- Room for the installation of a gas boiler

- boiler room requirements

- Requirements for the room for the installation of a turbocharged unit

- Requirements for industrial gas boilers

- Basic requirements for gas boilers.

- Rules and regulations for the installation of gas-fired boilers

- wall

- Outdoor

- Main regulatory documents

- According to SP62.13330.2011:

- Safety regulations

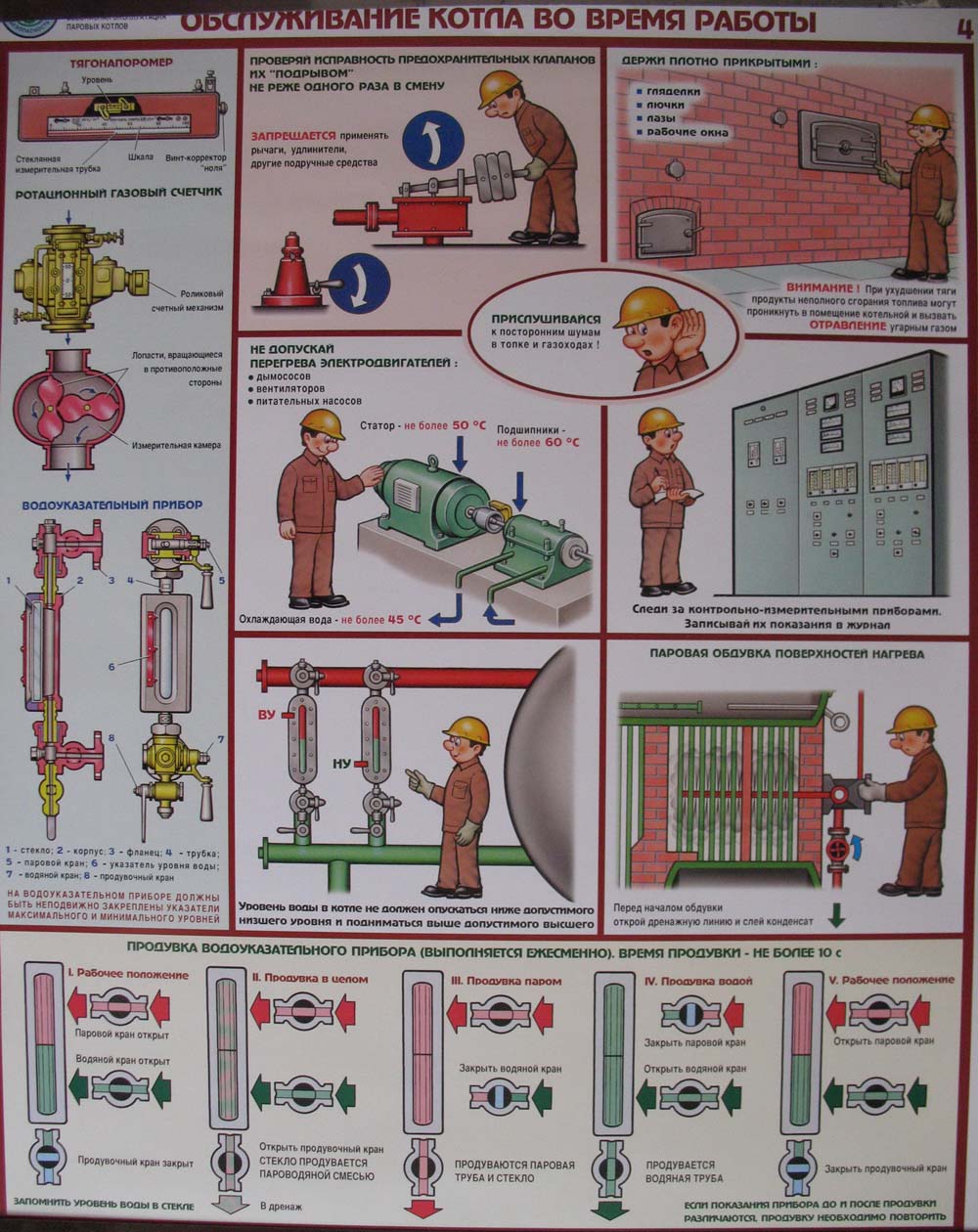

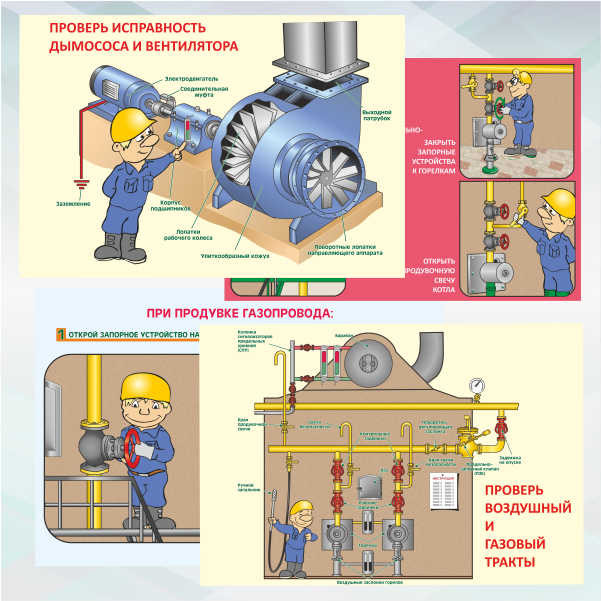

- Basic rules for using a gas unit

- Can I install the equipment myself?

- Air duct materials in gas boiler rooms

- Brick exhaust ducts

- Ceramic ventilation pipes

- Steel air ducts

- Installation: recommendations and diagrams, the main stages of the installation of the chimney

- General requirements

- Installation steps

- Video description

- Connecting a ceramic chimney

- Video description

- Apparatus classification

- floor standing

- wall

- Service life of units

- Rules and regulations for installing a gas boiler in a private house

- Boiler room in a private house in a separate room (built-in or attached)

- Special requirements for attached boiler rooms

- Conclusions and useful video on the topic

Room for the installation of a gas boiler

The volume of the room for a gas boiler depends on the type of unit and its power.All requirements for the boiler room or other place where the device is located are prescribed in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 .

Gas boilers differ in the type of combustion chamber:

…

- units with an open combustion chamber (atmospheric);

- devices with a closed firebox (turbocharged).

To remove combustion products from atmospheric gas boilers, you will need to install a full-fledged chimney. Such models take air for the combustion process from the room in which they are located. Therefore, these features require a device for a gas boiler in a separate room - a boiler room.

Units equipped with a closed firebox can be placed not only in a private house, but also in an apartment in a multi-storey building. The removal of smoke and the influx of air masses is carried out by a coaxial pipe that exits through the wall. Turbocharged devices do not require a separate boiler room. They are usually installed in the kitchen, bathroom or hallway.

boiler room requirements

The minimum volume of the room for installing a gas boiler depends on its power.

