- The principle of operation of the pyrolysis boiler

- Features of pyrolysis boilers

- Secrets of the development of a pyrolysis boiler

- How pyrolysis boilers work

- Advantages and disadvantages of pyrolysis boilers

- Tools and materials

- Advantages and disadvantages

- How does wood moisture affect efficiency?

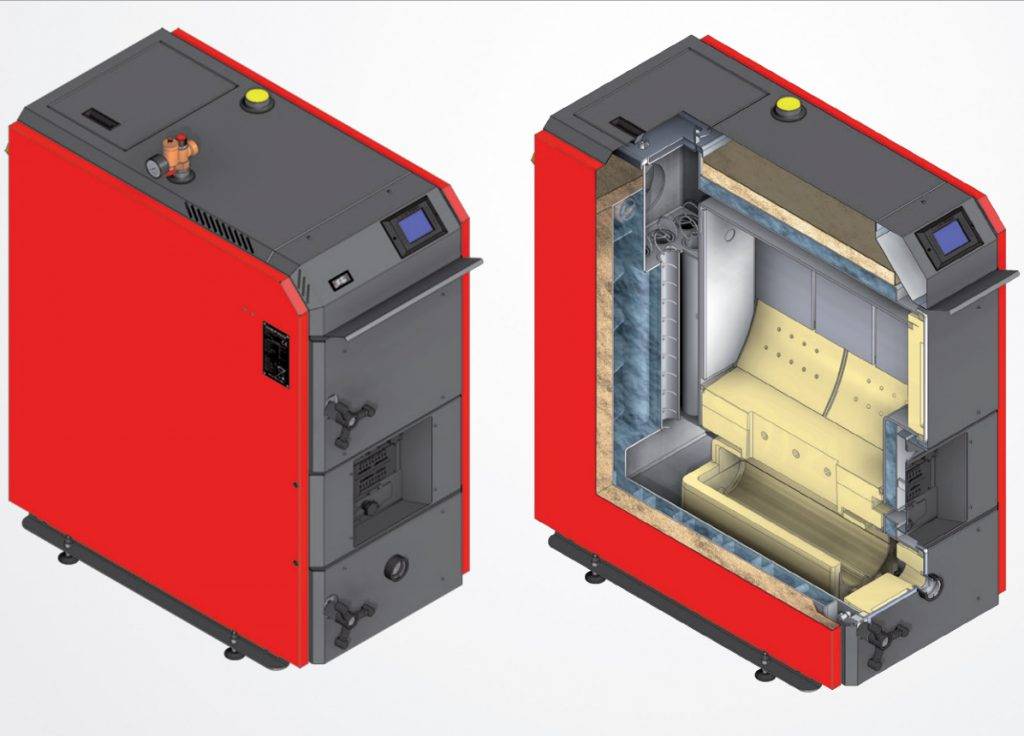

- Pyrolysis boiler - manufacturing scheme, main stages

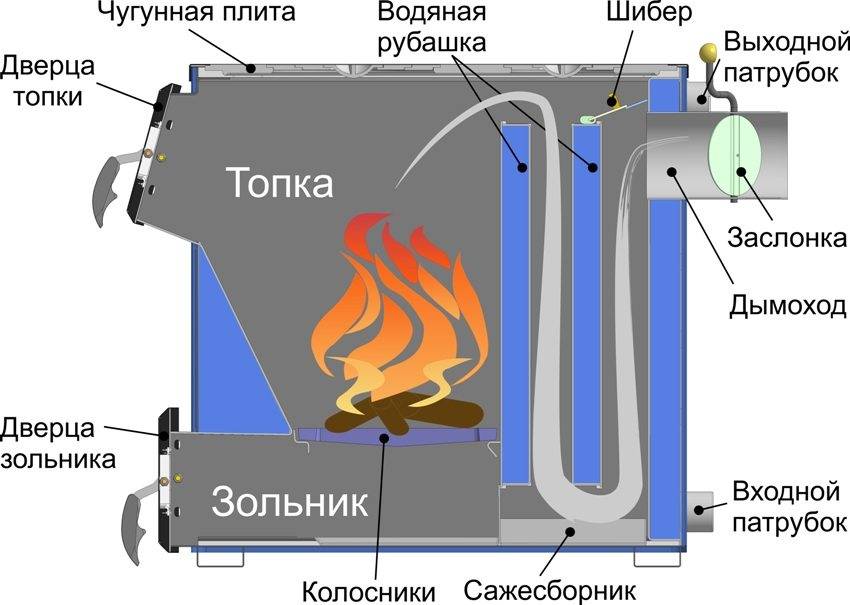

- Device and purpose

- Principle of operation

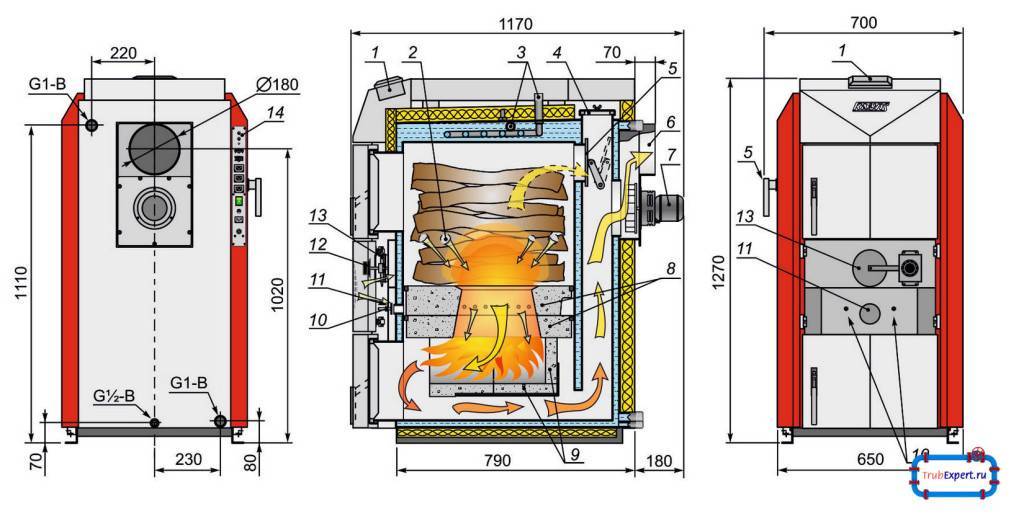

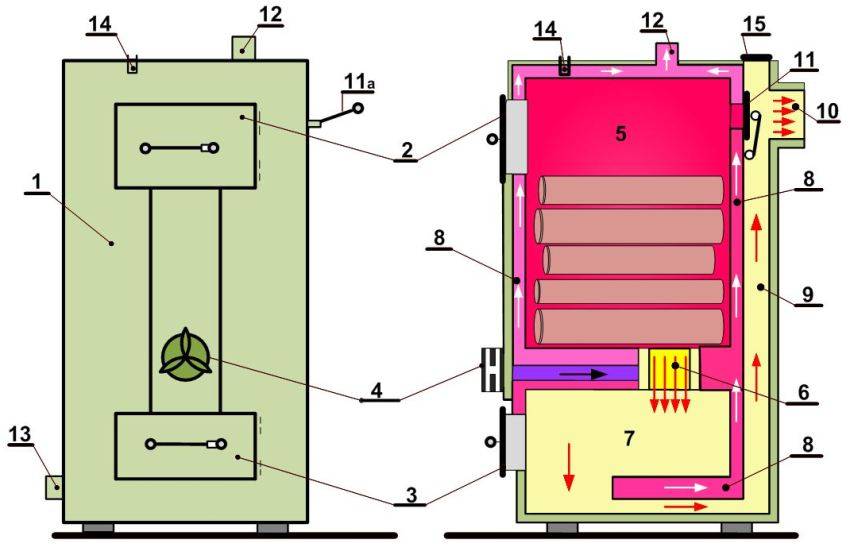

- The device and principle of operation of the boiler

