- Tips

- Types of security groups and the principle of choosing the appropriate model

- Lever models

- Models without lever

- Safety knots for large water heaters

- Models of the original performance

- Case marking difference

- Other types of valves

- Valve classification

- Valve device

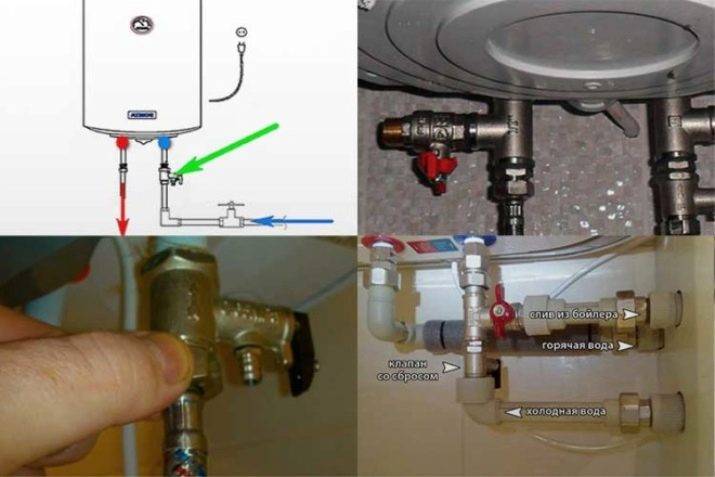

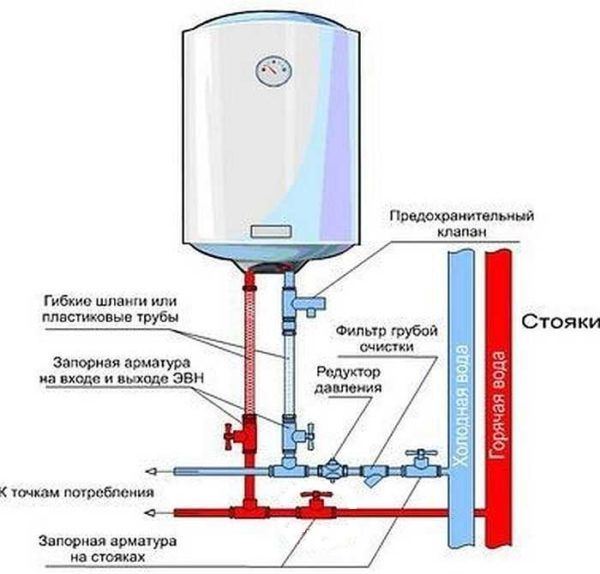

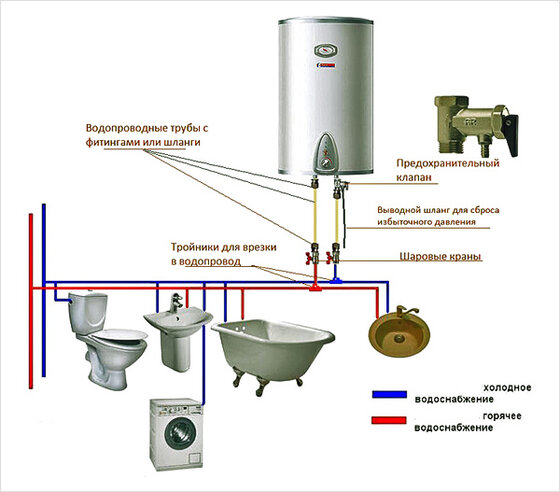

- Where to put the check valve

- On a well or in a well with a submersible pump

- with pumping station

- What threatens the absence of a safety valve

- Selection

- Gas storage water heaters

- Why is the safety valve on the water heater so important?

- How a safety valve works

- How does the valve work

- Valve device

- Common Check Valve Problems

- Purpose of valves

- Types of safety valves

- Selection of emergency fittings

Tips

Sometimes individual elements of the water heater or the entire system stops working properly. This reduces the safety of the structure and can lead to sad consequences. In this case, you need to find out the cause and place of the breakdown as soon as possible and either fix it yourself or call a specialist for this. Most often, thermostats, heating elements and safety valves fail. Moreover, a problem in the work of one of them can instantly affect the rest.You should never install elements that do not match the parameters of the boiler in their parameters or have different connection methods.

Problems cannot occur on their own, they have certain causes.

Most often they are as follows.

- Untimely replacement of damaged parts. For example, the check valve should be changed at least once a year. It's cheap and doesn't cost much.

- Incorrect installation of the entire system. If the fuse insert in the pipe is made with insufficient waterproofing or too far from the boiler inlet, the system will not work properly.

- Voltage fluctuations in the mains can lead to failure of the heating elements of the system.

- The presence of a factory marriage or lack of preventive examinations. In order to choose the right heater and fuses, you need to carefully study all the information when buying. And even the highest quality device needs to be checked periodically.

- Scale formation or corrosion. Scale and corrosion on the non-return valve can cause water to leak back into the pipeline or corrode various connections, violating their tightness.

The most basic malfunctions can be divided into several types. Most often, the broiler starts to flow. This can be either a manufacturing defect or a crack acquired due to corrosion. Such a tank cannot be repaired on its own, it will have to be completely replaced. Water dripping from pipe joints indicates a leak. From the safety valve, water, on the contrary, should sometimes drip. If it is always dry, then it should be replaced.

