- Possible consequences

- Pressure switch for a gas boiler: a device, an overview of popular faults and their repair

- What can be repaired without gasmen?

- Relay breakdowns: types and solutions

- What to do to restore the system

- What are the types of wall-mounted boilers Ariston

- How does it work?

- Principle of operation

- Causes of failure

- Descriptions of the double-circuit boiler Ariston

- Causes of failure

- Setting the pressure switch of the washing machine

- Removing air pockets in the system

- Boiler fan diagnostics

- Conclusions and useful video on the topic

Possible consequences

If you do not replace the faulty pressure switch in time, you may soon encounter the following problems:

If you do not replace the faulty pressure switch in time, you may soon encounter the following problems:

- Water ceases to fill the tank and the heating element fails. All this leads to a breakdown of the heating element (how to replace the heating element with your own hands?) Before washing, always check the presence of water in the tank.

- Washed items are removed from the drum not completely squeezed out or completely wet.

- Tank overflow. A breakdown of the relay can lead to uncontrolled flow of water into the tank, which leads to overheating of the processor and a deterioration in the condition of the entire device (read how to repair the washing machine tank here).

A washing machine, like any other electrical equipment, is prone to breakdowns due to wear and tear of parts. You can learn how to identify malfunctions and repair or replace a pump, pump, drain, bearings, as well as see instructions for disassembling equipment of different brands on our website.

Pressure switch for a gas boiler: a device, an overview of popular faults and their repair

The pressure switch in the design of a gas boiler is a device that is not familiar to every owner of gas equipment. The mechanism, which is, in fact, a differential type pressure switch, is triggered by the traction force of the smoke flow generated by the fan system. But how does the pressure switch for a gas boiler work, why is it needed and what kind of malfunctions is it prone to?

We will consider these issues in more detail in our article - we will talk about the design features of this part, which acts as a controller for the normal operation of the fan and the flue gas removal system. A technical analysis of the pressure switch will help to understand the operation of a gas burner, fully master the operation of the boiler, and respond correctly to emergency shutdowns.

What can be repaired without gasmen?

There are several main causes of failures. This is the improper operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or poor-quality components.

When repairing yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

During the repair of gas equipment, the main danger is a possible gas leak.

Therefore, it is necessary to carefully carry out all manipulations for the installation and dismantling of components and parts of the device.

Particular attention should be paid to the replacement of components associated with the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for their elimination allows you to independently make simple repairs. It is worth remembering that serious repairs can only be done by gas workers, but there are procedures available for independent home craftsmen.

Boiler manufacturers strongly recommend calling gas service employees to fix problems associated with breakdowns in the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently set up, repair and restore the functions of specific automation in a gas boiler.

There are three main elements in the design of a typical gas boiler, these are:

- Gas burner closed / open type;

- Specific security blocks;

- Heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, chimney, boiler control devices, multi-level security systems.

Most often, users have problems of the following nature: the boiler emits an unpleasant smell of gas, does not turn on, turns off during operation, does not heat pipes or smokes

Most of these items cannot be changed and repaired by yourself. In the event of intervention in the design of the boiler, its owner loses the right to restore working capacity at the expense of the manufacturer during the warranty period. But what and how the masters from the organization with which the contract for the maintenance of the unit and the supply of gas is repaired must be known.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is produced in cases of weakening of traction by mechanical manipulations or with the use of chemicals.

- Checking the tightness of the water supply connections, gas supply lines, heating circuit branches.

- Installation of a voltage stabilizer.

Once again we warn that all actions for the implementation of which it is necessary to remove the casing from the boiler must be performed by a representative of the gas service.

However, if the warranty is not important for you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade aqueous solutions of citric acid (100g / 1l) or suitable household chemicals that can dissolve calcium deposits.

- Servicing the blower fan. Replace the fuse or the fan itself, check the electrical circuit connected to it, lubricate the bearings with technical fluid.

- Nozzle cleaning. Clogged nozzles cause a weak burner flame. They periodically need to be cleaned with a fine sandpaper and remove dirt with rags with household chemicals.

- System pressure regulation.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to make a visual inspection of it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the warranty from the manufacturer has already expired.

If you smell gas, you should immediately forget about your own intervention. It is necessary to shut off the gas supply, immediately produce salvo ventilation and call an emergency gang. The detailed rules for the operation of gas equipment are set out in the following article, the contents of which we strongly advise you to read.

