- How to use the hand tool

- How to connect fittings

- Pincers are not a beast, but an installation tool

- Performance characteristics of pipes made of metal polymers

- Preparing pipes for pressing tongs

- Instructions for use

- The secrets of competent installation of such parts

- How to choose a press tongs?

- Mounting secrets from experts

- Device and purpose

- Which fittings require pressing tongs

- How to use press tongs correctly

How to use the hand tool

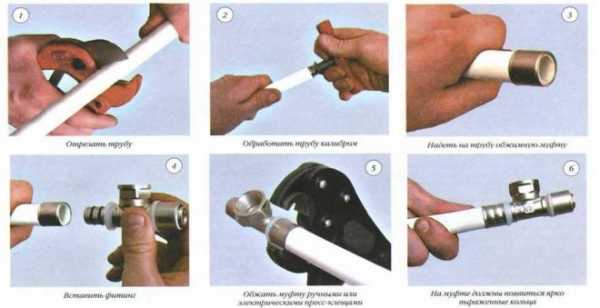

If you decide to carry out crimping yourself, then you should strictly adhere to all stages.

- First you need to measure the desired part of the metal-plastic pipe. For these purposes, you can use a tape measure or marks located on the outer surface of the product. Naturally, you need to choose a segment with a small margin.

- With the help of special scissors, a part of the metal-plastic pipe is cut off. For a perfect cut, hold the lower edge of the guillotine shears parallel to the pipe and push them in slightly.

- Next, the trimmed ends are calibrated using the appropriate tool. Thanks to this, it will be possible to align the press and remove the internal chamfer.Then a crimp sleeve is put on the pipe and the fitting fitting is inserted, after which it is necessary to press the metal-plastic pipe to the connecting element.

- The location of the pipe in the sleeve itself should be checked. If everything is done correctly, you can safely proceed to crimping.

- Press tongs are laid on a flat surface, spreading the handles by 180 °. At the same time, the upper part of the clip is carefully disconnected and a part of the press insert corresponding to the diameter of the pipe is inserted there.

- The second half of the insert is placed in the lower part and the key holder is snapped into place. Then a node is placed here, which is a pipe and a fitting. At this point, you need to make sure that the sleeve is located in the press insert itself. After that, the handles must be moved to the stop.

Press tongs are an indispensable tool, thanks to which you can self-assemble the pipeline. If done correctly, the connection will be strong and durable. Naturally, such equipment is not cheap, but with regular installation work, it will quickly pay off.

How to connect fittings

For the installation of press fittings, a type of tool such as a crimping press is used.

The type of this connection can be divided into three main components:

- a body, which can be in the form of a tee, coupling, angle;

- a sleeve that is just subjected to compression and does not lose its shape during operation (usually made of stainless steel);

- clip, the task of which is to connect the body and sleeve to each other.

For the quality and tightness of the connection, the following steps must be performed:

-

We measure and cut the pipe at a right angle.

- We perform calibration (to eliminate ovality when cutting the pipe).

- We put a sleeve on the pipe.

- Then we insert the fitting into the pipe.

- After that, the sleeve is crimped with manual or hydraulic tongs (compression is performed once, repeated is not allowed).

Pincers are not a beast, but an installation tool

If everything is clear with press fittings, now we will take a closer look at the tool for their installation. These are pressing tongs that can be manual, electromechanical or hydraulic.

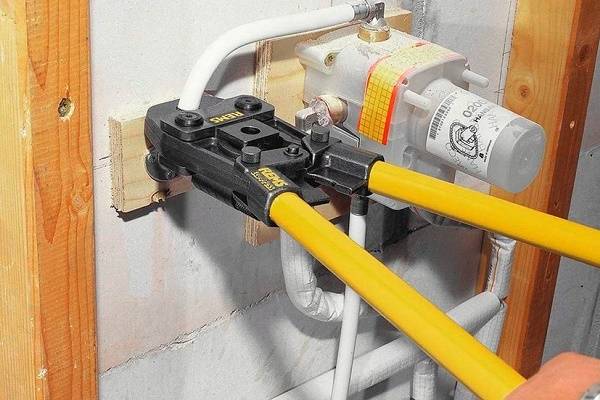

At home, manual press tongs will be enough

For home and infrequent use, a hand tool will suffice; if the work is done correctly, it will not yield to its hydraulic counterpart as connections, and its purchase price is lower.

