- The economic side of the coin

- Manufacturing and assembly instructions

- Stage 1. Preparing the necessary equipment

- Types of briquettes

- By shape

- Briquettes RUF

- Briquettes Nestro

- Briquettes Pini&Kay

- Production process

- Briquette production

- Manufacturing steps

- Manufacturing Equipment

- Necessary materials

- Applied equipment

- Types of fuel briquettes

- Ready-made equipment for home production

- Briquette manufacturing technology

- homemade press

- Manual

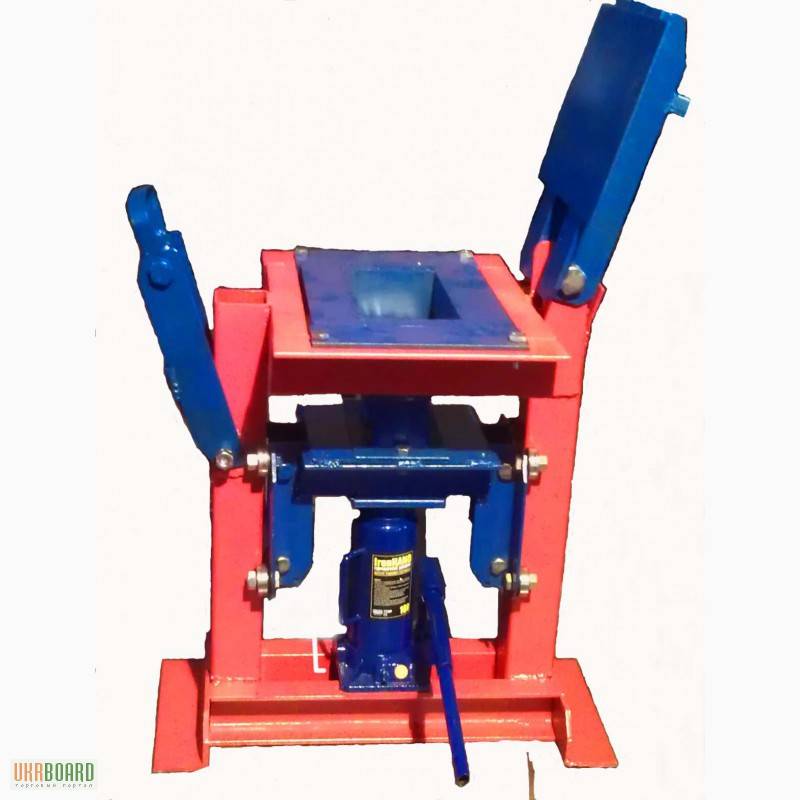

- From the jack

- Advantages and features

- Equipment for the production of briquettes

- Stage 4. Formation of briquettes

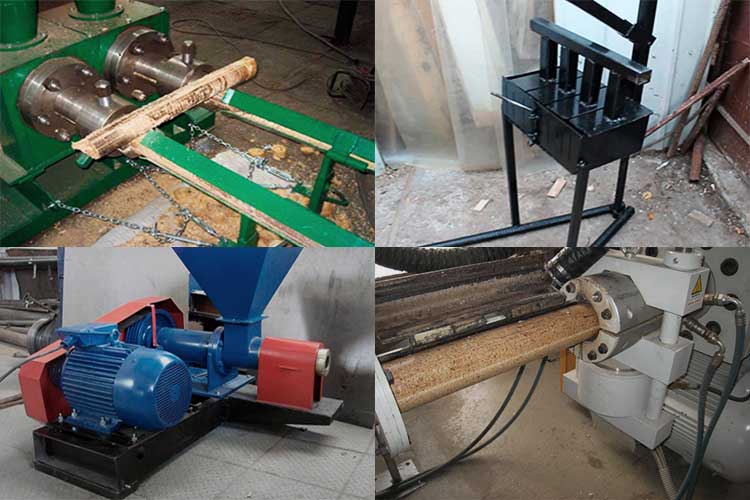

- Press with screw mechanism

- Equipment for creating heating material

- Equipment for the production of briquettes

- The process of making briquettes with your own hands

- industrial production

- Conclusions and useful video on the topic

The economic side of the coin

For the production of 1 ton of fuel briquettes, you need to take about 2 tons of wood waste or 1.5 tons of straw. At the same time, electricity consumption is approximately 100 kWh / t.

