- Safety valve - all about the types, principle of operation and device

- Installation and setup rules

- Necessary tools and materials

- Work progress

- Choice

- Device and principle of operation depending on the type

- Lever-cargo

- spring

- Thermal relief valves

- Safety Relief Valve Selection Criteria

- Pressing mechanism

- lifting height

- Movement speed

- Diameter

- Manufacturer

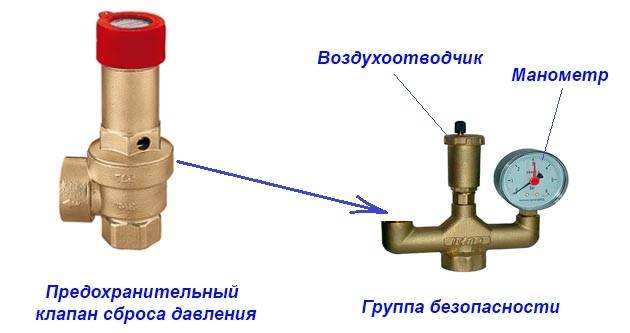

- Types of security groups and the principle of choosing the appropriate model

- Lever models

- Models without lever

- Safety knots for large water heaters

- Models of the original performance

- Case marking difference

- Other types of valves

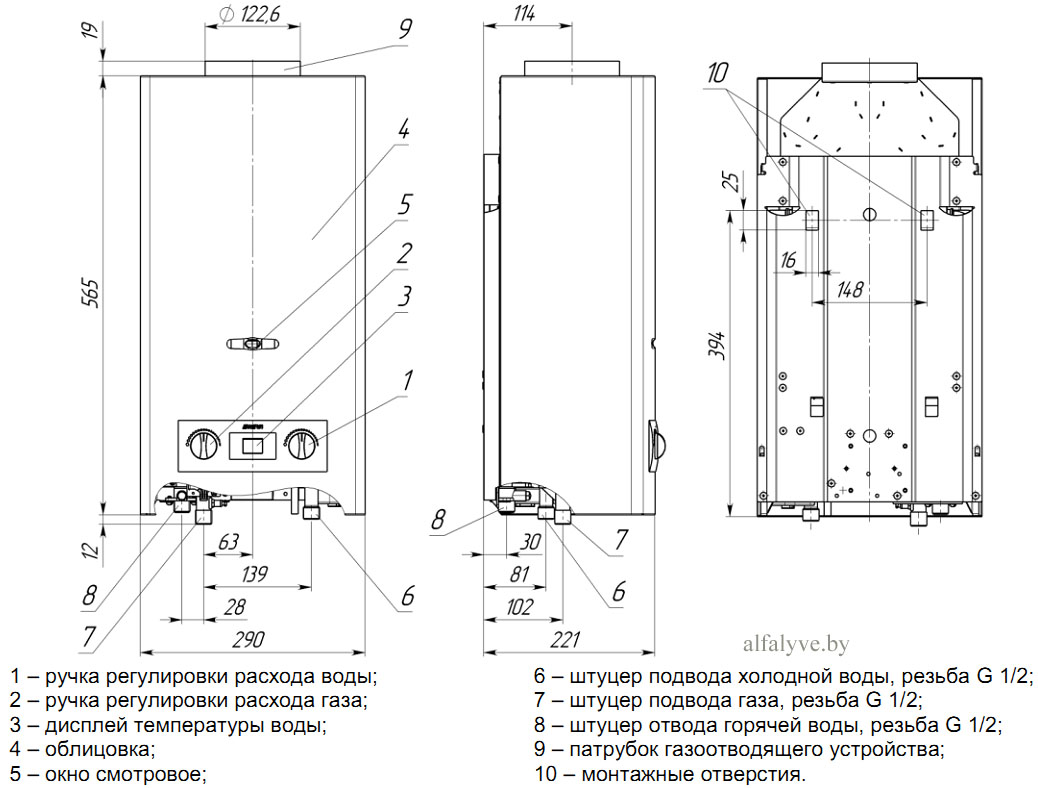

- Design features and sizes

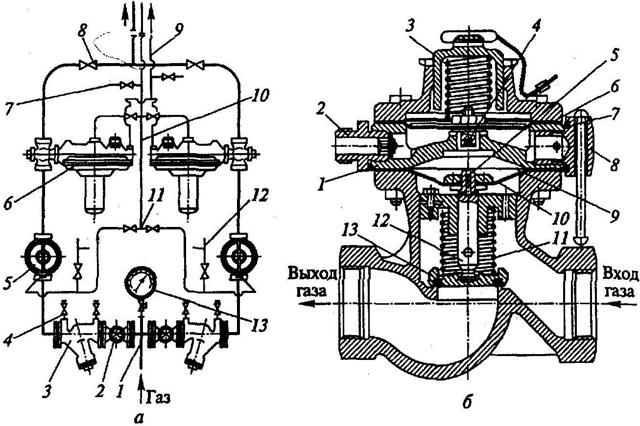

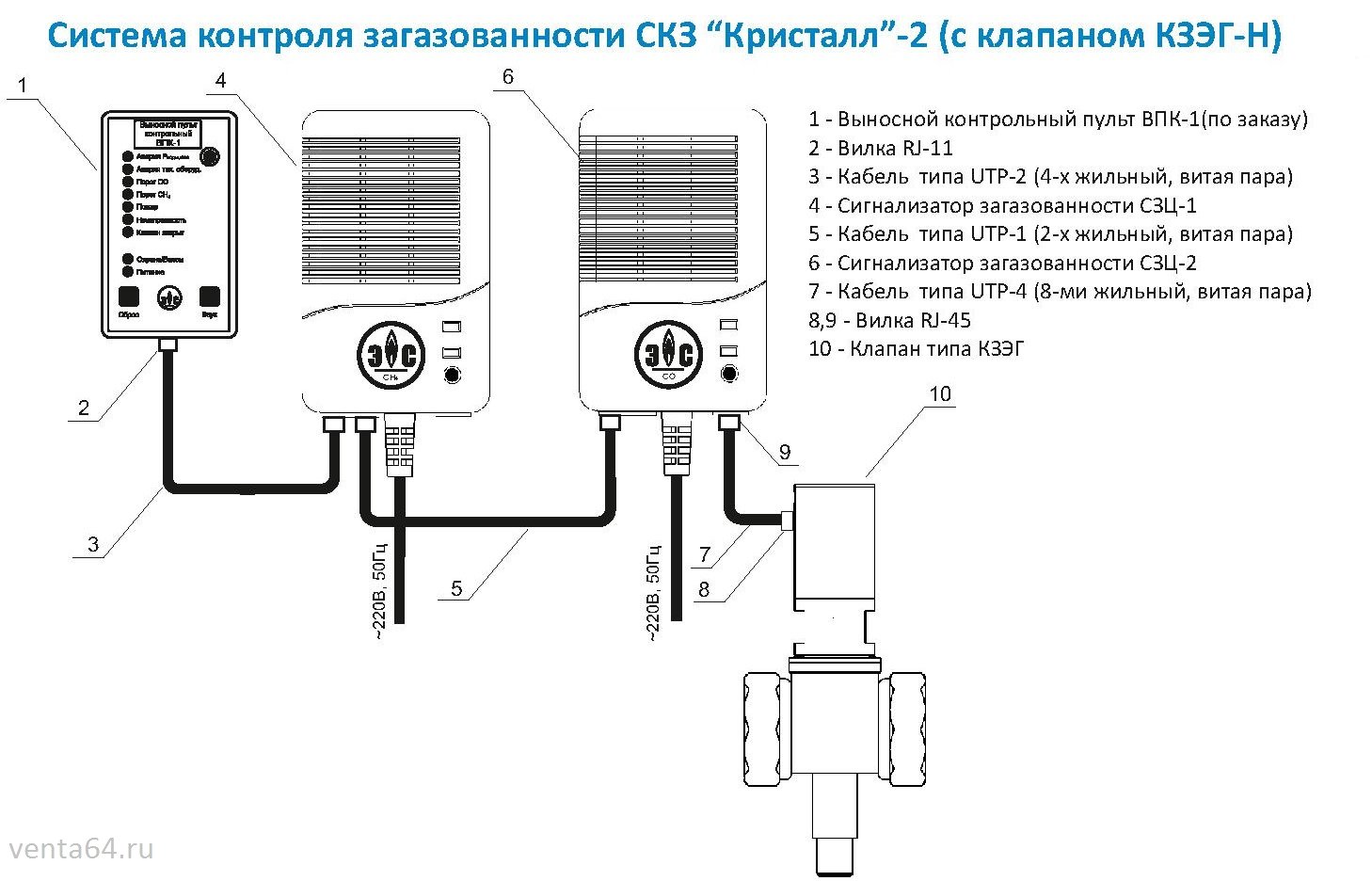

- Purpose, device, classification of PZK

- Valve operating conditions

- Why Battery Valves Are Needed

- Varieties

- Valve installation requirements

- Conclusions and useful video on the topic

Safety valve - all about the types, principle of operation and device

In the market of safety fittings for boilers and heating systems, the main niche is occupied by spring-loaded safety valves. Many manufacturers make models of various diameters and for various tuning ranges.The main purpose of the safety valve is to protect pipeline systems and boilers from overpressure. The advantage of this equipment is its automatic operation. If the set pressure of the coolant is exceeded, the valve opens and begins to discharge excess coolant into the outlet pipeline. When the pressure falls within the operating limits, the valve closes automatically and stops the discharge of the coolant.

