- Popular Models

- Selection of the volume of the accumulator

- Types of hydraulic tanks for water supply systems

- Operating recommendations

- The principle of operation of the system without a hydraulic tank

- Hydraulic accumulator device

- Types of hydroaccumulator tanks

- Choice for home environment

- Types of structures and their device

- Advantages and disadvantages of pumping stations with a hydraulic accumulator

- Repair and prevention of the hydraulic accumulator

- Causes of breakdowns and their elimination

- Possible malfunctions

- Conclusions: which accumulator is best

Popular Models

In today's market, there are many different models of hydraulic accumulators. However, among them there are the most popular devices for a private home.

| Name | Characteristics | Price |

| AQUABRIGHT GM-80 V | Tank for 80 liters made in Russia, working pressure is 10 atmospheres, maximum temperature is 99 degrees | 3 500 rubles |

| Ultra-Pro vertical (Zilmet) | The tank with a volume of 100 liters has a reinforced membrane that can work with aggressive water compositions. Working pressure up to 10 atmospheres, maximum temperature - 99 degrees, vertical arrangement. | 12 000 rubles |

| Hydraulic accumulator SPERONI AV 100 | The storage capacity is 100 liters, the maximum allowable pressure is 10 atmospheres, the maximum temperature is 99 degrees.This model is available in horizontal and vertical versions. The membrane is made of high-strength food rubber. | 14 400 rubles |

| Hydraulic accumulator vertical Dzhileks pl./fl. 100l. | Tank with a capacity of 100 liters and a working pressure of up to 9 atmospheres. It is characterized by high quality and durability at a low cost. Possesses a reliable membrane. The flange is made of plastic. | 5 400 rubles |

| Hydraulic accumulator VCF-36L, vertical | Small capacity tank, designed to be used in tandem with low power pumps. Tank volume - 36 liters, working pressure up to 8 atmospheres. Characterized by high quality material and durability. | 4 000 rubles |

This rating is indicative and based on popularity among consumers.

Selection of the volume of the accumulator

However, given the price, there is no need to overpay extra money for additional capacity. For these purposes, special plastic tanks are designed that are built into the water supply system.

Moreover, if in the future it is planned to increase consumption points, you can buy an additional hydraulic tank. Their total volume will be summed up. For example, if two devices of 40 and 80 liters are installed in the system, then the total working power will be 120 liters.

Types of hydraulic tanks for water supply systems

Hydraulic accumulators available on the market, the principle of operation of which is the same, are divided into several types according to a number of features and functional features. First of all, according to the installation methods, they distinguish:

- Horizontal - used for large volumes of water. It is somewhat more difficult to operate due to the low location of the neck (you have to completely drain the water to change or inspect the working membrane or spool).

- Vertical - used for small and medium volumes. Easier to operate, since there is no need to completely drain the water and dismantle part of the piping, as is the case with horizontal tanks.

According to the temperature of the working fluid, hydraulic tanks are:

- For hot water - a heat-resistant material is used as a material for the membrane. Most often it is butyl rubber. It is stable at water temperatures from +100-110 degrees. Such tanks are visually distinguished by red color.

- For cold water - their membrane is made of ordinary rubber and cannot work stably at temperatures above +60 degrees. These tanks are painted blue.

Rubber for both types of accumulators is biologically inert and does not release any substances into the water that spoil its taste or harm human health.

According to the internal volume of hydraulic tanks there are:

- Small capacity - up to 50 liters. Their use is limited to extremely small rooms with a minimum number of consumers (in fact, this is one person). In the version with a membrane or hot water cylinder, such devices are often used in closed-type heating systems.

- Medium - from 51 to 200 liters. They are used exclusively for hot and cold water supply. They can give water for some time when the water supply is turned off. Versatile and reasonably priced. Ideal for houses and apartments with 4-5 residents.

- Large volume from 201 to 2000 liters. They are able not only to stabilize the pressure, but also to provide consumers with a supply of water for a long time in the event that its supply from the water supply is turned off. Such hydraulic tanks have large dimensions and weight. Their cost is also great.They are used in large buildings such as hotels, educational institutions, sanatoriums and hospitals.

Operating recommendations

After the accumulator is installed, it must be properly maintained. About one should be checked once a month pressure switch settings and adjust them if necessary. In addition, it is necessary to check the condition of the housing, the integrity of the membrane and the tightness of the connections.