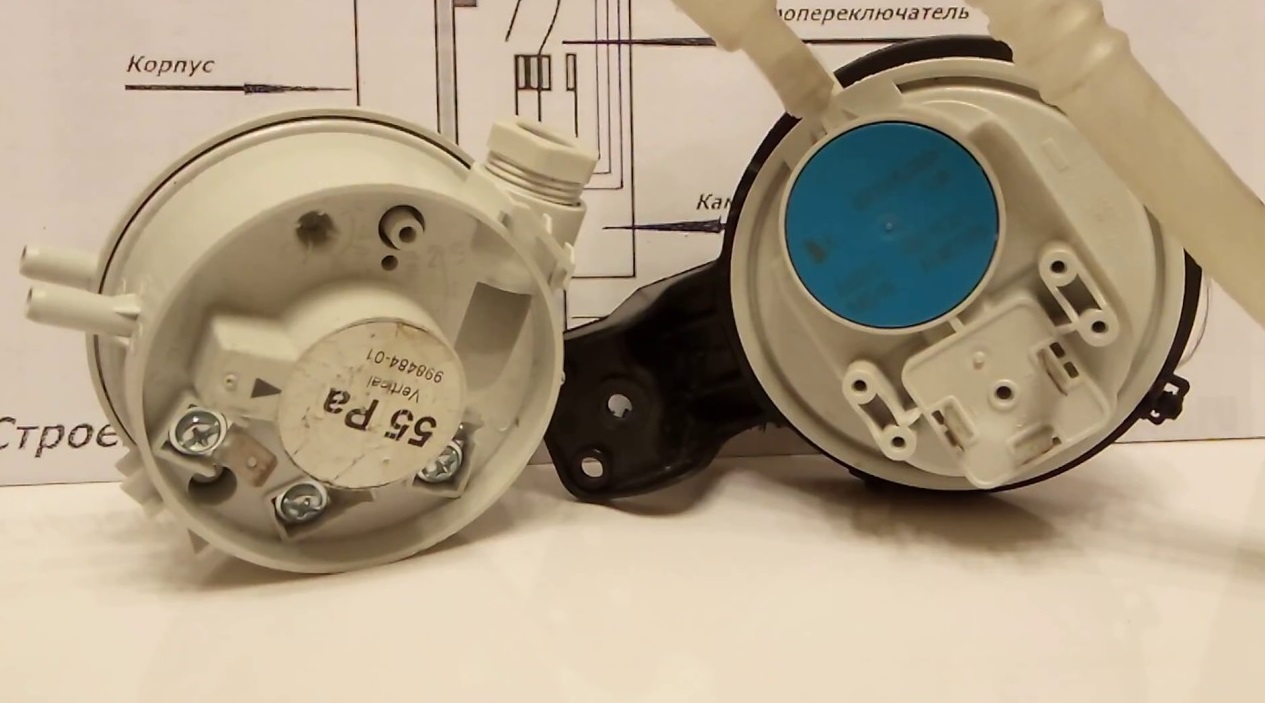

Relay breakdowns: types and solutions

Pressure switches, like other devices, can fail. Repair in most cases is impractical, they immediately replace worn out, faulty working parts with new ones. In any case, you must first inspect the system yourself, try to find out the cause of the malfunction, and, if possible, take action.

If the pressure switch itself causes malfunctions in the functioning of the system, then the only way to solve the problem is to replace the device. You can clean and change contacts, but these expensive manipulations will not give the desired results.

Air leaks from the relay when the receiver is on are due to the fault of the starting valve. In this case, the restoration will be simple, fast and cheap - it is enough to put a new gasket in place of the worn old one.

When the compressor turns on often, the adjusting bolts should be checked - they are probably loose and / or displaced.Separately, double-check the on-off threshold of the pressure switch, make the settings according to the diagram described in the previous section.

What to do to restore the system

The list of measures depends on the type and complexity of the breakdown. The most difficult case is when the compressor does not work at all. The first thing to do is to check the contacts for melting, to make sure that there is no erosion that occurs as a result of electrical sparks.

A group of contacts burns as a result of electrospark erosion and opening of contacts. If you find items on sale that can be installed in place of the old ones, repairs will be relatively simple and inexpensive. But it is not always possible to do this, since many modifications have been discontinued.

Other ways of doing things:

- clean problem surfaces (the effect will last for 3 months or more);

- install new contacts in the clamps of the terminal.

To install new terminals, air masses are bled from the receiver, the ejector power is turned off, and the relay is removed. The protective housing is also dismantled, the wire that is connected to the contact group is disconnected. With a screwdriver, remove the terminal with all contacts, drill burnt and simply questionable lines. The wire is replaced with copper wire or in another convenient way. The wire is optimally selected according to the diameter of the hole. It should sink into the landing nest as tightly as possible. After inserting the element into the hole, a crimp is made on both sides.

The same actions are repeated with the rest of the burnt areas. When the assembly of the contact group is completed, it is installed in the old place, the pressure switch cover is screwed on.

What are the types of wall-mounted boilers Ariston

All Ariston boilers are divided into 3 series. They have different technical indicators and functions, namely:

- Clas - this series means more bulky and powerful devices for heating residential premises. They are equipped exclusively with special regulators that automatically regulate the gas supply. This is necessary to save fuel, which is very convenient in terms of utility costs and frequent business trips for the home owner.

- Genus. These are the most innovative and multifunctional models of Ariston gas units. They have more features than other boilers from this manufacturer. Along with the equipment itself, the buyer will receive additional accessories such as a fan required for smooth speed control, as well as heat exchangers, primary and secondary. All devices from the Genus line are distinguished by the presence of a large liquid crystal display. It will display all the characteristics that correspond to the operation of the boiler at the moment.

