- Content:

- Mandatory requirements for vessels subject to inspection

- 3.3 Inspection of the outer and inner surfaces of the cylinders

- The frequency of calibration of pressure gauges

- Fire extinguishing system test

- Permissible operation period

- Technical examination - cylinder

- Unsuitable for further use

- Cases where the use of a pressure gauge is prohibited.

- Design and types

- PRESSURE OF THE CYLINDER

- CYLINDER VERIFICATION

- PRICE OF SURVEY AND CERTIFICATION OF CYLINDERS

- Gas cylinder valve repair

- Calibration of pressure gauges: terms, methodology, rules

- Calibration of pressure gauges: rules

- Terms of verification of pressure gauges

- Do I need to calibrate gauges?

- Checking gas alarms in Sevastopol

- Conclusions and useful video on the topic

Content:

Pressure gauges are instruments that are used to measure the excess pressure of a gas. In the case of flame treatment of metal surfaces, this device is indispensable, since only with its help you can get information about what kind of gas pressure is maintained in the cylinder.

The use of pressure gauges is necessary in order to maintain ideal pressure in the system, therefore gas reducers are equipped with pressure gauges.Since the pressure gauge for a gas reducer is required to measure high pressures, it does not have the usual type of sensing element. This is a copper tube, the peculiarity of which is that it not only has a much narrower cross section, but also has a large number of turns, around the axis of which the tube moves when pressure is applied to the gearbox itself. In addition to the conversion function, the copper tube plays the function of a damper, and therefore, it is it that is the main part of the pressure gauge.

Under the pressure of the gas, the tube straightens, therefore, the greater the gas pressure, the more the tube straightens. The tube itself is connected to the arrow, which allows you to transfer the movement of the tube to the arrow. The arrow itself displays the actual pressure value.

Since pressure gauges are designed for a certain pressure, each gauge has a red line mark corresponding to the maximum allowable pressure. It is strictly forbidden to load pressure gauges with pressure exceeding their upper limit of measurement.

Spring pressure gauges are installed on oxygen and acetylene reducers. The pressure gauge for the gas reducer is connected to the high and working pressure chambers with a wrench, fiber and leather gaskets are used to seal the connection.

Mandatory requirements for vessels subject to inspection

Technical requirements for vessels, which are presented for the next survey, are established by the relevant guidelines. In terms of propane-butane cylinders, such a document is RD 03112194-1094-03, and in terms of methane equipment - RD 03112194-1095-03. Both documents were approved by the Ministry of Transport of the Russian Federation in 2002.

Before presenting an automobile cylinder to a specialized inspection point in due time, it is necessary to perform an independent inspection and make sure that it meets the requirements of the governing documents:

- the expiration date has not expired;

- outside the cylinder is cleaned of oil and other contaminants;

- the type of vessel and its design are in accordance with regulatory requirements;

- the automobile cylinder is equipped with standardized filling, consumable and other fittings provided for by the design; the tee has the necessary plugs;

- cylinders do not contain gas residues;

- all valves are closed.

RD 03112194-1094-03 and RD 03112194-1095-03 allow the presence of parts and fittings for cylinders of various designs, but only within the limits of changes made by the manufacturer during the period of being in production of a particular product.

Vessels must be emptied from gas motor fuel residues at specially equipped sites. The rules do not allow the presence of excess gas pressure in cylinders. If there is excess pressure, the cylinder is not allowed for examination and is unconditionally returned to its owner.

The basis for refusal to conduct the survey is the presence of cracks, bruising, various kinds of shells, scratches on the outer generatrix of the hull, exceeding 10% of the structural wall thickness. Also, cylinders with missing full or partial passport data are not subject to testing, the appointed certification period has expired, the standard shelf life has expired.

