- Installation and setup rules

- Necessary tools and materials

- Work progress

- pressure regulator

- 3 Selection criteria

- Safety valve

- Types of safety valves

- Three way valves

- How to drain water through the valve?

- Selection of emergency fittings

- Types of security groups and the principle of choosing the appropriate model

- Lever models

- Models without lever

- Safety knots for large water heaters

- Models of the original performance

- Case marking difference

- Other types of valves

- Operating principle

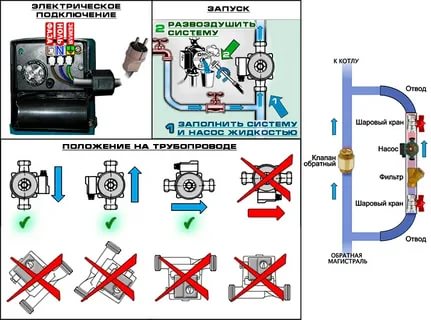

- Check valve installation rules

- Why Battery Valves Are Needed

Installation and setup rules

Having planned an independent installation of a safety valve for heating, you should prepare a set of tools in advance. In work, you can not do without adjustable and wrenches, a Phillips screwdriver, pliers, tape measure, silicone sealant.

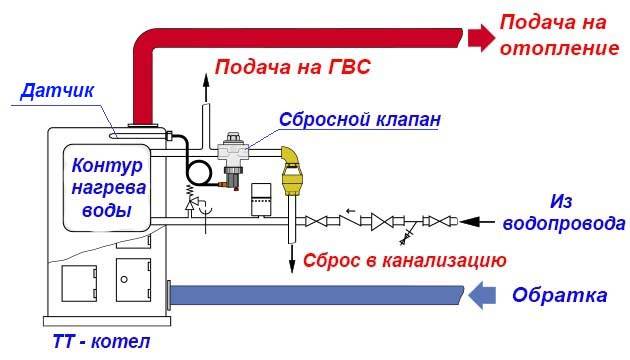

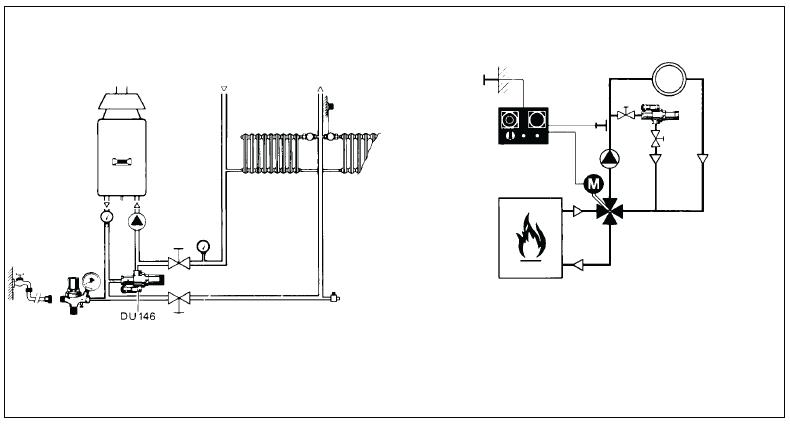

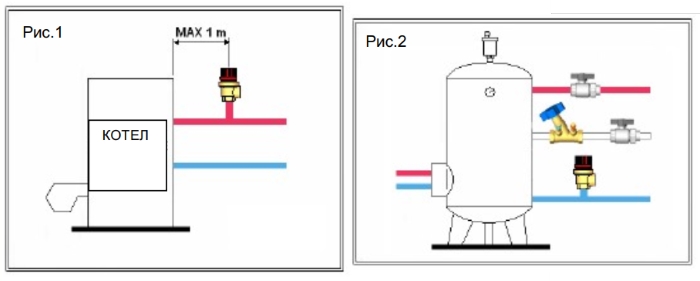

Before starting work, you need to determine a suitable place for installation. The safety valve is recommended to be mounted on the supply pipeline near the boiler outlet. The optimal distance between the elements is 200-300 mm.

All compact household fuses are threaded. To achieve complete tightness when winding, it is necessary to seal the pipe with tow or silicone.It is undesirable to use FUM tape, as it does not always withstand critically high temperatures.

In the regulatory documentation that comes with each device, the installation process is usually described step by step.