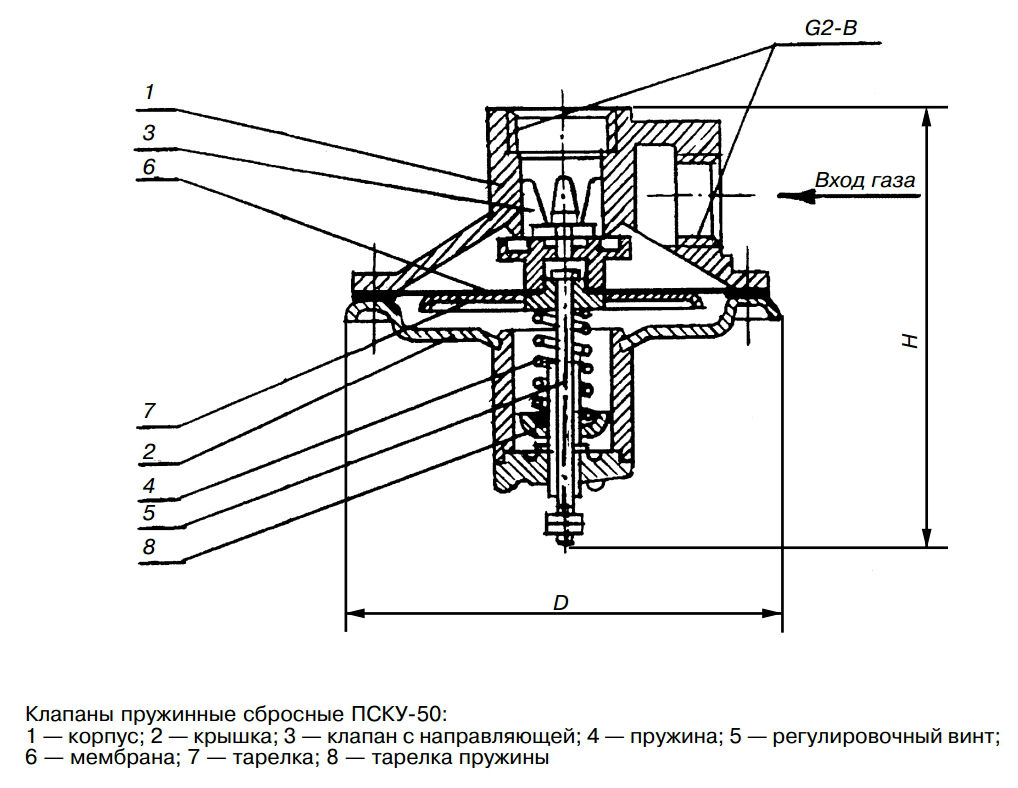

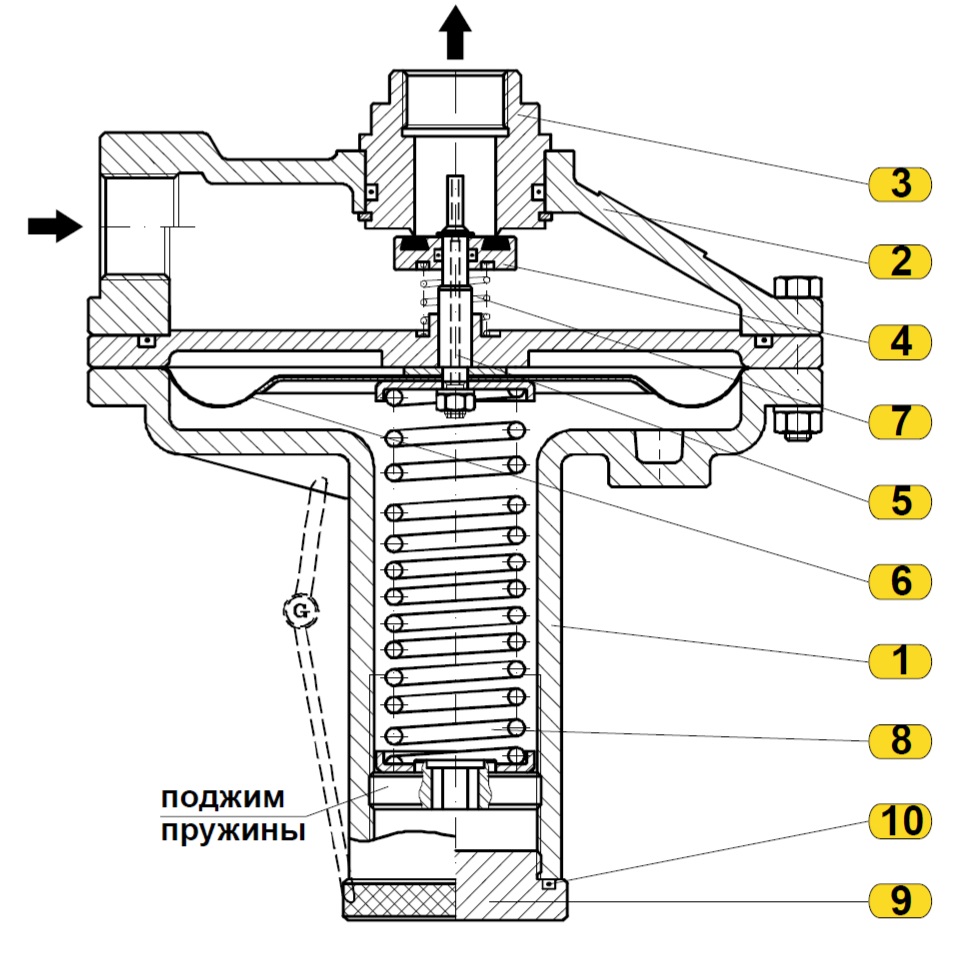

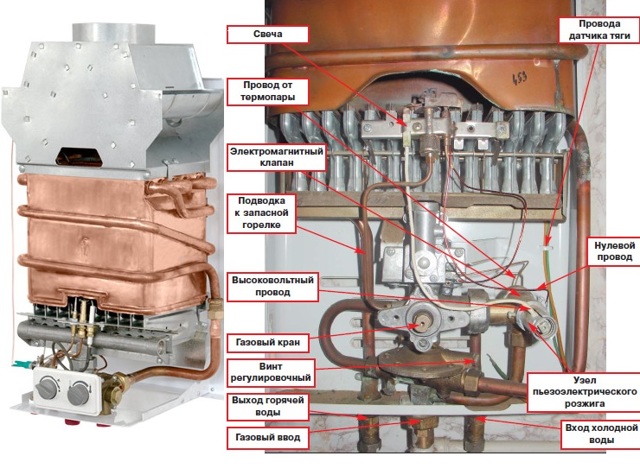

Spring Relief Valve Device

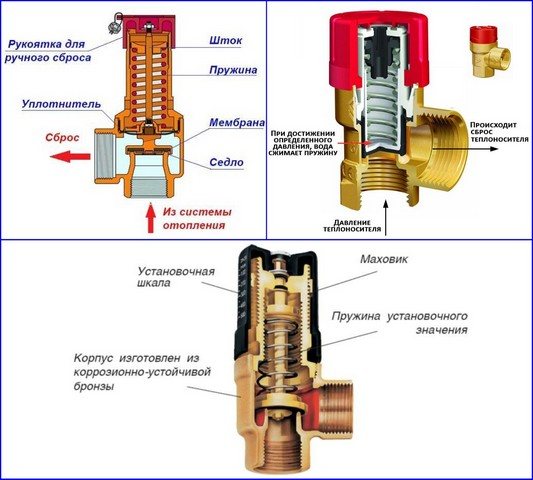

The spring-type safety valve is a body made of brass or bronze, inside of which there is a safety spring mechanism. This mechanism is based on a steel spring, protected from external influences by a plastic cap, which also functions as a test pen. The test handle allows, if necessary, to manually force the opening of the valve to check its performance. For reliable protection of the spring mechanism from the ingress of coolant into it, there is a membrane made of ethylpropylene rubber.