- Egis. The units from this series are small in size and attractive in appearance, which have earned them great popularity among owners of small apartments. The device will fit well into any interior. An important feature of these boilers is that, given their size, they have a fairly high level of efficiency and low fuel consumption, which is controlled by an intelligent control system.

How does it work?

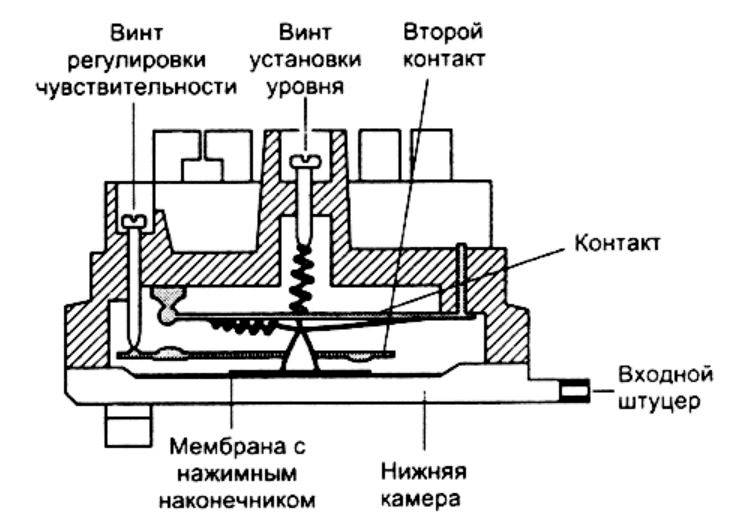

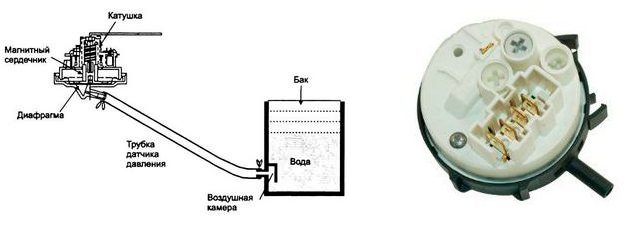

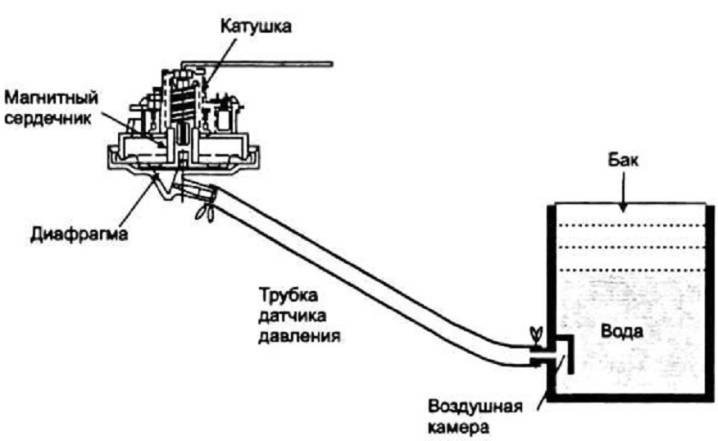

The differential relay has a pair of contacts interconnected by two control circuits. During normal (normal) operation of the heating device, one block of contacts is closed, while on duty - the second.

The operation of the device can be described in more detail as follows.

- The first mode is operation at normal pressure. At this time, the thermostatic membrane of the controller does not change its position, and one pair of contacts closes. The boiler operates normally by passing current through the described circuit.

- The second mode is activated when one of the mechanisms of the system fails: the relay moves inside and the diaphragm flexes. The first block of contacts of the smoke sensor is disconnected, and the second, on the contrary, closes. The heating equipment stops working.

The pressure switch is triggered by the slightest change in temperature in the combustion chamber, registers the appearance of condensate, monitors all pressure indicators in the boiler.