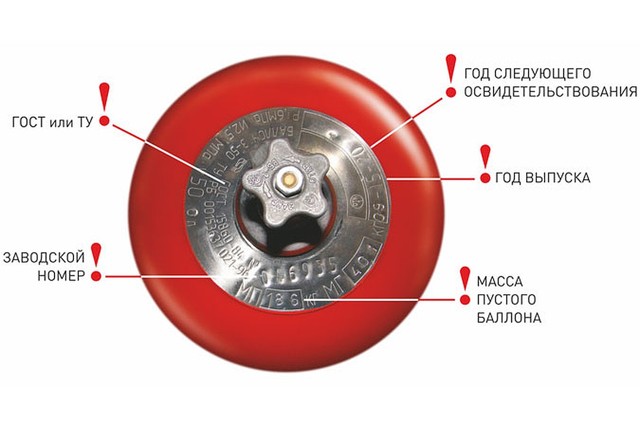

Examination of cylinders is accompanied by marking in compliance with the rules governing the rules for applying labels.The brand of the point that carried out the check, the date of the conducted and the scheduled date of the next survey are applied to the marking plate of the manufacturer by the method of embossing. The stamp is applied in one line in Arabic numerals, the height of which should not be less than 8 mm. The appointed time for the next inspection can be duplicated by a white inscription on the outer generatrix of the cylinder, previously painted with red enamel. In addition, white warning labels must be applied to the outer generatrix of the cylinder.

3.3 Inspection of the outer and inner surfaces of the cylinders

3.3.1 Exterior and interior inspection

surfaces are carried out in order to identify defects that reduce the strength of cylinders,

and identifying deviations from the requirements of the industrial safety

03-576 and GOST

949.

3.3.2 Inspection is subjected to 100% of the external and internal

surfaces, cylinder neck thread.

3.3.3 When inspecting the outer surface

balloon use magnifiers up to 20-fold increase. For sizing

of detected defects use universal measuring tools -

calipers according to GOST 166, calipers according to

GOST 162 and others.

The measurement error should be no more than 0.1 mm.

Inspection is carried out in accordance with the requirements of RD 03-606.

3.3.4 When inspecting the internal surface, use

lighting with an electric lamp with a voltage of not more than 12 V, which is inserted into

balloon or endoscope.

3.3.5 A container, on the surfaces of which

revealed cracks, captivity, shells, should be discarded.

A cylinder, on the surfaces of which dents, risks,

corrosion damage and other defects with a depth of more than 10% of the nominal

wall thickness, should be discarded.

Nominal wall thickness values depending on the type

cylinders correspond to table 1 GOST

949 and are given in the table.

Cylinder, the neck thread of which has tears, chipping

or wear, should be discarded.

Throat thread wear is controlled by calibers according to GOST

24998.

It is allowed to repair the thread of the cylinder neck according to

technology developed by OJSC RosNITI.

3.3.6 On the upper spherical part of the cylinder must be

stamped and clearly visible passport data specified in.

On cylinders with a capacity of up to 5 liters or a wall thickness of less than 5

mm passport data can be stamped on a plate soldered to the cylinder, or

applied with paint.

A cylinder that does not have at least one of the passport

data should be discarded.

| Capacity | Diameter | Wall thickness of cylinders, mm, not less than | ||||

| cylinder, l | cylinder, parts, mm | carbon steel | alloy steel | |||

| pressure, MPa | ||||||

| 9,8 | 14,7 | 19,6 | 14,7 | 19,6 | ||

| 0,4 | 70 | 1,6 | 2,2 | 2,9 | 1,6 | 1,9 |

| 0,7 | ||||||

| 1,0 | 89 | 1,9 | 2,8 | 3,6 | 1,9 | 2,5 |

| 1,3 | ||||||

| 2,0 | ||||||

| 2,0 | 108 | 2,4 | 3,4 | 4,4 | 2,4 | 3,0 |

| 3,0 | ||||||

| 3,0 | 140 | 3,1 | 4,4 | 5,7 | 3,1 | 3,9 |

| 4,0 | ||||||

| 5,0 | ||||||

| 6,0 | ||||||

| 7,0 | ||||||

| 8,0 | ||||||

| 10,0 | ||||||

| 12,0 | ||||||

| 20,0 | 219 | 5,2 | 6,8 | 8,9 | 5,2 | 6,0 |

| 25,0 | ||||||

| 32,0 | ||||||

| 40,0 | ||||||

| 50,0 |

3.3.7 Outdoor

the surface of the cylinder must be painted in accordance with Table 17 PB

03-576 (Appendix Table A.1).