The calorific value of this heating product is 19 MJ/kg, which is much higher than that of ordinary firewood (only 10 MJ/kg).

With the right choice of equipment, manufacturing and storage of products, the technology pays off in about 2 years.

After reading my article, you can decide for yourself what is better: to make heating material from unnecessary raw materials, save time and money, or continue heating with wood. Indeed, when using briquettes, it is possible to dispose of waste unnecessary in everyday life, and to heat a summer house or a bathhouse with environmentally friendly fuel briquettes. If you want to organize your own production of pellets, then you will simply need information about the organization of the technological chain, and my new book “Typical mistakes of equipment manufacturers when planning the production of pellets” will help you with this.

Manufacturing and assembly instructions

The order of operations in the manufacture of the press is as follows:

- From the channels it is necessary to weld the base of the device.

- From the corner we make 4 racks 1.5 meters long. They are welded vertically and with the same pitch.

- Next, it is necessary to make a drum from a pipe or sheet of tin, in which the raw material will be mixed. If you have a broken washing machine, drum, as well as bearings, you can remove it from it.

- The drum must be attached to the racks. If possible, it should be equipped with an electric motor. If the motor is too high-speed and it is not possible to reduce the drum rotation speed to an acceptable value due to the difference in pulley diameters alone, a gearbox should be used.

- Under the drum, it is necessary to fix a tray through which the prepared material will be fed into the matrix.

- In the walls of the pipe used as a blank for the matrix, it is necessary to make several holes with a diameter of 3–5 mm. They must be distributed evenly so that air and water are squeezed out throughout the entire volume of the briquette.

- A flange must be welded to the matrix from below, to which the removable bottom will be screwed. This bottom is cut from a steel sheet in the form of a disc with lugs.

- The matrix is welded or screwed to the base under the loading tray.

- We cut out a round punch from a steel sheet. It's just a disk, the diameter of which allows it to freely enter the matrix.

The stem is made of a pipe: a diameter of 30 mm is sufficient. On one side it is welded to the punch, and on the other side it is attached to the hydraulic unit.

Under the matrix we fix the receiving tray

It is important to install in such a position that it does not interfere with the removal and installation of the removable bottom of the matrix. diameter as the punch.

To reduce the time spent on removing the finished briquette from the die, and thereby make the machine more productive, a spring with a disk of the same diameter as the punch can be welded to the bottom of the die.

After turning off the hydraulic unit and removing the punch, the product will be ejected by the spring automatically.

Stage 1. Preparing the necessary equipment

There are a number of enterprises that specialize in the production and sale of equipment for the production of fuel briquettes. Moreover, such equipment is usually brought, installed and tested (for an additional fee), and sometimes even trained in proper operation.

So, for work you will need:

- device for grinding raw materials;

- drying complex;

- a special press, which can be screw, mechanical or hydraulic.

Of course, if you produce briquettes at home, then you can do it without a drying complex, because ready-made briquettes can be dried simply in the open air. And if sawdust is used as a raw material, then a chopper is also not needed.

Also take care of a box with cells of the same shape - you can make it yourself from any box by nailing strips of appropriate sizes to divide into the same sectors. In these sectors you will fill up the feedstock!

Often, home craftsmen resort to another option - the independent manufacture of pressing equipment.

Types of briquettes

Eurowood differ both in appearance and in composition. Eco-friendly firewood is created in three types of standard shapes.

By shape

Depending on the shape and pressure of the press with which they were made.

Briquettes RUF

Rectangular "RUF". For their pressing, hydraulic presses with a pressure of 350 to 400 bar are used. The rectangular shape of the briquettes, resembling a brick, simplifies their transportation and long-term storage.

Briquettes Nestro

Cylindrical "NESTRO". When forming them, shock-mechanical and hydraulic presses are used, in which the pressure reaches 600 bar. Such fuel pellets have low moisture resistance.

Briquettes Pini&Kay

Multifaceted (extruded) "Pini&Kay". This species is distinguished by radial holes in the center and a characteristic dark color; are produced at high temperature up to 200-300 C and mechanical press pressure up to 1100 bar. They are characterized by high resistance to moisture and mechanical stress.