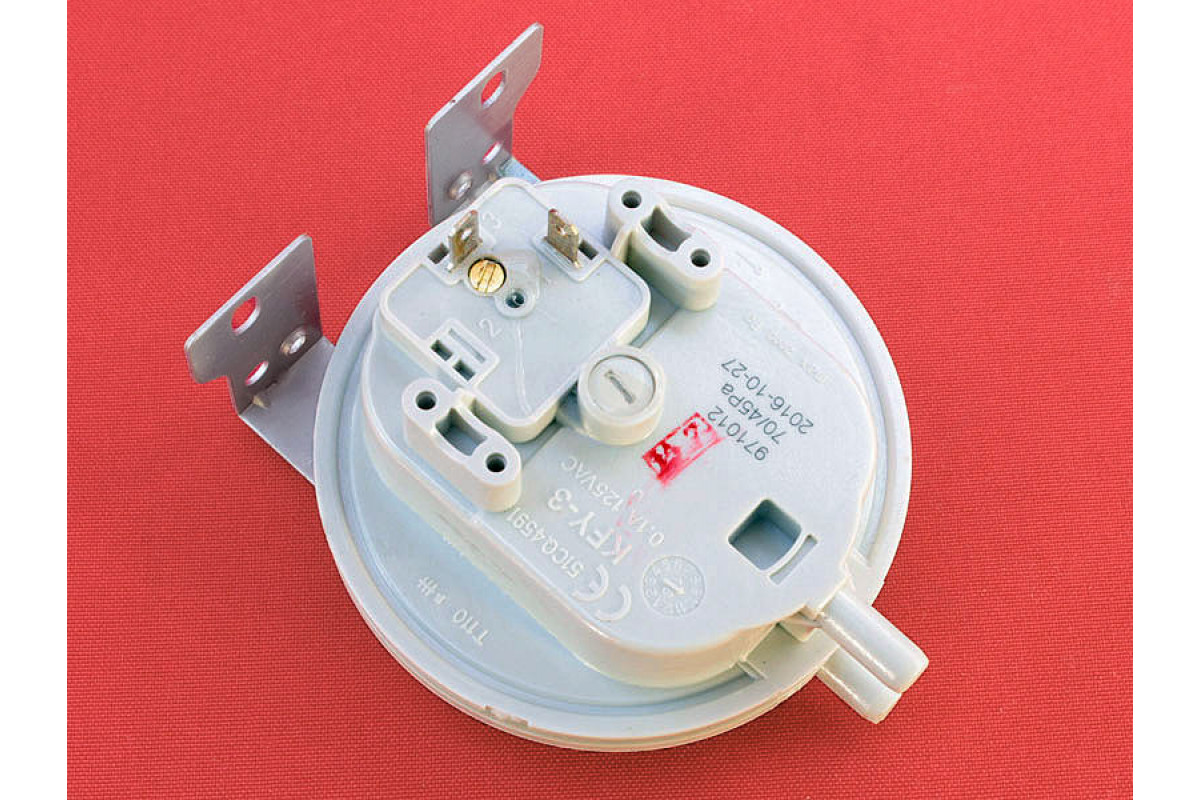

Principle of operation

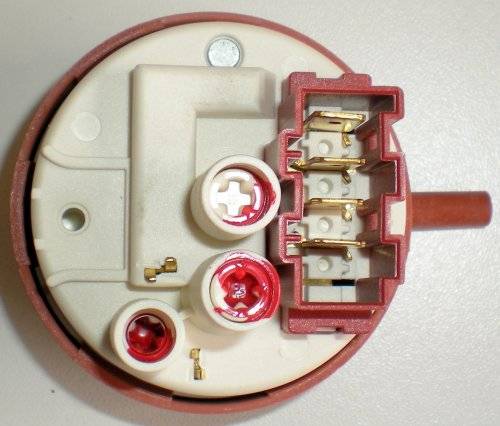

Each automatic washing machine has a water level sensor. It is he who gives an electrical signal to the controller of the washing machine in the form of information about the presence or absence of liquid in the tank, which will be used to clean things in one mode or another. When water enters the unit, pressure increases in the pipe and sensor chamber.

When the water in the tank reaches a certain level, it switches to the upper position, and the electrical circuit of the lamellas is closed. When the water is drained, the pressure drops. In this case, the stem drops to the lower position, as does the contact plate. As in the previous case, the electrical circuit is broken.

Causes of failure

The smoke exhauster may be faulty for the following reasons:

- Damaged inductor.Under the influence of high temperatures arising from the removal of hot gases or motor overload, the wire insulation is melted, which leads to an inter-turn short circuit or to a break in the coil winding.

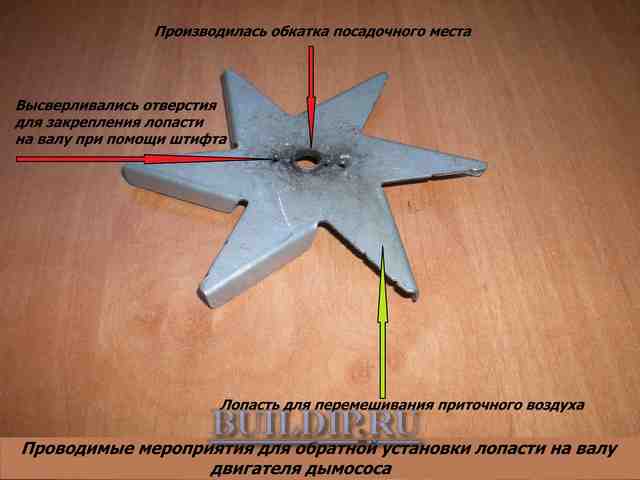

- Turbine out of balance. In the process of removing smoke, the fan blades are covered with soot, dust, etc., which leads to a change in the center of gravity of the wheel.

- Worn bearings. The armature shaft is equipped with sliding or rotation bearings. When the turbine is unbalanced, there is insufficient lubrication, the service life of these units is reduced.

- There is no power supply to the smoke exhauster. The impeller will not rotate if the control board module responsible for supplying power to the fan fails.

- Low mains voltage. When the electrical voltage supplied to the boiler is less than 195 volts, the pressure switch can turn off the fan, because due to a decrease in power, sufficient vacuum is not created. An underestimated supply voltage of the gas boiler does not lead to a breakdown of the fan, but creates a malfunction effect.

