- The secrets of competent installation of such parts

- How to choose a press tongs?

- Mounting secrets from experts

- Tools for the installation of metal-plastic pipes

- American

- Cranes

- Press couplings

- Some secrets of installing clamping coupling devices

- Compression couplings

- Types of tools

- Manual drive

- Mechanical

- hydraulic

- Electro-hydraulic option

- Features of using press tongs

- Do-it-yourself crimping features

- Installation and replacement rules

- Criterias of choice

- An example of the layout of the water supply system

- Negotiate an exchange

- When and how to get started

- Related videos

- The design of metal-plastic pipes

- The composition of pipes made of metal-plastic

- Forms of release of metal-plastic pipes

- Press connection or compression fitting?

- Possibilities of press fittings

- Benefits of press fittings

The secrets of competent installation of such parts

Installation of parts is very fast and quite simple. For its implementation, you will need a special tool, without which it is impossible to compress the fitting.

How to choose a press tongs?

Press tongs for fittings - a device designed to install a part on a pipe. Manual models and more complex hydraulic models are available.For independent work, the first option is quite suitable, since it is the easiest to use and cheapest. And in terms of the quality of the connections made with its help, they are not inferior to those in the process of which a professional hydraulic tool was used.

When purchasing equipment, it must be borne in mind that it is designed to work with a certain pipe diameter. There are models equipped with special inserts that make it possible to work alternately with pipes of several diameters. In addition, on sale you can find improved variations of the tool. They are marked with:

-

- OPS - the device increases the forces applied to it by using step-type clamps.

- APC - during the process, automatic control over its quality is carried out. The press will not open until the crimp is successfully completed.

APS - the device independently distributes the force that is applied to it, depending on the size of the fitting.

Crimp press tongs - necessary fittings installation tool. Manual and hydraulic models of special equipment are available

What to look for when buying connectors

The reliability of the connection largely depends on the quality of the parts.

When buying press fittings, experts advise paying attention to the following points:

- The quality of the markings on the case. Companies that produce quality parts do not use cheap molds. All symbols on the body of the fittings are printed very clearly.

- Part weight. For the production of high-quality products, brass is used, which has a fairly large weight. It is better to refuse a fitting that is too light.

- The appearance of the element.Low-quality parts are made of thin metal that looks like aluminum. It is not able to provide a quality connection.

You should not save on fittings and try to buy them "cheaply" at a dubious outlet. In this case, there is a high probability of subsequent alteration of the entire pipeline.

Mounting secrets from experts

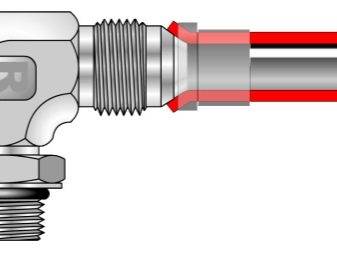

Let's start by cutting pipes. We measure the required length and cut the element strictly perpendicular. It is best to use a special tool for this purpose - a pipe cutter. The next stage is the processing of the end of the pipe. We insert a caliber inside the part, straightening a small ovality that inevitably forms during cutting. We remove the inner chamfer using a chamfer for this. In its absence, you can do this operation with an ordinary sharp knife, and then clean the surface with an emery cloth.

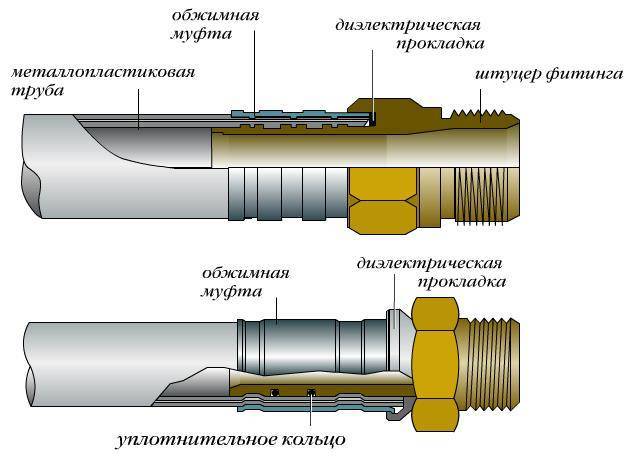

At the end of the work, we put the press fitting on the pipe, controlling the tightness of its fit through a special hole. There are models in which the ferrule is not fixed to the fitting. For their installation, such operations are performed. We put the crimp sleeve on the pipe. We insert a fitting inside the element, on which the sealing rings are fixed. To protect the structure from electrocorrosion, we install a dielectric gasket at the contact area of the metal connecting part and the metal-plastic pipe.