The second common malfunction most often is the lack of heating.This is almost always due to a malfunctioning heating device or thermostat. Sometimes the emergency cut-off works in this way when the boiler is constantly turned on to the maximum temperature.

Often, when the boiler is operating, the walls, the perimeter of the outlet and the surrounding space can heat up. The most dangerous in this case is the heating of the plug or socket. The reason may be poor contact or breakdown of the heating element. If the water heater does not run on electricity, but on a gas network, then the chimney may become clogged with ice, which will close the steam outlet. In this case, it is quite easy to clean it.

If the water heater does not provide enough warm water, you need to check whether the inlet and outlet pipes are mixed up. And if hot water enters the kitchen faucet with little or no pressure, while the mixer is working properly, you need to check the safety valve. It can become clogged with rust or dirt, after cleaning it, the water pressure will be restored.

A high-quality safety valve for boilers with a volume of not more than 200 liters, installed on a standard household heater, can last at least ten years. It is necessary to regularly clean it of sediment and check the performance of the entire system. Once every three to four years, it is advisable to dismantle it and wash it with special chemical solutions that can be purchased at hardware stores.

During installation, it is imperative to follow the above rules and conduct a quality check of the system with cold water under pressure. If you have any doubts about your own abilities, it is better to entrust such responsible work to professionals. After all, not only property, but also the health of all residents depends on quality work.

For why you need to install a safety valve for the water heater and what happens if you do not install it, see the following video.

Types of security groups and the principle of choosing the appropriate model

The standard safety valve for a boiler may differ in several design features. These nuances do not change the functionality of the device, but only simplify the use and maintenance. To choose the right safety unit, you need to know what kind of safety valves for boilers are and how they differ.

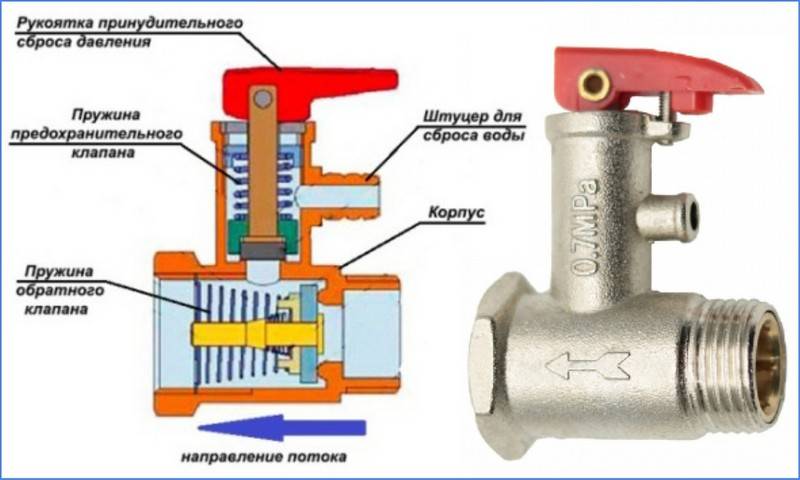

Lever models

The most common type of standard safety knot is the lever model. Such a mechanism can be activated manually, which is convenient when checking or draining water from the boiler tank. They do it like this:

- horizontally located lever is installed vertically;

- direct connection to the stem actuates the spring mechanism;

- the plate of the safety valve forcibly opens the hole and water begins to flow from the fitting.

Even if complete emptying of the tank is not required, a control drain is performed monthly to check the operation of the safety assembly.

Products differ in the design of the lever and the fitting for discharging water. If possible, it is better to choose a model with a flag fixed to the body. The fastening is made with a bolt that prevents manual opening of the lever by children. The product has a convenient herringbone shape with three threads, which ensures a secure fit of the hose.

The cheaper model does not have a flag lock. The lever can be accidentally caught by hand and unnecessary draining of water will begin. The fitting is short, with only one threaded ring.Fixing the hose to such a ledge is inconvenient and can be torn off with strong pressure.

Models without lever

Relief valves without a lever are the cheapest and most inconvenient option. Such models often come with a water heater. Experienced plumbers simply throw them away. The nodes work similarly to lever models, only there is no way to manually perform a control drain or empty the boiler tank.

Models without a lever come in two versions: with a cover at the end of the body and deaf. The first option is more convenient. When clogged, the cover can be unscrewed to clean the mechanism. A deaf model cannot be checked for performance and descaled. The liquid discharge fittings for both valves are short with one threaded ring.