The principle of operation of the spring-loaded safety valve

The principle of operation of the safety valve is based on the mutual opposition on the gate of water pressure, which tends to open the valve, and the spring force, aimed at holding the gate in the closed position. The safety valve will be closed until the water pressure on the gate exceeds the force of the spring. It should be noted that the valve starts to operate already at a pressure of about 3% less than the setting pressure.If the pressure in the system continues to grow, then this leads to a further rise of the valve (proportional to the pressure of the coolant) and a uniform increase in the volume of discharged water. Full opening of the safety valve occurs at a pressure of approximately 110-115% of the setting (depending on the model). After the excess coolant is discharged, the pressure in the system will begin to decrease, and as soon as the force of the safety valve spring overcomes the static and dynamic pressure of the outflowing water, the shutter will close. Complete closing of the safety valve will occur when the pressure in the system drops to 80% of the setting.

Spring Relief Valve Setting

The setting of the safety valve is carried out at the place of installation, after completion of all installation work and flushing of the heating system.

The pressure setting in the spring-loaded safety valve is performed by turning a special adjusting screw that compresses the spring, which presses the valve against the seat. After that, the pressure of the valve operation, its full opening and closing is checked.

In some safety valves, the manufacturer has already set and fixed the response pressure at the factory, so self-adjustment of the pressure in them is no longer possible. They have a special non-removable cover that protects against valve reconfiguration. For ease of use, manufacturers introduce color marking of caps in accordance with the setting pressure: black - 1.5 bar, red - 3 bar, yellow - 6 bar (Valtec VT 490 safety valves).

Manufacturers recommend periodically cleaning the safety valves in cases where the heating system is operating stably, without overpressure. This is due to the fact that the valve is out of operation for a long time, which can cause it to become clogged with various contaminants. To clean the safety valve (“undermining”), it is necessary to turn the cap in the direction of the arrow until a characteristic click is heard. This procedure avoids leaks, most of which are caused precisely by clogging and subsequent loose fit of the valve to the valve seat.

Tell your friends about us:

Source

Installation and setup rules

Having planned an independent installation of a safety valve for heating, you should prepare a set of tools in advance. In work, you can not do without adjustable and wrenches, a Phillips screwdriver, pliers, tape measure, silicone sealant.

Before starting work, you need to determine a suitable place for installation. The safety valve is recommended to be mounted on the supply pipeline near the boiler outlet. The optimal distance between the elements is 200-300 mm.

All compact household fuses are threaded. To achieve complete tightness when winding, it is necessary to seal the pipe with tow or silicone. It is undesirable to use FUM tape, as it does not always withstand critically high temperatures.

In the regulatory documentation that comes with each device, the installation process is usually described step by step.

Some key installation rules are the same for all valve types:

- if the fuse is not mounted as part of a safety group, a pressure gauge is placed next to it;

- in spring valves, the axis of the spring must have a strictly vertical position and be located under the body of the device;

- in lever-loading equipment, the lever is placed horizontally;

- on the section of the pipeline between the heating equipment and the fuse, it is not allowed to install check valves, taps, gate valves, a circulation pump;

- to prevent damage to the body when the valve is rotated, it is necessary to select with a key from the side where the screwing is carried out;

- a drain pipe that discharges the coolant into the sewer network or return pipe is connected to the outlet pipe of the valve;

- the outlet pipe is not connected directly to the sewer, but with the inclusion of a funnel or pit;

- in systems where the circulation of the liquid occurs in a natural pattern, the safety valve is placed at the highest point.

The conditional diameter of the device is selected on the basis of methods developed and approved by Gostekhnadzor. In resolving this issue, it is wiser to seek help from professionals.

If this is not possible, you can try using specialized online calculation programs.

To reduce hydraulic losses during medium pressure on the valve disc, emergency equipment is installed with a slope towards the boiler plant

The type of clamping structure affects the adjustment of the valve. The spring fixtures have a cap. Spring preload is adjusted by rotating it. The adjustment accuracy of these products is high: +/- 0.2 atm.

In lever devices, adjustments are made by increasing the mass or moving the load.

After 7-8 operations in the installed emergency device, the spring and the plate wear out, as a result of which the tightness may be broken. In this case, it is advisable to replace the valve with a new one.

Necessary tools and materials

To install the valve you will need:

- wrench;

- fum - tape or tow;

- special paste for sealing joints.

Work progress

Each product designed to relieve excess pressure is supplied with installation instructions, which should be carefully read before starting work. Before installation, it is also necessary to disconnect the water heater from the mains and drain the water from it. The valve must be placed on the cold water line up to the stopcock. The valve installation sequence is as follows:

- marking the installation site;

- removal of a part of the pipe with a size corresponding to the length of the device body;

- threading at the ends of pipes:

- coating the threaded part with tow or fum tape;

- winding the valve onto the pipe threads;

- connecting to another branch pipe a tube leading to the sewer system.

- tightening the threaded connection with an adjustable wrench;

- sealing the junction with a special paste;

- setting the device, in accordance with the passport values (if necessary).

Choice

It is very important to choose the right safety valve for the heating system, which will prevent the boiler from boiling over and reduce the pressure. For the valve to work correctly, you must:

- Select spring equipment in which the spring will counteract the coolant pressure.

- Decide on the size and type of device so that the pressure in the heating system does not exceed the permissible values, since it is this that should help the system work.

- An open valve must be selected if water is discharged into the atmosphere, and a closed one if water is discharged into the return pipeline.

- Full lift and low lift valves should preferably be selected based on capacity.

- When discharging water into the atmosphere, it is recommended to install devices of an open type. For oil-fired boilers, low-lift valves should be selected, for gas-fired boilers, full-lift valves.

