- Design and principle of operation of the device

- Safety valve device

- The principle of operation of the device

- Why is it not enough to install a non-return valve?

- Common Check Valve Problems

- Types of safety fittings

- Purpose

- Valve Model Selection Tips

- Mounting and connection methods

- Installation on a water heater

- Choosing the right model

- Correct installation

- How to choose a boiler model?

- Why is the safety valve on the water heater so important?

- How a safety valve works

- How does the valve work

- How to install the valve

- Installation

- Conclusions and useful video on the topic

Design and principle of operation of the device

To begin with, we will analyze in detail the device and the principle of operation of the safety valve.

Safety valve device

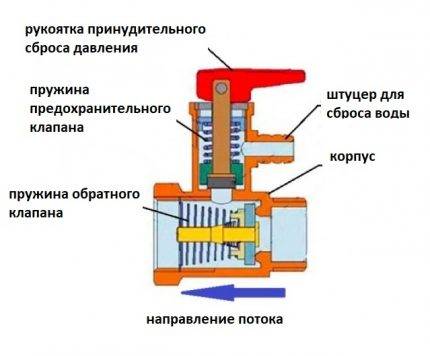

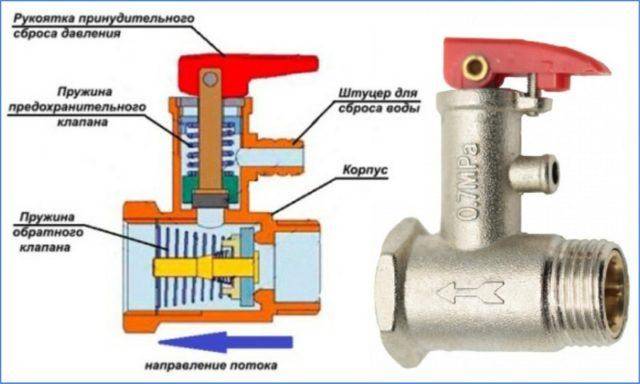

The safety valve, like other types of fittings, has a simple design and is a combination of two spring mechanisms enclosed in a common metal case.

There is no fundamental difference between brass and steel products, but brass is a little more expensive and, according to reviews, lasts longer. The springs inside the case are made of chrome-plated steel.

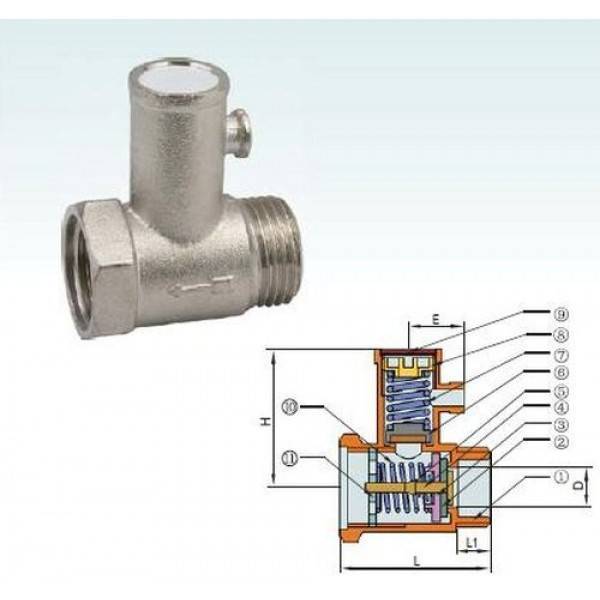

A diagram that clearly shows the internal contents of the valve.A part that prevents the reverse flow of water cuts into the pipe, and a safety module with a movable spout is located perpendicularly

A diagram that clearly shows the internal contents of the valve.A part that prevents the reverse flow of water cuts into the pipe, and a safety module with a movable spout is located perpendicularly

The principle of operation of the device

Both cylinders, located perpendicularly, have a similar design, but a different purpose. The part located along the course of the water has a spring inside and a “plate” with a sealing ring.

The spring keeps the mechanism closed and prevents the liquid from returning to the pipeline. The end parts of the cylinder are equipped with a male-female thread for inserting into the cold water system and connecting to the boiler fitting.

