- Household pumping stations

- Automatic pumping stations

- Vortex

- Centrifugal

- Sewage pumping stations (SPS)

- Equipment selection criteria

- Device diagram

- Briefly about the device of the pumping station

- Water supply of apartments

- Specifications

- Choosing a location for a water supply station

- The main types of pipes that are used for water supply systems

- The principle of operation and the device of a pumping station for water supply with a hydraulic accumulator

- Pumping stations with built-in ejector - design description

- Scheme of connecting a pumping station to a well in the country

- How to calculate the volume of a hydraulic accumulator?

- Water purification

- Models

Household pumping stations

cottages

- self-priming;

- automatic.

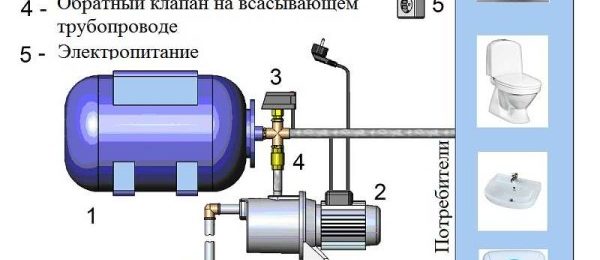

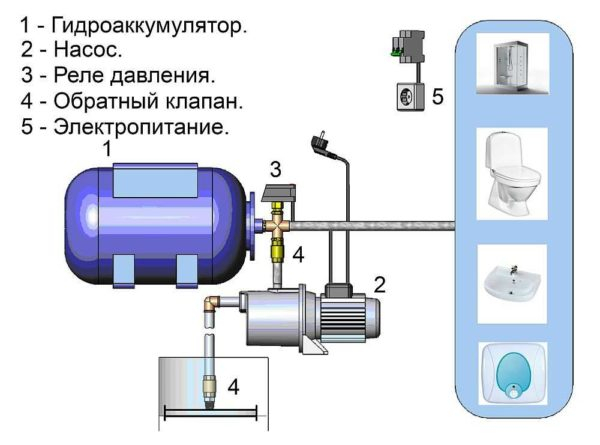

The composition of this type of household pumping stations includes:

- pump;

- hydraulic accumulator with a membrane tank;

- pressure switch.

Automatic pumping stations

In such pumping stations there is no membrane tank. The water pressure is electronically controlled. Separately, the installation of the necessary sensors is carried out. This makes the operation of the pump safer. The pump is fairly compact.

Briefly, the operation of an automatic pumping station is described as follows: the pump supplies the water it has previously pumped into the accumulator and is turned off.The pumped out water is used until the pressure in the accumulator drops to a certain fixed level. At this moment, the pressure switch sends a signal to the pump, it turns on, and the process repeats again.

new entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives makeSecrets of growing seedlings from the Japanese, who are very sensitive to the land

Also, all pumping stations are divided into 3 types:

Vortex

The pressure in such stations is formed by creating a large number of vortices. They are formed due to the work of the impeller. The disadvantage of this type of station is that initial pressure is required to start them. Such pumps are sensitive to fluctuations in atmospheric pressure, so they are installed indoors.

Centrifugal

It is thanks to the centrifugal wheel that the necessary pressure is created in centrifugal pumping stations. This pressure also lifts up water even from very big depth. Usually this type of station is used for wells. This station will be able to withstand temperature fluctuations in the water that it supplies.

Sewage pumping stations (SPS)

Such installations are considered rather cumbersome. They consist of a housing, and it includes several pumps, sensors and pipelines. As a rule, gravity sewerage is also quite enough. The price of a pumping station depends on the configuration and brand of its manufacturer.

Equipment selection criteria

Factory pumping stations are equipped with a surface-type pump. There are pumping systems that involve the use of submersible pumps.In their case, the storage tank may be smaller, since submersible pumps create more pressure in the system and turn on less often. To protect them, there is no need to install a large storage tank.

Let's analyze the device and the principle of operation of the pumping station. Surface pumps come with different injectors:

- The internal injector allows you to work with a depth of up to 8 meters, however, at the outlet, such designs are capable of creating a pressure of up to 6 bar. They are not afraid of air congestion and pump them along with water. Their disadvantage is the high noise of the working process, which makes it necessary to equip a soundproof box.

- The external injector works with a depth of up to 50 meters. Such products are economical, but give an efficiency of up to 40%. They are much quieter, but the output pressure leaves much to be desired.

Each homeowner independently chooses the type of pump depending on their needs and desired characteristics. The variety of offered pumping stations has a large selection. Here you can find any option that matches the features of your own water supply.