Read about hand tools here

For industrial use or for professionals who are professionally involved in the installation of various pipelines, hydraulic or mechanical ones are more suitable, which are able to perform a large number of pipe connections in a short period of time.

Man working with hydraulic tongs

The press fitting tool market today is represented by such companies as VALTEK, VIEGA, REMS, PEXAL, VIRAX and many others.

Advice! If you need to carry out minor work to mount press fittings, you do not need to buy a tool. Many stores offer to rent it. In the store, you leave a deposit (which is returned upon the return of the press tongs) and money for renting the tool.

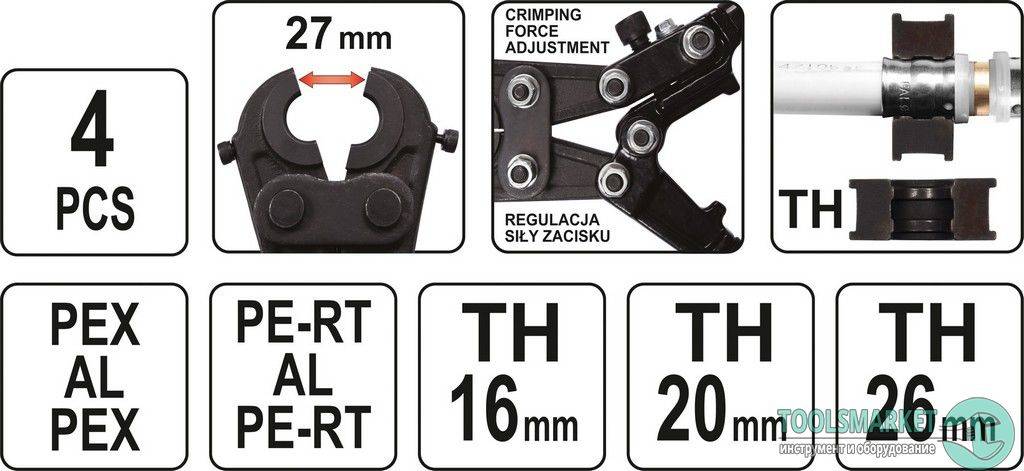

Modern kits have nozzles for different pipe diameters.

Different types of press tongs are designed for mounting pipes of a certain diameter.But now there are models that can use special liners to work with the same tongs with different pipe diameters.

There are also improved versions of models that can be recognized by marking:

- OPS - due to the use of step-type clamps, the applied forces for crimping the sleeve increase.

- APC - automatic control of work is carried out, and the press will not open until the end of the successful compression of the sleeve.

- APS - the device automatically distributes the applied forces.

Electromechanical devices are powered by the mains, but there are models that can be powered by batteries, which makes them more versatile.

Advice! Experts recommend using tools for press fittings and the fittings themselves to make connections between piping systems, if possible. one manufacturer, for example, this is a company Valtex, but there are others. This will serve as an additional factor in the quality of the work carried out and the tightness of the system as a whole.

Today, prices for manual press tongs start from 70 USD and above, for professional electro-hydraulic - prices start from 500 USD.

We hope that the article was useful to you. If not difficult, please click the social media buttons below.