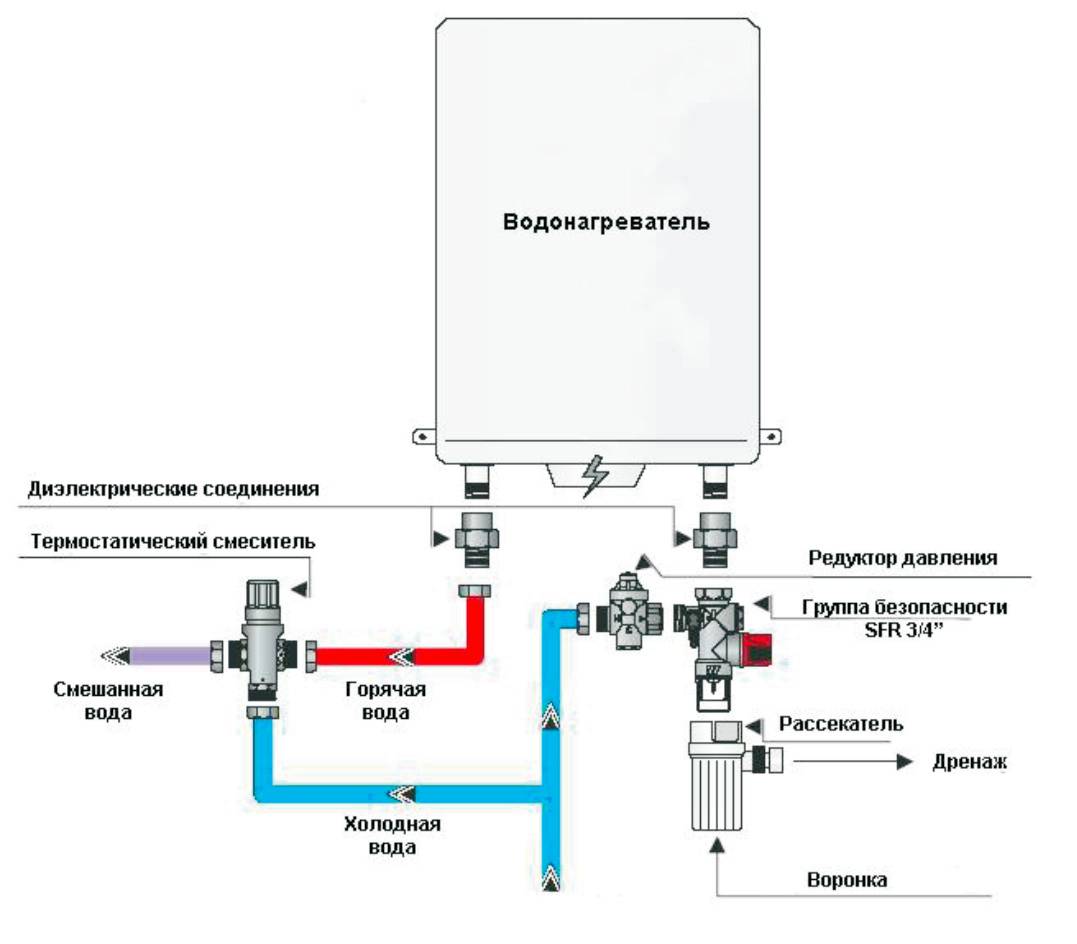

Safety knots for large water heaters

Improved safety valves are installed on water heaters with a storage tank capacity of 100 liters or more. They work in a similar way, only they are additionally equipped with a ball valve for forced draining, as well as a pressure gauge.

Particular attention should be paid to the fluid outlet fitting. He's carved. Reliable fastening prevents the hose from being torn off by strong pressure and eliminates the inconvenient use of the clamp

Reliable fastening prevents the hose from being torn off by strong pressure and eliminates the inconvenient use of the clamp.

Models of the original performance

For lovers of aesthetics and comfort, manufacturers offer safety nodes in the original design. The product is completed with a pressure gauge, chrome-plated, gives an elegant shape. Products look beautiful, but their cost is high.

Case marking difference

Quality products on the case must be marked.The manufacturer indicates the maximum allowable pressure, as well as the direction of water movement. The second marking is an arrow. It helps to determine which side to put the part on the boiler pipe.

On cheap Chinese models, markings are often missing. You can figure out the direction of the liquid without an arrow. The check valve plate must open upwards in relation to the boiler nozzle so that water from the water supply enters the tank. But it will not be possible to determine the permissible pressure without marking. If the indicator does not match, the safety unit will constantly leak or, in general, will not work in an emergency.

Other types of valves

When they try to save money on the security group, they try to install a blast valve designed for the heating system on the water heater. The nodes are similar in functionality, but there is one caveat. The blast valve is not able to gradually release the liquid. The mechanism will work when the excess pressure reaches a critical point. The blast valve can only bleed all the water from the tank in case of an accident.

Separately, it is worth considering the installation of only a check valve. The mechanism of this node, on the contrary, locks the water inside the tank, preventing it from draining into the pipeline. With excess pressure, the working plate with the rod is not able to work in the opposite direction, which will lead to a rupture of the tank.

Valve classification

Immediately make a reservation that the safety valve for the boiler is able to function both in everyday and in emergency conditions. Below are its main varieties.

- The non-return locking device is closed using a special device, which can be manual or mechanical.

- The inlet valve is mounted at the end of the vertical section of the water pipe in front of the circulation pump. It is equipped with a mesh that protects the pump from impurities in the water.

- At the steel device, the spool is located perpendicularly (relative to the water supply).

- The shutter of the spherical device has the form of a spherical element, which is pressed by a spring. Such devices are used in highways of small diameter, mainly plumbing.

According to the principle of operation, valves can be:

- direct type;

- indirect;

- for two positions

- proportional.

But according to the height of raising the constipation, the devices can be:

- full-lift;

- medium-lift;

- low-lift.

In the first case, the height is a quarter of the saddle diameter, the scope of such devices is gas and liquid media. For medium lifts, this figure is 0.05-0.25 diameters, the application is a liquid medium, without the need for increased throughput. For low-lift cranes, this height is only 0.05 of the diameter.

According to the degree of load on the spool, the devices are divided into two more categories.

- Lever-cargo - they use an electromagnetic drive.

- Magnetic-spring - in them, the force of the load, transmitted by means of a special lever, acts on the spool.