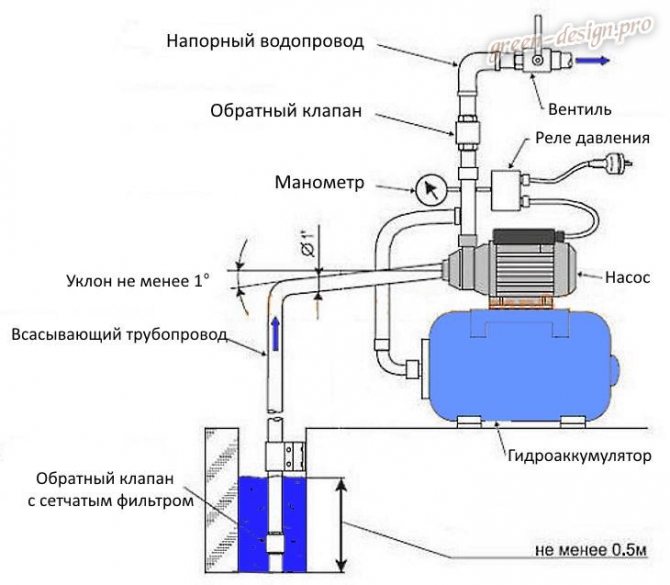

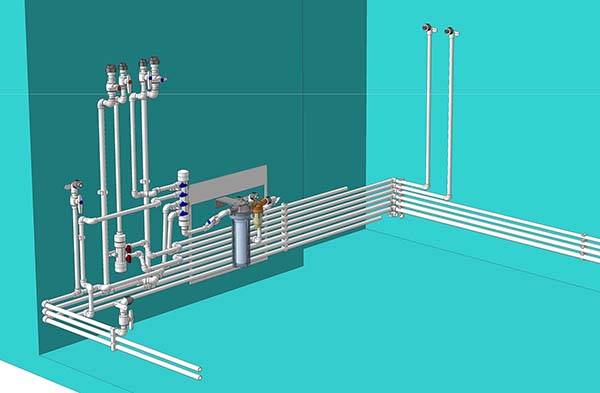

Device diagram

Different types of pumping stations for sewage differ from each other in design, but regardless of the modification, their main elements are a pump and a sealed tank in which waste products are collected. The tank with which the sewer pumping station is equipped can be made of concrete, plastic or metal. The task of the pump, which is equipped with a sewer station, is to raise the wastewater to a certain level, after which they enter the storage tank by gravity.After the tank is filled, wastewater is pumped out of it and transported to the place of their disposal.

SPS device of the middle class

Often, the design scheme of a household sewage pumping station includes two pumps, while the second of them is a backup and is used in cases where the main one is out of order. Several pumps are mandatory equipped with sewage pumping stations serving industrial and municipal enterprises, characterized by a large volume of wastewater. Pumping equipment for SPS can be of various types. Thus, domestic sewage pumping stations are usually equipped with pumps with a cutting mechanism, with which the fecal matter and other inclusions contained in wastewater are crushed. Such pumps are not installed at industrial stations, since solid inclusions contained in the wastewater of industrial enterprises, getting into the cutting mechanism of the pump, can lead to its breakdown.

The device and connection of a small-sized SPS, located indoors

In private homes, mini sewage pumping stations are often installed, the pumps of which are connected directly to the toilet bowls. Such an aesthetically designed KNS (a real mini-system equipped with a pump with a cutting mechanism and a small storage tank) is usually installed directly in the bathroom.

Serial models of sewage pumping stations are equipped with polymer tanks that are buried in the ground, while the neck of such a tank for sewage pumping stations is located on the surface, which facilitates scheduled inspections, maintenance and repair of the tank, if necessary.The neck of the storage tank before the start of operation of the SPS is closed with a lid, which can be made of polymeric material or metal. The connection of such a tank to the sewer system, through which wastewater enters it, is carried out using nozzles. In order for wastewater to enter the storage tank evenly, a special bumper is provided in its design, and the water wall is responsible for ensuring that no turbulence occurs in the liquid medium.

KNS are divided by layout into horizontal (left) and vertical (right)

In equipping sewer pumping stations for a private house, there are control devices and automatic control mechanisms. Additional elements supplied by industrial sewage systems and installations for servicing the home sewer system include:

- a source that provides backup power to the equipment that is part of the SPS;

- pressure gauges, pressure sensors, elements of valves;

- equipment that provides cleaning of pumps and connecting pipes.

According to the design, KNS are with submersible pumps, dry design and multi-section

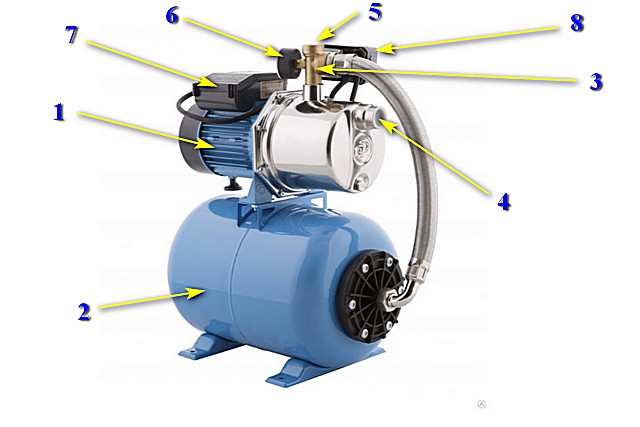

Briefly about the device of the pumping station

A ready-made pumping station equipped with the manufacturer is a mechanism for forced water supply. The way it works is extremely simple. The pump pumps water into the metal tank of the accumulator. The pressure, reaching a certain level, causes the pump to turn off.