- woody. The raw materials for them are all waste processing wood products: shavings, chips, sawdust, bark, slab.

- From agricultural waste. Husks of cereals, corn and sunflower waste, peat, charcoal - all this turns into raw materials for eurofirewood. They do not have as high heat transfer as other types.

- Coal. Coal dust briquettes are the best in terms of heat transfer.

Production process

Stages of production of fuel briquettes (click to enlarge)

Stages of production of fuel briquettes (click to enlarge)

The production of combustible briquettes at home is divided into the following stages:

- procurement of raw materials;

- its grinding;

- drying the prepared fraction;

- its crushing.

DIY manufacturing:

- mixing the prepared fraction and the binding element;

- adding water;

- loading into the press;

- pressing;

- drying;

- packaging and transport to storage.

Fuel briquettes are an excellent type of fuel for various types of boilers, fireplaces and stoves. And making them at home can save you a lot of money. That is why, if there are appropriate conditions, it is simply necessary to make such a type of fuel as briquettes.

How to make a press for making fuel briquettes, see the following video:

Briquette production

The raw materials for the manufacture of briquettes are all kinds of waste from agricultural enterprises, woodworking, furniture production and other industries that use wood and plants. The technology for the production of fuel briquettes from sawdust makes it possible to use up to four cubic meters of waste to create one cubic meter of the finished product, which has a positive effect on the environment. Companies that produce sustainable firewood rid the planet of a huge amount of garbage.

The cost of raw materials for briquetting varies depending on its type and quality, as well as on the region from which it is delivered. The quality of the supplied raw materials is one of the main factors for the success of the production of environmentally friendly clean fuel.

It is important to have reliable suppliers who, according to laws and regulations, ensure environmental safety in their production. Numerous agricultural complexes and farms, woodworking enterprises and sawmills become such suppliers.

The technology for the production of environmentally friendly fuel is divided into several stages. Each of them uses special equipment, and the established temperature and pressure standards are observed. But the main element in the creation of briquettes is the binder. The connecting components are melted during the production process and bind together the fractions of the raw materials.

Waste wood from deciduous trees does not need the addition of binders, because it already contains resin, which becomes a binder during heating. Agricultural waste, on the other hand, requires additional substances such as lignin. Lignin is considered the basic component in fuel briquettes. In terms of composition, it is environmentally friendly, as it is obtained only from the remains of parts of plants.

The production of sustainable firewood begins with the preparation of the dryer and setting the desired temperature inside the fan. After that, the bunker with auger feed is loaded, feeding the material into the drying chamber. Moisture is removed by air currents, so only ordinary steam escapes into the atmosphere.No harmful substances are released during the drying of the material, which is why the production of fuel briquettes is called environmentally friendly.

Manufacturing steps

The main stages of production:

- Grinding / crushing of raw materials to a fraction of not more than 3 mm. Waste is shredded in a chipper. The rotating drum of the device, equipped with sharp knives, crushes the chips and separates the larger ones for re-grinding to the required size.

- Drying. The heat generator dries the fractions with hot air. The amount of moisture in the raw material should not exceed 15%.

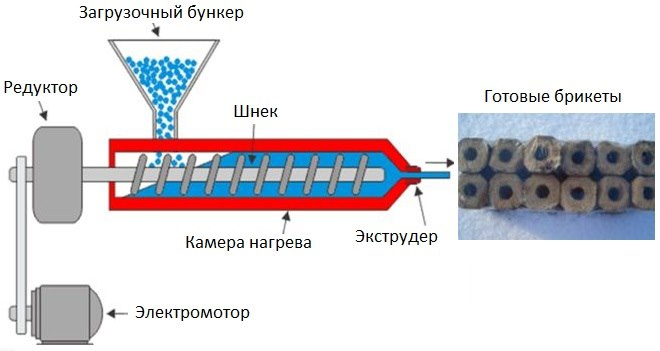

- Briquetting. In the extruder, the line for briquetting wood waste begins, and not only. The prepared mixture is sent for pressing. Under conditions of high pressure and at a special temperature, the raw material is squeezed out of the extruder and cut into individual briquettes.