The most common failure in hydraulic tanks is a rupture of the membrane. Constant cycles of tension - compression over time lead to damage to this element. Sharp drops in pressure gauge readings usually indicate that the membrane has torn, and water enters the “air” compartment of the accumulator.

To make sure there is a breakdown, you just need to bleed all the air from the device. If water flows out of the nipple after it, then the membrane definitely needs to be replaced.

Luckily, these repairs are relatively easy to make. For this you need:

- Disconnect the hydraulic tank from the water supply and power supply.

- Unscrew the bolts that hold the neck of the device.

- Remove damaged membrane.

- Install a new membrane.

- Assemble the device in reverse order.

- Install and connect the hydraulic tank.

At the end of the repair, the pressure settings in the tank and the pressure switch should be checked and adjusted. The connecting bolts must be tightened evenly to prevent warping of the new diaphragm and to prevent its edge from slipping into the tank housing.

Replacing the accumulator diaphragm is relatively easy, but care must be taken to ensure that the new diaphragm is the same as the old one.

To do this, the bolts are installed in the sockets, and then literally a couple of turns of the first bolt are alternately made, move on to the next one, etc. Then the membrane will be pressed against the body equally around the entire circumference. A common mistake newcomers make to repairing a hydraulic accumulator is the incorrect use of sealants.

The installation site of the membrane does not need to be treated with a sealant, on the contrary, the presence of such substances can damage it. The new membrane must be exactly the same as the old one in both volume and configuration. It is better to first disassemble the accumulator, and then, armed with a damaged membrane as a sample, go to the store for a new element.