Descriptions of the double-circuit boiler Ariston

One of the most important components in all gas boilers is the burner, in this case it can be modulating or conventional. The first option is more popular than the second. When using it, the entire system will be regulated automatically, without human intervention. In this case, the power of the installed heating equipment depends on the temperature indicators.

The burner is also divided into 2 types:

open;

It is the safest, since it does not involve the entry of combustion products into the room in case of emergency. Also in this case, the owner may not worry about building a chimney. It is necessary to bring a special coaxial pipe to the closed burner, it can always be brought out in any accessible place.

An open-type Ariston boiler, in any case, requires a chimney to bring combustion products outside. Also, do not forget about natural traction. Air will enter the system from the living quarters, so it will have to be constantly ventilated.

The coaxial pipe used in the closed combustion system has the advantage of being made of 2 layers. One is necessary for the removal of combustion products, and the other will ensure that fresh air enters the boiler. Thus, the owner of the equipment does not have to constantly ventilate the room and worry about natural draft. The room will always have enough oxygen.

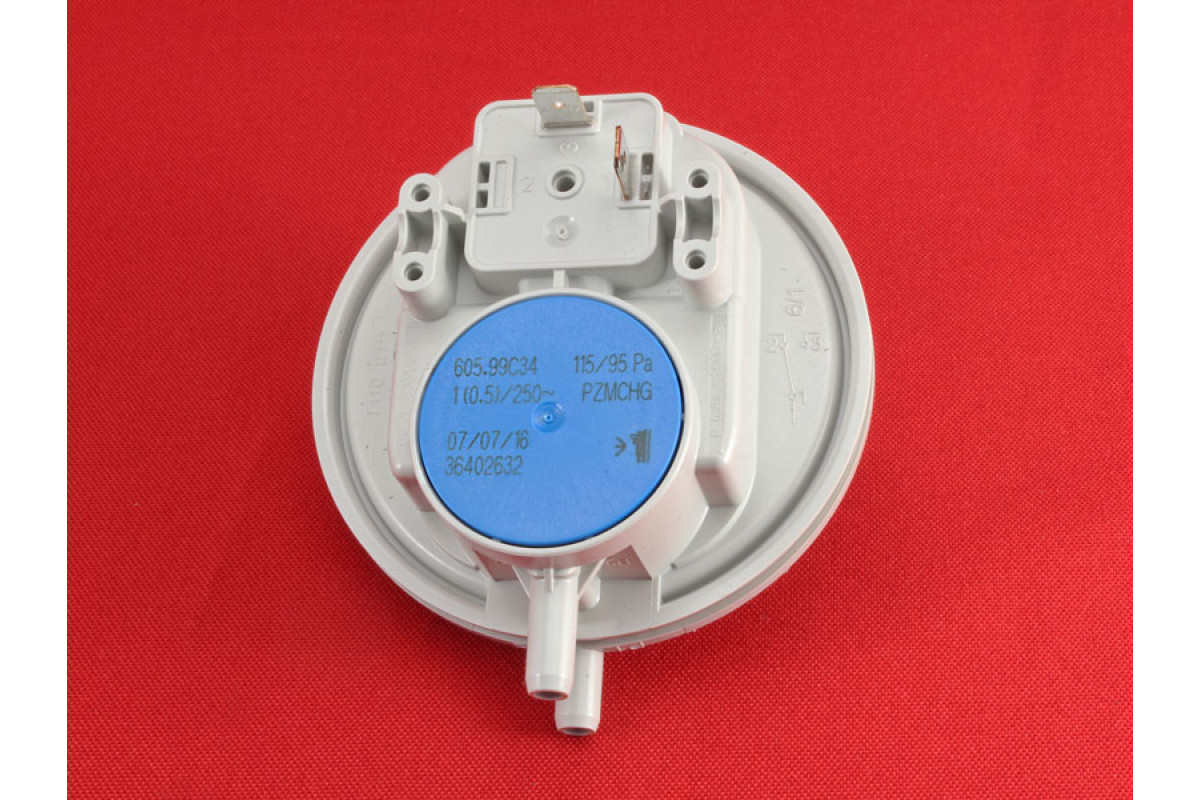

Causes of failure

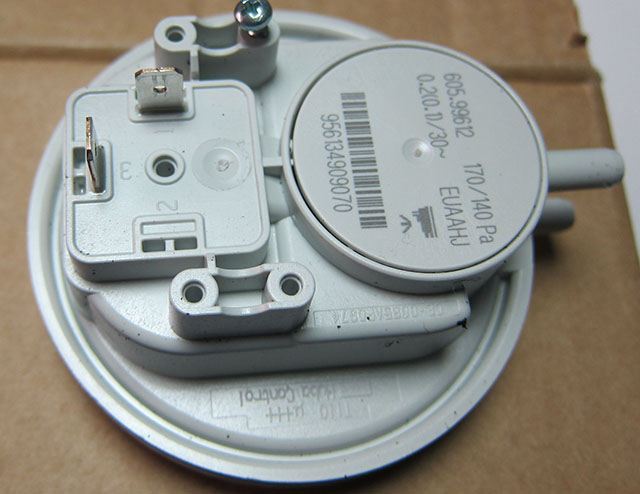

In the conditions of constant operation of a double-circuit boiler, breakdowns or inaccurate information supply by the smoke sensor are possible.

