- Water heated floor does not heat at all: the main reasons

- Reason 1. Lack of thermal insulation

- Norms and rules

- Heating cable failure

- Pipes and walls

- Expansion tank problem

- Do-it-yourself leak elimination

- How does underfloor heating work - the basic principle

- Failure of the thermostat

- Short circuit protection

- Cable damage

- Uneven heating

- Other sources of noise in heating pipes

- Norms and rules

- We carry out repairs of a water-heated floor - do not panic | Hearth

- Channel cleaning

- The heating battery is leaking: what to do depending on the type of defect

- How to fix a leak between two radiator sections?

- Elimination of a defect at the junction of the riser with the pipe

- Fixing a cracked radiator

- Restoring the integrity of the heating pipe

- Devices for detecting leaks in walls and floors

- Taps and valves

- Water floor repair

- Murmur, whistle

- Conclusions and useful video on the topic

Water heated floor does not heat at all: the main reasons

The system can last at least 50 years, but for this you need to install high-quality pipes and other structural parts: a pump, a bypass, a manifold, a balancing valve and a thermostat. If the warm water floor does not heat, the following factors may be the causes of this problem:

- The circulation pump has stopped working. During operation, this device vibrates slightly and makes a small noise.If not, you need to change the pump.

- Ball valves closed.

- Air has entered the system. In this case, you will have to call specialists, since it is difficult to solve the problem on your own.

- The pipeline was damaged during installation operations.

Reason 1. Lack of thermal insulation

The most common reason why a warm floor does not cope with the functions assigned to it is that you simply forgot to properly install thermal insulation, or did not install it at all. Often, a conventional polyethylene foam substrate is used as thermal insulation. And the substrate is simply not intended for thermal insulation of warm floors. Instead, you need to use polystyrene foam 5-10 cm thick.

How to fix?

Learn one thing. You will have to pay extra for a warm floor. But perhaps the situation will be corrected by a higher temperature supply to the warm floor and the use of more powerful heating equipment. But don't overdo it. The maximum temperature should not exceed 70 degrees. And it doesn't have to be permanent. Otherwise, the pipe will quickly become unusable.

Norms and rules

If you do not clean the chimney for a long time, it becomes clogged with soot and creates an obstacle to the passage of smoke.

If you do not clean the chimney for a long time, it becomes clogged with soot and creates an obstacle to the passage of smoke.

Most often, smoke occurs due to trouble with the chimney. It is either clogged or initially equipped incorrectly. The most important point is the height of the chimney. SNiPs indicate the exact dimensions for different structural dimensions of roofs or the location of the pipe structure itself on the roof. For houses with flat roofs, this parameter cannot be less than 60 cm, if you count from the highest point of the parapet or add-ons, for example, a terraced canopy.

If there is a garden with tall trees around the house, or neighboring houses are located nearby and higher, it is better to make the pipe larger so that the smoke does not beat against obstacles, but freely escapes into space.

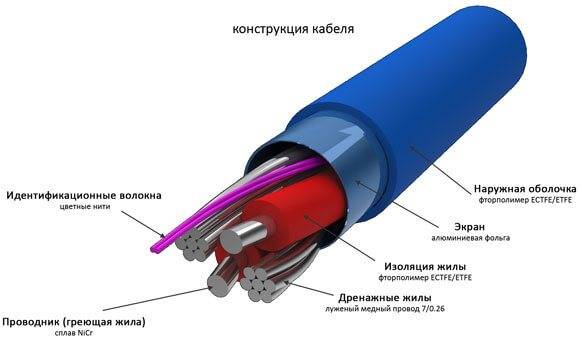

Heating cable failure

If the owners have a question about how long the warm floor heats up, then this usually means that this process takes too long, which can often be explained by a system malfunction (read: “Warm floor - why it doesn’t work, how to troubleshoot "). As for electric underfloor heating, here their poor functioning can be caused by the wrong choice of the heating cable category, as well as its power. In order to correctly calculate all the parameters, do not neglect the help of professionals who can always give good advice on installation and provide all the necessary photo and video materials for installing the structure.

It also happens that the long heating of the warm floor on an electrical basis is due to the failure of the temperature sensor or thermostat. If such malfunctions are detected, the equipment must be replaced.Underfloor heating - characteristics and types, look at the video:

Pipes and walls

In old houses, where pipes have not been changed for decades, extraneous noise often appears. In places where the water supply enters the apartment or bathroom, a small gap forms between the pipe and the wall. Therefore, the pipe gets the opportunity to vibrate.

The water main can be partially recessed into the wall. If you have such an option, inspect part of the wall along the pipe. If a crack is visible, then the pipe is loose and vibrates.

In this case, it is easy to correct the situation.Clean the old mortar along the entire length of the pipe. Instead, close the resulting space with alabaster.

Sometimes pipes are located in metal holders, clamps or brackets. Over time, they loosen and give the pipes room to vibrate. The issue can be resolved in three ways:

- Replace holders or brackets;

- Tighten fasteners;

- Lay rubber gaskets between the holders and the pipe.

Expansion tank problem

The volume of water filling the heating circuit varies depending on the heating level. When the temperature rises, the volume of water increases, which entails a change in the hydraulic pressure inside the closed heating system.