A more powerful spring is installed inside the second cylinder, which is in a neutral state even with a slight increase in pressure.

If there is a sharp increase in pressure above normal in the line, then the spring works and opens the hole for the ejection of fluid. The outer end of the cylinder is covered with a plug, screw or lever device.

The appearance of the safety valve with a plastic lever: 2 - thread for tapping into the cold water network, 3 - thread for connecting to the boiler, 8 - mini-pipe for liquid outlet, 9 - lever for forced opening

The yellow marker in the figure circles the area on which the marking is embossed. It indicates the maximum pressure rating at which the valve operates. The pressure is indicated in MPa, but it is easy to convert it to atmospheres: 0.7 MPa = 7 atm.

Also on the body is an arrow indicating the direction in which water moves from the cold water system to the heating tank.

Although it is convenient to drain water through the hole in the valve, experts recommend not to use manual control too often.

It is necessary to use the lever for forced opening of the valve as little as possible, and for prevention or repair, water can be drained in another way, for example, by unscrewing the water supply pipes.

Why is it not enough to install a non-return valve?

The safety device is a component, so you do not need to search in stores and select a spare part for installing a new water heater. But when transferring, the part may be lost.

Apparently, this is why some craftsmen who install a used boiler, instead of a safety model, insert a typical check valve, which is strictly prohibited by the instructions.

This binding is incorrect. To drain the water, a horizontal outlet with a shut-off valve is made, and a check valve without a safety mechanism is connected below this assembly.

Anyone who starts operating a boiler with incorrect piping risks not only equipment, but also people's lives. The balanced thermodynamic action when heating water can get out of control, and then an ordinary water heater turns into a real explosive device.

The pressure, increased to 5-6 atmospheres, raises the temperature of the water inside the tank to a critical boiling point, and then even higher. A huge amount of steam accumulates and an explosion occurs.

The consequences of the explosion of a household water heater in a city apartment. The result of improper piping of the boiler was knocked out doors and destroyed walls not only for the owners of the equipment, but also for the neighbors

When using a standard safety valve for a home water heater, everything is different: when a critical pressure level is reached, the spring in the device compresses and releases some of the liquid out.

Due to this, the pressure inside the system is balanced and the equipment continues heating in the normal mode. For this reason, the installation of a fuse is mandatory and regulated by the installation requirements.

Thus, the safety device performs a number of functions that are important for the normal operation of the boiler.

Boiler manufacturers strongly recommend professional water heater installation. If this is not possible, then all installation steps must be carried out strictly according to the instructions, in compliance with all standards and the mandatory installation of a safety module.

Common Check Valve Problems

If you notice even the slightest sign that the check valve is not working or is working, but not correctly, then you should immediately look for the cause of the breakdown. Get it repaired or replaced right away, which is even better. The fact is that the cost of such a valve is much lower than the cost of the water heater as a whole, so such a move would be more than appropriate. The causes of failure can be different, let's look at the most common of them.

- The valve stops flowing water. The reason for this is often its clogging with scale or dirt. In this case, you should dismantle the device, clean it, and install it back. It is advisable to install a filter on the supply pipe so that this does not happen in the future.

If water starts to drip from the valve after the water in the boiler begins to heat up, then there is nothing to worry about. This is due to the direct duty of the valve - when the pressure rises, it begins to dump excess fluid and the latter, in turn, begins to drip.To fix this, connect a hose to the drain hole of the device so that the other end is submerged in water.

The valve can also leak when cold water flows through it. This is often due to high pressure in the pipeline (which occurs due to its poor condition). In this case, you should check whether the valve is working - for this you need to install a 100% working model instead. If the device is working, and the pressure in the tank is still more than three atmospheres, then the only thing that can be done is to additionally install a reducer that would reduce the pressure inside the plumbing system. There are a great many such gearboxes, so when choosing a particular model, consult a specialist first. Another way out is the installation of an expansion tank.