3.3.8 When inspecting the cylinder, the serviceability and

reliability of fastening of the neck ring and shoe.

3.3.9 Cylinder with defective or loose ring on

neck is allowed for further survey after fixing

rings or replacements.

Weak or new rings are fastened

caulking by hand or expanding the end surface of the neck with annular

punch on a press with a force of 500 to 600 kN according to the instructions approved

the head of the organization conducting the survey. Depth of indentation

punch into the metal of the neck of the cylinder from 1 to 2 mm.

A sketch of the neck ring is shown in Figure B.1 of the application.

3.3.10 Cylinder with oblique or weak nozzle

shoe or a faulty shoe is allowed for further survey

after changing the shoe according to the instructions approved by the manager

organization conducting the audit.

The defective shoe is removed from the cylinder on the press or knocked down

manually.

Shoe nozzle is produced on a horizontal press with a force of

800 to 1000 kN. The shoe blank is preheated to a temperature of

900 to 1000 °C.

The shoe blank is cut from defective cylinders or pipes

with a diameter of 219 mm with a wall thickness of 5.2 to 8.9 mm according to GOST 8732.

The length of the workpiece is 125 + 5 mm.

The shoe must be tightly fitted on the cylinder with a gap between

the support plane of the shoe and the bottom of the cylinder is not less than 10 mm. At the end of the support

the surface of the shoe should be formed into a square.

It is allowed to skew the support plane of the shoe relative to

the normal to the generatrix of the cylinder body is not more than 7 mm on the width of the shoe.

(Changed edition, Rev. No. 1).

3.3.11 Repair shoe or neck ring

permitted only after venting the gas, dismantling the valve and the corresponding

bottle degassing.

3.3.12 Cylinder with non-repaired ring or shoe

further examination is not allowed and if it is impossible to repair

must be culled.

The frequency of calibration of pressure gauges

A pressure gauge is a device that measures pressure in an apparatus, tank, or pipeline. There are several types:

- spiral;

- membrane.

Spiral gauges consist of a metal spiral that is connected by a transmission element connected to the pointer on the dial.The higher the pressure, the more the spiral unwinds and pulls the arrow along with it. What is reflected in the increase in pressure indicators on the scale of the device.

The diaphragm pressure gauge gives readings by clamping a flat plate that is connected to the transmitter element. When pressure is applied, the membrane flexes and the transmitting element presses on the dial hand. So there is an increase in pressure indicators.

To check the compliance of the accuracy parameters of the meter declared by the manufacturer, and to control the metrological serviceability of the device, without which it is impossible to use the pressure gauge in areas falling under the GROEI (state regulation of ensuring the uniformity of measurements), as well as to ensure that the device serves the specified period and operation is safe, it is necessary to periodically carry out manometer verification. The rules established by the state state that, depending on the technical characteristics of the device and the manufacturer's instructions, the reconciliation period is from 12 months to 5 years.

Regular inspection of the device after a year was considered the most common, but now manufacturers are improving the characteristics of the equipment, more and more often there are devices with a verification period of 2 years. It is worth remembering if the pressure gauge must be inspected and verified after a certain period from the date of production, and not from the moment it is put into operation.

The service life of the pressure gauge is set by manufacturers, on average they are 8-10 years. It is necessary to keep a log of pressure gauge checks in order to check the device on time.

Fire extinguishing system test

The program and methodology for testing gas fire extinguishing is regulated by the following regulatory documents:

The program and methodology for testing gas fire extinguishing is regulated by the following regulatory documents:

- GOST R 50969-96;

- GOST R 51057-200;

- GOST R 53281-2009.

During testing, the following is checked:

- The volume of gas and the degree of filling of the cylinder;

- The duration of the supply of gas fire extinguishing mixture;

- The rest of the mixture in the container;

- The effectiveness of the elimination of the source of ignition;

- Strength and completeness of all elements of the installation after start-up and accompanying vibration, readiness of the structure for reloading;

- Information component:

- Recall speed of the receiving and control device;

- Formation of a notice to the central security console and decoding of its information content;

- Timeliness of submission of all commands on loops.