For crimping any models of press fittings, we use a tool that is suitable in diameter. We grab the sleeve with a clamp press tongs and reduce their handles to the stop. After removing the tool, two uniform ring strips should remain on the fitting, and the metal should be bent in an arcuate manner.Compression can be performed only once, there should not be any repeated operations. This leads to a broken connection.

The installation of press fittings for metal-plastic pipes takes place in four main stages, which are shown in the figure

Press fittings for metal-plastic provide a very strong, durable connection. Their wide range allows the implementation of pipelines of various configurations. In addition, they are very easy to install. Even a beginner can install press fittings. This requires patience, accuracy and, of course, a careful study of the instructions. The result of the efforts will surely please you with a hand-made pipeline that is reliable in operation.

Tools for the installation of metal-plastic pipes

One of the main advantages of MP pipes is the ease of their installation. Some elements can even be installed manually, but a certain tool is still required to perform basic installation work.

A pipe bender is a tool often used in the installation of metal-plastic, which allows you to manually change the slope of the elastic pipe for the most tight grip. Most often used when the standard round shape needs to be changed to oval. This is a simple and safe device for domestic use, which minimizes the risks of product deformation or destruction. Works with almost all types of sections.

The spring pipe bender is designed for home use. The mechanism of action is simple - the spring is inserted inside and unbends at the place of the intended bend.

Hydraulic units are professional grade devices. They work with the help of a pump, which allows you to minimize the mechanical pressure on the pipe.This guarantees precise and safe bending of the pipe in the right place.

Press tongs are a tool for precise and accurate processing of parts of MP pipes, which allows you to create a reliable, durable clutch of system elements.

Pliers for manual work allow using them without special skills in everyday life if it is necessary to correctly crimp the coupling on pipes with a diameter of up to 20 mm. Such a tool is good for doing small do-it-yourself repairs, but more powerful devices take part in larger events - electrically driven pressing tongs, which evenly and with jeweler's precision process surfaces with a diameter of up to 110 mm.

An electric press tool is used mainly by professionals, but it is impractical to use it for personal purposes due to its impressive dimensions.

American

American fittings for metal-plastic pipes are called the most convenient and popular type of fittings. Added to this is high reliability.

This threaded type of connection is considered exotic, and it is said that the Americans were involved in its creation. Hence, in fact, the name "American" came from.

At its core, this is a coupling with a union nut that can be dismantled many times. To make a joint with this variant of shaped products, you only need to tighten the nut.

The masters also claim that with the help of an American it is very convenient to perform actions with heating radiators.

Based on this structural element, it is possible to create a joint of the highest level of tightness, for these reasons this type of joint is widely used in high-temperature systems with the same pressure level.

Cranes

Cranes are fittings for metal-plastic pipes, which are a series of shut-off and control valves. They are used for various pipelines. It can be lines with a supply of cold, as well as hot water. When installing a crane, you need to remember some rules.

Cranes are of the following types: straight, angled and combined. With their help, it is easy to design a system of high complexity.

The cost of cranes differs depending on the complexity of their design.

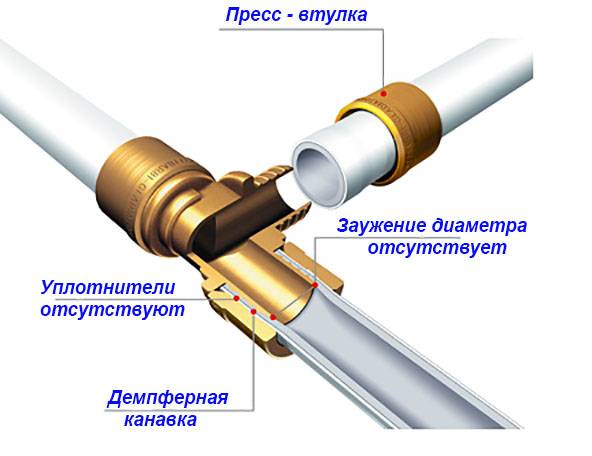

Press couplings

Watch video - pressing or crimping F

Crimping fittings for metal-plastic pipes are called press fittings. The device of this mechanism is described a little higher, and such couplings exist in several types. This allows, by means of a press fitting, to build the wiring of all configuration options.