At this moment, the elements of the heating circuit would undergo an increased load, fraught with their breakdown. But this does not happen, since the design of the boiler is supplemented by a security system, including an expansion tank, which receives the resulting excess water.

The device and principle of operation of the expansion tank, divided by a membrane into two chambers, location air valve and pipe for connections to the water main

For installation on heating pipelines, open and closed expansion tanks are used. Open tanks are installed outside boiler rooms, for example, in attics, and are equipped with a whole system of pipes for connecting expansion, circulation, signal, overflow pipes.

All models of wall-mounted both double and single-circuit boilers are equipped with built-in expansion tanks. They are of a closed type, have only one branch pipe and two internal cavities separated by a membrane.To ensure the standard pressure in the expansion tank, there is air or an inert gas, such as argon, in its upper cavity and there is an air valve with a nipple.

The excess coolant through the pipe enters the lower cavity. The membrane is bent, the air is compressed in the upper cavity, and the coolant occupies part of the internal space of the expansion tank.

The excess coolant generated during heating is discharged by the safety valve of the boiler itself or the heating system. If necessary, the liquid is replenished through the make-up valve of the boiler.

In open and closed expansion tanks, leaks occur at the points of threaded connections of branch pipes with pipes. To eliminate them, tighten the union nuts or replace the gaskets, as mentioned above.

The metal casings of expansion tanks are prone to corrosion due to the presence of oxygen bubbles in the water mass. Corrosion leads to the formation of fistulas (holes), which become the place of leakage of the coolant.

The more often you have to pump a new portion of water into the system, the higher the risk of damage to the expansion tank housing and other metal components. In the presence of fistulas, the tank is changed to a new one.

Do-it-yourself leak elimination

Before you seal a leak in a heating boiler or in a heating pipe system, it is worth preparing a certain tool. It can be a welding machine or a thermal imager. To fix a leak, use the following instructions:

- A hidden leak is best "enlightened" with a thermal imager.Such diagnostics will allow you to find the location of the breakdown with high accuracy and prevent minor fistulas that can become a problem. Elimination of the problem area is carried out by replacing the emergency section of the heating main or tightening the docking element.

- In case of violation of the integrity of the membrane in the expansion tank, repairs are not carried out. In this case, you need to buy a new product in the store.

- A cracked heat exchanger is one of the most difficult problems to diagnose. If you have welding experience, you can try to brew the fistula yourself. However, it is better to resort to the help of a qualified specialist or to hand over the heating equipment to a service center.

- A faucet that is not closed to the end is the most harmless reason that is often forgotten to be checked. Eliminated by a complete revision of all shut-off valves. They are stretched and set to the required value.

Of course, you can fix the leak of the heating boiler without welding. In this case, it is necessary to act depending on the location of the breakdown. The first thing to do is turn off the entire system and let the coolant cool down. After that, you need to drain all the fluid from the system. If a leak is detected in an open section of the heating main, a plumbing clamp with a rubber gasket is applied. The place of leakage on the heat exchanger can be sealed with liquid welding.

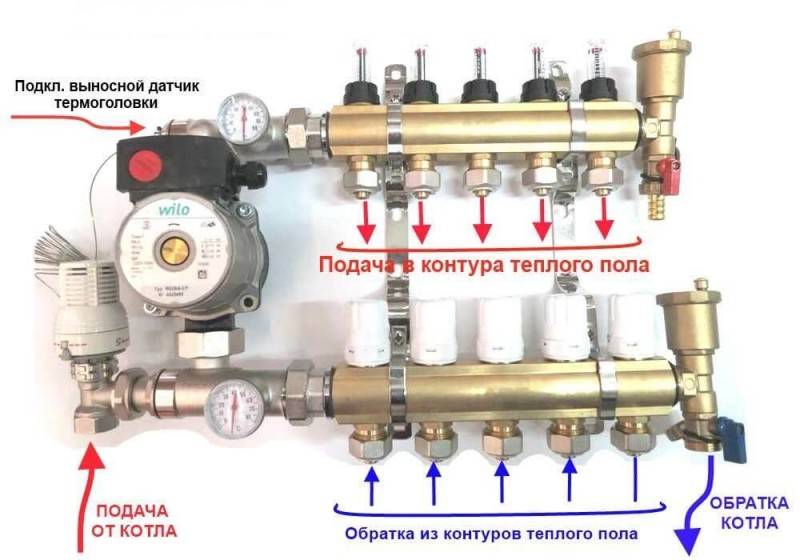

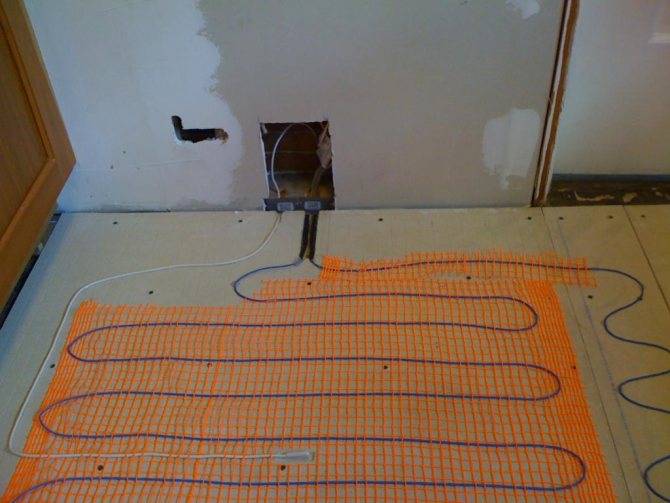

How does underfloor heating work - the basic principle

Knowledge of the basic principles of operation and design of the system will help to quickly detect a breakdown and eliminate it. The heating system built into the floor structure provides uniform heating of the surface. The popularity of such a system is ensured by the fact that the heat is distributed around the perimeter of the floor and evenly warms the entire room.