- Pros and cons

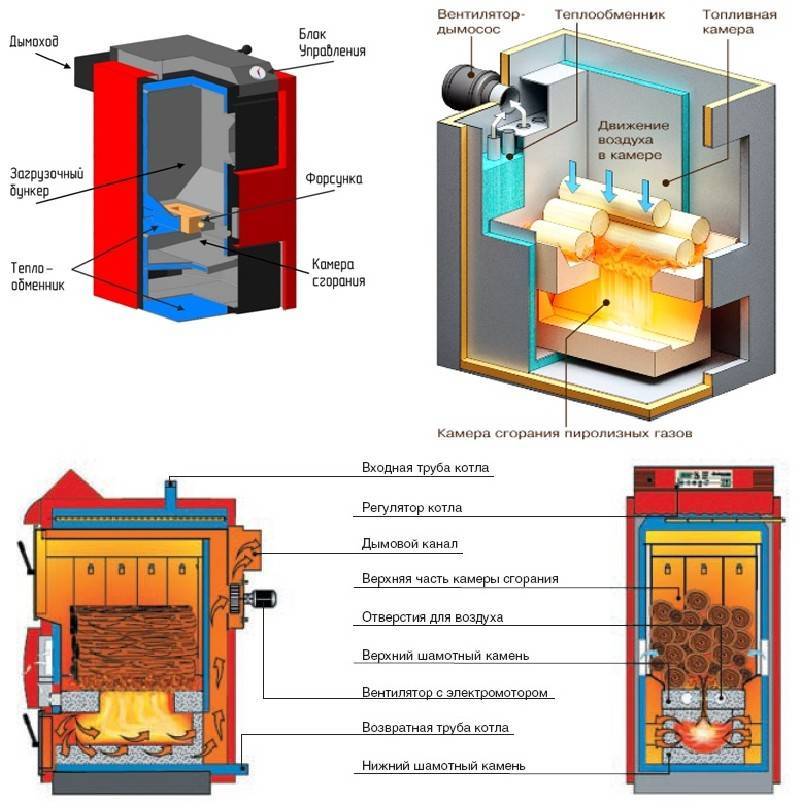

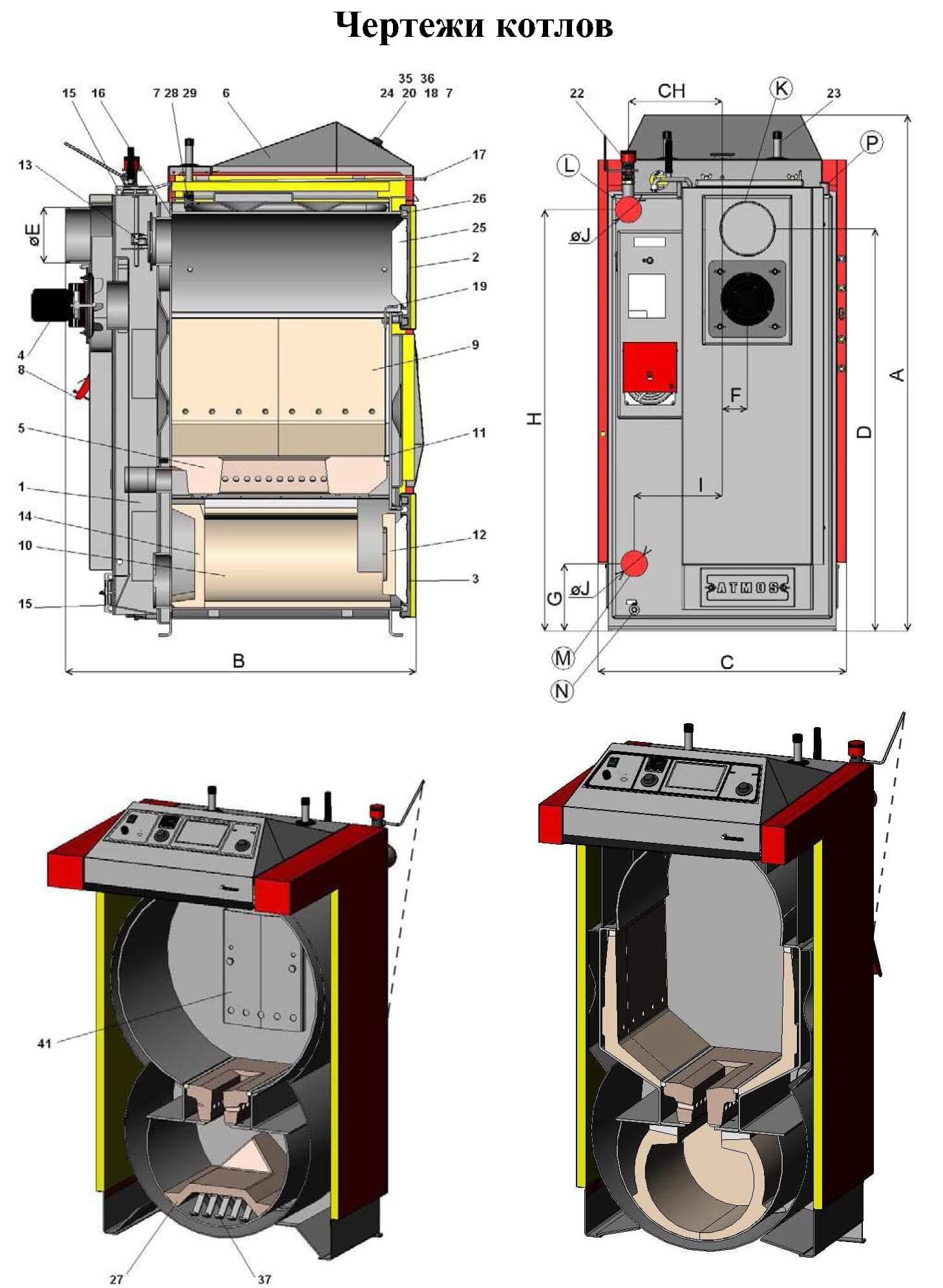

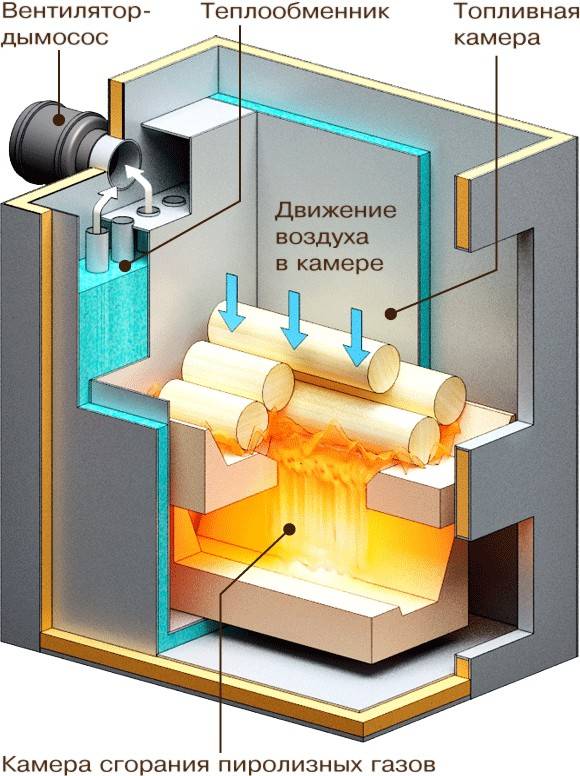

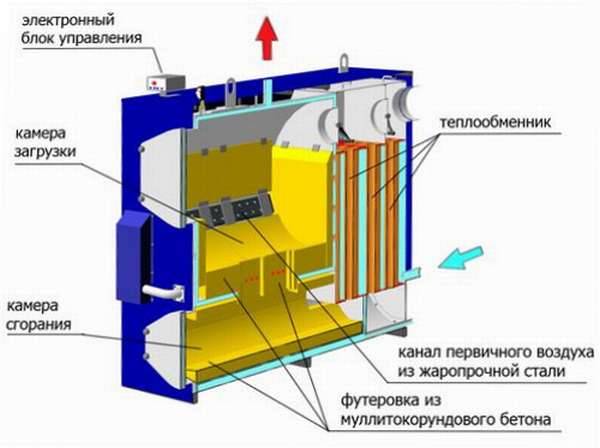

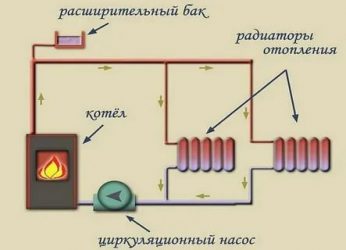

The principle of operation of the pyrolysis boiler

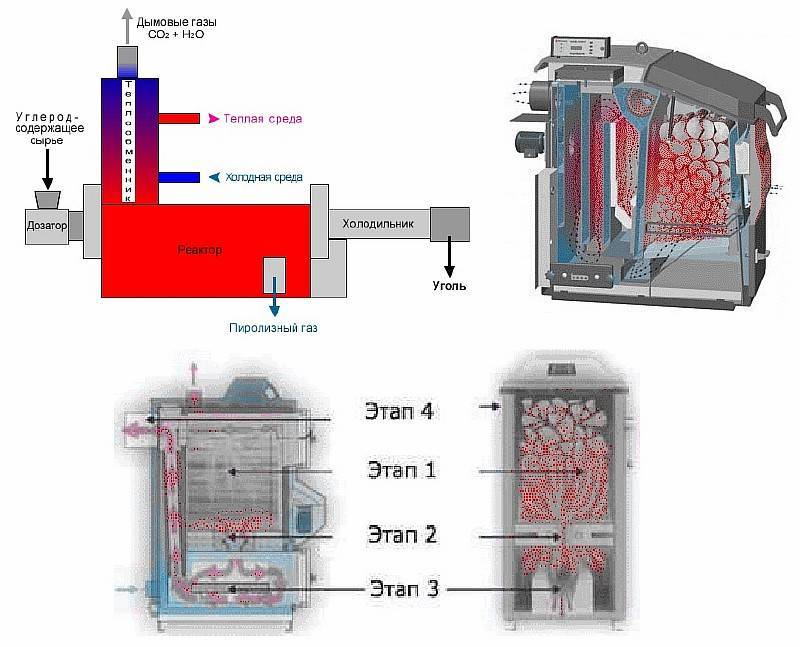

Pyrolysis is a process with a powerful exotherm, in which complex organic matter (in our case, coal, wood, peat, biofuel in the form of pellets, etc.) decomposes into a simpler composition - solid, liquid and gaseous phases. For the decomposition process, it is necessary to provide a temperature and limit the supply of oxygen, which is carried out in a gas-generating boiler. To load into the furnace section of the boiler, you need fuel that has characteristics that meet the manufacturer's recommendations, otherwise there will be no expected effect. Combustion occurs at high temperatures, but simultaneously with oxygen deficiency. Wood or coal fuel under such conditions does not burn with a flame, but rather sinters with pyrolysis decomposition, with a release of energy much greater than during conventional combustion in air. The main products are solid and volatile fractions (coke oven gas).

