- Can I fix the problem myself

- Reasons for leaking safety valve

- The purpose of the thermostat for the water heater

- Electric Water Heater Repair Tools You May Need

- It is a kind of thermal valve that prevents

- The water in the boiler is rotten There is a solution

- Water in the boiler rots - causes and myths

- If the water in the boiler is rotten, no need to hesitate

- How to adjust the safety valve?

- How does an electric water heater work?

- Faucet contamination

- Hot water does not flow from the boiler: why and how to fix it

- scale

- pressure reducer

- Thermostat

- Mixer

- How to fix a leak with your own hands

- Installation problems

- Impact of corrosion

- Poor quality pipes or their incorrect connection

- Worn flange (gasket)

- Heater body rusted

- No grounding

- When the boiler is turned on, the valve drips

- What is a safety valve for?

- Trouble-shooting

- Scale clogging

- Failure of the pressure reducer

- Thermostat failure

- Clogged mixer

Can I fix the problem myself

Troubleshooting a water heater requires the user to be familiar with water heaters.This will help him not to confuse anything and the actions to correct the breakdowns will not cause even more problems.

If there is no such experience, then when dismantling various parts of the water heater, disassembling its parts and components, it is better to invite a specialist who repairs devices of this class and brand. The measures are connected with the fact that in different models of devices from different manufacturers, there are necessarily significant design and functional features, their own specifics of functioning. This applies to both the appearance of the device and the features of the configuration, the layout of its internal parts and elements.

For example, one well-known company decided to equip its water heaters with connecting elements in the form of self-clamping clamps, and another uses nuts to connect pipes, and the use of anything else, in this case, will be useless.

In heating devices of other companies, the coil of the water heating element is placed in a hole with a diameter of 65 mm. To fasten it to the tank, special tools are needed, and the bolts that are screwed in are so tightly joined with the nuts that it is simply impossible to unscrew them with all the desire. As a result, when something fails in the device, it will not be possible to quickly open its case. In addition, all fastener parts, and there may be more than 12 of them, will have to be removed with a grinder, and the likelihood that, by removing the bolts, you can also remove part of the body at the same time is very high. In addition, the boiler is an electrical device, and in order to work with it, you need to know which wire should be connected to one or another element.And not knowing and not observing safety precautions when working with electrical appliances can lead to dangerous consequences, the most harmless of which will be a short circuit in the wiring.

It is impossible to do without contacting specialists in the event of interruptions in the operation of the boiler, because difficulties are caused not only by the breakdown of parts of the device, but also by external factors that in no way depend on the user or on the device that he is trying to fix on his own.

Nevertheless, it is necessary to carry out preventive maintenance of the device from time to time: change filters, inspect the internal tank for leaks and possible damage, check the integrity of the electrical wiring, at the slightest suspicion that the device is not working correctly. In the event of a breakdown, contact the service center for troubleshooting. Then the water heater will last a long time, it will be safe to use it.

Reasons for leaking safety valve

- Discard excess volume. When the liquid inside the tank is heated, the volume also increases. That is, when a full tank is heated, the volume will increase by 2-3%. These percentages will be merged. Therefore, there is nothing to be afraid of here, since dripping water enters the process of operation of household appliances.

- Part failure. It is worth distinguishing where the volume is being reset, and where the component has failed. If the water heater is turned on, the water is heated but not used, then a small amount of it should flow out. For the average operation of the water heater (cooking, washing dishes), the liquid should flow out periodically and a little more than usual. Accordingly, during long work, for example, taking a shower, it will flow out even more.If water drips constantly, regardless of the level of work, then this indicates a breakdown of the device.

- blockage. The spring opens the valve, but cannot close it, as pieces of scale or any other debris interfere. In this case, water will always flow out, even when the boiler is turned off.

- High pressure in the water supply. In this case, it will also flow all the time, regardless of the state of the boiler. In order to understand that the reason is in it, and not in the blockage, it is necessary to measure the pressure of cold water in the water supply. If it is more than the set pressure, then the safety mechanism will come into action, and this will lead to leakage.

The purpose of the thermostat for the water heater

In addition to all of the above, the thermostat is responsible for the safe operation of the boiler. To be more precise, when the water temperature rises, the pressure inside the sealed tank also rises, and if this growth is uncontrollable, then an explosion will soon occur. This can be dangerous not only for equipment, but also for human health, if you are nearby at this moment. The temperature regulator is a device through which the optimum temperature level is also maintained.

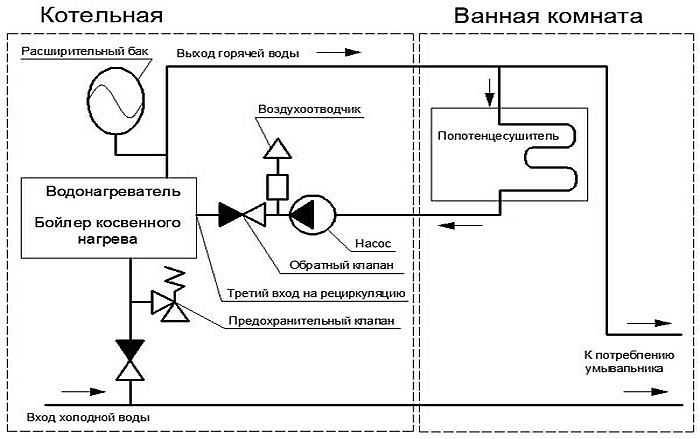

Starting with a hot water tank. When hot water is used, cold water enters the bottom of the tank at the same time. This will cool the bottom thermostat and the bottom element will heat up. If enough hot water is used to cool the top thermostat, the bottom element will shut off and the top element will heat up.

Electric Water Heater Repair Tools You May Need

Taking the above information, let's say that you have a normal amount of hot water, but when you use a lot, it takes a long time to heat up the backup. Let's say you have hot water, but it runs out quickly. Garden hose - to drain tankMultimeter - to test power, thermostats or elements.

- Element tool - for replacing elements.

- Screwdriver - for replacing elements or thermostats.

It is designed to cut off power to the water heater if the water temperature should rise to dangerous levels.

This is a kind of thermal valve that prevents:

- Overheat;

- Explosion;

- I damage not only equipment, but also nearby property.