During the intake of water, the pressure in the system drops, and at a certain moment, when the values \u200b\u200bset by the owner are reached, the pump starts working again. The relay is responsible for turning the device off and on, the pressure level is controlled using a pressure gauge.

Violations in the operation of a household pumping station can cause breakdowns of plumbing equipment

Water supply of apartments

To understand how apartments are supplied with water, you should consider the most popular connection schemes.

- Consistent water supply. Pipelines of hot and cold water, with this connection, run in parallel, so tees are used to connect various equipment. Consistent water supply does not require high costs, and water is supplied to users from a common main.

- Collector water supply. This connection scheme ensures constant pressure in the system, without drops and shutdowns. High pressure allows you to turn on plumbing fixtures at the same time, as separate pipes go to consumers. The collector circuit is considered quite expensive, and its installation requires knowledge, as well as a specialized tool.

Specifications

Regardless of the depth of the well (8.10, 15 or 20 meters), all pumping stations are divided into domestic and industrial. For a private house, household units are used. However, they may have different performance characteristics.

In order for your unit to meet the needs of the family in water, as well as the parameters of the hydraulic structure, it is necessary to pay attention to the following technical characteristics when choosing:

equipment power, measured in W;

device performance in cubic meters per hour (this characteristic is selected after determining the needs of residents for water);

liquid suction height or the maximum mark to which the pump can raise water (these characteristics depend on the depth of the water intake, for example, for wells with a depth of 15-20 meters, you need an aggregate with an indicator of at least 20-25 m, and for wells with a depth of 8 meters, a device with a value 10 m);

the volume of the accumulator in liters (there are units with a volume of 15, 20, 25, 50 and even 60 liters);

pressure (in this characteristic, it is necessary to take into account not only the depth of the water mirror, but also the length of the horizontal pipeline);

additional protective functions will not interfere (protection against "dry running" and overheating);

it is also important to consider the type of pump being used. For example, a submersible pump is mounted in a well, so it does not make noise during operation, but it is more difficult to repair and maintain it.

A surface-type unit is easier to maintain and repair, but makes more noise during operation.

To make it easier for you to choose a unit suitable for a country house, we give approximate technical characteristics of such a device:

the power of the device should be in the range of 0.7-1.6 kW;

depending on the size of the family, a station with a capacity of 3-7 cubic meters per hour will suffice;

lifting height depends on the depth of the well or well;

the volume of the hydraulic tank for one person is 25 liters, with an increase in family members, the volume of the storage tank should increase proportionally;

the choice of the device for the maximum pressure should be done taking into account the depth of the hydraulic structure, the length of the horizontal pipeline leading from the unit to the house, as well as the height of the house (if there are water consumption points on the upper floors: bathrooms or bathrooms);

well, if the device will have protection against "dry" operation

This is especially important for hydraulic structures characterized by unstable water levels. Then the pump will not be able to pump out all the water and run idle;

in addition, a surface-type pumping station will need protection against motor overheating

The thing is that in submersible units, the motor is constantly in the water, so it is effectively cooled. But the motor of a surface station can easily overheat and fail. To prevent this from happening, you need protection against overheating, which will work in time and turn off the pump.

Choosing a location for a water supply station

When choosing a location for a pumping station, it is necessary to focus on the characteristics of the hydraulic pump. Every ten meters of a horizontal pipe between the water source and the pump reduces its suction capacity by 1 m. If they are supposed to be separated by more than ten meters, then the model of the pump unit must be selected with an increased suction depth.

The automatic station of the autonomous water supply system can be located:

- on the street in a caisson near the well;

- in an insulated pavilion built specifically for pumping equipment;

- in the basement of the house.

The stationary outdoor option provides for the arrangement of a caisson and the laying of a pressure pipe from it to the cottage below the freezing level of the soil. When installing a year-round pipeline, laying it below the seasonal freezing depth is mandatory. When arranging temporary summer highways for the period of residence in the country, the pipeline is not buried below 40 - 60 cm or is laid on the surface.

If you install the station in the basement or basement, then you do not have to be afraid of the pump freezing in winter. It is only necessary to lay the suction pipe below the freezing line of the soil so that it does not freeze in extreme cold. Often a well is drilled right in the house, then the length of the pipeline is significantly reduced. But not in every cottage such drilling is possible.

Installation of water supply pumping stations in a separate building is possible only if the equipment is operated during a period of positive temperatures. However, for areas with very low winter temperatures, this option, designed to function all year round, needs to be insulated or a heating system installed. It is better to immediately mount the pumping station right in the heated house.

