- Benefits of sawdust logs

- Do-it-yourself press for making fuel briquettes

- Building a plant from scratch

- Making a press based on a finished mechanism

- How to grind raw materials

- Equipment for the production of briquettes

- Videos for a snack

- The economic side of the coin

- How to make briquettes?

- General information about briquettes

- homemade press

- Manual

- From the jack

- Types of fuel briquettes

- Briquette manufacturing technology

- Is it worth making briquettes at home?

- Manufacturing and assembly instructions

- Necessary materials

- Ready-made equipment for home production

- Homemade briquettes - pros and cons

- Conclusions and useful video on the topic

Benefits of sawdust logs

In favor of briquettes pressed from sawdust, the following arguments can be made:

- Long burning - 4 hours.

- Minimal smoke production.

- Environmental friendliness. The raw materials are natural materials, so the beds can be fertilized with ashes.

- High energy efficiency. It far exceeds the energy capabilities of firewood, comparable only to high-quality coal.

- constant combustion temperature.

- Profitability. The cost of 1 ton of such fuel will be cheaper than the corresponding amount of firewood or coal.

- Possibility of self-production.

Disadvantages are also present.Chief among them is the fear of moisture. It is impossible to store them in the open air, because. they quickly absorb moisture, therefore, they will burn poorly. Therefore, it is necessary to allocate a dry room for storage.

Any significant mechanical impact on sawdust briquettes is contraindicated. If you buy special equipment for their manufacture, the cost will be high and not always justified.

Replacement of coal and firewood for sawdust briquettes, allows you to make the heating of suburban housing more environmentally friendly. While heating with damp wood leads to the release of harmful substances, "Eurowood" is completely safe in this respect.

Replacement of coal and firewood for sawdust briquettes, allows you to make the heating of suburban housing more environmentally friendly. While heating with damp wood leads to the release of harmful substances, "Eurowood" is completely safe in this respect.

It is beneficial to establish handicraft production if sawdust is free, and existing equipment can be used as an installation.

Do-it-yourself press for making fuel briquettes

The purchase of ready-made equipment for the manufacture of briquettes, depending on its capacity, will cost from 300 thousand to 1 million rubles.

Of course, for a private trader who wants to start manufacturing this fuel purely for his own needs, such costs are inappropriate, since they will not pay off soon. It would be more correct to make a press from improvised materials, especially since there is nothing complicated in its design.

You can build the necessary equipment from scratch or use ready-made mechanisms.

Homemade machine

Building a plant from scratch

You can create a significant effort required to compress the raw material using:

- lever (it can be influenced by its own weight);

- screw mechanism.

A lever press can even be made from wood; for a screw press, you will definitely need steel blanks and a lathe.

A screw extruder (sawdust press) can theoretically also be made by hand, and some craftsmen even succeeded, but such an undertaking is very expensive due to the complex processing of parts and the need to use special high-quality steel.

Heating on pellets is not only economical, but also environmentally friendly, because recycled materials are used as fuel. You can make or convert solid fuel for pellets.

You will find detailed instructions for making a solid fuel boiler with your own hands.

Doubt about choosing a pellet boiler? At this link: you will find reviews of real users about these boilers. Read and draw your own conclusions.

