- Periodicity of registration

- Features of the ventilation test

- Order of conduct.

- Order diagnostics from professionals

- Reasons for conducting a ventilation audit

- Basic goals

- Execution algorithm

- Verification documents

- Passport of the ventilation system

- Audit frequency

- The correct system is.

- Signs and causes of a decrease in the efficiency of the ventilation system

- Checking ventilation as a vital necessity

- The frequency of checking ventilation in the house, in the apartment

- For premises of residential buildings in which there is no gas-powered equipment

- Frequency of ventilation checks for buildings using gas appliances

- What tasks does professional expertise solve?

- Algorithm for drawing up an act

- For non-residential premises

- Schools and kindergartens

- List of works performed during certification

- Order of conduct.

- How are measurements taken?

- What will be included in the ventilation control program?

- Program coordination.

- Features of maintaining a document

Periodicity of registration

Most modern buildings require a single passport to be produced. This is provided for non-changing ventilation systems. But for many industrial complexes there is such a thing as periodic certification.This is due to the expansion of workspaces or the reorientation of production.

If the enterprise has retrained into a more hazardous production, then the ventilation must be replaced or improved, respectively, by issuing a new passport. Periodic certification is also necessary for frequent inspections by supervisory authorities.

Certification is one of the methods for monitoring the health of ventilation. The more parameters that are checked for documenting, the better the system will be prepared for continuous operation.

The operating organization is responsible for the operation of the ventilation system, so calling a certification specialist is their direct responsibility. Checking air exchange by sticking a sheet of paper to the ventilation grille is already an outdated and poor-quality method.

Modern verification is carried out with high-precision electronic instruments, and the data is carefully processed and analyzed. Identified defects are eliminated.

The passport of the ventilation system is the main document, it is issued only for serviceable systems, and proves its complete readiness for operation. The validity period of the passport ends after the complete dismantling of the ventilation system and its cancellation under the relevant act.

Features of the ventilation test

Determining the efficiency of the ventilation system is carried out by accredited organizations using high-tech equipment. After the verification is completed, calculations are carried out, on the basis of which an expert opinion is issued.

In the course of the survey, the obtained results are compared with the regulatory requirements. Moreover, not only the efficiency of air exchange is evaluated, but also its multiplicity.

The highest measurement accuracy is provided by specialized instruments. To conduct the survey, an agreement can be concluded with an accredited organization.

The highest measurement accuracy is provided by specialized instruments. To conduct the survey, an agreement can be concluded with an accredited organization.

Verification of documentation confirming the efficiency of ventilation systems is checked by Rospotrebnadzor. In the presence of violations, the administration of the educational institution is responsible

Verification of documentation confirming the efficiency of ventilation systems is checked by Rospotrebnadzor. In the presence of violations, the administration of the educational institution is responsible

If deviations are detected during the verification process, professionals provide recommendations for debugging the system. Rostekhnadzor checks the documentation. In case of defects, the administration of the educational institution is expected to penal sanctions.

The frequency, timing of inspections, as well as the norms, are established by sanitary norms:

- the use of the ventilation system is allowed after commissioning, obtaining technical passports;

- SanPin regulates the frequency of checks at least once a year or upon delivery of the facility, and in schools, the ventilation system is checked before the start of the school year;

- natural, general exchange networks are checked at least once every 3 years.

The above specifications are relevant for ventilation that works correctly.

When commissioning has not been carried out or has been carried out incorrectly, ventilation systems often operate with reduced efficiency.

Order of conduct.

Sanitary and hygienic control is carried out according to a pre-formed program. Such a document can be developed both by the enterprise and through the involvement of specialized organizations. It is worth considering that turning to professionals will allow:

- take into account the requirements of existing legislative and regulatory documents;

- take into account all the features of the production process and installed equipment;

- reduce document development time;

- avoid shortcomings.

The cost of the described service can be from 19,900 rubles, the minimum development period is from 7 days.

An important point in the formation of the document in question is the frequency of control.

For existing enterprises, it is:

- in case of release in production operations of substances belonging to hazard classes 1 and 2 - at least once a month;

- for local supply and exhaust ventilation systems - at least once a year;

- for systems of natural or mechanical general ventilation - at least 1 time in 3 years;

- for newly installed or reconstructed systems - immediately after installation.

New or reconstructed ventilation systems are accepted by a special commission, which, in addition to the developers and employees of the enterprise, must include a representative of Rospotrebnadzor.

