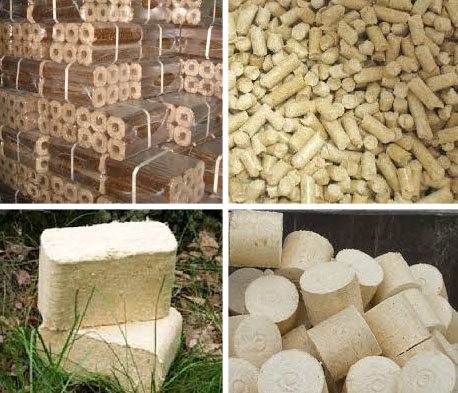

- Eurobriquettes PINI KAY

- Advantages of fuel briquettes

- What is Eurowood and can it be an efficient fuel?

- Pellet classification

- Blitz Tips

- What are fuel briquettes made of?

- Fuel quality criteria

- Possible heating systems

- Differences between pallets and pallets

- Fuel feed mechanism

- Classification of briquetted products

- pyrolysis gas

- Coal for a good boiler

- What is more profitable to use

Eurobriquettes PINI KAY

In shape, they repeat square pencils without a lead. This hole is provided by manufacturing technology to create additional traction. Therefore, they have a very high thermal efficiency. Before getting to consumers, the briquettes for strength and removal of excess moisture were pre-fired.

Such briquettes are more expensive than firewood and many other types of fuel. Easy to transport and fold for storage. Their shape is ideal for fireplaces. They are taken to nature instead of firewood for fires. In terms of heat transfer, there is no equivalent to briquettes made of wood and sunflower husks using PINI KAY technology. No binders of inorganic origin are used in the production of briquettes using PINI KAY technology. They are pressed at high temperature and under high pressure. In this case, the substance lignin is released, which sticks the sawdust together.

Advantages of fuel briquettes

Fuel briquettes are distinguished by the ability of high heat transfer. Their calorific value is 4600-4900 kcal/kg. For comparison, dry birch firewood has a calorific value of about 2200 kcal/kg. And birch wood of all types of wood has the highest heat transfer rates. Therefore, as we see, fuel briquettes give 2 times more heat than firewood. In addition, throughout the combustion, they maintain a constant temperature.

Long burning time

Briquettes are also characterized by a rather high density, which is 1000-1200 kg/m3. Oak is considered the most dense wood applicable for heating. Its density is 690 kg/cu.m. Again, we see a big difference in favor of fuel briquettes. Good density just contributes to the long-term burning of fuel briquettes. They are able to give a steady flame from laying to complete combustion within 2.5-3 hours. With the supported smoldering mode, one portion of high-quality briquettes is enough for 5-7 hours. This means that you will need to add them to the stove 2-3 times less than if you fired wood.

Low humidity

Humidity of fuel briquettes is no more than 4-8%, while the minimum moisture content of wood is 20%. The briquettes have such a low moisture content due to the drying process, which is an essential step in the production.

Due to their low humidity, briquettes reach a high temperature during combustion, which contributes to their high heat transfer.

Minimum ash content

Compared to wood and coal, the ash content of briquettes is much less. After burning, they leave only 1% ash. Burning coal leaves up to 40% ash.Moreover, the ashes of the briquettes can still be used as fertilizer, and the ashes of coal will still have to be disposed of.

The advantage of heating with briquettes is that the cost of cleaning and maintaining the fireplace or stove is much reduced.

Environmental friendliness

The choice of fuel briquettes for heating in the house is a great option for people who care about their health. Briquettes practically do not emit smoke and other harmful volatile substances, so you can fire the stove without charcoal even with a low chimney draft.

Unlike coal, the combustion of briquettes does not form dust that settles in the room. Also, since briquettes are fuel produced from waste, there is less damage to the environment.

Ease of storage

Fuel briquettes are convenient both to use and store. Unlike shapeless firewood, briquettes have a fairly regular and compact shape. Therefore, even if you try to put firewood as carefully as possible into a compact woodpile, they will still take up 2-3 times more space than briquettes.

No condensation on chimneys

Since firewood has a higher moisture content, during combustion, it forms condensate on the walls of the chimney. Depending on the moisture content of the wood, there will be more or less condensation, respectively. What is bad about condensate in a chimney is that it narrows its working section over time. With heavy condensate, after one season you will notice a strong drop in draft in the chimney.

8% humidity of the briquettes practically does not form condensate, consequently, the chimney's working capacity is maintained longer.