- Package. The briquettes are hermetically packed, after which they are sent to the warehouse.

Manufacturing Equipment

The main equipment for the manufacture of fuel briquettes are an extruder and a press.

An extruder is a machine that softens / melts materials and gives them the desired shape by extruding a compressed mass through a die. The machine consists of several main fragments: a body with a heating element, a main screw and an extrusion head for creating briquettes of a certain shape at the exit from the machine.

The press is an apparatus for squeezing the prepared mixture of fractions to a high density and ergonomic consistency. Pressing allows you to form the most compact and suitable for long-term storage and use of briquettes.

There are several types of press:

- Manual press for briquettes.This is a simple metal structure, which includes a mold, a support part, a piston and a handle. This type of press is light weight and easy to transport.

- Hydraulic Press. The hydraulic press includes a variable displacement piston pump, an electric motor and a hydraulic oil tank. It is used only in rooms with maintaining a positive temperature.

- Impact mechanical press. Forms briquettes according to the principle of impact extrusion. The press piston is placed horizontally inside the cylindrical pump.

Necessary materials

In addition to the hydraulic installation, you will need some types of rolled steel:

- Channel.

- Equal-shelf corner 100x100 mm.

- Sheet thickness 3 - 6 mm. A punch will be cut out of it. The thickness of the workpiece depends on the diameter of the matrix: the larger it is, the thicker the punch should be.

From the same sheet we cut out a removable bottom for the matrix.

- A pipe with a diameter of 25 - 30 mm - a punch rod will be made from it.

- Thick-walled pipe - blank for the matrix. The diameter depends on what size briquettes the user wants to receive. The thinner they are, the higher their density, but the productivity of the machine will decrease.

- A large diameter pipe is a blank for the mixer body. If there is no suitable pipe, the drum can be made from a sheet of tin.

- Galvanized steel for the manufacture of trays.

In total, two trays are required - for loading the prepared material into the matrix and for receiving finished briquettes.

Applied equipment

Most often, such companies are engaged in setting up and installing such equipment. They even teach how to use such devices.You can also purchase equipment from organizations that manufacture pallets, briquettes and production lines.

To make fuel briquettes at home, you need to have:

- waste crusher;

- drying machine;

- press for creating briquettes (screw type, impact or screw).

It should be noted that at home you can do without a dryer, you can simply dry the briquettes on the street. And if you are going to use sawdust as the basis, you can also neglect the crusher.

For the most skilled residents, we can recommend making a homemade press in your workshop. With sufficient skill, such a machine may not be inferior to industrial counterparts, the drawings of which were developed by a group of engineers.

On the network you can find many schemes for the manufacture of a home-made press, it is for them that you can carry out its layout and assembly. It is clear that such a machine will be effective depending on the type of construction chosen and the quality of its execution.

For those who decide to make such a machine, following one of the schemes found, weld the frame of the structure, install a working element on it, which, unfortunately, cannot be made at home. Next, to the working element, attach a drive in the form of an engine of an electric, diesel or gasoline type and add systems for supplying mass and removing finished briquettes.

Types of fuel briquettes

Briquettes are divided into types depending on their shape. Basically, the following types can be found on the market:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from sawdust of natural wood with the addition of special components.

- Nestro.Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading tank, then fed for pressing by means of a screw. The mass is distributed by dispensers according to the forms under pressure.

- Pini kay. In shape, these are polyhedrons with the number of faces from 4 to 6. In the production process, they are subjected to high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

The chemical composition and heat transfer of all these types of pressed sawdust is the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. The high density and slight hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

In addition to sawdust, sunflower husks, buckwheat, paper, small branches, fallen leaves, straw are used for the production of briquettes. The equipment for this has a fairly simple design, and you can make it yourself

If you have the necessary raw materials to form briquettes, you can make them yourself.

Ready-made equipment for home production

The production of fuel briquettes requires special equipment.

Therefore, in order to create high-quality products with your own hands, you need to purchase:

- Shredding device.

- Drying machine.

- Press.

But it is not advisable to buy expensive machines for briquetting wood waste at home.

It makes sense to use powerful installations only in the manufacture of fuel briquettes in large volumes.

