline section;

- a flame that went out without shutting down and for any other reason;

- poor ventilation, insufficient draft in the chimney;

- change in sensor readings, which clearly indicate a malfunction in the system;

- detection of incorrect operation of the system or control devices, one or more.

To prevent emergency situations, it is recommended to check the electrical cable and its insulation daily. Any defect requires its prompt replacement. The presence of water supply or water containers in the gas boiler room is a prerequisite

Additional precautions include:

- purchase of fire extinguishers;

- fire alarm installation;

- stock of sand, other safe bulk material.

For large boiler houses, it is necessary to prepare evacuation schemes, however, as a rule, this requirement does not apply to "gas rooms" serving private houses.

The room for this type of heating equipment, first of all, is designed to ensure the safety of people, so talking about the principle of operation of a gas boiler is not entirely correct. It is the equipment that operates in it, and the room only creates optimal conditions for the devices. And for a person protected by its walls from far from the safest type of fuel.

At the end of the topic - a popular video, short, capacious and, judging by the reviews, honest:

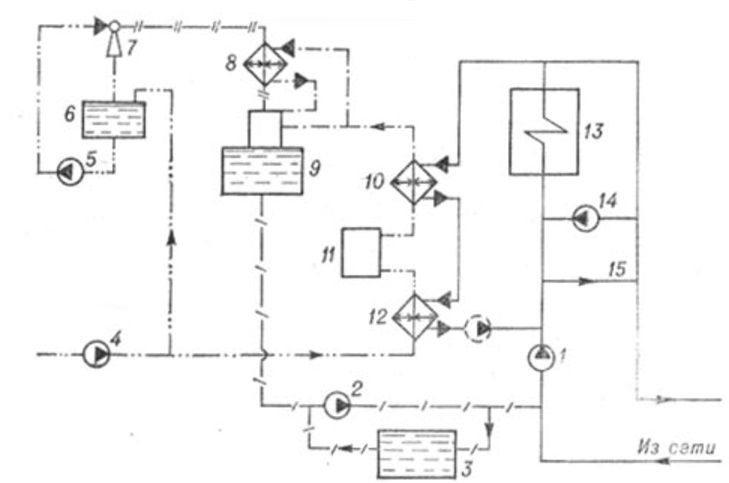

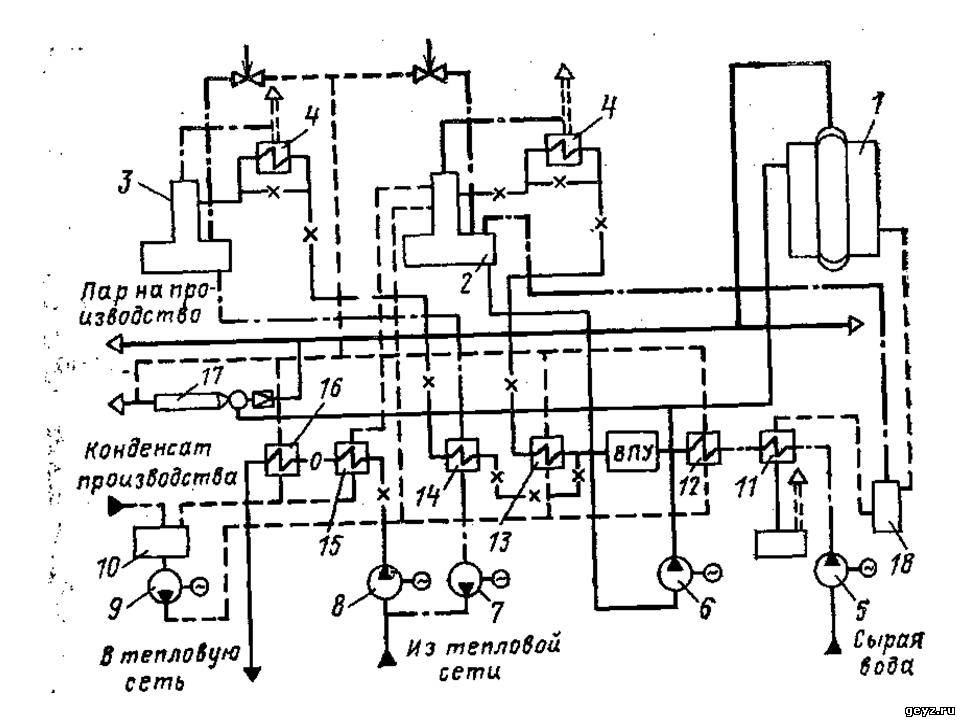

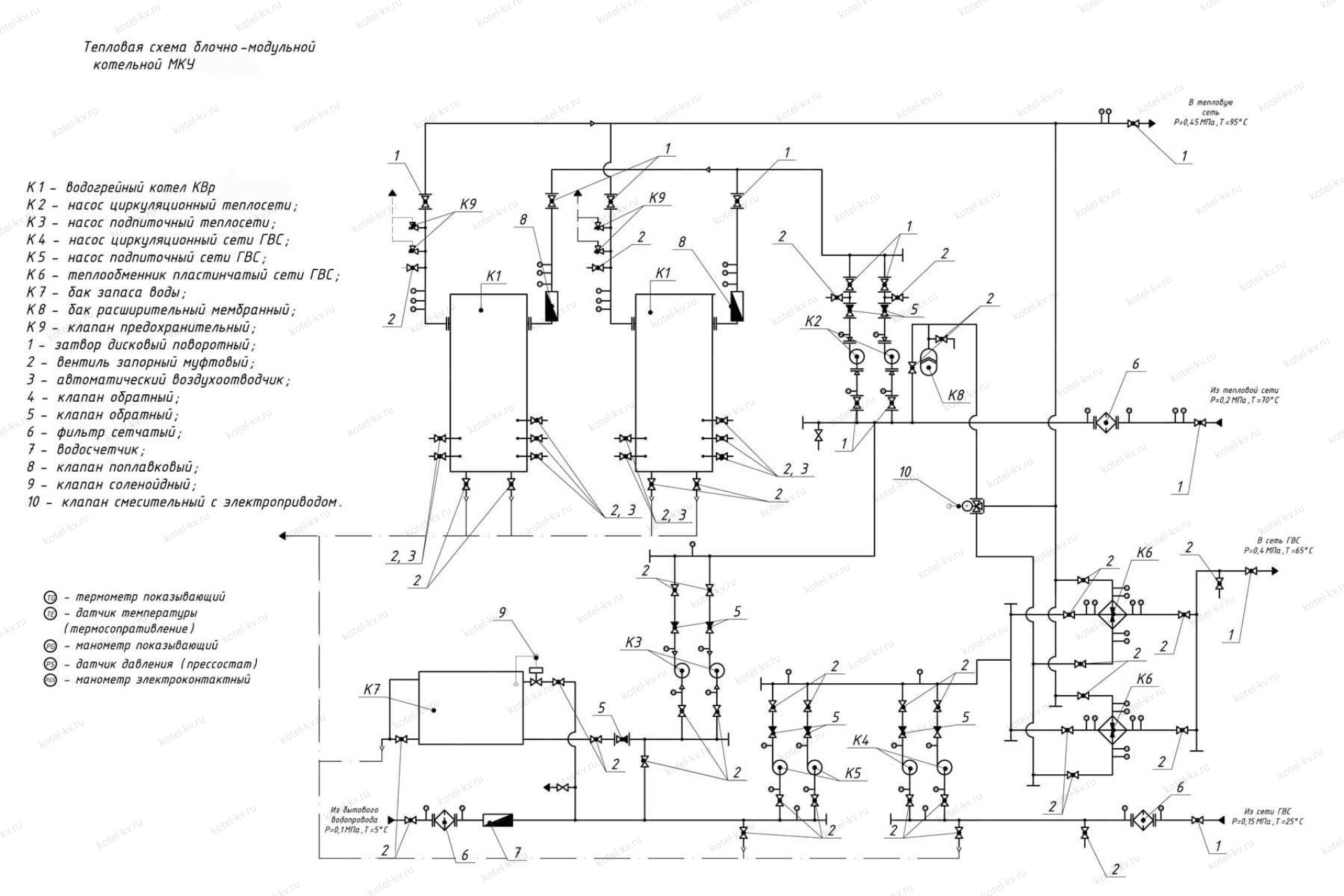

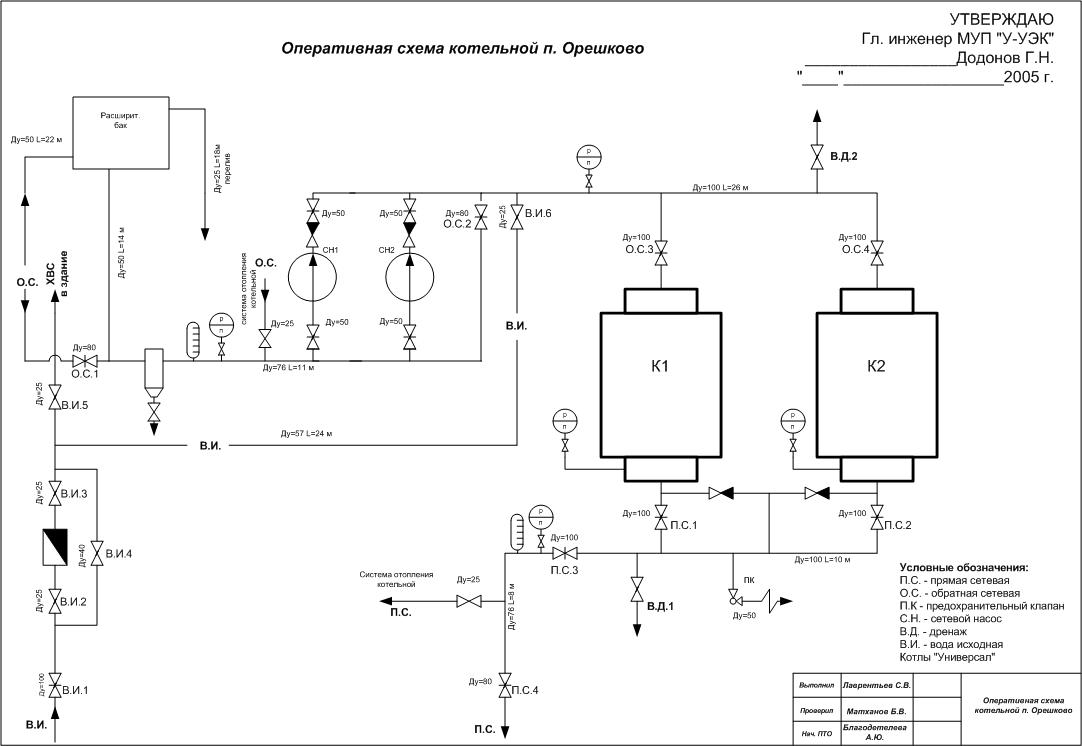

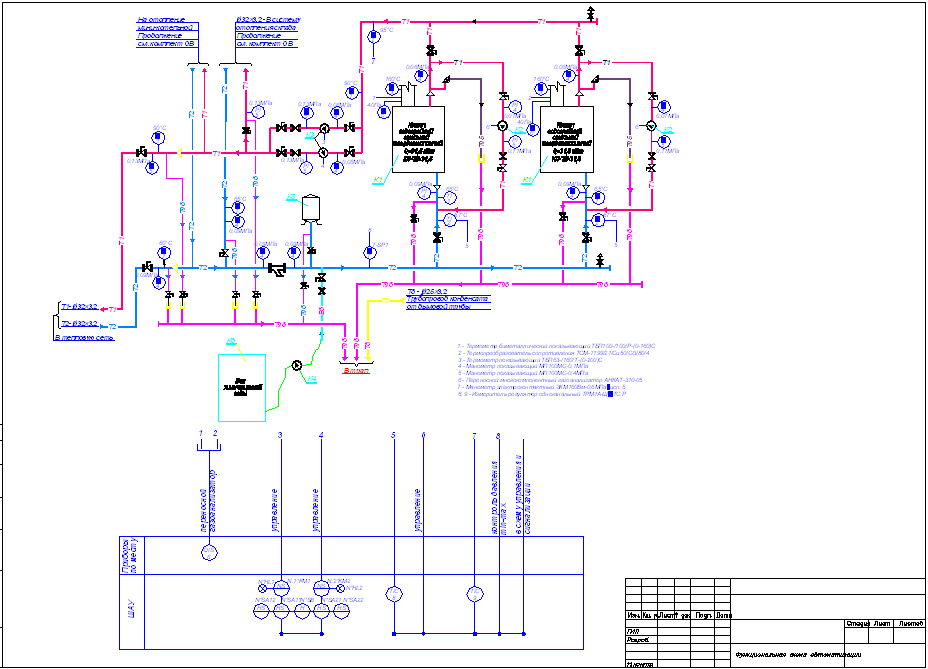

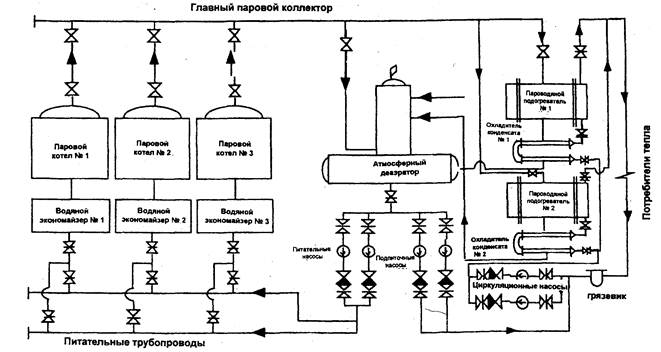

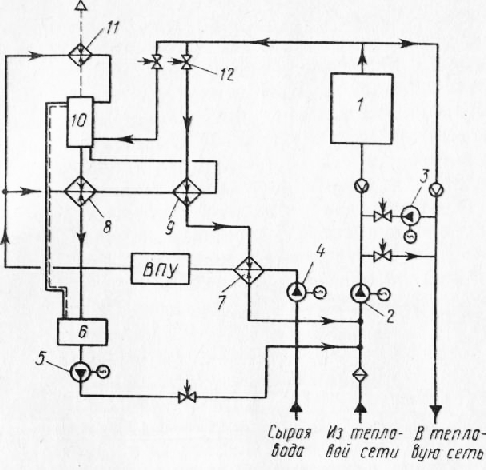

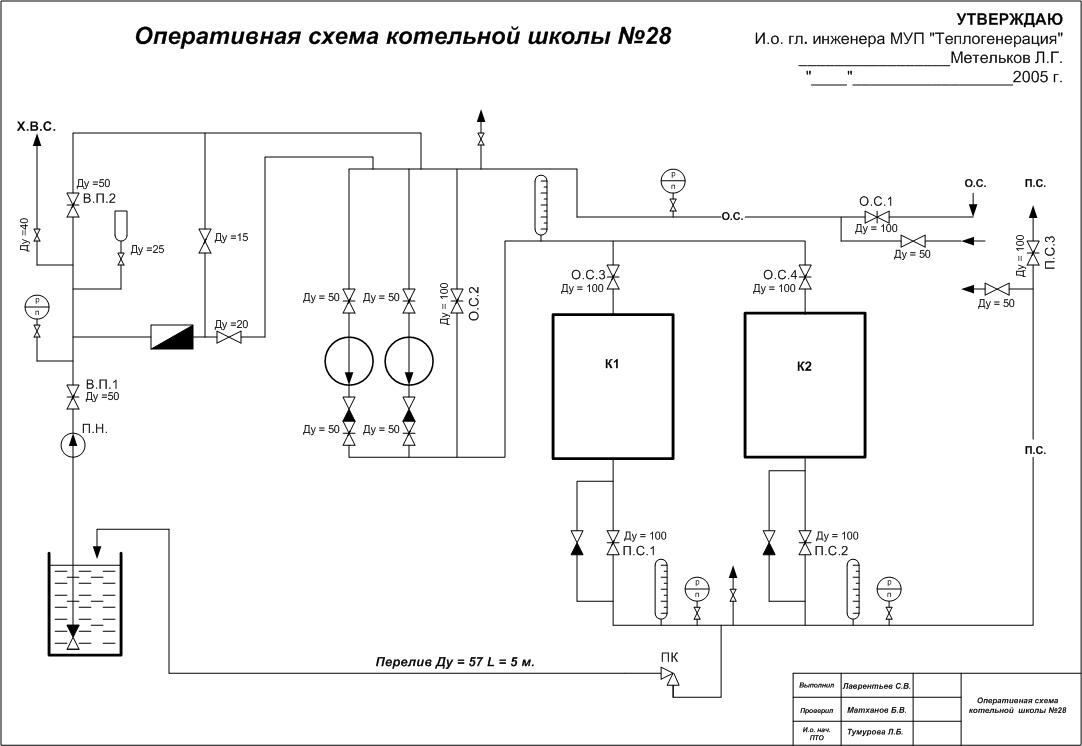

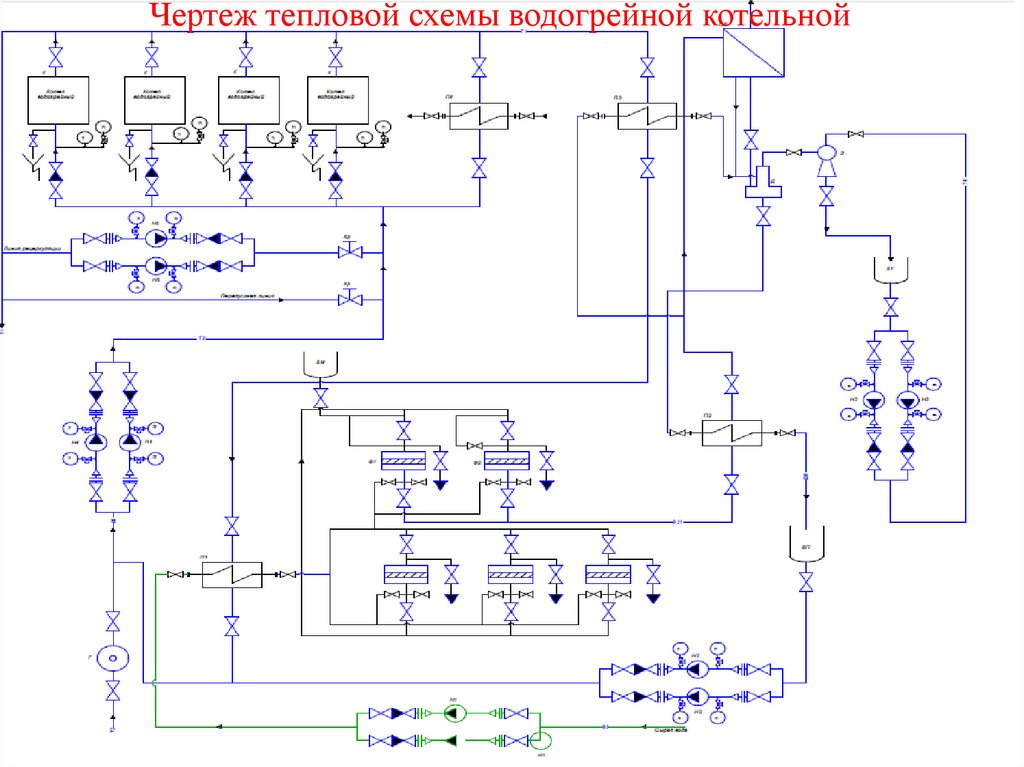

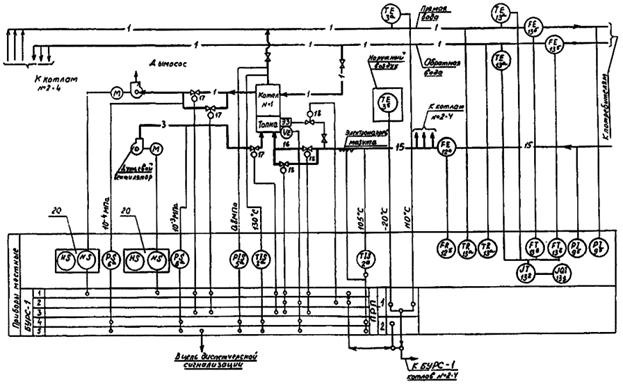

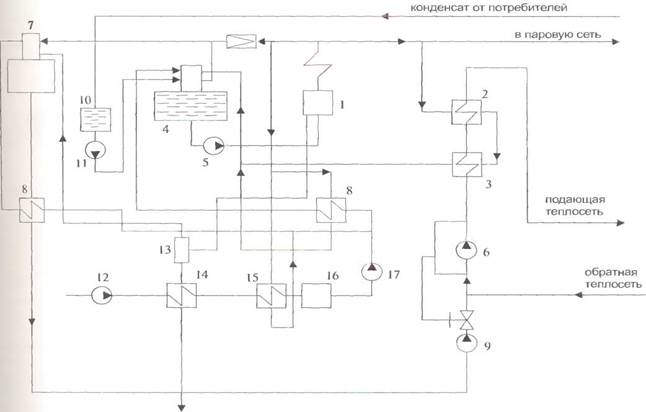

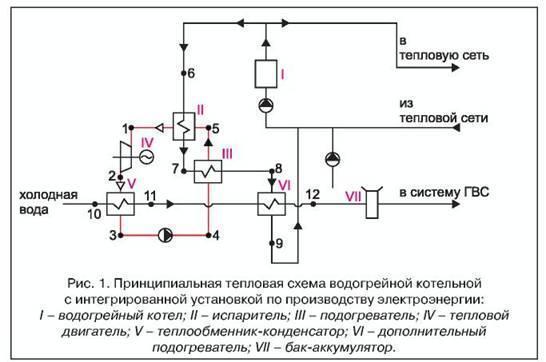

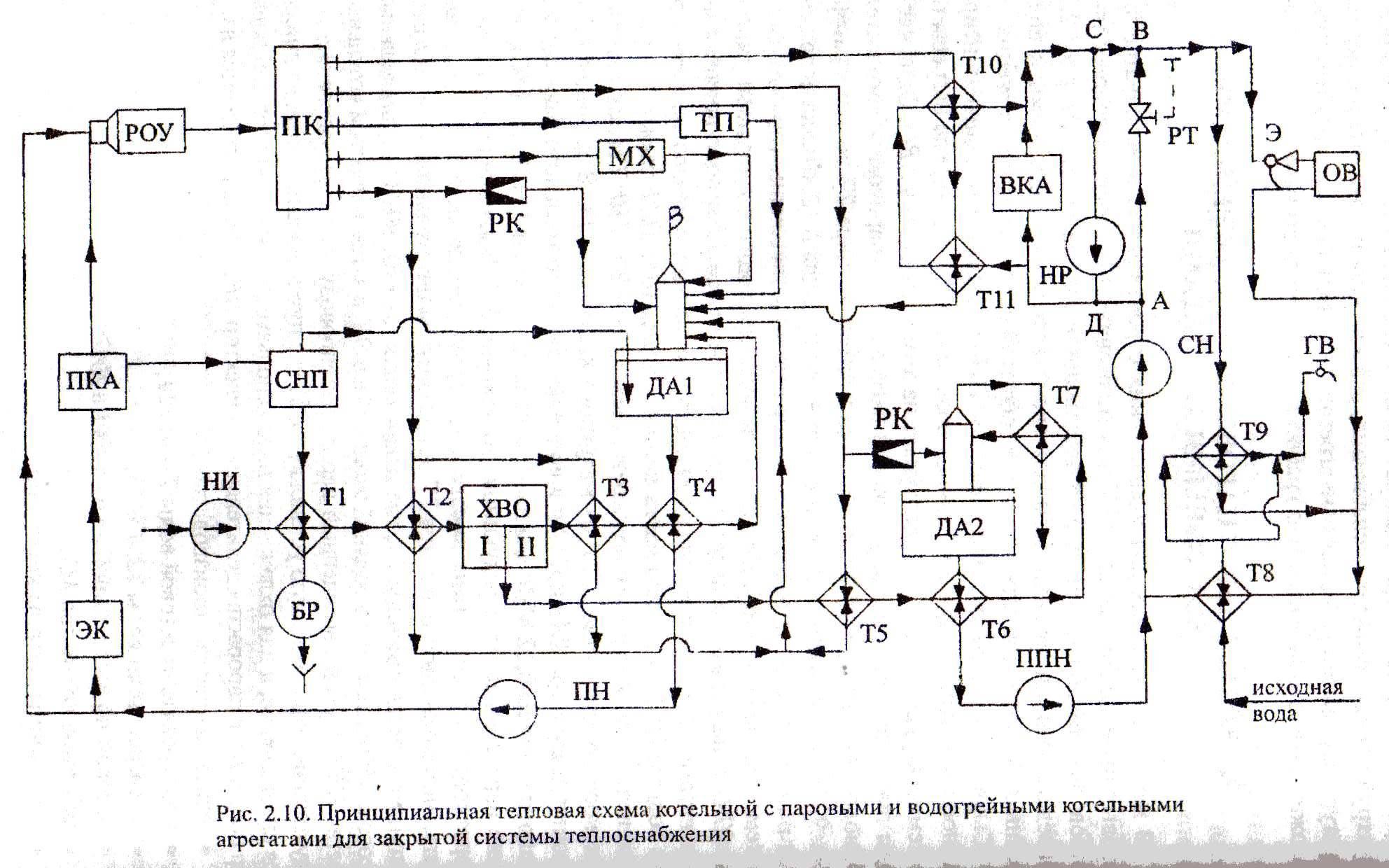

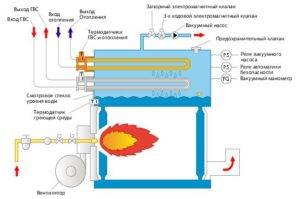