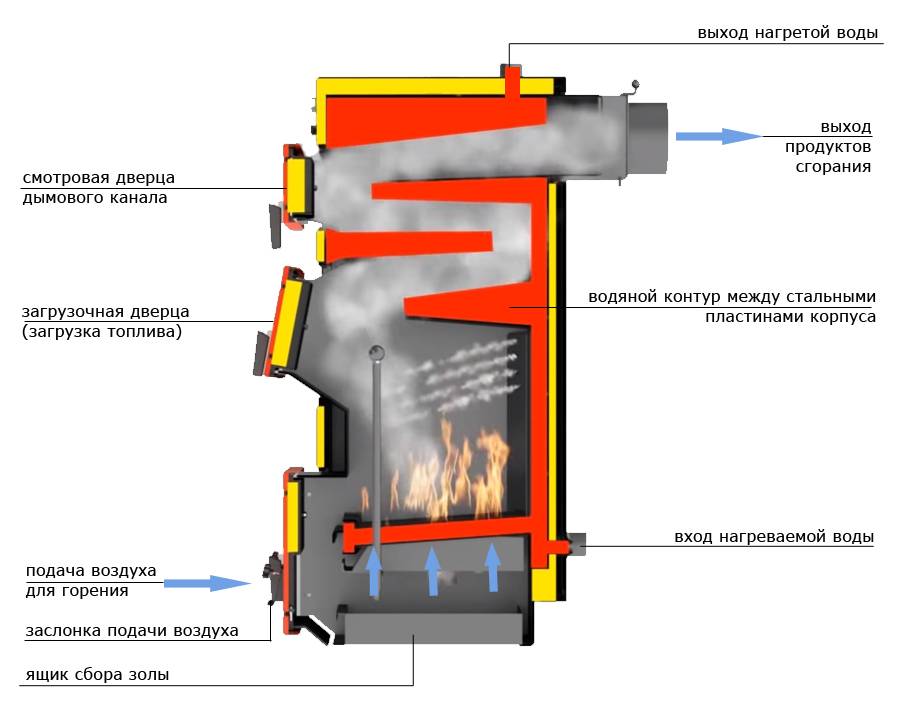

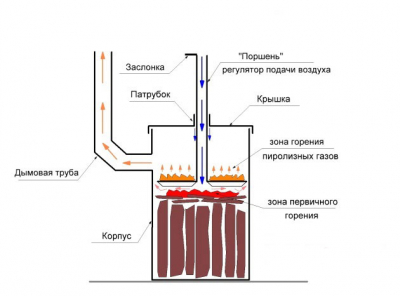

The unit has two chambers, the upper chamber is used to implement the exothermic reaction of fuel pyrolysis at a temperature of 300⁰С to 800⁰С. The chambers are structurally independent and are separated by grates and regulators - gate valves. The upper gasification chamber, into which the fuel is loaded, is sealed and oxygen is in short supply in it. There is solid fuel on the grate, it creates an obstacle to heat removal, down into the second chamber, only air passes, and its flow is weak. The result is a slow smoldering and decomposition process, or pyrolysis. And the result of pyrolysis is charcoal and pyrolysis, or coke oven gases, CO and, in a small part, carbon dioxide.

The mixture of pyrolysis gas and air is also sent to the lower section of the combustion chamber, where the temperatures are much higher - up to 1200⁰С, and during combustion it releases heat that is incomparable in quantity with heat transfer from the combustion of solid fuel in air. The lower compartment of the second combustion chamber is nothing more than a nozzle type device made of heat-resistant ceramics or fireclay bricks. Aerodynamics in such a firebox gives high resistance, so the draft is forced by turning on the smoke exhauster. The heat from the combustion of gas is used for efficient heating of housing. In fact, pyrolysis boilers do not work on wood or coal, but on the gas emitted. Gas combustion processes are easier to control, so the automation of gas generating units is more perfect.

The solid phase burns very slowly, with a constant release of thermal energy. Volatile coke oven gas also burns, and the heat transfer from this process is somewhat greater than during the combustion of the solid fraction. The efficiency from the use of firewood and coal increases significantly.

The gas generating unit, for all the simplicity of its design, can be compared with a home laboratory complex that extracts gas from firewood, peat briquettes, coal, and other fuels for subsequent combustion with much greater heat transfer.

The scheme of the pyrolysis unit is considered simple, which attracts home craftsmen. For the construction of the boiler, special equipment is not required, the main conditions are the body with the necessary parameters, ensuring tightness in the combustion chamber and a strict dosage of incoming air.

With the advent of pyrolysis boilers, classic wood-burning boilers began to be considered obsolete, despite their prices - half the price of pyrolysis boilers with a similar power. One load of firewood into the pyrolysis unit gives the combustion time and heat supply many times greater than for a conventional solid fuel boiler. New units pay off in a short time. Double-circuit boilers provide even greater savings, since hot water, unlike heating, is required for housing not seasonally, but all year round. Also called such a plus as the ability to use wet material for the firebox (up to 40-50% moisture). But dried firewood is more efficient and economical. Wood-burning pyrolysis boilers have gained recognition, among other things, because in many regions and settlements, dry wood material is inexpensive, and often free. Drying damp wood during the summer season is also not a problem, and the consumption for a pyrolysis boiler is very economical.

Features of pyrolysis boilers

Traditional wood-fired boilers are annoying because they require constant supervision. That is, every 2-3 hours they need to put more and more portions of fuel in them, otherwise the pipes in the house will become cold.It is especially hard at night, when instead of a restful sleep, the household gets a headache in the form of cooling down heating. On the one hand, sleeping in a cool place is good for health. On the other hand, meeting the morning, desperately chattering your teeth, is not very pleasant.

Classic boilers for home heating have another important drawback - low efficiency. The fuel in them burns very quickly, most of the heat simply escapes into the atmosphere. Together with it, combustion products containing combustible gases fly into the air. They can be used to obtain additional portions of heat - this is what happens in pyrolysis boilers for long-term combustion.

As you already understood, solid fuel pyrolysis heating boilers are devoid of both of the above disadvantages. They are endowed with capacious fireboxes, burning solid fuel according to a slightly different principle. Here are their main features:

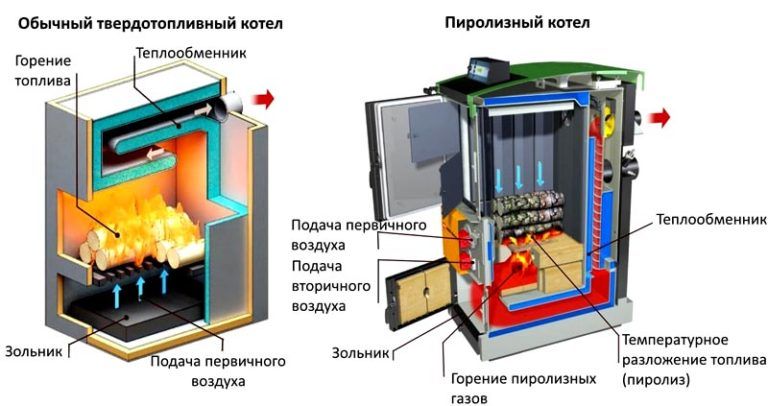

The principle of operation of a solid fuel pyrolysis boiler is very simple. Although this figure does not cover all the nuances, it conveys the essence of the technology in full.

- Large volume of the furnace - up to several tens of liters. Due to this, the frequency of approaches for laying fuel is reduced several times;

- The pyrolysis principle of combustion - allows you to get much more thermal energy from the same amount of firewood;

- Quite large - in fact, there are two fireboxes. In one, firewood slowly burns out, and in the second, the products of combustion released from the wood are burned;

- Low combustion temperature - reduces the thermal load on the metal.

Long-burning pyrolysis boilers are somewhat more complex than their traditional counterparts, but they provide significant fuel savings.

It should be understood that due to the complex design, often containing elements of automation, pyrolysis boilers are characterized by a high price. Therefore, the initial cost of their purchase may seem large. But in the future they will definitely justify themselves.