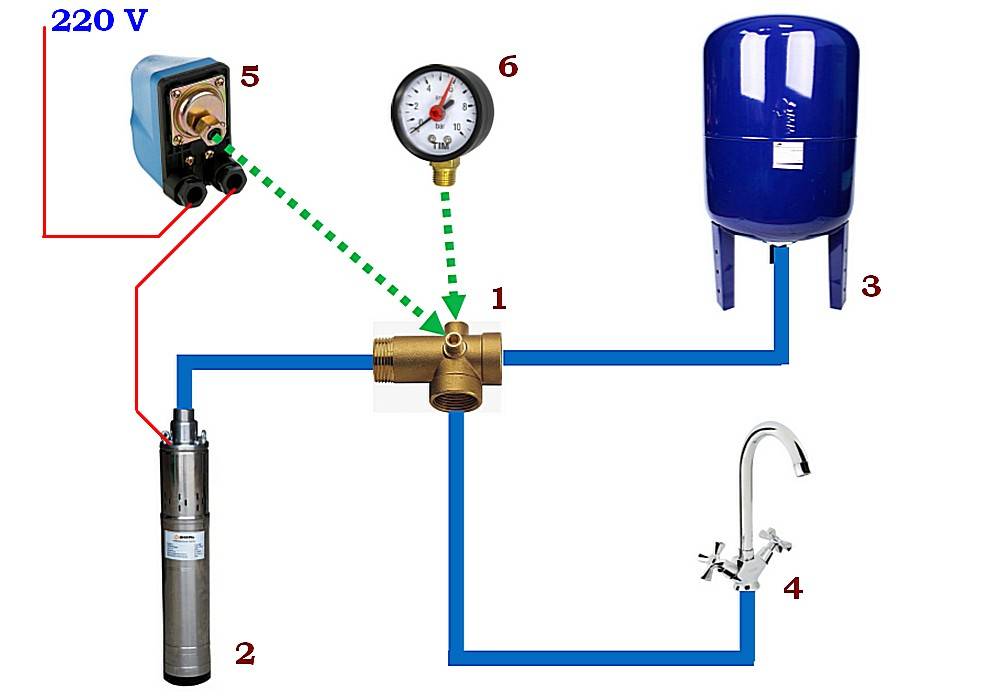

The principle of operation of the system without a hydraulic tank

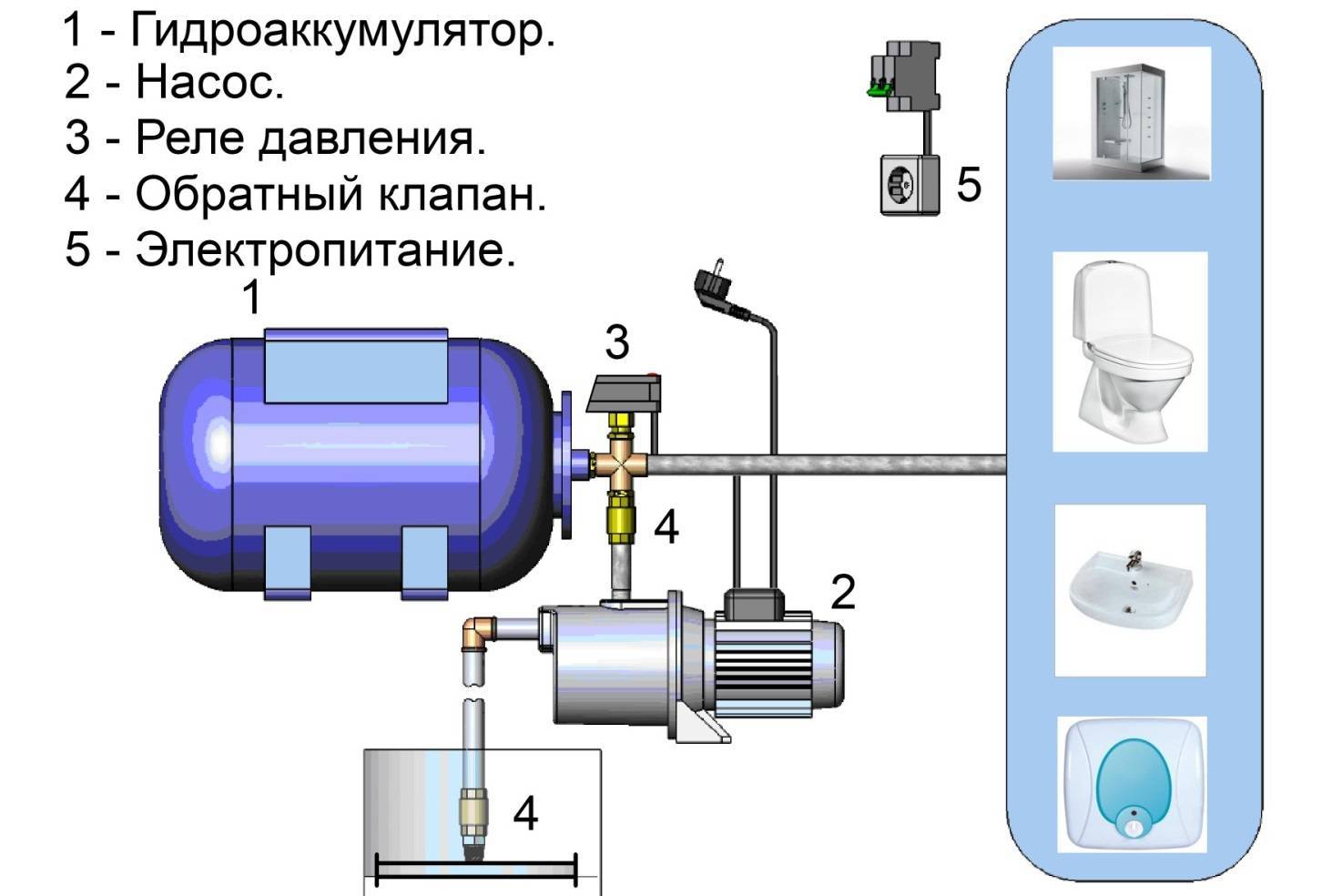

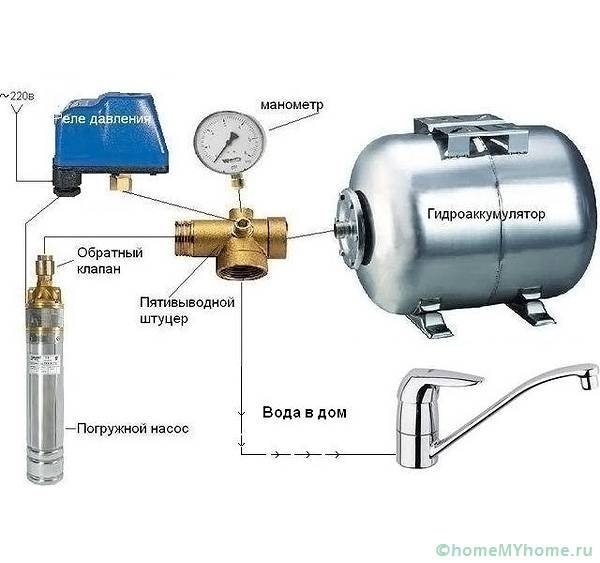

The equipment that pumps water works the same way: it takes liquid from a source - a well, a well - and pumps it into the house, to the points of water intake. The pump can be both submersible and surface.