Water may also drip from under the lower valve cover. In this case, you should remove the cover and determine where it is leaking from. To do this, under the cover there is a small hatch leading inside the boiler. There is a special sealing gasket, and if it flows from this hatch, then most likely the gasket needs to be replaced. But it can also be a factory defect - that is, the hatch was incorrectly centered. Often this can be fixed, but if it flows, as they say, from all the cracks, then this is a clear sign that the boiler itself needs to be changed.

Video review of various models

Types of safety fittings

Safety valves may have various valve actuation mechanisms. Therefore, they are divided into the following types:

- spring;

- lever (lever-cargo);

- impulse (magnetic-spring);

- devices with collapsing membranes.

For domestic boilers, only spring valves are used. They can perform the protective functions of both a reset, a drain, and a drain fuse.

The spring-loaded water pressure relief valve for a water heater consists of a body, a non-return valve and a safety valve with springs, and an outlet fitting. Many models have a manual bypass opening lever. The body has an external thread at the inlet and an internal thread at the outlet.

The shape of the water outlet can have a simple round pipe with a shoulder at the end, or a herringbone pipe. Both forms serve to securely hold the hose being put on. The hose is used to divert excess water to the drain.

On the body there must be a mark on the value of the limiting pressure and an arrow indicating the direction of the flow of water to fill the boiler.

Many models have a lever for manual opening (not to be confused with lever-weight valves, which have a different principle of operation of the mechanism). If there is a lever, you can manually check the operation of the valve on the boiler. And also use it to drain water from the tank, including in an emergency. Such a lever is also called undermining, as it serves to undermine the valve, that is, to tear it off the seat in case of sticking. Although just this name came from the lever-cargo type.

If a safety device model without a lever is installed, an additional tap must be installed to drain the water. And in such a model, it will no longer be possible to check the operation of the device manually. The fact is that the opening of the valve fitting is small, about 5 mm.With a high content of mineral salts in the water and regular digging, this hole becomes clogged with salt deposits. What can become a significant obstacle to draining water at high pressure. Therefore, it is worth checking the condition of such a hole once a year.