What is Eurowood and can it be an efficient fuel?

Most summer residents attended to the preparation of firewood back in June-September.But what if there is not enough fuel? Or was it not purchased on time for one reason or another? Or is it necessary to kindle a fireplace on rare trips to the country? The way out of the situation can be the so-called eurofirewood

Eurowood is compressed briquettes made from sawdust, husks, straw, grass or peat, which can be used in stoves, fireplaces and even solid fuel boilers. Natural raw materials are pressed under pressure without using toxic binders, so eurofirewood can be called an environmentally friendly product. But our consumer is not primarily interested in this. Much more important is the effectiveness of "alternative logs".

As practice shows, this fuel burns surprisingly hot. If ordinary firewood gives 2500-2700 kcal / kg of heat, then briquettes from compressed sawdust - 4500-4900 kcal / kg. That is almost twice as much.

Such high rates are explained by the fact that compressed briquettes undergo efficient drying during the production process, and the heat transfer during combustion directly depends on the moisture content in the fuel. For European firewood, this figure is about 8%, while, as for ordinary wooden logs, it is about 17%.

Eurowood is destroyed by moisture, so they need to be stored in a dry place.

Of course, above we have given average figures. The calorific value of eurofirewood depends on several factors. First of all, from raw materials. Best of all shows itself ... the husk of seeds and cereals. The vegetable oils contained in them provide the maximum calorific value - 5151 kcal / kg. True, when they burn, they create a rather thick smoke that settles on the walls of the chimney in the form of a black coating.

Compressed sawdust is almost as good as husk. They form up to 5043 kcal / kg, while there is significantly less ash and soot from them.

Straw also gives off heat well (4740 kcal / kg), but at the same time it smokes. Oddly enough, pressed grass burns quite cleanly and efficiently - 4400 kcal / kg. Rice closes the rating - it produces a lot of ash and little heat - 3458 kcal / kg.

In addition to raw materials, there is another important factor - density, more precisely, the amount of combustible substance per cubic centimeter of volume. For oak firewood, which is rightfully considered the best, this figure reaches 0.71 g / cm³. But high-quality fuel briquettes are even denser - up to 1.40 g/cm³. However, options are possible.

There are three main types of eurofirewood, depending on the density and shape.

Pini-kay

— fuel of maximum density (1.08–1.40 g/cm³). Made in the form of square/hexagonal briquettes. To ensure efficient air circulation in the furnace, manufacturers make a through hole in each such "log".

Nestro

- firewood of medium density (1–1.15 g / cm³) and cylindrical shape.

Ruf

- small bricks of the lowest density 0.75–0.8 g / cm³. The least efficient fuel of all listed.

Eurowood made from peat cannot be used to heat boilers, fireplaces and stoves. They are intended only for industrial needs, as they contain unsafe volatile substances.

So, given the wide range, it will not be difficult to choose the best eurofirewood in all respects. What limits their distribution? The answer is simple - the price. As of December 2020, this fuel costs from 5,500–9,500 rubles. per ton. This is two to three times more expensive than regular logs.Therefore, eurofirewood is usually used as an "ambulance" in case traditional fuel is not at hand.

The high price obliges to be vigilant when buying. An unscrupulous manufacturer may neglect the cleaning of raw materials or deliberately add leaves and other debris to it in order to reduce the cost of production. Also, mistakes or deliberate negligence during drying are not ruled out, due to which the briquettes will turn out to be too wet.

It is impossible to determine the quality of the product by eye, it is also impossible to check it on the spot. To protect yourself from an unsuccessful purchase, you should first of all check the documentation. It should contain detailed characteristics of the product and information about the tests carried out.

Also, given the high cost of Eurowood, it is advisable to take a couple of kilograms for testing before purchasing a large batch. Only by testing the fuel on site, you can be sure of its effectiveness.

Pellet classification

According to their grade, pellets are divided into 3 types:

- Industrial pellets. Gray-brown granules. They contain approximately 0.7 mass fraction of ash due to the fact that the wood, which is the material for the manufacture of this type of pellet, has not been debarked. In other words, these wood pellets contain a large amount of bark. Due to the high content of bark, not all boilers can work with such fuel, this leads to their breakdown. But their advantage lies in the cost: industrial pellets cost less than premium quality pellets by about half the amount. And if a person has a boiler that can handle this type of pellets, then you can use them without any problems. However, cleaning the boiler due to this fuel will take place more often.