Order diagnostics from professionals

Modern ventilation systems used in industry are complex installations consisting of many elements. They combine high-precision electronics and sophisticated mechanics, the effectiveness of which can only be reliably assessed by qualified specialists.

Our company has the appropriate accreditation for each type of mandatory measurements, as well as a staff of experienced specialized engineers and technicians, guaranteeing a high-quality inspection of ventilation systems based on:

- A complete set of permits, including SRO permits, licenses of the Ministry of Emergency Situations, certificates of attestation of laboratories

- Own instrument park with certified devices

- Compliance with applicable government regulations and standards

Reasons for conducting a ventilation audit

It can be quite difficult to independently detect the inefficient functioning of ventilation without special devices. Therefore, some residents of modern houses with centralized systems complain of migraines or insomnia, which may be due to ventilation failures caused by:

- Design errors and inconsistencies

- Re-planning of premises

- Incorrect assembly

- Unbalanced ventilation elements

The importance of efficient operation of ventilation systems is growing in production and industrial facilities, where not only dust and heat, but also fetid and harmful fumes can penetrate into the air. Therefore, the survey is carried out if:

- Lost design documentation

- The object is put into operation

- Certification or certification required

- Security Conclusion Required

- According to the instructions of the inspection authorities

The reason for the check can also be fires, accidents and outbreaks of infections in apartment buildings, catering establishments, educational and medical institutions.

Basic goals

A ventilation audit helps to identify hidden problems that can result in abnormal situations or accidents. Its implementation allows:

- Make sure efficiency calculations are correct at the design stage

- Find out the performance of equipment under increased loads

- Establish compliance of the output thrust with current regulations

Based on these measurements, temperature and air flow rates, as well as pressure losses, are calculated both in mines and in the system as a whole.

Execution algorithm

- Indoor climate indicators, including carbon dioxide

- Air components within the working area, determined by gas or aerosol analysis, which is most relevant for industrial premises

- Aerodynamic tests in accordance with GOST 12.3.018-79

Measurements and sampling are carried out using modern devices and tools, which, in addition to a tape measure, a thermometer and a flashlight, include:

- Micromanometer for measuring pressure

- Pneumatic tubes for air transmission

- Funnel anemometer for determining air velocity and flow

- Tachometer for determining the speed of mechanisms

The results obtained are entered into a summary table or into a digital act, where the calculation of the ventilation efficiency is performed by special programs developed for computers.

Verification documents

After performing verification activities for the maintenance of ventilation systems, the customer is issued an efficiency test report containing:

- Direction of the examination: serviceability, frequency of air exchange, presence of traction, patency of channels

- Varieties of work performed: the correct arrangement of elements, the multiplicity of air in each surveyed room; cleaning filters and grids, checking automation

- Description of the technical condition of the examined ventilation system

Passport of the ventilation system

The document is drawn up by specialized organizations before the facility is put into operation and contains:

- Main characteristics of the ventilation system

- Aerodynamic test results

- Airflow measurement data

- Air Outlet Routing Metrics

- Axonometric scheme

Inspection certificates and a passport are required to assess the actual state of ventilation, its compliance with the design and standards, as well as to prevent emergency situations, attestation or certification.

Audit frequency

- 1 time in 1 month - for industrial premises with the possibility of penetration of explosive and flammable or toxic substances of hazard class 1-2

- 1 time in 1 year - for domestic and public premises equipped with a supply and exhaust system

- 1 time in 3 years - for office and residential premises with natural or mechanical ventilation

A timely audit is not limited to the preventive detection of malfunctions, problem areas and a forecast of the further performance of ventilation. He also successfully solves the problems associated with the modernization and extension of the effective functioning of ventilation.

The correct system is.

What specifically needs to be checked to ensure that the system is working properly? Ventilation ducts and shafts are subject to mandatory checks - during the check it is found out whether there is vibration, what are its causes, whether the shaft is clean or there are blockages, whether leaks are found, whether the ventilation grilles are in good condition, how umbrellas work over shafts and deflectors.

We will not bore you with technical terms - professionals themselves know what they should check and how to ensure reliable operation of ventilation in an apartment building. Moreover, they will pay fines (up to 50,000 rubles) for failure to perform this work - the activities of the companies are controlled by the State Housing Inspectorate and the prosecutor's office.

Signs and causes of a decrease in the efficiency of the ventilation system

Condensation often forms on the walls or a mirror in the bathroom, and air stagnation is felt in the living quarters (living room, bedroom), and odors in the kitchen are not removed after cooking, but spread throughout the home.