Criteria for choosing water heaters

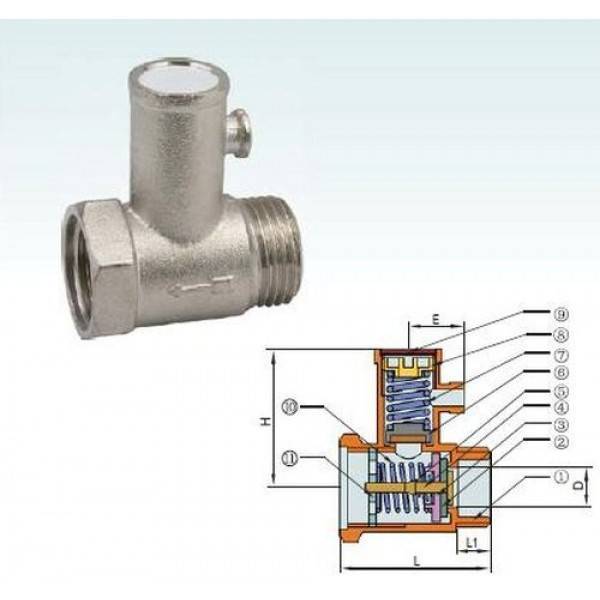

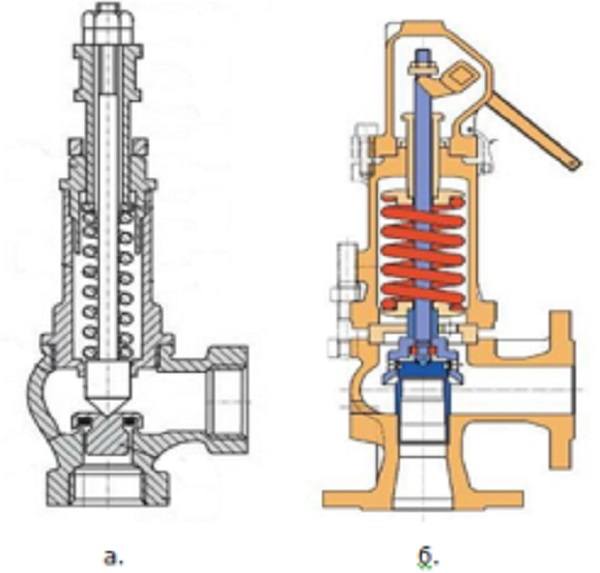

Valve device

From a structural point of view, this device is extremely simple. It consists of a pair of cylinders having a common cavity and located perpendicular to each other.

- The larger cylinder has a so-called poppet valve inside (it is pressed by a spring), thanks to which water moves freely in one direction. Simply put, this is a well-known non-return valve. At each end of the cylinder there is a threaded part, with which the device is connected to the pipeline and the boiler.

- The small cylinder is perpendicular. From the outside, both sides are closed with plugs, and the body is equipped with a drain pipe. It is characteristic that this cylinder is also equipped with a check valve, but the direction of its operation is opposite.

Important information! Quite often, the valve is equipped with a lever - through its drainage can be opened forcibly.

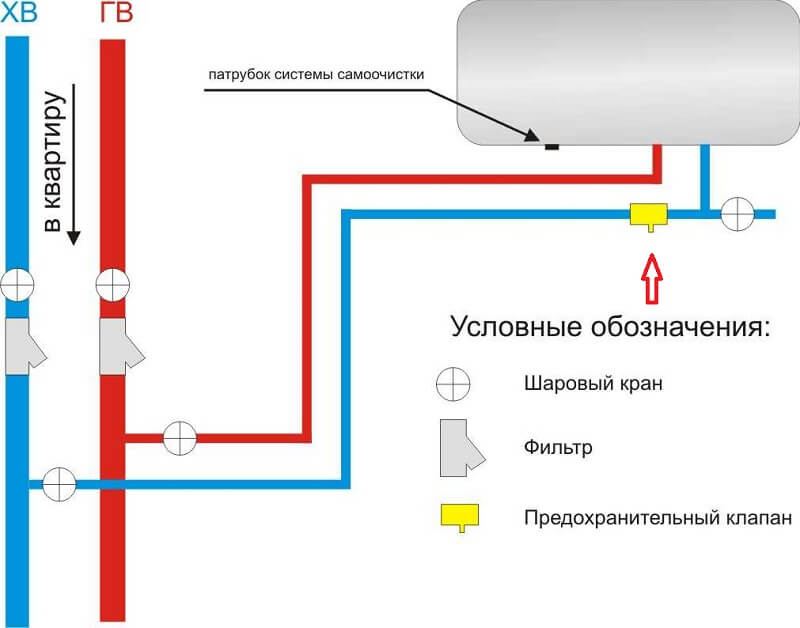

Where to put the check valve

To begin with, a few words about how the check valve for water is indicated on the diagrams. There is a special icon for it. These are two triangles with their vertices facing each other. One of the triangles is shaded, one is not. The direction of movement of the working medium is indicated by an arrow. In the opposite direction, the flow is closed.

Graphic designation of the check valve in the diagrams

In general, there is no clear indication of where exactly the check valve should be placed.

It is important that it performs its functions, and the place of its installation is a secondary matter. It is necessary that the water supply or heating system works correctly

And its specific place is determined by the parameters of the system and by ease of maintenance. The exception is the water supply in the apartment. Here they will clearly tell you, we put the check valve in front of the counter and nothing else.