What is a schematic diagram of a boiler room

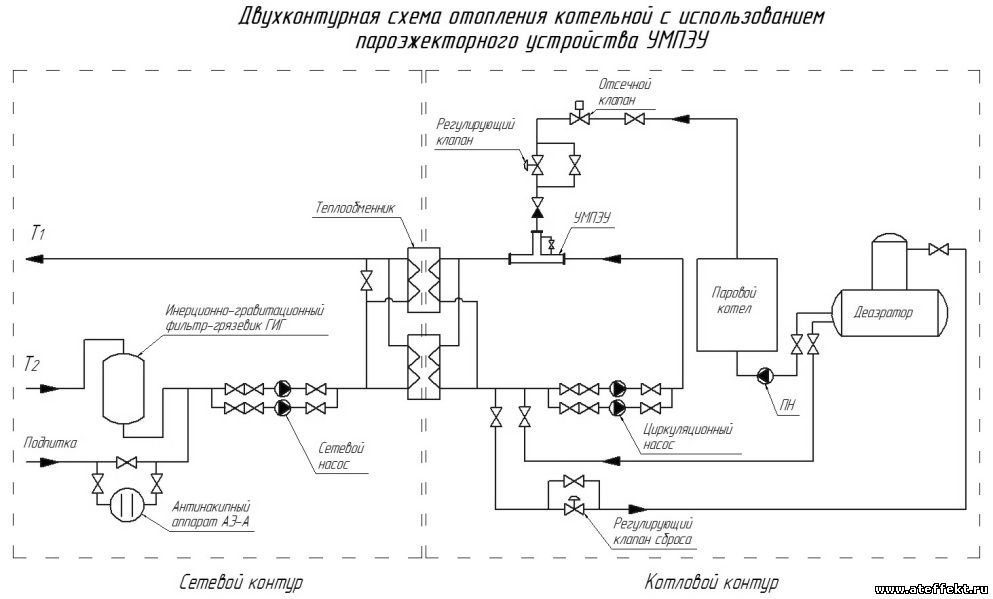

The graphic drawing should reflect all mechanisms, devices, devices, as well as pipes connecting them. The standard schemes of the boiler house include both boilers and pumps (circulation, make-up, recirculation, network), and accumulator and condensate tanks. It also provides for fuel supply devices, its combustion, as well as devices for deaeration of water, heat exchangers, the same fans, heat shields, control panels.

Those heat networks that operate on water are divided into two groups:

- Open (liquid is taken in local settings);

- Closed (water returns to the boiler, giving off heat).

The most popular example of a circuit diagram is an example of an open type hot water boiler. The principle is that the circulation pump is installed on the return line, it is responsible for delivering water to the boiler, and then throughout the system. The supply and return lines will be connected by two types of jumpers - bypass and recirculation.