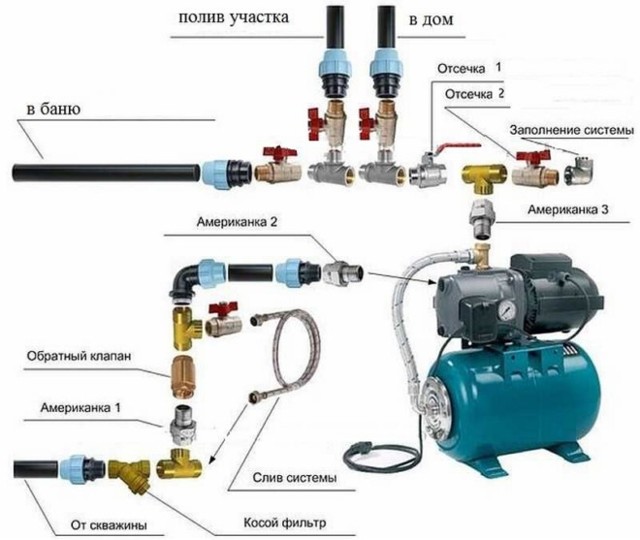

The role of connecting lines is performed by pipelines made of polypropylene pipes or flexible hoses. In the same way, water is supplied to the bathhouse, garage, summer kitchen, swimming pool.

So that water can be used in autumn or early spring, it is recommended to insulate the well, and bury the pipes to a depth of 70-80 cm - then the liquid will not freeze even during frosts

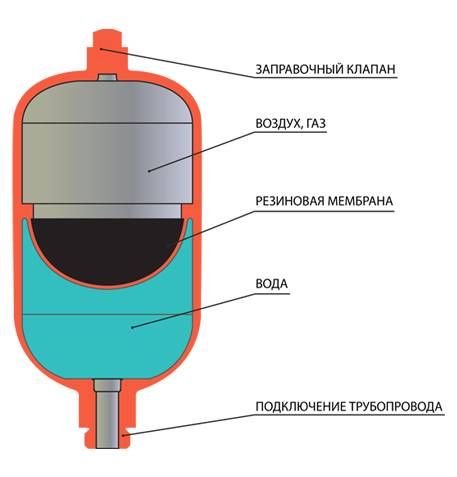

The difference concerns the use of additional devices, such as a hydraulic accumulator, a pressure switch, etc. It is extremely dangerous to install pumping equipment without means of control and adjustment - primarily for the equipment itself.

The simplest example of equipment for providing residents of summer cottages with water in the summer is a garden AL-KO pump. With it, you can water the plants, organize a shower, fill the pool with water

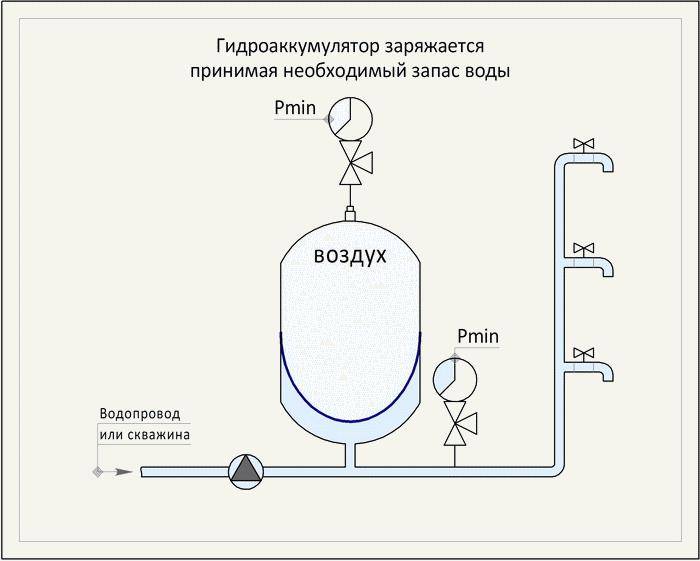

If you need a large amount of water or a more stable supply, another important element is included in the circuit - a storage tank. First, water enters it, and only then - to consumers.

When using domestic pumps, the liquid volume is usually between 2 and 6 m³/h. This amount is usually enough if the station is connected to a well or well and serves a country house.

The pump functions are controlled by a pressure switch responsible for adjusting the pressure. For control, it is easiest to install a pressure gauge, which is usually equipped with automation of pumping stations.