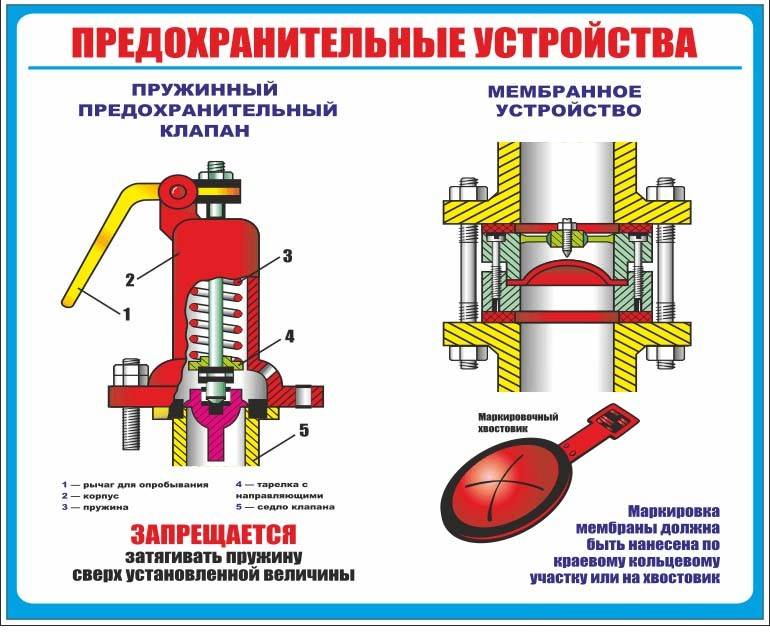

Device and principle of operation depending on the type

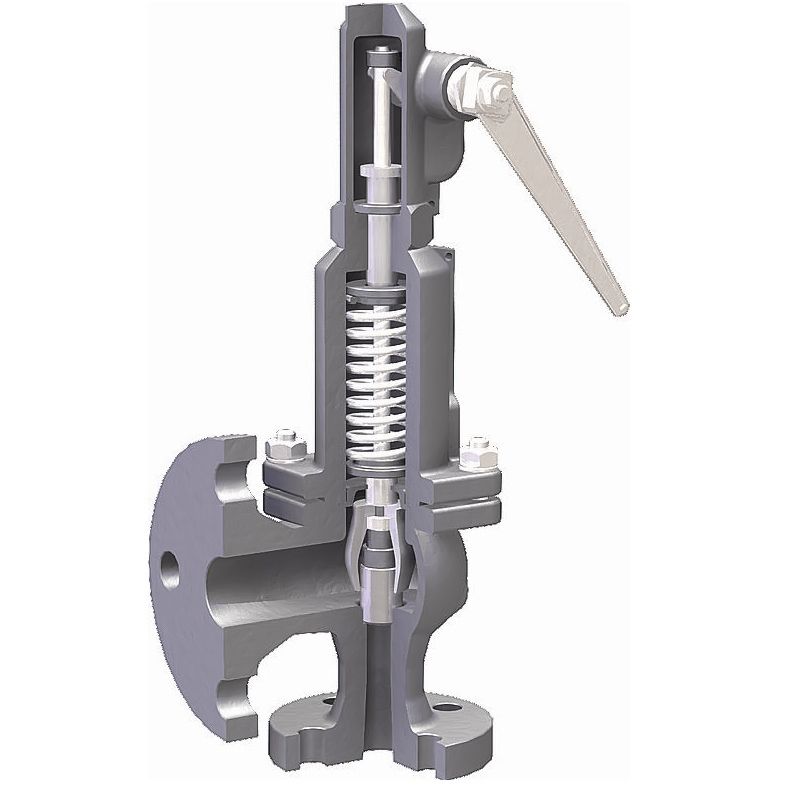

Lever-cargo

Lever safety valves are used exclusively in industrial systems, designed for heavy loads and pipeline diameters over 200 mm.

The load hung on the lever exerts pressure on the rod. When the force exerted by the pressure in the system on one side exceeds the force exerted by the load on the other side, the stem opens, releasing coolant or steam. As soon as the pressure force inside the system becomes insufficient (it does not reach a critical point), the rod under the weight of the load on the lever closes the system.

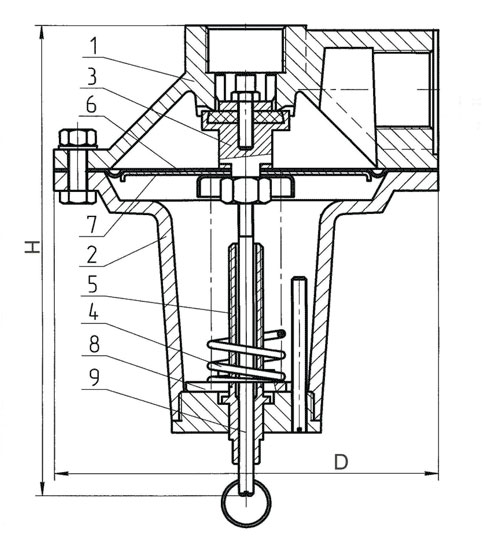

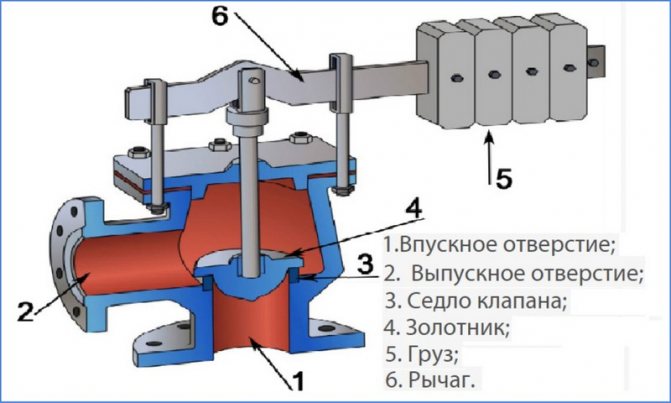

Lever-load relief valve in section.