The main types of pipes that are used for water supply systems

The pipeline is one of the main elements of a quality water supply network. The material for pipes should be of high quality, with a long service life, and, if possible, anti-corrosion properties. The most common types of pipes are:

- Steel. Often used at the end of the last century, since at that time there were no difficulties in obtaining real steel.Steel pipes have one significant advantage - durability. The service life is quite long, with proper maintenance they can be used up to 20-30 years or more. The main disadvantage is the tendency of steel to corrosion.

- Copper. Expensive material, therefore, it is practically not used in modern pipelines. The service life of copper pipes is several times longer than that of steel products. Copper does not corrode and does not require frequent maintenance. In case of damage, copper pipes can be soldered. In addition to many positive qualities, this material is able to have a bactericidal effect on the transported liquid.

- Metal-plastic. Most often, metal-plastic pipes are used in modern pipeline laying. This product is easy to install and maintain. Plastic pipes are much cheaper than steel or copper pipes, they are lighter, they are easy to transport and install. They have a long service life if properly handled.

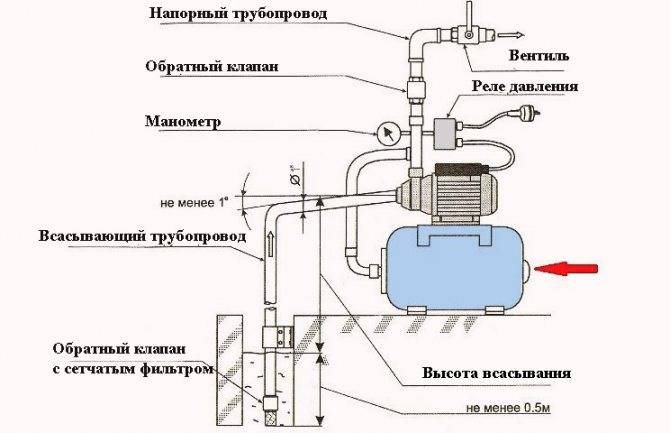

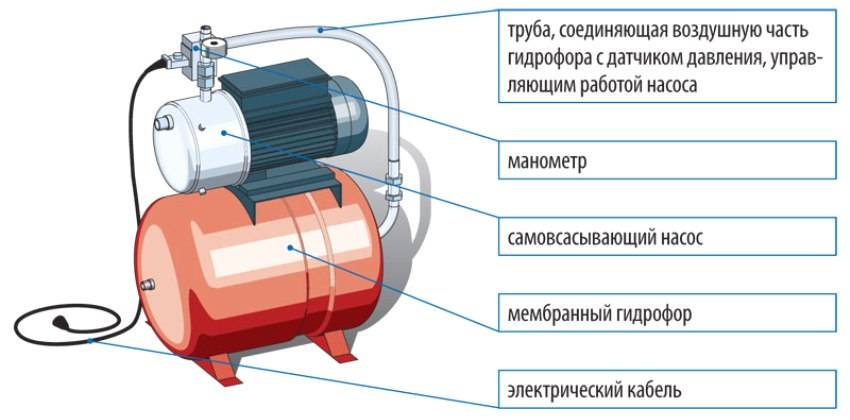

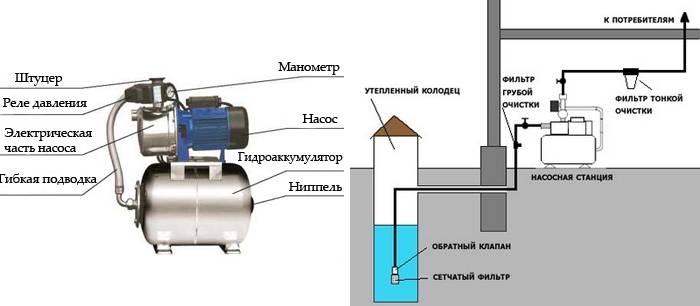

The principle of operation and the device of a pumping station for water supply with a hydraulic accumulator

All modern stations operate on this principle. Instead of a storage tank, a hydraulic accumulator is used here - a sealed container divided into two compartments by an elastic membrane. Moreover, air is pumped into the first compartment, and water is pumped into the second.

Pumping station with hydraulic accumulator

As a result, the more water in the second compartment, the higher the pressure at the outlet of the accumulator (the air behind the elastic membrane is compacted and begins to work as a shock absorber).Accordingly, it becomes possible to regulate the pressure in the home water supply even if the battery is placed in the basement of the building. The pressure in the conduit is provided by compressed air, which presses on the membrane.

And the filling of the accumulator is monitored by a special pressure sensor that turns the station pump on and off. This design eliminates the very possibility of leakage due to overfilling of the battery.

However, such a scheme also has disadvantages. The most important of which is a small amount of "reserve" of water. The capacity of a typical battery is 20-25 liters. For momentary needs, this is quite enough, but such a system can no longer serve a well with a small debit.

In addition, a hydraulic accumulator is a rather expensive product, because it operates under a sufficiently high pressure. Therefore, it is produced only from steel, which leads to another problem - the threat of destruction of the tank due to corrosion. However, this trouble is easily eliminated - the container can be made of stainless steel or galvanized.