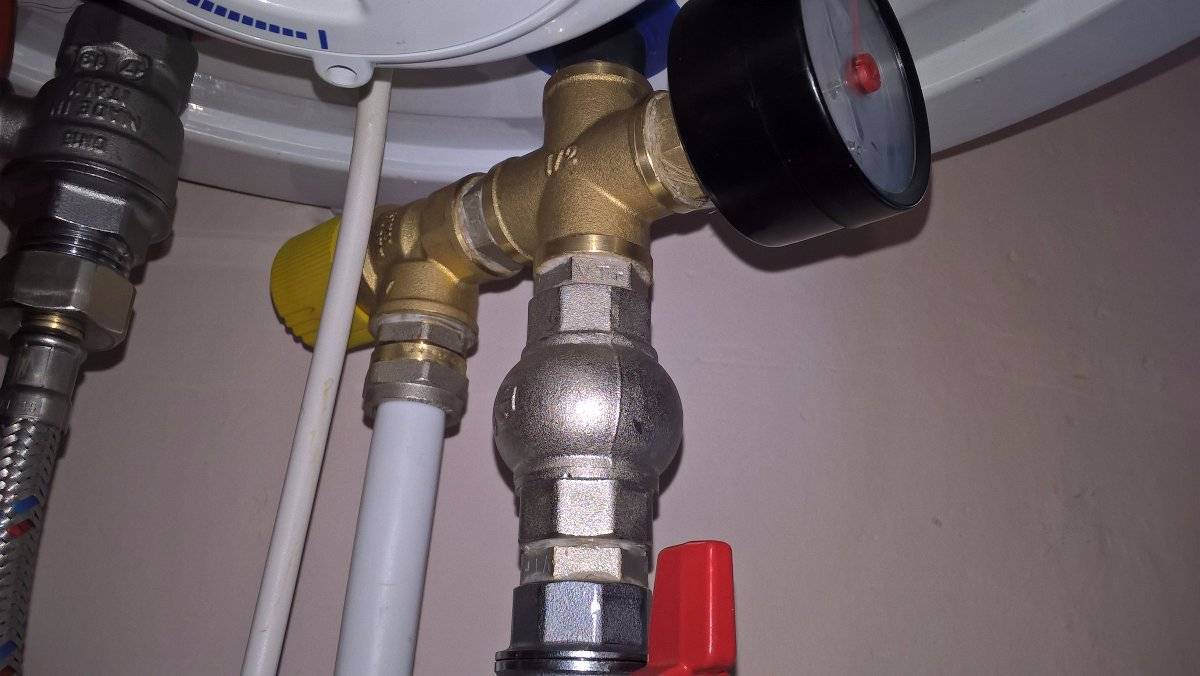

For water heaters with a tank volume of more than 100 liters, safety units with a safety valve of slightly larger sizes are provided. Often they are equipped with pressure gauges and a ball valve for forced drainage of water, which does not interfere with the operation of the safety device. And besides, they can have an adjusting screw to set the value of the valve actuation pressure.

Purpose

Without exception, all manufacturers of storage water heaters prescribe in the instructions for use a categorical ban on operating the device without a safety valve. And in the installation instructions, the installation method is described in detail. This is due to the ability of water to expand significantly when heated. Since boiler tanks have a certain margin of safety, the systematic effect of internal pressure can simply break them. This can cause very dangerous injuries, as well as significant financial costs. If 50-100 liters of hot water flood several lower apartments.

Valve Model Selection Tips

As mentioned above, water heaters are sold with a safety valve. In this regard, when buying a new model, especially a branded one, you do not need to take care of the selection of the part.

The need to purchase arises in three cases:

- you got an already used boiler without strapping elements;

- the fuse was lost during the move;

- the valve is broken or worn.

Knowing the model of the boiler, you can easily pick up a new element. In the operating instructions for the equipment, you can find the parameters of the maximum pressure - the same should be stamped on the body of the new part.

A valve with a lower limit pressure or, conversely, a product with a margin does not need to be bought. In the first case, you will observe a constant leak from the tank, in the second case, the valve simply will not work in the event of an emergency.

The thread diameter must match the dimensions of the mounting fitting and the cold water pipeline. In addition to the device itself, you will need a linen thread on the pipe or a rubber gasket if flexible piping is used.

Sometimes a valve is installed between the boiler pipe and the fuse to drain the water. This is an acceptable, permitted piping scheme, but under one condition - the valve must be mounted on a horizontal outlet from the water supply line. There must not be any locking devices between the safety valve and the water heater.