Some key installation rules are the same for all valve types:

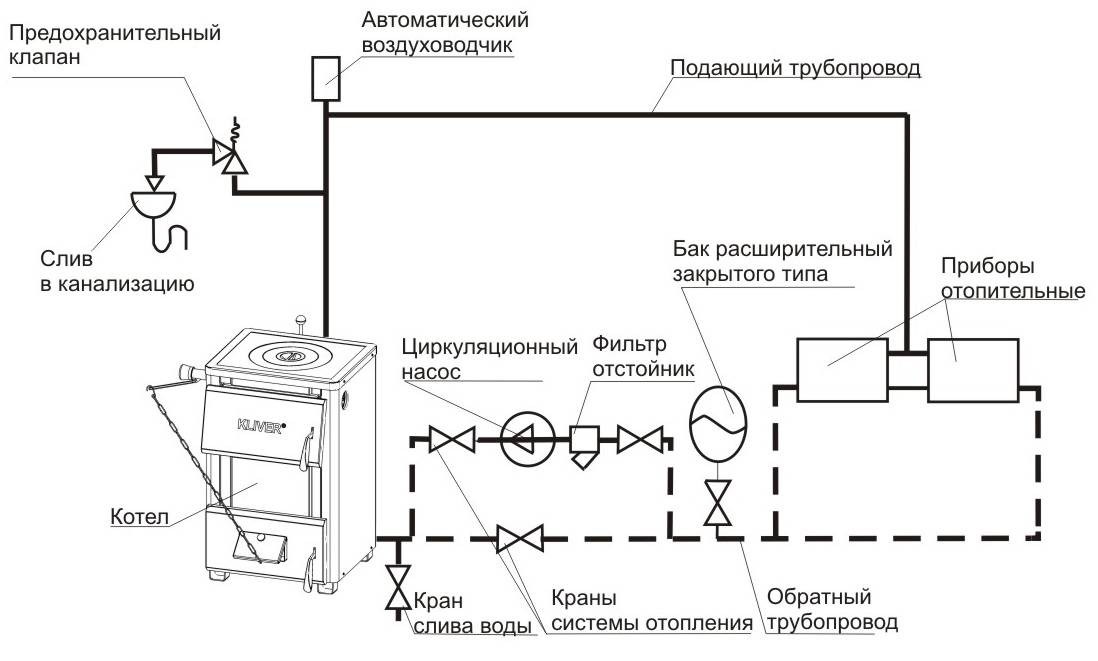

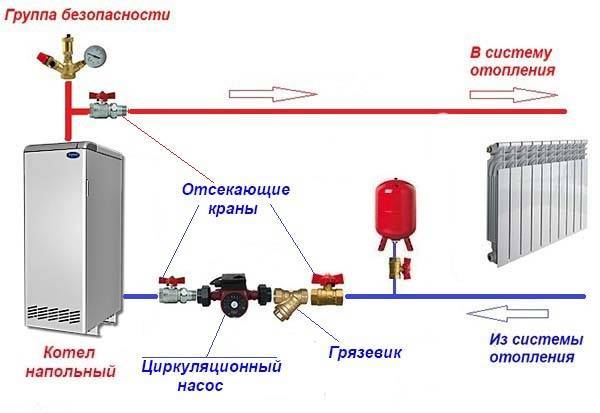

- if the fuse is not mounted as part of a safety group, a pressure gauge is placed next to it;

- in spring valves, the axis of the spring must have a strictly vertical position and be located under the body of the device;

- in lever-loading equipment, the lever is placed horizontally;

- on the section of the pipeline between the heating equipment and the fuse, it is not allowed to install check valves, taps, gate valves, a circulation pump;

- to prevent damage to the body when the valve is rotated, it is necessary to select with a key from the side where the screwing is carried out;

- a drain pipe that discharges the coolant into the sewer network or return pipe is connected to the outlet pipe of the valve;

- the outlet pipe is not connected directly to the sewer, but with the inclusion of a funnel or pit;

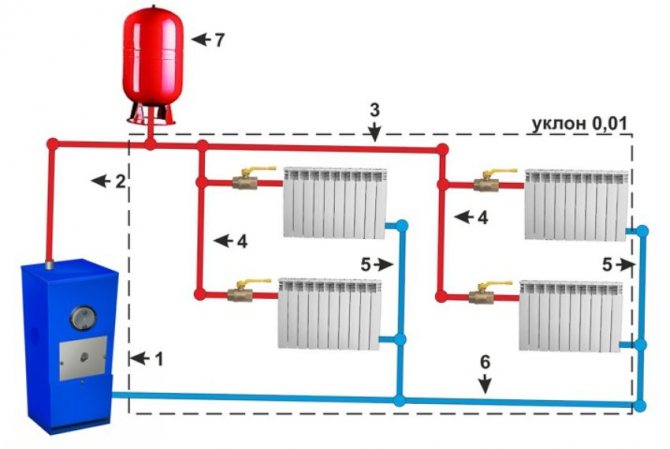

- in systems where the circulation of the liquid occurs in a natural pattern, the safety valve is placed at the highest point.