Lever-load relief valve in section.

Thus, the critical pressure at which it is necessary to reset is regulated by the length of the lever and the weight on it.

spring

More modern and cheaper is the spring-loaded safety valve. It is not inferior in efficiency to lever-cargo, reliable and has compact dimensions, therefore it is widely used in individual heating systems for private houses.

A spring relief valve works on the same principle, only instead of a load, a spring acts on the stem:

- from the inside, a stream of water or steam exerts pressure on the shutter of the device;

- on the other hand, a spool pressed by a rod, which is acted upon by a spring;

- the pressure in the system exceeds the clamping force of the spring, the spool rod rises, depressurization occurs;

- the coolant or steam exits through the outlet pipe;

- the pressure inside the system decreases and becomes lower than the clamping force of the spring, which closes the shutter again, returning the mechanism to its original position.

The principle of operation of a spring-loaded safety valve designed for an individual heating system.

The principle of operation of a spring-loaded safety valve designed for an individual heating system.

There are both designed for a specific pressure (for example, 3, 6 or 8 bar), as well as adjustable valves, the critical pressure for which to release is set during installation. They can also be open or closed. The first discharge water or steam into the external environment, closed valves - into the pipeline connected to them.

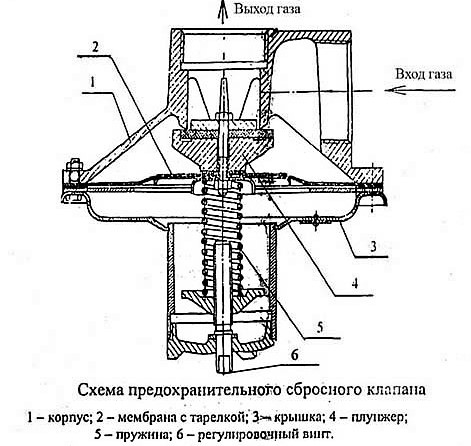

Thermal relief valves

Spring loaded safety valves are also imperfect. In addition to the fact that they work exclusively in closed systems (since the boiling of the coolant in a system with an open expansion tank can occur without increasing pressure), spring mechanisms are triggered when the temperature of the coolant has already exceeded a significant mark - over 95-100 ° C.

The most effective, but extremely expensive, is the thermal relief valve, which responds to an increase in the temperature of the coolant, and not the pressure in the system.The principle of operation lies in the same membrane, which is controlled by a spring, but it is not driven by the pressure of the water flow, but by a thermosensitive liquid, which expands significantly when heated from the coolant.

Safety Relief Valve Selection Criteria

Pressing mechanism

Lever-load safety valves are designed for heavy loads and a pipe diameter of at least 200 mm, therefore they are used in industrial heating systems.

For individual heating of a private house, it is better to purchase a device with a spring mechanism; this is a standard, reliable and commonly used type of relief valve.

lifting height

Pressure relief valves have different valve lift heights:

-

Low-lift model PS-350.Low-lift. The gate height in low-lift valves does not exceed 1/20 of the seat diameter. They have a relatively low throughput and a simple design. Are applied in highways with a liquid heat carrier. As a rule, low-lift safety fittings are sufficient for a heating system with a water circuit with a power of up to 40-43 kW. To prevent an accident in such systems, it is necessary to discharge a small amount of coolant.

- Full lift. The seat height in full lift valves is greater than or equal to the seat diameter. As a rule, these are lever-load mechanisms, which are more expensive and complex in design. Full lift valves have a high flow capacity and can be installed on lines in which gases, steam or compressed air circulate.

Full lift model PN 16.

Movement speed

According to the response speed, safety valves are divided into proportional and two-position.

In heating systems of a private house, it is better to use proportional valves, again, they are sufficient for most systems. The shutter cover of such devices opens gradually, in proportion to the increase in pressure in the line, respectively, and the volume of the discharged coolant increases proportionally. These valves do not self-oscillate, they maintain the correct pressure level and are cheaper.

Two-position safety fittings are characterized by instant undermining and full opening of the valve. Such a mechanism allows you to quickly dump large volumes of coolant, however, it creates a risk of water hammer: due to the rapid discharge of a large amount of liquid coolant, the pressure in the line decreases significantly, after which the valve closes abruptly. Therefore, two-position safety valves are recommended to be installed on lines with a compressible medium (air, gas, steam).

Diameter

The diameter of the pressure relief valve in the heating system must not be smaller than the inlet connector. Otherwise, the constant hydraulic pressure will interfere with the operation of the mechanism.

Manufacturer

Since safety valves have a fairly simple design, and modern models are in most cases made of brass using the same technology, there are no critical differences between fittings from different manufacturers.

Types of security groups and the principle of choosing the appropriate model

The standard safety valve for a boiler may differ in several design features. These nuances do not change the functionality of the device, but only simplify the use and maintenance.To choose the right safety unit, you need to know what kind of safety valves for boilers are and how they differ.

Lever models

The most common type of standard safety knot is the lever model. Such a mechanism can be activated manually, which is convenient when checking or draining water from the boiler tank. They do it like this:

- horizontally located lever is installed vertically;

- direct connection to the stem actuates the spring mechanism;

- the plate of the safety valve forcibly opens the hole and water begins to flow from the fitting.

Even if complete emptying of the tank is not required, a control drain is performed monthly to check the operation of the safety assembly.

Products differ in the design of the lever and the fitting for discharging water. If possible, it is better to choose a model with a flag fixed to the body. The fastening is made with a bolt that prevents manual opening of the lever by children. The product has a convenient herringbone shape with three threads, which ensures a secure fit of the hose.

The cheaper model does not have a flag lock. The lever can be accidentally caught by hand and unnecessary draining of water will begin. The fitting is short, with only one threaded ring. Fixing the hose to such a ledge is inconvenient and can be torn off with strong pressure.