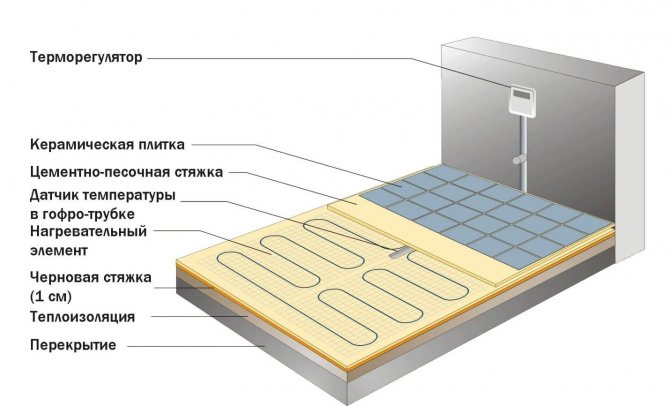

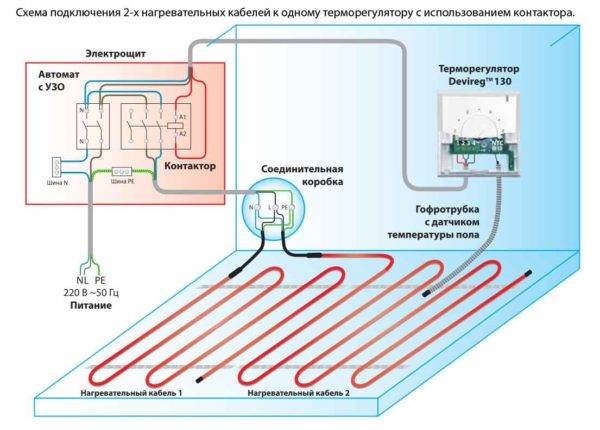

The two most common types of underfloor heating are water and electric. The principle of operation of the electrical system is that an electrical cable is mounted in the screed or directly under the finish, due to the heating of which the floor is heated. The system is controlled by a thermostat. When it overheats, it automatically shuts off.

Wiring diagram for electric floor heating

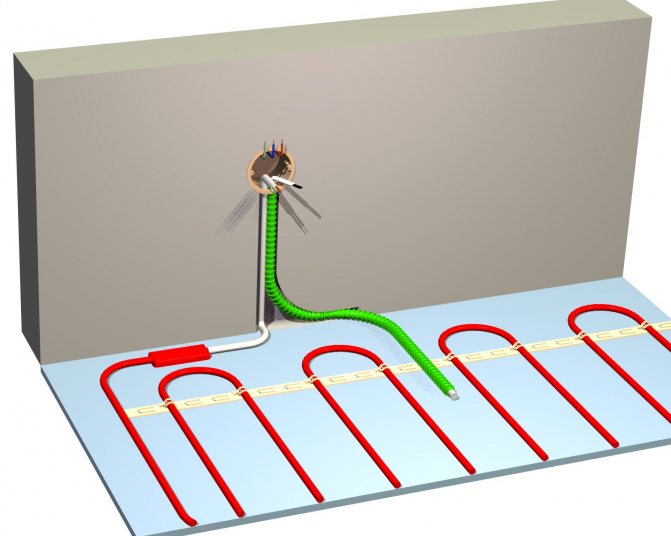

The heat carrier of a water-heated floor is pipes, also mounted in a screed or fixed in a “dry” way using screeds or staples to a reinforcing mesh, insulation or special mats with bosses. Pipes filled with water are connected to a control system that regulates the floor temperature.

The principle of laying a water floor

The operating costs of these two varieties are different - a water floor is more economical, but where its installation is not possible, an electric one is installed. As for installation - electrical wires are cheaper, they are easier to install, they do not create any sounds during operation and do not need additional equipment - a water pump will be required for a water floor.