The conditional diameter of the device is selected on the basis of methods developed and approved by Gostekhnadzor. In resolving this issue, it is wiser to seek help from professionals.

If this is not possible, you can try using specialized online calculation programs.

To reduce hydraulic losses during medium pressure on the valve disc, emergency equipment is installed with a slope towards the boiler plant

The type of clamping structure affects the adjustment of the valve.The spring fixtures have a cap. Spring preload is adjusted by rotating it. The adjustment accuracy of these products is high: +/- 0.2 atm.

In lever devices, adjustments are made by increasing the mass or moving the load.

After 7-8 operations in the installed emergency device, the spring and the plate wear out, as a result of which the tightness may be broken. In this case, it is advisable to replace the valve with a new one.

Necessary tools and materials

To install the valve you will need:

- wrench;

- fum - tape or tow;

- special paste for sealing joints.

Work progress

Each product designed to relieve excess pressure is supplied with installation instructions, which should be carefully read before starting work. Before installation, it is also necessary to disconnect the water heater from the mains and drain the water from it. The valve must be placed on the cold water line up to the stopcock. The valve installation sequence is as follows:

- marking the installation site;

- removal of a part of the pipe with a size corresponding to the length of the device body;

- threading at the ends of pipes:

- coating the threaded part with tow or fum tape;

- winding the valve onto the pipe threads;

- connecting to another branch pipe a tube leading to the sewer system.

- tightening the threaded connection with an adjustable wrench;

- sealing the junction with a special paste;

- setting the device, in accordance with the passport values (if necessary).