All these factors indicate that the ventilation system does not cope with its task of providing fresh air, as well as its effective exhaust.

You can check the draft force in the air duct by bringing a strip of paper to the ventilation grille. The quality of the system is determined by the intensity of the fluctuations: the larger they are, the better the air exchange.

Maintenance of ventilation allows you to prevent most of the possible negative consequences, including: blockage in one or more sections of the ventilation duct, depressurization of the air duct, equipment failure, reduced efficiency due to clogged filters or other equipment components. But it is impossible to completely exclude the possibility of a sudden breakdown, since due to the combination of various conditions, there is always a danger of a malfunction. But this probability can be reduced if the frequency of ventilation maintenance is observed.

Checking ventilation as a vital necessity

It may very well be that behind the ventilation grate the shaft is clogged with dirt.

It may very well be that behind the ventilation grate the shaft is clogged with dirt.

Ventilation of premises is understood as the entry of air into the apartment from the outside, ensuring its ventilation, displacement of gaseous waste products of humans, animals, etc. Ventilation systems include devices and equipment that ensure the regulation of air exchange.There are several types of ventilation systems, but in multi-storey residential buildings, it mainly operates supply and exhaust type of ventilation.

The absence or inefficient work of it will immediately be noticed by the owners of apartments in a multi-storey building. Main features:

- deterioration in the well-being of people;

- penetration of odors from neighbors;

- the formation of mold, fungus in the bathroom and bathroom;

- high humidity in the rooms, linen that does not dry out for a long time;

- the spread of odors from the toilet, kitchen throughout the apartment.

If these symptoms are present, a ventilation check is performed. Its main goal is to eliminate the listed problems, prevent damage to household items and furniture. The main requirement is the creation of a healthy microclimate.

The frequency of checking ventilation in the house, in the apartment

For premises of residential buildings in which there is no gas-powered equipment

Checking the condition of the ventilation ducts and, if necessary, cleaning them is carried out:

-

-

- upon acceptance of ventilation ducts into operation;

- during the reconstruction and repair of ventilation ducts;

- during the operation of ventilation ducts (periodic check) - at least 2 times a year, in spring and autumn;

- in the absence of traction detected during operation (at the request of residents);