- Agropellets.The color of such fuel varies from gray to dark gray. The color depends on the material from which the pellets are made. You can often find sawdust pellets. This type is usually obtained from crop waste, such as straw, hay, leaves and others. Therefore, sometimes this kind of fuel is called straw pellets or leaf pellets. This type of fuel is the cheapest, since a huge amount of ash falls out during combustion, even more than during the combustion of industrial pellets. They are usually used at large thermal power plants; regular cleaning of slags is required. However, this type of fuel causes a number of problems: the highest ash content and the problem of transportation, because of this, agro-pellets are cheaper than other pellets. During transportation, half of the granules crumble into dust due to their softness. And, as you know, such dust will no longer serve as material for boilers - the boilers will become clogged even more. Therefore, in order to use this type of fuel, the best option would be to be close to the very place where agro-pellets are produced.

- White pellets. By name it is clear that the granules of this class are distinguished by their slightly gray, yellowish white or completely white color. They have their own pleasant smell - the smell of fresh wood. Such pellets are expensive, as their ash content is the lowest and is approximately 0.5%. If you use such fuel for heating, you can forget about cleaning the boiler for the next couple of months. When using them, the equipment will serve for a long time, and little ash will be released from them.

There is also a separate type of pellet that is not included in this classification:

Peat pellets - such fuel is characterized by high ash content.Such material is ecological and eco-friendly. Due to the ash content, these pellets are used only in industry. And most often - in improving fertilizers.

Blitz Tips

- In the manufacture of a homemade screw extruder, only high-quality steel should be used.

- It will not be possible to reproduce the production process of briquettes with the release of lignin on home-made equipment, therefore it is recommended to add clay, cheap wallpaper glue or corrugated cardboard to the crushed raw materials. These components will be used as a binder.

- The simplest and most affordable are do-it-yourself devices equipped with a manual screw drive. The perforated form is filled with prepared sawdust mixed with a binder. Forming is carried out by tightening the screw. Such a press has one significant drawback - low productivity.

- Some craftsmen use a hydraulic jack to assemble a home press. It is worth noting that such a device is not capable of creating a pressure of even 300 bar. A small amount of water and a binder added to the crushed raw material will help improve the quality of the briquettes.

- Crushed sawdust is used for the press, so the equipment should be supplemented with a rotary machine, on which raw materials can be prepared for pressing. You can also make a chopper with your own hands from an old washing machine. To do this, it is enough to install knives instead of an activator.

What are fuel briquettes made of?

Wood fuel briquettes are made from wood waste - roughly speaking, these are pressed sawdust that has undergone a certain preparation. The preparation process includes grinding and drying. As a result, raw materials are born, ready to go under the press. Some sawdust does not need drying at all, as it is almost dry.

Most often, this type of fuel is produced from ordinary sawdust.

Safe organic compounds act as binders in fuel briquettes for furnaces, and some types of eurofirewood are made without an adhesive base. The harvested raw material is sent under the press, forming dense, neat bars, ready for further use. Roasting can be used as an additional processing - it all depends on the manufacturer and the technologies used by him.

The resulting wood briquettes for furnaces are sent to consumers - they are suitable for heating houses and non-residential buildings, and are used to kindle fireplaces. They can also replace firewood at a picnic, but in this case you will not hear the sound of crackling firewood. But get an even flame, without flying coals and sparks.

Fuel quality criteria

As you might guess, in order to release a significant amount of thermal energy, pellets must be of the appropriate quality. Unfortunately, given the ever-increasing popularity of this heating method, low-quality fuel samples from unscrupulous manufacturers or outright crooks began to appear on the market. Of course, the use of artisanal technologies does not allow for effective heat transfer. There is an erroneous opinion among many owners of pellet boilers that fuel consumption depends on the color of the pellets.This is not true at all. High-quality dark-colored pellets are made on the basis of wood fractions containing tree bark, light yellow pellets are made from furniture industry waste, and dark brown pellets are made from logging waste. High quality pellets have a fairly high density, the numerical value of which exceeds 1, so they must sink in water. Also, an important parameter that determines the quality of this type of solid fuel is the amount of ash remaining after complete combustion of pellets (ash content). According to the norms adopted in a number of European countries, this figure should not be more than 1.5%. In other words, after burning 10 kg of fuel, no more than 150 g of ash should remain. If this indicator is higher, a significant amount of slag will be formed during combustion. And this significantly reduces the performance of the boiler.