It is possible to make briquettes as a material for heating a private house without a dryer. It is easy to remove moisture from harvested raw materials in a natural way. To do this, sawdust or wood shavings are laid out in a small layer on the street under a canopy.

Often a homemade press is used to create compact fuel. Such a device will not provide a high compression density of the material, but still make it possible to make fuel suitable for home use.

Briquette manufacturing technology

The process of production of heating material is laborious and requires sequential operations.

If necessary, prepare raw materials before use:

- Crushing of material;

- Drying of crushed raw materials;

- Grinding (the better the components of the briquettes are crushed, the higher the heat transfer rates).

To make your own hands, the raw materials must be mixed with a binder. For this, clay is quite suitable in accordance with 1 to 10, where 1 kg of clay and 10 kg of crushed material are taken.

The resulting mixture must be mixed with water to form a homogeneous mass, it is important that it is neither liquid nor solid.

The resulting mass must be loaded into special equipment. During pressing, excess liquid comes out and the product receives its final shape. If you use a homemade press, then there is a possibility that a small amount of moisture will still remain inside the product.

An obligatory moment in the manufacture of heating material is drying after pressing. You can dry it outdoors, under the sun's rays and wind.The time of this stage depends on the volume of briquettes, as well as on the pressing technologies used.

After drying, the product must be moved to a special place for storage or packaged.

homemade press

If you have a drawing and certain design skills, you can make a press for fuel briquettes with your own hands.

Home-made devices for briquetting are of two types - functioning from a jack and with a manual drive.

A description of the assembly of the structure will help you understand how to make a press, and which option is best to use.

Manual

To make a hand press, a punch is required. It is constructed from a thick metal sheet. A pressure lever is attached to the material, and the structure is fixed with hinges.

The punch is installed in a special mold. Usually it is made square. A mold is made from metal. Holes are drilled with a thin drill in the lower part and on the sides, which ensure the release of moisture during the pressing process.

To collect the released water, a container is used in which the finished press is installed.

From the jack

To obtain better quality solid fuel and improve the design of the press, a hydraulic jack is used.

The manufacturing process of such equipment consists of the following stages:

1. The base for the press is formed from the channels. All metal parts are fastened by welding.

2. Racks are attached to each corner of the prepared base in a vertical position. Each support is taken 1.5 meters high.

3. A mixer is welded to the racks. The drum can be made from a pipe with a large diameter or you can take a finished part from an old washing machine.

four.A galvanized steel tray is fixed under the mixer, from which the raw materials will penetrate into a special form.

5. Holes are created in the thick-walled pipe intended for the matrix. They should be evenly spaced throughout the round contraction. The width of each opening should be from 3 to 5 millimeters.

6. At the bottom of the mold, a flange is fixed with a welding machine, to which the bottom is screwed.

7. The finished form is connected to the base.

8. After that, a punch is cut out of the steel sheets. It must have the same shape as the matrix. Using a rod, the punch is connected to a hydraulic element.

The assembled mechanism is fixed above the form to the racks. The tray is attached to the bottom.

To speed up the process of extracting pressed briquettes, it is recommended to weld the disk and spring to the bottom of the die. It must match the diameter of the punch. Such a mechanism will automatically eject finished products after turning off the hydraulics.

Pressed wood raw materials require drying. The lower the humidity of the briquettes, the better they burn. In addition, dry briquettes have a higher heat transfer.

Do-it-yourself compact fuel can significantly reduce the cost of heating a house. Ready-made briquettes can be used both for the boiler and for the furnace. But it should be borne in mind that the quality of products largely depends on the density index.

It is almost impossible to make pressed firewood using home-made equipment that will burn for a long time and give off a large amount of heat.

Therefore, if it is necessary to use fuel with high performance, then it is better to purchase it in specialized stores.

Advantages and features

- wood chips, sawdust, chips;

- from leaves;

- agricultural crop waste;

- from paper;

- peat;

- coal;

- from manure.

All of these types of waste are natural, self-regenerating sources. Fuel briquettes made at home are distinguished by their environmental friendliness, they burn out completely, while practically not giving off smoke.

Such fuel can perfectly warm a bath or sauna, they flare up and begin to give heat very quickly. They will be especially beneficial for people who like to cook dishes on the grill, because the fat that will drip onto the fuel will not ignite.