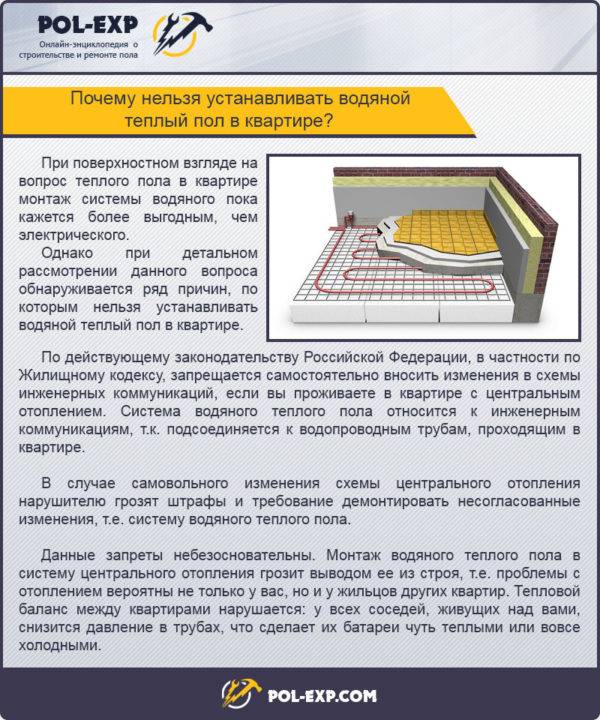

Why is it impossible to install a water heated floor in an apartment?

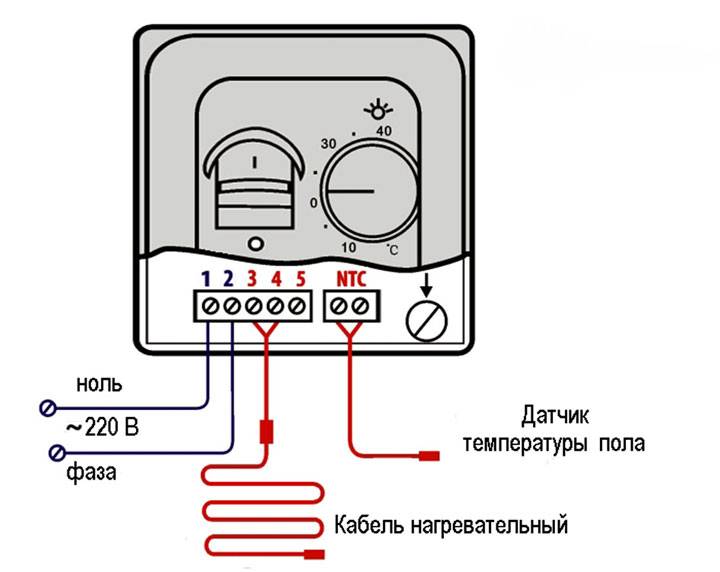

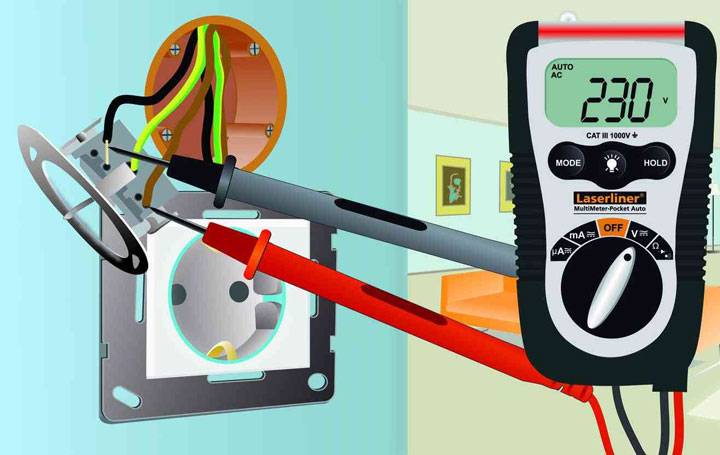

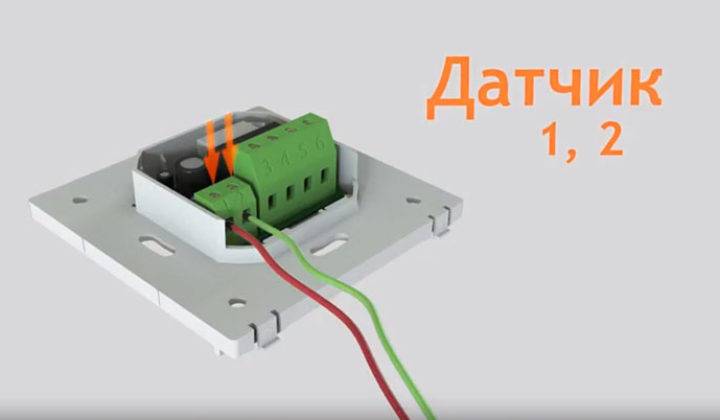

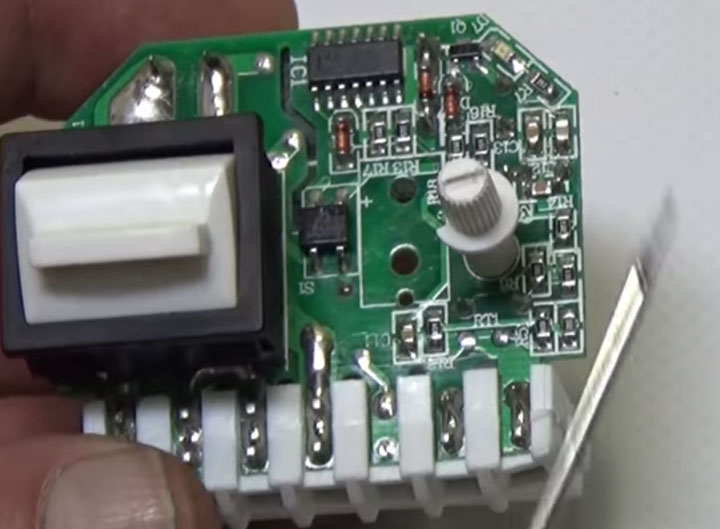

Failure of the thermostat

When the electric underfloor heating does not turn on at all, troubleshooting should begin with the thermostat. First, pull it out of the seat so that all the terminals are visible.

