- 5 Overview of gas water heaters

- Principle of operation

- Model Features

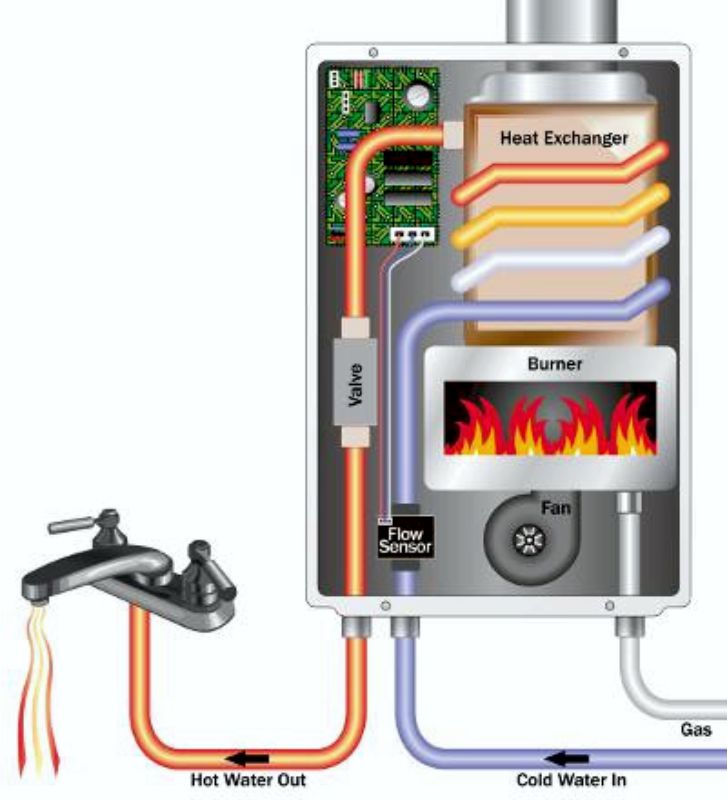

- How it works

- Operating principle

- The most common breakdowns

- Classification

- Internal details of the column, their purpose

- What is the device of the water heater

- Unit device

- Device device outside

- The internal structure of the unit

- The column does not ignite initially

- How to replace the membrane

- Number 3. Boiler lining

5 Overview of gas water heaters

Modern columns, regardless of the manufacturer and type of ignition, have common working units: gas; water connection; smoke exhaust; electrical appliances.

But the inclusion of water heating equipment, depending on the manufacturer and model, may differ to varying degrees:

- Bosch units. Equipment from the German company Bosch is characterized by intuitive operation. Models equipped with electric ignition are identified by the letter "B". In order to turn on the Bosch geyser, it is necessary to open the gas valve and supply water. You should also check the batteries for 1.5 volts and type "R". On the front panel of the unit there is a button, thanks to which you can light the Bosch geyser.

- Neva.Apparatuses from the domestic company "Neva" are produced already fully tuned to a certain gas pressure and type of fuel. And if in order to light the Bosch column, you just need to press a button, then here the situation is different. To begin with, you will have to install LR20 batteries in a special compartment. Further, all available toggle switches are turned on at a minimum. And also opens the water and gas valve. The control knob on the front panel is moved to the ignition position, after which it is sunk to the maximum. And after that, the start button is turned on.

- Models from Astra. The equipment from this company is not very convenient, because before using the column, you will have to move the special handle to the left, press and hold the start button for 5 seconds, set fire to the igniter. But the main inconvenience is that here the burner is located under the central fitting.

- Systems from Junkers. The launch of systems from this company may differ depending on the marking. So, if the column is equipped with piezo ignition, it will be denoted by the letter "P". Automatic models are ignited by batteries and are marked "B". If “G” is found in the model, then such heaters have a fully automatic Hydro Power system, that is, a built-in hydrodynamic generator.

The instructions supplied with such equipment may not always answer your questions. Therefore, when purchasing a column, it is preferable to ask the seller about everything, as well as to consult what and in what cases the equipment will be most effective and useful.

Principle of operation

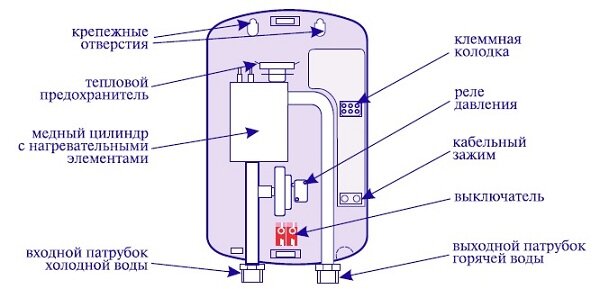

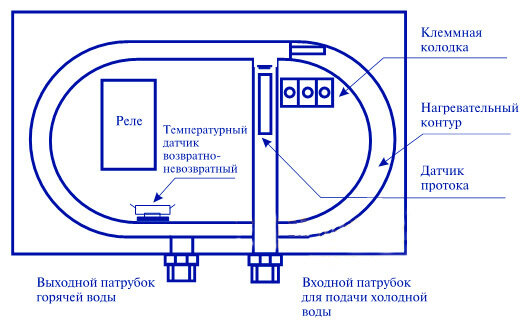

Since the flow boiler operates with high power, reliable wiring is required for connection.A standard connection is made with a three-core cable, where L is a phase, N is zero, E is ground.

After turning on the equipment, electricity is supplied to the flow sensor. If the water pressure in the system is sufficient, the sensor closes the contacts. After that, the heating element relay is activated, and heating starts. Thermal sensors turn on in case of overheating. The circuit is completed by a light on the panel that lights up when the boiler is running.

Here is a detailed diagram of the device device:

Model Features

Models of different brands may differ according to several criteria.

Heating element type:

- Open - consists of a plastic case with a spiral inside. When power is applied, the coil heats up and transfers heat to the passing stream.

- Closed - the principle of operation is the same, only the spiral is enclosed in a case made of brass or copper. It is more fireproof.

Control:

- Mechanical (hydraulic) type. It is adjustable with a switch and has 6 power modes. The system consists of a block and a membrane that, when flowing, shifts and pushes the shutdown button. The downside of mechanics is inaccuracy - it may not work with insufficient pressure.

- Electronic type. Contains microprocessor and sensors. This precise system allows you to maintain the set temperature, as well as adjust the power to save energy.

Varieties:

- Closed type (pressure). Provides high pressure pipes to serve multiple draw points. You will be able to use the shower and faucet in the kitchen at the same time. In this case, the water temperature will not decrease.

- Open type (non-pressure). Connected to one point of the fence. They have a compact body, so they can be installed separately on a faucet or shower.