For branching and turns, bends, angles and tees are used. And for the design of the linear highway, adapters and docking elements are installed. In addition, the unification of these shaped devices makes it possible to dock metal-plastic pipes with copper and other types of assortment.

It should be noted that crimping products for metal-plastic pipes create a one-piece connection, which has its significant advantages:

- High level of strength. In the area with the installed press fitting, the working pressure indicator is up to 10 atmospheres.

- A long period of use of crimping shaped devices on metal-plastic lines. And the high performance of the connection throughout the entire period of operation does not change. Manufacturers claim that press fittings, if properly installed, can last more than half a century.

- The joints do not need to be serviced.Thanks to this property, the joints can be mounted in a hidden way.

- Press couplings are not afraid of temperature changes.

- Installation is easy and in a short time.

- The use of pressure fittings reduces the consumption of pipe assortment and fittings, which by and large reduces the cost of broaching the line.

Some secrets of installing clamping coupling devices

Despite the fact that clamp fittings for metal-plastic pipes are easy to install, there are some nuances that you need to remember. First of all, these are the right pliers for the job.

Without this high-quality tool, it is not necessary to talk about the reliable operation of the highway

When buying, you need to pay attention not only to the manufacturer of tools for clamping parts, but also to the fact that this tool is intended to work only with a certain volume of pipe rolling

Although there are models that allow you to work with several diameters of clamping mechanisms. The new improved models of clamping pliers have special markings: OPS, APC and APS. Also, consumers can find on sale manual and hydraulic versions of special equipment for clamping devices.

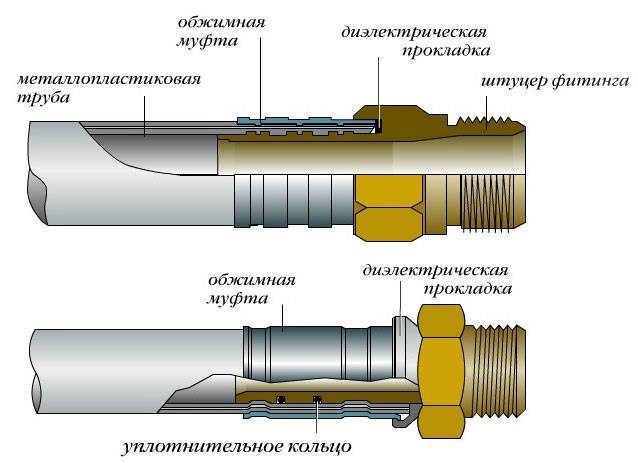

Compression couplings

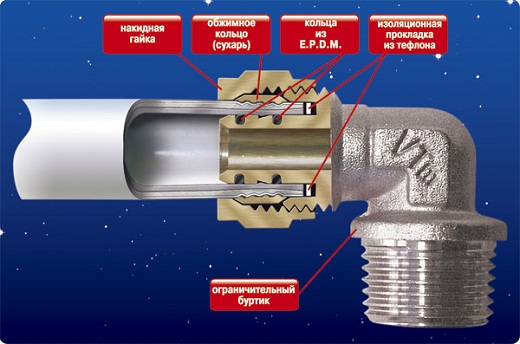

Compression fittings for connecting metal-plastic pipes on network highways are very common. The device of the compression element is as follows: crimp ring, union nut, fitting.

Installing a compression fitting is not difficult. Its sequence is:

- pipe billet is leveled;

- a cut is carefully made on it, for which marking is first done;

- the cut zone is processed by a reamer, and the tubular product is given a rounded regular shape;

- a compression fitting nut and a cut ring are put on the workpiece;

- the moistened fitting is “sit down” on the pipe so that the end part of the pipe rests against the edge of the coupling;

- the nut is tightened until it stops by hand;

- then tighten the nut with a wrench, making no more than one or two turns.

When mounting compression couplings, wrenches equipped with additional levers should not be used.

Types of tools

To make a strong one-piece connection using press fittings, you need to use a special tool, which is classified depending on the type of drive.

Manual drive

Manual crimping pliers are more commonly used at home. This is due to the low price of the tool, the simplicity of the design. The pliers are designed to work with fittings up to 32 mm in diameter, which limits their scope.