If you have an electronic type, when dismantling it, never press your fingers on the screen, otherwise it may crack.

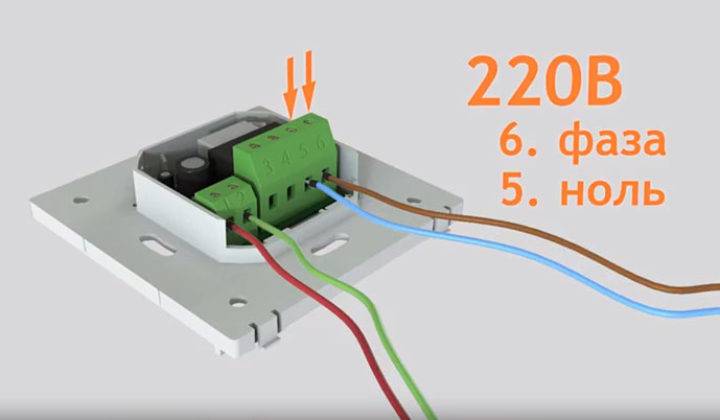

First of all, check with a multimeter if 220V comes to the thermostat at all? Maybe it's not the floor, but all the problems in the power cable.

Use a multimeter or voltmeter, and not a simple indicator that simply shows the presence of a phase. The phase may come, but there will be no zero - hence the failure of the entire system.

On most thermostats, manufacturers sign and mark all terminals:

L and N - the place where the power is connected (phase and zero, respectively)

In certain models, it is recommended to strictly observe the “polarity” and not to confuse zero with phase. Why?

To do this, it is enough to disassemble the regulator and then you will see that zero is fed directly through the track to the heating cable. The phase is broken through the relay. For example, this is exactly what is done in the RTC 70.26 model.

That is, if you mix up the "polarity", then the phase will always be on duty on your warm floor. Even when the built-in switch is turned off! Be careful.

L1 and N1 - outgoing load, heating cable or mat

Sensor - temperature sensor

Of course, there may be another designation of the terminals:

If a terminal voltage there is power and it is normal, then be sure to double-check the reliability of the contacts in the remaining clamps.

It happens that over time, the contact is weakened and the thin wiring simply falls out and stops contacting. As a result, the underfloor heating software gives this as an error - “Accident. Breakage of the underfloor heating sensor.”

It seems that they touched the thermostat or turned on and off the general machine and it all worked. You start looking for a problem somewhere deep, and it is on the surface - poor contact in the terminal block.