It is he who is responsible for controlling the heating of water at the moment when the device is connected, and also for ensuring that the heating element is blocked in time. Almost every manufacturer seeks to supply the boiler with a thermostat. Products come in different models, however, they all have the same principle of operation. At the moment when you need to connect the equipment to the network, you need to immediately adjust the level of water heating.

If the limit switch needs to stop, the reset button will pop up. When the water in the tank has cooled, the button can be pressed to reset the limit switch. When the limit switch trips, there is a reason. This could be a faulty thermostat, a grounded item, or the limit switch itself.

It is a kind of thermal valve that prevents

The water heater thermostats control the temperature of the water and act as switching relays, sending energy where it is needed.The cells will always have a voltage of 120 volts, even when the thermostats are turned off. When the thermostat calls for heat, it will send another 120 volts to the element it controls. This will give the cell 240 volts, causing it to heat up.

Next, adjustable water heating is carried out, and the relay installed on the thermostat is responsible for opening the contacts of the heating element. When the tank is completely cooled down, the temperature drops below normal, and the contacts of the heating element of the relay close, due to which the system starts up, and the liquid in the tank heats up again.

The water in the boiler is rotten There is a solution

The easiest way to appreciate and enjoy the benefits of a boiler is during the period of replacement and repair of the pipeline, when a lonely icy stream of water flows from the tap. For owners of private houses with autonomous water supply, a water heater is of particular importance, since his work directly provides the supply hot water.

However, you still have to pay for convenience - spending time on caring for the container, removing scale and fighting unpleasant odors. The first signs that the water in the boiler is rotten will be a characteristic change in the smell and taste of water.

Water in the boiler rots - causes and myths

Before judging the degree of freshness and purity of water, it is necessary to find out in which cases the water acquires such a strange smell, the main reasons are:

1. The presence of hydrogen sulfide in the water. Water treatment at a treatment plant does not always provide the proper water quality, many systems are outdated and do not function at full capacity.

Often, the smell of hydrogen sulfide is not noticed when opening a tap with water, because for a clear distinction it is necessary to conduct a simple test - fill the bottle with cold tap water halfway, close the lid, shake thoroughly. After that, unscrew the lid and smell it. If a specific smell is felt, this means that the water initially contains hydrogen sulfide.

In this case, both cold and hot water contain the source of the smell, while remaining fresh. At the same time, the idea that the water in the boiler is rotten disappears. This problem is solved by installing a water treatment system with the removal of hydrogen sulfide.

Predisposing factors for water damage are prolonged stagnation of water in the tank with infrequent use of the boiler and insufficiently high heating temperatures.

Bacteria, forming the so-called biofilm, quietly retain their vital activity at a temperature of 60 °, tenaciously attached to the walls of the container.

3. The culprit of a similar situation, in which hot water changes its quality, while cold water remains quite suitable, is considered to be insufficient saturation of water with oxygen. For anaerobic bacteria, it is impossible to think of a better habitat - there is a small amount of oxygen, the water temperature is optimal for life and rapid reproduction.

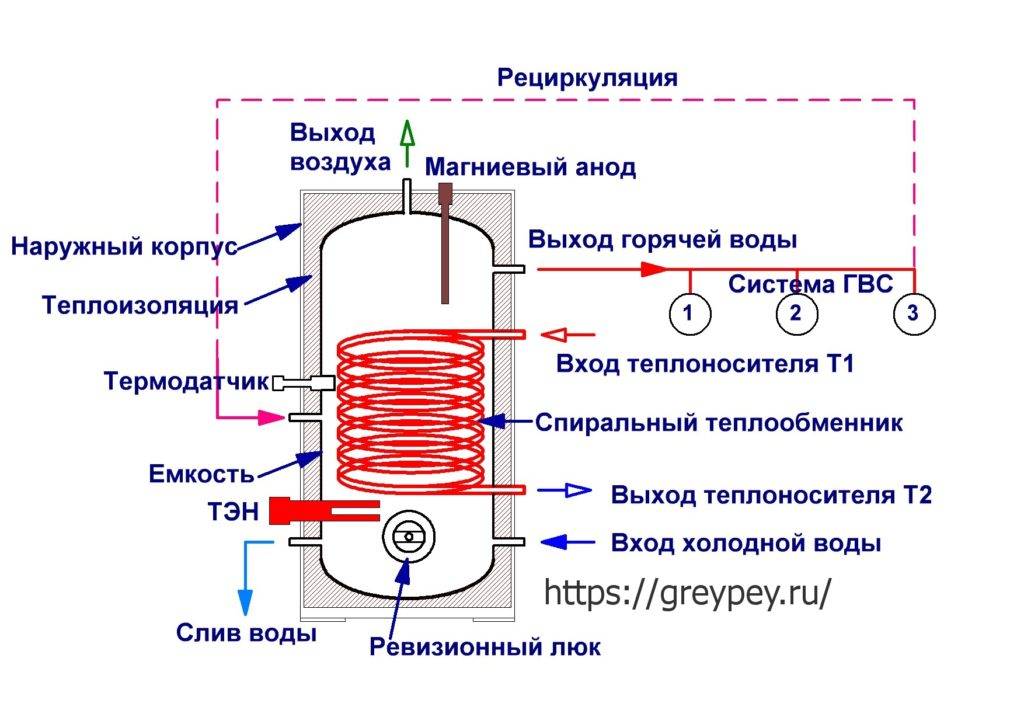

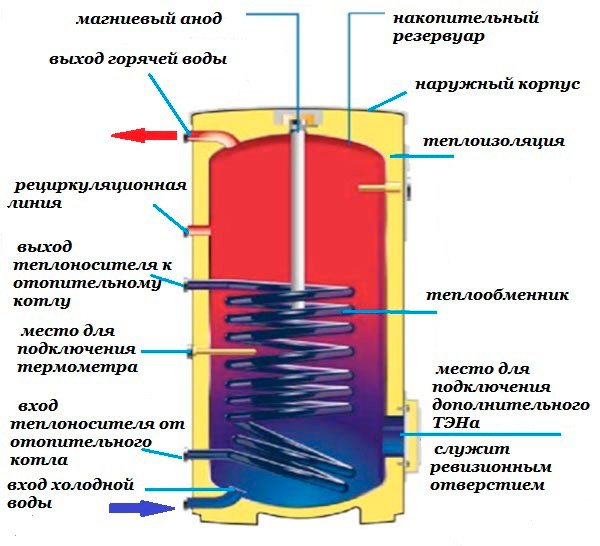

4. As mentioned above, the tank and working elements of the boiler require care and periodic inspection. An important detail of the water heater is an anode made of magnesium alloy. It is designed to prevent corrosion of the tank walls and scale deposits.