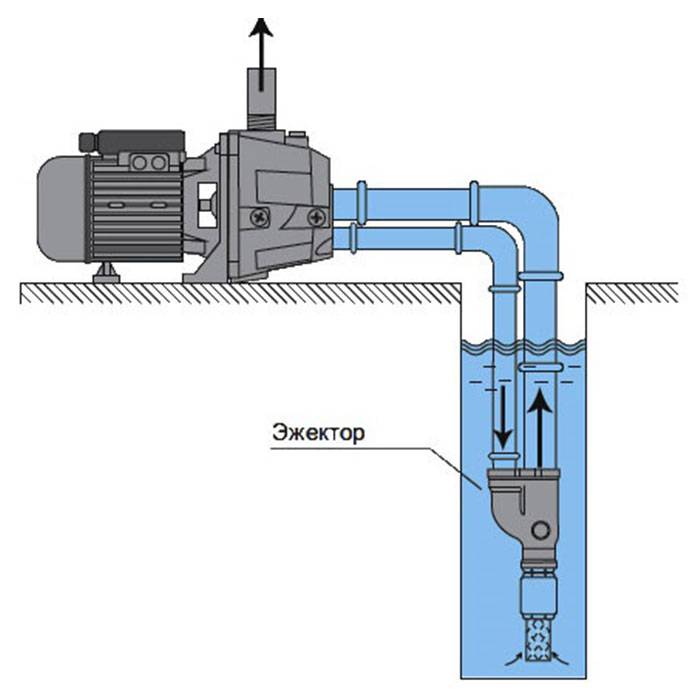

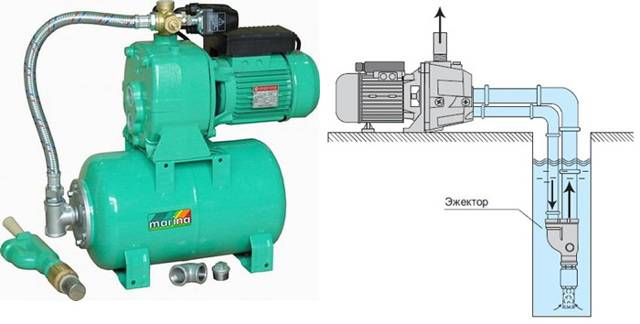

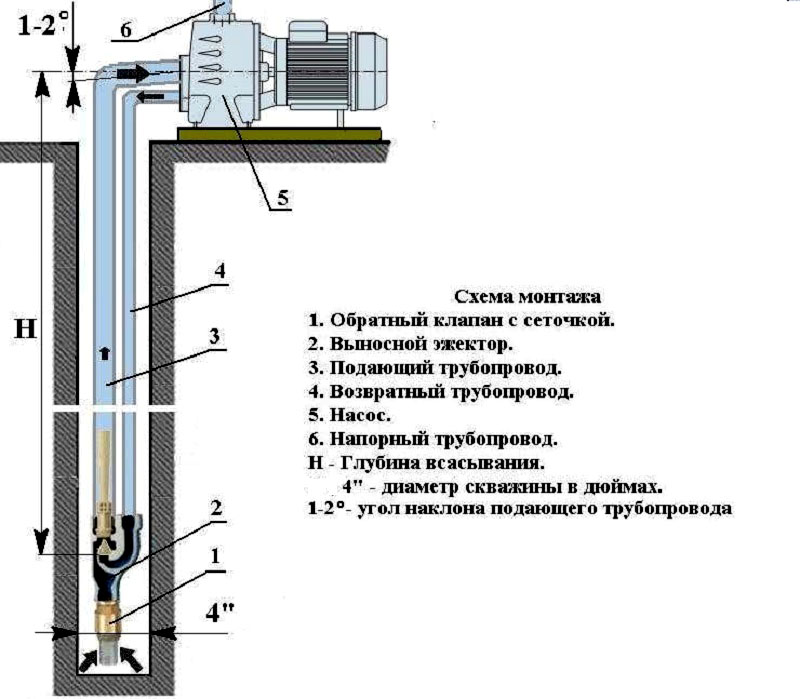

Pumping stations with built-in ejector - design description

Stations with an internal ejector can be equipped with both hydraulic accumulators and storage tanks. The design feature, in this case, lies in the design of the intake assembly of the pump itself.

Pump stations with built-in ejector

Water from the well rises through a pipe in which a vacuum is created. Moreover, the condition for transporting the liquid creates a special pump assembly - the ejector - pumping air through itself, “carbonated” water and, finally, 100% liquid. The air content in the liquid can reach up to 25 percent.

The pump connected to the built-in ejector is always centrifugal - it works on the impeller.The vibration analogue simply cannot withstand such volumes of air in the pipe. As a result, such a pump is very noisy during operation and pumps out water only from a well up to 10 meters deep. At the same time, a pump with a built-in ejector practically does not react to the presence of sand in the liquid.