The high density of the briquettes makes them highly resistant to fire hazards, they can be stored close to the boiler and do not waste time on transportation. As you can see, the manufacture of sawdust briquettes is the most convenient option for stoves or fireplaces, the same boilers that run on solid fuels.

It is important to know: the main advantage of natural type fuel briquettes is their heat transfer, cleanliness and efficiency.

Unlike the same wood (firewood), fuel briquettes flare up faster and have less smoke, due to their low humidity. When they burn, few sparks are released, the temperature will be constant. In addition, briquettes have the correct shape, which makes their use and storage much more convenient.

The main disadvantages of briquettes are the ability to absorb moisture and be damaged by mechanical forces. It should be noted that the technology for the production of briquettes at home will not be cheap, including a dryer, the press itself and a crusher.

Unless, of course, you do not have ready-made, already crushed raw materials.So, you should not rush to buy such equipment.

Equipment for the production of briquettes

Pressing and drying equipment, which is a production line for the production of briquettes, is not available at home due to its high cost and dimensions. Home craftsmen use home-made machines that allow the mixture for fuel briquettes to be molded into bricks or “washers”. The main elements of such an installation are the mechanism that creates pressure, and the form itself. How to combine them into one whole is up to you, there are many options.

At the moment, a home-made briquette press is made by home craftsmen in 3 versions:

- with manual drive;

- with the use of jacks;

- with hydraulic drive.

The first option is the easiest. A frame is made from a metal profile pipe for welding, which, for convenience, can be attached to the wall of a house or barn. At the bottom of the frame, a round or rectangular shape is fixedly installed, and a long lever is attached to the top on a hinge. A pressure element is attached to it, which enters the mold with a small gap.

The second and third options differ in that the sawdust press is mechanized with a jack or a hydraulic drive installed instead of a lever. In order for water to flow out of the mold during pressing, several small holes are made in its bottom part. The design of such a machine is shown in the video:

Stage 4. Formation of briquettes

Step 1. First, take the prepared raw materials (sawdust, etc.) and mix it with dry clay. For a kilogram of waste, approximately 100 grams of clay will be required, therefore, the ratio will be as follows: 10: 1.Add a small amount of water to the resulting mixture, mix everything thoroughly again. Make sure that the mixture does not turn out to be too thin or too thick - ideally, it should be perfectly sculpted.

Attention! In this case, one should take into account the fact that the density of the finished product is inversely proportional to the amount of added water. Moreover, if there is too much liquid, the briquettes will dry for a long time.

You can add some finely chopped paper to the mixture - this will greatly improve combustion.

Step 2. Pour the resulting mixture into pre-prepared molds and compress thoroughly. Try to get the maximum amount of liquid out of the products under pressure. Leave for a while briquettes in this form.

Step 3. Next, dry the finished products. For drying, it is advisable to use a firebox, although in its absence you can do it in the sun. Make sure it dries completely! If the briquettes turn out to be raw, they will not only not burn, but will also crumble due to their low strength. And in order to somehow increase strength, cover the products with dry leaves or paper when drying.

Step 4. As soon as the briquettes are completely dry, lay them in a pre-prepared place and then use them for their intended purpose.

And here is another interesting production option.

Press with screw mechanism

Such a press can be called the simplest, made by home craftsmen. The mixture is poured into the perforated molding container, after which it is placed under the frame. Slowly tighten the screw, creating the desired pressure.The principle of operation and the device of such a press can be clearly seen in the figure.

Screw sawdust briquetting machines of this type to produce pressed briquettes have not become very popular because they have a very low productivity. It takes a long time to load the mold, turn the screw and take out the finished product.

It is much easier and faster to make "brick" briquettes on a homemade press, which uses a long lever and a system for "pushing" briquettes out of the mold. To make the process faster, some summer residents weld two forms to the frame.

Not all masters are satisfied with manual work. There is also advanced mechanized equipment. For example, to make a manual sawdust briquette machine more productive, you can replace the manual drive with a hydraulic jack. Of course, the assembly of such a unit will require some effort, but the result will increase the efficiency of the machine.

In no do-it-yourself press, where a hydraulic jack is used, you can not get pressure above 300 bar. To get closer to the factory technology, it is necessary to add water and use additional binders

.