The element subjected to the greatest dynamic loads during testing is the pipeline. Increased demands are placed on its strength and reliability.

Testing of pipes and fittings is carried out according to the following regulations:

- Visual inspection of all external parts of the pipeline;

- All spray nozzles (except the last one) are covered with plugs.

- Block access to cylinders or distribution manifold.

- Fill the system with water through the last nozzle and muffle it;

The test pressure of gas fire extinguishing systems is 1.25 of the working pressure, however, the pressure is injected into the system in steps:

- 0.05 MPa;

- 0.5 from the worker;

- Operating pressure ;

- 1.25 of the working pressure;

- Between periods of rise, an exposure of 1-3 minutes is made. at this time, using a pressure gauge, it is determined whether a leak has begun;

- Under maximum pressure, the system is maintained for 5 minutes.

- After the end of the test work, the liquid is drained, and the pipelines are intensively blown with compressed air.

Permissible operation period

In accordance with the FNP ORPD, the service life is set by the manufacturer.According to paragraph 485 of the rules, if the manufacturer's technical documentation does not contain data on the service life of the cylinder, then the service life is set to 20 years.

The greatest demand is for containers manufactured in accordance with GOST 949-73 “Steel cylinders of small and medium volume for gases at P (p) <= 19.6 MPa (200 kgf / sq. cm). Specifications (with Amendments No. 1-5)". According to clause 6.2. warranty period of use - 24 months from the date of commissioning.

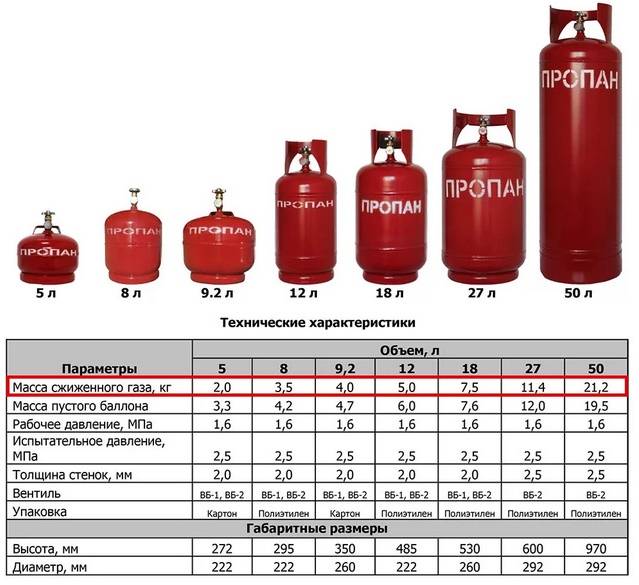

Devices manufactured in accordance with GOST 15860-84 “Welded steel cylinders for liquefied hydrocarbon gases for pressure up to 1.6 MPa. Specifications (with Amendments No. 1, 2) ”according to clause 9.2, have a warranty period of use - 2 years and 5 months from the date of sale through the distribution network, and for non-market devices - from the date of receipt by the user.

In accordance with the methods of technical diagnostics MTO 14-3R-004-2005 and MTO 14-3R-001-2002 developed for devices manufactured in accordance with GOST 15860-84 and GOST 949-73, respectively, the service life should not exceed 40 years, subject to conditions for the examination once every 5 years, after which the devices are rejected.

It is forbidden to use cylinders manufactured according to the above GOST before 02/01/2014, the service life of which is over 40 years.

According to paragraph 22 of the Technical Regulations of the Customs Union "On the safety of equipment operating under excessive pressure", cylinders manufactured after 02/01/2014 are operated according to the estimated service life specified by the manufacturer in the device passport.

Read more about the service life and storage conditions of a gas cylinder in this material.

We solve legal problems of any complexity.#Stay home and leave your question to our lawyer in the chat. It's safer that way.

Ask a Question

Technical examination - cylinder

Technical certification of cylinders includes inspection internal and external surfaces of cylinders; checking the mass and capacity; hydraulic test.