The technological scheme can be taken from any reliable sources, but it would be good to discuss it with specialists. He will advise you, tell you if it is suitable for your situation, explain the whole system of action

In any case, this is the most important design for a private house, so attention should be maximum

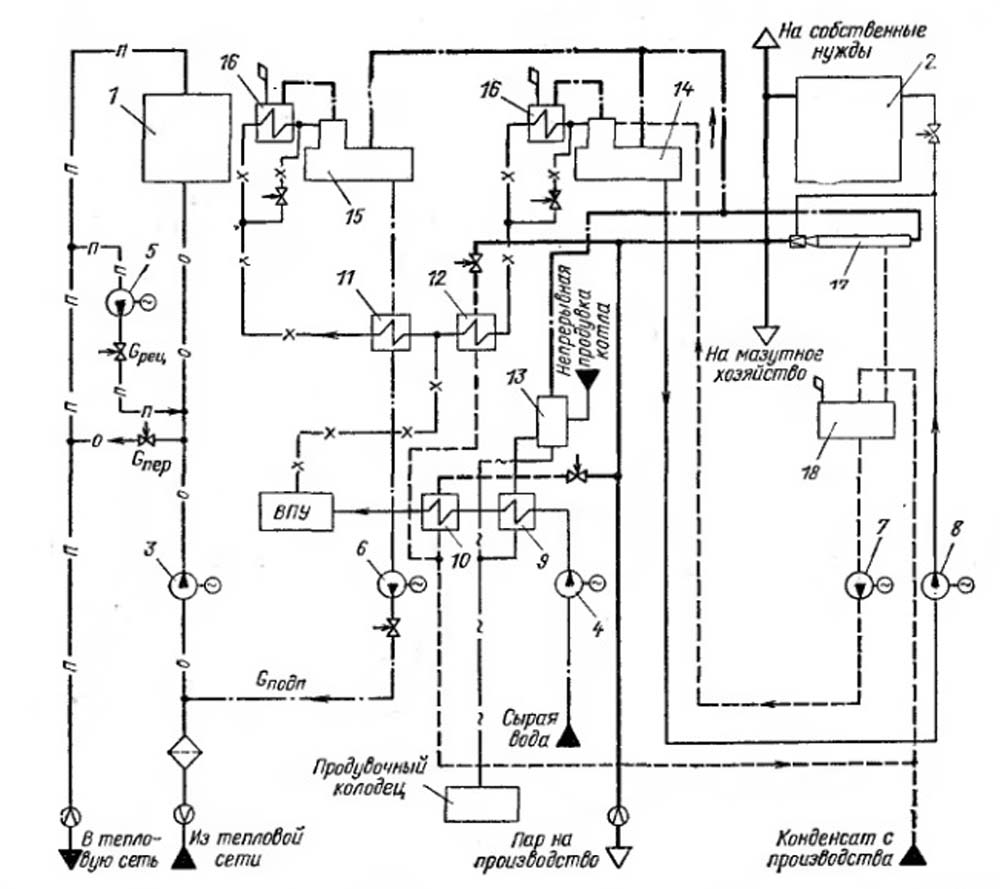

Designing a boiler room in a private house: general provisions

The heat supply system operates around the clock for almost 7-8 months, "burning" tens of thousands of rubles in the furnaces of boilers. Therefore, all homeowners strive to optimize the performance of the system. Moreover, to strengthen the reliability of the design and reduce the energy consumption of heating devices, an accurate calculation of the thermal schemes of hot water boilers, performed at the design stage, will help.