Secrets of the development of a pyrolysis boiler

Do-it-yourself pyrolysis oven scheme.

In order for the boiler device to be brought to an ideal state, it is advisable to perform some actions. An adjustable blower fan can be installed under the fuel tank. It is designed to blow air directly into the boiler itself. Under the influence of artificially forced air, accelerated combustion of fuel occurs. All these works can be done by hand. The installation of this technique does not require special skills.

To increase the amount of heat generated, automation must work smoothly and clearly, fuel bunkers must be in optimal positions.

It is possible to achieve an extension of the combustion period of the fuel if, during the construction of the boiler, the separation of the fuel chambers is carried out with one's own hands. At the same time, fuel will be burned in one of them, and gases will be collected in the other. When using a two-zone gasification system, it is possible to achieve energy independence of the boiler and a constantly high power level. The power of a wood-burning stove can be increased by placing grates at the bottom of the fuel bins.

A high-quality heat storage in pyrolysis boilers (unlike coal-fired devices) is the installation of a jumper directly in the combustion chamber. Automation in this case performs its immediate function.

The design of the pyrolysis boiler is designed in such a way that there is no need to grind firewood before supplying fuel to it - the main thing is that they can pass through the oven door.

Wood-fired pyrolysis boilers can function and exude great thermal energy when using sawdust, peat briquettes. Some boilers can even run on coal. Installing such a boiler does not require much effort and time. The main thing is to correctly understand the principle of its operation and make a high-quality chimney

It is very important that the chimney has sufficient draft to blow out residual gases. It is not difficult to do it yourself.

How pyrolysis boilers work

The principle of operation of the pyrolysis boiler is to generate combustible gases and from subsequent combustion. In order to be able to understand how it works, one should recall an interesting experience from a physics school textbook. There it was proposed to enclose some wood chips in a glass flask, stoppered with a thin tube. The flask was placed under the burner, after some time the pyrolysis reaction began in it. After that, combustible gases began to come out of the tube, which were easily set on fire and burned with a bright flame.

The principle of operation of the pyrolysis boiler is based on a similar reaction, only on a large scale. There are two cameras involved here:

- Combustion chamber - a preliminary ignition of the fuel is carried out in it, after which the firewood is here in the slow smoldering mode, with limited air access;

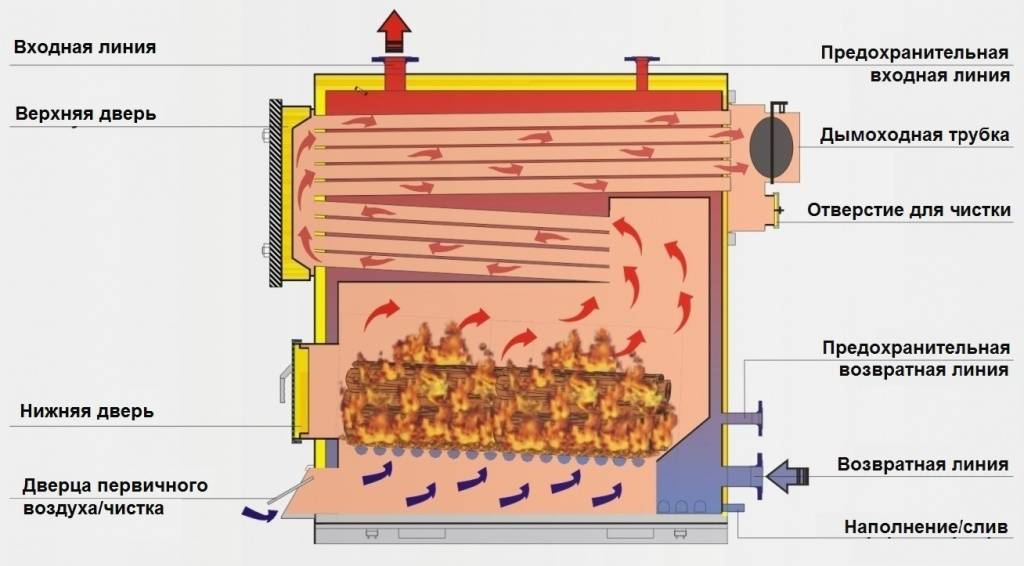

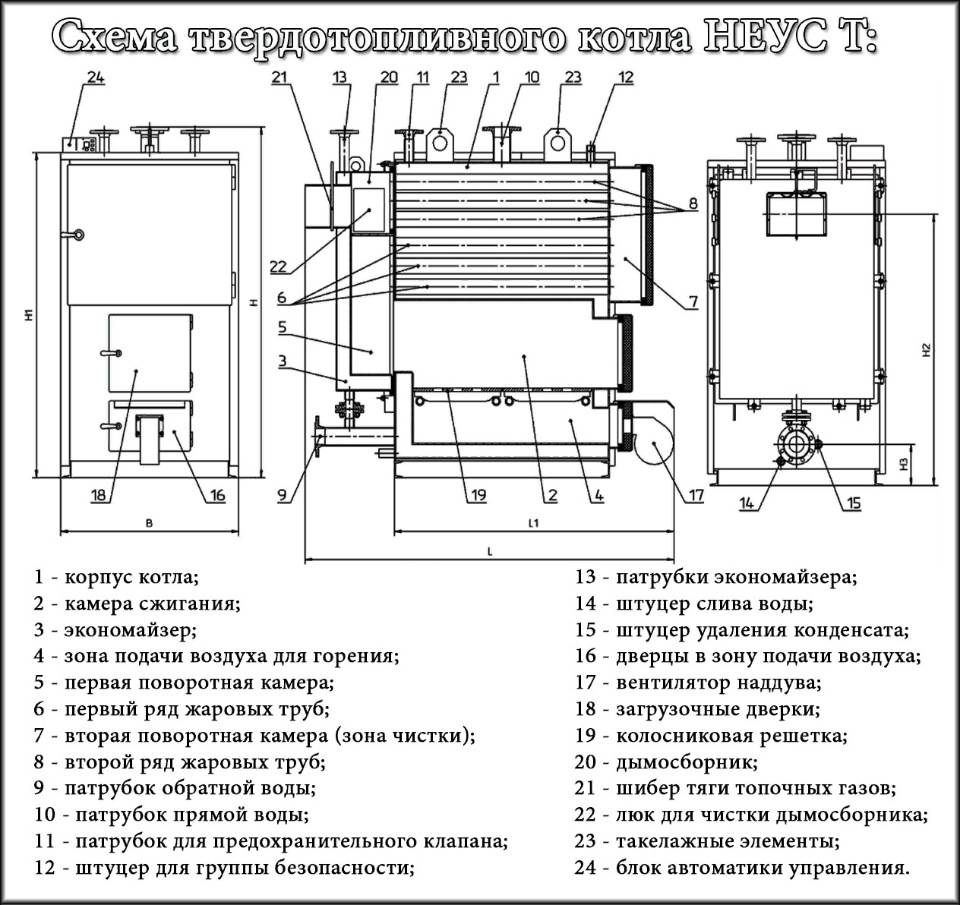

- Afterburner - pyrolysis products burn here, giving rise to heat that goes to the fire-tube heat exchanger.