Where to put a check valve on the water when entering it into the apartment - after the meter

For example, in the piping of the boiler on the supply pipe, there must be a check (shut-off) valve.It prevents hot water from entering the system, which can occur when the water heats up and thereby creates increased pressure, which can "transfer" the plumbing. In this case, it is better to place the return valve closer to the source of hot water so as not to expose other piping elements and cold water pipes, which are far from always made of metal today.

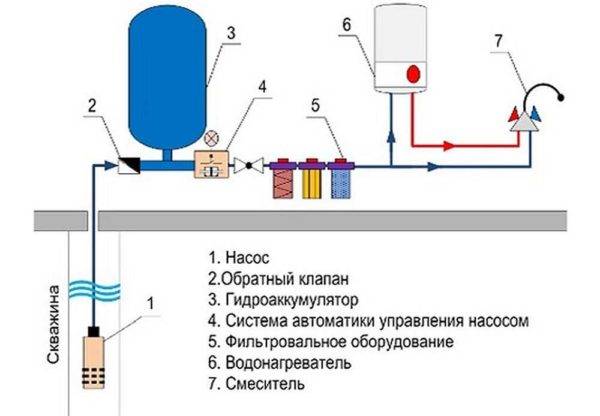

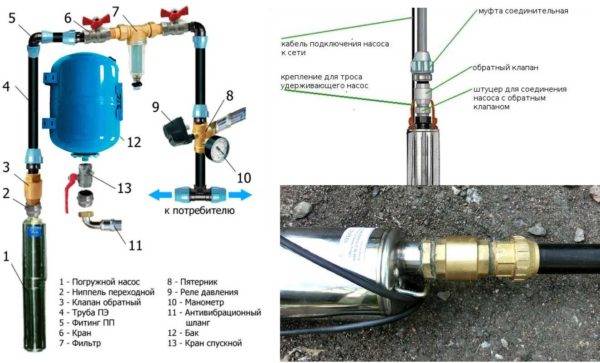

On a well or in a well with a submersible pump

If you look for information on where to put a check valve on a submersible pump, the information may be contradictory. Some advise putting it right at the pump outlet, others - at the entrance to the house or in the pit, if we are talking about a well. Oddly enough, all three options work. Just for different occasions.

The installation location of the check valve in the water supply system is selected depending on the parameters of the system and equipment

It is possible to put a check valve in the house or in the pit above the well if the vertical section of the pipeline does not exceed 7 meters. The length of the horizontal section (if it is without slope) does not play a role. With such a length of the pipeline, water will not flow back into the well or well.

Installation location of the check valve in a water supply system with a submersible pump

If the water surface is below seven meters (the pump draws water from a depth of more than 7 meters), we put a check valve after the pump. You can immediately (as in the photo above), or you can put a filter, then a check valve. It is permissible to install the valve a couple of meters above the water level. It no longer plays a big role. But this method of installation - at a depth - is inconvenient for maintenance. Sooner or later, the valve will either have to be cleaned or replaced.If it is in a well or in a well, everything must be taken out to the surface. The replacement itself takes a matter of minutes. It takes about five minutes to unscrew the thread, remove the old one, check / clean or put in a new one. But all the preparatory work is hard, wet and unpleasant. So, if possible, we transfer the check valve to the house or pit.

with pumping station

As already mentioned, some models of pumping stations have a check valve. Should I put a second one on the suction pipe? Again, if the water rises less than 7 meters, you can do without it or put it at the entrance to the house.

For a pumping station, a non-return valve with a filter is better

If the vertical rise is greater, it should be set at the entrance. What for? And because when the pump is turned off, the water will flow back. And when turned on, it will pump air, and only then water. And let's say right away that not all stations normally tolerate such a regime. Therefore, if you hear that the water returns to the well or well after the pump is turned off, it is better to redo the system.

Check valve with filter for installation with a pumping station

As you can see, in this scheme, a check valve is installed at the end of the pipe. Since it is sensitive to pollution, it is better to clean the water first. You can wind standard filters, or you can put it with a built-in mesh. Which option is better? Probably the first one anyway. First, you can collect as many filters as you need in series to supply relatively purified water. Secondly, it is cheaper to change one filter or one valve than a filter with a valve. There is more fuss during installation, but not critical.

What threatens the absence of a safety valve

So, if there is no element that closes the return flow of moisture into the tank, then the boiler will no longer work normally even if there is a stable pressure. As the temperature rises, the pressure of the water begins to increase, and as a result, sooner or later it will exceed the pressure of its supply. Therefore, hot water will begin to be discharged into the plumbing or toilet tank, then cold water will flow into the water heater, and heating will continue to go on, while electricity will be wasted.

Also, in the absence of a valve, the water pressure of the water supply can drop sharply, this often happens at night when cold water is turned off during repairs. Thus, draining water from the water heater can cause the heating element to burn out.

It is worth saying that installing a check valve is a huge mistake in this situation, because the water heater can break or fail at any time. And if the material from which it is made is not too strong, then when the water tap is opened normally, the pressure of the tank will drop, the boiling point of water will be set at one hundred degrees, and this will provoke a flow of steam, which can lead not only to damage to the water heater tank, but and the big bang.