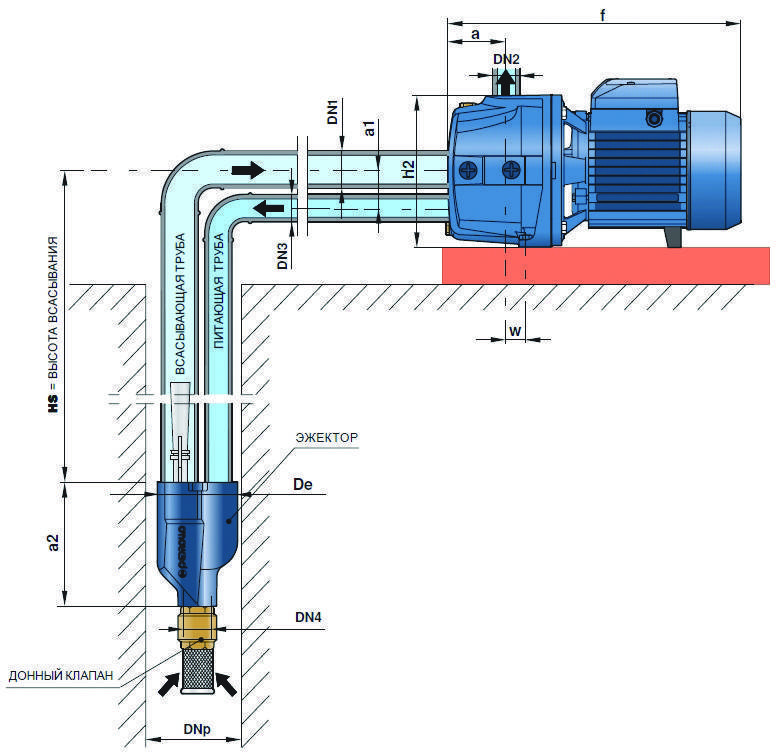

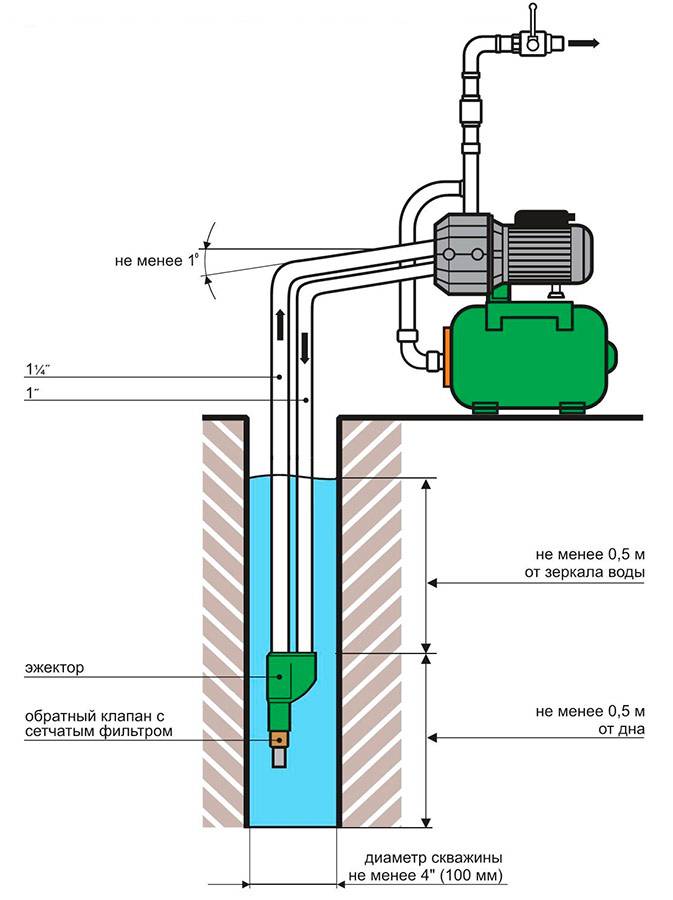

The principle of operation and design of stations with an external ejector Pumps with an external ejector differ from the above devices in the location of the intake unit. It is outside the pump housing. Moreover, two hoses are supplied to the external ejector - a vacuum one, in which a vacuum is created, and a pressure one, which creates a working pressure in the ejector.

Water rises along the vacuum "sleeve" and merges into the accumulator or flows into the discharge "sleeve". The pressure in the discharge sleeve is maintained by the pump and provokes, by means of an ejector, a vacuum in the vacuum pipe.

The remote intake unit (ejector) is serviced by a vibration pump, which is characterized by rejection of heavily polluted and “carbonated” water. However, since the ejector is buried below the well mirror, there are practically no problems with the latter. And from particles of sludge, the intake opening of the ejector will be protected by a filter grid.

The main advantage of such a design scheme lies in the practically unlimited depth of the serviced well. However, due to the structural features of the pump, most of the remote ejectors are submerged to the level of 60 meters. At the same time, the station with a remote intake unit works absolutely silently.