The service life varies depending on the composition of the water, the intensity of work

When replacing the anode, it is very important to purchase a quality part.

If the anode contains cheap commercial magnesium, which contains a lot of sulfide, then this will affect the quality of the boiler water - its properties, and especially the smell, will deteriorate.

If the water in the boiler is rotten, no need to hesitate

It is required to drain the old water, rinse the container with sodium hypochlorite to kill bacteria.

The main task for the elimination and prevention of subsequent reproduction of microorganisms is to eliminate predisposing factors. First of all, water of the appropriate quality must flow into the boiler, for this it is necessary to install water purification filters.

You should set the maximum heating temperature and actively use the boiler. It is not necessary for the water heater to stand idle and store water for a long time, which will lead to stagnation and inevitable pollution. Remember, water purification for the home and its preparation is the key to a healthy life.

How to adjust the safety valve?

In fact, all these devices have a factory preset, which cannot be changed, and in most designs it is impossible. Nevertheless, there are valves with an adjusting screw, twisting or unscrewing it changes the spring compression force, and hence the product response threshold. But remember that by changing the position of the screw in one direction or another, you set a new critical pressure very approximately, and this is unreliable in terms of safety.

The correct way is to adjust the safety valve using the selection method according to the nameplate pressure and nothing else. An exception is adjustable devices with a printed scale, but it makes no sense to put them, since the maximum working pressure of the boiler is a constant value.And therefore - purchase and install high-quality products in accordance with the technical requirements and they will properly serve for a long time.