How it works

The flow model differs from the storage boiler in that there is no tank for accumulating hot water in the design. Cold water is directly supplied to the heating elements and comes out already heated through a mixer or faucet.

Consider the example of a Termex instantaneous water heater device:

As you can see, the electrical circuit of the heater is quite simple. All structural elements can be easily found and purchased if the device fails.

Now let's move on to the second, no less important issue - consider how a tankless water heater works.

Operating principle

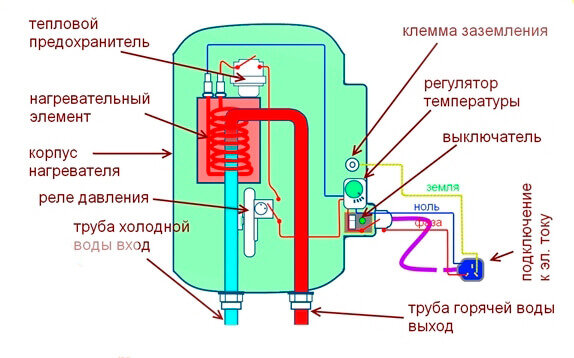

So, using the example of the Termex heater provided above, we will consider its principle of operation.

Connection to the mains is carried out with a three-core cable, where L is a phase, N is zero, and PE or E is ground. Further, power is supplied to the flow sensor, which is triggered and closes the contacts if the water pressure is sufficient for operation. If there is no water or the pressure is very weak, the heating will not turn on, for safety reasons.

In turn, when the flow sensor is triggered, the power control relay is turned on, which is responsible for turning on the heating elements. Temperature sensors, which are located further in the electrical circuit, are designed to turn off the heating elements in case of overheating.

In this case, the temperature sensor T2 is turned on after the heating elements have cooled down in manual mode. Well, the last element of the design is a neon indicator that displays the process of heating water.

That's the whole principle of operation of a flowing electric water heater. If suddenly the device fails, use this diagram to find the faulty element.

In other models, there may be a modified scheme of operation, for example, there will be a thermostat, as in the image below.

When cold water is supplied, this membrane is displaced, thereby pushing the activation lever through a special rod. If the pressure is weak, the displacement will not occur and the heating will not turn on.

The most common breakdowns

Finally, I will give some of the most common breakdowns of geysers. The most common problems that can be observed in the operation of heaters:

Clogging of the coil with scale. If the pressure in the hot water tap is low, while cleaning the gearbox did not solve the problem, then the coil is clogged. In this case, it must be washed with a remover, such as Antinakipin;

Antinakipin - descaling agent

A depressurized coil can be soldered

- Doesn't ignite. There are several reasons why the column may not light up:

- low water pressure;

- there is no draft in the chimney - perhaps a foreign object got into the chimney;

- the batteries are exhausted (applies to speakers with automatic ignition);

- Doesn't heat water well. There may be several reasons:

- blockage of gas equipment;

- the need to adjust the burner - in modern columns there is a valve that allows you to adjust the gas supply to the burner.

To extend the life of the column, install a quality filter at the inlet

That's all the most common malfunctions of gas water heaters that you can fix yourself. The service manual, which usually comes with the passport, will help with this.

If you are not sure that you can fix the breakdown yourself, it is better to seek help from specialists. Price repairs start from 300 rubles excluding the cost of parts.

Performing serious operations, such as soldering a radiator, costs 1000-1200 rubles. Prices are current in spring 2017.

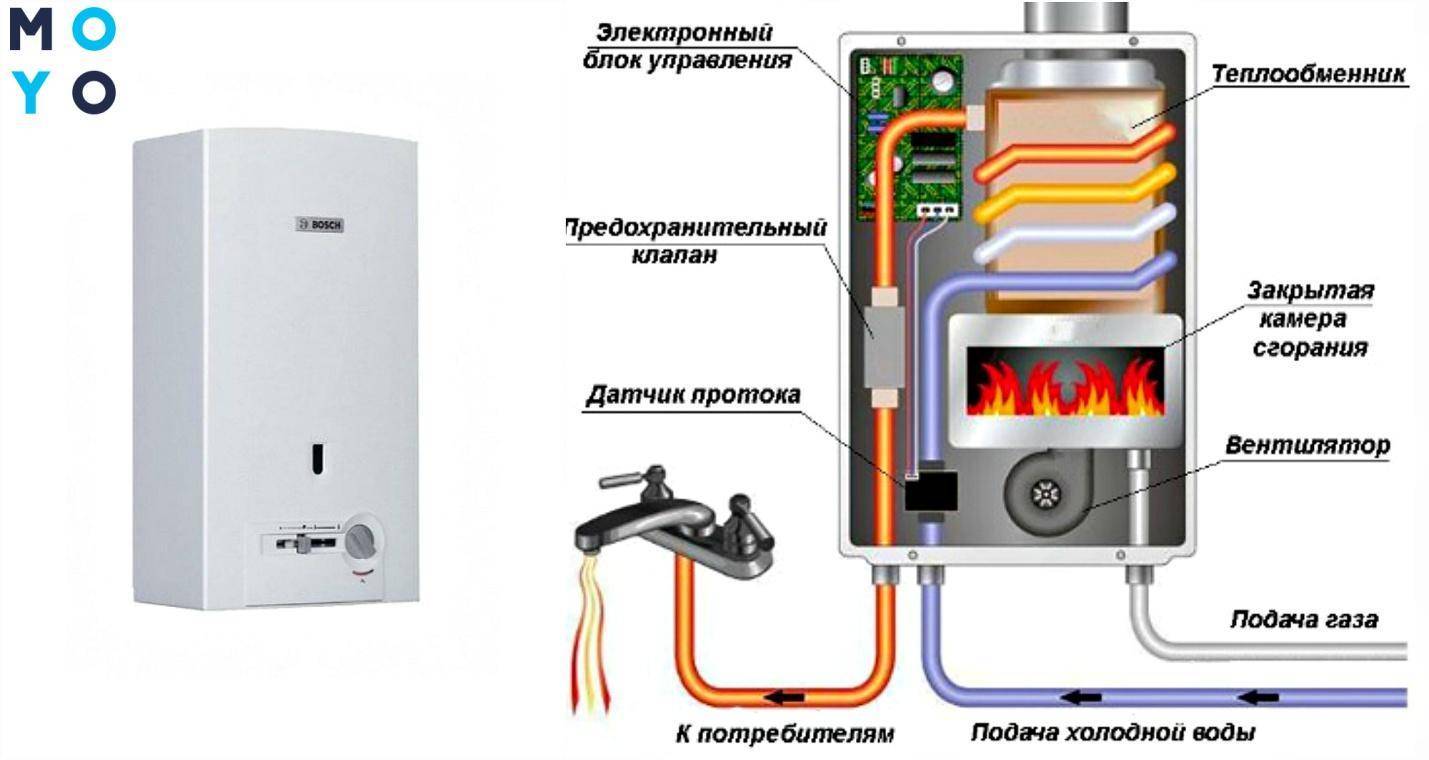

Classification

Gas instantaneous water heaters are included in the hot water supply system of a residential building. The device heats the water in the stream with the released heat from the burnt gas.

