- What does simple mean?

- Necessary materials

- How to make a rough oven with your own hands

- How to determine the optimal location of the furnace

- Additional material selection tips

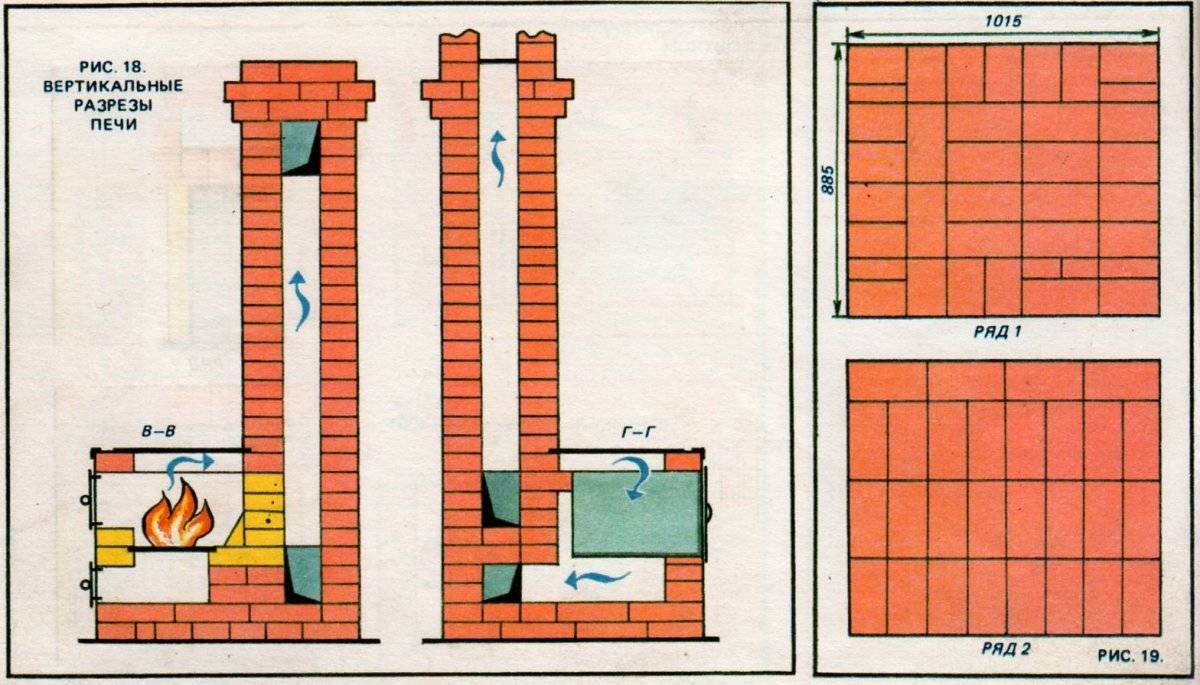

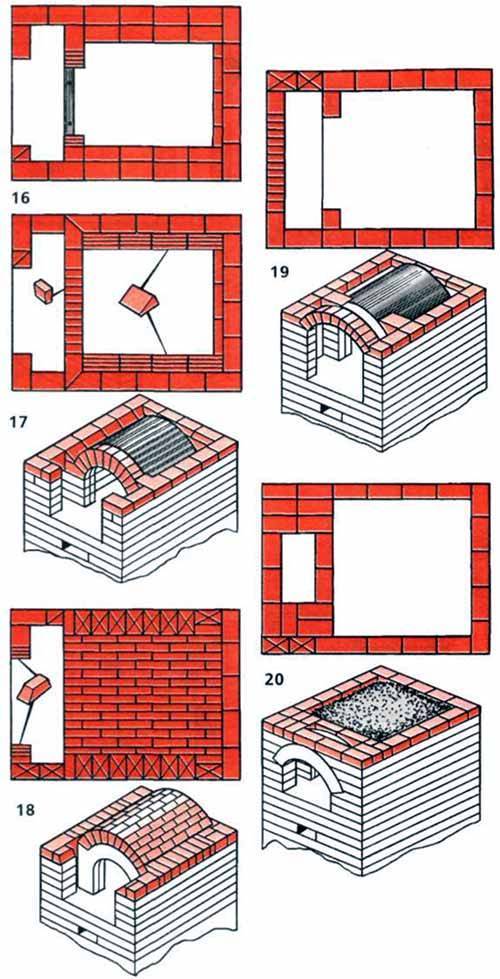

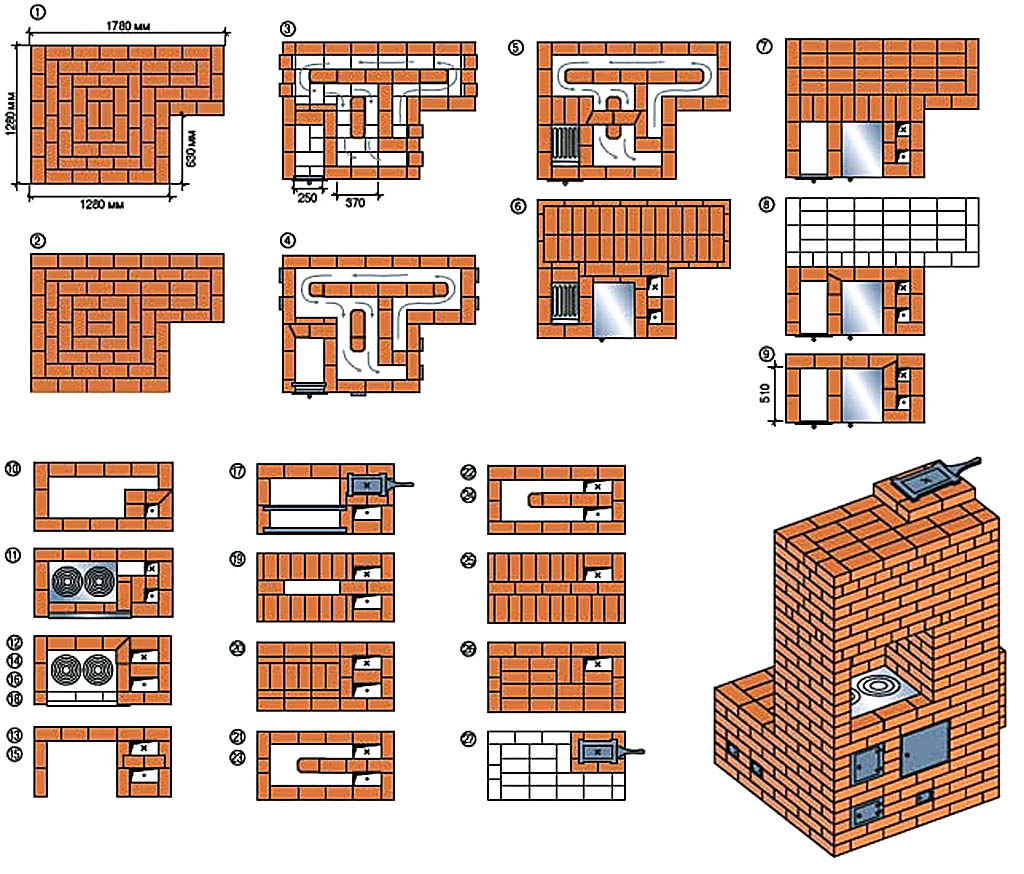

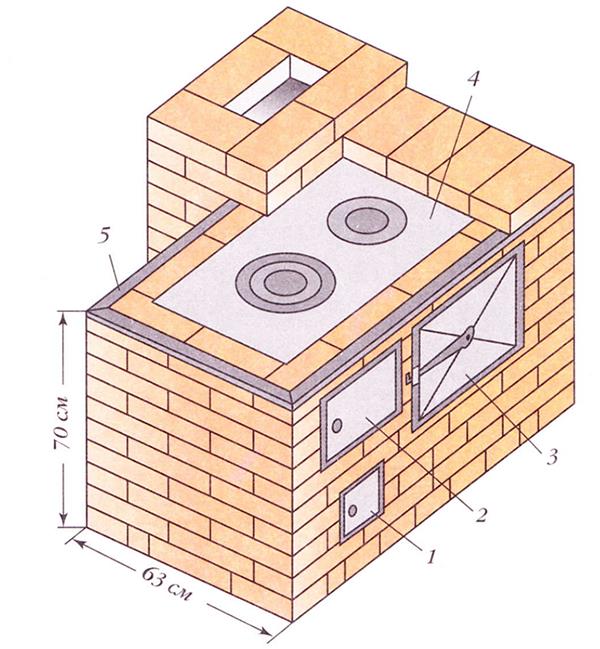

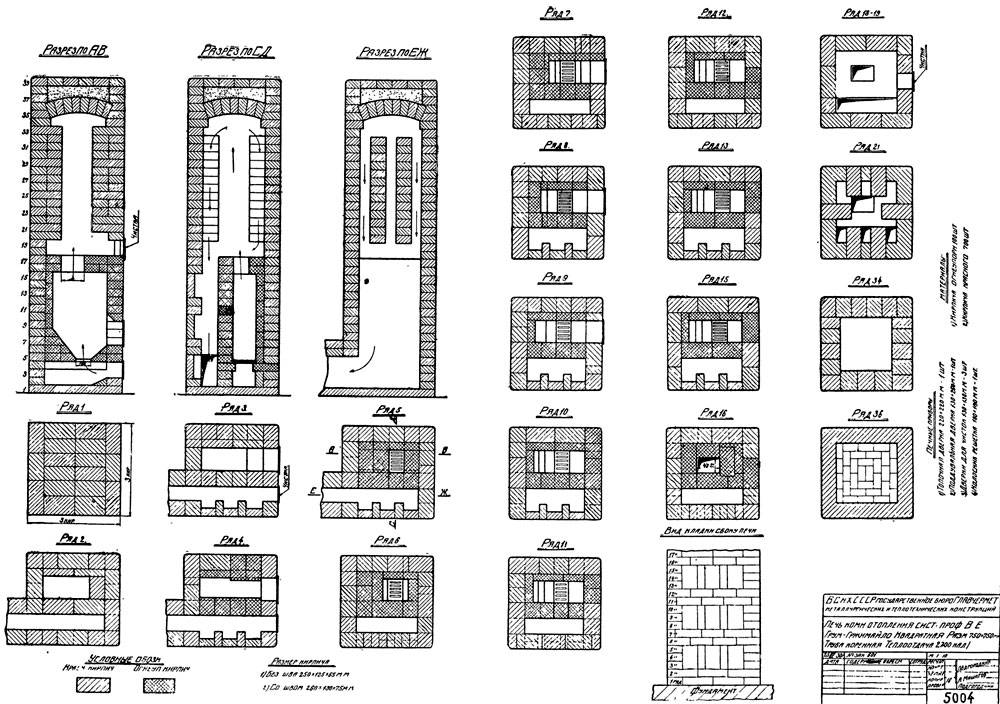

- Scheme of the simplest brick oven for summer cottages and houses

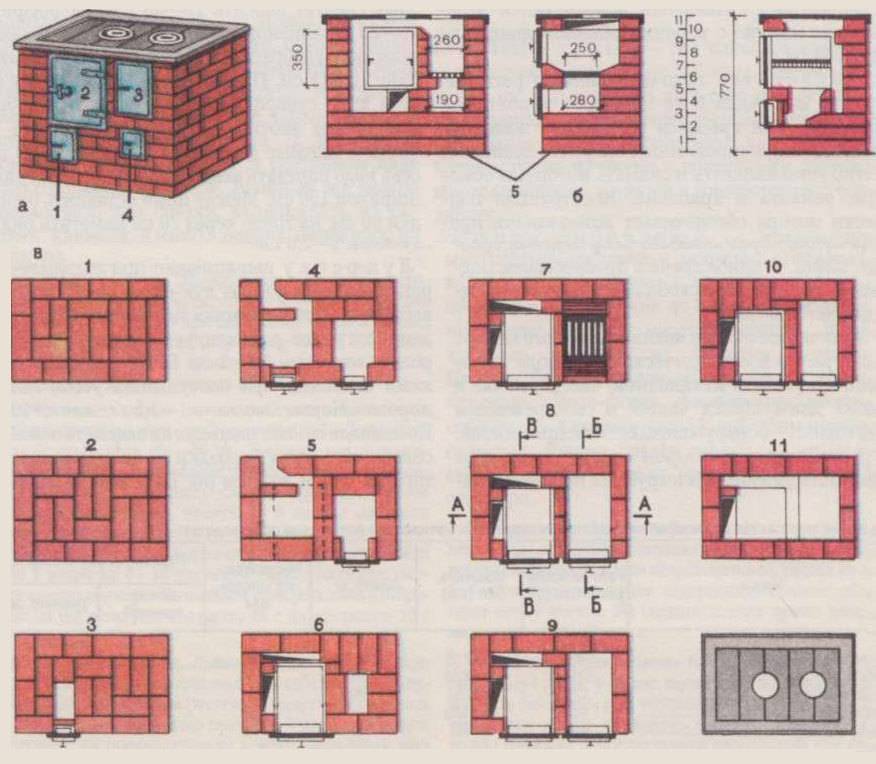

- Stove with hob

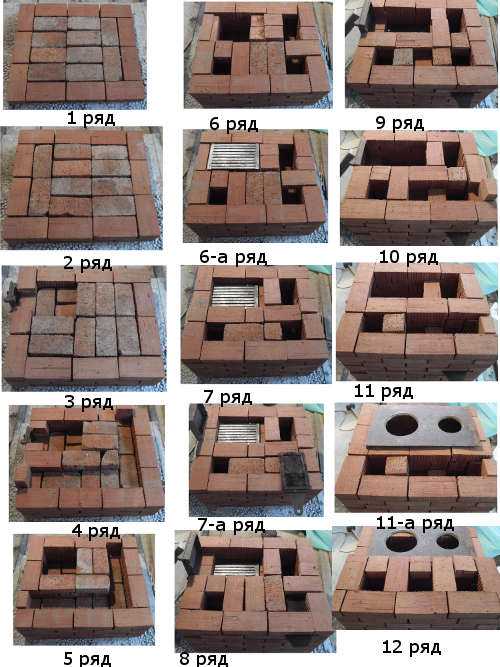

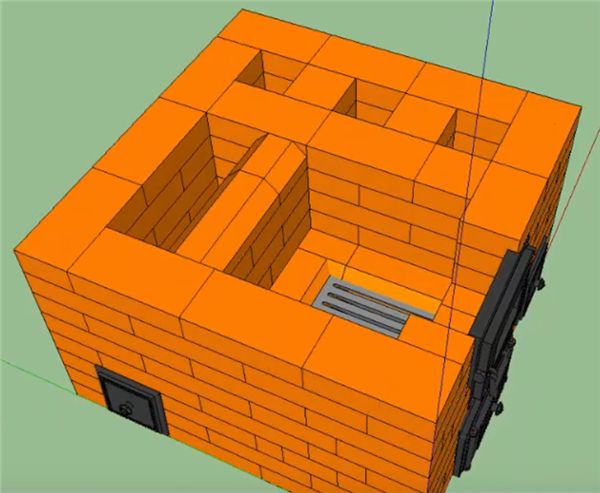

- Laying process step by step

- Foundation fixing

- The erection of the ashpit and the body

- Firebox design

- Fixing the chimney

- Varieties of brick ovens

- dutch stove

- Sauna brick stoves on wood

- Russian oven

- Heating and cooking stove

- What are the ovens

- Construction of the furnace foundation

- Advantages and disadvantages of a brick oven in the house

- The use of brick ovens

- masonry process

What does simple mean?

Further, it is understood that a simple oven, which can be quickly made with one's own hands, should satisfy the trace. requirements:

- A person constructing such a furnace does not have to be deeply versed in the furnace business. Ideally, he does not need to understand anything about it at all;