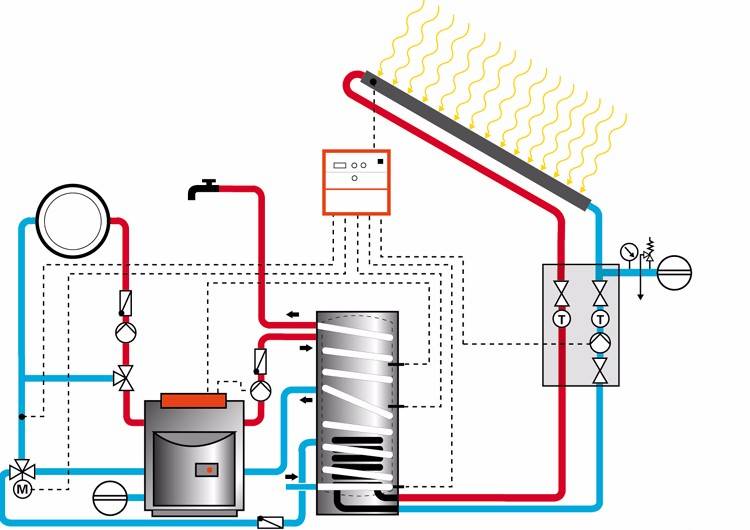

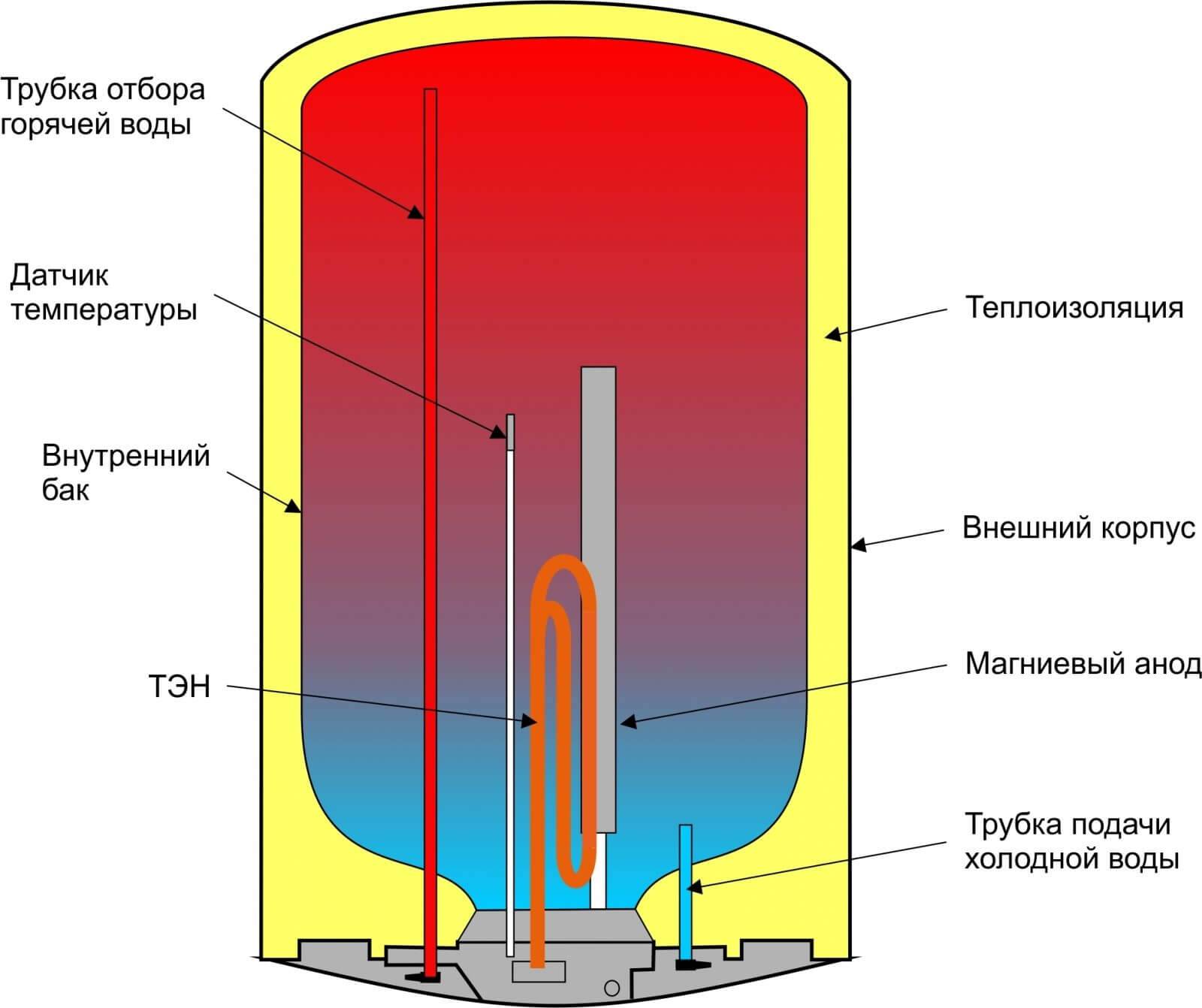

How does an electric water heater work?

When current passes through a conductor with resistance, according to the Joule-Lenz law, it heats up (here is the formula that determines the ratio of the parameters of the values \u200b\u200bof thermal energy and electric current according to it - Q \u003d R * I 2. here Q is thermal energy, R is resistance, I is current ). By placing the conductor in water, the released heat is transferred to it.

Although, it should be noted, today water heaters have been announced that operate on the principle of direct energy transfer (through microwave radiation) to water molecules, but it will take time until they are widely distributed.

It should be noted that all electric boilers are equipped with temperature control systems, they can be assembled according to the simplest scheme using bimetallic switches, or be more complex up to the use of microprocessors.

Also, almost all heaters, and especially storage heaters, have overpressure protection systems, most often these are safety valves.

Faucet contamination

Liquid will flow in a trickle if mixer spout congestion has occurred. The pressure will be equally bad for both cold and hot water. To fix the problem, you need to carry out a number of procedures.

- Close the riser to turn off the water.

- Remove the mixer carefully.

- Unscrew the spout from the common body.

- Remove the mesh and rinse it under running water. In case of formation of salt deposits or dense dirt, let it soak in a special cleaning solution.

- Rinse the mixer spout thoroughly and clean the insides of dirt with a brush.

- Reassemble the faucet in reverse order and reinstall it. Don't forget to open the riser.

This procedure may take some time, as an alternative, you can simply change the clogged mixer for new. Experts recommend replacing worn parts every few years to avoid serious breakdowns in the future.

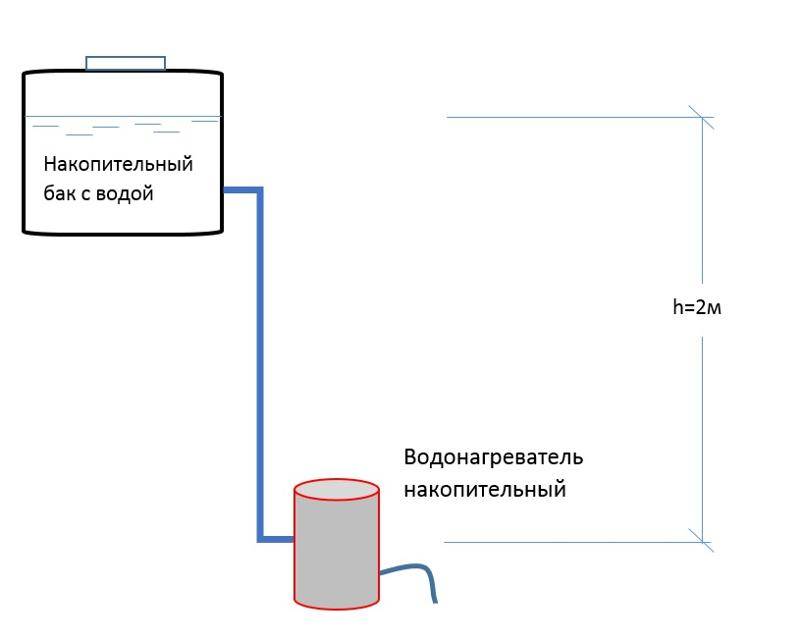

Hot water does not flow from the boiler: why and how to fix it

The function of the storage water heater is to achieve and maintain the set water temperature. After prolonged use, situations may arise when the jet pressure becomes weak or cold water runs from the tap instead of warm. These problems appear as a result of improper maintenance of equipment, for example:

- scale deposits on the heating element;

- malfunction of the pressure reducer;

- failure of the thermostat;

- mixer contamination;

- incorrect heating mode.

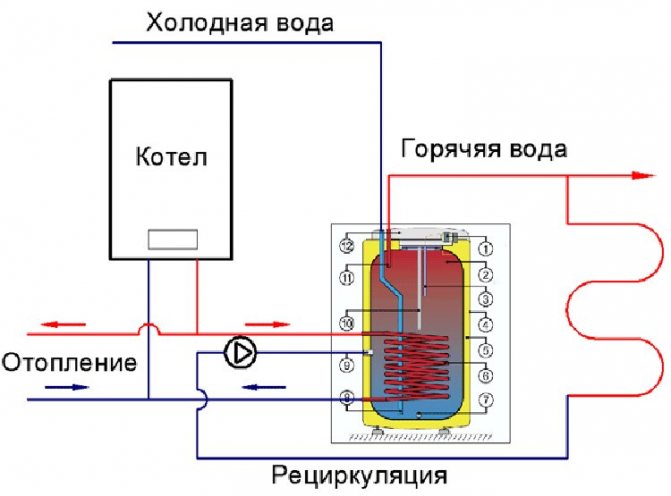

Before turning on the equipment, you need to shut off the hot water supply to the riser and open the tap on the mixer. If this is not done, the air from the tank will not come out and the tank will not fill up. In addition, heated water will go to the neighbors through the riser, and cold water will flow from the boiler or stop flowing altogether.