Technical certification of cylinders, with the exception of those discussed below, is carried out at least once every 5 years also at filling enterprises or filling stations. At the same time, the inner and outer surfaces are examined, a hydraulic test is carried out and the mass and capacity of the cylinder are checked. Acetylene cylinders are subjected to external inspection, pneumatic testing and porous mass testing.

Technical certification of cylinders carried out in accordance with the Rules for the Design and Safe Operation of Pressure Vessels and paragraphs.

Technical certification of cylinders is carried out in accordance with the Rules for the Design and Safe Operation of Pressure Vessels of the USSR Gosgortekhnadzor and IV-B - 165 - IV-B - 172 of these Rules.

Technical certification of cylinders, as mentioned above, is produced once every 5 years at a gas distribution station or a special point.

Technical certification of cylinders is carried out in accordance with the Rules for the Design and Safe Operation of Pressure Vessels.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the certificate of cylinders. The stamps on the cylinders in this case are not put.

results technical examination of cylinders with a capacity of more than UN n are entered in the certificate of cylinders.The stamp on the cylinders in this case is not put.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the passport of the cylinders. The stamp on the cylinders in this case is not put.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the certificates of cylinders. The stamps on the cylinders in this case are not put.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the passport of the cylinders, in this case they do not put a stamp on the cylinders.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the passport of the cylinders. The stamp on the cylinders in this case is not put.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the certificate of cylinders. The stamps on the cylinders in this case are not put.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the passport of the cylinders. The stamp on the cylinders in this case is not put.

results technical examination of cylinders with a capacity of more than 100 liters are entered in the certificate of cylinders. The stamps on the cylinders in this case are not put.

Unsuitable for further use

Why cylinders that have worked out the standard service life, but have passed the technical examination, should not be accepted for refueling?

According to paragraph 485 of the Rules ..., even gas vessels that have successfully passed the technical test and have served the regulatory period are unsuitable for further use.

The same paragraph states that if cases of successful re-certification after November 2014 are found,containers whose service life has expired, these results should be canceled, since according to the new Rules. examination of cylinders beyond their service life is prohibited.

A material that has used up its strength resource is capable of collapsing at any time.

All these measures and more stringent regulations are aimed at enhancing the safety of the operation of gas containers in which the contents are under pressure.

This is due to the increased use of end-of-life cylinders and, as a result, the occurrence of accidents.

To resist the requirements of these Rules ... means to endanger not only your health and life, but also the lives of other people, which is not only unreasonable, but also criminal.

What requirements must gas cylinders meet, how to use them correctly, what is an examination and what procedure do cylinders go through at a gas filling station? About it in the video:

Didn't find an answer to your question? Find out how to solve your particular problem - call right now:

For storage and transportation of compressed and liquefied gases, containers made of metal or composite materials are used. These vessels are designed for the fact that the gas will be stored in them under a certain pressure. So, GOST 15860-84 determines that the operating pressure in a propane tank should not exceed 1.6 MPa. There are also containers designed for a higher pressure of 5 MPa. All containers used for gas storage must be tested and periodically surveyed.

Checking the gas cylinder

Examination of a gas cylinder is an event that is necessary first of all for its owner.The certification can ensure that the cylinder is safe to operate and can be used for its intended purpose, otherwise they are not allowed to be used. There is a single survey procedure, during which the surfaces of the cylinders are inspected to detect damage to the surface.

They perform a quality check of marking and coloring for compliance with the requirements of GOST, the condition of the crane. In addition, in the process of certification, hydraulic tests of gas storage tanks are carried out. The results of the inspection and tests carried out are recorded in the passport that accompanies the product throughout its operation.

Without carrying out such measures, refueling and operation of containers for storage and transportation of gas are unacceptable. Inspection of cylinders and issuance of a conclusion on them can only be carried out by an organization that has all the necessary permits and powers from the relevant state supervisory authorities.

Vessels for the storage of gases must be certified once every few years. The duration depends on several parameters - on the material, for example, if the cylinders are made of alloyed or carbon steel, then it is enough for them to go through this procedure once every five years. Cylinders installed on cars as part of LPG must be certified in three or five years.