Depending on the operating conditions, flowing gas heaters are divided into types.

According to the ignition method, the device is automatic and with manual piezo ignition. The first option assumes that when the tap is opened, the burner turns on automatically (it also turns off). The fire is switched on by electronic ignition. You do not need to supervise the operation of the device. Manual piezo ignition is a connection with a button. Such a device must be mounted in an accessible place.

The subsequent division is done taking into account the power of the device. A low power device includes 17-19 kW speakers; with an average power indicator there will be a device of 22-24 kW; a high-power column is 28-30 kW. The more water consumption points and the number of family members, the greater the power indicator should be at the gas column.

The constancy of the temperature regime of the water in the tap depends on the type of burner of the device. Separate the burner with constant power, when the burner operates at the same power with different water supply. Then, depending on the pressure, the temperature of the liquid in the tap will also change. The modulating type burner adjusts to the water pressure in the water supply. Therefore, the temperature will be the same regardless of the pressure of the liquid.

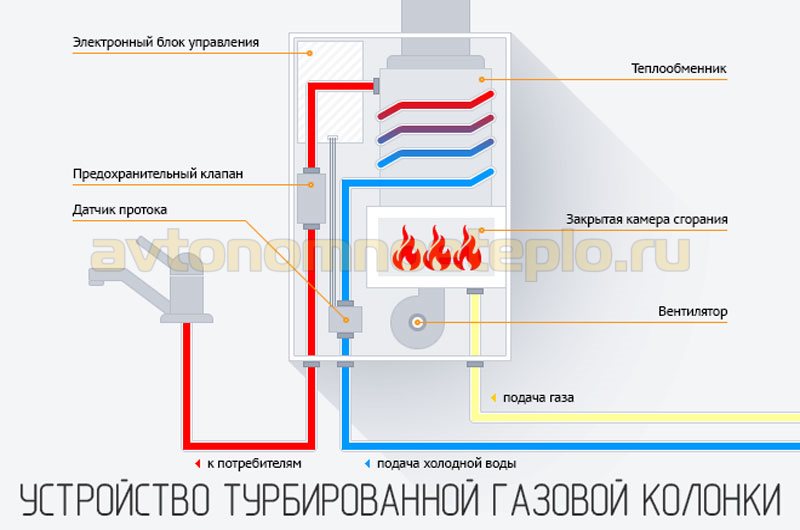

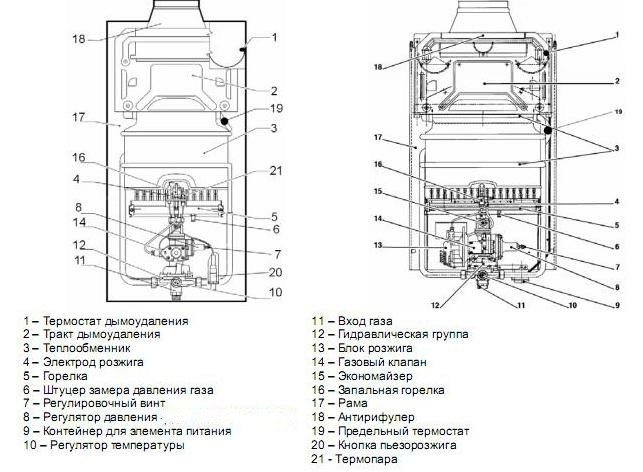

The device is divided into a design with smoke removal in a natural way. When the removal of gases occurs with traction. The second type of column is turbocharged structures (chimneyless model). Combustion products are forcibly drawn out by means of a fan built into the column design. It starts working from the first seconds of ignition of the burner.