To find out the cause of the breakdown, you should first turn on the mixer valve, disconnect the appliance from the mains, empty the tank and proceed with the inspection. You may be able to troubleshoot on your own.

scale

Hard water and high temperatures contribute to the rapid deposition of salts on the walls of the boiler and the heating coil. Scale complicates the process of heating water, and a violation of heat removal can lead to burnout of the heating element. If during the inspection it turned out that the electric heater is covered with a layer of deposits, you must perform the following steps:

- remove the protective cover;

- unscrew the bolts on which the heating element is attached;

- remove and clean the part by soaking it in a solution of citric acid;

- install the spiral in place;

- use a tester to check the contacts.

If after cleaning the heating element is operational, then the design is assembled in the reverse order. But what to do when the spiral is out of order? In this case, you will have to replace the burned-out electric heating element.

Scale on the heating element

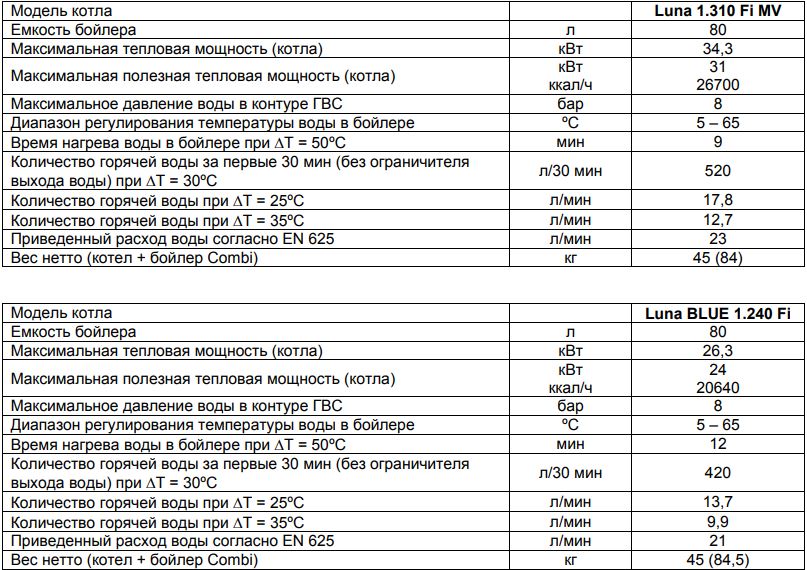

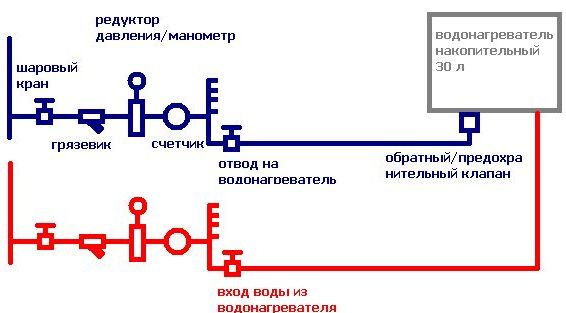

pressure reducer

In the water supply system, pressure surges from 2.5 to 7 atmospheres occur. To protect the boiler from deformation due to such drops, a special regulator is mounted at the inlet to it. After the correct setting of this unit, the water from the accumulator and the tap flows with the same force. The pressure at the inlet to the tank and the outlet from it must be the same. If the water pressure from the device is too weak, you need to adjust the gearbox or replace it.

Low pressure in the cold water pipes can also cause insufficient water supply from the boiler. To make sure of this, you need to turn the valve on cold water. If it flows in a thin stream or is completely absent, repair work is probably underway.

pressure reducer

Thermostat

Water heating does not occur if the thermostat does not turn on the heating element. You can troubleshoot a part as follows:

- disconnect the contacts and remove the thermostat from the housing;

- press the safety button;

- heat the copper tip (the button will turn off if the element is working);

- Measure the resistance across the contacts with a multimeter.

Perhaps the overheating protection just worked, and the device was restored to working order. If the tester is silent, the thermostat is out of order, it needs to be changed.

Thermostat replacement

Mixer

Water flows out of the boiler in a thin stream - this may indicate a blockage in the mixer. You will need to unscrew the spout from the mixer body, rinse the filter mesh from debris, walk along the inner contour with a brush and assemble the structure back. A faulty hot water faucet valve can also be the cause of low water pressure. If the components are very worn out, it would be better to buy a new mixer.

Installing a filter system at the boiler inlet will help to avoid frequent replacement of consumables.

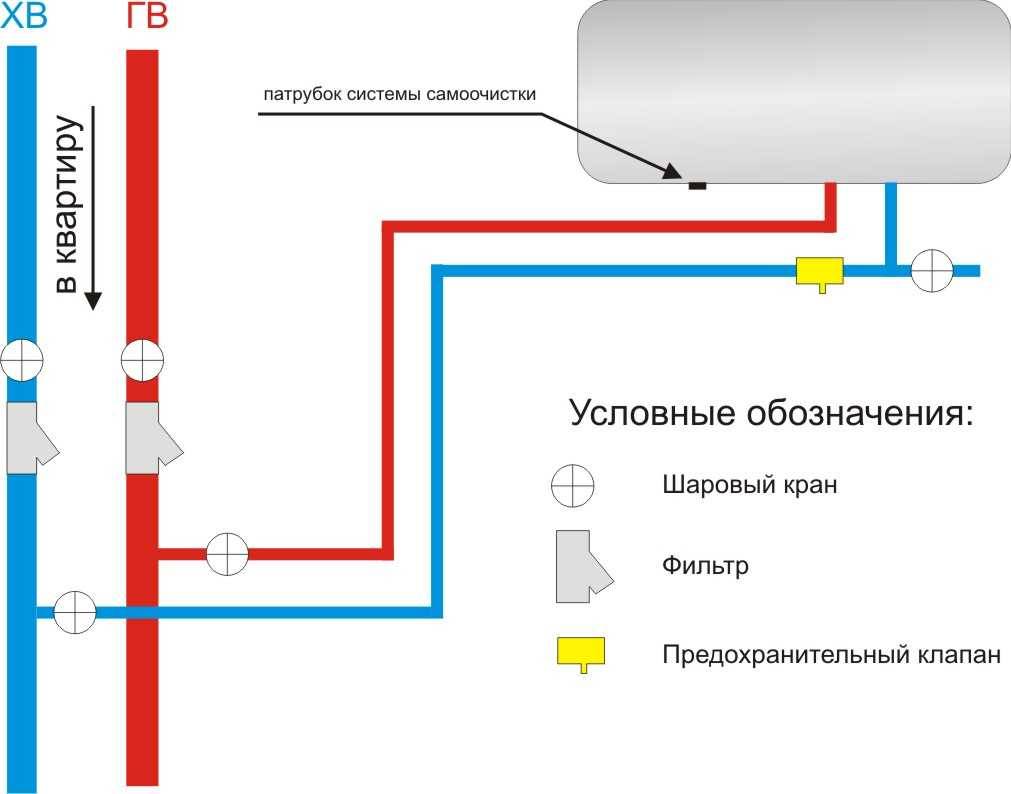

How to fix a leak with your own hands

How to identify a breakdown and deal with it yourself.

