- How to calculate the volume of a room?

- Selection, installation and operation of cast iron heating batteries

- Resistance to poor quality coolant

- Disassembly and disassembly of a cast iron battery

- Mounting methods for aluminum and bimetallic radiators

- Towel dryers

- Video: Replacing heating radiators in an apartment

- Disadvantages of cast iron batteries

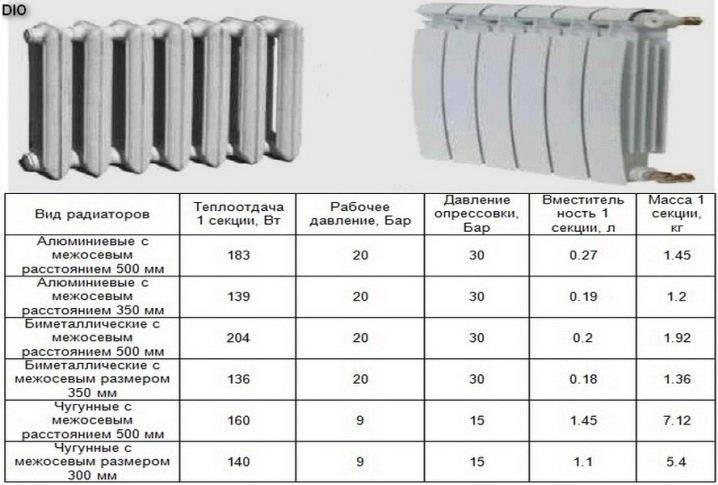

- The main differences between batteries

- Which batteries should you choose?

- aluminum batteries

- Steel radiators

- Bimetallic batteries

- Preparatory work

- Assembly of cast iron radiators

- Painting the radiator after assembly

- How to correctly determine the location of the radiator

- Ability to hold pressure

- How to calculate the required sections

- Conclusions and useful video on the topic

How to calculate the volume of a room?

If we take into account the heat flow of the room, but it is necessary to determine not its area, but its volume. The volume is multiplied by the heat flow of the room, and the resulting parameter is divided by 160 W, that is, the power of one section.

The volume of the room should also be considered if the ceiling in it is higher than 3 meters. In this case, calculations should proceed from the fact that 40 W of battery power is required to heat one cubic meter of air.

If the room is located in the corner of the building, on the first or last floor of a panel house, or has more than one window, then the power required for heating should be multiplied by a factor of 1.2.

It is not necessary that the required number of sections be in one battery. If you need a lot of them, then you can simply install several small radiators in different parts of the room. So the heat will be distributed throughout the room much more efficiently and the load on the walls will be less.

Before buying and installing a cast-iron battery for heating an apartment or house, be sure to calculate the required number of sections. And remember that in this case it is better to play it safe than to buy a radiator of insufficient power.

Selection, installation and operation of cast iron heating batteries

Stages of mounting the radiator to the heating system.