Hand pliers ( / retooling)

Mechanical

The tool consists of two long handles, which are connected by a gear mechanism. The principle of operation is to use a system of levers, through the transfer of physical effort.

hydraulic

Hydraulic tongs are used for installation work without much effort. The handles are connected to a hydraulic cylinder, which is actuated after they are squeezed. The cost of a hydraulic tool is higher than that of a manual or mechanical one, it needs to be serviced regularly.

Electro-hydraulic option

Power tools are used by professionals who are constantly involved in plumbing work. The power tool can be operated from a battery or after being connected to a 220 volt network. Cordless tools have little power, but can be used anywhere.Plug-in electric tongs are powerful, but not mobile.

Plumber ( / vodobroingenering)

Features of using press tongs

Despite the practicality and functionality of press tongs, there are places where it is very inconvenient to use such a tool. Repair and installation professionals say that when working with strobes laid in a false wall or under a false ceiling, it is wiser to take not pliers, but a press gun. It completely eliminates injury and makes it possible to control the process with one hand.

A press gun is a modern handy tool that allows you to crimp tubular material in the most inconvenient places and in confined spaces. However, it is not cheap and it is not advisable to buy it for one-time homework.

In addition, the tool can be rotated around the joint axis of the pipes, thus making an accurate, even and reliable crimping.

Practical advice on the production of pressure testing of metal-plastic pipes, tested in practice by plumbers, is given in the following article, the contents of which we advise you to familiarize yourself with.

Do-it-yourself crimping features

You can pressurize a do-it-yourself water-heated floor using a hydraulic or pneumatic method.

- Preparation according to the type of coating. For concrete screed, pressure testing is carried out before pouring. In the presence of a polystyrene or wooden surface - but closing the heating main with plywood or plasterboard.

- Communication testing. All heating circuits are connected to a distribution manifold and tested individually. The areas are filled with water until the air is completely expelled. For adjustment, return and supply valves are used.

- Cold testing of metal-plastic communications. It can be made a cold coolant with a pressure of 6 bar and withstand the system for 24 hours. If the pressure does not increase, the line is working.

- Checking polyethylene pipes. The system is loaded with pressure, 2 times more than the standard, but not less than 6 bar. After 30 minutes, the indicator is restored. The operation is carried out three times, then the pressure is brought into the pressure mode and left for 24 hours. If the indicator fell by less than 1.5 bar, the system is working.

Additional testing is performed by pressurizing the coolant at a temperature of 81-86 degrees for 30 minutes. At this time, the fittings are inspected, if they are weakened, they are tightened.

Installation and replacement rules

Users have long appreciated the main advantage of metal-plastic lines - simplified installation technology

However, adherence to the rules in the work is of no small importance. Negligent attitude to the assembly process and replacement of old lines with new ones can lead to negative consequences

Do-it-yourself installation of a plug-in connector is very convenient. You can remove and replace the mount if the system is leaking at the junction. It is also possible to reuse the part. Multiple mounting and dismounting is possible due to the fact that the body of the connecting elements is usually made of metal. At the ends of the part there is an external thread. A split ring and a tightening nut are put on the pipe.

To properly connect the highway with a detachable part, you need to disassemble the elements into components.The parts that are put on the pipe must be moved a few centimeters from its end. The fitting of the connector housing must be screwed into the metal-plastic. There is a groove on the body part, into which the end of the line should abut.

To the point of contact of the line with the body, you need to move the split ring and the screw nut. In this case, the ring must be inside. The free element of the connecting part must be fixed with a nut. The connection of the part at the initial stage of assembling the system is possible by hand, then it should be screwed with a spanner wrench.

To achieve absolute tightness of the connection, you need a special tool for crimping. They make a circular crimp line with a connected fitting. The threaded pair will play the role of a load source. In this work, do not make too much effort. The end of the pipe pressed against the inside of the connector may simply burst. The appearance of a characteristic creak when tightening may indicate the likely formation of cracks on the nut itself.

The category of conditionally detachable fittings includes connecting elements, which are also called compression fittings. These elements also have an external thread at the edges. There is both a ring and a union nut. The part is installed only once. The installation of the products is generally identical to the installation described above.