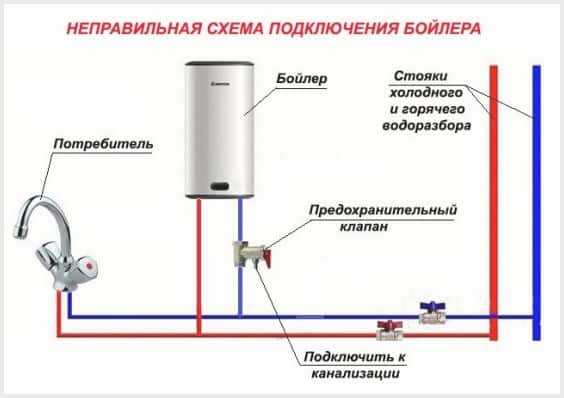

Installation problems

Shortly after connecting, you may notice water dripping from the tank. In this case, the shell of the body can be inflated or deformed.

At self-installation you forgot about safety valve, or it has been connected incorrectly. As a result, the container overflows with water and swells, after which it flows. You need to install a valve. It protects the system from overpressure.

- If the valve is installed incorrectly or if it breaks, the tank is deformed while draining water from the system.

- You turned off the boiler and turned off the water. At this time, the hot water inside cools down, and the body shrinks.

- The product is filled to the brim with water. During heating, it expands, and the tank swells.

In case of deformation, repair is impossible, you will have to install a new device.

Impact of corrosion

Have you replaced the magnesium anode in a long time? Then don't be surprised if the boiler is leaking. Magnesium attracts salts that are contained in water. As a result, impurities settle on the anode and destroy it, while the tank and the heating element remain intact. If the anode has been destroyed for a long time, corrosion of the metal case begins.

Poor quality pipes or their incorrect connection

Water dripping from pipes or connections? Sealing the joints will help fix and fix the problem: you need to replace the gasket or fum-tape. It is recommended to use metal-plastic pipes, because the body suffers as a result of water hammer.

Worn flange (gasket)

The heating element and the magnesium anode are mounted on the flange, a gasket is installed for tightness. If it is worn out, it will leak from below. Replace it with a new one or tighten the fixing nuts more tightly.

Heater body rusted

Dry heating element has a shell of steel and enamel - wear entails corrosion. How to repair a leaking element? Only replacement will help.

No grounding

Why is it necessary to ground the device? In the event of a breakdown of current to the case, the latter will be subjected to electrocorrosion. In addition, it is life-threatening: tap water or the surface of the tank can be electrocuted.

If it's not the worn parts of the water heater that can be replaced, then the tank is beyond repair. When the hull itself broke down, you have to buy new equipment.

How to avoid malfunction? Only by correct operation:

- Make sure that the pressure in the line does not exceed 3 atm. Otherwise, you need to install a reduction gear.

- Once every six months, inspect the equipment, clean the tank and heater from scale, change the anode.

- Install a water filter if the water in the area is hard.

It is always better to prevent a breakdown than to repair it. Follow instructions.

When the boiler is turned on, the valve drips

The situation is simulated when the water heater is turned on without water intake.

The reason for the discharge of water will be a valve failure.

This is explained simply: with the initial heating of the liquid, its volume increases by 3%. This surplus is discharged into the sewer. But after the heating device simply keeps the water at a constant temperature. The valve must not drip.

The appearance of drops indicates a malfunction of the device or its clogging with debris particles.

The second, considered situation, paints a picture of the correct operation of the mechanism.

The water heater works with increased water intake (take a shower). The volume of hot water leaves, cold liquid enters in its place. The new supply begins to heat up - “new” excess water appears, which is continuously discharged into the sewer.

The third situation arises when the water intake is stretched over time. Water discharge does not have to be permanent. Drips from safety valve intermittently. This indicates the correct operation of the device.

For example, washing dishes. The water withdrawal process is extended. Water also should not drip constantly.