-

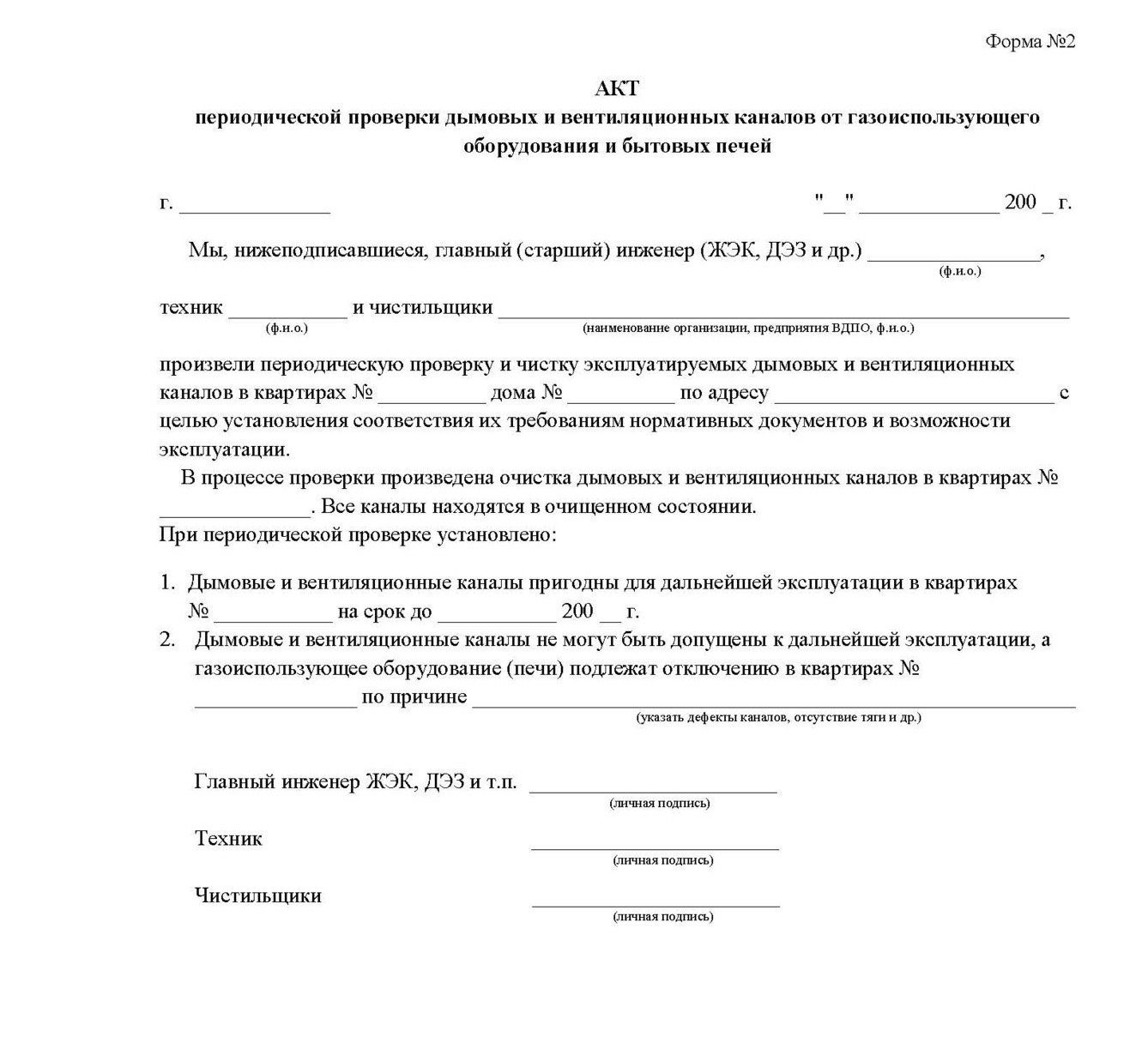

Frequency of ventilation checks for buildings using gas appliances

Decree of the Government of the Russian Federation of May 14, 2013 N 410 "On measures to ensure safety when using and maintaining in-house and in-house gas equipment"

Item 12. Checking the condition of smoke and ventilation ducts and, if necessary, cleaning them is carried out:

a) upon acceptance of smoke and ventilation ducts into operation during gasification of the building and (or) connection of new gas-using equipment;

b) during the reconstruction and repair of smoke and ventilation ducts;

c) during the operation of smoke and ventilation ducts (periodic inspection) - at least 3 times a year (no later than 7 calendar days before the start of the heating season, in the middle of the heating season and no later than 7 days after the end of the heating season) ;

d) in the absence of traction detected during operation (at the request of residents);

during maintenance and repair of in-house (VDGO) and (or) in-house (VKGO) gas equipment;

when diagnosing intra-house and (or) intra-apartment gas equipment;

for emergency dispatching support of gas equipment.

What tasks does professional expertise solve?

The management company is obliged to annually check the ventilation in the apartment

The management company is obliged to annually check the ventilation in the apartment

Most often, the cause of misted glass, the formation of fungus, dampness and stale air in the room lies in the mistakes of designers and builders. Their correction is impossible without radical measures: a major overhaul or reconstruction of the house. An independent inspection reveals the flaws of builders during the installation of shafts, ducts, highways, and also proposes measures to eliminate them.

Checking the ventilation in the apartment by the management company should be carried out on the basis of the "Rules for the maintenance of common property in an apartment building". The document contains a list of sequential steps to maintain it in good condition. This includes:

- system performance analysis and maintenance;

- Troubleshooting causing excessive levels of vibration and noise during operation;

- development of restoration and repair measures, etc.

If the building with inefficient ventilation is a multi-apartment new building, then it is covered by the warranty. (at least 5 years). It is necessary to require the developer to conduct an inspection of the ventilation system, troubleshooting.

In the event of a dispute in an apartment building, an independent examination is carried out. The examination allows to identify the reasons for the inefficiency of ventilation, non-compliance with construction and installation rules when installing ventilation shafts. Indicates a list of works to improve aeration. All proposals are documented. Recommendations are given to improve efficiency system operation in different areas of apartments and houses.

Algorithm for drawing up an act

At the top of the page indicate the exact name of the act itself. Below is a description of the object of verification and the actual address at which it is located.

Paper header - on the right side, starts from the date of compilation. This form is considered the most effective in comparison with any existing protocols.

Then those who are members of the commission are listed. Be sure to include the following information:

- Surnames.

- Initials.

- Job title.