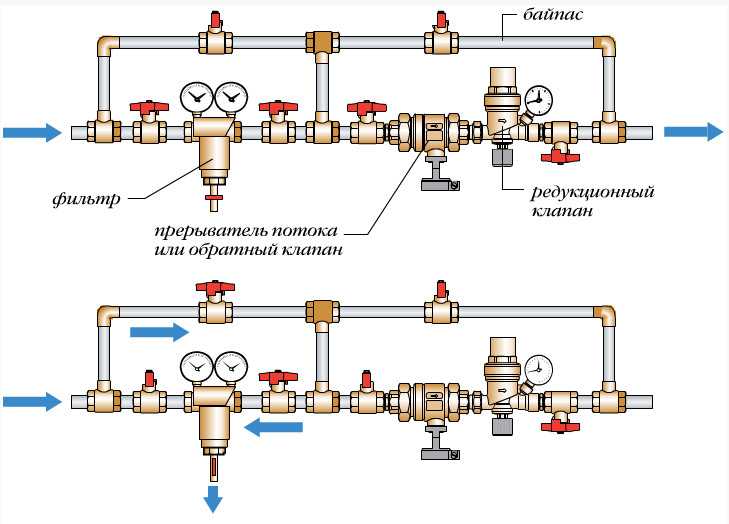

pressure regulator

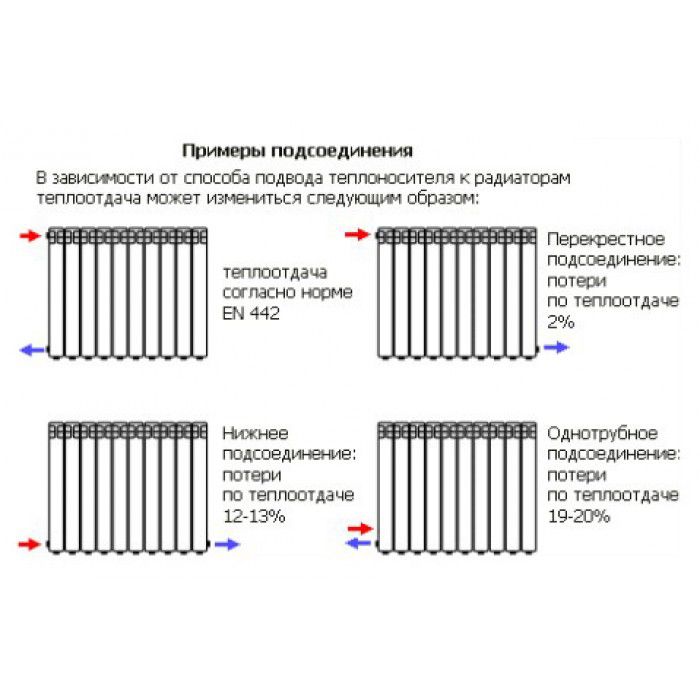

The operation of the batteries and the pump is disrupted due to high or low pressure levels. Correct control in the heating system will help to avoid this negative factor.The pressure in the system plays a significant role, it ensures that water enters the pipes and radiators. Heat loss will be reduced if the pressure is standard and maintained. This is where water pressure regulators come in handy. Their mission is, first of all, to protect the system from too much pressure. The principle of operation of this device is based on the fact that the valve of the heating system, located in the regulator, works as a force equalizer. From the type of pressure, regulators are classified into: static, dynamic. It is necessary to choose a pressure regulator based on throughput. This is the ability to pass the required volume of coolant, in the presence of the necessary constant pressure drop.

3 Selection criteria

Before dwelling on a specific safety valve, it is imperative to get acquainted in detail with the technical characteristics of the boiler equipment.

Do not neglect the study of the manufacturer's instructions, which describe all acceptable values. Several factors play a major role during product selection:

- The diameter of the through holes in the safety valve.

- The highest possible indicator of the coolant pressure in the boiler.

- The power of thermal equipment.

It is necessary to check that the pressure regulator is within the range within which the parameters of a particular boiler are located. The set pressure must be in the region of 27-32% more than the operating mode, which is required for the normal operation of the system.

The diameter of the valve must be less than the section of the pipe. Otherwise, constant resistance will not allow the fuse to fully perform its functions.

The best material for manufacturing the product is brass.This metal has the lowest rate of thermal expansion, when the destruction of the body from the action of high pressure is excluded.

The adjustment block is made of heat-resistant plastic materials that retain the required rigidity even during contact with boiling water.

Safety valve

The name of the device speaks for itself. Its main function is to relieve unforeseen loads that may arise under certain circumstances. Plus additional adjustment of the coolant flow.

By the way, it can be installed on any section of the pipeline

At the same time, it is not the place that is important, but the convenience of service, if such a need suddenly arises.

Types of safety valves

- The simplest option is brass sleeve fuses. Their design is simple - threads are cut on both sides, and the valve is a spring-loaded stem with an EPDM gasket. This is a direct-flow model, the valve of which opens under the pressure of the coolant flow. Back pressure closes the line. This is one of the cheapest devices, but it lasts a very long time, which is time-tested.

- There is another brass version, but with a more complex design, where the pipes are connected in perpendicular planes. It uses a stainless steel stem and spring. Install it directly after the circulation pump. The principle of operation of such a device is quite simple. The pressure of the coolant compresses the spring, which begins to put pressure on the rod. He opens the channel through which the coolant is squeezed out of the system, saving it from bursting pipes and other elements.By the way, the maximum temperature that the valve can withstand is 120C.

- There are a large number of varieties of check valves, which are also included in the safety group. Their main function is to prevent the backflow of the coolant from occurring if the pressure suddenly drops in the system.

There are several main types - disk, ball, flag and others. But they are all divided into spring-loaded and springless. With the first, everything is clear - there the main emphasis is on the counteraction force of the spring. The second type is when the return of the locking element occurs under the action of its own mass.