The union nut is put on the pipe. She wears a ring with her. A connector fitting is placed in the end part of the pipe. The nut together with the ring is pressed over the point of contact of the fitting with the line. O-rings present in the connection save if the pipe is leaking.If problems occur, you can pull out the connector, but you will have to replace it with a new element. Re-installation is excluded. Crimping is performed in an identical way (similar to the first option).

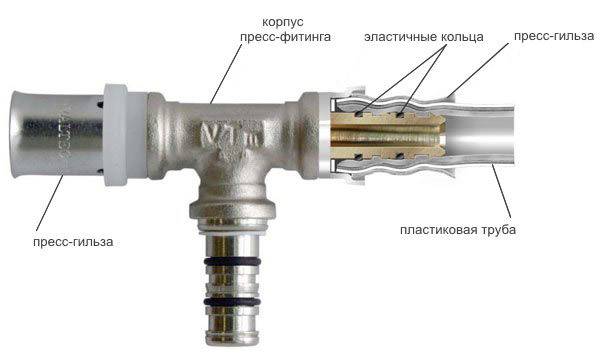

It is impossible to install a press fitting without special tools. This is a prerequisite for this part. The press fitting has a similar body, with obligatory fittings. The difference is the absence of nuts and ferrules. Here, a special sleeve acts as a tightening element, with which the point of contact of the line with the fitting is pressed.

During installation, the sleeve is put on the pipe, and a connector fitting is inserted into its end

It is important to achieve the most dense joining of the metal-plastic with the connector body. Next, the connection is placed in the vise of the press and pressed

Dismantling of such a connection is not possible. However, the tightness in this case is almost 100 percent. Therefore, products can be used in cases where it is necessary to mask the pipe in the wall.

In conclusion, it is worth mentioning that connectors for metal-plastic are manufactured and supplied to the market by leading manufacturers of such highways. For example, the Belgian firm Henco is the market leader in press fittings. The company also offers decent compression products.

Another representative of the segment is Valtec. The compression and press fittings of this company are considered to be of the same quality as the products of the Belgian manufacturer.

A wide variety of products is offered by the German brand Rehau. This is a world famous company producing high quality products. However, branded products are usually sold at very high prices.

For information on which fitting is better to choose for metal-plastic pipes, see the following video.

Criterias of choice

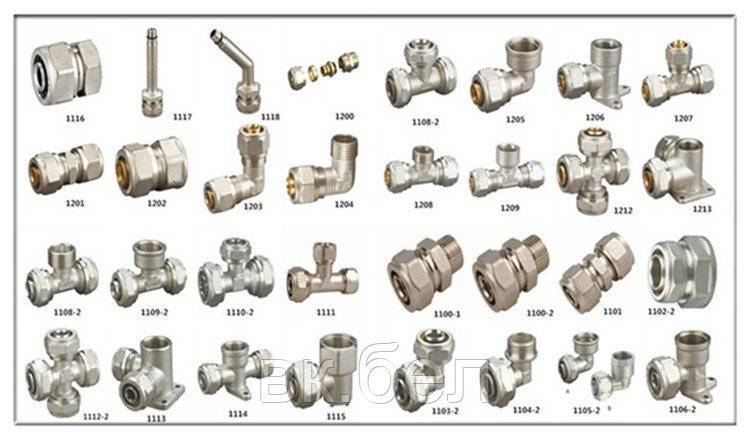

The main selection criteria for fittings are size and type. Experts also advise taking into account the materials of manufacture. But the use of fittings made of materials other than those used in the production of pipes is allowed. For example, brass fittings are great as connectors for copper products. Also, these options can be used for metal-plastic pipes. Copper fittings are suitable for any pipes. Products made of polypropylene or polyvinyl chloride should be used for highways made of the same materials.

It is strictly not allowed to combine copper elements with galvanized steel lines. Corrosion that occurs when two metals interact has a bad effect on the service life of products.

Now it’s worth understanding the criteria for choosing specific products. For example, couplings should be considered as connectors for straight pipe sections of the same size. If at any point the main pipe should change its direction, then a branch can be created using a tee. If a branch of a perpendicular direction is connected to the main line, so-called crosses are needed. These parts are characterized by four outlets and create versatile outlets.

If you need to connect lines of different diameters, you will also have to buy adapters. If a new flexible line is connected to an old rigid type line, fittings are needed. If any of the ends of the line is a dead end and requires hermetic clogging, plugs will come in handy.Squares are rarely required, but if the line at some points should change direction by 90 degrees, then these products will have to be purchased.