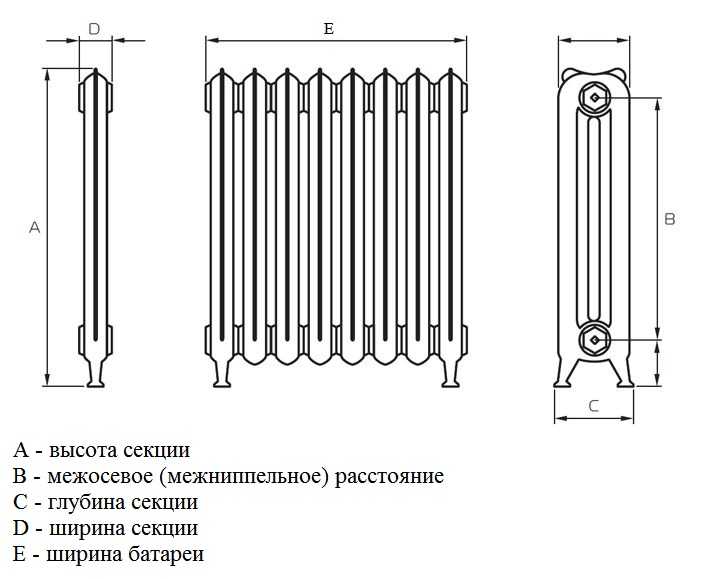

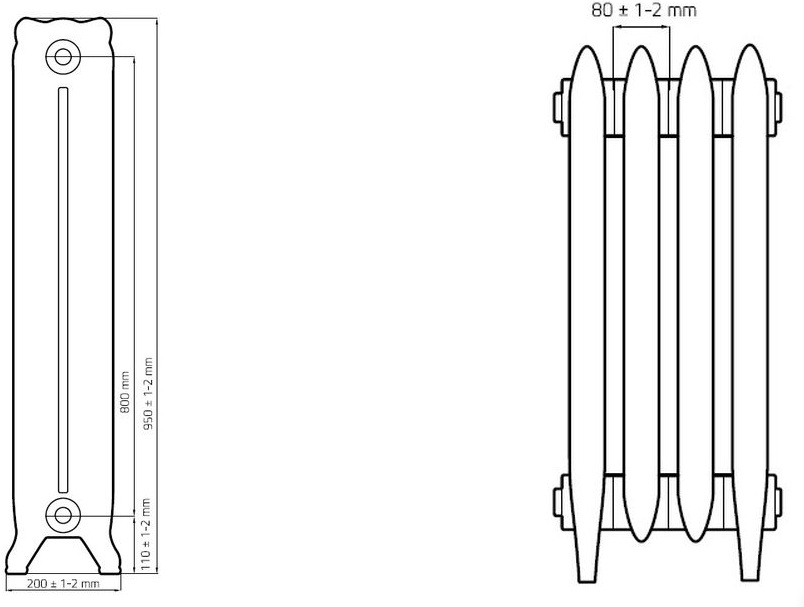

If the choice (lightweight or cast iron radiators) is made in favor of the latter, then it is necessary to calculate the number of batteries in the room and the number of radiators in each of them. To do this, you need to know the technical characteristics of a particular model, first of all, the amount of heat generated. Another important task is to determine the place for installing batteries and the method of mounting: wall or floor. Based on this, a specific sample is selected. Almost most of the cast-iron heating radiators photos can be found on the Internet. Cast iron radiators have a different external volume, including they can be quite voluminous or completely flat, and have different heights and widths.

A common place in a living room where a battery can be installed is a niche located under the window sill. Its parameters dictate the size of the battery.The technical characteristics of this battery should provide 1 kW of heat per 10 m² of room area. Moreover, if the volume of the room is larger than usual due to the high ceiling, or it has a second window, then 1.2 kW of heat is needed for the same area. If the room occupies a corner position, it makes sense to add a few extra sections, since there is more heat loss there.

The mounting method dictates both the weight of the battery and the strength of the wall near which it is placed. If it is hung on the wall, then it is worth remembering that at least three brackets are required for each of the batteries. Today, floor mounts are often used for cast iron batteries, and many models have ready-made legs. If the wall is made of wood, then you should use corner mounts. Next, you need to carefully bring the pipes supplying the coolant and screw them, ensuring the tightness of the thread as much as possible. At the same time, do not overdo it in the application of force, so as not to disrupt it, otherwise water will begin to leak.

Repair of a cast iron battery most often consists precisely in eliminating leaks at the junctions with pipes. The question arises: how to wash the radiator from the inside? It also has an uncomplicated, albeit time-consuming, solution. It is disconnected from the battery, and then with the help of a flexible brush and a hose with high water pressure, all accumulated dirt is easily washed out. Like repairs, this procedure is best left to a specialist. Independent steps can be quite successful, but they can also lead to damage.

Cast iron batteries will become an uninterrupted and trouble-free source of heat for you, your children and grandchildren.

Resistance to poor quality coolant

Another disadvantage of central heating is the questionable quality of the coolant.Hot water coming from pipes to radiators is neither clean nor chemically neutral. And it also contains a considerable fraction of the smallest grains of sand and pebbles that can act on the inner walls of the battery, like an abrasive.

Cast iron is chemically absolutely “calm”, so high levels of alkalis or acids in hot water will not harm it. And in the summer, when there is a general drain of water from the system, it will not rust. But she does not like small pebbles-abrasives - they wear out gradually. However, if the radiator walls are quite thick, this is not so critical.