All this economy is cooled by a water jacket.

Studying the principle of operation of the pyrolysis boiler, it may seem to you that the effectiveness of this technique is extremely small. In fact, a lot of gases are released. If we look into the afterburner, we will see a powerful roaring flame there, releasing a wild amount of thermal energy.

Combustion chambers in pyrolysis boilers can be located in any sequence. For example, one above the other or sequentially, one after the other. There are also units in which afterburning is carried out under the main furnace. The intensity of combustion is regulated by means of a blower fan or with the help of a blower door. It should be noted that the adjustment range is quite large - if necessary, the flame can be extinguished almost completely.

The principle of operation of the pyrolysis boiler provides for the preliminary ignition of wood fuel. We need the firewood to take up the flame well. To do this, the throttle valve and blower are opened, a portion of firewood with small splintered firewood is placed in the firebox for ignition. We set it on fire, we wait for the appearance of a stable fire. Now our pyrolysis boiler is ready for full launch. We perform the following actions:

Due to the design of the pyrolysis boiler, hot air does not fly into the chimney immediately, but first passes through a special compartment. This allows the system to significantly increase its efficiency in comparison with conventional boilers.

- Close the throttle valve;

- We close the blower door;

- We turn on automation;

- We observe the temperature increase in the system.

Let's see how the pyrolysis boiler works inside - there is a lot of interesting things going on here. Firstly, after blocking the access of oxygen, our cheerful flame turns into embers. And secondly, after starting the automation, the blower fan turns on, the pyrolysis products are sent to the afterburner, where a powerful flame begins to rage. This principle of operation is implemented in all pyrolysis boilers. The differences are only in the adjustment scheme - somewhere electronics is responsible for automatic adjustment, and somewhere simple mechanics.

Advantages and disadvantages of pyrolysis boilers

Like other heating equipment, pyrolysis boilers have pros and cons according to various criteria.

The disadvantages of long-burning boilers are mainly their cost. Such equipment is several times more expensive than classic direct combustion devices.

Unlike standard boilers, pyrolysis boilers require less fuel in order to maintain the temperature in the room for a long time.

Another plus is the small amount of waste.

With prolonged burning of organic matter, practically no ash remains from it.

The disadvantages also include high requirements for the moisture content of firewood. This threshold should not be higher than 20%, otherwise they will not be able to burn and release gas.

Tools and materials

To mount such a unit on your own, you will need the following set of tools and materials:

- Thermal sensor.

- Fan.

- Strips of steel of various thicknesses and widths.

- A set of professional pipes with a diameter of 2 mm.

- Sheets metal 4 mm thick.

- A set of pipes of various diameters.

- Cutting wheel with a diameter of 230 mm.

- Grinding wheel with a diameter of 125 mm.

- Manual circular saw (Bulgarian).

- Several packages of electrodes.

- Welding machine.

- Electric drill.

If you plan to make your own pyrolysis boiler, then the recommended steel thickness should be 4 mm. To save money, you can use steel 3 mm thick. For the manufacture of the body of the device, you will need durable steel that can withstand high temperatures.

Advantages and disadvantages

The advantages of such a setup include:

- The highest efficiency among all solid fuel boilers, it is 90-93%.

- Approximately 3 times less harmful substances are emitted, which makes them more environmentally friendly.

- Long interval between fuel loadings, about 12 hours for softwoods and 24 hours for briquettes, pellets and hardwoods.

- The low amount of tar in the exhaust gases prolongs the service life of the chimneys.

Flaws:

- Requires low moisture fuel. The best option is 20%.

- The cost of such boilers is higher than all other types of such equipment.

- Forced draft installation makes it dependent on electricity.

How does wood moisture affect efficiency?

Wood for pyrolysis boilers must be dried to 15-20% moisture. Such a result is difficult to obtain with natural drying, so this can be considered the main disadvantage of this type of boiler.

Raw firewood emits more water vapor, which mixes with the gas-oxygen mixture and reduces its energy consumption. An example of such a decrease in numbers:

- Burning 1 kg of firewood with a moisture content of 20% - power 4 kW;

- Burning 1 kg of firewood with a moisture content of 50% - power 2 kW.

Pyrolysis boiler - manufacturing scheme, main stages

To independently assemble a gas-generated heating unit, you must adhere to the following requirements:

The necessary elements should be cut with a grinder.

The opening for loading fuel is located slightly higher than that of solid fuel devices.

To control the amount of air entering the combustion chamber, it is necessary to install a limiter. It can be made using a pipe with a diameter of 70 mm, while the length should be slightly larger than the boiler body.

Using a welding machine, a steel disk is welded, which, together with the pipe walls, should form a gap of approximately 40 mm.

To install a limiter in the boiler lid, you need to make an appropriate hole. It must be rectangular. The opening is closed with a door equipped with a steel overlay. This will ensure a secure fit. Below is a hole designed to remove water.

Using a pipe bender, it is necessary to bend the pipe designed to move inside the coolant boiler. This ensures maximum heat transfer.

Regulation of the amount of coolant sent to the device can be carried out by means of a valve mounted outside.

As soon as the first start-up of the equipment is completed, the combustion products should be free of carbon monoxide. If this condition is met, the pyrolysis boiler piping (the diagram is indicated) is done correctly

It is important to regularly monitor the condition of the welds of the device and remove the resulting soot and ash from it in a timely manner.

An excellent option would be to share a pyrolysis boiler not with classic water heating, but with air heating systems. As a result, air will be transferred through pipelines and returned to the system through the floor. Such a system has numerous advantages: it does not freeze in severe frosts, there is no need to drain the coolant during the departure of the owner.

Device and purpose

A pyrolysis boiler for heating a private house works by burning fuel at a very high temperature and with limited air access. Instead of solid fuel, a new one is actually created - a special gas. It is additionally burned in a special chamber, which is usually located below the solid material intended for backfilling. Accordingly, the air is pumped first into the upper part, and from there it enters the lower chamber. Since this is contrary to the laws of physics, they have to be overcome artificially, using fans or pumps.

The lack of oxygen in the air used helps to make combustion more protracted than in conventional boilers or furnaces. It is possible to extend the time of heat transfer from one portion of firewood, for example, up to 20 hours. Miracles, of course, do not happen: they give off thermal energy in small portions. But for a greenhouse, such a solution turns out to be even a plus, because it allows you to maintain a stable temperature without overheating and hypothermia.