Conditionally non-separable elements, which are also called welded, can be used for highways operated in temperature ranges from -70 to +450 degrees. The possible working pressure of the system is 16 MPa. The main difference between these products from others is a smooth surface. The main selection criterion is the identity of standard sizes of trunks and connectors.

Threaded fittings are ideal for metal-plastic plumbing systems. The thread type of connectors is usually cylindrical. The same thread is supplied with pipes made of metal-plastic. Fittings can be used to connect lines with an internal temperature environment up to 100 degrees. The diameter of pipelines, as a rule, is 5 cm. Threaded connectors are used not only for water pipes, but also for oil pipelines and gas pipelines. They are used in other industries.

One-piece or compression fittings are suitable for joining flexible type water pipes with the same size. Usually they are also made of flexible materials. In terms of mechanical reliability, these elements are not very good. They are mainly used for cold water systems. This is due to the fact that when exposed to high temperatures, flexible materials usually lose their qualities. Due to the fact that the sealing ring of the product is elastic, the tightness of the joints is broken.

The calculation of the number of connectors can be done if there is a diagram of the entire trunk system of metal-plastic pipes. The scheme must necessarily include all branches, as well as points where plumbing will be installed.At these points, it is necessary to mark the names of the connectors that will need to be installed. When the whole scheme is ready, count and write down the required number of products.

The connecting fittings required for the installation of the system are also selected taking into account the inner diameter of the pipe.

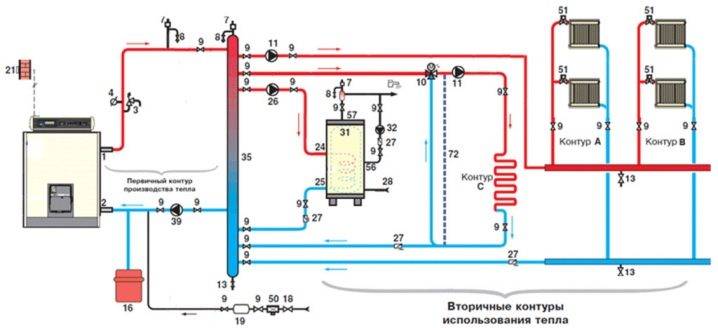

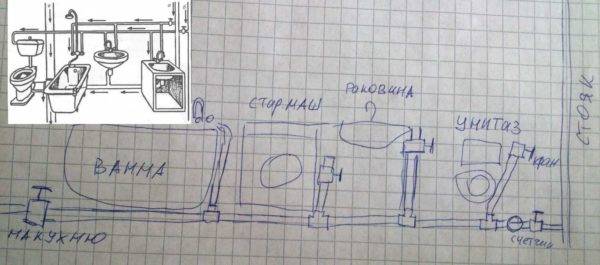

An example of the layout of the water supply system

First, draw a plumbing plan. This can be done on a piece of paper, indicating the necessary fittings.

Please note that for the installation of taps it is necessary to install a fitting with a threaded end. Taps are needed on outlets to household appliances and plumbing fixtures, to heating radiators

This makes it possible to turn off devices without blocking the entire system. The type of thread and its size are selected depending on the type of faucet used.

An example of a water supply system on metal-plastic pipes

Also, transition fittings are needed before and after the meter (water or heating depends on the type of system). Having drawn a detailed plan, put down the dimensions in all areas. According to this drawing, consider how much and what you need. Fittings can be purchased strictly according to the list, and it is advisable to take pipes with some margin. Firstly, you could make a mistake when measuring, and secondly, in the absence of experience, you can spoil some piece - cut off less than required or crimp it incorrectly, etc.

Negotiate an exchange

When buying everything you need, agree with the seller that, if necessary, you can change / return some fittings.Even professionals often make mistakes with them, and even those who decide to do the wiring of the plumbing or heating system from metal-plastic with their own hands and even more so. No one will take the remains of the pipe back from you, and fittings - easily. But to be sure, keep the receipt.

Sometimes it is more convenient to use collectors. They allow you to connect several consumers in parallel. There are collectors for plumbing and for heating (when distributing a warm floor)

When and how to get started

Arriving home, lay out the fittings, proceed: the installation of metal-plastic pipes in the summer can be done immediately, in the winter you need to wait a while (12 hours) until all the elements warm up to room temperature. It is desirable to cut off at a time one piece of pipe of the desired length. It's a little longer, but you won't get confused. Further actions depending on the selected type of fittings.