Even difficulties in manufacturing parts do not stop home craftsmen. They were able to make their own screw press, which produces very good quality briquettes. However, they had to spend a lot of money to make the screw and housing using high alloy steels.

Such a machine requires an electric drive, the power of which should exceed 7 kW, and this is an additional financial investment.

Equipment for creating heating material

To date, there are many companies supplying equipment for the production of fuel briquettes, often they also offer installation services. In some cases, they conduct lessons on how to use the devices.

For the manufacture of do-it-yourself fuel you will need the following:

- for grinding recyclables;

- Briquetting press (hydraulic, screw or shock-mechanical;

- finished product.

If it is possible to dry the material in the fresh air or get it dry from other industries, then you can do without a drying complex, but it should be noted that the sawdust should have a moisture content of no more than 13%. And when using sawdust, a crusher is not needed.

Equipment for the production of briquettes

In industrial conditions, the grinding of wood waste is carried out on special mechanisms - crushers. Such an important part of the technological process as drying is carried out using dryers, which are of two types - drum and aerodynamic.

Forming of products is carried out on a hydraulic press. With a force of at least 30 MPa, it compacts the mass. At the same time, no substances need to be added to the raw materials for bonding, because. under these conditions, due to compression and high temperature, wood glue - lignin - is released.

Briquettes of any shape can be obtained on a shock-mechanical press, but their density is not very high.

There is another method for obtaining "euro firewood" - extrusion. It is based on the fact that with a force of about 40 MPa the mass is pushed through the calibrated holes by means of a screw, while forming products in the form of cylinders or hexagons. At the exit, they are cut with special knives.

The productivity of screw extruders is higher than that of mechanical or hydraulic presses.

On the surface of briquettes made on industrial equipment, manufacturers often apply a letter print. Basically, it is evidence of precise adherence to technology.

On the surface of briquettes made on industrial equipment, manufacturers often apply a letter print. Basically, it is evidence of precise adherence to technology.

It is irrational to buy such installations for making your own hands and harvesting fuel briquettes; there are other options for this.

The process of making briquettes with your own hands

The technology for the production of compressed fuel has its own characteristics.

The whole process of making wood briquettes is built on several stages:

1. Preparation of raw materials. All waste used must have a uniform consistency. Therefore, the raw material must initially be completely crushed.

2. Drying. The material prepared for pressing must be dried. After drying, the raw material should contain no more than 15 percent moisture.

3. Briquetting. This stage is the final one. Pressing crushed and sufficiently dry raw materials is carried out using a hydraulic press or by extrusion. Both manufacturing methods involve the process of strong squeezing of the prepared raw materials. As a result, lignin is released from the natural material, due to which the dry bulk mass sticks together.

It's pretty easy to do this:

- Soak small wood residues in water.

- Mix wet raw materials with clay in a ratio of 1 * 10.

- Using a homemade press, form a briquette.

The resulting fuel is dried in natural conditions on the street. Instead of clay, as a binder, you can use wallpaper glue or cardboard soaked in water.

industrial production

If we talk about industrial production, here fuel briquettes are made using one of three possible technologies:

- through hydraulic presses and at high pressure - as a result, products are obtained that look like small bricks;

- by means of screw presses under pressure and heat treatment - as a result, briquettes come out having the shape of an empty polyhedron;

- by means of hydraulic or mechanical presses at high pressure - as a result, products of a cylindrical shape.

To learn more about this process, watch the thematic video.

Conclusions and useful video on the topic

Creating a homemade lever press. Production of main parts and description of the principle of operation:

Refinement of the machine design and the process of pressing briquettes:

Machine for simultaneous production of several briquettes based on a hydraulic jack:

It is not difficult to make a sawdust briquetting machine on your own. Lever, hydraulic or screw pressure generation can be used to choose from. But it must be remembered that the quality of manufactured products will depend not only on the assembled mechanism, but also on the preparation of raw materials.

A properly set process will help provide your economy with high-quality and cheap fuel and even arrange its implementation.

Do you want to talk about how you made briquettes for heating with your own hands? Do you have valuable recommendations on the topic of the article that you are ready to share with site visitors? Please write comments in the block below, post photos and ask questions here.