Bimetal during the heating season is also resistant to chemically active water. However, in the summer, when water is drained from the system for repair and maintenance work, air appears in the radiators, and the steel core may be attacked by corrosion. So the bimetal falls a little short of cast iron in terms of endurance.

Poor quality coolant: Cast iron + | Bimetal + —

Disassembly and disassembly of a cast iron battery

The end caps are unscrewed, and then the nipples between the sections. Often, the futorks and sections stick strongly, you have to apply force to turn the stuck futorka. When the radiator appears in the form of simple cast-iron parts, each of them is cleaned of rust deposits by any available mechanical method. Cast iron is not afraid of scratches, so you can chip off or beat off unyielding, stuck pieces of hardened dirt.

When the radiator is temporarily dismantled from the heating system, it is necessary to use this situation to complete the battery with additional sections. The calculation of cast iron radiators to determine the optimal number of sections is simple.We use the required value of 100 W to heat 1 square. meters of housing and the minimum heat output of the section indicated in the passport of the cast-iron "accordion" is 125 W.

For a large room of 24 sq. meters will need at least:

24 x 100 = 2400 W of thermal energy.

It can be obtained from:

2400 / 125 = 19.2 pieces of sections. Round up with a margin. This means that at least 20 sections are needed, which is equivalent to two ten-section cast-iron batteries.

After determining the required number of sections, it remains to decide how to increase the batteries in accordance with the size of the windows and their location. Radiators are unified for any type of piping to the riser, having two end points for connection in the design. Nipples with gaskets made of paronite or rubber are screwed into the threaded inlets cleaned from rust and dirt and pressed for connection by the next section.

Flushing batteries, carried out once every two or three years in such a simple way, will help extend the life of cast iron batteries, which, as mentioned above, with elementary maintenance can work for more than half a century.

- Types and classification of screens for radiators

- Modifications of heating batteries

- How to choose aluminum batteries, and what factors affect it?

- A brief overview of metal radiators

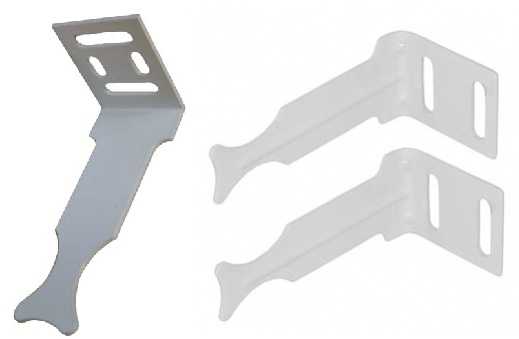

Mounting methods for aluminum and bimetallic radiators

Very similar products are used. Only they are made of thinner metal. In general, brackets for sectional radiators of any type are very similar. There are universal corner brackets for aluminum and bimetal radiators.They have a recess for the collector at the top and bottom, so they can be mounted both on the right and on the left.

Special corner brackets for lightweight sectional radiators

There are no floor aluminum and bimetallic radiators. But there are racks that allow you to install any of them on the floor. In this case, the rack is first fixed on the floor, and then the heater is installed and fixed on it.

Floor mounting of aluminum radiators helps out if the walls cannot withstand even such a small weight (if they are made of drywall or aerated concrete, other similar materials).

Any sectional radiator can be mounted on such racks

It will not be possible to hang anything on the now fashionable glass wall.

But then you need to pay attention to how the whole structure looks from the back side. In this case, it is more expedient to use convectors built into the floor for heating. floor models of tubular radiators (at the same time they can serve as a fence), cast-iron retro radiators

floor models of tubular radiators (at the same time they can serve as a fence), cast-iron retro radiators.

Towel dryers

Bathroom towel warmer itself is a clear example of how to improve the heat transfer of a pipe. The "serpentine" of the device is nothing more than an artificially increased area of thermal radiation. Since earlier they were only part of a common heating branch, it was possible to change the diameter. Therefore, the heat transfer area was increased by simply increasing the length.

By the way, just a stainless steel water heated towel rail will look good in black. Shiny and chrome products, although they look beautiful, prevent heat transfer between the pipe and the environment.