| Gas boiler power, kW | Minimum volume of the boiler room, m³ |

| less than 30 | 7,5 |

| 30-60 | 13,5 |

| 60-200 | 15 |

Also, a boiler room for placing an atmospheric gas boiler must meet the following requirements:

- Ceiling height - 2-2.5 m.

- The width of the doors is not less than 0.8 m. They must open towards the street.

- The door to the boiler room must not be hermetically sealed. It is required to leave a gap between it and the floor 2.5 cm wide or make holes in the canvas.

- The room is provided with an opening window with an area of at least 0.3 × 0.3 m², equipped with a window. To ensure high-quality lighting, for every 1 m³ of the volume of the furnace, 0.03 m2 of the area of the window opening should be added.

- The presence of supply and exhaust ventilation.

- Finishing from non-combustible materials: plaster, brick, tile.

- Electric light switches installed outside the boiler room.

Note! Installing a fire alarm in the boiler room is not a mandatory, but recommended condition. It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

The boiler must be freely accessible from the front panel and from the side walls.

It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

…

Requirements for the room for the installation of a turbocharged unit

Gas boilers with a closed combustion chamber with a power of up to 60 kW do not require a separate furnace. It is enough that the room in which the turbocharged unit is installed meets the following requirements:

- Ceiling height over 2m.

- Volume - not less than 7.5 m³.

- Has natural ventilation.

- Closer than 30 cm next to the boiler there should not be other appliances and easily combustible elements: wooden furniture, curtains, etc.

- The walls are made of fire-resistant materials (brick, slabs).

Compact hinged gas boilers are even placed between cabinets in the kitchen, built into niches. It is more convenient to install double-circuit units near the water intake point so that the water does not have time to cool before it reaches the consumer.

In addition to generally accepted standards, each region also has its own requirements for a room for installing a gas unit

Therefore, it is important to find out not only how much space is needed to install a gas boiler, but also all the nuances of placement operating in a given city.