For non-residential premises

The document has different forms, depending on whether it is drawn up for residential or non-residential premises. In the case of non-residential, references to the following information are required:

- signatures;

- conclusions along with suggestions;

- information on whether compliance with GOST has been established or not;

- a description of the method that was used to organize the check;

- technical documentation attached to the ventilation itself;

- check time and address at which the object is located;

- positions and information on the chairmen, members of the commission.

The document is more detailed when it comes to residential facilities. A sample act of ventilation efficiency may look like this:

Schools and kindergartens

Especially a lot of questions arise for large rooms with equipment in the amount of 10 or more pieces. In this case, additional employees may be needed for verification - with the status of an electrician, for example.

In addition to the information already mentioned above, such acts should contain the following descriptions:

- Exact list of equipment related to ventilation.

- Air exchange coefficient. And the extent to which it complies with accepted standards.

- Norm according to the attached drawings.

- The lower part is supplied with the seal of the head of the enterprise and his signature together with the representative of the construction and contracting organization responsible for the verification. The signature of the representative of the supervisory organization is also required.

List of works performed during certification

Since all certification measures are aimed at clarifying strictly standardized information, only typical procedures are performed. It is categorically impossible to do, as already mentioned, without deep testing of ventilation systems. First of all, they study the design features and the practical state of the air supply systems. They must fully satisfy both the official working draft and the norms of the standards.

Thereafter:

- understand whether the tightness of hidden areas is broken;

- look at the work of the main part of the equipment at idle;

- make sure that the fans have the characteristics declared in the documentation (or do not have).

The next step is to check the efficiency of air exchange through ventilation in fact and whether it meets design standards.

Important: the regulatory authorities can and should also check the natural circulation in order to find out whether the information on it underlying the projects is correct. Measurement of the volume of sound that occurs during the operation of ventilation is carried out at several points

Where they are located is determined in advance using special calculations. This applies to a greater extent to acoustics and deserves a separate discussion.

Order of conduct.

Sanitary and hygienic control is carried out according to a pre-formed program. Such a document can be developed both by the enterprise and through the involvement of specialized organizations. It is worth considering that turning to professionals will allow:

- take into account the requirements of existing legislative and regulatory documents;

- take into account all the features of the production process and installed equipment;

- reduce document development time;

- avoid shortcomings.

The cost of the described service can be from 19,900 rubles, the minimum development period is from 7 days.

An important point in the formation of the document in question is the frequency of control.

For existing enterprises, it is:

- in case of release in production operations of substances belonging to hazard classes 1 and 2 - at least once a month;

- for local supply and exhaust ventilation systems - at least once a year;

- for systems of natural or mechanical general ventilation - at least 1 time in 3 years;

- for newly installed or reconstructed systems - immediately after installation.

New or reconstructed ventilation systems are accepted by a special commission, which, in addition to the developers and employees of the enterprise, must include a representative of Rospotrebnadzor.

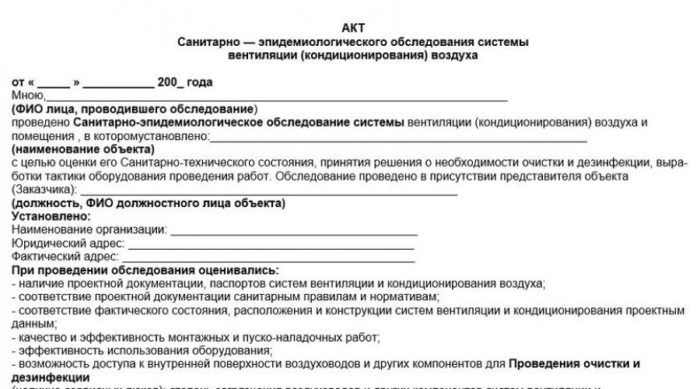

How are measurements taken?

In accordance with the developed program, further control is carried out by the sanitary laboratory of the enterprise (if the relevant accreditation certificate is available), or by an external accredited laboratory under the relevant agreement.

In turn, the laboratory makes instrumental measurements of the concentration of pollutants in the air of the working area, determines the parameters of the microclimate of the premises, the parameters of the efficiency of ventilation systems and the level of influence of physical factors that arise during their operation.

The requirements for measurement methods and equipment used are established by the above Guidelines No. 4425-87 of 09/05/1987. The results obtained are compared with the indicators given in regulatory documentation, for example, in such as SanPiN 2.2.4.3359-16 (approved by Resolution No. 81 Chief State Sanitary Doctor of the Russian Federation of 21.06.2016) or GOST R EN 13779-2007 of 01.10.2008

Control over compliance with the requirements of the program is carried out by employees of Rospotrebnadzor. The results of the measures taken are recorded in the passport of ventilation systems, or used as the basis for its development. Protocols of instrumental measurements are filed to the developed production control program.