For vertically oriented systems such as radiators, the way in which the inlet and outlet pipes are connected matters. The heat output of one device with different installations can change significantly:

- 100% efficiency - diagonal connection (hot water inlet from above, outlet from the reverse side below);

- 97% - one-way top entry;

- 88% - lower;

- 80% - diagonal reverse (with a lower entry);

- 78% - one-sided with a bottom inlet and waste water outlet.

Video: Replacing heating radiators in an apartment

You will be interested

Rating of the best bimetallic heating radiators for an apartment

Which bimetallic heating radiators are better - sectional or monolithic, true bimetallic or semi-bimetallic

How to choose bimetallic radiators - selection criteria and calculation of the required quantity

Which heating radiators are better aluminum or bimetallic

Which heating radiators are better to choose for an apartment with a central heating system

Technical characteristics of cast iron heating radiators, their advantages and disadvantages

Properties and technical characteristics of bimetallic heating radiators

Disadvantages of cast iron batteries

Despite a lot of advantages, cast iron radiators are endowed with a number of disadvantages. This was facilitated by both structural features and the properties of the cast iron itself. For example, cast iron batteries are difficult to integrate into automatic temperature control systems.

Due to the inertia of heat transfer, it is rather difficult to control the temperature set in the room. After all, after turning off the boiler, cast-iron radiators will give off their heat for another hour, warming the surrounding air.

It takes about half an hour to reheat the entire mass of the battery and the water it contains. During this period, the room will practically not warm up.

There are also other disadvantages, including:

- large volume of coolant;

- significant weight of one radiator;

- design uniformity.

A large volume of water in the battery has its drawbacks. It takes more time and energy to warm up the entire coolant.

In addition, there is an increase pump load, which is forced to pump a significant amount of water in one warm-up cycle.

The volume of the cavities of a cast-iron battery is at least 2 times greater than that of an aluminum battery and 4 times greater than that of a bimetallic one.

The large weight of the devices is also a disadvantage that worries installers and service providers more than residents. However, with self-assembly of the heating system, one cannot do without an assistant when attaching a cast-iron battery. The weight of one of its sections is about 7 kg.

Such a disadvantage as design uniformity is due to the technological features of cast iron casting - they do not allow you to create elegant details from this material. Here are the batteries and they look the same.

Due to the simplicity of the design, the energy efficiency of the MS-140 battery models is one of the worst, but the price of such devices is also the lowest.

To diversify the model range, manufacturing companies produce cast-iron radiators with a beautiful pattern on the surface, but their cost is 10-20 times higher than the price of simple models.

However, if there are no funds for expensive exclusive models, you can purchase ordinary radiators, and then disguise them with screen for batteries.

Intricate patterns, different heights and widths of radiators provide some variety among more expensive radiators. This allows designers to integrate cast iron batteries into sophisticated interiors.

Another disadvantage is the vulnerability of equipment to water hammer. The fact is that cast iron is a strong, but rather fragile material. According to GOST 8690-94, radiators must withstand a short-term pressure of 1.5 MPa.

But sometimes the pressure can exceed this value. This occurs with a sharp start-up of the pump and the absence of compensators. As a result, cast iron batteries may crack or burst.

Battery rupture is often accompanied by preliminary clicks and hiss. These sounds should alert and force to block the access of the coolant to the radiator

In many cases, the advantages of cast iron radiators far outweigh their disadvantages. It is this fact that helps such batteries to maintain a good position in the heating systems market.

The main differences between batteries

There are two types of pressure in district heating plants:

- Working.

- Crimping.

The latter is always higher. For aluminum radiators operating pressure counts up to 16 atmospheres, which corresponds to the performance in thermal networks. Sometimes the pressure can reach up to 28 atmospheres, which is a critical value for aluminum radiators. Experts do not recommend using them in apartment buildings. Not only because of the pressure, but also because of the characteristics of the coolant. In private households, the pressure in the boiler usually does not exceed 1.5 atmospheres, so aluminum radiators are more preferable.

Crimping pressure is more relevant, it is necessary to know about its existence. Before the start of the heating season, it is recommended to test the tightness of the entire system. In professional language, this process is called: pressing. That is, at a higher pressure (1.5-2 times), water will be driven through the radiators.

In private houses, the pressure in the heating system is objectively lower. In high-rise buildings, in order for water to rise to a height of ten meters (three-story building), a pressure of one atmosphere is required.