In addition to the characteristics described above, high quality pellets should have the following characteristics:

- The humidity of the pellets should not be more than 10%, otherwise the consumption of pellets will be significantly increased due to the need to compensate for the loss of heat capacity.

- The dust content must not exceed 11%. Exceeding this indicator is accompanied by an increase in ash content.

The packaging must be sealed. The most optimal option is when the granules go on sale in special bags with a waterproofing film on their inside. Such packaging allows the granules to retain their original quality characteristics for many years. Currently, 1 kg of fuel costs from 6 to 10 rubles.If a large bunker is used with the boiler, it is best to purchase fuel in large bags (big bags). The mass of one such bag is 900 kg.

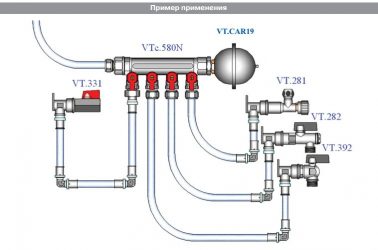

Possible heating systems

For a house and a large area, the following heating systems on sawdust are used:

- Bake. It is used to heat the adjacent space. As you move away from the oven, the temperature drops rapidly.

- Stove with water register or heater. The operation of the heating system combines local heating of the room directly from the furnace, as well as heating and delivery of the required coolant to remote areas of the building through an air duct (for air) and a pipe (for water, antifreeze).

- Water heating by means of installed radiators, which transfer heat energy to the room air due to the constant circulation of the heated liquid.

- Air heating differs from water heating in another coolant and is considered an expensive heating option. To implement such a heating system, it is necessary to lay a network of air ducts and install automatic devices for humidifying very dry air.

- Warm floor. The system can work with different coolant. With such heating, a comfortable microclimate is created at all levels from floor to ceiling. The downside is the high cost of the required materials, the complexity of the work, the need for thermal insulation of the floor from the side of the foundation, basement or soil.

When heating a building, the boiler is increasingly becoming the center of the heating system. Unlike a stove, which heats only the place where it is installed, a boiler heats a coolant that transfers heat to heating appliances throughout the house.

Differences between pallets and pallets

Pallets and pallets consist of boards and bosses, with the boards forming a lattice.

The difference between pallets and pallets is that the latter are suitable for transportation not only with a forklift, but also with a crane.

This expands the scope of their application.

Structurally, they are arranged in the same way, and the difference is obtained due to a more successful selection of shapes and sizes.

Often, those who need containers for transporting various goods do not buy finished products, but only the main element, that is, bosses, which are a jumper between the upper and lower gratings of boards.

The softer the wood of this part, the less durable the pallets are and the higher the likelihood of damage to the package of goods from a nail head that has come out of the board.

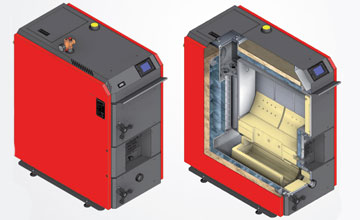

Fuel feed mechanism

Boilers for heating on solid fuels operate autonomously and can be dispensed with with little or no maintenance. Sawdust is fed by several means.

The receiver has open access to the outside of the building. It is equipped with a screw transmission connected to the storage. When the bunker is fully loaded with fuel, the conveyor starts working - it supplies fuel to the mechanized compartment.

There are two types of storage, they differ in the technique of feeding sawdust into the boiler:

- hopper with an inclined base, cone-shaped, with a screw mechanism in the lower part;

- agitator with blades, sawdust is loaded by rotation.

From storage, not all fuel enters the furnace immediately. Pyrolysis type wood chip boilers are equipped with a drum and a screw transmission, which supply fuel in parts.

Classification of briquetted products

In accordance with the listed technologies, equipment used for production, there are three types of briquettes:

- In the form of a brick, obtained by hydropressing under pressure up to 400 bar (about 4 kgf / cm 2).

- Cylindrical - about 50 cm long, 10 cm in diameter, using methods of hydro- or mechanical pressing with pressure from 400 to 600 bar (4-6 kgf / cm 2).

- Pini-key - with radial holes, obtained by processing on screw (extruder) presses, with simultaneous exposure to high pressure (up to 110 bar) and high temperature (250-350 ° C) modes. Differ in duration of burning, the increased thermolysis, density and resistance to shock influences.

The density of briquettes is a fundamental value that directly affects the calorie content, mechanical resistance, resistance to moisture.