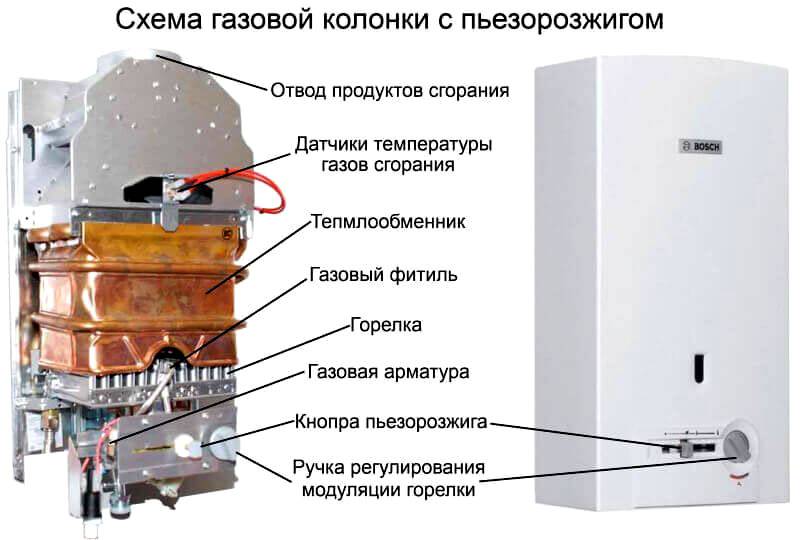

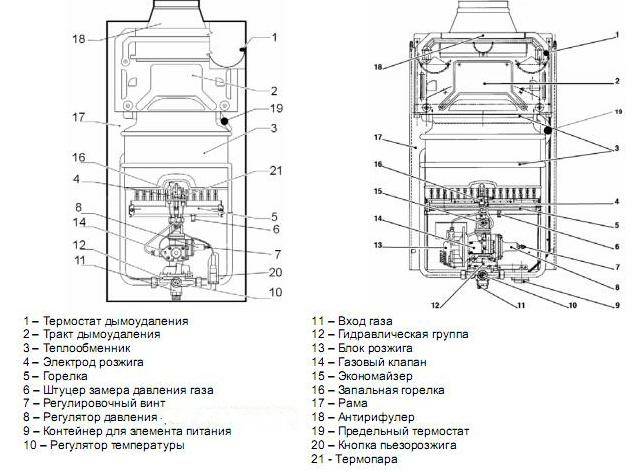

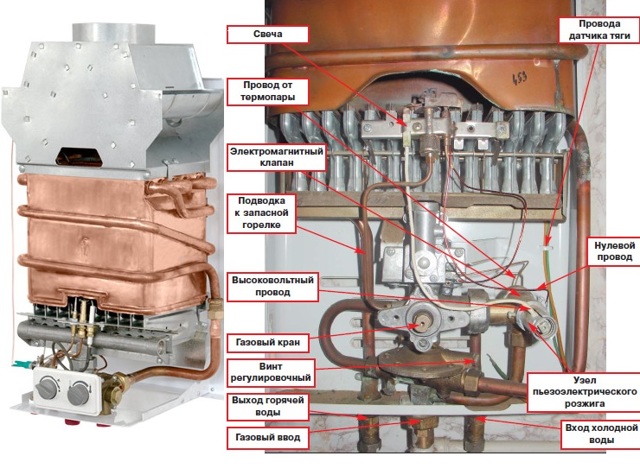

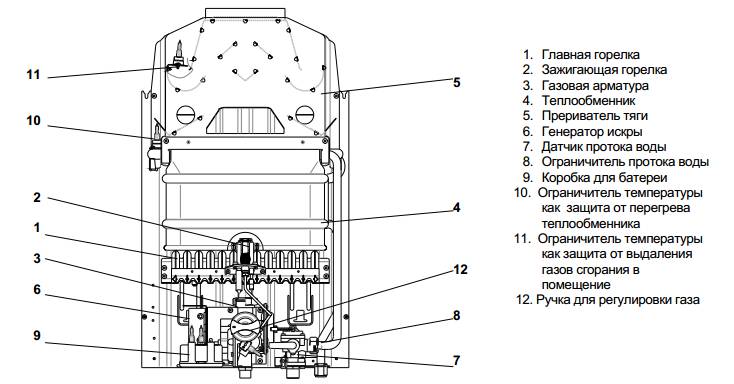

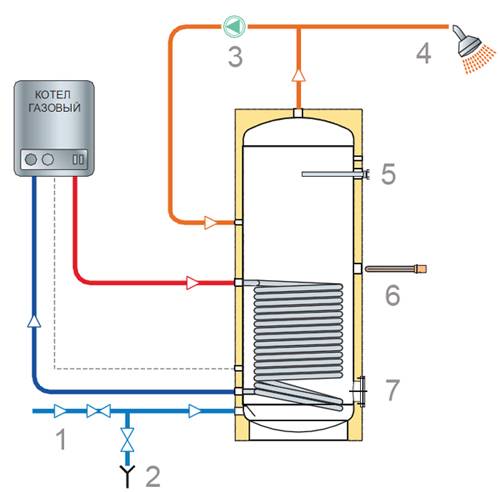

Internal details of the column, their purpose

Before looking inside the column, it should be clarified that there are 2 types of modern gas flow models:

- With an open combustion chamber. The air necessary for burning the gas will flow through the viewing window or from the bottom of the structure without compulsion, naturally from the room.

- With a closed type of combustion chamber. They are called: turbocharged. The necessary air enters the combustion zone by force, with the help of a fan.

This division is important to know, because the columns are structurally different from each other. Installation of the device is carried out on the wall

It is connected to water and gas pipes.

The device is installed on the wall. Water and gas pipes are connected to it.

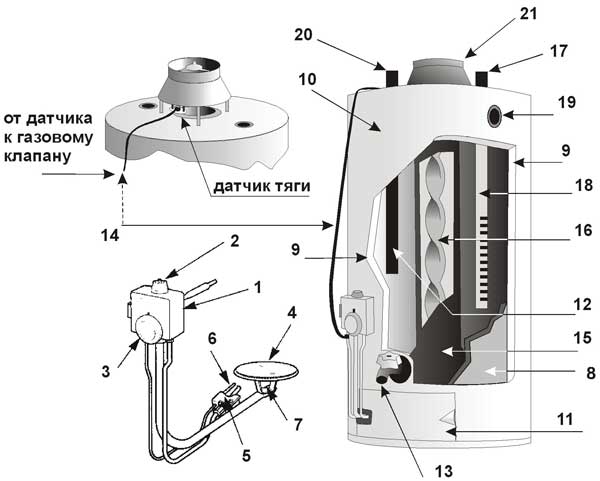

A simple atmospheric water heater consists of components and parts:

- light metal body;

- gas burner with igniter;

- finned type heat exchanger with a casing and a copper coil;

- automatic sensor for adjusting the intensity of combustion;

- the safety valve is installed on the mechanical water unit;

- ignition system;

- the chimney is connected through a branch pipe, which is located on the diffuser.

- combustion products accumulate in the diffuser. Inside it has a thrust sensor. Wires to the gas valve depart from it;

- a flame sensor is also connected to the gas valve. It is located in the combustion zone;

- water and gas supply is carried out through the lower pipes. They end with fittings for accession.

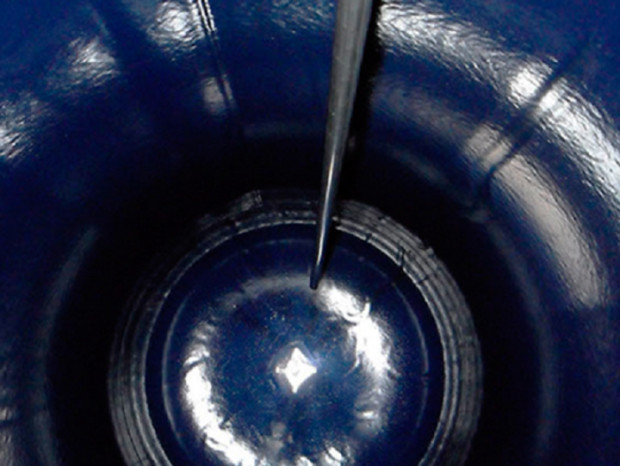

In the photo, an atmospheric gas water heater is painted on the details.

Modern columns are set on fire with electrodes that can ignite the gas with an electric discharge.