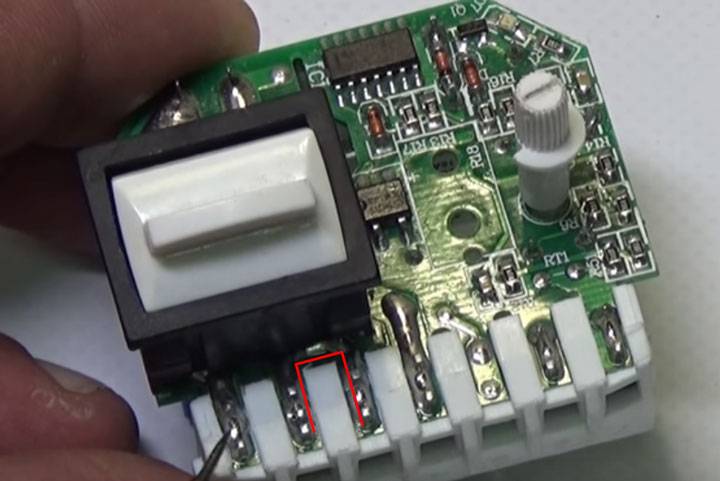

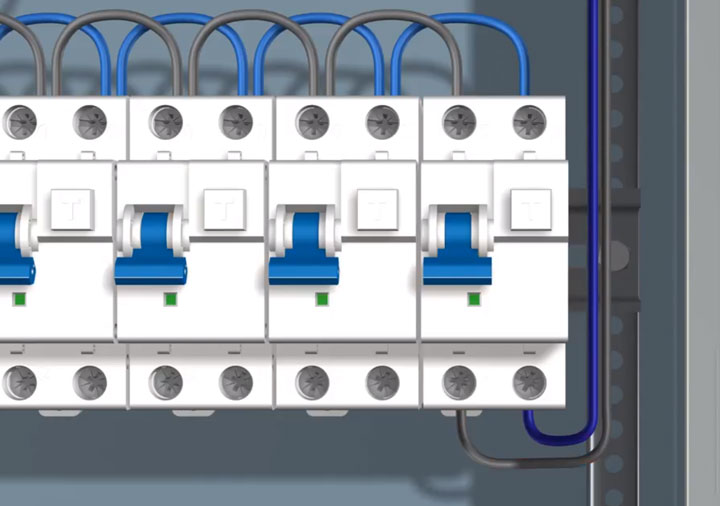

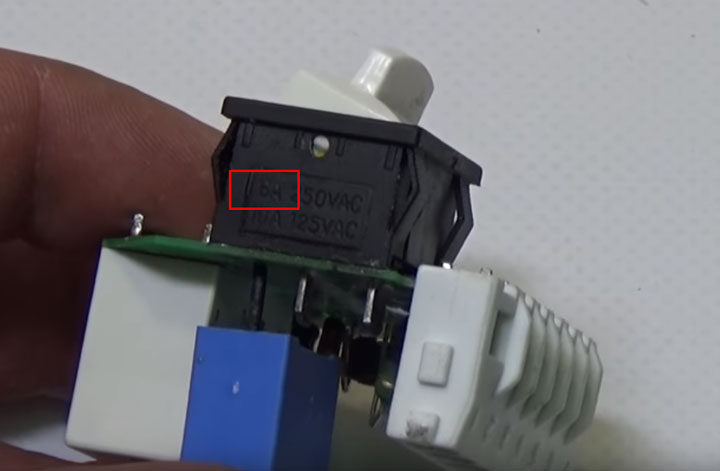

Short circuit protection

No fuses are usually installed in thermostats, do not look for them inside. In fact, the function of a fuse in electric underfloor heating systems should be performed by an automatic switch + RCD or diff. automatic in your shield.

In some models of regulators (for example RTC 70), there is a built-in switch. They can manually, without running to the electrical panel, turn off the heated floors.

Many mistakenly think that it is through it that all the current passes to the heating cable. This is not true. This switch is only responsible for supplying power to the board, hence its low operating current - 6A.

Cable damage

During installation work, you must carefully handle the heating element, as it can be accidentally damaged. If you ignore this requirement, over time it will burn out. In addition, unpleasant situations occur during the installation of flooring using a drill, when one inaccurate action may be enough to damage the cable.

To find the location of an open circuit, you must use a special detector to search for wiring (for example, the E-121 signaling device) or a thermal imager. Using these devices, you can determine the area where the cable is damaged. Then dismantling work should begin: remove the floor covering and remove the screed (if it was made). If ceramic tiles are used as a facing material, they must be removed over the gap with a hammer.

If the warm floor does not heat, the cause of this trouble may be a loss of contact in the coupling. This happens in the case of a steep bending radius of the heating cable. As a result of high mechanical tension, it spontaneously pulls out of the joint.To eliminate this problem, it is necessary to warm up the coupling (for example, with a building hair dryer), and then release the problem area with a clerical knife and make a new twist by crimping with a copper sleeve. In addition, it is better to wrap the wire with heat shrink tubing or electrical tape.

Uneven heating

If the warm floor does not heat well, the cause may be the uneven distribution of water in the pipes. This is due to the fact that in longer circuits, the coolant will cool faster even at the same fluid supply rate. To solve this problem, you need to try to adjust the water supply on the collector, as well as adjust the level of the electric drives.

To understand if the actions performed helped, you should wait a few hours. The time for the system to fully heat up depends on many factors: the heater power, the type of flooring, the coolant supply rate and the thickness of the screed.

Other sources of noise in heating pipes

As you can see, the main cause of noise in the heating system is an installation error. But there are a few others too:

- The presence of a large pressure drop;

- The coolant does not meet the proper technical conditions of operation;

- The pump in the boiler room at home may also just sound loud;

- If the boilers run on diesel fuel, then over time soot can accumulate in them. As a result, the patency of communications worsens - and an unpleasant noise is heard.

Even at the stage of drafting a heating system in private housing, it is necessary to exclude screw valves and small valves. It is better to use ball valves instead.They have no constriction under the valves, debris will not accumulate there.

Screw valve - a valve for regulating the output of liquids.

If a low-quality pump is used during the operation of the heating system, it can also make extraneous sounds that will be transmitted through the pipes. But even a high-quality pump can fail over time. In this case, the solution is obvious: repair or replace the pump altogether.

Norms and rules

If you do not clean the chimney for a long time, it becomes clogged with soot and creates an obstacle to the passage of smoke.

Most often, smoke occurs due to trouble with the chimney. It is either clogged or initially equipped incorrectly. The most important point is the height of the chimney. SNiPs indicate the exact dimensions for different structural dimensions of roofs or the location of the pipe structure itself on the roof. For houses with flat roofs, this parameter cannot be less than 60 cm, if you count from the highest point of the parapet or add-ons, for example, a terraced canopy.

If there is a garden with tall trees around the house, or neighboring houses are located nearby and higher, it is better to make the pipe larger so that the smoke does not beat against obstacles, but freely escapes into space.

We carry out repairs of a water-heated floor - do not panic | Hearth

All problems of heating systems have an unpleasant property to manifest themselves at the most inopportune time.

Troubles occur during severe frosts, when stopping the heating is fraught with defrosting of the system, failure of pipelines and other incidents that are not easy and troublesome to deal with.