With absence accumulator pressure switch connected directly to the pumping station or integrated into the pipeline together with a dry-running relay

In addition to equipment for pumping water, you will need an electrical cable, a mains connection point and ground terminals. If the ready-made solution does not meet the requirements, the station parts can be purchased separately, and then assembled at the installation site. The main condition is the correspondence of the elements of the system according to the characteristics.

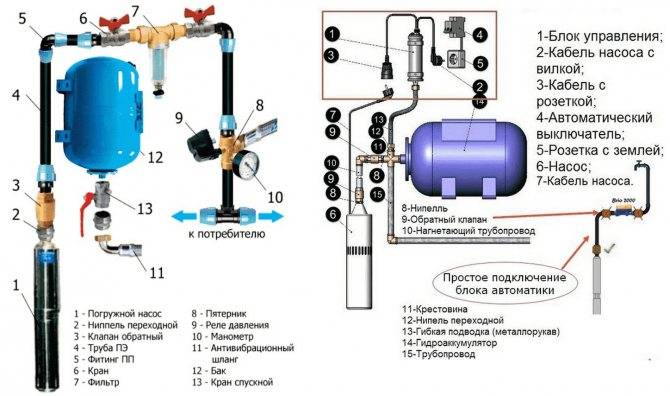

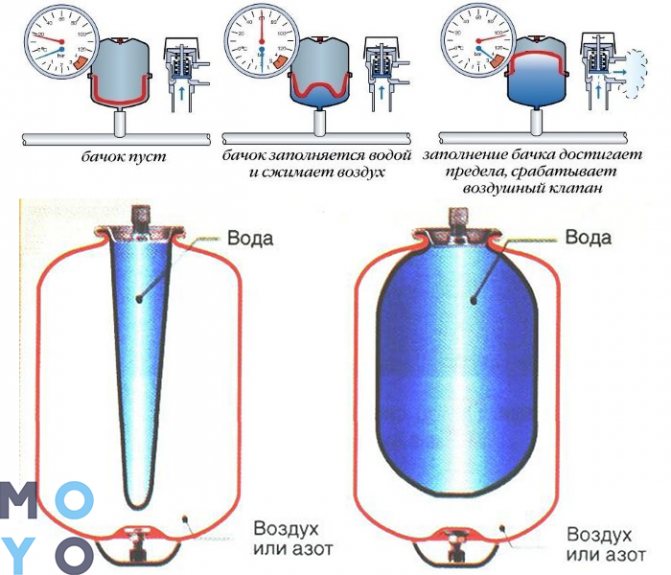

Hydraulic accumulator device

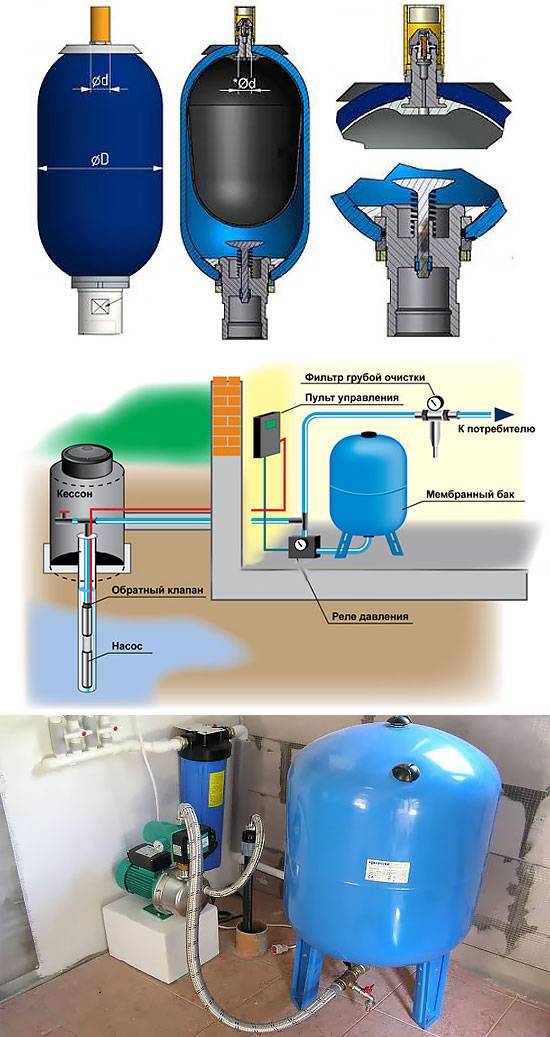

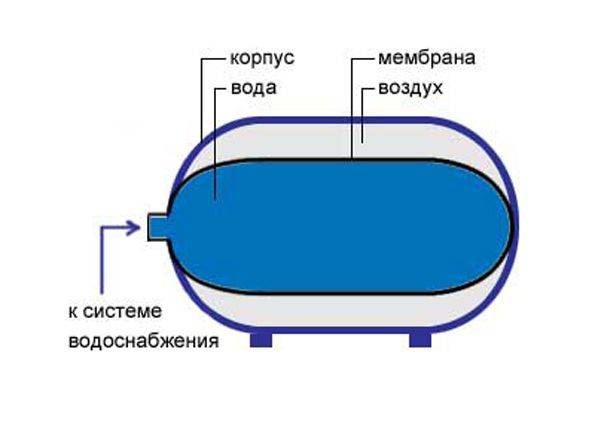

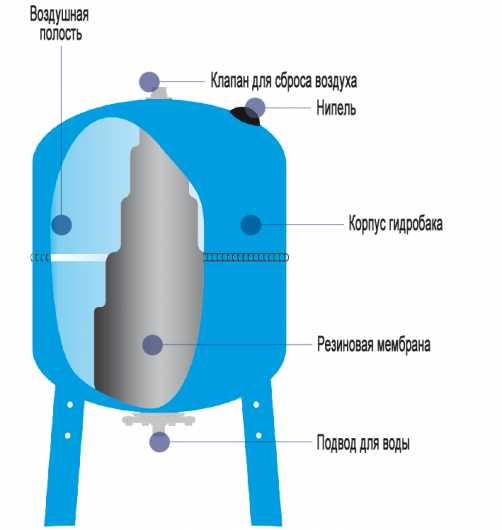

The device of a standard hydraulic accumulator with a replaceable membrane (the most common type) is quite simple. Inside the accumulator there is an elastic membrane of spherical or pear-shaped form.

In operating mode, there is water inside the membrane, and between the walls of the tank and the membrane there is pre-pressurized air or other gas (the pre-injection value is indicated on the label). Thus, water does not come into contact with the walls of the accumulator, but only with the membrane, which is made of a material suitable for contact with drinking water.

The neck of the membrane remains outside the body of the accumulator and is securely attracted to it by a removable steel flange using screws. Thus, the membrane is removable and can be replaced with a new one without much effort.

All hydraulic accumulators have a nipple in their design (as in a car wheel), which is directly connected to the air cavity of the tank. Through this nipple you can adjust air pressure inside the tankusing a conventional air pump or compressor.

The nipple is located under a protective plastic cap, which is easily unscrewed by hand.