Making a press based on a finished mechanism

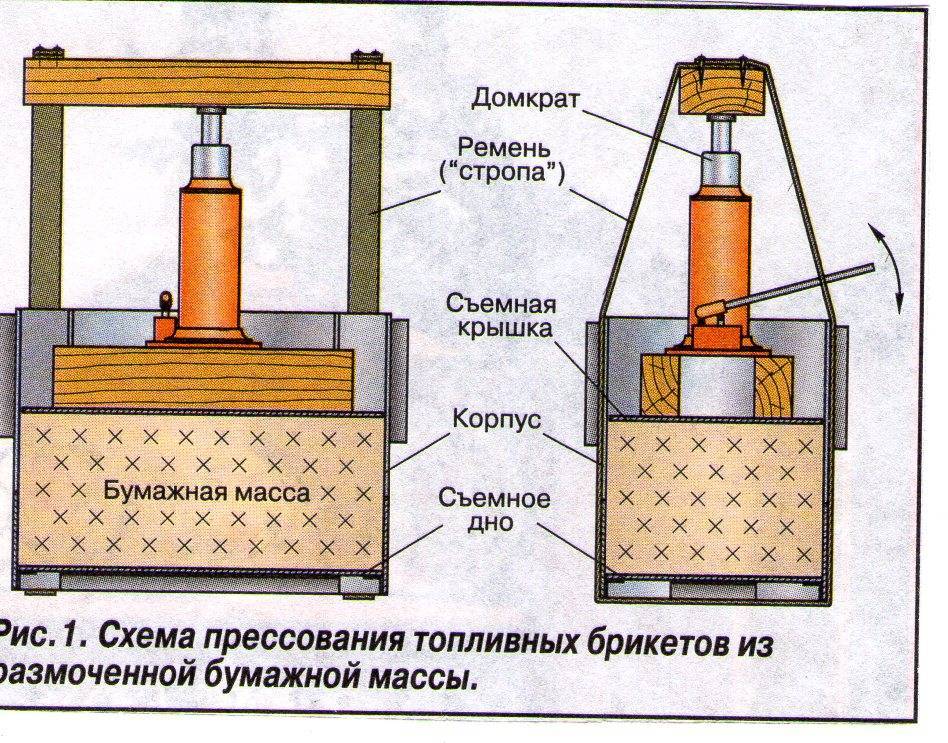

For the manufacture of briquettes, you can adapt some device that is more affordable than a real machine - a jack or a small hydraulic press. It remains only to provide a punch and a matrix.

It should be understood that any homemade press, even made on the basis of a hydraulic jack, will not be able to develop efforts that ensure the release of lignin.

Therefore, instead of it, third-party binders have to be added to the raw materials.

In this capacity, apply:

- Cheap glue, for example, wallpaper.

- Clay (1 part is added to 10 parts of sawdust).

- Soaked paper, including corrugated cardboard - the lignin contained in it, upon contact with moisture, exhibits its sticky properties (this property of the paper is used when spraying a heat insulator of the Ecowool type).

Another difference from industrial technology is that the source material is not dried, but rather soaked in water - then the particles stick together better. Then the finished briquette is dried in the open air.

How to grind raw materials

For the hassle of making a home-made press, one should not forget about such an important stage in the production of briquettes as grinding raw materials. It is very difficult to cut it by hand - mechanization is also needed here.

Some make shredders on their own from an old activator washing machine - they install knives instead of an activator.

Another option is to purchase a rotary machine.

The purpose of this device is precisely the crushing of vegetation - summer residents use it to make fertilizer from leaves and grass.

Equipment for the production of briquettes

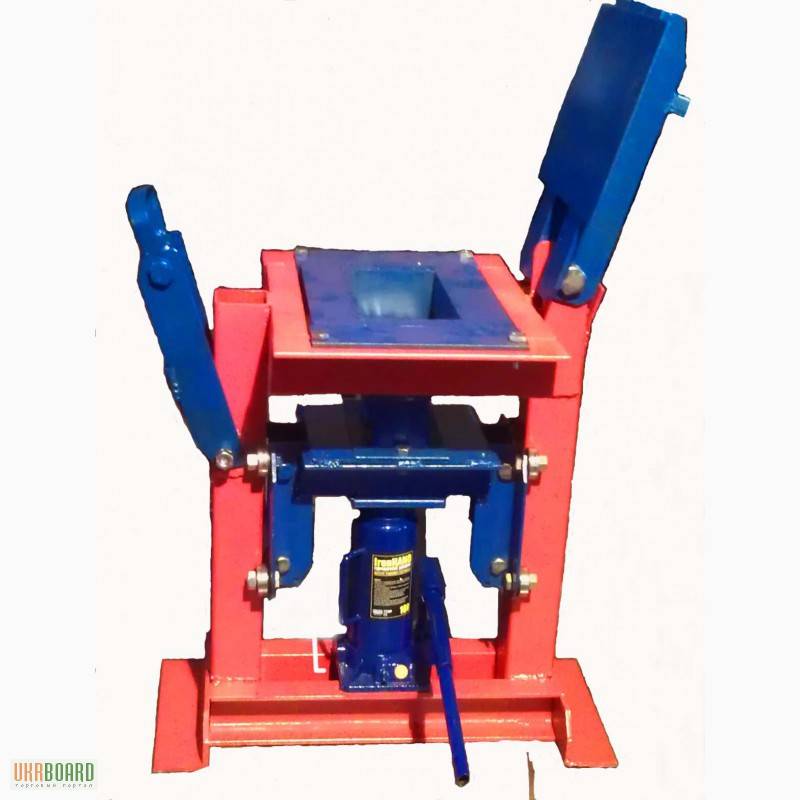

Pressing and drying equipment, which is a production line for the production of briquettes, is not available at home due to its high cost and dimensions. Home craftsmen use home-made machines that allow the mixture for fuel briquettes to be molded into bricks or “washers”. The main elements of such an installation are the mechanism that creates pressure, and the form itself. How to combine them into one whole is up to you, there are many options.