The use of a pyrolysis boiler for a bath deserves a separate discussion. It turns out to be more practical than both gas and electric heaters. In terms of efficiency and convenience, it is ahead of many stoves, especially when compared with home-made designs.Any pyrolysis boiler has a horizontal segment (the so-called "hog"), which is designed to connect the structure to the chimney. The wall thickness in this place is 4.5 mm, and the usual length reaches 50 cm.

The characteristics of the pyrolysis boiler allow us to consider the increased (in comparison with simple solid fuel alternatives) cost quite appropriate in most cases. The time of use of one load of fuel is difficult to predict in advance, it depends on a large number of factors. In technical documentation and popular descriptions, the minimum and maximum possible numbers are usually given.

They are affected by:

- humidity of the used fuel;

- temperature in the house and on the street;

- quality of insulation;

- features of the heating system.

Dry distillation is controlled by a nozzle that doses the flow of atmospheric air

Importantly, boilers operating on the principle of pyrolysis are able to dry the stocks of firewood or coal stored in the same room. Features of the operating mode exclude the ingress of not only carbon monoxide or carbon dioxide into the living quarters, but also safer water vapor

Most designs work best with very well dried wood.

Principle of operation

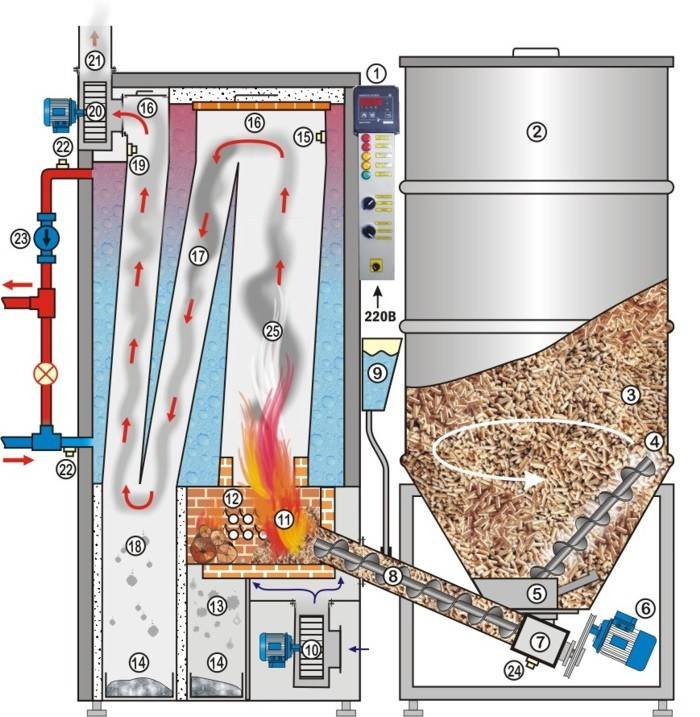

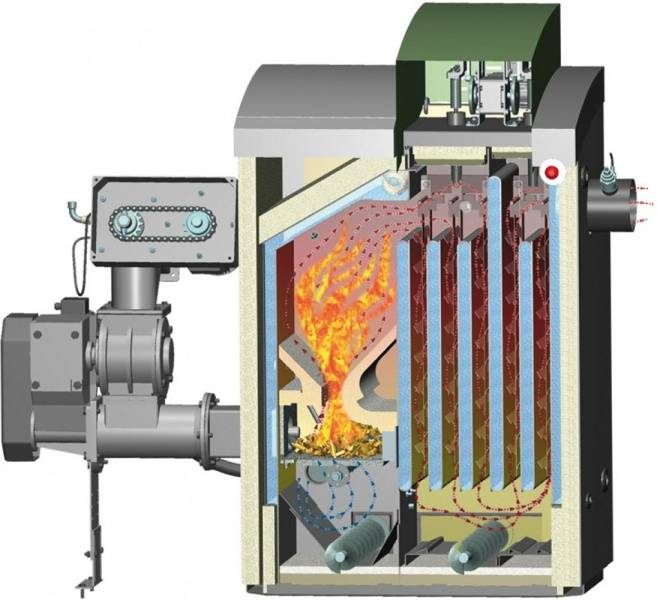

The boiler runs on solid fuels, usually on wood, peat, lumber waste, special wood briquettes, coal and pellets (granules made from crushed wood, resin, needles, etc.). Especially popular are devices of a universal type, capable of consuming almost all types of solid fuels.

According to the method of heat transfer, boilers are:

- Air.

- Steam.

- Water (most common).

According to the principle of fuel combustion:

- Traditional. They work on wood and coal. The principle of operation is the same as that of a conventional wood-burning stove.

- Long burning. Innovative development in the field of heating equipment. Solid fuel boilers for long burning have the form of an elongated combustion chamber, surrounded on all sides by a water jacket. When burning, the flame does not spread from bottom to top, but from top to bottom, resembling in this respect the process of burning a candle. The principle of operation of the long-burning boiler allows to achieve complete combustion of the fuel. At the same time, the burning interval of one bookmark of fuel increases (up to 7 days). The long-burning boiler operates, as a rule, at a consistently high coolant temperature, which increases its efficiency by an order of magnitude. The uninterrupted and safe operation of such models is achieved by including emergency extinguishing fans, a safety valve and a circulation pump in the design.

- Pellet. Special pellets are used here as fuel. Such boilers are additionally equipped with an automatic pellet feeding system and a fuel storage bin. Thanks to electronic sensors, the presence of fuel inside the furnace is monitored. Such a system requires a stable electrical supply.

- Pyrolysis. Unique equipment, where, along with the energy from the combustion of solid fuel, the heat release of gases is also used. This makes it possible to convert a small amount of fuel into a significant portion of thermal energy.As a result, an increase in the efficiency of the boiler and a decrease in harmful emissions are achieved.