Cylinders, which operate in stationary conditions and are intended for the storage of inert gases, undergo the necessary examinations once every ten years.

The designated inspection periods must be strictly adhered to. It's all about safety.If the containers are intended for the storage and transportation of propane, acetylene or other explosive gas, any defect on the outer surface of the cylinder can lead to irreparable consequences.

As soon as doubts arise about the performance of a gas storage tank, it is necessary to withdraw it from circulation and purchase or rent a new one.

Cases where the use of a pressure gauge is prohibited.

If there is no seal or brand in the pressure gauge, the calibration period is overdue or the gear pointer does not return to the initial mark, by more than half of the permissible error when turned on, then it is forbidden to use such a pressure gauge.

In addition, it is not allowed to use an instrument in which the glass is broken or has other damage that could affect the correct readings.

In conclusion, we note that a serviceable pressure gauge can serve as a guarantee of the safety of working with gas welding equipment.

Measuring devices and tools require control using metric meters. Pressure gauges that analyze the pressure of liquids and gases are installed on heating boilers, gas cylinders, and used on production units. In order to obtain the correct readings of the device and protect the employees of the enterprise, periodic calibration of pressure gauges should be carried out.

Design and types

Propane (CH3)2CH2 is a natural gas with a high calorific value: at 25°C, its calorific value exceeds 120 kcal/kg

At the same time, it should be used with special precautions, since propane is odorless, but even at its concentration in air of only 2.1% it is explosive

It is especially important that, being lighter than air (the density of propane is only 0.5 g / cm 3), propane rises, and therefore, even at relatively low concentrations, is a danger to human well-being

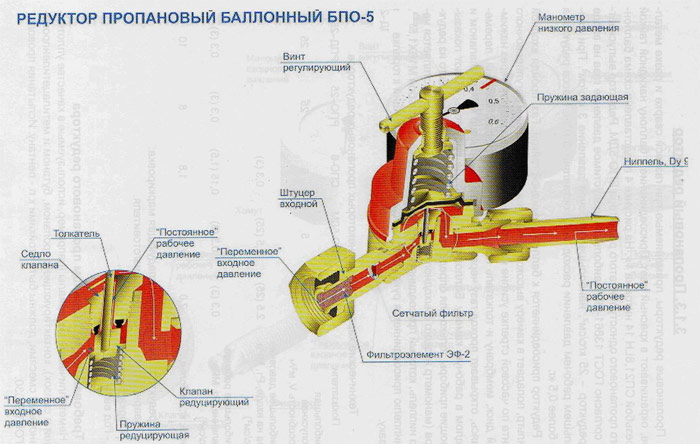

A propane reducer must perform two functions - to provide a strictly defined pressure level when any device is connected to it, and to guarantee the stability of such pressure values during further operation. Most often, gas welding machines, gas heaters, heat guns and other types of heating equipment are used as such devices. This gas is also used for the propane cylinder of a car running on liquefied fuel.

There are two types of propane reducers - one- and two-chamber. The latter are used less frequently, since they are more complex in their design, and their distinctive ability - to consistently reduce the gas pressure in two chambers - is used in practice only with increased requirements for the permissible level of pressure drops. BPO 5-3, BPO5-4, SPO-6, etc. are considered common models of gearboxes. The second digit in the symbol indicates the nominal pressure, MPa, at which the safety device is triggered.

Structurally, a single-chamber propane reducer of the BPO-5 type (Balloon Propane Single-chamber) consists of the following components and parts:

- Corps.

- pusher.

- Valve seat.

- Reducing spring.

- membranes.

- Reducing valve.

- Connecting nipple.

- Inlet fitting.

- setting spring.

- mesh filter.

- pressure gauge.

- Adjusting screw.

The main technical characteristics of propane reducers are:

- Maximum throughput in terms of gas volume per unit of time, kg / h (marked with a number located immediately after the letter abbreviation; for example, a propane reducer of the BPO-5 type is designed to pass no more than 5 kg of propane per hour);

- Maximum inlet gas pressure, MPa. Depending on the size of the device, it can be in the range from 0.3 to 2.5 MPa;

- Maximum output pressure; in most designs, it is 0.3 MPa, and adapted to the same indicator for a gas-consuming unit.