Mounting and connection methods

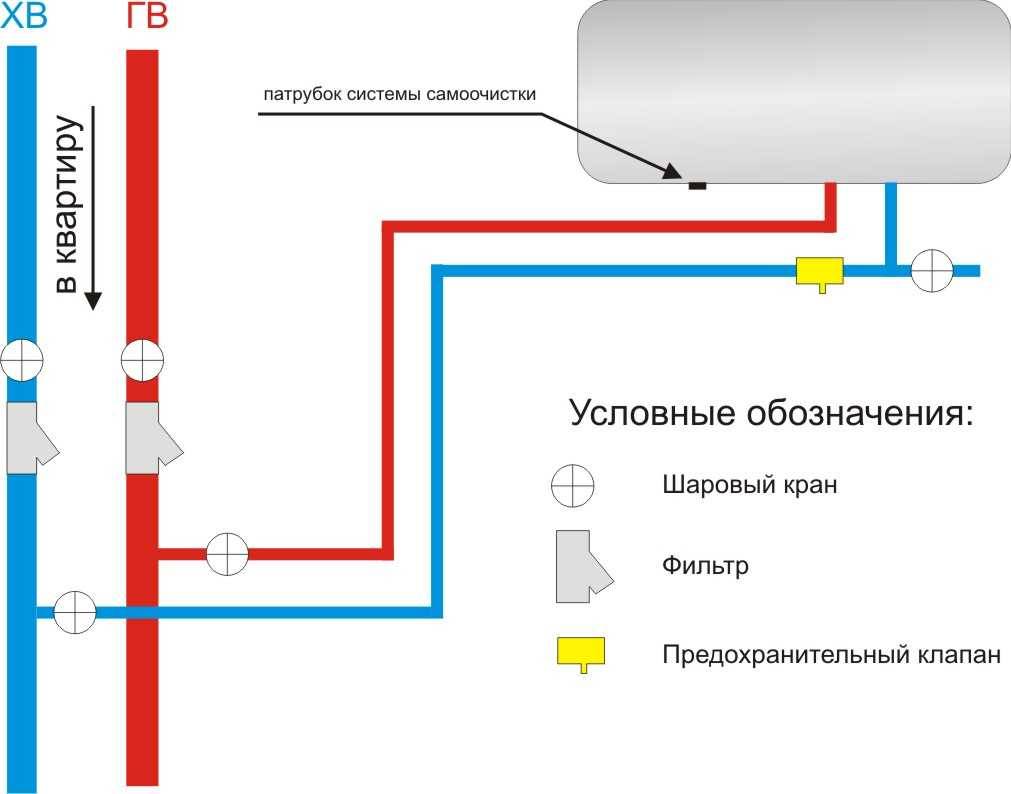

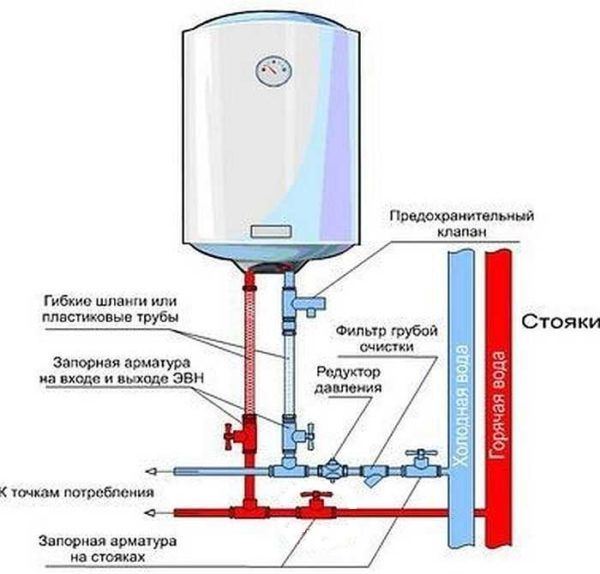

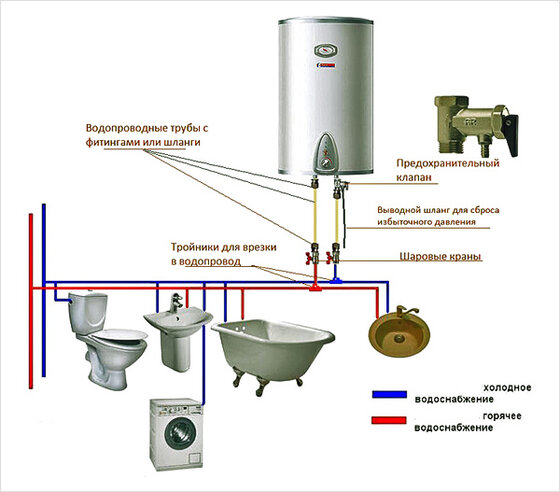

Safety valve connection diagram

To install a relief valve, you will need a minimum set of tools:

- additional polypropylene pipe - for supplying cold water to the water heater;

- tee - made of brass, it is necessary for attaching a shut-off valve, the required diameter is 1/2 inch, it is twisted 3-4 turns;

- drain valve - will be required in case the storage tank is empty for repair work, transportation, etc .;

- American - quick coupling, designed to combine two threads without their rotation;

- polypropylene fittings - connecting elements for pipes, withstand high temperatures and pressure drops within the system.

Before installing a non-return valve for the heater, make sure that the boiler is disconnected from the mains and drained of water.