To do this, you just need to calculate the options for placing the boiler, expansion tank, additional heater, along the way, having decided on the features of the wiring and the nuances of circulation.

That is, you need to draw up a boiler room project, consisting of the following documents:

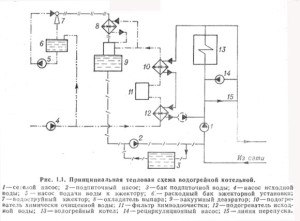

Principal thermal diagram of a hot water boiler house

- Schemes of placement of all components of the system in the house itself. This document will be useful at the pipeline installation stage.

- Layouts of heaters, pumps, expansion tanks and other equipment. This document during the assembly of the water heating and heating branches of a hot water boiler house.

- Specifications for all system components. This document is used in the process of purchasing materials and equipment.

Moreover, all three documents can fit on one schematic diagram of a boiler house, drawn up in a simplified form (when the icons are replaced by drawings of equipment and shut-off and control valves).And further in the text we will consider several varieties of such schemes.

Warning SMS messages about emergencies and critical system parameters

Based on signals from relays and GSM sensors, the controller generates and sends SMS messages (if a mobile operator card is available), warning messages about critical parameters of systems that ensure the operation of the boiler and boiler room.

SMS messages in emergency situations are generated automatically. It is also possible to request, from telephone numbers connected to the controller, the state of the boiler room and temperature parameters. For each situation and for each event during the operation of the boiler equipment, a specific SMS message is provided, which explains what is happening in the boiler room operation support system.

The GSM antenna of the module should be placed in the zone of the best GSM signal reception and in such a way that the GSM network signal is not weakened by metal. The distance to any metal surface must be at least 5 cm.

If there is a GSM module of the boiler room, it is necessary to regularly check the operability of the module, i.e. it is necessary to send SMS messages to its number in

format: "Huh?". The frequency of requests for the current state of the GSM module and equipment connected to it is determined by the manager operating this equipment at the facility (there are no restrictions on the number of requests).

Before installing the main equipment, it is necessary to coordinate with the commissioning organization the route for laying cable channels in the boiler room under the automation lines and provide the necessary indents from walls, pipelines and collectors at their places.

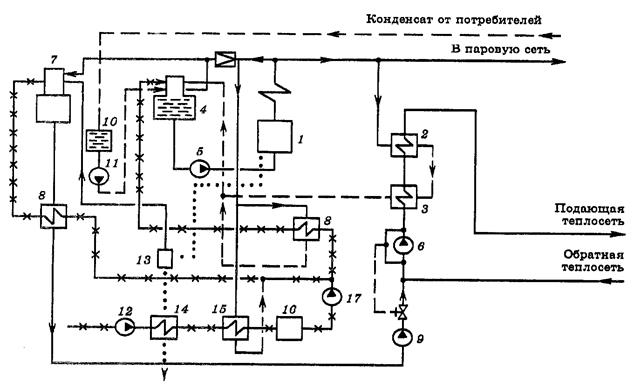

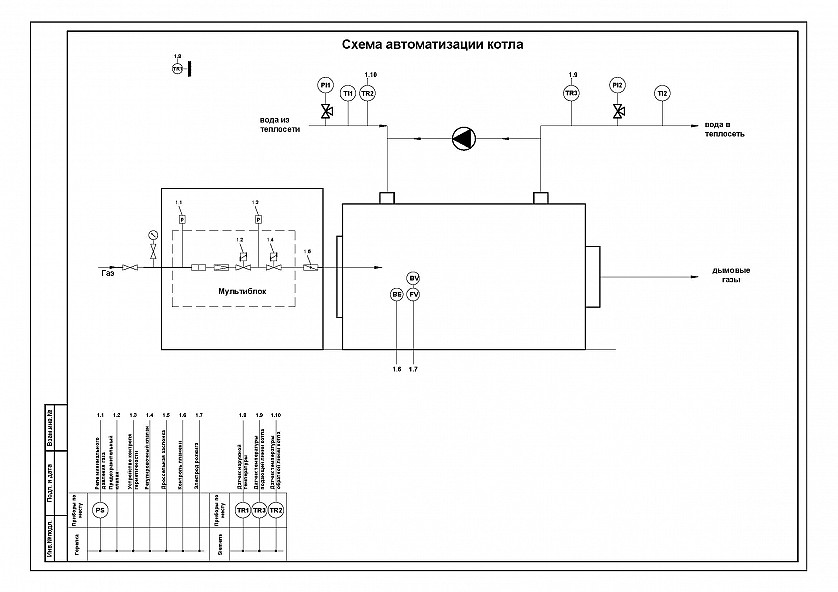

Automation of boiler equipment

It would be foolish not to take advantage of the opportunities that facilitate the operation of heating systems. Automation allows you to use a set of programs that control heat flows depending on the daily routine, weather conditions, and also help to additionally heat individual rooms, for example, a pool or a nursery.

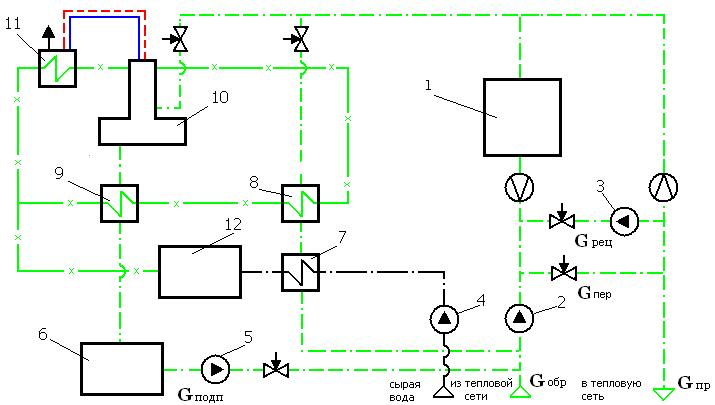

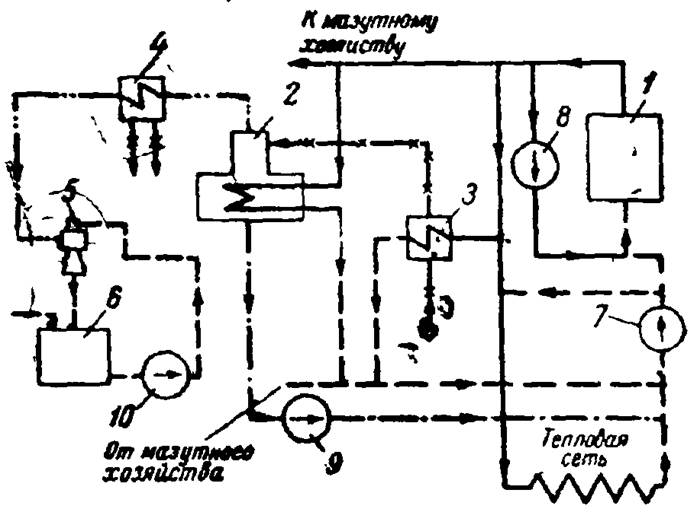

An example of an automated circuit diagram: the automatic operation of the boiler house controls the operation of the water recirculation circuits, ventilation, water heating, heat exchanger, 2 underfloor heating circuits, 4 building heating circuits

There is a list of user functions that adapt the operation of the equipment depending on the lifestyle of the inhabitants of the house. For example, in addition to the standard program for providing hot water, there is a set of individual solutions that are more convenient and even economical for residents. For this reason, a boiler room automation scheme can be developed with the choice of one of the popular modes.

Good night program

It has been proven that the optimal night air temperature in the room should be several degrees lower than the daytime temperature, that is, the ideal option is to lower the temperature in the bedroom by about 4 ° C during sleep. At the same time, a person experiences discomfort when waking up in an unusually cool room, therefore, early in the morning the temperature regime must be restored. Inconveniences are easily solved with automatic switching heating systems for night mode and back. Night time controllers are operated by DE DIETRICH and BUDERUS.