The following negative aspects can lead to such consequences.

- Contact oxidation. When the fan is turned on, a switch beep is heard, however, due to oxidation processes on its current-carrying elements, the circuit cannot close.

- Membrane wear. The operation of the pressure switch can deteriorate significantly if the technical properties of its moving element (membrane) deteriorate.

- Cork from debris, damage to the condensate collector tube. If the tube is cracked, torn, or clogged, flooded with water, the smoke sensor may start to give an error in the readings.

Decreased fan performance. The deterioration of the fan operation entails a deterioration in the operation of the pressure switch itself.

Setting the pressure switch of the washing machine

Along with the serviceability of all elements of the sensor, its fine tuning is of paramount importance. It must operate accurately at certain pressure levels, sending the necessary signals to the central control unit. The amount of water supplied to the tank depends on this, which is different at each stage of washing.

Precise calibration of pressure switches is carried out at the factory using special ohmmeters, and under normal conditions no additional adjustment is required. Washing machine repairmen not only do not recommend, but also categorically deny the possibility of adjusting the pressure sensor at home.

On the adjusting bolt of almost any pressure switch there is a seal, the integrity of which must not be violated. Even if you simply insert a screwdriver to turn the bolt half a turn, and then turn it the same half turn in the opposite direction, fine tuning will be lost. In this case, no one can guarantee the normal operation of the washing unit.

Experiments with adjusting the water level sensor, as a rule, lead to the failure of the heating element or the entire unit as a whole. If the cause of failures in the operation of the washing machine is indeed the pressure switch, it is changed entirely, and it is best if this operation is carried out by the service center master, followed by high-quality diagnostics.

Removing air pockets in the system

Better to start with batteries. To remove air jams, a Mayevsky crane is usually installed on them.We open it and wait for the water to run. Did you run? We close. Such manipulations must be done with each heater separately.

How to start the boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-feeding the system with liquid.

Now the hardest part - start of gas boilers requires air to be bled from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny cap in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electric power and set the water heating regulators to the working position.

Releasing air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and a loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is airy, it will be so. We take a screwdriver and slowly unscrew the cover in the middle of the pump - as soon as water begins to seep out from under it, we twist it back. After two or three such manipulations, the air will come out completely, incomprehensible sounds will subside, the electric ignition will work and start working. We check the pressure again and, if necessary, add water to the system.

Basically, everything. While the system is warming up, you can do a detailed study of the instructions (if, of course, you have not already done so) and debug the system, which involves starting the boiler.Everything is simple here - the batteries closest to the boiler must be screwed on, and the distant ones should be run to the fullest. Such debugging is carried out by means of control valves installed on the pipe connecting the supply to the heating radiator.