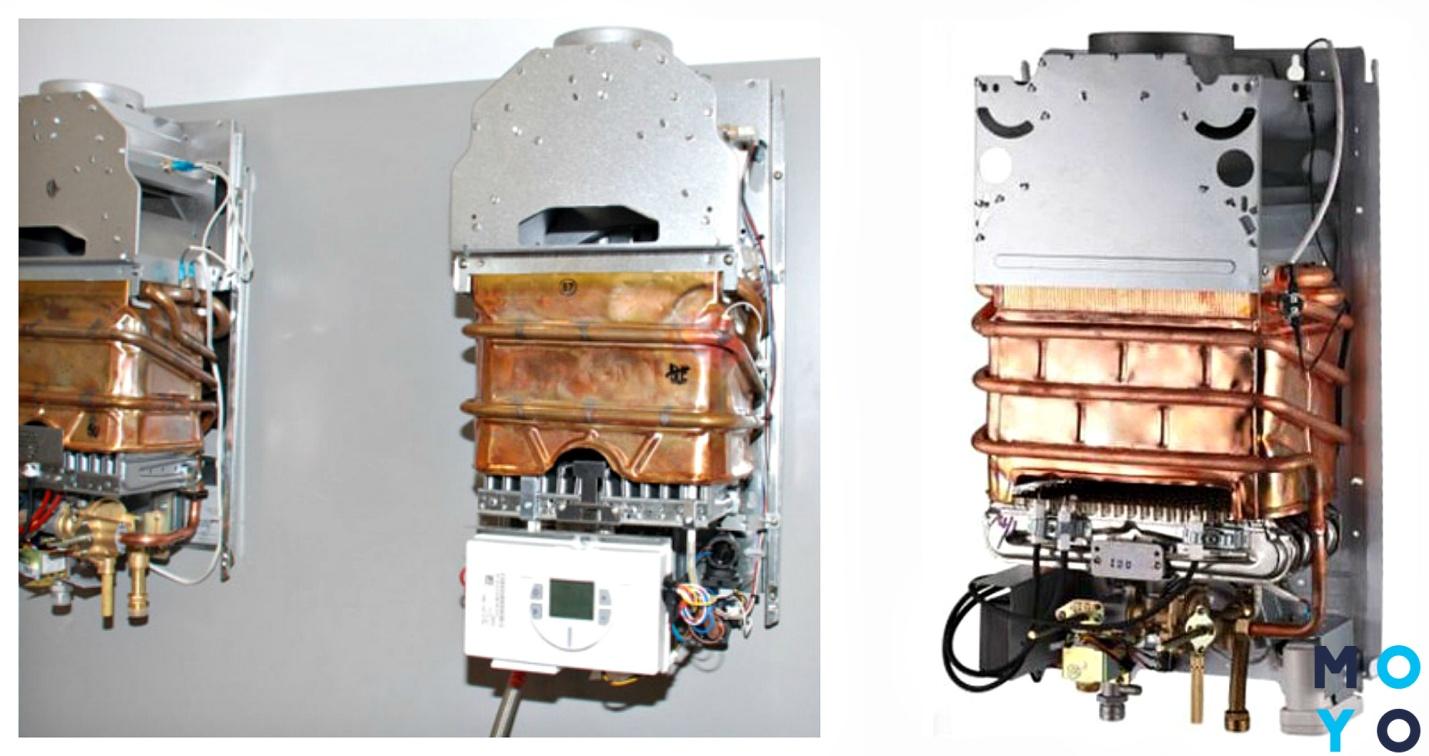

A geyser without a chimney (calibrated) differs from atmospheric, although they are similar in design to each other:

- The turbocharged column has a modulating burner model. The intensity of burning changes automatically. On the atmospheric - burner with manual control.

- For burning the flame, air is supplied by a fan. Its operation is controlled by an electronic unit.

- Ignition is carried out automatically. The system is powered by electricity.

- An important role is played by the water temperature control sensor, which is connected to the controller. It keeps the water heating at a certain level, for example 60 degrees.

The photo shows a turbocharged gas water heater, in which all functions are automated. The set temperature is displayed on the LCD.

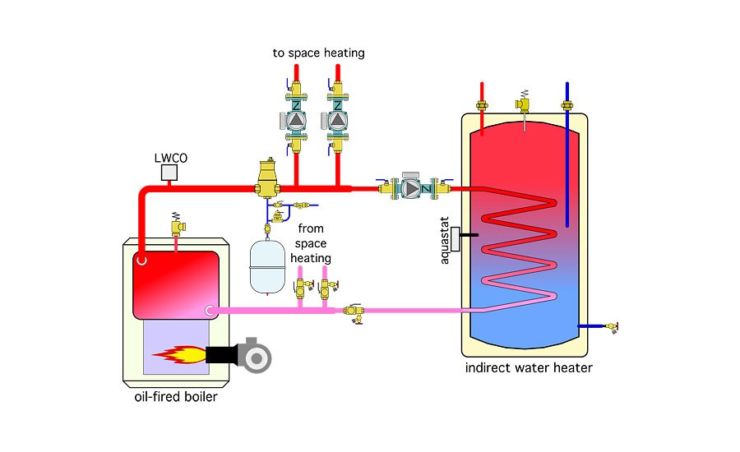

What is the device of the water heater

So, as we have established, the principle of operation of a storage type water heater is that the water is first transferred to thermal energy, which leads to its heating, and then the heat flow decreases and remains at a level sufficient to maintain the required temperature. In a flow device, water is heated as it passes through the heating elements. Therefore, at the outlet, it has a significantly lower temperature than that of the accumulative one, although heating to it occurs very quickly.

Storage water heaters have the following device:

- A container that is filled with pressurized water from a plumbing system. Its size varies from 10 to 100 liters.

- The outer casing, under which there is a thick layer of thermal insulation.

- Electric heating element (TEH) or magnesium anode. In the case of the gas version - chimneys and a gas burner. This is the "heart" of the device, which actually provides heating of the water in the tank.

- A branch pipe for supplying cold water from the system and a branch pipe for the outlet of hot water from the device. It is often equipped with a safety valve that opens when the pressure in the water heater is exceeded.

- An electronic control unit that receives signals from temperature sensors and regulates the operation of the entire device. It also has buttons for manually setting the heating parameters, including the maximum temperature and the speed of heating the water.

The principle of operation of a storage water heater is based on the features of a thermos. The large tank of heated water is encased in a cocoon of insulating material to minimize calorie loss. As a result, cooling is very slow. A full tank can cool down to room temperature after turning off the device only after 2 - 3 days. This allows you to use hot water even when the power is turned off.

When the water cools down to a certain temperature, the heating elements turn on and it heats up again.So that hot water does not mix with cold water and the temperature does not drop quickly, the storage type water heater always provides for the following: cold water entering the tank from below displaces hot water. Her fence from the tank occurs opposite from above. In this way, the uniformity of the temperature of the water that enters the faucet from the water heater is guaranteed.