Utilities do not always adhere to GOSTs, sometimes the pressure “jumps” in large ranges, so it’s better to buy batteries with a margin

Manufacturers often indicate different units of measurement in performance characteristics. One bar corresponds to one atmosphere, if the calculation is in megapascals, then in order to convert them into familiar atmospheres, you need to multiply by a factor of 10. Example: 1.3 megapascals corresponds to 13 atmospheres.

Half of the heat that aluminum radiators give off is the so-called heat rays. The rest of the heat is convection currents, they are generated when air masses move from bottom to top. This design effectively enhances heat dissipation.

Heat dissipation is measured in watts, for an aluminum battery with an axis of up to half a meter, heat dissipation can be up to 155 watts. Aluminum batteries have a high heat transfer, according to this indicator they are ahead of cast iron ones.

Cast iron radiators largely depend on the battery model. During the Soviet Union, cast iron batteries occupied up to 90% of the market, the design was especially popular: P140.

- The power of such a product ranged from 0.122 to 0.165.

- Average weight within 7.5 kg.

- Surface area 0.25 sq. meters

- Functional pressure 9.2 atm.

In order for the room to have an acceptable temperature in winter, it should be borne in mind that 140 watts of power is required per square meter (if there is one window and one outer wall). The temperature of the battery must be at least 65 degrees. If the room is too large, then ten square meters will require about 1.5 kW of power. All figures are given for guidance. More accurate you can get with the help of heat calculations.

Old cast-iron batteries work properly, but they look outdated. Often, heating devices are covered with special gratings or screens. There are also modern modifications that have a modern appearance. Particularly interesting are the products of the World Cup factory in the city of Cheboksary.

Example:

- ChM-1: depth up to 72 cm, power 0.076 to 0.12 kW, weight of one section 4.2 kg. Withstands pressure up to 9 atm.

- ChM - 2 also withstands pressure of nine atmospheres. Depth up to 1.1 meters, power 0.1082-0.143 kW. One section weighs up to approximately 6 kg.

Interesting models (MC-110) are produced by the Setehlit plant, the radiators are compact and easily fit into various openings.

Cast iron radiators are produced in Turkey, the Czech Republic and China. There are very attractive models that look ultra-modern. Example: Conner makes a "Modern" model: has only 82 cm deep, withstand pressure up to 12.2 atm., and power from 0.122 to 1.52 kW. The weight of one section does not exceed 5.5 kg.

Which batteries should you choose?

There are many models of radiators made of various alloys on the modern market. Each has its own positive characteristics and features of use.

aluminum batteries

Radiators from such material are produced in two types - cast and extruded. The former are a one-piece monolithic structure, while the latter are made of aluminum parts welded together. Sheet-type batteries are more durable and reliable.

Regardless of the type, aluminum radiators have common basic technical characteristics:

- section weight - from 1 to 1.47 kilograms;

- permissible maximum coolant temperature - 110 degrees;

- product power - from 82 to 212 watts;

- the maximum volume of liquid in one section is 0.46 liters;

- working pressure - from 6 to 24 atmospheres.

Aluminum batteries have been manufactured since the 1980s. Nowadays, products have improved quite a lot and have not lost their popularity.

aluminum batteries

aluminum batteries

The main advantages of aluminum heating radiators include:

- the small weight of a product promoting its fast installation and transportation;

- high level of heat transfer due to the rapid heating of the metal and the intensity of heat exchange;

- the ability to adjust the temperature even with a small amount of coolant;

- relatively low price of the product;

- good strength;

- decent look.

Along with the advantages of aluminum batteries, they have some disadvantages of application:

- low resistance to corrosion;

- the possibility of formation due to the chemical process of air in the system.

If we take into account extruded models, then we can highlight their weak point - threaded connecting fasteners. With a sharp increase in pressure in the system, the integrity of the structure may be violated

Steel radiators

The installation of such radiators is justified in private houses with a local autonomous heating system. A feature of this type of device is:

- working pressure - from 6 to 13 atmospheres;

- the maximum water temperature in the batteries is 110 degrees.