Heating wiring with metal-plastic pipes is done only on press fittings

After completion of the installation of metal-plastic pipes, the pipeline is checked. If it is a water supply, it is enough to open the tap at the inlet. This should be done gradually and smoothly. The system will immediately begin to fill with water. If nothing leaked anywhere, you did everything right. If any connections have leaked, they must either be redone - if press fittings were used, or tightened - if the assembly was on crimp connectors.

If a heating system was assembled from metal-plastic pipes, before starting it must be pressure-tested - tested with increased pressure by pumping cold water into the system. If the test is successful, you can do a trial run of heating.

Related videos

Once again, Valtek specialists (Valtek), whose products are considered one of the best on the market, will explain how to properly install metal-plastic pipes.

The design of metal-plastic pipes

The composition of pipes made of metal-plastic

The inner layer of polyethylene acts as the basis of the metal-plastic pipe, which gives the pipe strength and performs a load-bearing function.

A layer of aluminum foil is attached to it by means of an adhesive composition, which prevents the diffusion of oxygen and stabilizes the pipe.

The edges of the foil are butt welded together by a laser. The temperature of their linear expansion stabilizes metal-plastic pipes, which becomes comparable with the expansion temperature of metal pipes. At the same time, the outer polyethylene layer of white color carries out a decorating and protective function.

The general design of the pipes is as follows:

- polyethylene layer;

- a layer of glue;

- aluminum layer;

- another layer of glue;

- outer layer of polyethylene.

Thanks to this unique design, the service life of metal-plastic pipes is very long.

With all this, each structural layer of the metal-plastic pipe has its own separate function. So, cross-linked polyethylene, which makes up the inner layer, provides the inner surface with the necessary smoothness, protecting it from overgrowing with scale and other types of layers.

Both polymer layers protect the aluminum core from the formation of galvanic pairs with steel and brass elements of the pipeline, reduce the thermal conductivity of the pipes and the intensity of condensate formation on them.

The design of the metal-plastic pipe

Forms of release of metal-plastic pipes

The outer diameters of metal-plastic pipes produced by modern manufacturers range from 16 to 63 mm. The most common are diameters of 16, 20, 26 mm, sometimes when forming an extensive wiring of large houses, diameters of 32 and 40 mm are also used.

For the distribution of water supply in an ordinary apartment, a metal-plastic pipe is quite suitable - the diameter of which is 16 or 20 mm. For example, the main piping can be formed from products with a diameter of 20 mm, while 16 mm pipes can be used to lead to a bathtub, faucets and other household appliances.

Pipes are supplied in the form of coils, the dimensions of metal-plastic pipes in which are from 50 to 200 m in length.

Metal-plastic pipe: pipe sizes can be almost any, since coils sometimes accommodate pipe lengths up to 200 m

This is interesting: How to choose the right glue for PVC pipes + pipe bonding technology - write down the points

Press connection or compression fitting?

When assembling a pipeline from metal-plastic, two types of fittings for metal-plastic pipes can be used:

- Compression;

- Press fittings.

It would seem that the use of compression fittings is easier, because when using them you do not have to purchase a special tool. In addition, the installation of such fittings does not require special experience and specific skills. For installation, a minimum set of tools is required: a cutter, a calibrator, a set of wrenches, a mounting spring.

However, in the event that you need to get a really reliable connection, you must use compression fittings for metal-plastic pipes. In addition, the installation of a press fitting takes less time than the installation of a compression fitting.

If carried out crimping of metal-plastic pipes using press pliers, the connection is more reliable. And installation takes less than a minute.

Possibilities of press fittings

The range of press fittings is quite wide, so you can use them to create any wiring. Couplings and adapters are used for linear connection of pipes.

To perform turns, tees, angles, bends, crosses are used. In addition, with the help of such fittings, it is possible to connect a metal-plastic pipe to a metal pipe, provided that the latter has a thread.

Benefits of press fittings

Connections with press fittings will be durable and strong. There is no need to control them during pipeline operation.

- The connection technology is quite simple; neither specific knowledge nor special experience is required to perform the work. But the use of this type of connection assumes that he will use a special crimping tool for metal-plastic pipes.

- The use of press fittings allows you to install as quickly as possible.