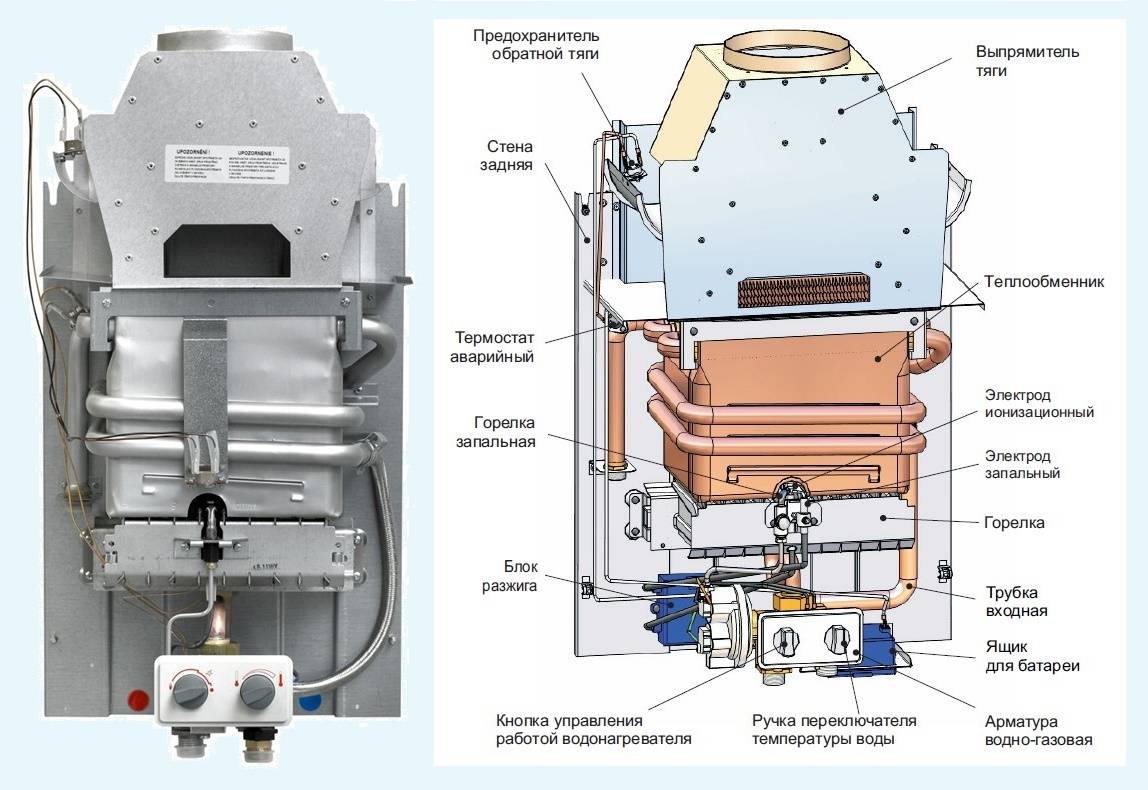

Unit device

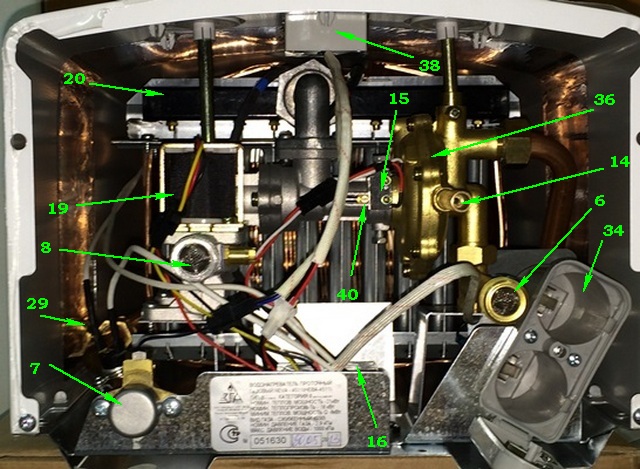

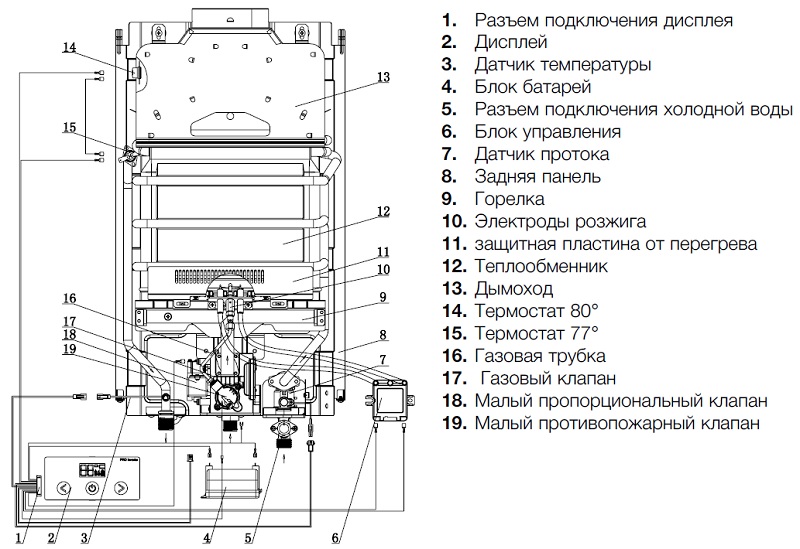

Gas water heaters, regardless of the manufacturer, have similar components, the presence of which may differ slightly for different models. For example, consider the Neva gas column device.