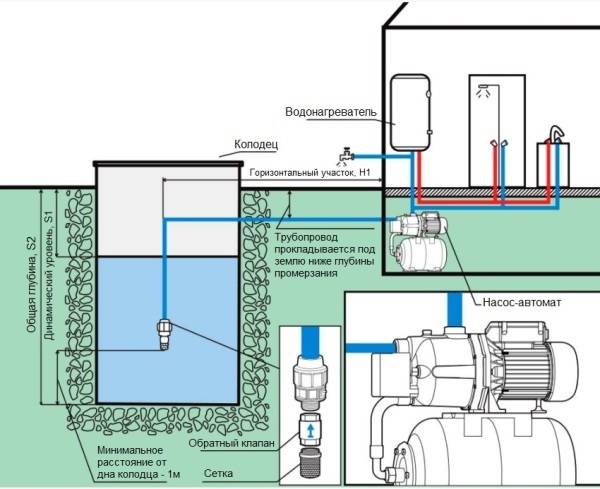

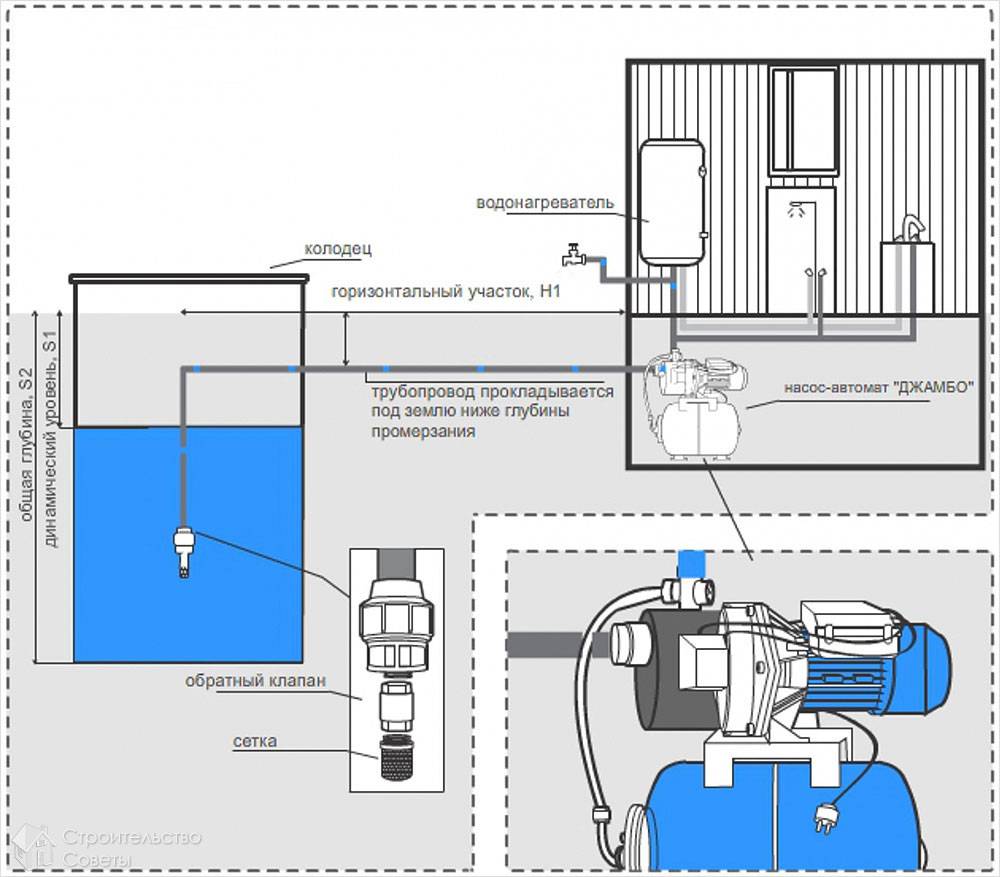

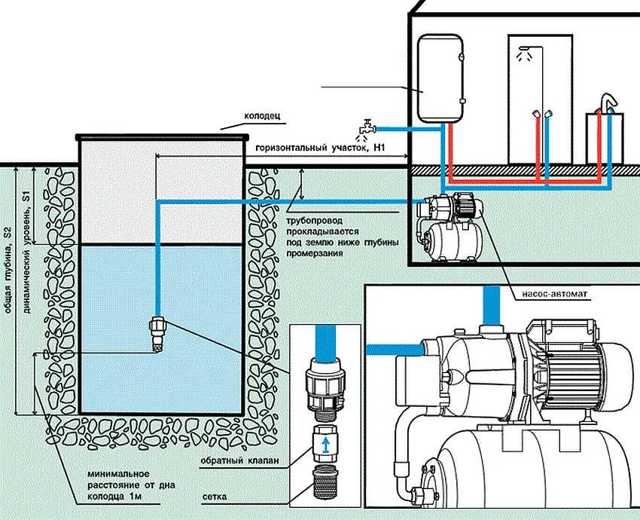

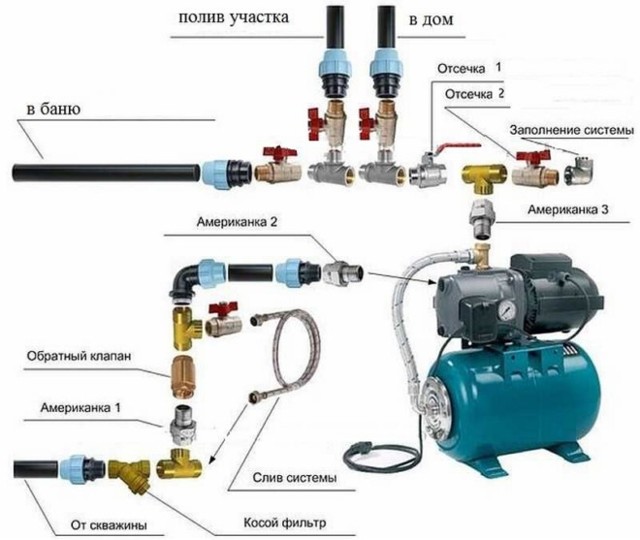

Scheme of connecting a pumping station to a well in the country

The pumping station can be placed inside the well, if there is a place for this, in addition, utility rooms are often allocated for it in the house itself or in the room

Pay attention to the depth at which the pipeline will be. The pipe must not only be insulated, but also placed below the freezing depth of the soil, so that during the cold season the water in it does not freeze

In order for the system to work correctly, you need to choose not only the type of pump, but also the depth at which it will work. The deeper the water source and the farther it is from the building, the more powerful the pump itself must be. There should be a filter at the end of the pipe, it is located between the pipe and the pump, protecting the latter from debris entering the mechanism.

Devices usually write at what depth they are designed, but it is worth taking a more powerful one, since the calculation is carried out only from the bottom of the well to its surface, not taking into account the distance to the building. It is easy to calculate: 1 meter of the vertical location of the pipe is 10 meters of its horizontal location, since it is easier to supply water in this plane.

Depending on the type and power of the pump, the pressure may be stronger or weaker. It can also be calculated. On average, the pump provides 1.5 atmospheres, but this is not enough pressure for the normal operation of the same washing machine or hydromassage, the water heater may require a higher temperature.

In order to control the pressure, the equipment is equipped with a barometer. Depending on the pressure parameter, the size of the storage tank is also calculated. Station performance also plays an important role. This parameter indicates how many cubic meters per minute the pump is capable of delivering.You need to calculate based on peak water consumption, that is, when all the taps in the house are open or several consumer electrical appliances are working. In order to calculate which pumping station is suitable for giving in a well, you need to know the performance. To do this, add up the number of water supply points.