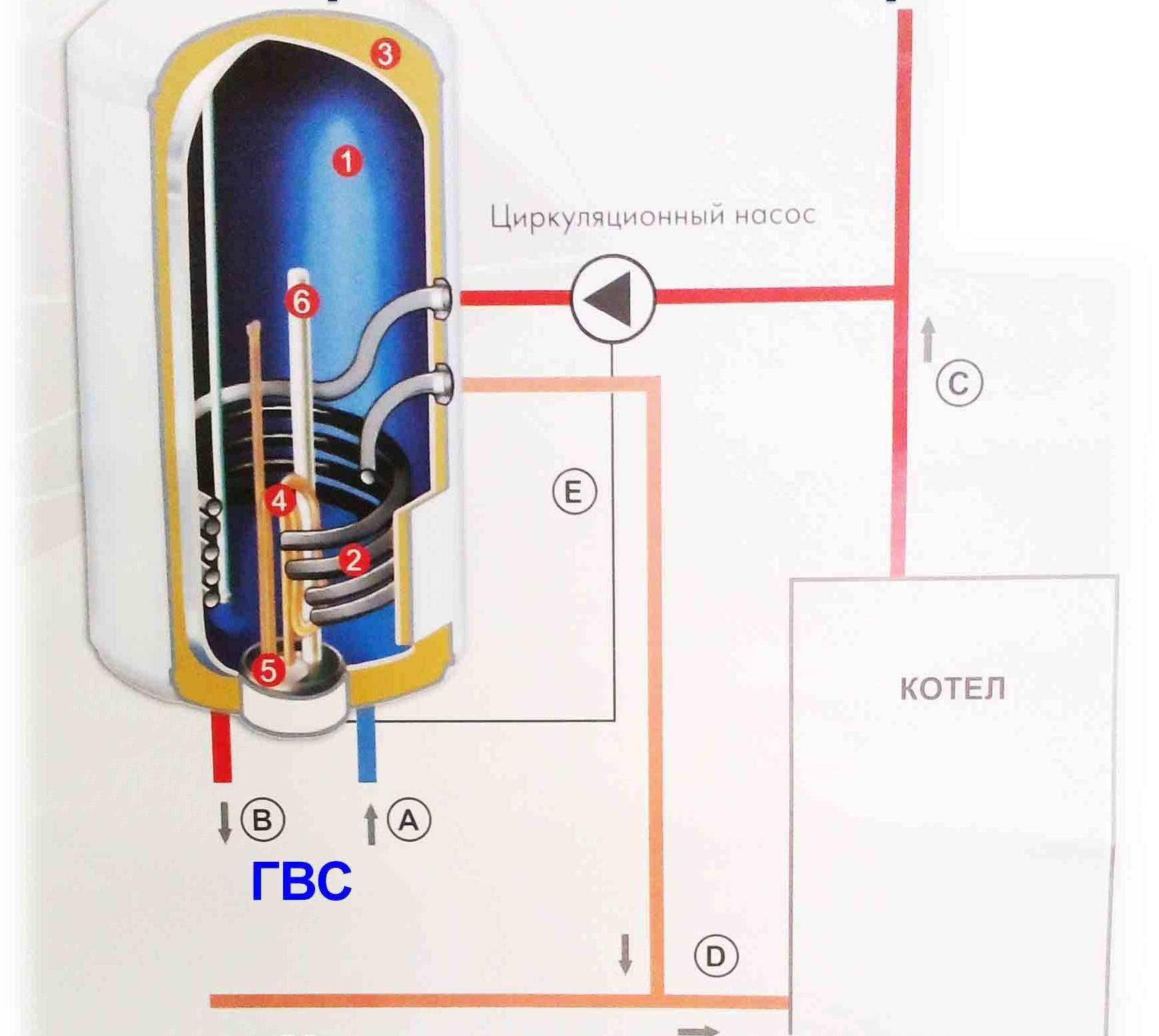

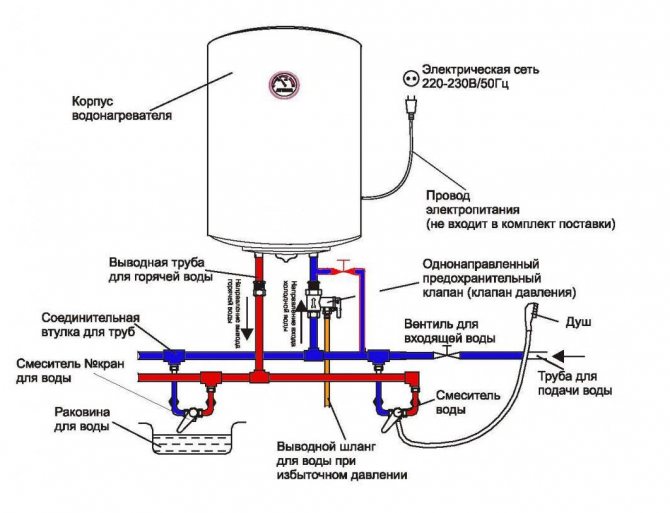

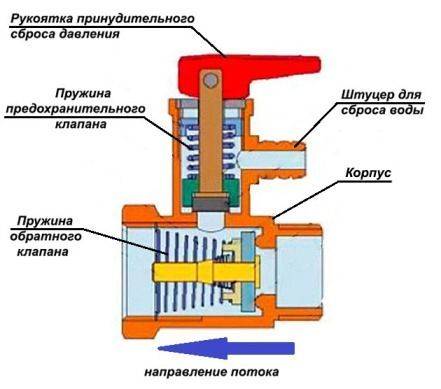

What is a safety valve for?

The safety valve, which is included in the delivery set of any storage water heater, is an integral element of the safety group of this device. It is prohibited by the manufacturer to operate the water heater without it, and it is simply unsafe.Any water heater has a working water pressure that has both a minimum threshold (the minimum pressure required for normal operation of the device) and a maximum threshold (exceeding which can damage the device). The maximum threshold, in turn, consists of two values:

- Pressure in the water supply line. This is the pressure with which water is supplied to the device.

- The pressure that occurs in the water heater tank when water is heated.

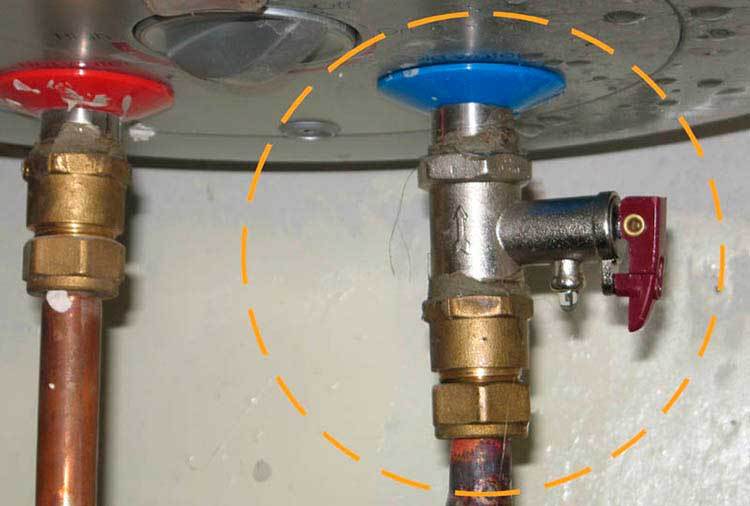

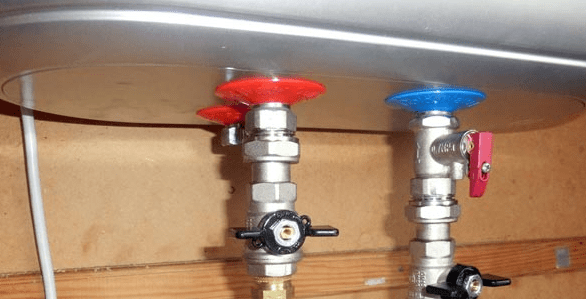

The safety valve is designed for a pressure no greater than the maximum working pressure of the water heater. The valve is installed in accordance with the instruction manual for a specific model of the water heater. For most models of water heaters, it is mounted on the cold water supply pipe and performs the following functions:

- prevents spontaneous draining of water from the water heater when the cold water supply is turned off in the main network;

- relieves excess pressure in the internal tank of the water heater;

- can be used to drain water from the appliance;

Now let's look at these functions in more detail:

The figure above shows the safety valve in section. One of its elements is the check valve mechanism. It is he who is responsible for retaining water in the EWH tank and does not allow it to return to the water supply system

Accordingly, when installing the valve, it is important to prevent damage to this mechanism, therefore, manufacturers recommend twisting 3-3.5 turns of the thread.In the valves offered by our company, this problem is solved systemically, by means of a restrictive metal platform, beyond which it will not be possible to screw the valve, and therefore it is impossible to damage the check valve mechanism.

The next item on the list, but not least, is the safety valve mechanism. As mentioned earlier, for any EWH there is a maximum water pressure threshold, which consists of two indicators: the pressure in the water supply system and the pressure that occurs when the water expands during heating

When the total pressure begins to exceed the value of the maximum threshold, the stem begins to compress the safety valve spring and thus opens the fitting hole to drain the water. The pressure is released and the water heater continues to operate normally.

From here there are several important points that I would like to draw your attention to:

It is important to know the pressure in your water supply system, with a high value, the likelihood of a permanent operation of the safety valve increases significantly. In this case, it is recommended to install a reducer to reduce the main pressure in the network

The gearbox is not included in the EWH delivery set and must be purchased separately.

It is strictly forbidden to restrict the movement of the forced pressure release handle by rigidly fixing it in its normal position, as this makes it impossible for the safety mechanism rod to move and thus does not allow excess pressure to be released.

Since the release of excess pressure is accompanied by the appearance of drops water from the water outlet - it is recommended to make a tap from the safety valve fitting (any flexible tube or hose is enough) to the sewer (sink, bathtub, drain tank or siphon). Another function of the safety valve is to drain water from the device. Due to its time-consuming nature (this is not the fastest process, especially for large volumes), this method is relevant mainly in cases where the installation of the device did not provide for the possibility of quickly draining water. To do this, you must: disconnect the EWH from the network, shut off the cold water supply to it and open the hot water tap at the water intake point (mixer). After that, raise the handle for forced water discharge and drain through the fitting.

ATTENTION!!! The safety valve is not intended to protect the device from sudden pressure surges in the water supply network. To solve this problem, a special device is installed in the system - a hydraulic shock absorber.

It is forbidden to use the storage water heater without a safety valve, or with a valve whose pressure exceeds the maximum set for this device. In the event of the above violations, the consumer's warranty obligations do not apply to the water heater.

Trouble-shooting

Having found a problem node, you need to start restoring the boiler's performance. The procedure depends on the specific reason that prevents the device from working normally. Let's consider the most common situations.

Scale clogging

Clogged water heater

Scale is deposits of insoluble carbonate salts on the walls of appliances for heating water. It is found in kettles, washing machines, water heaters.

The amount of scale depends on the hardness of the water. In regions with hard water, even for a year of operation of the boiler, the amount of salts deposited on the walls may be enough to completely block the lumen of the heating element tubes or significantly narrow it.

If scale has caused the failure of the water heater, repairs must be carried out in the following order:

- Open and remove the protective cover from the water heater.

- Unscrew the nuts holding the heating element in place and remove it.

Dismantling the heating element

Wash the boiler walls and the heating element coil from carbonate deposits. Organic acid - lemon or oxalic - will help dissolve the hard crust. You can also use industrial products - antiscale. Soak the part in an acidic solution to free it from accumulated deposits.

Cleaning the heating element from scale

- Using a tester, make sure that the heating element coil has not burned out due to a violation of heat removal by scale.

- If the spiral is intact, assemble the device in the reverse order of dismantling.

If the heating element is out of order, you will have to look for a new one or buy a new boiler - you need to choose the most economical solution. If repairs require large financial costs, it is more profitable to immediately purchase new equipment.

Failure of the pressure reducer

The pressure drops of the incoming water in the system can be from 2.5 to 7 atm. To compensate for surges at the inlet to the boiler, a special unit is installed - a gearbox. Its task is to ensure equal pressure at the outlet of the boiler and from the tap. If it fell due to the failure of the gearbox - it is necessary to adjust its operation or replace the broken part.

Low pressure in the main water supply also leads to a drop in pressure at the outlet of the water heater or instantaneous water heater. Unscrew the hose and check the pressure level: if water comes from the main water supply in a thin stream or does not flow at all, it is worth waiting, as the problem may arise due to repair work. If the pressure has not recovered within a few hours, it is worth contacting Vodokanal.

Thermostat failure

If the water leaving the boiler does not heat up enough or does not heat up at all, the cause may be the failure of the thermostat - it is he who is responsible for maintaining a constantly high temperature. To diagnose, turn off the power to the boiler and remove the thermostat from the housing.

Next, you need to perform the following steps:

- Press the thermostat button.

- Heat up the copper tip of the thermostat. If the node is healthy, the button should be disabled.

- Ring the thermostat circuits with a tester.

Typically, a thermostat malfunction is caused by an overheat protection trip. As a result of the operations performed, the device should start working, and the problems will disappear after it is installed in place. If the tester shows an open circuit, you will have to replace the burned-out thermostat.

Clogged mixer

If water comes out of the boiler with sufficient pressure, and it runs slowly from the tap, the reason lies in the clogging of the mixer with scale or rust. You will need to turn off the water, disassemble the mixers and thoroughly clean the filter mesh. You also need to inspect all the sealing gum and make sure that the crane boxes are working properly.