At the moment, a home-made briquette press is made by home craftsmen in 3 versions:

- with manual drive;

- with the use of jacks;

- with hydraulic drive.

The first option is the easiest. A frame is made from a metal profile pipe for welding, which, for convenience, can be attached to the wall of a house or barn. At the bottom of the frame, a round or rectangular shape is fixedly installed, and a long lever is attached to the top on a hinge. A pressure element is attached to it, which enters the mold with a small gap.

The second and third options differ in that the sawdust press is mechanized with a jack or a hydraulic drive installed instead of a lever. In order for water to flow out of the mold during pressing, several small holes are made in its bottom part. The design of such a machine is shown in the video:

Videos for a snack

Good luck and see you again, Andrey Noak was with you!

Sawdust, agricultural waste, leaves and other plant debris are all excellent fuels.

But for an ordinary boiler, it becomes "digestible" only in the form of pressed briquettes - without processing it will have to be added every 5 minutes, and most of it will spill through the grate.

Powerful presses for working with such raw materials are produced today in abundance, but due to the high cost, buying such a unit is only beneficial for the purpose of organizing permanent production.

The average person has to make a press for making fuel briquettes with his own hands.

The source material, most of which is usually sawdust and wood trimmings coming from woodworking enterprises, is crushed and thoroughly dried.

In the end, the moisture content of the raw material is brought to 8% - 10%.

In addition to components of plant origin - wood waste and husks of various agricultural crops - coal dust can be used to make briquettes.

The next stage is, in fact, the manufacture of briquettes from the prepared mass.

To do this, use one of two methods:

- Pressing:

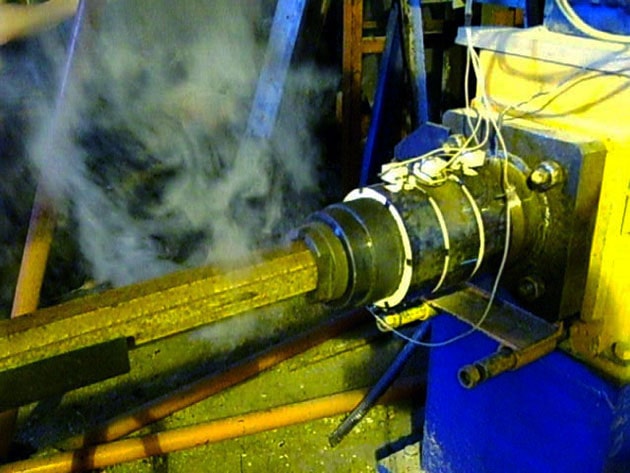

raw materials are poured into round or rectangular shapes (this element is called a matrix), where it is compressed using a powerful hydraulic press. The part that directly affects the raw material is called the punch. The machine develops a pressure of 300 - 600 atm. - Extrusion:

The extruder is very similar to the screw meat grinder. The screw pushes the raw material through a gradually narrowing molding channel and the resulting pressure reaches 1000 atm.

Strong compression leads to the following phenomena:

- The temperature of the mass is greatly increased.

- Particles of raw materials begin to release a sticky substance - lignin. Under heating conditions, it reliably binds the loose mass, turning it into a solid solid briquette.

- The density of the material increases to 900 - 1100 kg / cu. m. For comparison: the density of wood is only 500 - 550 kg / cu. m. Along with the density, the energy value of the fuel per unit volume also increases: now its stock for the winter will take up half the space. Yes, and a pressed chock will burn longer than an ordinary log.

The economic side of the coin

For the production of 1 ton of fuel briquettes, you need to take about 2 tons of wood waste or 1.5 tons of straw. At the same time, electricity consumption is approximately 100 kWh / t.