Despite the relatively low technical characteristics, steel radiators are very popular. The use of devices has the following advantages:

- compact structures;

- Possibility of temperature control by means of a thermostat;

- high heat transfer rates;

- a wide variety of manufactured models;

- the cost is much lower than many new types of batteries being produced.

Among the shortcomings, the most significant are:

- incompatibility with an open type heating system;

- susceptibility to corrosion;

- special requirements for the quality of the heat carrier used.

Steel radiators

Steel radiators

The presence of various chemical impurities in the liquid used in the steel battery can cause the destruction of the material. In this case, sometimes there is a leakage of the coolant due to violations of the tightness of the joints. Therefore, steel radiators are not installed in multi-storey new buildings.

Bimetallic batteries

Radiators of this type are advanced models that combine all the advantages of aluminum and steel products. The device has been widely used due to its high technical characteristics:

- maximum internal working pressure - 60 atmospheres;

- heat transfer - up to 190 watts;

- the maximum temperature of the coolant is 110 degrees.

There are many advantages of using bimetallic radiators:

- long operational term - up to fifty years;

- high heat output and rapid heating of the room;

- good anti-corrosion properties;

- high level of strength;

- the possibility of installing additional sections;

- maximum sensitivity to thermostat commands;

- availability of models with different design solutions.

Bimetallic batteries

Bimetallic batteries

The material withstands high hydraulic shocks typical for central heating systems.

The disadvantage of bimetallic radiators is the high price. As a rule, they are more expensive than products made of aluminum or steel. Cheap bimetallic batteries do not have corrosion protection, so rust will form on the product over time.

Preparatory work

In order to correctly select the necessary parts and calculate their number, you should know the type of wiring of the heating system - one- or two-pipe. In a single-pipe heated coolant rises through the riser, and the heaters are connected to the descending line. In a two-pipe coolant moves from the heater to the heaters and vice versa. One line is designed to supply hot water, the second - to return the cooled coolant to the boiler. There are two ways to connect system elements - horizontal and vertical.

All the nuances of the connection should be clarified before the start of work. Before installation, it is necessary to drain the water from the system, dismantle the old heaters, remove the fasteners on which they were held. The supply of hot coolant to the system must be stopped until the end of the work.

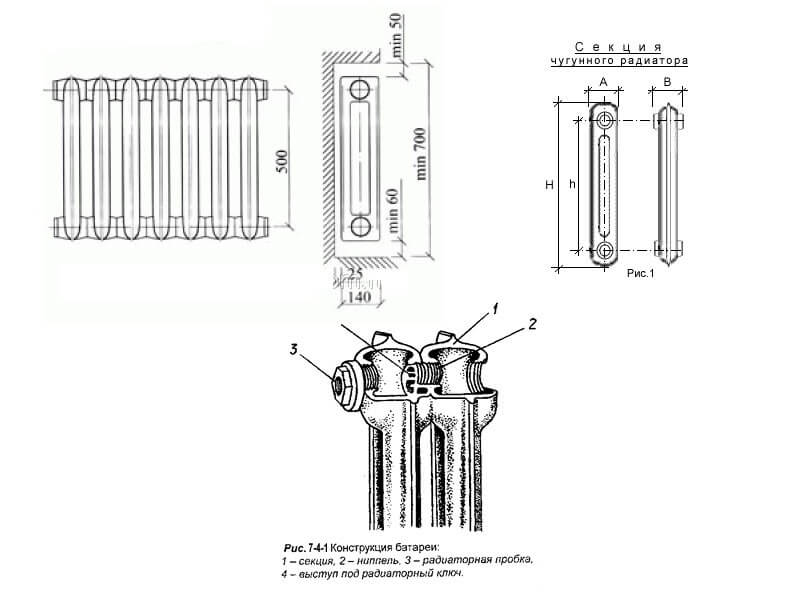

Assembly of cast iron radiators

The first step is to group the sections. To do this, you need radiator keys.The device is fixed on a workbench, radiator keys must be inserted into the lower and upper holes so that they rest against the internal protrusions. Both nipples must be deployed at the same time to avoid skewing the sections, so the manipulation is performed with an assistant. The nipples must be lubricated with drying oil, they are put on gaskets. The keys are rotated in the opposite direction to the thread. If it is left, then turn to the right, and if it is right - to the left. You need to screw in 1-2 threads.