- The furnace must operate on low-quality waste fuel with a thermal efficiency (this is an analogue of the efficiency of thermal engines) of at least 35-40%;

- A brick oven should not require long-term drying after construction and “accelerating” furnaces to bring it to its rated thermal power;

- It should also consist of no more than 115-120 bricks, so that all the necessary materials can be brought at a time in the trunk of a car or on a trailer to it;

- Furnace fittings (doors, hobs, burners) should be the most common (so that you can use used ones) and / or cheap;

- The laying of a brick oven should not contain complex joints, sawn (cut by a grinder) bricks, transitions from red brick to fireclay and steel mortgages.

Necessary materials

Before you fold the stove for your home yourself, you need to prepare the necessary materials and tools for this.

The following materials will be required:

- Building bricks. They are needed in two varieties - burnt full-bodied and fireclay refractory. The raw material for the first variety, intended for the construction of the outer part of the body and the chimney, is red clay. Inside, the firebox and the chimney channel are lined with fireclay bricks: it has a lighter shade and can withstand heating up to +1200 degrees.

- Concrete solution for the foundation. It is prepared independently from cement (grade M400 or M500), sifted sand (quarry or river), crushed granite (fraction size 25-35 mm) and cold clean water. The pillow under the foundation is covered with granite rubble stone 150-250 mm in size.