The calorific value of this heating product is 19 MJ/kg, which is much higher than that of ordinary firewood (only 10 MJ/kg).

With the right choice of equipment, manufacturing and storage of products, the technology pays off in about 2 years.

After reading my article, you can decide for yourself what is better: to make heating material from unnecessary raw materials, save time and money, or continue heating with wood.Indeed, when using briquettes, it is possible to dispose of waste unnecessary in everyday life, and to heat a summer house or a bathhouse with environmentally friendly fuel briquettes. If you want to organize your own production of pellets, then you will simply need information about the organization of the technological chain, and my new book “Typical mistakes of equipment manufacturers when planning the production of pellets” will help you with this.

How to make briquettes?

The technological process used in production cannot be carried out at home. The reason is the lack of press or extrusion equipment capable of creating a pressure of at least 30 MPa. Without this, it is impossible to isolate lignin from wood and home-made briquettes are not compressed. The solution is simple: you need to add a binder, which is ordinary clay. It is mixed with sawdust in a ratio of 1:10 by weight (1 kg of clay per 10 kg of waste), diluted with water and mixed thoroughly.

The resulting composition is filled into the form and the mechanism is activated. If the production of fuel briquettes is done manually, then it is necessary to apply maximum effort and hold the lever until the water runs off. Then the product is carefully removed and placed on a platform under the open sun to dry. You can again start filling out the form and extruding the next "brick".

General information about briquettes

The raw material for this type of biofuel is small wood waste, mainly sawdust. Of course, you can burn them anyway, but it's not very convenient, it takes a lot of fuel and it quickly burns out. And all because the density of the wood pulp is low, much more heat will be obtained if the raw material is pre-compressed.This is the technology of briquette production.

First, sawdust and other waste are processed, crushed and dried. The moisture content of the raw material before pressing should be in the range of 6-16%, which is what the drying equipment provides. Then comes the actual production of fuel, which is done in two ways:

- using a hydraulic press, the raw material is molded into rectangular or cylindrical briquettes. The process takes place at a pressure of 30 to 60 MPa and high temperature;

- by extrusion on a screw press, a 4- or 6-sided briquette is squeezed out of the finished mixture under a pressure of about 100 MPa. The product undergoes heat treatment.

It should be noted that the production fuel briquettes from sawdust provides for the addition of binder components to the composition of the mixture. Under the influence of high pressure and temperature, the particles stick together with lignin, which is found in any wood. The result is "bricks" or "sausages" whose calorific value is up to 5 kW/kg. The production process is shown in the video:

homemade press

If you have a drawing and certain design skills, you can make a press for fuel briquettes with your own hands.

Home-made devices for briquetting are of two types - functioning from a jack and with a manual drive.

A description of the assembly of the structure will help you understand how to make a press, and which option is best to use.

Manual

To make a hand press, a punch is required. It is constructed from a thick metal sheet. A pressure lever is attached to the material, and the structure is fixed with hinges.

The punch is installed in a special mold. Usually it is made square.A mold is made from metal. Holes are drilled with a thin drill in the lower part and on the sides, which ensure the release of moisture during the pressing process.

To collect the released water, a container is used in which the finished press is installed.

From the jack

To obtain better quality solid fuel and improve the design of the press, a hydraulic jack is used.

The manufacturing process of such equipment consists of the following stages:

1. The base for the press is formed from the channels. All metal parts are fastened by welding.

2. Racks are attached to each corner of the prepared base in a vertical position. Each support is taken 1.5 meters high.

3. A mixer is welded to the racks. The drum can be made from a pipe with a large diameter or you can take a finished part from an old washing machine.

4. A galvanized steel tray is fixed under the mixer, from which the raw materials will penetrate into a special mold.

5. Holes are created in the thick-walled pipe intended for the matrix. They should be evenly spaced throughout the round contraction. The width of each opening should be from 3 to 5 millimeters.

6. At the bottom of the mold, a flange is fixed with a welding machine, to which the bottom is screwed.

7. The finished form is connected to the base.

8. After that, a punch is cut out of the steel sheets. It must have the same shape as the matrix. Using a rod, the punch is connected to a hydraulic element.

The assembled mechanism is fixed above the form to the racks. The tray is attached to the bottom.

To speed up the process of extracting pressed briquettes, it is recommended to weld the disk and spring to the bottom of the die. It must match the diameter of the punch. Such a mechanism will automatically eject finished products after turning off the hydraulics.