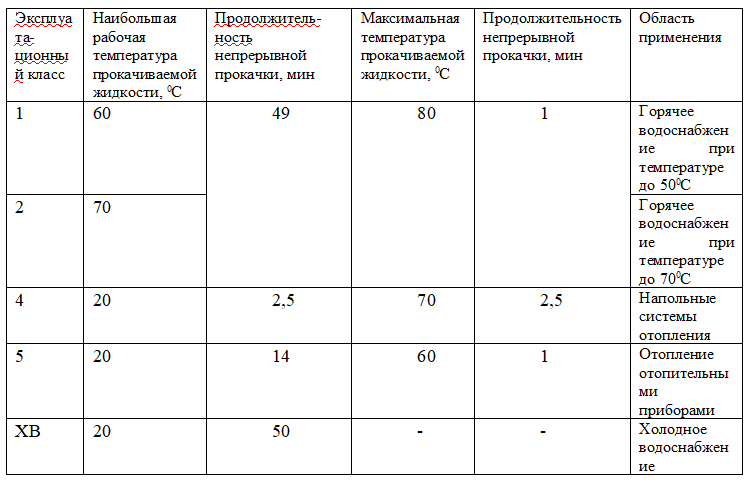

Performance characteristics of pipes made of metal polymers

Under metal-polymer plumbing pipes, GOST R 53630-2015 means products that are sewn together with two or more alternating layers of dissimilar materials - plastic (polyethylene or polypropylene) and metal (most often aluminum).

Such pipes are divided into two classes - perceiving or not perceiving dynamic loads.

In the second case, the operational parameters are determined according to the technical requirements of GOST 32415-2013.

These options include:

- Nominal pressure for which the pipeline is designed;

- The lowest long-term strength;

- Hydrostatic stress in the pipe wall.

According to these indicators, the values of the maximum deviation and ovality of the pipeline walls are calculated, which are given in GOST 32415-2013.

According to the indicated indicators, the design and material of pipeline fittings are selected - fittings of compression or press types.

The performance of metal-plastic pipes is established depending on their operating class:

According to the above normative data, the crimping force is determined, the technology and tools for pipe crimping are adopted.

Preparing pipes for pressing tongs

Immediately before the assembly of metal-plastic systems, i.e. before using pressing tongs and carrying out crimping measures, the tubular material is prepared accordingly.

During the marking of the metal-plastic pipe material, it is imperative to add a small overlap (2-3 cm) from both ends of the part. Otherwise, after inserting the fitting, the fragment will be shorter than necessary according to the estimate. The position of an incorrectly installed press fitting cannot be corrected. You will have to cut out the entire fragment and install a new one in this place

The sequence of actions is relevant for any type of tool and requires mandatory compliance:

- Using a tape measure, measure the required amount of pipe material from the bay and make a mark with a marker where the intended cut will be.

- Scissors for cutting metal-plastic cut off a part of the required length, making sure that the resulting edge is as even as possible and makes a clear right angle with the conditional central axis of the product.

- When using a guillotine tool for work, its lower edge is kept strictly parallel to the pipe surface, only slightly pressing the cutting part into the pliable material.

- When trimming is done, the resulting end edges are treated with a calibrator. It corrects and aligns the shape of the cut and gently chamfers the inside.

- The crimp sleeve is removed from the fitting and put on the edge of the pipe. The fitting is inserted directly into the cut.

- The end parts of the connection elements are pressed tightly, and the joint area is insulated with a sealing gasket. It protects the material from corrosion and ensures the tightness of the entire system as a whole.

- The control of the placement of the pipe in the sleeve is carried out through a round cut in the edge zone.

When the appropriate preliminary preparations are completed, the press tongs are used and the crimping operation is carried out.

Instructions for use

Regardless of the type of installation and equipment you choose, there is a general procedure for preparatory work. These rules will facilitate the arrangement of the pipeline and are desirable for execution:

- you need to draw up a pipe layout plan, this will help calculate the amount of material and couplings;

- places of work must be carefully cleaned to prevent dust and dirt from entering the connection points in order to avoid leaks in the future;

- if you need to connect to an existing system, you need to check its integrity and prepare the insertion point;

- pipes should be cut so that the cut is exactly 90 degrees to the longitudinal axis of the pipe, this is necessary to ensure reliability and tightness;

- guided by the diagram, lay out all pipes and couplings to check the cutting and the number of all the necessary connection elements.