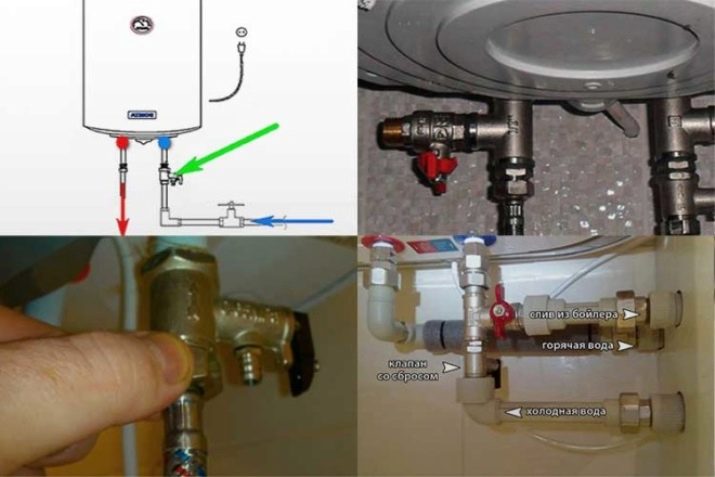

The valve is mounted in the place where cold water enters the heater. The installation consists in screwing one thread to the cold water supply, and the second to the boiler inlet. Be sure to use a sealant - it can be tow or fum-tape.

This method of installation is considered the most reliable. Some craftsmen do not use tees and additional fuses. In this case, the valve is mounted on the branch pipe of the heater itself. For ease of connection, it is recommended to lower it 1-2 cm below the body.

After installation, it remains to provide a drain for excess water through a special fuse hole. For these purposes, a flexible plastic tube is used, which is similar to a dropper system. It can be both colored and transparent.

One end of the tube for draining water is fixed on a fuse, and the other is taken out to a place to collect moisture.

There are three main tube output options:

- into the sewer with a tee;

- directly to the outlet;

- into a container specially installed under the boiler (for example, a bucket).

More hygienic, aesthetically pleasing and practical is the outlet to the sewer using a tee.

There is also a way to drain the drain directly into the drain, but if you lower the drain pipe into the toilet, then when the boiling water comes out, it can burst.

Installing a container to collect moisture is generally a decision of improvident owners.Such a system is only effective if moisture emissions are minimal. But in case of an emergency, it will not save, since the volume of drained water increases significantly and the installed capacity may not be enough.

If the idea of \u200b\u200bmasking the pipeline arises to maintain the design of the room, then professionals recommend following these rules:

- for maintenance of hidden fittings, it is necessary to equip a special access hatch;

- it is better to fix the safety valve with pressure control directly on the boiler fitting;

- to avoid excessive pressure on the valve spring, the length of the pipe between the fuse and the storage tank should be no more than 2 m.

Only in this case, hidden details will not bring discomfort to the life of the user.

If from time to time drops of water appear on the valve nozzle, then do not be afraid. This indicates that the device is working.

You can start to worry when the water flows constantly or does not flow at all, as this indicates that the valve is not working.

Installation on a water heater

Choosing the right model

Usually boilers are already sold with a safety valve of a certain parameter. If the valve is missing, then you have to purchase it yourself. The approximate price for a safety device is 250-450 rubles.

When buying a valve for a water heater, pay attention to the threaded part. If everything is in order with it, then you should pay attention to what working pressure the valve is designed for.

This value can be found by looking at the technical passport for the equipment. If it is below the prescribed pressure level, then water will constantly flow from the safety device.A valve with a pressure level higher than set in a critical situation may not save the boiler from overheating.

Correct installation

- Before installing the appliance, the boiler must be turned off and the water drained.

- A safety device is placed at the cold water inlet to the heater. For installation, a sealant is used: fumlenta or tow. On the other hand, the device is connected to a cold water supply.

- If it is known that the plumbing system is subject to pressure drops, then in this case it would be reasonable to put a water reducer upstream of the valve.

- Water may drip from the faucet from time to time - this is quite normal, although it may annoy some people. It is an indication of the performance of the device. In general, it is a good idea to connect the drain pipe and the sewerage system with a flexible transparent hose in order to evaluate the operation of the device.

Some users try to hide the safety valve for the water heater and place it as far away from the heater as possible.

This approach is not forbidden if two conditions are met:

- It is forbidden to install locking devices of any kind between the boiler inlet and the safety device.