From the point of view of power supply, it is more convenient to use those systems that are powered by a 22-volt network. Some stations operate 380 V phases, but such motors are not always convenient, because a three-phase connection is not available in every home. The power of a household station may vary, on average it is 500-2000 watts. Based on this parameter, RCDs and other devices are selected that will work in conjunction with the station. In order to prevent the design from overheating, many manufacturers install automation that will turn off the pumps in the event of an emergency load. The protection also works if there is no water in the source when power surges occur.

How to calculate the volume of a hydraulic accumulator?

The size of the tank determines how often the pump motor will turn on. The larger it is, the less often the installation works, which allows you to save on electricity, increase the resource of the system. Too large a hydraulic accumulator takes up a lot of space, so a medium-sized one is usually used. It holds 24 liters. This is enough for a small house in which a family of three lives.

Trailer work accumulator expansion tank

If up to 5 people live in the house, then it is better to install the tank at 50 liters, respectively, if more than 6, it should be at least 100 liters.It is worth noting that the standard tanks of many stations hold 2 liters, such a hydraulic tank can only cope with water hammer and maintain the required pressure, it is better not to save money and immediately replace it with a large one. It is the number of water users in the house that will determine which pumping station to choose for a summer residence.

Water purification

Do not forget that the water from the well, even if it is suitable for drinking, may have impurities, for example, sand, small stones, various debris can get into it, which can be disposed of using a special system for water purification. The most commonly used filters. They are placed outside so that it is convenient to change them. They can have different fractions and purify water to varying degrees. At the outlet, deep fine filters are used.

Models

- Gilex.

- Vortex.

- Ergus.

- Bison.

- gardena.

- Wilo SE.

- Karcher.

- Pedrollo.

- grundfos.

- Wilo.

- Poplar.

- Unipump.

- Aquario.

- Aquarius.

- Biral.

- S.F.A.

- Vortex.

- waterstry.

- Zota.

- Belamos.

- Pedrollo.

Before choosing a pumping station for a summer residence with a well, it will not be superfluous to find out how things are with the maintenance of the products of the selected manufacturer, are there any nearest dealers who can provide spare parts.