As mentioned above, there are three main options for connecting cross-linked polyethylene. The selection of equipment and tools depends on the choice of method. For all methods, you will need nozzles for the diameter of the pipes and a pruner.

The first method is the easiest to perform. In addition to pipes and pruners, only compression couplings and a pair of wrenches will be required. These tools are needed to tighten the nuts after being pushed into place.

It is important to remember: you need to control the process of tightening the nuts so as not to damage the thread. Screw tight, but don't overtighten.

The second method is pressing. You will need a calibrator, scissors, an expander and a press.

There will be no difficulties with scissors, their purpose is simple - to cut the pipe into the sizes we need. We process its edges with a calibrator, chamfering from the inside. This tool is necessary to give the pipe a rounded shape after cutting.

Then we take the expander (expander) of the manual type, which is very easy to use. We deepen the working edges of the device inside the pipe and expand it to the desired size. This should not be done at one time, as the material can be damaged. We do this gradually, turning the expander in a circle. The advantages of this device are the price and ease of use.This is an amateur instrument.

The electrically powered expander is equipped with a rechargeable battery, designed to speed up the work of the installer. It significantly saves the effort of the worker and time for the installation of systems. Naturally, this device is many times more expensive, but if you need to work a lot, it will perfectly fit and justify the costs. There are hydraulic expanders. After we prepare the pipe, you need to install a fitting in it. To do this, we need a press vise. They are also hydraulic and mechanical. Before use, they must be removed from the storage case and assembled in the working position.

After assembling the tool and installing the coupling into the pipe, the connection is installed with a press. That is, the fitting enters its place, and pressure is applied from above with a mounting sleeve. Manual presses are recommended for small pipe diameters and low demand.

Hydraulic presses require virtually no effort during crimping. The fittings and sleeve are simply installed in the groove on the device, then they easily and smoothly fall into place. This tool can be used even in places that are inconvenient for installation, it has a swivel head. And the last option for connecting cross-linked polyethylene is welded. As mentioned earlier, it is the most expensive and rarely used, but the most reliable. For it, in addition to the scissors already familiar to us, expanders, special couplings will also be needed. Electrofusion fittings have special conductors for heating.

After preparing the equipment and components, we proceed to welding. To do this, we install an electric-welded coupling at the end of the pipe. It has special terminals to which we connect the welding machine.We turn it on, at this time all the elements are heated to the melting point of polyethylene, about 170 degrees Celsius. The coupling material fills all the voids, and welding occurs.

If the device is not equipped with a timer and a device that can read information from the fittings, you need to monitor the instrument readings in order to turn everything off in time. We turn off the equipment, or it turns off on its own, we wait until the unit cools down. Pipes are often supplied in reels and may lose their shape during storage. For this, you need a hair dryer. With its help, it is possible to eliminate this drawback by simply heating the deformed segment with warm air.

In the next video, you will find an overview of tools for installing XLPE heating and plumbing systems.

The secrets of competent installation of such parts

Installation of parts is very fast and quite simple. For its implementation, you will need a special tool, without which it is impossible to compress the fitting.

How to choose a press tongs?

Press tongs for fittings - a device designed to install a part on a pipe. Manual models and more complex hydraulic models are available. For independent work, the first option is quite suitable, since it is the easiest to use and cheapest. And in terms of the quality of the connections made with its help, they are not inferior to those in the process of which a professional hydraulic tool was used.

When purchasing equipment, it must be borne in mind that it is designed to work with a certain pipe diameter. There are models equipped with special inserts that make it possible to work alternately with pipes of several diameters.In addition, on sale you can find improved variations of the tool. They are marked with:

-

- OPS - the device increases the forces applied to it by using step-type clamps.