- Clay-sand mortar for masonry. It consists of red clay without impurities, sifted sand (river or quarry) and pure water. Clay can be dug up in a nearby ravine or bought at a hardware store in powder form.

- Metal furnace elements. We are talking about a cast-iron grate, metal cleaning doors, cast-iron blower doors, cast-iron firebox doors, a chimney damper, a steel reinforcing mesh for the foundation, a cast-iron hob with round burners.

- Mineral wool in slabs 20-50 mm thick.

- Asbestos sheets (8-10 mm).

- Asbestos cord (3-10 mm).

- Reinforcing bars made of steel (8-12 mm).

- Roofing material (it can be replaced with polyethylene construction film).

How to make a rough oven with your own hands

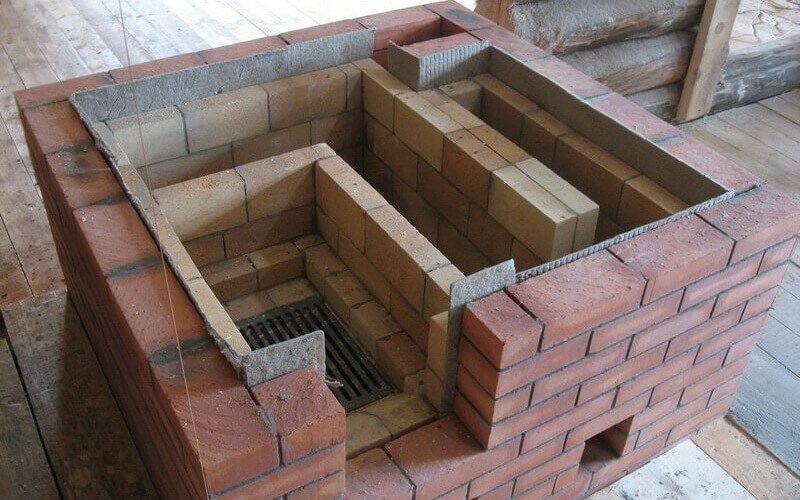

The oven consists of the following parts:

- A firebox is a working chamber into which fuel is loaded. Equipped with a door.

- Blower - a chamber attached below the firebox. Serves to improve traction. A door is also attached here to regulate the air supply. A grate is installed between the firebox and the blower.

- A chimney is a pipe that removes carbon dioxide from a home. Equipped with a soot cleaning door and damper.

- Smoke circulation (convector) - vertical (sometimes horizontal) channels through which hot gases from the firebox pass. They connect the firebox to the chimney and accumulate thermal energy.