Therefore, if you are going to install a relief valve, consider the following:

- when dumping residual water during heating, the parameters of the zone of its normal pressure should be maintained;

- try to prevent the backflow of liquid from the boiler;

- be sure to smooth out water hammer, as well as pressure surges in the water supply.

Selection

Safety valve for boiler

The main rule that should be observed when choosing this device is the correspondence between the operating pressure of the mechanism and the characteristics of the heater. This parameter is indicated on the case or in the accompanying documents. Models that set the limits of action is better not to buy.

Pay attention to the presence of a forced liquid discharge lever. Inspect the threaded connections, and make sure that they are of good quality and that there are no thread defects

The drain fitting must be placed so that it is convenient to put a hose on it.

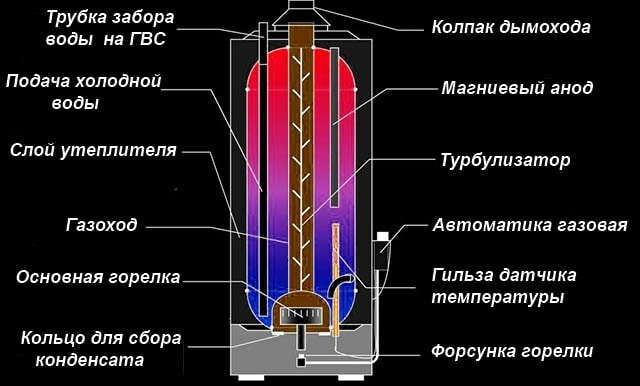

Gas storage water heaters

Externally, the unit resembles a vertical version of an electric storage device - a cylindrical body, pipe fittings and a thermometer on the front side. Only a chimney pipe appeared on top, and an additional section with gas equipment appeared below.

The internal structure of a boiler using natural or liquefied gas has significant differences:

- in the lower additional section there is an open (atmospheric) combustion chamber and a gas burner;

- the tank is pierced by a vertical flame tube, which discharges combustion products to the outside through an external pipe with a cap;

- a draft sensor and a turbulator are placed inside the chimney, forcing hot gases to move more slowly and actively exchange heat with the water reservoir;

- below the burner there is a condensate collection tank;

- fuel supply is controlled by safety automation - a non-volatile gas valve from SIT Group or another manufacturer;

- the tank has an immersion sleeve for the thermostat sensor connected by a capillary tube to a safety valve.

The pipes of cold and hot water in the drawing fell into the same plane, so they overlap each other.

The principle of operation of this type of boilers is the double heating of the tank with water - directly from the burner and the heat of the flue gases.

How does a gas-fired water heater work?

- After opening the valve, the gas enters the igniter, where it is manually ignited by a spark from a piezoelectric button. When the user sets the desired temperature by turning the knob, the main burner is switched on.

- The mass of water is heated from the combustion chamber and the chimney, the resulting condensate flows into a special container and gradually evaporates.

- Upon reaching the set temperature, the thermostat is activated, the automation turns off the main burner.

- When cooling or drawing water, combustion automatically resumes.

Boiler gas burners are round in shape and look like stove burners.

The rest of the design of the boiler is similar to electric appliances. The cold water pipe is at the bottom, the hot water intake is at the top, the magnesium anode protects the metal from corrosion. In the floor version, the connecting pipes come out of the top cover of the tank.

Why is the safety valve on the water heater so important?

To understand the importance of this safety device, you need to familiarize yourself with its design and principle of operation.

How a safety valve works

The device of the safety valve for the water heater is quite simple. Structurally, these are two cylinders with a common cavity, located perpendicular to each other.

- Inside the large cylinder there is a poppet valve, preloaded by a spring, which ensures the free flow of water in one direction. In fact, this is a familiar non-return valve.The cylinder ends at both ends with a threaded part for connecting the valve to the heater and pipe system.

- The second cylinder, placed perpendicularly, is smaller in diameter. It is muffled from the outside, and a drain (drainage) pipe is made on its body. A poppet valve is also placed inside it, but with the opposite direction of actuation.

Often this device is equipped with a handle (lever) that allows you to forcefully open the drainage hole.

How does the valve work

The principle of operation of the safety valve is simple.

The pressure of cold water in the water supply presses the “plate” of the check valve and ensures the filling of the heater tank.

Upon filling the tank, when the pressure inside it exceeds the external one, the valve will close, and as the water is consumed, it will again ensure its timely replenishment.

The spring of the second valve is more powerful, and is designed for increased pressure in the boiler tank, which necessarily increases as the water heats up.

If the pressure exceeds the maximum allowable value, the spring compresses, slightly opening the drainage hole, where excess water drains, thereby equalizing the pressure to normal.

Importance of proper valve operation

Perhaps the description of the device and the principle of operation of the valve did not bring complete clarity to the question of its extreme importance. Let's try to simulate situations where its absence can lead to

So, let's say there is no valve at the inlet to the heater that blocks the return flow of water supplied to the tank.

Even if the pressure in the plumbing system is stable, the device will not work correctly.Everything is explained simply - according to the laws of thermodynamics, when water is heated in a tank with a constant volume, pressure necessarily increases.

At a certain point, it will exceed the supply pressure, and the heated water will be discharged into the plumbing system.

Hot water can come from cold faucets or go into the toilet bowl.

The thermostat in this case continues to work properly, and the heating elements consume expensive energy for nothing.

The situation will become even more critical if, for one reason or another, the pressure in the water supply system suddenly drops, which is practiced quite often, for example, when the load at water stations is reduced at night.