Pressed wood raw materials require drying. The lower the humidity of the briquettes, the better they burn. In addition, dry briquettes have a higher heat transfer.

Do-it-yourself compact fuel can significantly reduce the cost of heating a house. Ready-made briquettes can be used both for the boiler and for the furnace. But it should be borne in mind that the quality of products largely depends on the density index.

It is almost impossible to make pressed firewood using home-made equipment that will burn for a long time and give off a large amount of heat.

Therefore, if it is necessary to use fuel with high performance, then it is better to purchase it in specialized stores.

Types of fuel briquettes

Briquettes are divided into types depending on their shape. Basically, the following types can be found on the market:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from sawdust of natural wood with the addition of special components.

- Nestro. Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading tank, then fed for pressing by means of a screw. The mass is distributed by dispensers according to the forms under pressure.

- Pini kay. In shape, these are polyhedra with the number of faces from 4 to 6.In the production process, they are subjected to high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

The chemical composition and heat transfer of all these types of pressed sawdust is the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. The high density and slight hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

In addition to sawdust, sunflower husks, buckwheat, paper, small branches, fallen leaves, straw are used for the production of briquettes. The equipment for this has a fairly simple design, and you can make it yourself

In addition to sawdust, sunflower husks, buckwheat, paper, small branches, fallen leaves, straw are used for the production of briquettes. The equipment for this has a fairly simple design, and you can make it yourself

If you have the necessary raw materials to form briquettes, you can make them yourself.

Briquette manufacturing technology

The process of production of heating material is laborious and requires sequential operations.

If necessary, prepare raw materials before use:

- Crushing of material;

- Drying of crushed raw materials;

- Grinding (the better the components of the briquettes are crushed, the higher the heat transfer rates).

To make your own hands, the raw materials must be mixed with a binder. For this, clay is quite suitable in accordance with 1 to 10, where 1 kg of clay and 10 kg of crushed material are taken.

The resulting mixture must be mixed with water to form a homogeneous mass, it is important that it is neither liquid nor solid.

The resulting mass must be loaded into special equipment. During pressing, excess liquid comes out and the product receives its final shape. If you use a homemade press, then there is a possibility that a small amount of moisture will still remain inside the product.

An obligatory moment in the manufacture of heating material is drying after pressing. You can dry it outdoors, under the sun's rays and wind. The time of this stage depends on the volume of briquettes, as well as on the pressing technologies used.

After drying, the product must be moved to a special place for storage or packaged.

Is it worth making briquettes at home?

In real life, do-it-yourself fuel briquettes from sawdust do not turn out quite the same as it is presented by some Internet resources. This casts doubt on the viability of the entire enterprise, and here's why:

- on colorful videos from the Internet, the process looks simple and easy. In reality, this is hard work; in order to prepare the right amount of fuel for the season, one must spend a lot of time and physical effort;

- the heat released by home-made briquettes during combustion is much lower than that of factory-made products. It's all about the insufficient density of the "bricks", since home appliances cannot provide the required pressing pressure;

- drying in the sun can not be compared with industrial dryers, so the fuel contains moisture that affects the calorific value;

- homemade fuel from sawdust contains clay, which is not burned in the boiler furnace. This means that there will be more ash.

Manufacturing and assembly instructions

The order of operations in the manufacture of the press is as follows:

- From the channels it is necessary to weld the base of the device.

- From the corner we make 4 racks 1.5 meters long. They are welded vertically and with the same pitch.

- Next, it is necessary to make a drum from a pipe or sheet of tin, in which the raw material will be mixed.If you have a broken washing machine, drum, as well as bearings, you can remove it from it.

- The drum must be attached to the racks. If possible, it should be equipped with an electric motor. If the motor is too high-speed and it is not possible to reduce the drum rotation speed to an acceptable value due to the difference in pulley diameters alone, a gearbox should be used.

- Under the drum, it is necessary to fix a tray through which the prepared material will be fed into the matrix.

- In the walls of the pipe used as a blank for the matrix, it is necessary to make several holes with a diameter of 3–5 mm. They must be distributed evenly so that air and water are squeezed out throughout the entire volume of the briquette.

- A flange must be welded to the matrix from below, to which the removable bottom will be screwed. This bottom is cut from a steel sheet in the form of a disc with lugs.