How to determine the optimal location of the furnace

It is necessary to determine the place in the house for the furnace according to certain parameters. The following indicators are taken into account:

- area of a residential building;

- how many rooms should be heated;

- what is the oven for and what kind;

- how will the gases be removed during combustion;

- the location of the furnace must comply with fire safety requirements.

The stove should heat every room in the house as evenly as possible. If this condition is not met, either an additional furnace or water heating system equipment will be required.

In order to heat the rooms adjacent to the kitchen, a heating and cooking stove is used. It is placed in the kitchen, and the rest of the rooms are heated by a heat-releasing wall.

At building a house from stone, you can immediately think over the layout of the chimneys in the walls, which will increase the usable area of \u200b\u200bthe house and ensure optimal heating.

When placing the stove on the border of the rooms, it is necessary to think over the place of its most successful placement so that the surfaces that transfer heat from the stove allow for a uniform and maximum distribution of heat.

Options for the location of the furnace in the house

Typically, a hallway or kitchen serves as a place to place the firebox. If the stove is well planned, it is almost invisible in the house. It does not clutter up the living space and is in perfect harmony with all interior elements. For example, a combination is often used. In one room there is one side of the building - a stove, and in the adjacent room, its second part - a fireplace. General chimney system.

Additional material selection tips

Brick Comparison Chart

You should buy brown clay materials for kiln masonry. They successfully withstand sudden changes in temperature, and if the stove has not been used for a long time, the masonry will not crack.

You should not make a choice in favor of silicate, cast or pressed bricks - their structure will not withstand the load.

Fireclay bricks are most suitable for laying the furnace, as they can withstand temperatures up to 1350C. It can also be used to build the entire structure, or you can lay out only the inner mile with it.

The use of yellow SHA 8 brick with specks or SHA from 22 to 45 is an excellent solution for laying the stove, but not for rooms with a high level of humidity, since its operation is possible only at 60% humidity.

In rooms such as a bath, it is best to use the following types of bricks:

- ceramic;

- refractory;

- clinker.

With all of the above, you can achieve an impeccable result.

Scheme of the simplest brick oven for summer cottages and houses

The heating stone stove in general is as follows:

- Below the floor level, a foundation is placed on which the insulation is laid.

- Trenches are installed on the floor - legs that provide heating of the lower part.

- Directly above them is a blower, as well as a stuffing box. It is needed for uniform heating in height.

- A blower door separates it from the main room.

- Directly above it is a firebox. A grate is laid on its bottom, which is also the arch of the blower.

- Directly above the firebox door is the firebox vault, behind which is a hail or mouth.

- Above, cleaning, a pass and convectors begin.

- Above the cleaning are two valves.

- Almost at the very top there is a ventilator outlet to the room, a smoke channel and a ceiling.

- The chimney is separated from the ceiling by an internal cut.

- At the very top is the mouth of the chimney.

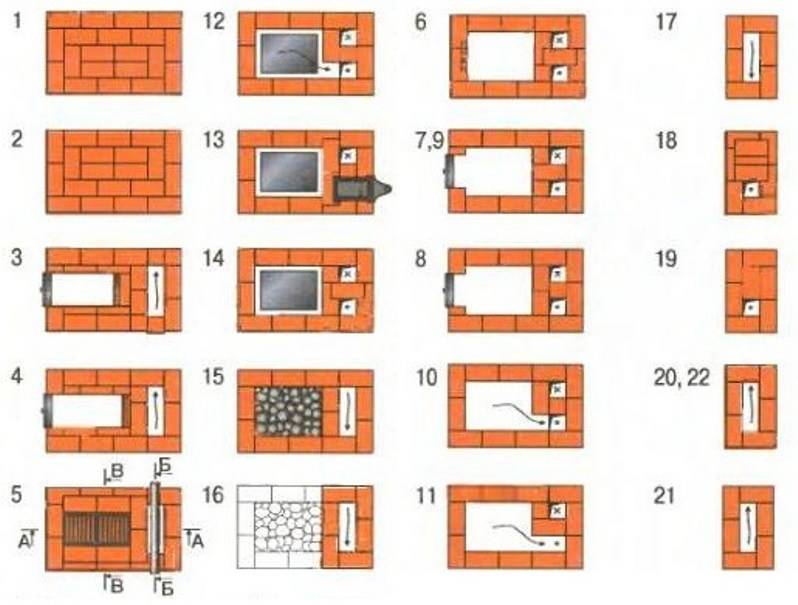

Stove with hob

In the simplest version, this design has small dimensions (width 2, and depth 3 bricks - 78x53 cm). However, even in such a limited area, it is possible to place a single-burner stove.

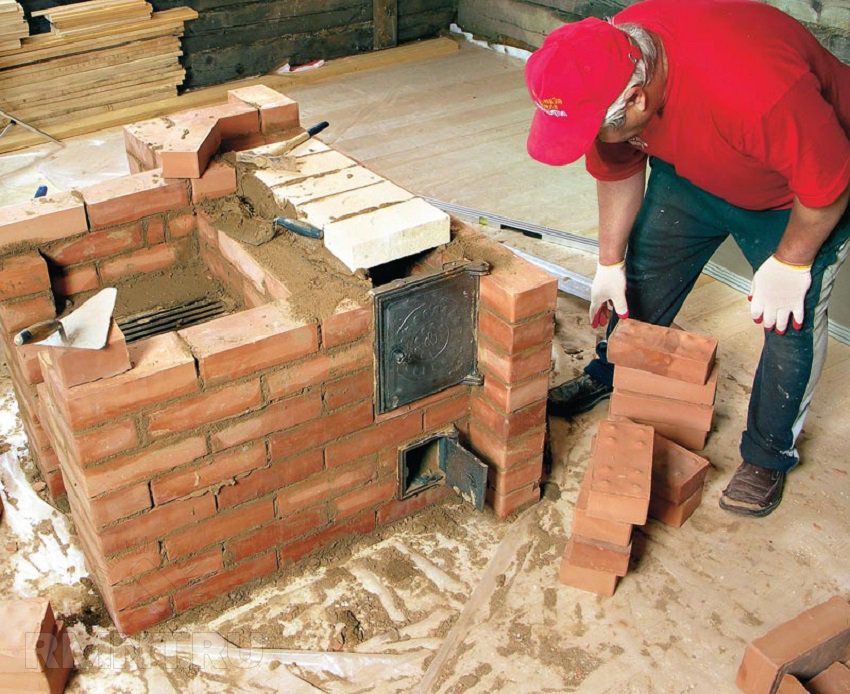

Work goes smoothly when everything you need is at hand.

Therefore, purchase the following materials and accessories in advance:

Solid red brick - 107 pcs;

Blower door - 1 PCS;

grate - 1 PC;

Single-burner cast-iron stove - 1 pc;

Furnace door - 1 pc;

Pipe valve - 1 pc.