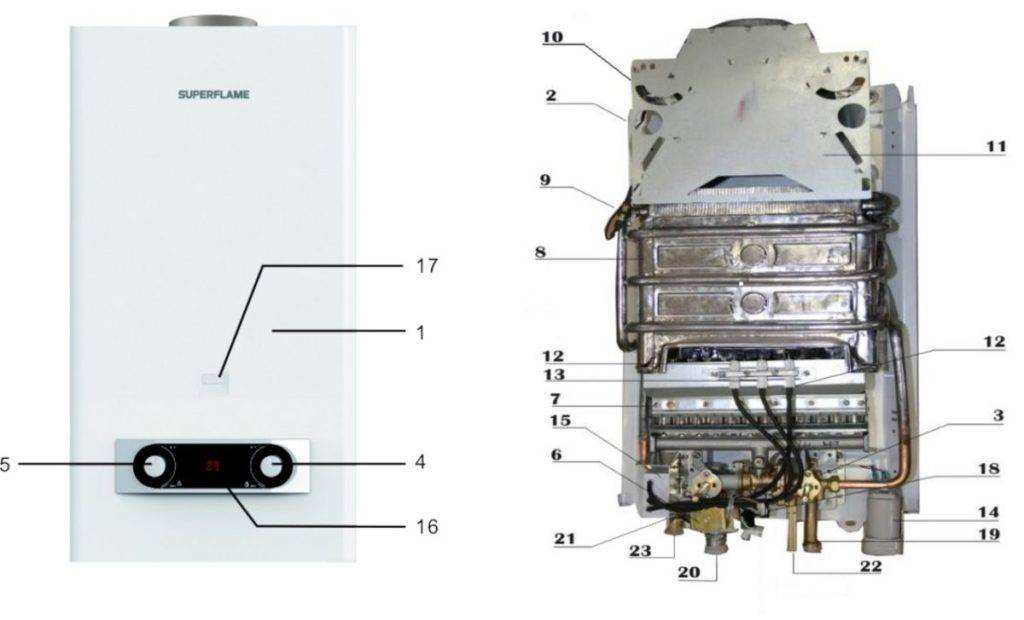

Device device outside

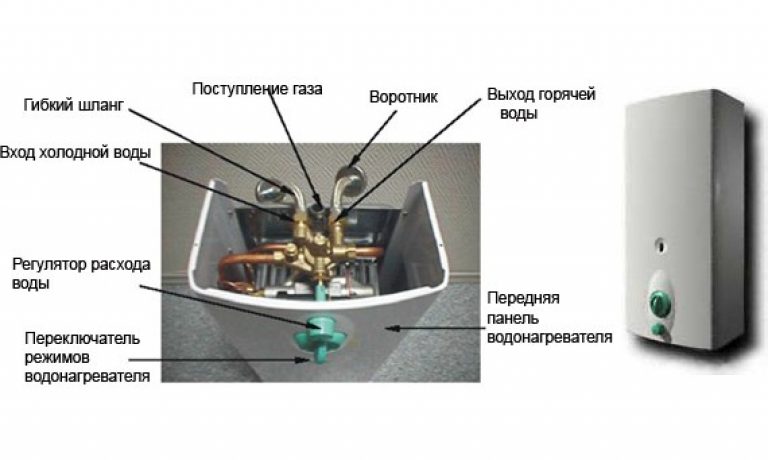

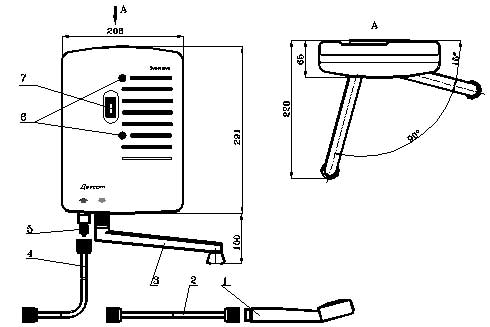

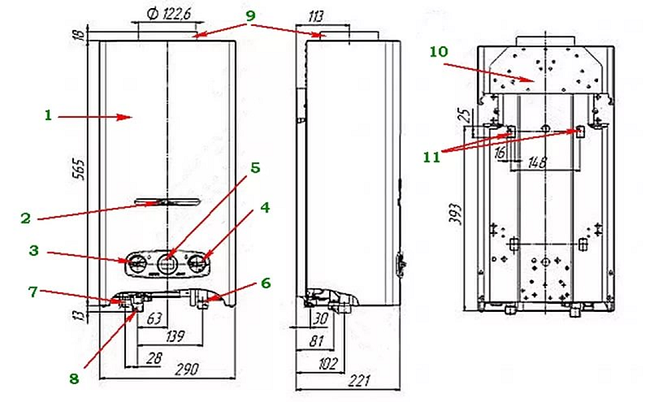

The diagram of the gas column is shown in the figure below.

Geyser scheme

The front part and sides of the water heater are covered with a metal casing (1). On the facade of the apparatus there is a viewing window (2) for visual control of the operation of the unit. Under the window there are regulators: a handle that regulates the gas flow (3) and a water flow regulator (4). Between the handles there is an LCD display (5), which displays the value of the temperature of the water supplied to the consumer.

At the very bottom of the apparatus there are pipes for supplying water and its output, as well as for supplying gas. On the right side of the water heater there is a branch pipe (6) to which cold water is connected from the water supply, and on the left side a pipe (7) is connected to drain the heated liquid. Next to it, but a little closer to the center, there is a branch pipe (8). A hose is connected to it, connecting the column to the gas main, and in some situations to the gas cylinder. At the very top of the water heater, there is a flange (9) for connecting the gas outlet pipe (chimney).

All elements of the unit are fixed on a metal base (10), which acts as the rear wall of the apparatus. It has 2 holes for hanging the unit on the wall using brackets.

The internal structure of the unit

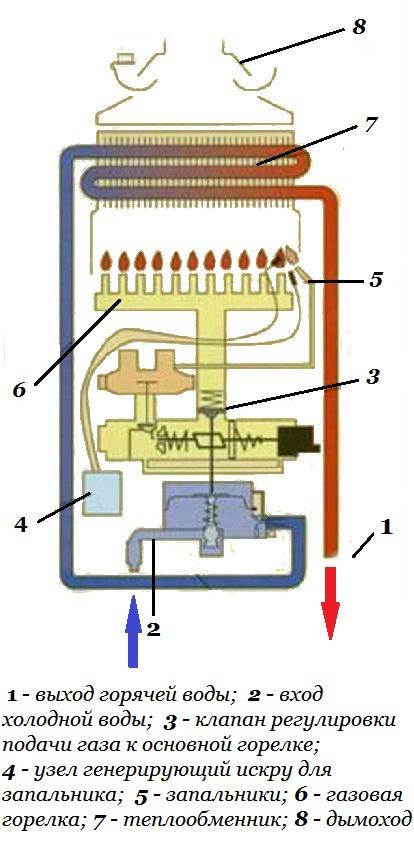

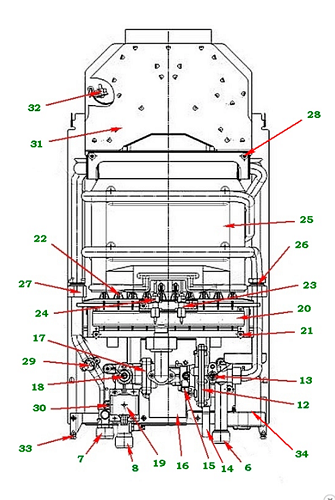

Now let's look at how the geyser is arranged from the inside, with the outer casing removed. As mentioned above, pipes numbered 6, 7 and 8 are designed to connect cold water, drain hot water and connect gas.

The unit's water block (12) is connected to the water inlet (6). A rod (13) emerges from the water block, on which a handle is attached to adjust the water pressure. Below is a cylindrical part (14), which has a notch on the walls. It performs the function of a plug that is removed to drain the liquid from the device if it needs to be repaired. The plug also has a safety valve that opens when there is excess pressure in the water supply.

In the center of the unit is the electronic control box (16). Wires leading to various elements of the unit and sensors are output from it in different directions.