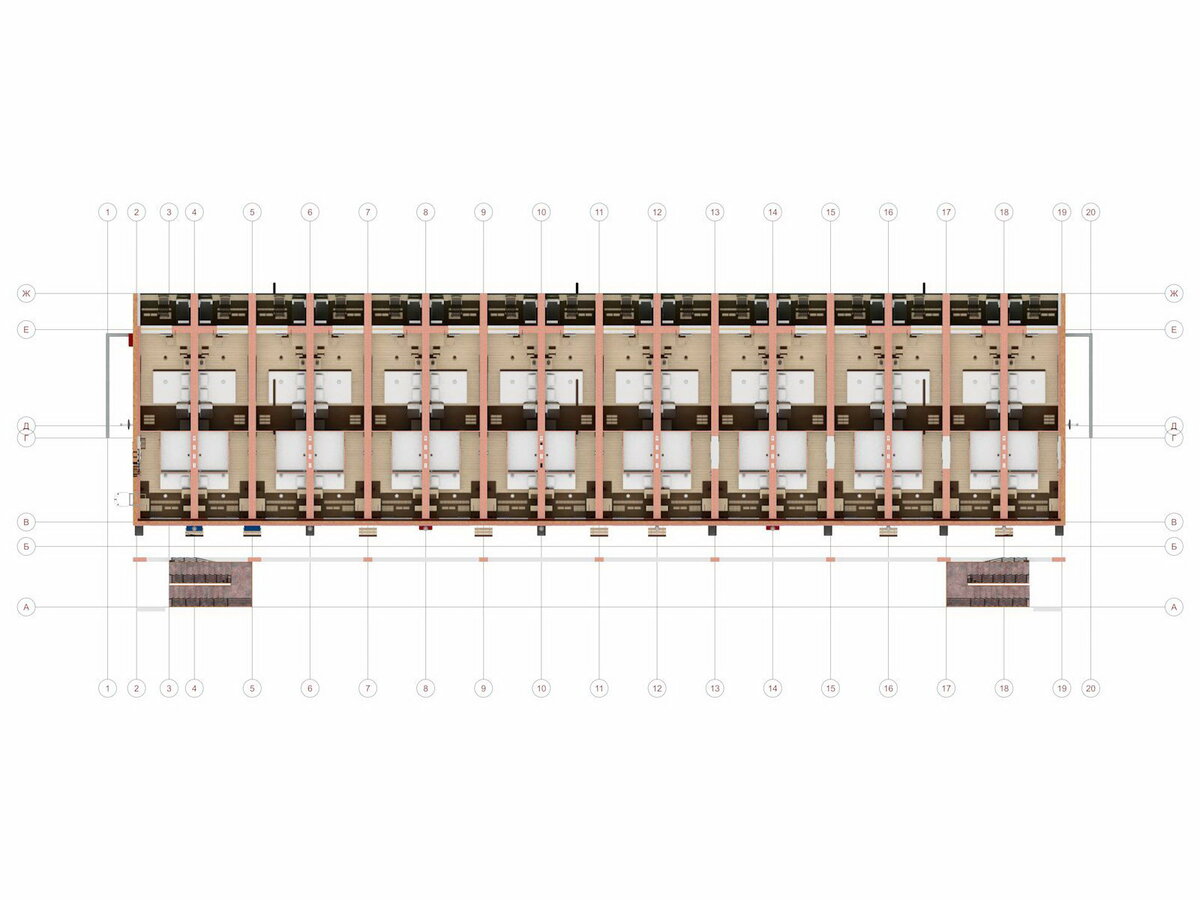

Requirements for industrial gas boilers

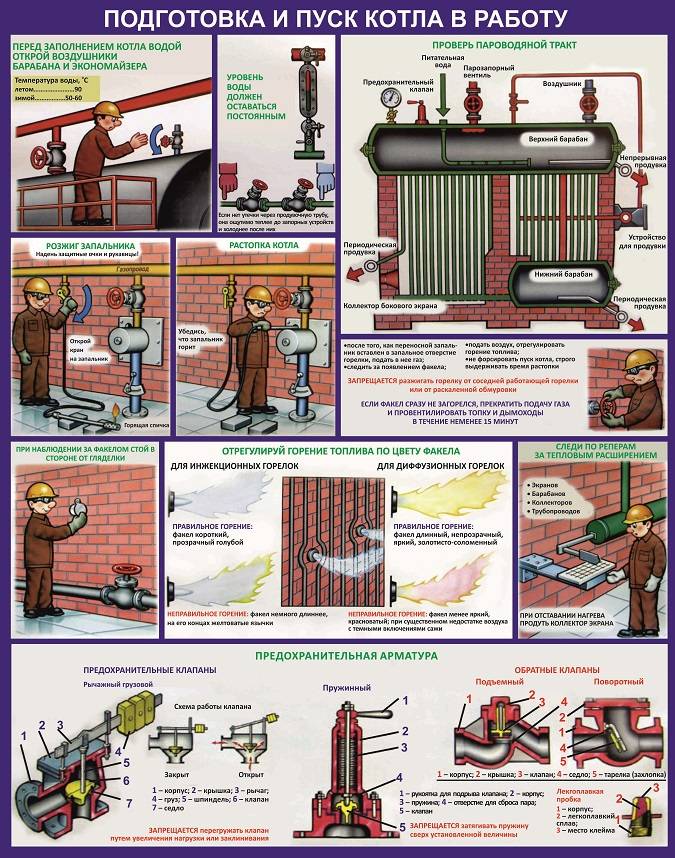

The gas is highly flammable due to which the state requirements for such objects are extremely high, and are enshrined in SP 89.13330.2012.

This code defines the requirements for thermal equipment at the stages of design, installation, repair or technical re-equipment and safe operation.

Basic requirements for gas boilers.

The operation of boiler plants is carried out in accordance with the established state regulatory regulations and rules in the field of production safety;

- Installation of boilers is allowed in separate buildings or in premises adjacent to the production building, disconnected from it by a firewall.

- It is forbidden to install gas heating units under objects where a large number of people can be concentrated and located under a fuel and lubricants warehouse.

- The floor covering in the boiler room is made of fire-resistant materials with a non-smooth structure.

- In rooms for the location of heating units with a total area of \u200b\u200bup to 200 m2, it is allowed to install one outlet, and more than 200 m2 - at least 2, placed oppositely.

- The doors of gas boiler rooms must open outwards and be equipped with vestibules in order to prevent the entry of cool air.

- The doors to the auxiliary premises must open towards the boiler room and have the equipment for self-closing.

- All rooms are equipped with natural or supply and exhaust ventilation.

- The placement of the equipment should not violate the distance for maintenance: from the front of the boiler units to the opposite one, more than 2 m, free passages between the equipment - at least 1.5 m.

Rules and regulations for the installation of gas-fired boilers

Such boilers are installed according to the project, which reflects all safety standards, the installation site and fireproof distances to the structural elements of the building are determined.

Prior to the start of construction and installation works, project documentation is coordinated with the relevant regulatory agencies, which also check it for compliance with state standards.