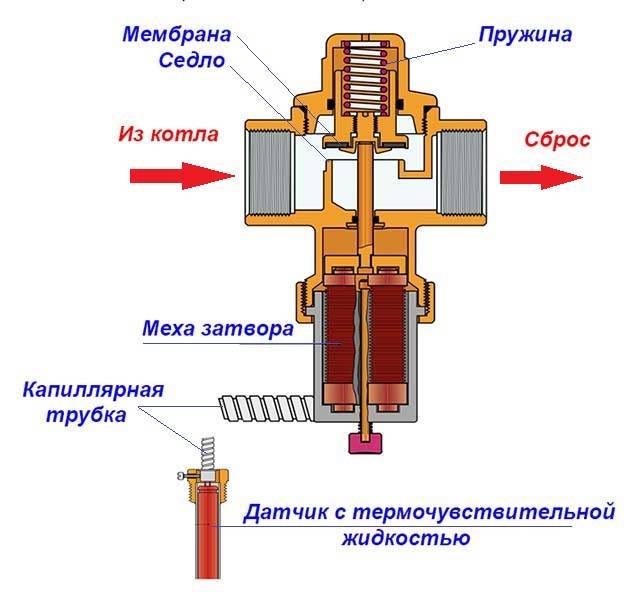

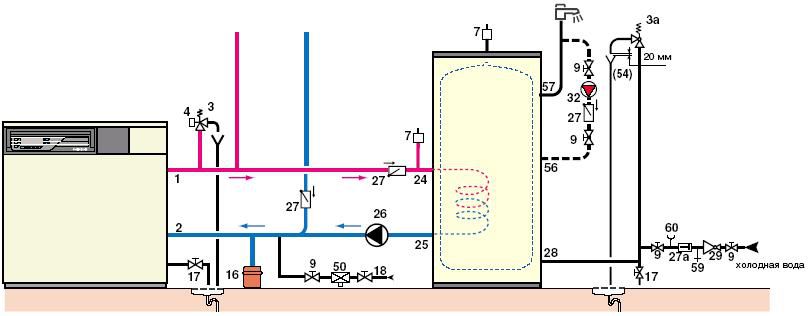

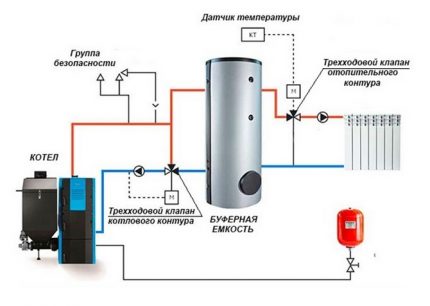

Three way valves. This type of valves is installed in heating systems where low-temperature circuits are provided. For example, when there is a condensing boiler in the circuit. Currently, manufacturers produce this type of valve with manual or electric switching. In the second case, it is necessary to connect the device to an alternating current network with a voltage of 220 volts.

Three way valves

Let's take a closer look at three-way valves, because consumers rarely encounter them, and they are simply unknown to many. There are three holes in their design - two outlets and one inlet. The coolant flow is regulated by a damper, which can be in the form of a rod or a ball. The rotational movement redistributes the flow of the moving fluid.

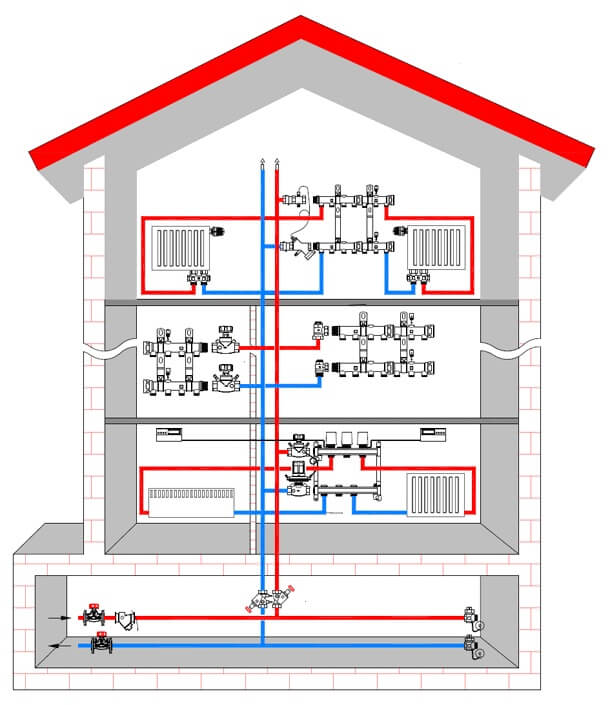

We have already mentioned condensing boilers, but three-way valves are not only used in these systems. Very often they are used when different heating systems operate from one heating boiler. For example, "warm floors" and conventional radiators.It is clear that for a warm floor it is not necessary to heat the coolant to a very high temperature. But what if there is only one boiler, and it heats hot water to the standard temperature for the entire system?

In this case, the three-way valve performs several functions at once:

- First, it separates the plots.

- Secondly, it delimits the flow density by branches.

- Thirdly, with its help, the heat carrier is mixed from the supply and return lines, before the latter is supplied to the “warm floor” heating system. That is, water will flow into underfloor heating at a lower temperature than to radiators.

A few recommendations. Get a servo model. This will relieve you of the need for constant monitoring of the temperature of the coolant. Such a device is automatic and operates from a sensor mounted in a low-temperature circuit. A change in temperature entails the operation of a shut-off device that opens or closes the water supply from the return line. So everything is simple.

And the last. The actuator may be included with the valve or sold as a separate item. And the valves themselves are made of steel, cast iron or brass. The latter are used in residential heating systems.