All manufactured propane reducers must fully comply with the requirements of GOST 13861.

PRESSURE OF THE CYLINDER

Crimping is the process of testing an automobile HBO cylinder for strength and tightness.

How is the verification carried out?

Hydraulic (water) and pneumatic (air) tests are performed:

Hydraulic: all air is removed from the vessel and filled with water;

Under pressure, a leak test is carried out, after which the cylinder is drained (drying);

Pneumatic: the vessel is immersed in a container with water and tested with compressed air or inert gas (in accordance with PB 03-576-03, it is allowed to replace one procedure with another).

The essence is the same - checking the tightness.

After successfully passing the pressure test, the automobile cylinder is considered fit for use and is transferred for verification (certification and branding).

CYLINDER VERIFICATION

Verification of a gas cylinder (propane and methane) serves as confirmation of the full compliance of the gas cylinder with safety requirements.

After all checks of the cylinder, its certification is carried out: documenting the permit for admission and further operation of the cylinder in the HBO system.

The client is given:

Certificate of performance of periodic tests of gas-balloon equipment installed on the vehicle (Form 2B);

Mark in the passport of the date of the next re-examination of the vehicle;

The verification documents of the gas cylinder of the car indicate that the vessel was subjected to external and internal inspection and hydraulic (pneumatic) tests and was found fit for further work in the HBO system of the car.

The results of the cylinder verification, namely the certificate in form 2B, must be carried with you. It may be required for presentation in three cases: at the request of the traffic police inspector, when undergoing vehicle maintenance (TO) and receiving a diagnostic card, as well as at some gas stations (which require cylinder verification certificates when refueling).

PRICE OF SURVEY AND CERTIFICATION OF CYLINDERS

The cost of work depends on the condition of the HBO cylinder identified during the certification (whether corrosion cleaning, priming, painting, etc. is required) and whether additional work is required (removal-installation or it is provided in a dismantled and prepared , cleaned from dirt form).

Cost of examination, re-certification, pressure testing and verification of 1 cylinder (without dismantling), including execution and issuance of papers on its verification (2a, 2b):

If the cylinder has corrosion (no more than 10% of the total surface of the vessel), then additional painting work is performed before pressure testing, according to the price list:

| Cleaning + preparation + priming + painting + application of technical inscription (restoration) | |

| 3 000 rub | 50l bottle (diameter 300, L up to 1000 mm) |

| 5 000 rub | for diameter 360, L 1300 mm |

| 7 000 rub | diameter 400 - 500, L 1000 mm |

Completion time - 2 days.

As you can see, the prices for all procedures are very inexpensive, given the volume of work with gas equipment. This is a small price to pay for the safety of the cylinder you carry in your car.

Gas cylinder valve repair

The main malfunctions of gas valves

In fact, the design of the gas valve is not difficult and there is nothing special to break in it. But nevertheless, for a number of reasons, it can either start to pass gas or completely fail. One of the reasons for its breakdowns is the careless attitude of the staff. For example, applying excessive force when opening or closing. This can either strip the thread or break the stem.

In addition, foreign particles entering the regulator may prevent them from fully closing the valve, and this will inevitably lead to gas leakage. In any case, at the slightest suspicion of defects in the body or mechanism of the gas valve, the cylinder must be removed from the workplace or amenity premises and sent for repair.

Yes, no doubt, the gas valve can be removed from the cylinder and inspected by yourself and, if necessary, purged or repaired, but we must not forget that any work with a gas cylinder carries a potential hazard. That is why there is a strict ban on dismantling gas valves independently in artisanal conditions. If there is even a small opportunity to transfer the repair of a gas valve to a workshop, then it is better to do so.

Calibration of pressure gauges: terms, methodology, rules

Various measuring devices can be installed in the compressed air injection system; a pressure gauge is widely used. Like many other devices, this one must undergo periodic maintenance. Only in this case, you can be sure that it will last for a long period, and the readings obtained will be accurate. Consider all the features of the pressure gauge verification procedure in more detail.