- The matrix is welded or screwed to the base under the loading tray.

- We cut out a round punch from a steel sheet. It's just a disk, the diameter of which allows it to freely enter the matrix.

The stem is made of a pipe: a diameter of 30 mm is sufficient. On one side it is welded to the punch, and on the other side it is attached to the hydraulic unit.

Under the matrix we fix the receiving tray

It is important to install in such a position that it does not interfere with the removal and installation of the removable bottom of the matrix. diameter as the punch.

To reduce the time spent on removing the finished briquette from the die, and thereby make the machine more productive, a spring with a disk of the same diameter as the punch can be welded to the bottom of the die.

After turning off the hydraulic unit and removing the punch, the product will be ejected by the spring automatically.

Necessary materials

In addition to the hydraulic installation, you will need some types of rolled steel:

- Channel.

- Equal-shelf corner 100x100 mm.

- Sheet thickness 3 - 6 mm. A punch will be cut out of it. The thickness of the workpiece depends on the diameter of the matrix: the larger it is, the thicker the punch should be.

From the same sheet we cut out a removable bottom for the matrix.

- A pipe with a diameter of 25 - 30 mm - a punch rod will be made from it.

- Thick-walled pipe - blank for the matrix. The diameter depends on what size briquettes the user wants to receive. The thinner they are, the higher their density, but the productivity of the machine will decrease.

- A large diameter pipe is a blank for the mixer body. If there is no suitable pipe, the drum can be made from a sheet of tin.

- Galvanized steel for the manufacture of trays.

In total, two trays are required - for loading the prepared material into the matrix and for receiving finished briquettes.

Ready-made equipment for home production

The production of fuel briquettes requires special equipment.

Therefore, in order to create high-quality products with your own hands, you need to purchase:

- Shredding device.

- Drying machine.

- Press.

But it is not advisable to buy expensive machines for briquetting wood waste at home.

It makes sense to use powerful installations only in the manufacture of fuel briquettes in large volumes.

It is possible to make briquettes as a material for heating a private house without a dryer. It is easy to remove moisture from harvested raw materials in a natural way. To do this, sawdust or wood shavings are laid out in a small layer on the street under a canopy.

Often a homemade press is used to create compact fuel. Such a device will not provide a high compression density of the material, but still make it possible to make fuel suitable for home use.

Homemade briquettes - pros and cons

The reasons why this type of fuel is very attractive are understandable. When a person has his own wood production or the ability to buy sawdust for a briquette cheaply, then thoughts about making them at home are quite natural. The fact is that not all heating equipment is suitable for burning sawdust. As a rule, wood chips in an ordinary stove or boiler burn out quickly and give off little heat, and even half will spill into the ash pan.

It turns out that everything is not so simple here either, and here's why:

- Buying factory drying and pressing equipment is an unreasonably expensive undertaking. It is cheaper to buy ready-made eurofirewood.

- You can make a briquette press yourself and make them in an artisanal way. But the products will be of poor quality and will give little heat, and take a lot of time.

After squeezing out the water and subsequent drying, the briquette becomes quite light.

The second point requires clarification. Due to the inability to comply with the technology, the “bricks” after drying are light due to their low density.Their specific heat of combustion is three times lower than that of wood, which means that they will need three times more for heating. The whole process will take a lot of time and take a lot of energy. And it is very difficult to store such a volume of fuel so that it does not accumulate moisture.

Informative video for enthusiasts who want to put pressure on manual briquetting of various household waste:

This is interesting: Do it yourself - a shed canopy from a metal profile

Conclusions and useful video on the topic

Creating a homemade lever press. Manufacture of basic parts and description of the principle of operation:

Refinement of the machine design and the process of pressing briquettes:

Machine for simultaneous production of several briquettes based on a hydraulic jack:

It is not difficult to make a sawdust briquetting machine on your own. Lever, hydraulic or screw pressure generation can be used to choose from. But it must be remembered that the quality of manufactured products will depend not only on the assembled mechanism, but also on the preparation of raw materials.

A properly set process will help provide your economy with high-quality and cheap fuel and even arrange its implementation.

Do you want to talk about how you made briquettes for heating with your own hands? Do you have valuable recommendations on the topic of the article that you are ready to share with site visitors? Please write comments in the block below, post photos and ask questions here.