How to drain water through the valve?

Usually, water is drained when diagnosing breakdowns. However, there are other situations where this procedure is necessary.

- Country boilers. At the end of the summer season, it is necessary to drain the water to prevent freezing. Ignoring the condition will lead to the rupture of the boiler in the winter.

- Accident. In this case, it will be necessary to free the boiler tank from water in order to eliminate malfunctions in the plumbing system.

Some installations are not designed for long periods of inactivity without water. This information is indicated in the instruction manual. In this case, bottled water comes to the rescue.

By using a safety valve, water is drained more smoothly and safely. To free the container, you need to perform a series of manipulations.

- The heating device is under a certain level of pressure, so it is necessary to close the shut-off element of the cold water inlet. Next, you should try to release water through the tap as much as possible.

- After the water is completely gone, the faucet is blocked. There is a lever on the valve. Drainage will begin as soon as air enters the tank. If the water heater is equipped with a stopper, it must be removed. If there is no technical hole, an additional faucet opens to drain water. It is located on the pipe.

- Air masses get inside, and water drains through the spout on the safety valve.

Draining is a long process, but it does not require much effort and special skills. The water heater for 50-80 liters will be empty after about 1.5 - 2 hours. If there is silt accumulation in the valve, the water drain will last from 3 to 4 hours.

Read also:

Selection of emergency fittings

When designing a water supply, heating system or process plant, it is necessary to clearly define the pressure limits allowed for its components or network sections. This takes into account parameters such as:

- performance of the boiler or main pump;

- volume and operating temperature of the working medium;

- features of its circulation.

Based on this, the type, cross-section, throughput, threshold value of operation, response speed and return time to the initial state, as well as the number and installation locations of safety valves are determined.

In domestic heating systems, spring valves are most often used. For liquid media, it is sufficient to use low or medium lift devices. The throughput should provide a quick pressure drop to acceptable values.

The design of the housing is determined by the place where the excess amount of the working medium is discharged. If it will be discharged directly into the environment, an open type valve is sufficient. If the discharge must take place in the drain, a body with an outlet pipe of the appropriate type of connection will be required. Most often use threaded or nipple.

In no case should you purchase a valve with an overestimated relative to the calculated response threshold. Such a device will not open at the right time. This can lead to equipment damage or even a complete system crash.

Types of security groups and the principle of choosing the appropriate model

The standard safety valve for a boiler may differ in several design features. These nuances do not change the functionality of the device, but only simplify the use and maintenance. To choose the right safety unit, you need to know what kind of safety valves for boilers are and how they differ.

Lever models

The most common type of standard safety knot is the lever model. Such a mechanism can be activated manually, which is convenient when checking or draining water from the boiler tank. They do it like this:

- horizontally located lever is installed vertically;

- direct connection to the stem actuates the spring mechanism;

- the plate of the safety valve forcibly opens the hole and water begins to flow from the fitting.

Even if complete emptying of the tank is not required, a control drain is performed monthly to check the operation of the safety assembly.

Products differ in the design of the lever and the fitting for discharging water. If possible, it is better to choose a model with a flag fixed to the body. The fastening is made with a bolt that prevents manual opening of the lever by children. The product has a convenient herringbone shape with three threads, which ensures a secure fit of the hose.

The cheaper model does not have a flag lock. The lever can be accidentally caught by hand and unnecessary draining of water will begin. The fitting is short, with only one threaded ring. Fixing the hose to such a ledge is inconvenient and can be torn off with strong pressure.

Models without lever

Relief valves without a lever are the cheapest and most inconvenient option. Such models often come with a water heater. Experienced plumbers simply throw them away. The nodes work similarly to lever models, only there is no way to manually perform a control drain or empty the boiler tank.

Models without a lever come in two versions: with a cover at the end of the body and deaf. The first option is more convenient. When clogged, the cover can be unscrewed to clean the mechanism. A deaf model cannot be checked for performance and descaled. The liquid discharge fittings for both valves are short with one threaded ring.

Safety knots for large water heaters

Improved safety valves are installed on water heaters with a storage tank capacity of 100 liters or more. They work in a similar way, only they are additionally equipped with a ball valve for forced draining, as well as a pressure gauge.

Particular attention should be paid to the fluid outlet fitting. He's carved. Reliable fastening prevents the hose from being torn off by strong pressure and eliminates the inconvenient use of the clamp

Reliable fastening prevents the hose from being torn off by strong pressure and eliminates the inconvenient use of the clamp.