Column device from the inside

On the left, symmetrically to the water block, there is a gas one (17). Both modules and are assembled in such a way that they represent a single structure. From it, as well as from the water one, a rod (18) comes out to adjust the gas supply. The valve (19) (solenoid) is located in the middle between the gas connection and the control cock.

Also on the gas block there is a microswitch (15), which is pressed by a special pusher when it is turned off. Above you can see the manifold (20) connected to the gas unit with a pipe fitting on the flanges. The manifold is attached to the body with 2 screws (21). Nozzles are located at the rear of the manifold.Through them, gas is supplied to the burner (22), which has 10 rows. Attached to the front of the collector are a pair of elements that are similar in appearance but perform different roles. On the right is the spark plug (23) that ignites the burners, and on the left is the flame sensor (24).

Above the collector is a copper heat exchanger (25). It just gives off the heat received from the combustion of gas to the water passing through it. On the right, a water unit (26) is connected to the heat exchanger, and on the left side, a branch pipe for discharging heated water (27). The heat exchange module is fixed to the unit body with 2 screws (28). There are 2 sensors installed on the hot water outlet. The top one (29) protects the water heater from overheating, and the one below (30) serves as a thermometer. From it there are wires to the LCD display fixed on the casing of the unit.

At the top of the apparatus, a device for removing waste combustion products (31) is installed. Thanks to a system of jumpers of various shapes, the flow of hot exhaust gases is directed towards the chimney channel. A draft sensor (32) is installed on the left, which is connected to the overheat sensor (29) through an electrical circuit. At the bottom of the water heater body there is a block (34) for 2 batteries (batteries). To fasten the outer casing of the device, there are places for screwing screws (33) on both sides of the casing.

You may be interested in: how to repair a geyser.

The column does not ignite initially

Before climbing inside the water heater, it is worth performing a number of elementary actions:

- Replace the batteries and clean the contacts in the battery compartment.

- Make sure that there is a natural draft of the chimney and a normal pressure in the cold water supply system.

- In a mains powered turbo dispenser, check the fuse. Try to switch the imported unit by turning the plug in the socket - some models are sensitive to the phase position.

- Clean the dirt filter installed on the cold water supply pipe. Sometimes the mesh at the inlet is provided by the design of the water heater itself.

- After opening the DHW mixer, observe the ignition electrodes - a spark should jump on them. In a turbocharged apparatus with a closed chamber, the clicking of discharges is clearly audible.

Repair of the heater begins with cleaning the electrodes and installing working batteries

Did the above activities fail? Then remove the speaker cover and proceed to troubleshooting, following the step-by-step instructions:

- Open the hot water (ask an assistant) and watch the movement of the stem, which should move the pressure plate away from the microswitch button. If the pusher does not move, the cause is 100% inside the water block. You will have to disassemble it, clean it and change the membrane.

- The stem presses on the plate, but the button remains depressed. Probably, the stroke of the pusher has decreased due to scale inside the “frog”, which needs to be opened and cleaned.

- The pusher moves, the button turns off, but there is no sparking. The microswitch is probably to blame, diagnosed as follows: disconnect its connector and close 2 terminals with a screwdriver. If the switch is out of order, then after a direct circuit, a spark will appear on the electrodes.

- The discharge slips on one needle, the second is silent.Remove the high voltage cable from the electrode body, cut slightly and reinsert.

- The “frog” functions, the microswitch is activated, the electrodes spark, but ignition does not occur. This means that gas is not supplied - the solenoid valve is closed. The culprits for breaking the circuit are thrust and overheating sensors; to check them, they must be closed one by one with a wire. Another option is a break or fracture of the supply wires, diagnosed by dialing with a multimeter.

It is necessary to close the connector connected to the impulse block, and not the plug of the microswitch

In some models of electronically controlled gas flow columns, a special flow sensor controls the launch. Operates on the principle of a limit switch - the water went, the circuit closed. Diagnosis is simple: open the DHW valve and ring the element contacts with an ohmmeter or a light bulb - it should light up. The algorithm for a complete check of the water heater is demonstrated by the wizard on the video:

How to replace the membrane

The procedure for replacing a rubber (or silicone) diaphragm differs little between columns from different manufacturers. To independently remove and disassemble the water-gas unit, you will need a standard tool - open-end wrenches, screwdrivers and pliers. The order of work is as follows:

- Shut off the gas and cold water taps on the supply pipelines, remove the casing of the device.

- Disconnect the pipes of the water supply and fuel supply.

- Unscrew the heat exchanger tube from the “frog” (located on the right), put it aside or disconnect the interfering wires.

- Unscrew the block fastening to the body and remove the assembly.

- Disassemble the membrane block by unscrewing 4-8 fixing screws.Pull out the unusable diaphragm and put in a spare one, having previously cleaned the inside of the camera from scale and dirt.

Number 3. Boiler lining

The inner surface of the storage boiler tank constantly interacts with water, so it must be as resistant to corrosion as possible. To date, water heaters are on sale, in which the inner surface of the tank is made of the following materials:

- stainless steel;

- enamel coating;

- glass ceramics;

- titanium coating;

- plastic coating.

Boilers in which the tank has a plastic inner lining are the cheapest, but their reliability is also questionable. Stainless steel tanks performed best. Manufacturers give them a 10-year warranty, and some additionally carry out passivation, increasing the warranty period to 12 years. From the point of view of durability and reliability, such tanks are preferable, but they are not cheap either. The most expensive boilers receive a titanium coating, which allows you to extend the service life by several more years.

Enamel-coated tanks are not much inferior to stainless steel counterparts. Thanks to the addition of special additives to the composition of the enamel, it receives the same expansion coefficients as the steel from which the tank itself is made, so this coating will not crack when heated. Enamel coating is improving day by day. Today you can find water heaters in which enamel is sprayed with silver ions. Due to this, antibacterial and anti-corrosion properties are increased.

Some experts note that plastic, enamel and glass ceramics can receive mechanical damage from temperature changes and when interacting with solid particles found in tap water. Nevertheless, enamel and glass-ceramic coatings are not the worst option for a boiler, although they are incomparable with stainless steel.

On the other hand, no matter how strong the inner coating of the tank is, the weak points are the same in all cases. These are the welds that are the first to rust. To prevent corrosion of the tank and the "wet" heating element, the design of all modern boilers provides for anode protection. To do this, use a magnesium, titanium or aluminum anode, the tank acts as a cathode. The anode can be called a consumable. It is better to change it every few years, while simultaneously cleaning the heating element and flushing the tank.

Remember that a quality boiler, made according to all the rules, cannot be cheap. The absence of a guarantee or its very short period should also indicate that the manufacturer, to put it mildly, is not sure about the quality of his products and wants to quickly relieve himself of responsibility for it.