It is important to note that for many manufacturers, membranes in accumulators with a volume of 100 liters or more are attached not only from below (through the flange), but also from above. A special hollow rod passes through the hole in the upper part of the membrane (yes, in addition to the neck, the membrane will have one more hole in the upper part), with a sealing element at one end and a thread at the other

The threaded end is brought out of the tank and is attracted to the latter by a nut. In fact, the part brought out is a threaded fitting. This threaded fitting can be simply plugged, or installed on it pressure switch and/or pressure gauge.

In this case, the accumulator (as well as the membrane to it) will be called a through passage.

Hydraulic accumulators come in vertical and horizontal versions. Vertical tanks are installed on legs, while horizontal tanks are on legs and have a platform for installing additional equipment. Equipment (pump, control cabinet, etc.). The fundamental point for choosing the layout is the specific installation location.

Types of hydroaccumulator tanks

Hydraulic accumulators differ in the type of installation: they are horizontal and vertical. Vertical accumulators are good because it is easier to find a suitable place for their installation.

Both vertical and horizontal varieties are equipped with a nipple. Together with water, a certain amount of air also enters the device. It gradually accumulates inside and “eats” part of the volume of the hydraulic tank. In order for the device to work properly, it is necessary to bleed this air from time to time through this same nipple.

According to the type of installation, vertical and horizontal hydraulic accumulators are distinguished. They have some differences in the maintenance process, but the choice is largely influenced by the size of the installation site.

In hydraulic accumulators that are installed vertically, a nipple is provided that is designed specifically for this purpose. Just press it and wait for the air to leave the device. With horizontal tanks, things are a little more complicated. In addition to the nipple for bleeding air from the tank, a stopcock is installed, as well as a drain to the sewer.