Hot water priority system

Automatic regulation of hot water flows is also one of the functions of the general automation of equipment. It is divided into three types:

- priority, in which during the use of hot water the heating system is completely turned off;

- mixed, when the boiler capacities are delimited to service water heating and home heating;

non-priority, in which both systems act together, but in the first place is the heating of the building.

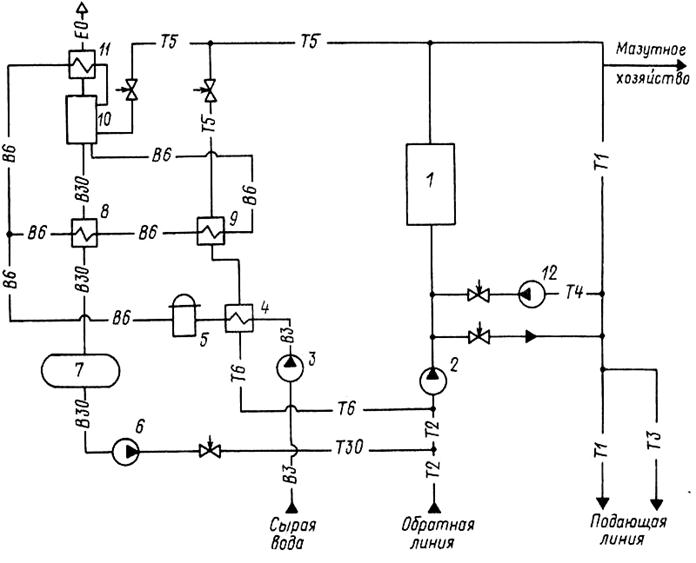

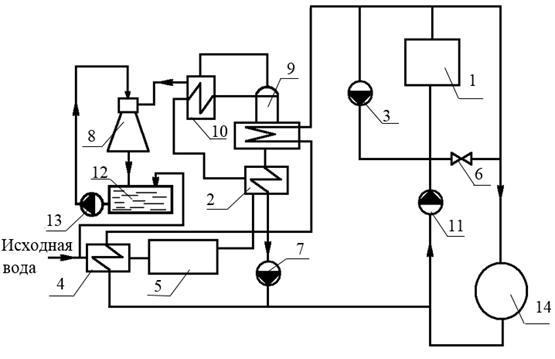

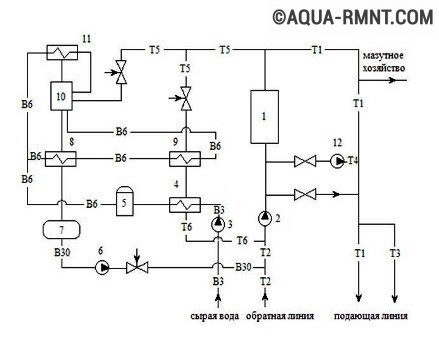

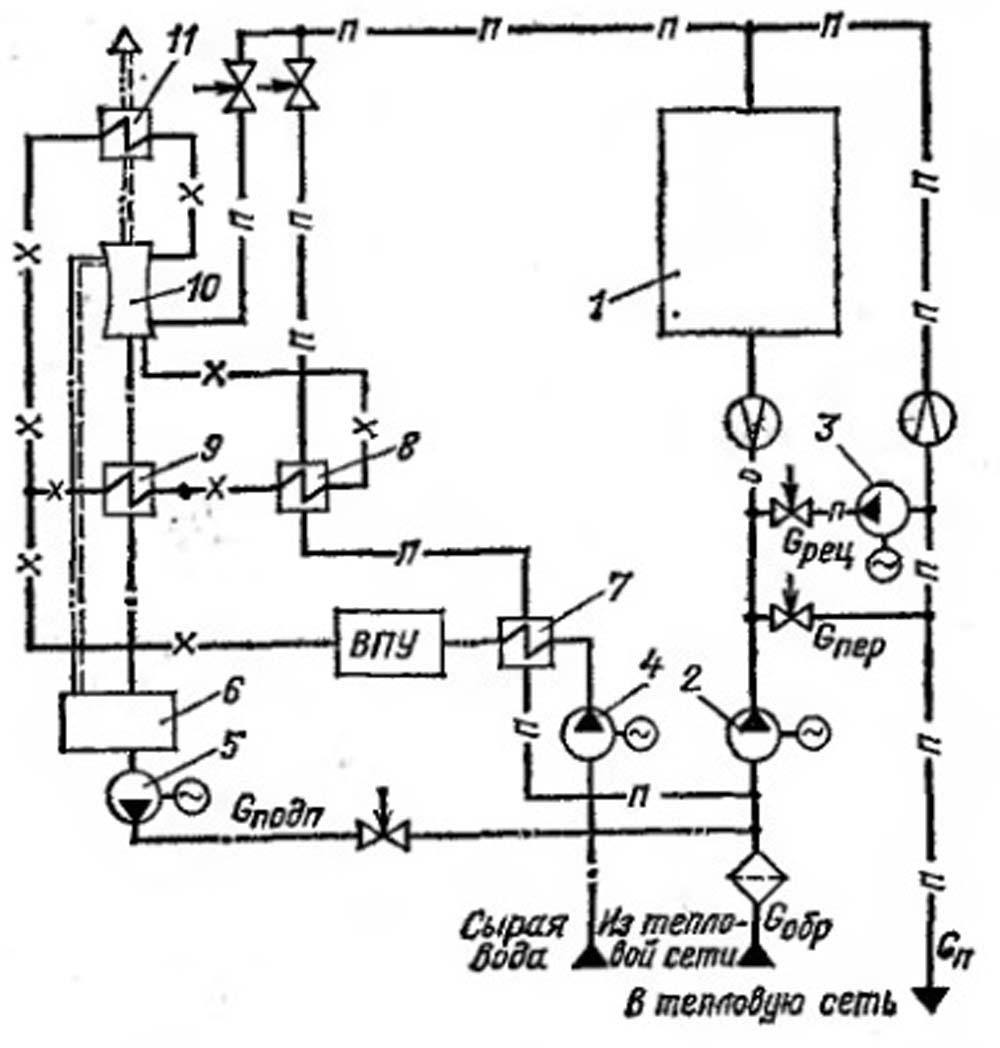

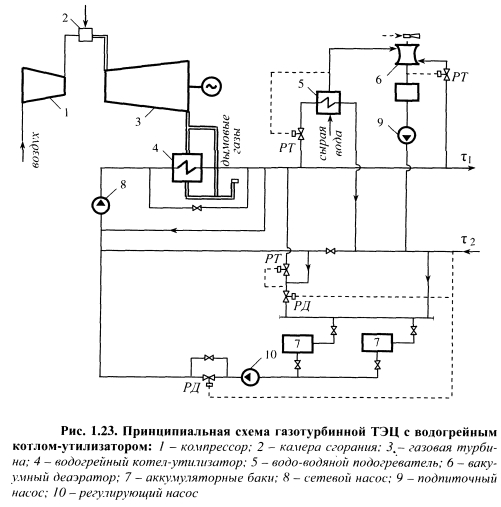

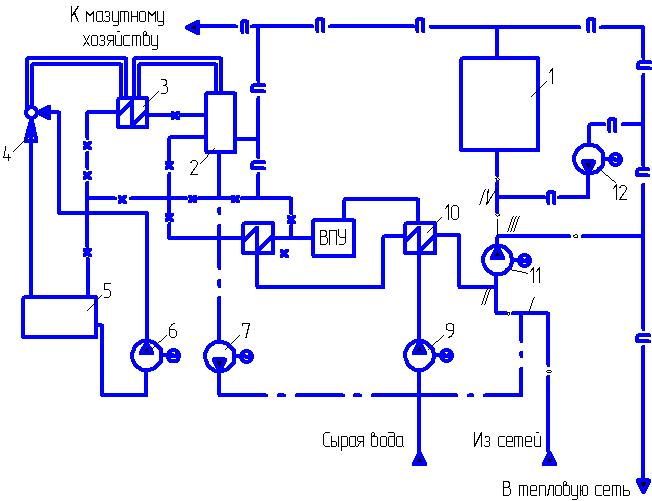

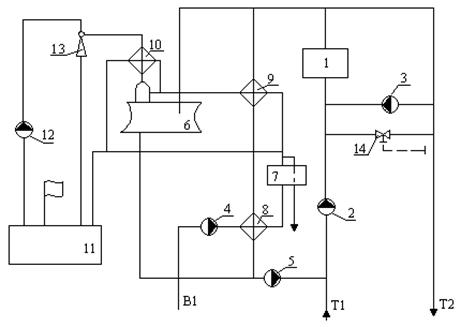

Automated scheme: 1 - hot water boiler; 2 – network pump; 3 – source water pump; 4 - heater; 5 – HVO block; 6 – make-up pump; 7 - deaeration block; 8 - cooler; 9 - heater; 10 - deaerator; 11 – condensate cooler; 12 - recirculation pump

Low temperature operating modes

The transition to low-temperature programs is becoming the main direction of the latest developments of boiler manufacturers. The advantage of this approach is an economic nuance - a reduction in fuel consumption. Just automation allows you to adjust the temperature, choose the right mode and thereby reduce the level of heating. All of the above points must be taken into account at the stage of drawing up a thermal scheme for a hot water boiler.