Refractory bricks are not needed for a wood-burning stove. Buying it is a waste of money.But red should be chosen carefully, rejecting cracked and uneven.

Solution preparation

The masonry mixture is made by mixing four parts of clay with one part of water and adding eight parts of sifted sand to them. The normal consistency is determined simply: the solution easily slides off the trowel, leaving no streaks on it. When laying, it should not flow out of the seams.

The volume of the solution is determined, focusing on the number of bricks. With an optimal seam thickness (3-5 mm), one bucket is enough for 50 pieces.

Having prepared the masonry mixture, you can start laying the foundation. Its width is made 10 cm more than the width of the furnace. The height of the foundation is chosen so that the bottom of the first row of bricks is at floor level.

Approximate prototype of the stove

If the underground is deep enough (50-60 cm), then it is not necessary to dig a hole under the foundation. It is enough to make a formwork on the ground with a size in terms of 76 x (51 + 10 cm). Two layers of roofing material are laid on its bottom to protect it from moisture. After laying the concrete, he is given a week to gain strength and then proceed to masonry.

The dimensions of the stove we are considering with a hob are 3 x 1.5 bricks (76x39 cm).

The first row is placed on a layer of clay mortar (4-5 mm). Having leveled the base, lay out the second one, leaving room for the blower door.

Before mounting the door, you need to screw a soft wire to it and lay its ends in the seams for better fixation.

There are four holes in the frame of the cast-iron door for the wire that serves to fix it in the masonry.

To compensate for the thermal expansion of the metal, a gap is left between the door and the brick. Before installation, its frame is wrapped with a wet asbestos cord.

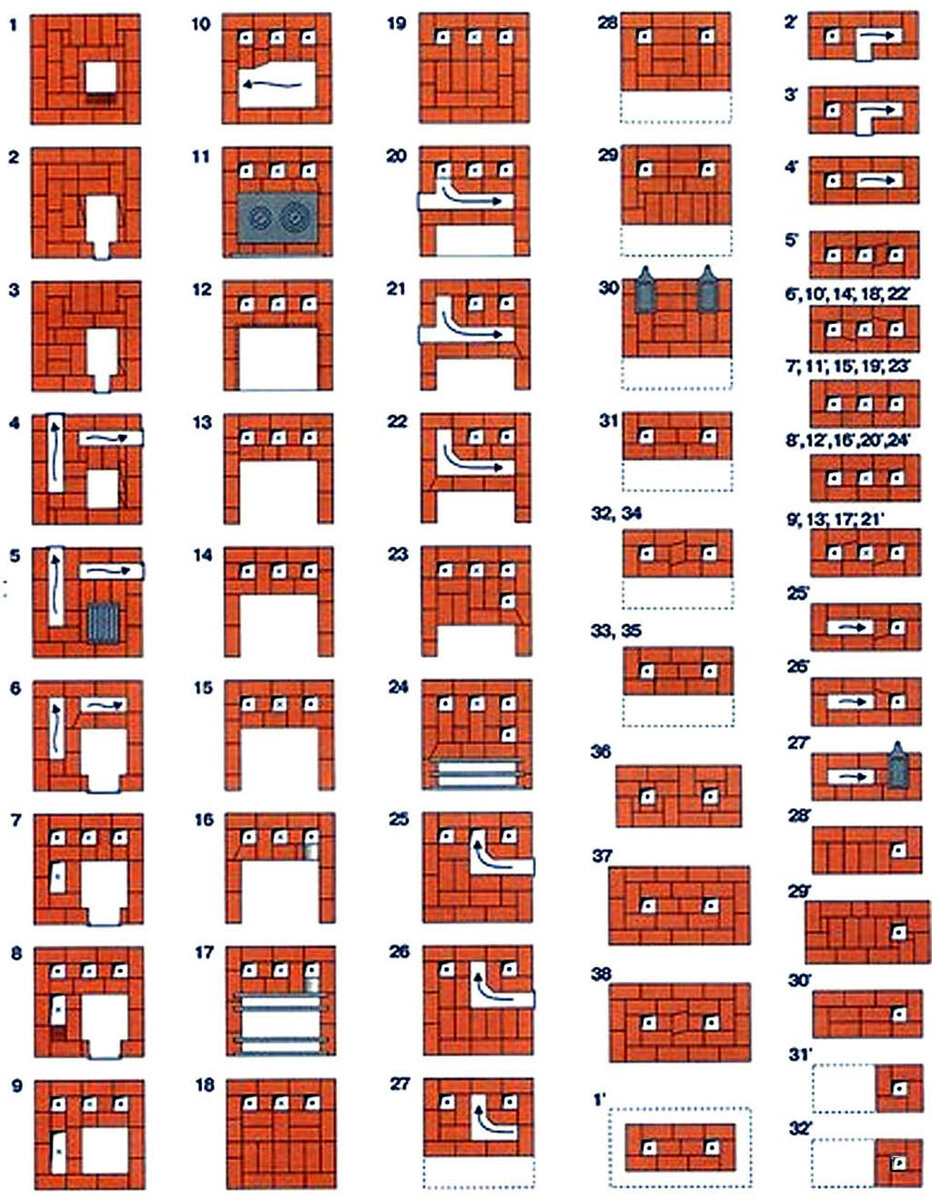

The laying of the third row is carried out, overlapping the seams of the second.At this level, a grate is installed in the firebox.