Or if the pipes turn out to be empty as a result of an accident or repair work. The contents of the boiler tank are simply drained into the water supply, and the heating elements heat the air, which inevitably leads to their rapid burnout.

It may be objected that the automation should prevent idle operation of the heater. But, firstly, not all models provide such a function, and secondly, the automation may fail.

It would seem that in order to avoid such situations, you can limit yourself to installing a conventional check valve? Some “wise men” do this, not fully realizing that by doing so they are literally “planting a bomb” in their home.

It is scary to imagine what can happen if the thermostat fails.

Water reaches the boiling point in the tank, and since there is no exit from the closed volume, the pressure rises, and with increased pressure, the boiling point of water becomes much higher.

Well, if it ends with cracking of the enamel on the inside of the tank - this will be the least evil.

When the pressure drops (crack formation, open faucet, etc.), the boiling point of water drops again to the normal 100 degrees, but the temperature inside is much higher.

There is an instantaneous boiling of the entire volume of liquid with the formation of a huge amount of steam, and as a result - a powerful explosion.

All this will not happen if a serviceable valve is installed. So, let's summarize its direct purpose:

- Do not allow water to flow back from the heater tank into the plumbing system.

- Smooth out possible pressure surges in the water supply, including hydraulic shocks.

- Discard excess liquid when it is heated, thus keeping the pressure within safe limits.

- If the valve is equipped with a lever, it can be used to drain water from the water heater during maintenance.

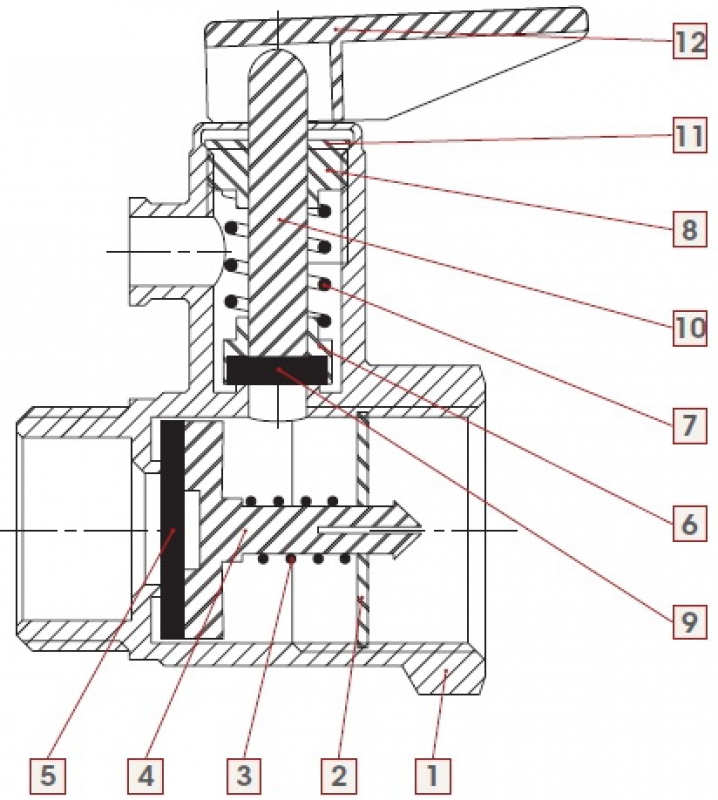

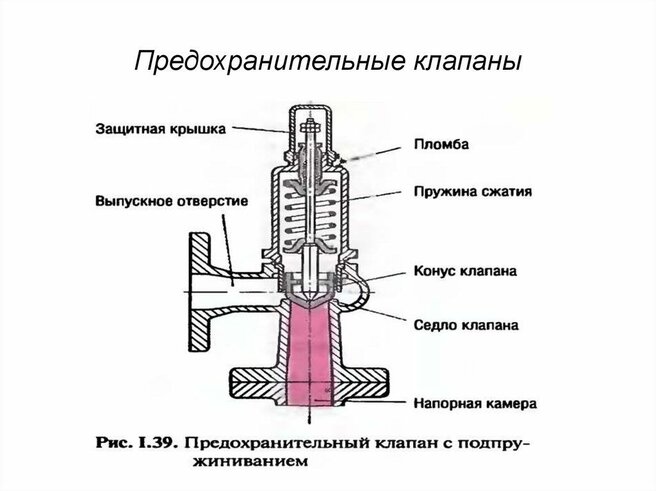

Valve device

The structural elements of valves for protection against excessive pressure are the following main elements:

- frame

- lid

- cap

- gate

- rod and spring on it

- device for opening a valve under "forced"

A so-called “saddle” is mounted on the thread in the body. A gold plate is installed on it. It is fixed on the valve axis with a guide sleeve. The saddle together with the spool form a valve. A rod is inserted into the spool. It presses the spool to the seat due to the force of the spring. The degree of compression of the spring is adjusted by a pressure screw with a lock nut.

The cap contains a device for forced opening of the valve. It consists of a lever, which is fixed on an axle with a fork. For complete and quick opening of the valve, a special clamping ring is provided. It is secured with a set screw.

A forced opening device is necessary to carry out a check of the equipment's performance from time to time. Parts of equipment intended for use in liquids and gases are coated with a special anti-corrosion compound.