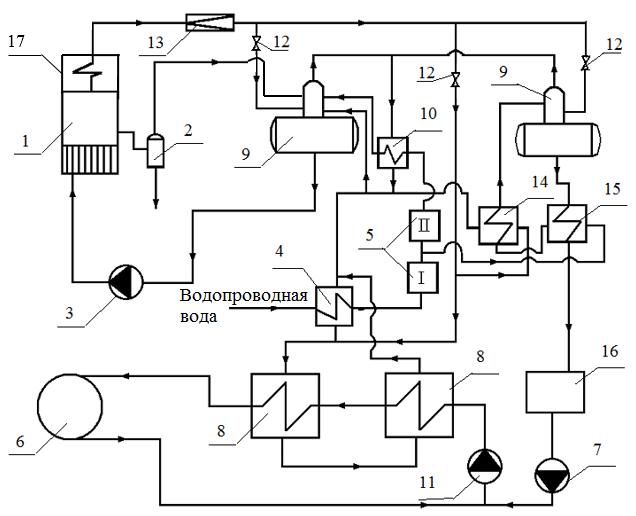

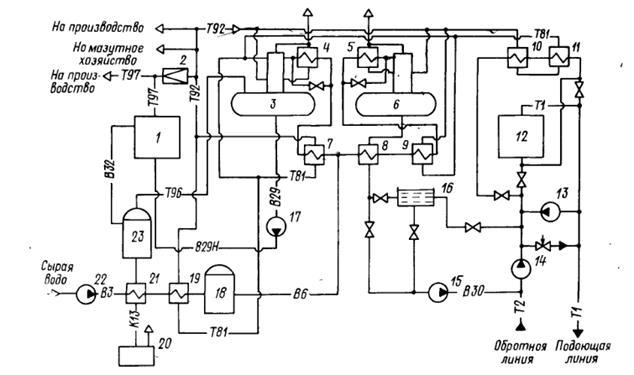

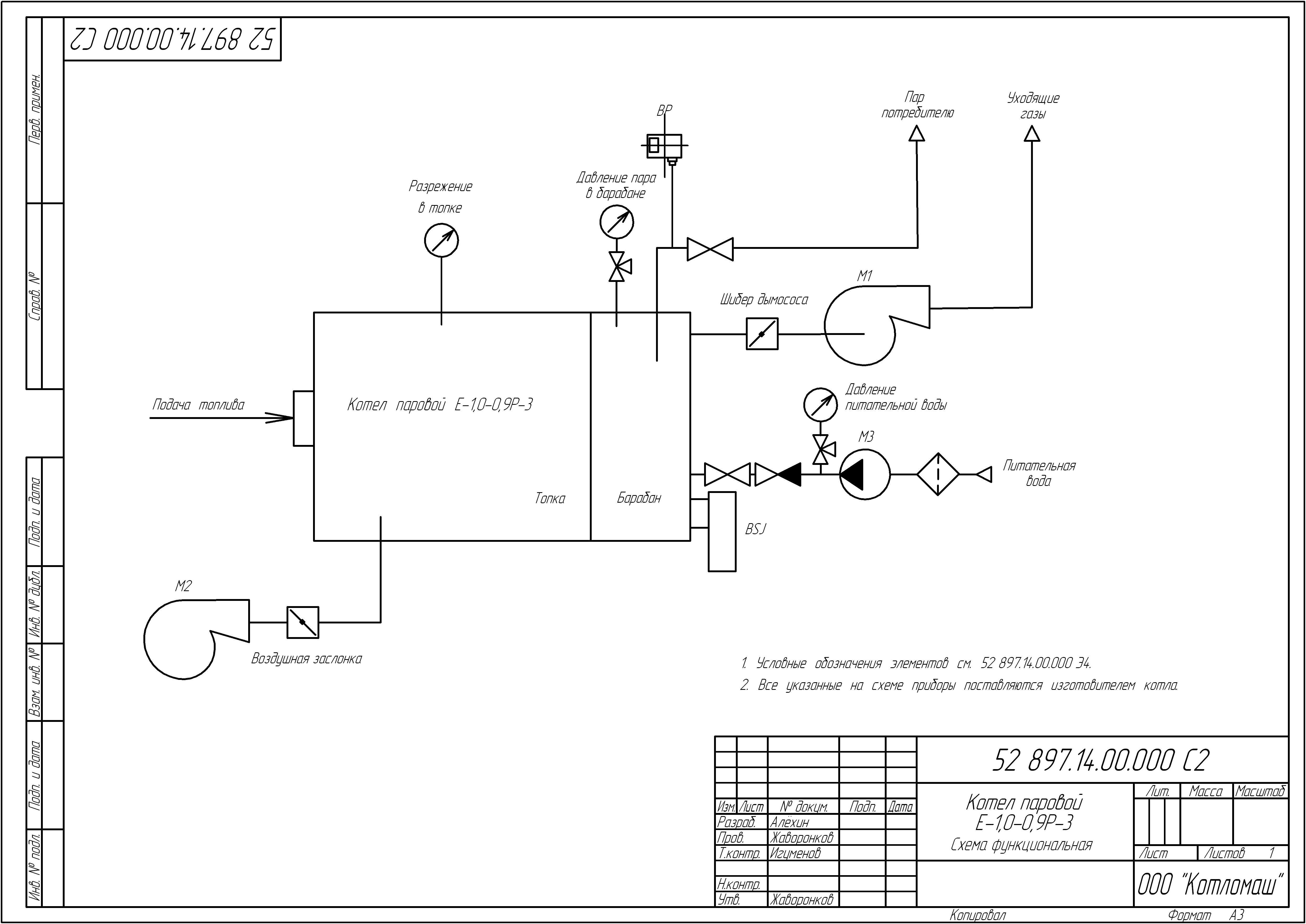

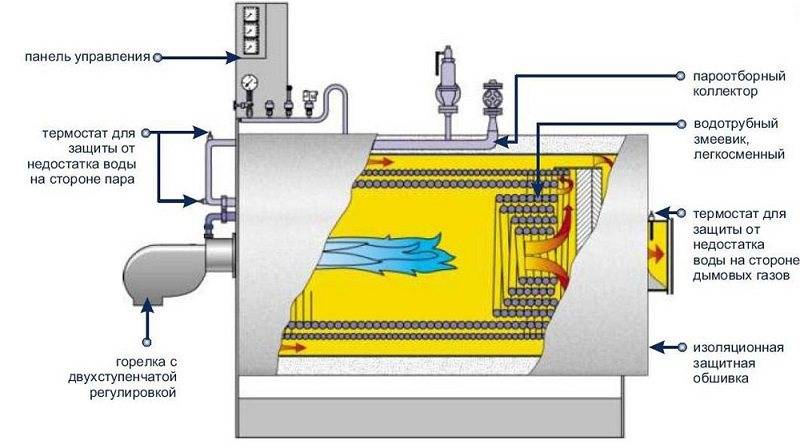

The principle of operation of the steam boiler

For the operation of high-pressure steam boilers, chemically treated water is used, heated through stacks of screen pipes, under the influence of hot flue gases formed as a product of the combustion of fossil fuels.