Some systems have a specific design, the features of which greatly complicate the repair work.The most difficult system to repair is a water heated floor, the failure of which can mean serious repair and restoration work.

All incidents with underfloor heating happen unexpectedly, and for prompt and correct troubleshooting, you need to be aware of what happens most often, what actions are needed to quickly solve problems. This question can affect any owner of a water heated floor, so you should consider it in detail.

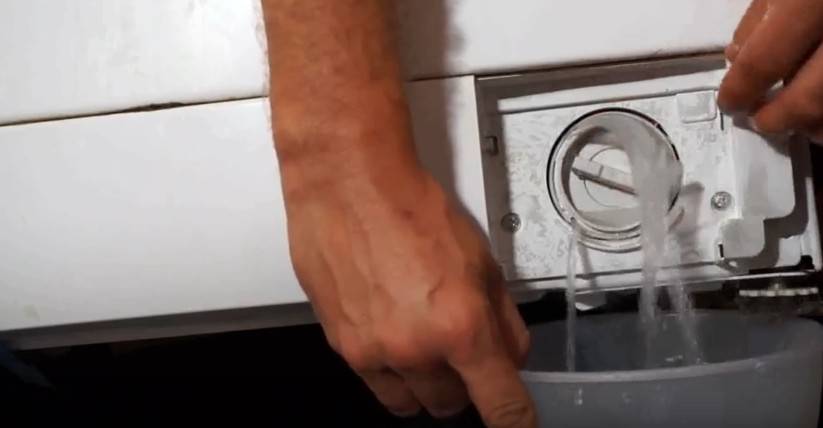

Channel cleaning

The device of chimneys in brick walls has two main options:

- vertical wells;

- horizontal channels.

If the building has a fireplace and a stove with a common chimney, it is possible to lock the gas path of the fireplace with a flue gas flow from the stove. For optimal functioning, smoke exhausters for fireplaces can be used.

When installing brick chimneys for their maintenance, cleaning should be installed - special doors.

What to do in the absence of purges? You should tap the walls for voids, determine the position of the channels. In places of turns, openings should be arranged for access to the inside of the channels. With a vertical arrangement of wells, cleaning should be arranged at the upper and lower turns.

If the channels are located horizontally, cleanings should be arranged on the sides, on the left and right turns, in the lower part of the channel. Cleaning should begin under the chimney outlet, gradually moving to the side and down.

One of the options why the stove smokes in the bath may be the damp masonry of the stove and chimney. In this case, you need to periodically heat the stove with a small amount of wood chips and ventilate the entire system by opening the doors of the furnace and blowing.

The stove always smokes for one reason - the draft is broken. And there are many factors that reduce traction. Smoke can occur only during kindling or be permanent, but in any case, the problem must be eliminated immediately, since it is dangerous to humans. In order to find out why is the oven smoking and combustion in the furnace worsened, it is necessary to check all channels of gas movement. In addition, the hull is examined for cracks and errors during masonry.

The heating battery is leaking: what to do depending on the type of defect

All recommendations can be specified in accordance with the location of the problematic phenomenon, in this case it is worth considering the 4 most common situations.

How to fix a leak between two radiator sections?

Here, additional sealing of the joint zone is required. The areas located between two sections of cast iron batteries, as a rule, have a rectilinear shape and are characterized by a small area, so that a defect can be quickly found and eliminated in a short time.

It is worth using the following algorithm:

- strengthen the guide screw with a conventional car clamp;

- you can make a clamp yourself using several steel plates (aluminum blanks will not work here). To tighten the loop, a bolted connection is used;

- the problem area must be isolated with a rubber gasket before applying the clamp. It can be replaced with a rectangular piece of fabric impregnated with epoxy glue.

It is necessary to wrap the joint between the radiators very carefully so as not to overtighten the connection, the same caution should be exercised when using the clamp further.

Elimination of a defect at the junction of the riser with the pipe

Here, the cause of moisture may be incorrect installation, the problem becomes noticeable after starting the heating system. The riser with the pipe is usually connected by welding or threading, in both cases, careless assembly, inaccurate welding, the use of pipes of different diameters cause smudges and necessitate immediate repair.

If strong mechanical pressure is applied to this one, for example, during children's play or when it becomes necessary to get to the top of the window, even small loads can cause a fracture at the joint or distortion. In this case, as in the previous case, a clamp in tandem with a rubber gasket can become a temporary measure.

Fixing a cracked radiator

The best solution may be to use classical welding, but this technique, firstly, is dangerous and time-consuming, and secondly, it requires the availability of equipment and relevant skills.

Cold welding is an excellent method for repairing a cracked radiator

Cold welding is an excellent method for repairing a cracked radiator

A suitable alternative is cold welding. The problematic area of \u200b\u200bthe radiator must be prepared - thoroughly dried and degreased. Next, you need to take a small ball of cold welding and press it firmly against the leak. The material polymerizes within a few minutes, half an hour is enough for it to solidify completely. This battery can be put into operation in a day, but after the end of the heating season, it will need to be replaced - cold welding is considered a temporary measure.