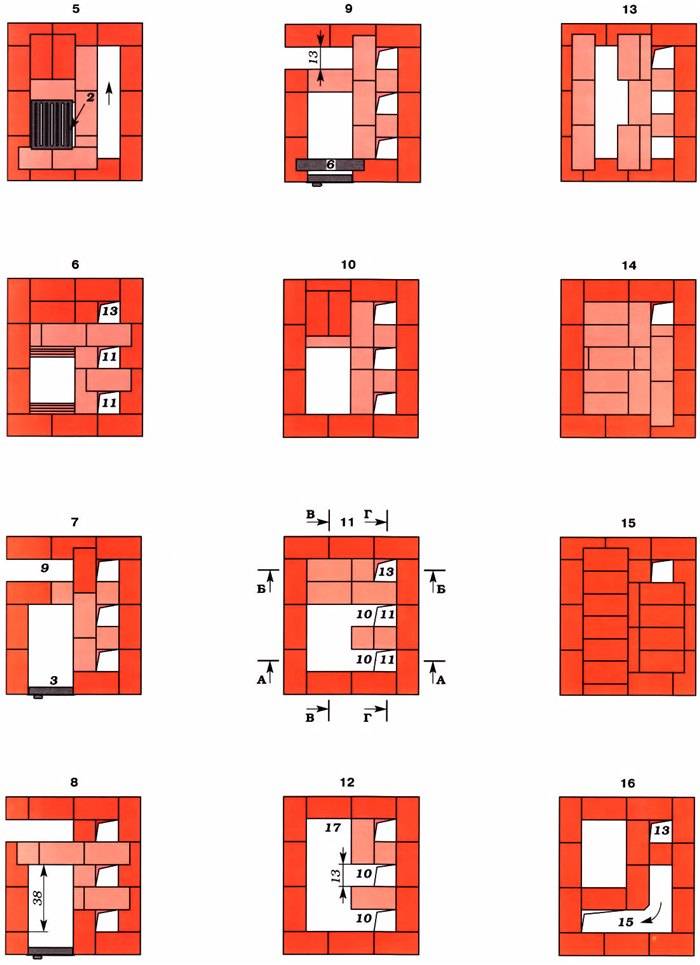

Ordering scheme from 1 to 8 row

The fourth row is placed on the edge, observing the dressing of the seams, and the walls of the combustion chamber are formed. Behind it there will be the first and only smoke circulation (see section A-A in diagram No. 2). To clean its bottom, a so-called knockout brick is placed in the back wall without mortar, periodically removed to remove ash. Inside the chimney, two supports are made from pieces of brick to support the internal partition.

The stones of the fifth row are placed flat, leaving room for the furnace door. In the back of the furnace, in order, we see the walls of two smoke channels. Their surface during operation must be thoroughly cleaned with a wet cloth from clay protruding from the seams.

This is an important condition for good traction.

Ordering scheme from 9 to 11 row

Having raised it into the masonry up to the eighth row, they close the furnace door, laying a wire in the seams that fixes its frame. At the same level, a brick with a beveled end is placed in the back of the fuel chamber - a smoke tooth. It improves heat transfer by preventing the rapid exit of flue gases into the chimney.

Having finished the ninth row, an asbestos cord is laid on it in a clay solution. It is necessary for sealing the joints of the cast-iron plate and brick. On the tenth row, the firebox is covered with a hob.

At the eleventh, a smoke damper is installed in the pipe. It is also sealed along the contour with an asbestos cord dipped in clay.

12th and 13th row - the formation of the walls of the pipe. After their completion, a light sheet metal pipe is placed on the furnace, which is brought out to the roof.

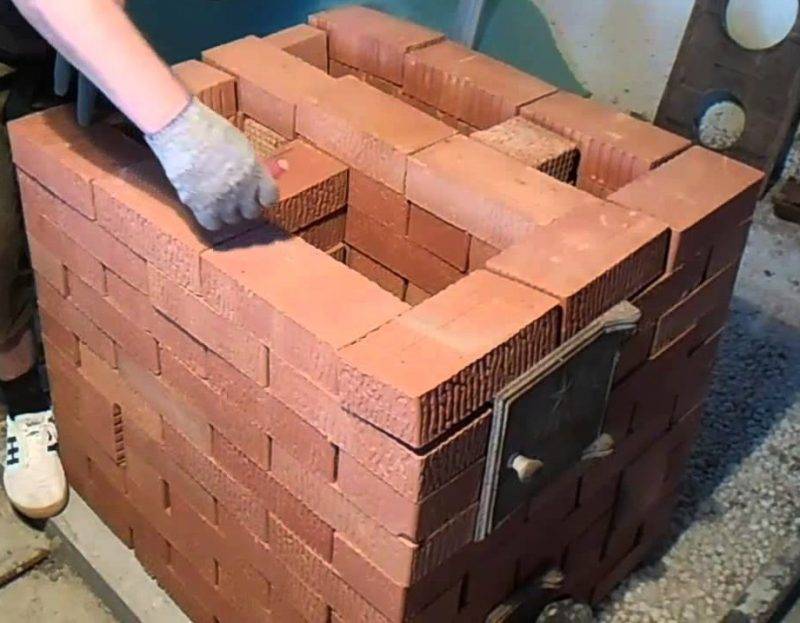

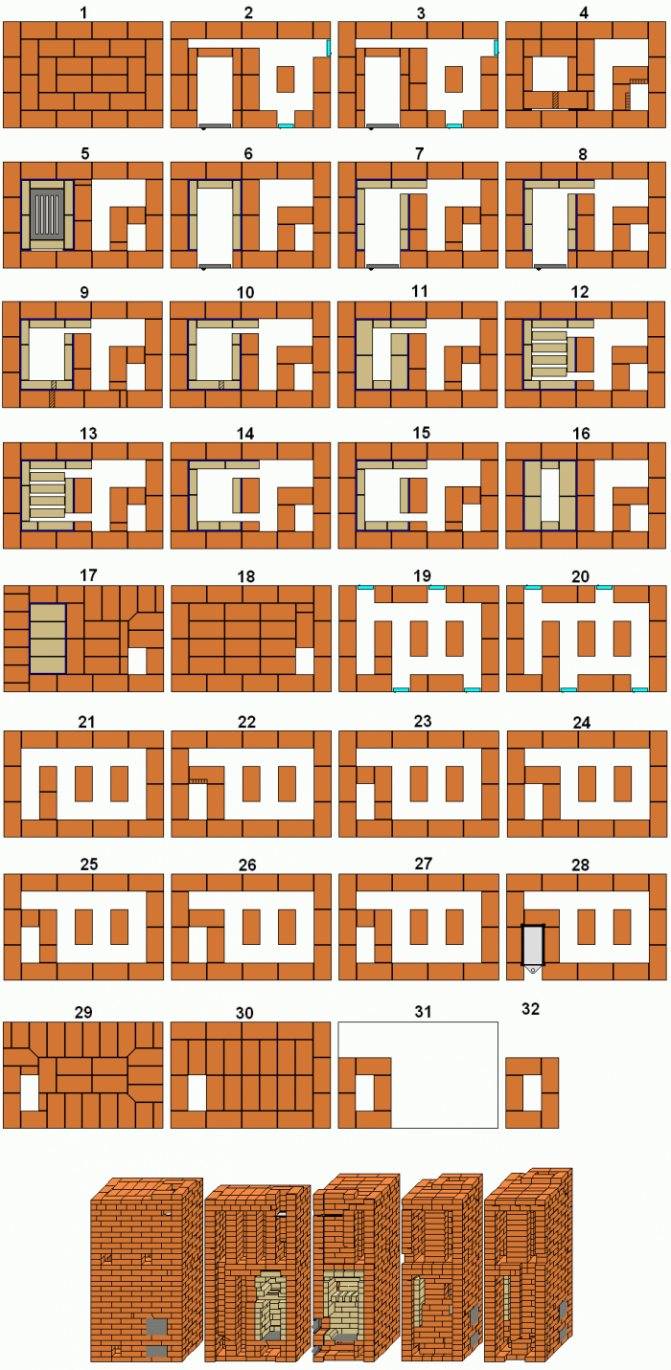

Laying process step by step

After developing a scheme for laying brick heating furnaces, purchasing material and tools, you can start laying out the structure. Most often, a 3 by 3 or 3 by 4 scheme is used. This minimizes material costs and simplifies the work of the master. To build a simple brick oven, you need to follow all the steps gradually.