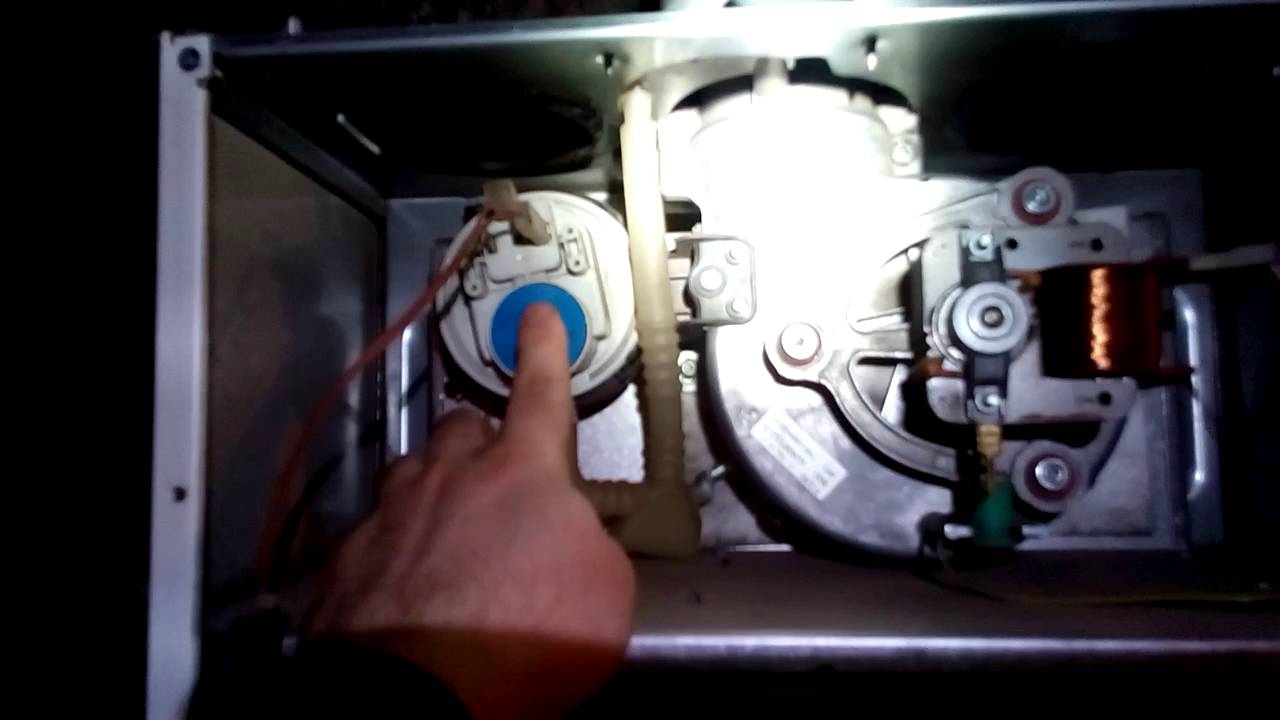

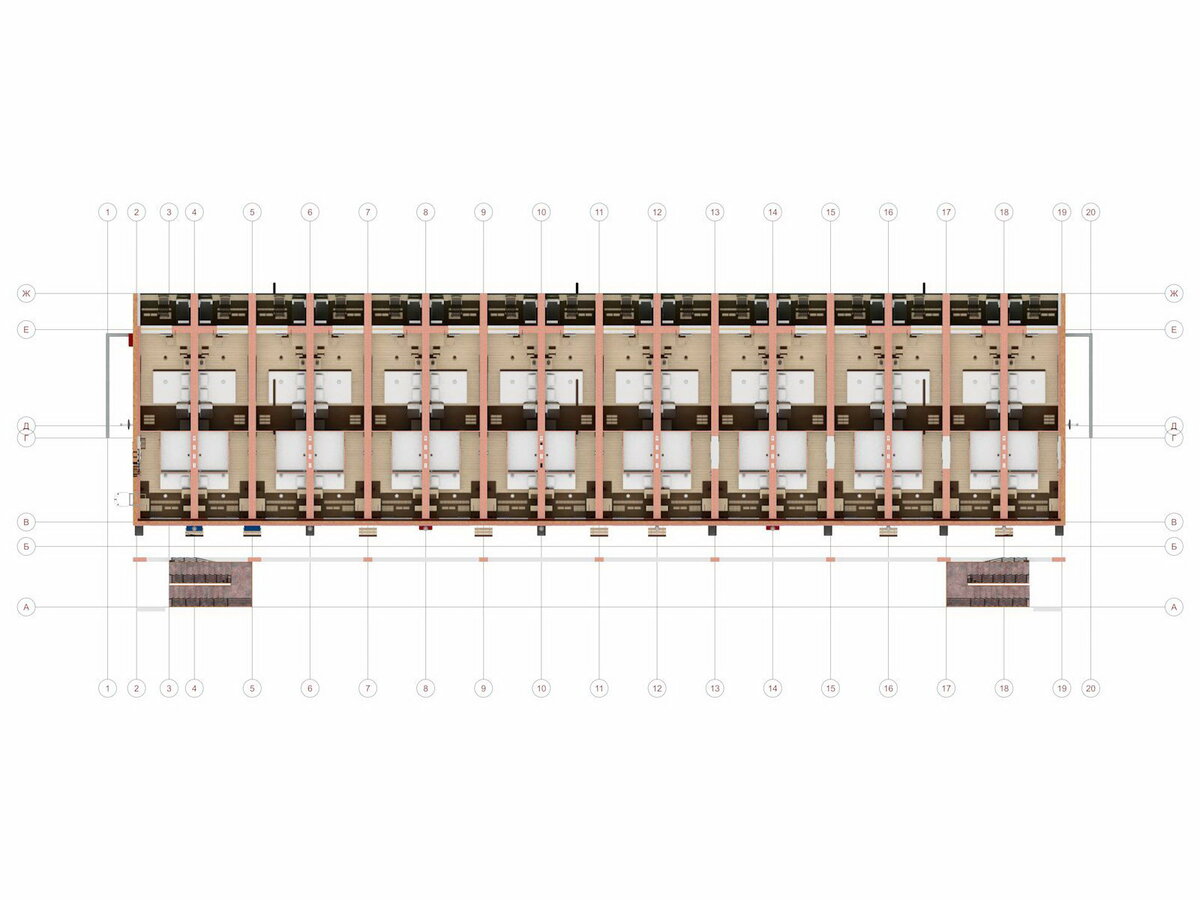

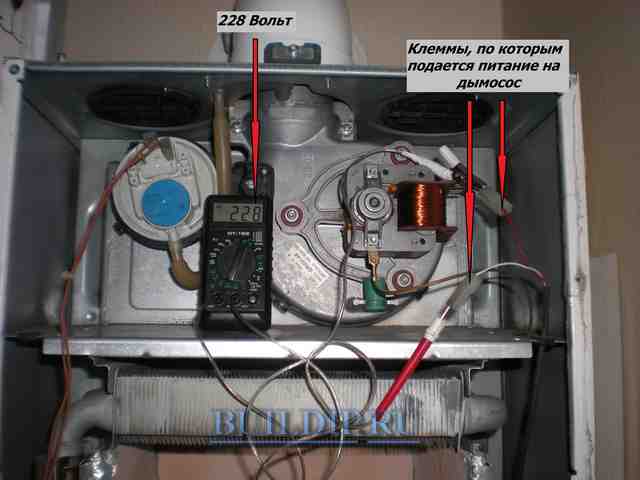

Boiler fan diagnostics

Before carrying out diagnostics, without fail, it is necessary to de-energize the device being repaired and dismantle the front cover for a detailed inspection of the fan. If one of the above symptoms of a malfunction occurs on a turbocharged boiler, you can proceed as follows:

- Check the mains voltage value. Connect the voltmeter to a power outlet. If its readings are less than 195 volts, then the pressure switch turns off the fan due to a decrease in its performance. Since the electrical components are powered by unstable voltage, it is advisable to connect the boiler to the electrical network through a voltage stabilizer.

- Check the inductor for an open circuit. A good stator winding has a resistance of 50 - 80 ohms.

Checking the motor coil of a gas boiler smoke exhauster.

Determine the voltage supply from the control board. On de-energized equipment, disconnect the power terminals from the smoke exhauster, connect a 250-volt voltmeter to them and start the boiler. After turning on the circulation pump, the electrical power from the control board will go to the fan, and in this case to the measuring device, which should fix about 220 volts. No reading indicates a problem with the fan control board module. The relay may be damaged. In such situations, the control module is restored or replaced with a similar one.

Checking the supply voltage of the turbocharged boiler fan.

Check the condition of the bearings

Turn on the heating or hot water mode and, while rotating the turbine, carefully, using a long thin object (pen, rod, screwdriver, etc.), shake the shaft in the bearing assembly to detect play

If this method does not suit you, then disconnect the motor from the smoke chamber and act (turn, wobble, etc.) on the impeller. Bearings should be replaced in case of severe wear of the seats or destruction of the cage. Rolling bearings are interchangeable without much difficulty. Well, the bushings are not for sale, you need to make them yourself, order from a turner, or, having selected a special clip for the inner diameter of the axle box, install a rolling bearing.

Checking the condition of the fan motor bearings boiler.

Blades for mixing the supply air are mounted on the motor shaft. When replacing the bearing located near the impeller, the blades are dismantled from the shaft, but it is almost impossible to install them back. In practice, the smoke exhaust system works stably without them.

Fan blade.