The device and principle of operation of the boiler

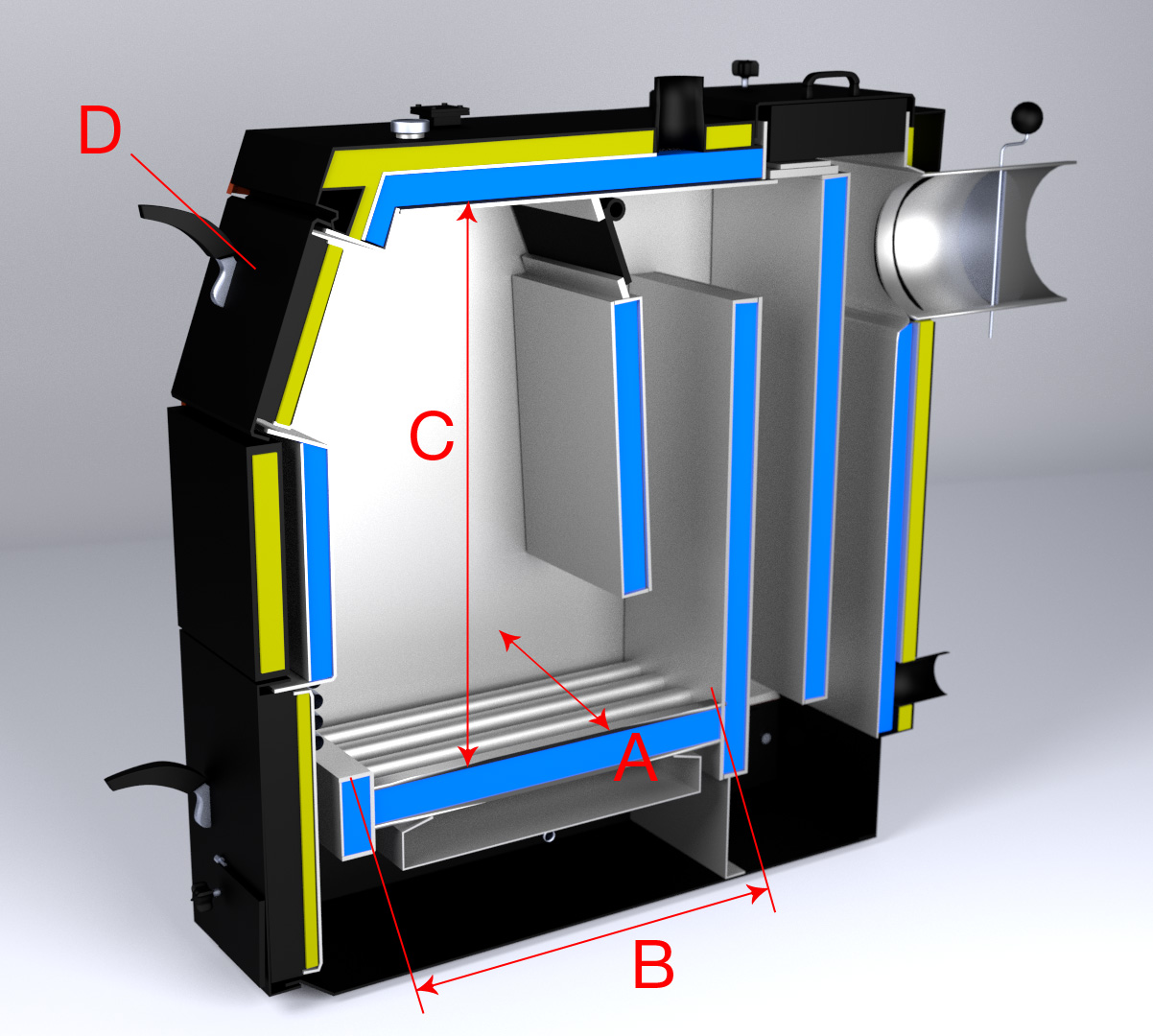

The primary combustion chamber or pyrolysis chamber resembles in its device the firebox of a conventional furnace. Solid fuel (firewood, sawdust, wood or peat briquettes, pellet granules) is placed through the loading window on a massive refractory grate - a grate that provides air flow to the fuel, which is called primary.

The principle of operation of the long-burning boiler

Pyrolysis gas forcibly, less often by gravity, enters the secondary chamber - the combustion chamber or afterburner chamber, into which a sufficient amount of air is supplied, which is called secondary. From contact with oxygen, heated to high temperatures (more than 300 degrees Celsius), the gas instantly flares up and burns with the release of a large amount of heat. The main function of the boiler is performed - heating the coolant.

The principle of operation of the pyrolysis boiler is shown in detail in the video.

Air is usually forced in with a small fan. Although in small models, a smoke exhauster is sometimes used to create traction.

This diagram shows the device of the lower combustion pyrolysis boiler. Firewood burns slowly with a small amount of oxygen and releases combustible gas ( )

The presence of forced ventilation can be considered the main difference between the pyrolysis boiler and the classic solid fuel model. The body of the device consists of two parts inserted into each other. The space between the walls is filled with a coolant, the role of which is traditionally played by water.

The combustion temperature can reach 1200°C.The water in the outdoor heat exchanger is heated and circulated through the heating system of the house. Remaining products of combustion are removed through the chimney.

In reproach to devices that use the pyrolysis principle of combustion, a relatively high price can be set. A conventional solid fuel boiler costs much less. But in long-burning boilers, firewood burns out almost completely, which cannot be said about a classic boiler.

Firewood for a pyrolysis boiler has certain requirements for size and humidity. Detailed information can be found in the manufacturer's instructions.

When choosing a pyrolysis boiler, it should be remembered that inexpensive low-power models are usually designed only for firewood. Expensive modifications are able to work on different types of fuel.

According to the method of fuel combustion, long-burning boilers with a double circuit can be divided into:

- Pyrolysis. Equipped with two combustion chambers. In one of them, the process of smoldering and gas release for pyrolysis occurs, in the other, the resulting gas is mixed with oxygen and burned. Equipment of this type is characterized by high environmental friendliness - a minimum amount of harmful substances is released into the atmosphere. During combustion, little soot is produced. If the boiler is equipped with automation, it will be possible to adjust the power.

- With upper combustion chamber. These boilers are very easy to maintain. The amount of automation for their stable operation is minimal, it is possible to function offline without electricity. There are also disadvantages - a lot of ash is formed during operation, there is a list of requirements for fuel types. For example, small chips or sawdust are not suitable for kindling.

- Pellet.For kindling such equipment, special pellets or compressed fuel briquettes are used. Such boilers are environmentally friendly, economical and efficient, have a long service life. One of the main disadvantages is the high price of the boiler and the special conditions that will have to be maintained for fuel storage. The room must be dry, high humidity will contribute to the deterioration of the pellets.

Pros and cons

It is not enough to study the reviews of owners and specialists on specific models, to get acquainted with the ratings of the best modifications. It is also necessary to answer the most important question: how do the advantages and disadvantages of pyrolysis boilers compare, do they actually justify the investment. And here there can be no universal answer, because a lot depends on priorities and on the peculiarities of using the equipment.

Any pyrolysis boiler, by virtue of its design features, has built-in automation. Working for many hours on one gas station frees up a lot of time and effort. As a fuel, almost any waste processing and harvesting of wood, and sometimes not only them, can be used.

The flip side of these benefits are:

- attachment to the operation of the power grid;

- mandatory installation of uninterruptible power supplies;

- unsuitability of raw wood;

- the inability to supply water to the heating circuit colder than 60 degrees (it forces corrosion);

- the inability to automate the loading of fuel itself (feeding from the bunker only makes manual work less common, but does not completely exclude it);

- the need for lining with fireclay bricks;

- increased cost compared to simple solid propellant devices.