- It is forbidden to carry the boiler and valve to a distance of more than two meters.

If there is abundant water leakage through the drainage pipe until the water is very hot, then this indicates too high pressure in the plumbing system. This rarely happens. In this case, it is worth installing a gearbox.

At the same time, it does not hurt to check if the purchased valve has a low pressure indicator and does not match the heater model. If it is normal, then it is worth checking the spring - perhaps it has “sat down” a little, and it needs to be replaced.

You should be wary if the valve remains dry at maximum heating rates. In this case, with a high degree of certainty, we can talk about its malfunction. You should not play Russian roulette, it is better to purchase a new device.

How to choose a boiler model?

If the water heater is equipped with a safety valve as standard, you must purchase the same model for replacement. However, sometimes situations arise when it is necessary to install the device on an old boiler model that is not equipped with such protection.

In such cases, it is customary to be guided by the color of the trigger handle:

In such cases, it is customary to be guided by the color of the trigger handle:

- red color - the model is designed for a limiting pressure of 0.6 MPa;

- black color - 0.7 MPa;

- blue color - 0.8 MPa.

The parameters of the boiler can be found in the instructions. Sometimes the limiting pressure is indicated on a special plate or paper sticker mounted on the body of the device.

It is necessary to choose a device in exact accordance with the upcoming load. If it is designed for less pressure, the water will constantly drain. If the valve rating is much higher than the working value, the device will not work when overloaded, creating a danger to the heater.

Why is the safety valve on the water heater so important?

To understand the importance of this safety device, you need to familiarize yourself with its design and principle of operation.

How a safety valve works

The device of the safety valve for the water heater is quite simple. Structurally, these are two cylinders with a common cavity, located perpendicular to each other.

- Inside the large cylinder there is a poppet valve, preloaded by a spring, which ensures the free flow of water in one direction.In fact, this is a familiar non-return valve. The cylinder ends at both ends with a threaded part for connecting the valve to the heater and pipe system.

- The second cylinder, placed perpendicularly, is smaller in diameter. It is muffled from the outside, and a drain (drainage) pipe is made on its body. A poppet valve is also placed inside it, but with the opposite direction of actuation.

Often this device is equipped with a handle (lever) that allows you to forcefully open the drainage hole.

How does the valve work

The principle of operation of the safety valve is simple.

The pressure of cold water in the water supply presses the “plate” of the check valve and ensures the filling of the heater tank.

Upon filling the tank, when the pressure inside it exceeds the external one, the valve will close, and as the water is consumed, it will again ensure its timely replenishment.

The spring of the second valve is more powerful, and is designed for increased pressure in the boiler tank, which necessarily increases as the water heats up.

If the pressure exceeds the maximum allowable value, the spring compresses, slightly opening the drainage hole, where excess water drains, thereby equalizing the pressure to normal.

Importance of proper valve operation

Perhaps the description of the device and the principle of operation of the valve did not bring complete clarity to the question of its extreme importance. Let's try to simulate situations where its absence can lead to

So, let's say there is no valve at the inlet to the heater that blocks the return flow of water supplied to the tank.

Even if the pressure in the plumbing system is stable, the device will not work correctly. Everything is explained simply - according to the laws of thermodynamics, when water is heated in a tank with a constant volume, pressure necessarily increases.

At a certain point, it will exceed the supply pressure, and the heated water will be discharged into the plumbing system.

Hot water can come from cold faucets or go into the toilet bowl.

The thermostat in this case continues to work properly, and the heating elements consume expensive energy for nothing.

The situation will become even more critical if, for one reason or another, the pressure in the water supply system suddenly drops, which is practiced quite often, for example, when the load at water stations is reduced at night.

Or if the pipes turn out to be empty as a result of an accident or repair work. The contents of the boiler tank are simply drained into the water supply, and the heating elements heat the air, which inevitably leads to their rapid burnout.

It may be objected that the automation should prevent idle operation of the heater. But, firstly, not all models provide such a function, and secondly, the automation may fail.