As the temperature rises, the water is converted into steam, which enters the application area to transfer thermal energy or the kinetic energy of the jet.

Schematic design of the steam generating boiler

Schematic design of the steam generating boiler

Principle of operation:

- Natural water enters the water treatment, where it is cleaned from suspended solids and softened. Then it is supplied in tanks of chemically treated water and fed into the unit using feed pumps for steam devices.

- Before entering the drum, the nutrient medium enters through an economizer - a cast-iron heat-heating device located in the tail section of the unit to reduce the temperature of the flue gases and increase the efficiency of the steam boiler.

- From the upper drum, water enters the lower drum through unheated pipes, and rises from it through lifting convective pipes in the form of a steam-water mixture.

- In the upper drum, the process of its separation from moisture takes place.

- Dry steam is sent to consumers through steam pipelines.

- If it is a steam generator, then the steam is reheated in the superheater.

The main mistakes in designing a heating circuit

Here I want to draw your attention to several key points in which the largest number of problems in designing a home heating system scheme is allowed. The first problem is precisely the lack of understanding that when designing a heating scheme, it is necessary to pay attention to pipe diameters

In our case, the diameters of the pipes are narrowed to impossible.

The first problem is precisely the lack of understanding that when designing a heating scheme, it is necessary to pay attention to the diameters of the pipes. In our case, the diameters of the pipes are narrowed to impossible.

Let's take a radiator heating system: The mains of the heating system are laid with 20 mm PPR pipes. At the same time, I very often say and show that the installation of heating begins with pipes 32 PPR, as an option.And that the radiators themselves are connected with a pipe dm 20 mm.

And here is another diagram and again a pipe dm 20 mm for all radiators. Yes, I do not exclude the use of at least a dm 25 pipe. But this is only when a competent designer calculates all the hydraulics for you and selects the necessary valves with adjustment and with exact numbers for adjustment.

In other cases, we start with pipes dm 32 mm with the ability to connect no more than 8 radiators of ten sections to it.

The same for the underfloor heating system. On the underfloor heating distributor from two to ten circuits with a length of not more than 100 meters each, it is necessary to mount a pipe dm 32 PPR. If there are more circuits and in number or length, then it is necessary to divide into two, three, and so on collectors.

They also often ask where to draw and mount the circulation pump, on the supply or return?

If you have a mono system, that is, either radiators or underfloor heating, then you can mount one pump on the return pipeline.

If the system is combined, where there are radiators, underfloor heating, an indirect heating boiler, then in such systems it is necessary to install circulation pumps for supply pipeline.

Since a check valve must be mounted behind the pump so that H5 is squeezed through other circuits. Also, in front of the pump for the underfloor heating circuit, it is necessary to mount three-way valve for adjusting the temperature of the coolant in underfloor heating.

And the pump should precisely draw the coolant from the valve and thus mix it, and not press into it: as in the diagram.

The controversy continues to this day about this. I propose not to argue, but to look at imported pumping modules or groups.At first, a three-way pump was mounted on all, and after that, a pump that pulls from a three-way valve.

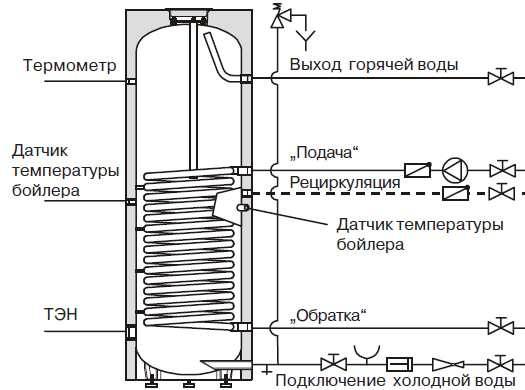

The same mistakes regarding the choice of pipe diameters were made when piping an indirect heating boiler. On almost all boilers, the output of cold, hot water and heating is 1 inch in size.

And why then reduce pipes, especially when we distribute water through distributors

Here it is important to keep the diameter of the main pipes from the boiler as much as possible.

Since water begins to be scarce just when the diameters of the pipes are reduced. And it often sounds from installers, like: Why do you need to overpay for pipes of a larger diameter?

And the lack of water is not his concern.

In addition to everything in the diagram, a three-way valve is also mounted on the indirect heating boiler. He is not needed there.

There is no need to mount a safety group on the boiler. We need to mount the group in our case for the supply of the main collector. And on the boiler at the cold water inlet, connect an expansion tank, a safety valve for 8-10 bar, a drain cock and a check valve.

The temperature switch is not mounted on the hot water recirculation pipe, but in the body of the boiler itself at a height of 1/3 from the bottom of the boiler.

In general, as usual, we want the best, but it turns out as always.

Separate building for the boiler room

Equipment with a power of 200 kW or more must be installed in a building separate from the house.

Along with the general requirements, in this case, some additional conditions are imposed:

- Heat resistance of the building material from which walls and roofs are constructed (including internal finishing).

- A separate boiler room must have a room volume of at least 15 m3.To the result obtained, 0.2 m3 is added for each kW of power involved in heating the home.

- Ceilings. Height - from 250 cm.

- Glazing area. It is determined by the formula 0.03 m2 / 1 m3 of the building volume.

- Window. Be sure to have a window or transom.

- The presence of a separate foundation for the boiler. It should not be higher than 15 cm in relation to the general level. If the weight of the heating equipment does not exceed 200 kg, it can be mounted on a concrete floor.

- Existence of system of emergency shutdown of gas. It is installed on the pipe.

- Doors. It is allowed to use only non-reinforced structures on weak hinges.

- Ventilation. Its power should be enough to ensure that in one hour all the air in the room is replaced at least three times.

Acceptance and placement of the boiler in the boiler room is strict: representatives of the gas service usually do not go for concessions.

Operating rules

After installing the boiler, it is first launched, which is a rather complicated process. It is clearly associated with serious rules and serious instructions.

Before kindling the boiler room, if it is on diesel or solid fuel, it is necessary to inspect it for damage and operational readiness.

- The superheater, air heater, collector lining and water supply, as well as all components in the water heating system, should be inspected.

- All third-party items, garbage from the furnace and gas ducts must be disposed of.

- You also need to inspect for plugs on the gas pipeline, steam, water or drainage lines.

- After the revision of the additional equipment, it must be put into idle operation, during which there should be no vibration or knocking sounds.If breakdowns occur during the inspection, they must be eliminated before the boiler is started.

- Before the first ignition, shut-off and individual dampers must be opened, and the fan guide mechanisms must be closed together with the smoke exhauster.

During work on automatic hot water boilers, a specialist must be present to control fuel consumption, pressure status and degrees in the boiler. For normal operation, chemical water treatment is mandatory, as well as control of the appropriate supply of water to the system. Water is supplied to the boiler manually or automatically. Feeding control is carried out by the operator according to the data of the instruments, indicating the degree of water in the drum.

For accounting in the boiler room, a special journal is provided that controls water treatment, indicators of the results of water analysis, fulfillment of the purge terms boilers and works on equipment repair. Boilers with a capacity of less than 0.7 t/h must be cleaned regularly if the scale thickness is 5 mm.

Do not leave hot water boilers unattended until the combustion in the furnace is completely finished, fuel waste is removed from it and the pressure is reduced to zero. Unauthorized people should not be allowed to equip boiler rooms, unless they have received permission from the administration. The room, boilers and all auxiliary equipment must always be in working condition and maximum cleanliness. Do not keep third-party and cluttering objects in the building. Doorways should be clear and doors should be easy to open.

Before starting the system, the gas ducts must be ventilated, lit, protected from the possible ingress of gas dust. The condition of the furnace and gas ducts is confirmed by the result of the analysis.If signs of gas contamination appear, fire should not be used in the boiler room.

The tightening of bolts and clamps during operation of the boiler must be carried out with the utmost care, only with a special tool, without the use of extension levers, with a responsible person

For information on how to make a boiler room so that the gas service accepts it, see the following video.