Calibration of pressure gauges: rules

The pressure gauges should be checked solely taking into account the basic rules and recommendations, since mistakes made can lead to a decrease in the accuracy of the product. The basic rules are as follows:

- First, a pressure gauge is inspected to determine the condition of the mechanism. Damage to the device may indicate that verification is not worth it at all. Some of the defects can be eliminated, for example, by replacing the protective glass, it all depends on the characteristics of a particular pressure gauge model.

- The most approximate conditions to operational are created. An example is the indicator of air humidity, atmospheric pressure and room temperature.

- At the beginning of the test, the pointer must be at zero. This eliminates the possibility of an error at the time of measurement.

If it is not possible to set the arrow to zero, then the device is adjusted using a special bolt.

Terms of verification of pressure gauges

The focus is on deadlines. The purpose of calibration is to improve the accuracy of the readings. Among the features we note the following points:

It is possible to independently carry out the procedure in question only if the device is installed as an element of irresponsible mechanisms.

Do I need to calibrate gauges?

Primary calibration of the device is carried out to determine the nominal pressure. In the future, control allows you to exclude the possibility of reducing accuracy.

Periodic calibration of the pressure gauge is required in order to exclude the possibility of its failure.

Some systems cannot be operated without the use of a pressure gauge.

If you do not carry out the procedure in time, you may encounter the following problems:

- Measurement error. In some cases, a small error does not reduce the efficiency of the compressor, in others, pressure accuracy is important.

- The service life of the pressure gauge is significantly reduced. Some damage to the mechanism during its long-term operation can lead to rapid wear. The cost of high-precision manometers is very high.

- There is a possibility of leakage of the medium, which will cause a decrease in pressure in the system.

In conclusion, we note that if it is necessary to calibrate the compressor measuring device, you can carry out such work yourself. To do this, you can purchase a special device in a specialized store. Other mechanisms, which are subject to higher requirements, should be checked exclusively by a specialist. After the procedure, a filling should be placed.

, please select a piece of text and press Ctrl+Enter.

Checking gas alarms in Sevastopol

CJSC "YUSTIR" performs verification of gas alarms, both at the facility and in a specialized laboratory, in accordance with the current verification methods.

Gas alarms are designed to prevent gas leaks: propane methane, carbon monoxide, etc., they are installed in boiler rooms and hydraulic fracturing. As a rule, signaling devices are calibrated once a year (depending on the model, the calibration interval may be different).

The purpose of verification is to identify a faulty gas contamination detector by simulating up to explosive concentrations using verification gas mixtures (CGM).

On-site verification - our specialists are ready to go to the site with the necessary equipment to calibrate gas alarms at the place of operation, to adjust and calibrate using test-gas mixtures.

Verification in the laboratory

Our company makes adjustments and repairs in an equipped laboratory, has a wide range of spare parts for the repair of gas pollution alarms, both domestic and imported.

The laboratory complies with all the requirements of the verification procedure, which is extremely important when setting up and calibrating, and calibrating gas detectors. If necessary, the organization has a large exchange fund of verified gas alarms, which allows delivery to the laboratory for subsequent repair of the device

Verification of gas analyzers is carried out at the installation site at the customer's site. Verification of gas detectors for carbon monoxide and methane (verification of gas sensors) should be carried out once a year.

CJSC "YUSTIR" carries out a complex of works on the organization of verification, calibration and repair of gas alarms. Verification of gas detectors is carried out with the issuance of certificates of verification of the established sample. The price includes a full cycle of carrying out a robot for checking gas alarms.

Conclusions and useful video on the topic

What you should be wary of when buying cylinders:

Recommendations for self-repair:

Only serviceable gas equipment can ensure the comfort and safety of homeowners

Regular checks are another way to protect citizens from an accidental accident, so the requirements of the gas service must be treated with attention and responsibility.

In the case of gas reducers, once a year, invite a specialist to check pressure gauges, and, if necessary, replace or repair equipment.

You can participate in the discussion, leave to the material, share your experience or ask questions of interest to our specialists - the contact block is located under the article.