Foundation fixing

The masonry scheme involves pouring the foundation. It can be done with crushed stone, garden or any other brick. The foundation must be completely filled with cement mortar and the layer carefully leveled. Then, the overlap should be left to dry completely and only after that continue the installation work.

The erection of the ashpit and the body

If the master does not have sufficient experience in laying on 3 bricks, it is better to lay out the first row without the use of a bonding mortar. Align it, and only then shift the mixture. To make the surface perfectly flat, you can pour dry sand under the base material. For additional support, formwork is also built, which can be removed only after the foundation has completely solidified. The plan involves installing a door on 2-3 rows. To minimize the gap between the brick and the frame, it is necessary to secure it with an asbestos cord.

Firebox design

After installing the door, install 3 more rows of bricks not on the edge, after that a couple more rows of ¼ elements. Then they lay out with refractory bricks and install the ceiling in the form of a grid. The main door is placed next to the grate and fixed with cement and wire cord.A small tin base is placed above the shutter and 2 layers of material are laid on it. Then a fireplace grate is placed on the refractory brick. The door is fixed.

Fixing the chimney

The right stove should end with a chimney, which you can make yourself. Even if the structure is placed in a brick house, the chimney must be designed. In the place where the element is located, it is divided into wells, which are reinforced with metal plates. After that, bricks are laid, and soot cleaners are installed above the topcha roof. The wells are separated by bricks and the furnace ceiling is erected. The space for the exit of smoke is left hollow. Then install the eaves and lay out the chimneys. After completing the basic installation work, you can do the cladding.

Varieties of brick ovens

Next, we will consider all the main models of furnaces. At the same time, you will learn that they can be not only cooking, but also heating and cooking. Another variety is a wood-fired sauna brick oven (it can be equipped with a conventional or fireplace insert). Let's take a closer look at them.

dutch stove

She is a rough oven - the simplest and most compact, which is why its efficiency suffers somewhat. Therefore, a large amount of generated heat simply flies into the pipe. Furnace heating with coarse is characterized by its simplicity. For example, a Dutch woman may simply not have a blower - in this way she is somewhat similar to the most ordinary fireplace. But in order to increase efficiency, it is still recommended to make a blower.

But such a brick oven is extremely simple in laying - the scheme of the stove is distinguished by its simplicity. Because of this, she earned her popularity. But it does not have a cooking surface.And this is also a plus, since the unit is compact. Channels for the passage of smoke rise in it like a snake from the bottom up, located one above the other. The main advantages of this furnace:

- Compactness - if you want to create stove heating for a private house of a small area, with a limited area of \u200b\u200brooms, then the Dutch rough stove will be the best option;

- A simple masonry scheme is available for a beginner stove-maker;

- The ability to give any shape - from rectangular to round or some other.

It should also be noted that there is a small load on the foundation - this is due to the low weight of the Dutch wood-fired brick oven. Therefore, a strong foundation can not be done.

Sauna brick stoves on wood

In some ways, they are similar to the above-described coarse ones, but they differ in a special design - in their design there are heaters filled with stones. The firebox in them does not go into the steam room, but into the next room. If necessary, the doors of the fireboxes are made of glass - thanks to this, a fireplace is formed in the dressing room, which serves as an excellent decoration.

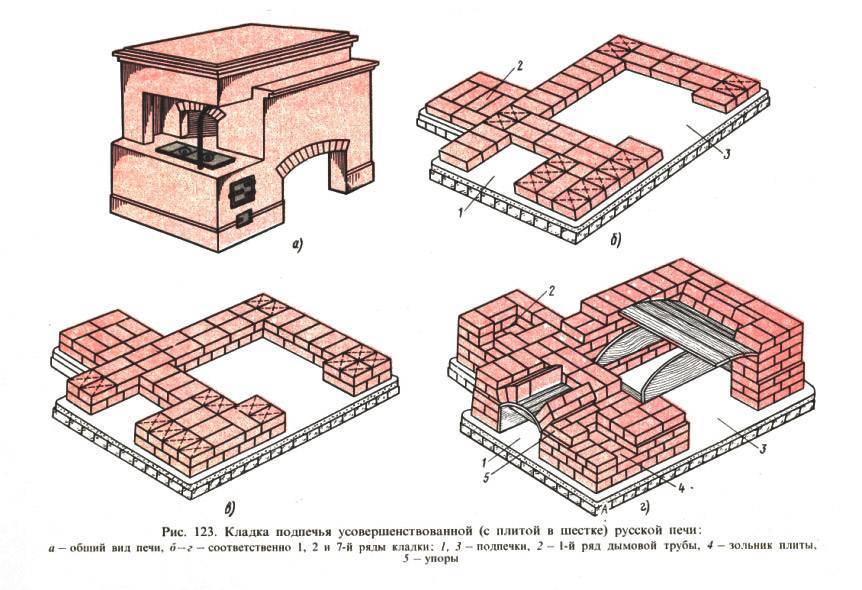

Russian oven

Considering the schemes of brick ovens for the home, you should definitely pay attention to the scheme of the Russian wood-burning stove. Such a stove will become a worthy decoration of the home. It is universal in use - it acts as a heater, is used for cooking (and right in the firebox), and is used to dry clothes at home.

And you can sleep on it, enjoying the warmth emanating from it.

It is universal in use - it acts as a heater, is used for cooking (and right in the firebox), and is used to dry clothes at home. And you can sleep on it, enjoying the warmth emanating from it.

Sleeping on a Russian stove is a special pleasure, now almost inaccessible. But at least once in your life you should give yourself such pleasure and sleep on a Russian stove heated with firewood.

Heating and cooking stove

The assembled brick oven for the house with your own hands can be made according to the universal scheme - according to Swedish. Such a stove (often referred to as a Swede) is wood-burning and is a multi-purpose device. It works as a heating unit, it can heat water and bake pies in the oven, it can be used to cook food in traditional dishes - using a simple hob.