Models without lever

Relief valves without a lever are the cheapest and most inconvenient option. Such models often come with a water heater. Experienced plumbers simply throw them away.The nodes work similarly to lever models, only there is no way to manually perform a control drain or empty the boiler tank.

Models without a lever come in two versions: with a cover at the end of the body and deaf. The first option is more convenient. When clogged, the cover can be unscrewed to clean the mechanism. A deaf model cannot be checked for performance and descaled. The liquid discharge fittings for both valves are short with one threaded ring.

Safety knots for large water heaters

Improved safety valves are installed on water heaters with a storage tank capacity of 100 liters or more. They work in a similar way, only they are additionally equipped with a ball valve for forced draining, as well as a pressure gauge.

Particular attention should be paid to the fluid outlet fitting. He's carved. Reliable fastening prevents the hose from being torn off by strong pressure and eliminates the inconvenient use of the clamp

Reliable fastening prevents the hose from being torn off by strong pressure and eliminates the inconvenient use of the clamp.

Models of the original performance

For lovers of aesthetics and comfort, manufacturers offer safety nodes in the original design. The product is completed with a pressure gauge, chrome-plated, gives an elegant shape. Products look beautiful, but their cost is high.

Case marking difference

Quality products on the case must be marked. The manufacturer indicates the maximum allowable pressure, as well as the direction of water movement. The second marking is an arrow. It helps to determine which side to put the part on the boiler pipe.

On cheap Chinese models, markings are often missing.You can figure out the direction of the liquid without an arrow. The check valve plate must open upwards in relation to the boiler nozzle so that water from the water supply enters the tank. But it will not be possible to determine the permissible pressure without marking. If the indicator does not match, the safety unit will constantly leak or, in general, will not work in an emergency.

Other types of valves

When they try to save money on the security group, they try to install a blast valve designed for the heating system on the water heater. The nodes are similar in functionality, but there is one caveat. The blast valve is not able to gradually release the liquid. The mechanism will work when the excess pressure reaches a critical point. The blast valve can only bleed all the water from the tank in case of an accident.

Separately, it is worth considering the installation of only a check valve. The mechanism of this node, on the contrary, locks the water inside the tank, preventing it from draining into the pipeline. With excess pressure, the working plate with the rod is not able to work in the opposite direction, which will lead to a rupture of the tank.

Design features and sizes

PSK cannot be made in a handicraft way, products are produced in the factory in accordance with the requirements of GOST or TU.

The material must be strong, wear-resistant, not prone to deformation from changes in operating conditions, not subject to the negative effects of corrosion. Most often it is brass or aluminum, but devices are also made from cast iron and stainless steel.

Product designs vary from manufacturer to manufacturer, but the most common type is the cone-and-seat device equipped with pipe fittings.

Product designs vary from manufacturer to manufacturer, but the most common type is the cone-and-seat device equipped with pipe fittings.

There are two threaded holes in the body. Their diameter depends on the type of PSK and is usually 1″ or 2″. For domestic networks, mainly two types of valves are used, differing in cross section - by 25 mm or 50 mm.

Table with the technical characteristics of the PSK. Devices can differ not only in cross-section, but also in the type of connection to the pipeline, operating pressure indicators, material of manufacture, body dimensions

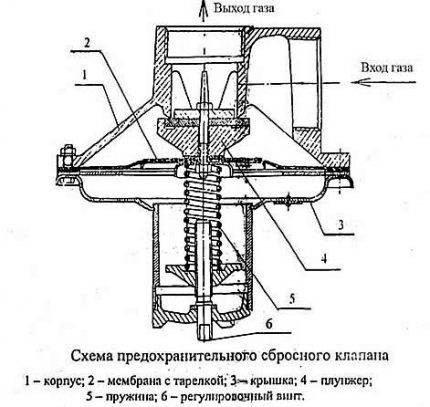

The principle of operation of the protective gas valve is simple: as soon as excess gas enters the device and begins to press on the membrane, it acts on the spring, which opens the outlet to the outside. As soon as the pressure drops to working parameters, the spring closes the hole.

Although the devices operate automatically, they are equipped with a forced opening mechanism. This is necessary in order to check the performance of the valve.

To test, you need to pull on a special element of the device - traction. This manipulation should be repeated several times to make sure that the mechanism works.

The shut-off and control valve is mounted in tandem with the valve, so that if necessary - if the valve suddenly does not work - quickly shut off the gas supply.

Purpose, device, classification of PZK

Increasing or decreasing the gas pressure after the pressure regulator in excess of the specified limits can lead to an emergency. With an excessive increase in gas pressure, flame separation from the burners and the appearance of an explosive mixture in the working volume of gas-using equipment, leakage, gas leakage in the joints of gas pipelines and fittings, failure of instrumentation, etc. are possible.A significant decrease in gas pressure can lead to flame flashback into the burner or flame extinction, which, if the gas supply is not turned off, will cause the formation of an explosive gas-air mixture in the furnaces and gas ducts of the units and in the premises of gasified buildings.

The reasons for the unacceptable increase or decrease in gas pressure after the pressure regulator for dead-end networks are:

- malfunction of the pressure regulator (jamming of the plunger, the formation of hydrate plugs in the seat and body, leakage of the valve, etc.);

- incorrect selection of the pressure regulator according to its throughput, leading to a two-position mode of its operation at low gas flow rates and causing outbursts of outlet pressure and self-oscillations.

For ring and branched networks, the reasons for an unacceptable pressure change after the pressure regulator can be:

- malfunction of one or more pressure regulators supplying these networks;

- incorrect hydraulic calculation of the network, due to which abrupt changes in gas consumption by large consumers lead to surges in outlet pressure.

A common cause of a sharp decrease in pressure for any network may be a violation of the tightness of gas pipelines and fittings, and, consequently, a gas leak.