It would seem that in order to avoid such situations, you can limit yourself to installing a conventional check valve? Some “wise men” do this, not fully realizing that by doing so they are literally “planting a bomb” in their home.

It is scary to imagine what can happen if the thermostat fails.

Water reaches the boiling point in the tank, and since there is no exit from the closed volume, the pressure rises, and with increased pressure, the boiling point of water becomes much higher.

Well, if it ends with cracking of the enamel on the inside of the tank - this will be the least evil.

When the pressure drops (crack formation, open faucet, etc.), the boiling point of water drops again to the normal 100 degrees, but the temperature inside is much higher.

There is an instantaneous boiling of the entire volume of liquid with the formation of a huge amount of steam, and as a result - a powerful explosion.

All this will not happen if a serviceable valve is installed. So, let's summarize its direct purpose:

- Do not allow water to flow back from the heater tank into the plumbing system.

- Smooth out possible pressure surges in the water supply, including hydraulic shocks.

- Discard excess liquid when it is heated, thus keeping the pressure within safe limits.

- If the valve is equipped with a lever, it can be used to drain water from the water heater during maintenance.

How to install the valve

A relief safety valve is installed on the cold water supply line to the boiler in accordance with the recommendations:

- stop valves cannot be placed between the valve and the water heater, only an American to disconnect the pipe;

- it is necessary to run a hose from the safety valve to the nearest drain into the sewer;

- for convenient emptying of the tank between the valve and the water heater, you can mount a tee with a ball valve on the outlet. How to do it right is shown in the photo:

Usually there are no problems during installation, the operation is really simple. But further operation, when it constantly drips from the safety valve, raises many questions from users.It must be understood that the mode of operation, in which water periodically drips from the discharge fitting, is considered absolutely normal, for this a tube is required that drains it into the sewer.

It is not normal when the pipe flows all the time or never drips. The absence of drips may indicate a malfunction of the valve, so it is recommended to periodically forcibly bleed some water using the appropriate handle.

There can be two reasons why the safety valve constantly flows:

- product malfunction;

- too high pressure in the water supply network.

In the first case, installing a new valve will help. But changing it to a device with a higher response threshold will be a mistake, you will endanger the destruction of your electric heater or indirect heating boiler. There are 2 ways: ignore and pay for extra water consumption, or additionally install a lowering pressure regulator at the entrance to the house.

Installation

Self-installation of the device, as a rule, does not cause difficulties. Before proceeding with the installation, it is necessary to disconnect the water-heating equipment from the electrical network and drain all the water from the tank, and then carry out the installation, adhering to the following simple recommendations:

- the safety element is installed at the cold water inlet to the boiler;

- during installation, it is necessary to use a FUM sealing tape or traditional tow;

- the second side of the fuse is connected to the cold water supply system;

- in the presence of pressure drops in the water supply system, a reducer is installed in front of the valve.

Valve Installation Diagram

A flexible and transparent hose is used to connect the drainage pipe to the sewer system. It should be noted that sometimes a special safety valve is replaced by a demolition device designed to discharge liquid in emergency mode.

Despite the similarity of functions, the principle of operation of such devices is noticeably different, so you should not count on the correct operation of such a device.

It is forbidden to mount locking devices in the area from the entrance to the water heating equipment to the safety valve, and also to remove the protective element more than two meters from the boiler tank.

Conclusions and useful video on the topic

In order for the installation process of shut-off and safety valves to proceed smoothly, without errors and misunderstandings, before installing the valve and other devices, familiarize yourself with the experience of experienced boiler owners.

Once again about the design and principle of operation:

A few points to note:

Like any piping fitting, the safety valve is a necessary device for the correct operation of the water heater. It should not be confused with a non-return valve and should only be installed according to the instructions.

If you have any difficulties with the selection or installation, contact experienced professionals who will bring your boiler to full readiness within half an hour.

Do you want to understand the purpose of the safety valve and the intricacies of its installation? Do you have any questions after reading our article? Feel free to ask our experts for advice in the comments section.

If you specialize in the installation of boilers, their maintenance and repair, and notice an inaccuracy in our material or want to supplement what has been said with practical recommendations, please write your opinion under this article.