Models of the original performance

For lovers of aesthetics and comfort, manufacturers offer safety nodes in the original design. The product is completed with a pressure gauge, chrome-plated, gives an elegant shape. Products look beautiful, but their cost is high.

Case marking difference

Quality products on the case must be marked. The manufacturer indicates the maximum allowable pressure, as well as the direction of water movement. The second marking is an arrow. It helps to determine which side to put the part on the boiler pipe.

On cheap Chinese models, markings are often missing. You can figure out the direction of the liquid without an arrow. The check valve plate must open upwards in relation to the boiler nozzle so that water from the water supply enters the tank. But it will not be possible to determine the permissible pressure without marking. If the indicator does not match, the safety unit will constantly leak or, in general, will not work in an emergency.

Other types of valves

When they try to save money on the security group, they try to install a blast valve designed for the heating system on the water heater. The nodes are similar in functionality, but there is one caveat. The blast valve is not able to gradually release the liquid. The mechanism will work when the excess pressure reaches a critical point. The blast valve can only bleed all the water from the tank in case of an accident.

Separately, it is worth considering the installation of only a check valve. The mechanism of this node, on the contrary, locks the water inside the tank, preventing it from draining into the pipeline. With excess pressure, the working plate with the rod is not able to work in the opposite direction, which will lead to a rupture of the tank.

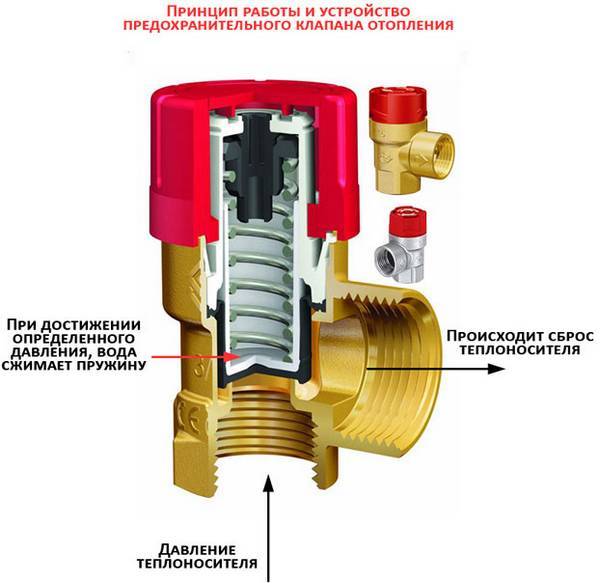

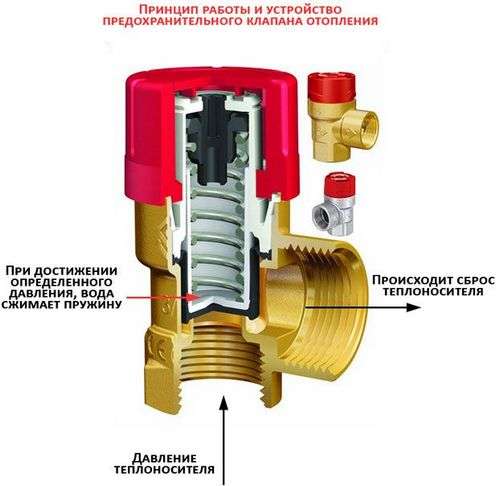

Operating principle

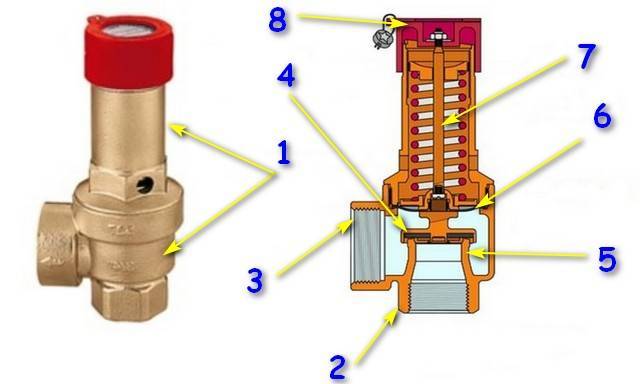

This device is constructed from a housing and two molded parts. The case itself is made of tap brass, which is created using hot stamping technology.

The main component of the valve is a steel spring. Due to the fact that it is quite elastic, it is responsible for the pressure force to which the membrane will be subjected, closing the passage to the outside. The membrane itself is located in the seat with a seal and it is pressed by a spring.

The extreme section of the spring rests on top of a metal washer, which is fixed on the stem and screwed to the plastic handle. The purpose of the handle is to adjust the safety valve in the heating system.