The installation of the boiler is carried out only by a specialized organization licensed to carry out such work. After the completion of the installation work, the boiler is put into operation on a commission basis consisting of representatives of the customer, the design organization of the installation company, city gas, architecture, capital construction, SES and the fire department. Thus, the owner must also know the requirements for the location of gas boiler equipment in order to properly prepare the terms of reference for the design.

wall

Boiler diagram on the wall

Boiler diagram on the wall

The requirements for the premises where it is planned to install a wall-mounted heating unit are primarily aimed at protecting building structures from fire

In this option, the owner will have to pay special attention to the wall on which they plan to fix the device, it must be able to withstand the weight of the structure and fire resistant

Basic room requirements for wall-mounted units:

- The volume of the room for the gas boiler is over 7.51 m3.

- The presence of powerful natural ventilation, a window block with a window and a door with an opening for air intake - 0.02 m2 should be placed in the room.

- The maximum distances to the enclosing elements of the building: floor - 80 cm, ceiling - 45 cm, walls on the sides - 20 cm, from the body to the rear wall - 40 mm, from the front of the unit to the door - 100 cm.

- The placement wall is covered with a fire-resistant material made of steel sheet with a thickness of more than 3 mm.

- Thermally insulate the side adjoining surfaces of walls and furniture.

Outdoor

For these models, more attention should be paid to the floor structure, since such structures are heavy, and heat losses from the body mainly go to the flooring underneath.

Therefore, in the area of the boiler unit, a base is made of non-combustible material, with reinforcement capable of withstanding the entire design of the heat supply system, with a boiler and an indirect heating boiler.

Room norms for installing a gas boiler with floor installation:

- Free access to the working elements of the boiler unit.

- The minimum area for placing one unit is at least 4m2, while no more than 2 devices are allowed in the room.