Restoring the integrity of the heating pipe

Steel pipes are used to supply the coolant, bandages with a gypsum-cement mixture are applied to them:

- cement is diluted in a small container to a medium-thick consistency;

- prepare bandage cuts about 30 cm long;

- bandages are soaked in cement mortar;

- the blanks are wound with force on the damaged area in several layers to ensure the strength of the connection.

If it is not possible to turn off the tap, the first bandage to be wound should be soaked in alabaster solution. The next layer can already be used with cement bandages.

Devices for detecting leaks in walls and floors

There are few such devices:

- Thermal imager. It detects temperature rises of several degrees. But:

- the water may be slightly warm;

- the leak may be hidden by a thick layer of concrete;

- location may be inaccessible to the instrument.

- Surface moisture meter - allows you to measure the high humidity of the wall surface.

The method gives low accuracy, it takes a lot of time. It is better to duplicate it with a thermal imager showing a large problem area, and then look for it with a moisture meter.

- Acoustic device, analogue of a hospital phonendoscope. Allows you to hear the sounds of a "trickle" flowing in the wall and find a leak.

Our company can eliminate almost all problems associated with leaks in heating systems, both in a private house and in Moscow enterprises.

We provide the following types of services:

search for leaks and localize these places;

we find the location of hidden plumbing and heating pipelines;

we carry out diagnostics of the state of pipelines;

we examine the premises and find the places of heat loss with the help of a thermal imager;

we localize and completely eliminate leaks in pipes with hot and cold water;

we can find places of violation of thermal insulation, and much more.

In case of problems, call our specialists at any time of the day. Departure of specialists within Moscow is free of charge and promptly on the day of treatment.

Water leakage is a phenomenon that, sooner or later, any homeowner who has a steam heating system in his home faces. Finding it is quite simple if the pipes are not laid in the thickness of the walls or floor. But fixing a leak in the heating system is a more difficult and even critically dangerous task if boiling water is gushing out of a torn pipe. It is better not to bring such a situation and take measures to eliminate coolant leaks at the first sign.

Taps and valves

Often water pipes hum when opening a faucet or flushing water. This is due to the fact that it moves unevenly through the system. And this means that somewhere there is a hindrance. Most often, such a hindrance is an old worn-out valve.

Finding a faulty node is easy. To do this, for each valve, do the following:

- Fully open the valve closest to the faucet or toilet;

- Drain or open the faucet;

- Gradually turn off the valve and listen to see if the sound level has changed;

- If there are no changes, move on to the next one, leaving this one completely open.

The valves cannot be repaired, the maximum that can be done is to change the gasket. But it is better to replace the faulty node. Fortunately, a good ball valve is inexpensive.

Water floor repair

Such a system is difficult to install and repair. But its advantage is that it rarely fails. According to conservative estimates, it will last 50 years.

The only way to get to the underfloor heating pipes is

The only way to get to the underfloor heating pipes is

The reasons why pipe damage is not frequent:

- A layer of screed, which is about 5 cm.

- The strength of the pipes, provided that they did not save when buying them.

- Ease of determining their location, subject to the creation of a diagram.

For repairs you will need:

- Press.

- Fitting.

- A piece of pipe, similar to the one mounted in the floor.

The repair process consists in removing the floor covering and screed at the site of damage. Next, a “patch” is cut in and pressed in to prevent leaks. Before restoring the screed, you should check if the pipes are leaking. To do this, put water on them. If everything is in order, then you can fill the screed and return the floor covering to its place.

Murmur, whistle

With the accumulation of air, it becomes audible how water murmurs in the heating pipes - a very common phenomenon. Air can enter the system during repair work, sucked in through loose connections - an air lock, regardless of its origin, prevents the normal circulation of the coolant. Not only does the water murmur annoyingly, but also the heaters do not heat up properly. In the event of the formation of an air lock that completely blocks the lumen of the pipe, the radiators after the problematic section of the pipeline will remain cold.

Air always accumulates at the highest points of the system, as it is lighter than water. It is there that special valves or automatic air collectors are usually installed. Radiators located at the end of a horizontal branch must be equipped with a Mayevsky crane. In some types of systems, each heater has a so-called "air vent".The nodes of modern designs are easily rotated by hand, older ones will have to be controlled using an adjustable wrench or a screwdriver.

First of all, you need to try to bleed the air from the radiators of your apartment. The operation starts with the coldest fixture, if any. Often it is local air pockets that interfere with heating. If this does not work, then you need to ask the neighbors from the top floor to find the appropriate faucet and open it. In difficult situations, it is better to call a qualified plumber. A characteristic whistle serves as an indicator of success - the release of air.

Conclusions and useful video on the topic

Methods for sealing threaded connections in individual heating systems using various materials:

Elimination of leakage from the overpressure valve in a double-circuit gas boiler:

In heating boilers, coolant leakage can occur in different parts of the heating and hot water circuits. Replacing the seal on threaded connections is not difficult to do on your own. To eliminate leakage through the fistula of the heat exchanger, you will need the skills of a plumber and a welder, considerable experience, and tools.

Repair of damaged elements is not always possible, sometimes it is more expedient to replace them. With the prompt elimination of leaks, there are no negative consequences and the boiler is operated in the same mode.