The principle of operation of the safety valve

It is important that the valve operates on time, without delay. This directly depends on the characteristics of its mechanism, the main components of which are the rod, spring and plate.

The main characteristic feature of the valve is the difference (in percent) between the pressure in the pipeline at the very beginning, when the stem is just starting to move, and the pressure at the moment when the passage is open to discharge excess coolant.

Read about the Safety valve for a water heater: device and principle of operation

This parameter is directly affected by the nominal pressure in the heating system. The speed at which the valve starts to operate depends on the operating pressure in the system - the higher its performance, the less time it will take to open the valve.

It is very important that the adjustment mechanism is not in contact with the coolant. The coils of the spring must be isolated from each other and in no case should they come into contact with each other.

If the safety valve is “out of work” for a long time, then the spring may “stick” - and then the valve may simply not open. Thanks to a special stem designed to retract the spring manually, it is sometimes possible to check the functioning of the valve.

In order for hydraulic resistance not to have a significant effect on the functioning of the part designed to protect the system from overload, the valve diameter must be identical to the diameter of the inlet pipe or be slightly larger.

In order to reduce hydraulic losses, the valve must be installed so that it tilts slightly towards the boiler.

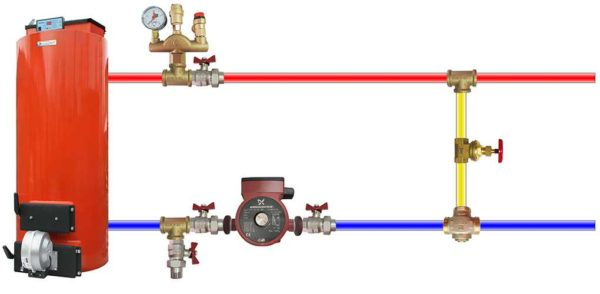

Check valve installation rules

When deciding where to put the check valve for heating, you need to be guided, first of all, by the requirements of the project.If the wiring diagram requires a check valve, it must be installed in the right place and taking into account all requirements and standards. As a rule, such fittings are installed at the time of piping the heating boiler.

Please note that for the correct installation of the check valve, you need to correctly select its type in accordance with the operating pressure and temperature of the coolant

In addition, it is important to mount the product in the manner indicated by the manufacturer in the technical data sheet for the valve. As a rule, the location of the check valves is determined at the design stage of the heating system. As a rule, the location of the check valves is determined at the design stage of the heating system.

As a rule, the location of the check valves is determined at the design stage of the heating system.

Installing check valves on the heating system allows you to cope with several tasks at once. First of all, such devices make it possible to prevent negative consequences for the heating system in case of emergency situations. In addition, it is a kind of insurance against unnecessary repair costs in the future. Another important point is the consistency of the operation of various devices looped into one system. It is achieved just by installing shut-off valves.

Thus, if you are worried about the durability and reliability of the heating and do not want to have additional costs in the future, then you should definitely consider having a check valve in the heating circuit.

When equipping a heating system, it is important not only to think over the parameters of its main functional parts (pipes, heating boiler, etc.), but also to pay attention to its small components and mechanisms, the quality of installation of which will largely determine heat supply. The element responsible for safe operation is the safety valve in the heating system, the main function of which is to protect against potential hazards associated with overloading the system, as well as to control the circulation of the coolant. Despite the relatively limited range of tasks it performs, the reverse valve for heating installed at different points in the system and is an important part of it

Despite the relatively limited range of tasks it performs, a check valve for heating is installed at different points in the system and is an important part of it.

Despite the relatively limited range of tasks it performs, a check valve for heating is installed at different points in the system and is an important part of it.

The element responsible for safe operation is the safety valve in the heating system, the main function of which is to protect against potential hazards associated with overloading the system, as well as to control the circulation of the coolant

Despite the relatively limited range of tasks it performs, a check valve for heating is installed at different points in the system and is an important part of it.

About what a relief valve for heating can be, as well as about features of its device and connection further and will be discussed.

Why Battery Valves Are Needed

Valves are also installed on the radiators and batteries of the circuit, but their main function is to remove air from the system.

The installed valve for the heating radiator can be manual and automatic. The manual valve is opened and closed manually with a key and a screwdriver.

The automatic valve on the heating battery does not require human intervention. It perfectly removes air, but its main drawback is its sensitivity to clogging due to contamination of the coolant. To remove dissolved air from the coolant and clean it from dirt and sludge, it is recommended to install air separators.