Safety valves are subject to mandatory revision and testing in specialized laboratories. Or directly at the place of use (in cases where it is impossible to send the device for examination to the laboratory). The operability of the equipment, the integrity of the parts, the quality of the seals are checked. The term of the audit is set by the organization with the appropriate authority. The audit is carried out according to the schedule. But at least once a year. This is necessary in the first place so that your heating system can function normally.

Common Check Valve Problems

If you notice even the slightest sign that the check valve is not working or is working, but not correctly, then you should immediately look for the cause of the breakdown. Get it repaired or replaced right away, which is even better. The fact is that the cost of such a valve is much lower than the cost of the water heater as a whole, so such a move would be more than appropriate. The causes of failure can be different, let's look at the most common of them.

- The valve stops flowing water. The reason for this is often its clogging with scale or dirt. In this case, you should dismantle the device, clean it, and install it back. It is advisable to install a filter on the supply pipe so that this does not happen in the future.

If water starts to drip from the valve after the water in the boiler begins to heat up, then there is nothing to worry about.This is due to the direct duty of the valve - when the pressure rises, it begins to dump excess fluid and the latter, in turn, begins to drip. To fix this, connect a hose to the drain hole of the device so that the other end is submerged in water.

The valve can also leak when cold water flows through it. This is often due to high pressure in the pipeline (which occurs due to its poor condition). In this case, you should check whether the valve is working - for this you need to install a 100% working model instead. If the device is working, and the pressure in the tank is still more than three atmospheres, then the only thing that can be done is to additionally install a reducer that would reduce the pressure inside the plumbing system. There are a great many such gearboxes, so when choosing a particular model, consult a specialist first. Another way out is the installation of an expansion tank.

Water may also drip from under the lower valve cover. In this case, you should remove the cover and determine where it is leaking from. To do this, under the cover there is a small hatch leading inside the boiler. There is a special sealing gasket, and if it flows from this hatch, then most likely the gasket needs to be replaced. But it can also be a factory defect - that is, the hatch was incorrectly centered. Often this can be fixed, but if it flows, as they say, from all the cracks, then this is a clear sign that the boiler itself needs to be changed.

Video review of various models

Purpose of valves

Valves are an important element in the heating and water supply system, they perform the following functions:

- control of cold water entering the tank;

- lowering the pressure level in the vessel in the case of a huge pressure of water and when heated;

- in case of repair, it allows you to drain the liquid from the tank;

- prevents liquid from flowing out of the container into the pipeline if there is no water in it.

the pressure rises.

In the absence of a safety valve, the container may simply explode and shatter into pieces, since the excess water simply had nowhere to go. A tube is attached to the outlet valve, which drains water into the sewer system.

In the event of high pressure in the water supply, it is equalized with a valve that removes excess water.

Types of safety valves

These security elements are classified in different ways.

| Principle of operation | Shutter height | Shutter opening method | Spool loading method | |

| 1 | direct action | low-lift | proportional | Spring |

| 2 | Indirect action | Full lift | two stage | Lever-gas |

| 3 | Pulse |

Spring - the most common, used for small boiler rooms. They have a simple and reliable design and the ability to easily adjust the working pressure in the system. Also, low cost can be distinguished from the advantages. Lever safety devices are not very popular, because, basically, the model range is represented by diameters from 50 mm. They are used in the industrial sector. Pulse devices are used on steam boilers with a pressure of more than 39 kgf / sq. cm (3.9 MPa). At least 2 pieces are installed on each boiler. (control and work).Among the advantages can be distinguished: simple design, affordable price.

Low lift and full lift

Low lift and full lift

In full-lift valves, the bolt rises to a height of at least 25% of the seat diameter. They are referred to as two-stage. They are characterized by high throughput, high cost and complex design.

Full-lift safety devices have a bell. Its job is to help the bolt reach full lift. Full-lift are used mainly in those systems in which the medium is compressed.

Proportional valves open the gate in proportion to the increase in pressure and the volume of the discharged medium increases proportionally with the rise of the gate. These protective devices are used for water and other liquid media.

The advantages of using a proportional valve include:

- shutter opening according to need;

- lightweight construction;

- low cost;

- fluctuations automatically occur.

The disadvantage of two-stage devices is the self-oscillation of the shutter. The reason for this is oversizing or variable emergency medium flow.

Selection of emergency fittings

When designing a water supply, heating system or process plant, it is necessary to clearly define the pressure limits allowed for its components or network sections. This takes into account parameters such as:

- performance of the boiler or main pump;

- volume and operating temperature of the working medium;

- features of its circulation.

Based on this, the type, cross-section, throughput, threshold value of operation, response speed and return time to the initial state, as well as the number and installation locations of safety valves are determined.

In domestic heating systems, spring valves are most often used. For liquid media, it is sufficient to use low or medium lift devices. The throughput should provide a quick pressure drop to acceptable values.

The design of the housing is determined by the place where the excess amount of the working medium is discharged. If it will be discharged directly into the environment, an open type valve is sufficient. If the discharge must take place in the drain, a body with an outlet pipe of the appropriate type of connection will be required. Most often use threaded or nipple.

In no case should you purchase a valve with an overestimated relative to the calculated response threshold. Such a device will not open at the right time. This can lead to equipment damage or even a complete system crash.

Safety valves, indirect acting

Characteristic of the valve of indirect action

Safety valves are usually installed in parallel in the pressure line. If pressure is reached relief valve setting opens and passes the flow (or part of the flow) from the pressure line to the drain.