What will be included in the ventilation control program?

This is a comprehensive document containing the basic information required when checking the effectiveness of the functioning of ventilation systems.

The content will include sections such as:

- general information about the object under study;

- information about the supply and exhaust ventilation systems installed in the production premises, indicating the location;

- data on sampling sites and control points;

- list of controlled parameters;

- frequency of control;

- list of recommended measurement methods and techniques;

- information about the persons responsible for the implementation of the program activities.

Program coordination.

First of all, the developed program for the control of ventilation systems is agreed upon by the head of the enterprise. In addition, in accordance with the established rules, the frequency of control is also required to be coordinated with the sanitary doctor of Rospotrebnadzor.

In addition, the document in question, as well as its results, are provided to Rospotrebnadzor if it is necessary to obtain a sanitary and epidemiological conclusion on project documentation for further examination.

Features of maintaining a document

Knowing all of the above is very good - no one argues with that. But for the customer of the work or for the owner of the building, other circumstances are more important

It is important for them to have clear criteria in order to understand whether the ventilation system passport provided by the contractor is correct. You also need to know what to enter in this document yourself, and what is not worth making.

There are three types of ventilation passports that are officially recognized.

The first type is the so-called construction type, the second is compiled during operation, and the third applies only to installations that clean gases. Additionally, they can draw up passports that take into account the specific moments of a particular industry. But this is a completely different topic. "Construction" passports are drawn up whenever commissioning is carried out

Important: this is required even in the absence of adjustment as such, because otherwise the operation becomes illegal

Characteristic features of a poorly drafted document will be:

- complete coincidence of design figures and actual data (in reality, this does not happen);

- lack of notes;

- an abundance of empty graphs (those who do not know enough about the ventilation adjustment are forced to skip them so as not to demonstrate their incompetence);

- mention of testing without specifying a specific date for them.

If the certification customer detects at least one of these signs, he has the right to return the document to the contractor and demand a reworking of the work or a refund of the amounts paid. The title page (although it is not always present) describes the identification information about the object. The heading of the passport contains an indication of the commissioning organization. Information about it should allow you to fully identify this structure. It is allowed (although not mandatory) to place corporate symbols.

If the organization has been accredited, it will definitely report the number of the certificate confirming this fact. This number will be required later - to draw up test reports. It substantiates the legitimacy of each conclusion drawn.As for the type of ventilation system, it must be signed in full, indicating the passports for the exhaust and inflow, for the humidifier and other components. In the future, it will be easier to navigate in such a document for both controllers and operational services.

If the number of installations exceeds 50–70, devices of the same type by purpose may be indicated in the documentation in color font. No standard regulates this, so the choice of color is at your discretion. Although construction practice implies writing the address according to the project, it is better for state inspectors to show the act, which indicates the real address of the structure

Important: it is also worth writing down the legal address of the contractor (along with the actual one), which helps to achieve the favor of the regulatory authorities. If everything is done in good faith, it is necessary to immediately provide for a reserve of free space, where the results of tests for efficiency will be reflected.

The problem of the building form is that it reflects a number of information that is unnecessary for practitioners, while not including really important information. Most often, this disadvantage is eliminated through the use of notes.

For fans indicate:

- numbers assigned at factories;

- full typical names of ventilation units that differ from the names of fans;

- settings of control blocks or rotational speed corresponding to passport parameters;

- other installed equipment;

- information about repairs (if any).

The passport must be accompanied by protocols recording the results of the tests. Usually building practice does without them, although this is just a habitual omission.In some cases, you can add instructions for using the ventilation system (if it is somehow different from the usual one). We are talking only about brief instructions (up to 1 sheet). Full instructions sometimes include up to 30 sheets; they do not need to be attached to passports.

Passports for exhaust devices are reduced if there is no section on the air heater. But the documentation compiled in production often grows due to information reflecting the replacement of individual components and modernization work. A full reflection of maintenance alone requires several pages.

As a result of tests, protocols are also added to the passports, reflecting:

- results of aerodynamic testing of the fan;

- tightness of pipeline channels;

- noise level;

- vibration intensity;

- overpressure.

A hint about checking the efficiency of ventilation systems is in the video below.