Warehouse of briquetted products

The higher the density, the higher the listed indicators accompanying it. Which fuel briquettes are better is up to consumers to decide, in accordance with their own needs and preferences.

pyrolysis gas

Sawdust is a good fuel for gas generators.

Sawdust is a good fuel for gas generators.

When using such equipment, there is no direct combustion of sawdust, but the release of combustible gas from them, which is then burned.

This allows you to get more energy over a longer period of time with the same amount of wood waste.

The principle of operation of such installations is as follows:

- sawdust is loaded into a metal container, but not rammed so that air passes between them;

- they begin to blow air from below so that there is forced draft in the installation;

- sawdust is kindled and waited for when they flare up strongly;

- when the sawdust flares up, they stop blowing air and almost completely block the natural flow of air;

- the unit switches to the pyrolysis mode - thermal decomposition of fuel into ash and combustible gases;

- the amount of air that enters the installation is sufficient to smolder part of the sawdust, which maintains the operating mode of the gas generator.

Outgoing gas contains:

- nitrogen;

- water vapor;

- carbon dioxide;

- hydrogen;

- carbon monoxide (carbon monoxide).

This will require electric valves that will cut off inactive boilers, as well as install fuel reloading systems.

Due to the low combustion temperature, fuel can be loaded both from below and from above. In both cases, auger feed is effective, but a large diameter auger with a small pitch is needed so that the sawdust cannot move along it under the influence of gravity.

Coal for a good boiler

The combustion temperature of coal can reach 1400 o C, the ignition temperature - 600 o C - these properties are used in energy-intensive processes in ferrous and non-ferrous metallurgy, where coal and anthracite are traditionally used. The combustion of coal (brown) is accompanied by increased heat transfer to heat metals up to 1200 ° C. At the same time, studies show that during the combustion of coal, up to 40% of volatile gases are released, and after their combustion, up to 14% of ash remains.

Coal briquettes for heating have significantly lower values for these indicators, while maintaining high characteristics in terms of calorific value (up to 5500 kcal). A briquette is a compressed mixture of crushed coal fractions and fixatives-fillers with a density of 1.4 g/cm3.High calorific value, absence of coal dust have made coal in briquettes a popular type of fuel used in private households and in enterprises where there is no centralized heating supply. Coal slag, formed during the combustion of fuel, can serve as fertilizer for plants in the area adjacent to the house.

What is more profitable to use

It is best to start the comparison with the price of fuel, because it worries us the most. If we take average indicators, then 1 cubic meter of fuel briquettes costs about 2 times more than ordinary firewood. As we know, fuel briquettes can be made from different materials, but the price of firewood also depends on the type of wood. If you choose the most expensive fuel briquettes and the cheapest wood, the cost may differ by 3 times.

Note that most often on the market there are products of two types of quality. High-quality briquettes are more dense without cracks and chips, often burned on the outside. Lower quality briquettes have a lower density, they are characterized by a multilayer structure, which is weakly vulnerable to damage. Such briquettes burn faster and release less energy.

Popular fuel for stoves in homes and baths

Let's compare the indicators at work:

- How long fuel briquettes burn - usually 2 hours, while simple firewood is about an hour.

- The heat transfer from fuel briquettes is noticeably higher, since the fire in the furnace is stable throughout the entire burning time. Firewood usually flares up quickly and gives off maximum heat immediately, and then gradually fades out.

- After using firewood, a lot of coal and ash appears in the firebox, while practically nothing remains of eurowood.

The main task is heating.They burn for a long time, emit a lot of heat, and at the same time do not take up much space in the house, do not litter, they are also environmentally friendly and safe to use like firewood is common. At the same time, they do not create a full-fledged atmosphere of comfort, do not crack, and often emit a more unpleasant odor when burned. No wonder they have the prefix "euro" in their name, this type of fuel was created primarily to save on heating.

If you use fuel briquettes for heating a house, then such a replacement for firewood for a stove is quite relevant, but for kindling a bath, such a choice will not always be justified. As well as for a fireplace, the task of which is not only to heat the house, but also to create an appropriate entourage, with which a substitute for firewood clearly cannot cope.

To evaluate the effectiveness of fuel briquettes in each case, experiments should be carried out, too many factors affect their work. Only after you are convinced of the merits of this alternative type of fuel, you can give it some assessment.

Recently, a lot of positive reviews have appeared on the network, indicating that it is more profitable to heat a house with eurowood than ordinary ones. We attribute this to the growing popularity of alternative fuels.