- APC - during the process, automatic control over its quality is carried out. The press will not open until the crimp is successfully completed.

APS - the device independently distributes the force that is applied to it, depending on the size of the fitting.

Crimping press pliers are a necessary tool for installing fittings. Manual and hydraulic models of special equipment are available

What to look for when buying connectors

The reliability of the connection largely depends on the quality of the parts.

When buying press fittings, experts advise paying attention to the following points:

- The quality of the markings on the case. Companies that produce quality parts do not use cheap molds. All symbols on the body of the fittings are printed very clearly.

- Part weight. For the production of high-quality products, brass is used, which has a fairly large weight. It is better to refuse a fitting that is too light.

- The appearance of the element. Low-quality parts are made of thin metal that looks like aluminum. It is not able to provide a quality connection.

You should not save on fittings and try to buy them "cheaply" at a dubious outlet. In this case, there is a high probability of subsequent alteration of the entire pipeline.

Mounting secrets from experts

Let's start by cutting pipes.We measure the required length and cut the element strictly perpendicular. It is best to use a special tool for this purpose - a pipe cutter. The next stage is the processing of the end of the pipe. We insert a caliber inside the part, straightening a small ovality that inevitably forms during cutting. We remove the inner chamfer using a chamfer for this. In its absence, you can do this operation with an ordinary sharp knife, and then clean the surface with an emery cloth.

At the end of the work, we put the press fitting on the pipe, controlling the tightness of its fit through a special hole. There are models in which the ferrule is not fixed to the fitting. For their installation, such operations are performed. We put the crimp sleeve on the pipe. We insert a fitting inside the element, on which the sealing rings are fixed. To protect the structure from electrocorrosion, we install a dielectric gasket at the contact area of the metal connecting part and the metal-plastic pipe.

For crimping any models of press fittings, we use a tool that is suitable in diameter. We grab the sleeve with a clamp press tongs and reduce their handles to the stop. After removing the tool, two uniform ring strips should remain on the fitting, and the metal should be bent in an arcuate manner. Compression can be performed only once, there should not be any repeated operations. This leads to a broken connection.

The installation of press fittings for metal-plastic pipes takes place in four main stages, which are shown in the figure

Press fittings for metal-plastic provide a very strong, durable connection. Their wide range allows the implementation of pipelines of various configurations. In addition, they are very easy to install.Even a beginner can install press fittings. This requires patience, accuracy and, of course, a careful study of the instructions. The result of the efforts will surely please you with a hand-made pipeline that is reliable in operation.

Device and purpose

The shape resembles ordinary tongs, but functionally they do not bite the parts, but clamp (press in). That's where the name came from. The device has a crimping head made of durable steel, comfortable long handles. The head is usually equipped with a set of nozzles for crimping several sizes.

Which fittings require pressing tongs

The device is required when crimping press fittings. Fittings are firmly crimped with press tongs at the end of the blanks (in this case, the upper sleeve of the fitting is deformed and pressed into the thickness of the plastic) and form a reliable hermetic connection.

How to use press tongs correctly

Before operating this tool, it will not be superfluous to familiarize yourself with the standard instructions for its use.

Crimping of fittings of metal-plastic pipes and their connection is carried out in the following sequence:

- First, a chamfer is removed from the side of the pipe trim. To get rid of ovality, a gauge is used that is inserted inside the pipe.

- A sleeve is put on the pipe.

- A fitting with mounted rubber seals is inserted into the pipe. A gasket made of a dielectric material is installed at the junction of the pipe with a metal coupling in order to prevent electrical corrosion.

- Next, the steel sleeve is compressed with any press tongs into which certain liners are inserted.

It is believed that press fittings provide a better connection than the compression type.They are often used in hidden systems that are laid in walls and floors. These, for example, include warm water floors - they hide directly in the screed. However, for crimping couplings, you cannot do without a special tool, which to some extent slows down home repairers, who, naturally, do not want to buy expensive equipment for one-time use.