All this applies to models capable of accumulating a liquid volume of more than 50 liters. If the capacity of the model is less, then there are no special devices for removing air from the membrane cavity, regardless of the type of installation.

But the air from them still needs to be removed. To do this, water is periodically drained from the accumulator, and then the tank is refilled with water.

Before starting the procedure, turn off the power supply to the pressure switch and the pump, or the entire pumping station if the hydraulic tank is part of such a device.After that, you just need to open the nearest mixer.

The water is drained until the container is empty. Next, the valve is closed, the pressure switch and the pump are energized, the water will fill the tank of the accumulator in automatic mode.

Hydraulic accumulators with a blue body use for cold water, and red - for heating systems. You should not use these devices in other conditions, since they differ not only in color, but also in the material of the membrane, and the ability to tolerate a certain level of pressure.

Usually, tanks intended for autonomous engineering systems differ in color: blue and red. This is an extremely simple classification: if the hydraulic tank is blue, then it is intended for cold water systems, and if red - for installation in the heating circuit.

If the manufacturer has not designated its products with one of these colors, then the purpose of the device should be clarified in the technical data sheet of the product. In addition to color, these two types of accumulator differ mainly in the characteristics of the material used in the manufacture of the membrane.

In both cases, it is a high quality rubber designed for food contact. But in blue containers there are membranes designed for contact with cold water, and in red ones - with hot water.

Often the hydraulic accumulator is supplied as part of the pumping station, which is already equipped with a pressure switch, pressure gauge, surface pump and other elements

Blue devices are capable of withstanding higher pressures than red containers. It is not recommended to use accumulators designed for domestic hot water systems for cold water and vice versa.Incorrect operating conditions will lead to rapid wear of the membrane, the hydraulic tank will have to be repaired or even completely replaced.

Choice for home environment

Multistage pump with hydraulic accumulatorThe pump is the main component of the plant.

Its performance should provide not only an effective intake from the source to the house, but also sufficient supply to moisten the soil, fill swimming pool and other household affairs.

When buying a pump, the buyer is required to understand at what depth of the source this installation should be designed.

Expert tip: For springs up to 9 meters deep, the best and most economical option is a self-priming pump.

This category of systems is divided into two types:

- single stage;

- multistage.

The latter is distinguished by a high level of noise insulation and its efficiency in terms of energy costs, while maintaining its characteristics and work efficiency.

Types of structures and their device

Depending on the pump used and the location of the pumping station, horizontal and vertical hydraulic accumulators are used in everyday life.

Such types of molding allow you to fit them into the space of any technical room. It is necessary to install the unit with the expectation of its convenient maintenance. It is necessary to provide access for repairs and, if necessary, draining water.

It is most rational to connect horizontal hydraulic tanks to external pumps, and vertical ones to submersible ones, but in any case, the final decision must be made on site, depending on the parameters of the entire system.

There are no fundamental differences in the operation of the units.The difference is in the method of bleeding off excess air that accumulates during operation in the plumbing system. With large volumes of water passing through the storage tank, dissolved air is released from it. It can create air pockets and hinder system operation.

In designs with a vertically located cylinder, the opening with the valve is located in the upper part of the unit, because air collects at the top of the cylinder. In horizontal hydraulic tanks, there is usually no such device. Additional installation of the pipeline from the ball valve, drain pipe and nipple is required.

Storage tanks up to 100 liters do not have air venting devices. Excess gas is removed after the water is completely drained.

Advantages and disadvantages of pumping stations with a hydraulic accumulator

If we talk about the advantages that a pump with a hydraulic accumulator has, then the most significant of them usually include the following.

- In water pipes served by pumping stations with a hydraulic accumulator, which is always full, a constant supply of water is ensured.

- A hydraulic accumulator for a pumping station, the main structural element of which is a membrane that creates the required pressure of the liquid medium in the system, ensures the supply of water to the pipeline even when the pump is not operating. However, water will flow into the pipeline when the pump is not working only until it runs out in the tank of the hydraulic tank.

- The use of a hydraulic accumulator eliminates such a negative phenomenon as water hammer in the pipeline system.

- Water pumps operated in conjunction with a hydraulic tank have a longer service life, as they operate in a more gentle mode, turning on only at those moments when the fluid level in the accumulator drops to a critical level.