- Clean the impeller from build-up. Due to the work in an aggressive environment, the turbine blades are overgrown with combustion products. Therefore, they must be periodically cleaned, and in cases of increased noise, balancing should be performed. The turbine is easily freed from plaque with a toothbrush under running water. To carry out dynamic balancing, the bearings must be serviceable and lubricated, the turbine must be cleaned of dirt. Use your fingers to set the rotation of the rotor. After stopping the turbine, put a mark on the upper blade. Again, several times, spin the rotor. If each stop the mark is in a different place and the wheel rotates easily, then there is no need to balance.When the position does not change, a load is fixed on the upper blade and the center of gravity is checked back. If the weight of the weighting agent is insufficient, then another load is attached. Balancing is performed as long as the mark, after each rotation, will be placed in different places.

- Check the correctness of the pressure switch. Since the smoke sensor controls the operation of the fan, it is possible that the smoke exhauster stops due to a malfunction. To determine the state of the pressure switch, its wires connected to terminals 1 and 3 are connected with a jumper when the fan is running. Starting the boiler indicates a malfunction of the smoke sensor or tube with a condensate collector.

Checking the health of the gas boiler pressure switch.

Violation of the tightness of the tube with the condensate collector creates air interference and the pressure switch membrane is not attracted to the microswitch. To check the integrity of the tube, you can immerse it in a container of water and, holding the side pipes, blow air through the top pipe. Air will escape through leaky places. If there is such a defect, the tube must be replaced. In emergency situations, damage can be repaired with silicone, electrical tape or hot melt adhesive.

Conclusions and useful video on the topic

The video discusses the structural details of the thrust sensors, the location of these components and their principle of operation:

If professional craftsmen are quite familiar with gas equipment, for the average user, troubleshooting a gas boiler is a “dark forest”. In addition, the handling of gas systems in the absence of appropriate knowledge is fraught with serious consequences.

Therefore, when there is a desire to independently replace or repair the same thrust sensor or some other equipment of the gas column, you first need to at least study the system. But the best way to eliminate defects in the gas system is to contact specialists.

Would you like to supplement the above material with useful comments on the principle of operation of the thrust sensor? Or would you like to share your sensor test experience with other users? Write your remarks and comments in the block below, add unique photos of your own testing.

Modern type gas boilers are complex units with the help of which residential premises are heated by heating water. They operate using explosive gas, so the design of such equipment requires the presence of special elements that control the operation of all mechanisms. Such control devices are called gas boiler pressure switches.