Hydraulic tests of the finished structure are carried out on a special stand, where, using a press, they create pressure 4-8 kgf/cm.kv. The performance of the device is checked by a manometer. If its performance begins to decline, it means that either defective sections are connected, or the work is done poorly. In the first case, the elements are replaced, in the second, the nipples are tightened. If there are minor damages, they can be repaired with epoxy glue. If the connections are not made correctly and the joints are leaking, the gaskets should be changed.

Painting the radiator after assembly

After testing, the heater is painted and dried. To obtain a durable and even coating, it is necessary to apply two thin coats of paint. As a result, radiators must meet the following requirements:

- Heat-resistant covering of the case of the device. It must withstand temperatures of 80 degrees without softening or releasing harmful substances into the atmosphere.

- Painting should be of sufficient quality to protect the radiator from corrosion as much as possible.

- The selected composition should not change in color.

Experts recommend using alkyd enamels as a coating, because. after drying, they are harmless and do not poison the air during operation.Option - acrylic compositions. They do not crack, do not change color and are resistant to heat. Both types of compositions have their advantages: alkyd enamels are cheaper, acrylic-based paints are more durable. Can also be used water-dispersion paints, which have a manufacturer's mark that they can be used for painting heating appliances.

How to correctly determine the location of the radiator

Heating devices are usually located under windows at a height of at least 6 cm from the floor and 5-10 cm from the bottom of the window sill. The distance to the wall should be at least 3-5 cm. The pipes of the system are placed at a slight slope, which is done in the direction of the coolant. If there is no slope or distortions appear when installing a cast-iron radiator, air will accumulate in the batteries, which will have to be removed manually. An “airy” radiator will not be able to warm up normally and give off heat. The center of the device should coincide with the center of the window opening plus or minus 2 cm.

Ability to hold pressure

In a traditional central heating system, typical for multi-storey buildings, the pressure is by no means stable. Sometimes there are even water hammers. After all, the cranes of circulation pumps, according to the rules, should turn on smoothly, but often workers do not follow these rules. And with a sharp shutdown of hot water, its pressure in the entire system jumps so that many batteries burst. Therefore, residents of apartments should definitely choose radiators with a good pressure margin.

Cast iron radiators can withstand 9-12 atmospheres of pressure. This may be enough until a strong water hammer occurs.If it does happen, then brittle cast iron, unfortunately, can burst. Therefore, if you look from this point of view, which is better than cast-iron radiators or bimetallic ones, then it is better, of course, to play it safe and take a bimetal.

After all, a bimetallic radiator is not afraid of any pressure surges - in the passport it has indicators for this parameter up to 20-50 atmospheres (depending on the model). So even powerful water hammers are not capable of breaking a high-quality bimetal product. And let's also mention models with a monolithic steel core - they can easily withstand up to 100 atmospheres. An example of such radiators can be Russian-made Rifar Monolit radiators, you can see its technical features in the photo below.

Ability to hold pressure: Cast iron - | Bimetal +

How to calculate the required sections

Earlier in domestic houses there were monolithic products. Of course, such a model can be bought now, but manufacturers have developed a sectional version. This is very convenient, as it makes it possible to independently calculate the number of required sections based on the quadrature of the room.

To select the required amount, you should use the following formula: room area (sq.m) X 100 watts, and then the resulting figure is divided by 180 watts (average power of one section). The result will be the number of sections for a room with one window.

Just remember that the shape of the heated room largely affects the size of the battery. If the room is angular, then another 25% is added to the resulting figure, and each window will require adding 10%.

In addition, the location of the room should also be taken into account.For example, if it faces east, then even in winter, weak rays of the sun will help keep the room warm, and if it faces north, then it can be very cold in the house.

Conclusions and useful video on the topic

The presented videos on cast-iron radiators will help in choosing a specific model and further explain their technical characteristics.

Cast iron radiator overview:

Comparison of thermal characteristics of radiators made of various materials:

The choice of heating radiators, including cast iron ones, must be made with the obligatory consideration of their technical characteristics. This will avoid breaking the heating circuit at maximum loads and provide sufficient heat to heated rooms.

Please write, share your experience of using cast iron radiators, ask questions in the block below. We are always ready to clarify incomprehensible points.