For any water supply system, you can choose the right accumulator

Among the shortcomings pumping stations with a hydraulic tank highlight the following:

- It is necessary to allocate a decent area for the installation of such equipment, which is explained by the large dimensions of the accumulator.

- If the pressure switch fails, the site on which such equipment is installed will be flooded with water.

- The features of the hydraulic tank device imply the need for regular (once every 2-3 months) bleeding of air from its tank, which ensures the efficiency of such equipment (the hydraulic accumulator device requires a special valve for this procedure).

Repair and prevention of the hydraulic accumulator

Even the simplest hydraulic tanks require attention and care, like any device that works and benefits.

The reasons for repairing a hydraulic accumulator are different. These are corrosion, dents in the body, violation of the integrity of the membrane or violation of the tightness of the tank. There are also many other reasons that oblige the owner to repair the hydraulic tank. In order to prevent serious damage, it is necessary to regularly inspect the surface of the accumulator, monitor its operation in order to prevent possible problems. It is not enough to inspect the GA twice a year, as stipulated in the instructions

After all, one malfunction can be eliminated today, and tomorrow not to pay attention to another problem that has arisen, which over the course of six months will turn into an irreparable one and can lead to the failure of the hydraulic tank. Therefore, the accumulator must be inspected at every opportunity, so as not to miss the slightest malfunctions, and to repair them in time.

Causes of breakdowns and their elimination

The reason for the failure of the expansion tank may be too frequent switching on / off of the pump, water outlet through the valve, low water pressure, low air pressure (lower than calculated), low water pressure after the pump.

Troubleshooting do-it-yourself hydraulic accumulator? The reason for repairing the accumulator can be low air pressure or its absence in the membrane tank, damage to the membrane, damage to the housing, a large difference in pressure when the pump is turned on and off, or an incorrectly selected volume of the hydraulic tank.

Troubleshooting can be done as follows:

- to increase the air pressure, it is necessary to force it through the tank nipple with a garage pump or compressor;

- a damaged membrane can be repaired at a service center;

- the damaged case and its tightness are also eliminated in the service center;

- you can correct the difference in pressure by setting too large a differential in accordance with the frequency of switching on the pump;

- The sufficiency of the tank volume must be determined before it is installed in the system.

Possible malfunctions

During the operation of the accumulator, many problems can arise, and it is necessary to know how to eliminate each of the malfunctions. To do this, it is necessary to take into account the reasons that can lead to such troubles.

- In case of malfunctions in the operation of the pumping unit, when it often turns on and off, the matter may be in the membrane. In this case, it is recommended to test its integrity and, in which case, replace it with a new one, having previously dried the metal case of the tank well.

- The occurrence of a leak near the pneumatic valve, through which air can be bled or the tank can be filled, is also associated with a violation of the integrity of the membrane. As in the previous case, the membrane must be replaced.

- There can be several reasons for too low valve pressure. The simplest thing is the insufficient thickness of the air gap. In this case, you only need to add a little air inside the hydraulic tank. The second reason is more serious. If the part through which the air escapes is broken, you will have to replace it. It may be necessary to carry out welding work.

- A leak in the pipe that comes from the pump may occur due to loss of tightness. In this case, try to tighten the flange a little tighter so that it fits snugly. If this does not help, it is recommended to completely replace the parts.

- If the pressure in the tap is uneven, despite the presence of a hydraulic tank, then the matter may be in the elastic cavity. Conduct a full inspection of it, test it several times. If you still have doubts about its tightness, then replace the existing part with a new one.

- Weak pressure is by no means connected with the membrane, but with the fact that your pump may not work correctly or even be faulty. Be sure to check the pump for operation. Repair it if a problem is found. The second reason may be the wrong choice of the volume of the accumulator. In this case, there is only one way - replacing the hydraulic tank with a suitable one.

Conclusions: which accumulator is best

In addition to the technical selection criteria discussed above, we will give a few more considerations regarding the quality of the accumulator materials.

Removable flange in the cylinder is usually made of stainless or galvanized steel

When buying, be sure to pay attention to this. If over time you cannot do without replacing the flange, specify where and for how much it can be bought

If tap water is intended for drinking, you need to make sure that the material from which the “pear” of the accumulator is made is safe for health. Well-known manufacturers guarantee the quality of the material, which cannot be said about small, little-known companies. True, it does not matter if such water is not supposed to be drunk. Otherwise, the choice is made on the basis of specific operating conditions: the required volume of water, pressure, optimal operation of the pump, the necessary water reserve in case of emergency shutdowns, installation conditions.