To prevent an unacceptable increase or decrease in pressure in the hydraulic fracturing (GRPSh), high-speed safety shut-off valves (PZK) and safety relief valves (PSK) are installed.

PZK are intended for automatic stop of gas supply to consumers in case of increase or decrease in pressure over the set limits; they are installed after the pressure regulators. PZK work at "emergency situations", therefore their spontaneous inclusion is inadmissible. Before manually turning on the slam-shut device, it is necessary to detect and eliminate malfunctions, and also make sure that the shut-off devices in front of all gas-using devices and units are closed. If, according to the conditions of production, a break in the gas supply is unacceptable, then instead of a shut-off valve, an alarm system should be provided to alert the maintenance personnel.

PSK are designed to discharge into the atmosphere a certain excess volume of gas from the gas pipeline after the pressure regulator in order to prevent pressure from rising above the set value; they are installed after the pressure regulator on the outlet pipeline.

In the presence of a flow meter (gas meter), PSK must be installed after the meter. For GRPSh, it is allowed to take out the PSK outside the cabinet. After reducing the controlled pressure to a predetermined value, the PSK must be hermetically sealed.

Valve operating conditions

After checking and revision, the valves are adjusted and undergo the necessary adjustment for a given pressure. Then the device is sealed. Installation without a seal is strictly prohibited. All safety valves have a technological passport or “operation cards”.

The service life of safety valves is directly dependent on proper operation and maintenance. Often in the process of operation various defects occur.

Among them are such common defects:

- a leak

- ripple

- badass

The leak is characterized by the passage of the working medium.Occurs when the seals are damaged and foreign objects get on them. As well as when the spring is deformed. Eliminated by blowing, lapping, replacing the spring, proper installation or a new adjustment of the valve.

Pulsation - too frequent opening / closing. Occurs with a narrowed cross section or high throughput. The problem is eliminated by the correct selection of the necessary parameters.

Seizures during operation occur as a result of distortions during assembly. Eliminated by machining and further proper assembly.

Why Battery Valves Are Needed

Valves are also installed on the radiators and batteries of the circuit, but their main function is to remove air from the system.

The installed valve for the heating radiator can be manual and automatic. The manual valve is opened and closed manually with a key and a screwdriver.

The automatic valve on the heating battery does not require human intervention. It perfectly removes air, but its main drawback is its sensitivity to clogging due to contamination of the coolant. To remove dissolved air from the coolant and clean it from dirt and sludge, it is recommended to install air separators.

Varieties

Existing types of valves are able to work with boiler equipment from leading foreign (Vaillant, Baxi, Ariston, Navien, Viessmann) and domestic (Nevalux) manufacturers on gas, liquid and solid fuels in situations where automatic control over the operation of the system due to the type of fuel is difficult or violated when the automation fails. Depending on the design and principle of operation, safety valves are divided into the following groups:

- According to the purpose of the equipment in which they are installed:

- For heating boilers of the above design, they are often supplied on fittings in the form of a tee, in which a pressure gauge is additionally installed to check the pressure and a vent valve.

- For hot water boilers, there is a flag for draining water in the design.

- Tanks and vessels under pressure.

- Pressure pipelines.

- According to the principle of operation of the clamping mechanism:

- From a spring, the clamping force of which is regulated by an external or internal nut (its operation is discussed above).

- Lever-load, used in industrial heating systems designed to discharge large volumes of water, their response threshold can be adjusted by suspended loads. They are suspended on a handle connected to the shut-off spool by the principle of a lever.

Lever-load modification device

- Locking mechanism actuation speeds:

- Proportional (low-lift spring) - hermetic constipation rises in proportion to the pressure and is linearly related to its increase, while the drain hole gradually opens slightly and closes in the same way with a decrease in the volume of the coolant. The advantage of the design is the absence of water hammer in various modes of movement of the shut-off valve.

- Two-position (full-lift lever-cargo) - operate in the open-closed positions. When the pressure exceeds the response threshold, the outlet opens completely and the excess volume of the coolant is bled off. After the pressure in the system is normalized, the outlet is completely blocked, the main design flaw is the presence of water hammer.

- By adjustment:

- Non-adjustable (with caps of different colors).

- Adjustable with screws.

- According to the design of the spring compression adjusting elements with:

- Internal washer, the principle of operation of which was discussed above.

- External screw, nut, models are used in domestic and municipal heating systems with large volumes of coolant.

- With a handle, a similar adjustment system is used in flanged industrial valves; when the handle is fully raised, one-time water can be drained.

Designs of various models of bleed valves

Valve installation requirements

The device for removing excessive water pressure is installed taking into account the expansion tank in the heating system. The safety valve is activated after the volume of the membrane tank is exhausted. The mechanism is placed on a pipeline connected to the boiler nozzle. Approximate distance - 20 - 30 cm.

In this case, it is imperative to fulfill the following conditions:

- If the valve is installed separately from the safety group, a pressure gauge must first be installed in order to control the pressure.

- Valves, taps, pumps must not be installed between the valve and the heating unit.

- A pipe is connected to the valve (outlet pipe) to drain the excess coolant.

- The protective mechanism is recommended to be installed at the highest point of the heat carrier circulation system.

- The protection device needs to be changed after seven or eight operations due to loss of tightness.

Conclusions and useful video on the topic

How the safety valve is arranged and what it consists of:

Emergency valve as part of the safety group:

Learn more about selecting and installing the optimal safety valve:

A safety valve is a simple and reliable equipment that will protect your home from unforeseen emergencies that occur in heating systems. To do this, it is enough to choose a high-quality device with suitable parameters, and then perform its competent configuration and installation.

Are you looking for the right safety valve for your heating system? Do you still have questions that you did not find answers to in the above material? Ask them to our experts by leaving a comment under the article.

Or maybe you want to supplement the material with interesting facts and useful recommendations? Or share the experience of personally installing the valve in the system? Write your opinion on the need for such a protective device, share tips on choosing based on personal experience.