Let's look at the features and advantages of such a brick oven:

- Large firebox for laying firewood - provides long-term burning;

- The presence of an impressive convector - efficient heating of rooms;

- The possibility of embedding water tanks and ovens - expands the functionality of the stove;

- The maximum use of the generated heat - the temperature of the combustion products here is quite low.

It is quite difficult to bring any specific typical drawing of the stove, since the laying patterns are different everywhere. There are also differences in filling - ovens are used somewhere, and somewhere there are built-in tanks for heating water.

The sizes of Swedish brick ovens on wood can be very different. Narrow options include the use of only the hob. If you need an oven, then the stove will increase slightly in size. That is, it can be not only compact, literally a few bricks wide, but also quite overall, occupying a decent area.

Some of these versatile wood-fired brick ovens require a strong foundation for themselves, which imposes restrictions on the possibility of their construction.

What are the ovens

Before you properly fold the stove in the house, you need to decide on its functions.

There are three types of such structures for a private house:

- For heating. The design includes a firebox and an overall chimney with many branches. The resulting flue gases give off their heat to the surrounding space through the walls of the chimney. Such stoves, which are heated mainly in winter, are usually equipped with houses with electric or gas stoves.

- For cooking. This appliance is intended exclusively for cooking. It is distinguished by the presence of a short straight chimney that immediately exits to the roof. A cast-iron stove is mounted on top of the firebox for cooking. In the gap between the firebox and the chimney, there is also a place for an oven (it provides a cooking mode, as in a Russian stove). In a similar way, summer kitchens and private houses with centralized and gas heating are usually equipped.

- Heating and cooking. With the help of such an oven, you can cook food and heat your home at the same time. Its design consists of a hob, an oven and a massive chimney pipe with a developed heat exchange system. The heating-cooking variety is the most widespread. With its help, both private residential cottages and small country houses are equipped.

Construction of the furnace foundation

Before you fold the stove yourself in the country, you will need to lay the foundation first.It is arranged separately on the ground, not connected with the main foundation of the house.

We put the base of the furnace with our own hands step by step in the following sequence of operations:

- Preparation of concrete mortar brand M200. In a container for mortar, 3.5 buckets of sand and one bucket of cement are mixed. After diluting the dry mixture with water, thorough mixing is carried out until a slightly fluid homogeneous mass is formed. Crushed stone is poured into the resulting slurry in the amount of 5-6 buckets, after which it is brought to the state of a homogeneous thick solution. To make the concrete more plastic, it is allowed to add a little liquid soap or dishwashing liquid to it.

- Pit dig. For the foundation, you need to dig a pit 45-60 cm deep. Its dimensions on each side should be greater than the dimensions of the furnace. The bottom of the trench is rammed, and the side walls are reinforced with plank or plywood formwork. Next, a sand cushion 10-15 cm high is poured, and a rubble stone with a layer of 15-25 cm is poured on it. Sometimes the walls are reinforced not with formwork, but with pieces of roofing material.

- Solution pouring. At the bottom of the trench, a reinforcing harness is equipped, for which a reinforcing harness made of welded reinforcing bars or steel pipes is used. Concrete is poured in several portions. To achieve a good density, the solution is pierced to the bottom with a wooden lath or a piece of reinforcement: this allows the air that has accumulated inside to come out. The upper part of the base is reinforced with steel reinforcing mesh. On top of it, a finishing layer of concrete 2-4 cm thick is formed.

- Leveling and solidification of the foundation. A rule is used to level the poured concrete mortar.It is necessary to achieve strict horizontality of the upper surface of the base: it should be inferior to the level of the finished floor by 8-12 cm. After that, the foundation is covered with a film of polyethylene, leaving it in this position for about 7 days until the solution completely hardens.

Advantages and disadvantages of a brick oven in the house

So, let's try to understand why an old heating appliance is often more preferable than its modern high-tech counterparts. There are several reasons:

- The body of the stove is an excellent heat accumulator: Due to this property, a brick stove has to be fired much less often than a conventional steel and even cast iron one. Some varieties keep heat up to 24 hours, while firewood needs to be thrown into the firebox of a metal stove every 4-6 hours.

- The ability to accumulate heat makes a brick oven more economical and less harmful to the environment than its metal "substitutes". The fuel in it burns in the optimal mode - with the highest heat transfer and almost complete decomposition of organic molecules into water and carbon dioxide. The resulting excess heat is absorbed by the brickwork and then gradually transferred to the room.

- The outer surface of the oven does not heat up to a high temperature.

Due to this, the thermal radiation generated by this unit is softer than that of hot steel stoves. In addition, upon contact with hot metal, the dust contained in the air burns, releasing harmful volatile substances (this can be recognized by the characteristic unpleasant odor). Of course, they cannot be poisoned, but they certainly cause harm to health.

A brick oven (this does not apply to stone ones) emits steam when heated, and absorbs it again when it cools. This process is called kiln breathing. Thanks to him, the relative humidity of the heated air always remains at a comfortable level - within 40-60%. When using any other heating device that is not equipped with a humidifier, the relative humidity in the room decreases, that is, the air becomes dry.

A steel furnace has nowhere to put excess heat, so it has to either be heated often, putting small portions of fuel, or operated in smoldering mode. In the latter case, the operating time on one tab of fuel increases, but it burns out with incomplete heat transfer and with a large amount of carbon monoxide and other environmentally harmful substances - the so-called. heavy hydrocarbon radicals.

What can be opposed to all of the above? The cooled room with a brick oven warms up for a long time. Therefore, homeowners are still advised to acquire an additional steel convector that will heat the air in forced mode while the stove is heating.

It should also be noted that a brick oven is a rather massive structure that should be built along with the house. And ideally, this should be done by an experienced master, who still needs to be found.

The use of brick ovens

The scope of application of stoves is not limited to their main functions - heating and cooking. Here are some other tasks that such a unit can solve:

- Smoking meat and fish.

- Remelting of scrap metal (cupola furnace).

- Hardening and cementing of metal parts (muffle furnaces).

- Firing of ceramic products.

- Heating blanks in the blacksmith shop.

- Maintaining the required temperature and humidity conditions in the bath.

But in poultry houses, greenhouses, greenhouses and livestock farms, it is not recommended to build a brick oven: here she will have to breathe putrefactive fumes, which will lead to rapid deterioration.

masonry process

The masonry mixture is prepared from sifted sand and clay. Clay is left in water for a couple of hours, after which it is sifted through a sieve.

The first rows are built with solid bricks. The sutures of the first row require dressing. After the first rows are ready, the brick will have to be cut.

The chopped side of the brick should be inside the masonry. This rule is also used in the construction of smoke paths. The chimney is built of red burnt bricks. And the opening of the firebox is created using a metal corner, a “castle” layout.

Before the first fire, it is recommended to wait 3 weeks.