- The height of the room is 2.20 m.

- Supply and exhaust ventilation, windows at the rate of 0.3 m2 per 10.0 m3 of room volume, a door with an opening of 0.8 m.

- The gap between the door and the front of the unit is -1 m.

- The walls and floor are made of non-combustible materials.

Main regulatory documents

Requirements for gas boilers are given in the following regulatory documents in force in 2020:

- SP 62.13330.2011 Gas distribution systems. (Updated version of SNiP 42-01-2002)

- SP 402.1325800.2018 Residential buildings. Rules for the design of gas consumption systems (acting on a voluntary basis by order 687)

- SP 42-101-2003 General provisions for the design and construction of gas distribution systems from metal and polyethylene pipes (it is advisory in nature)

- Instructions for the placement of thermal units intended for heating and hot water supply of single-family or detached residential buildings (MDS 41-2.2000) (it is advisory in nature)

Let us single out the most important requirements (point by point) that must be observed when designing and building a gas boiler house in a house, as well as when designing a gas pipeline route:

According to SP62.13330.2011:

pp. 5.1.6* Gas pipelines should be introduced into buildings directly into the room in which gas-using equipment is installed, or into a room adjacent to it, connected by an open opening.

It is allowed to provide for the entry of gas pipelines into the kitchens of apartments through loggias and balconies, provided that there are no detachable connections on the gas pipelines and access is provided for their inspection.

It is not allowed to introduce gas pipelines into the premises of the basement and basement floors of buildings, except for the inputs of natural gas pipelines into single-family and block houses and industrial buildings, in which the input is due to production technology.

pp. 5.2.1 Laying of gas pipelines should be carried out at a depth of at least 0.8 m to the top of the gas pipeline, case or ballasting device, except as otherwise specified. In those places where the movement of vehicles and agricultural vehicles is not provided, the depth of laying steel gas pipelines should be at least 0.6 m.

pp.5.2.2 The vertical distance (in the light) between the gas pipeline (case) and underground utility networks and structures at their intersections is recommended to be taken in accordance with Appendix B * SP62.13330.2011.

According to Appendix B * for underground laying of a gas pipeline (gas pressure up to 0.005 MPa) and the most common communications on the land plot of a private house:

- Vertically (when crossing) with water supply and sewerage - at least 0.2 m clear (between pipe walls)

- Horizontally (in parallel) with water supply and sewerage - at least 1 m

- Horizontally (in parallel) with power cables up to 35 kV - at least 1 m (with a protective wall, it can be reduced to 0.5 m)

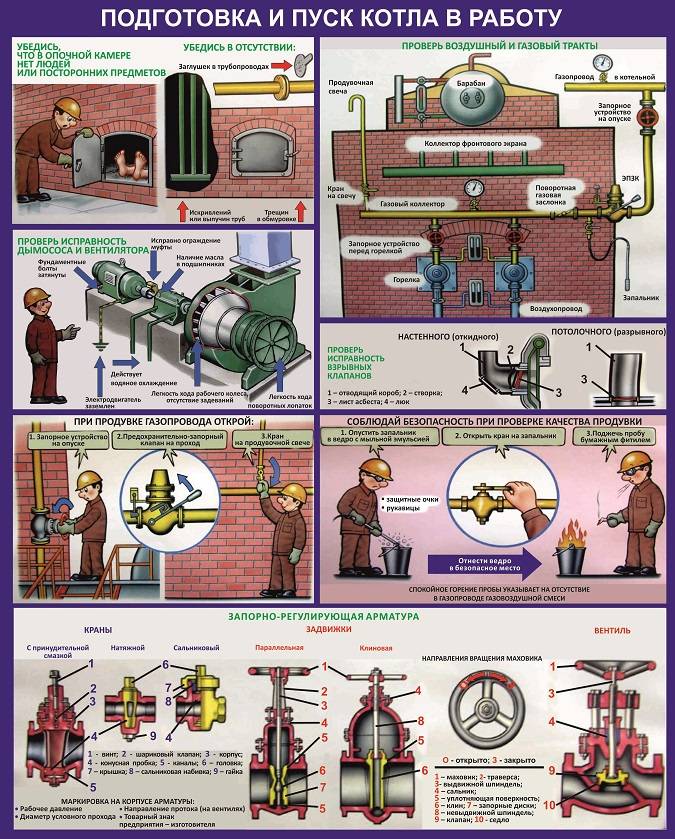

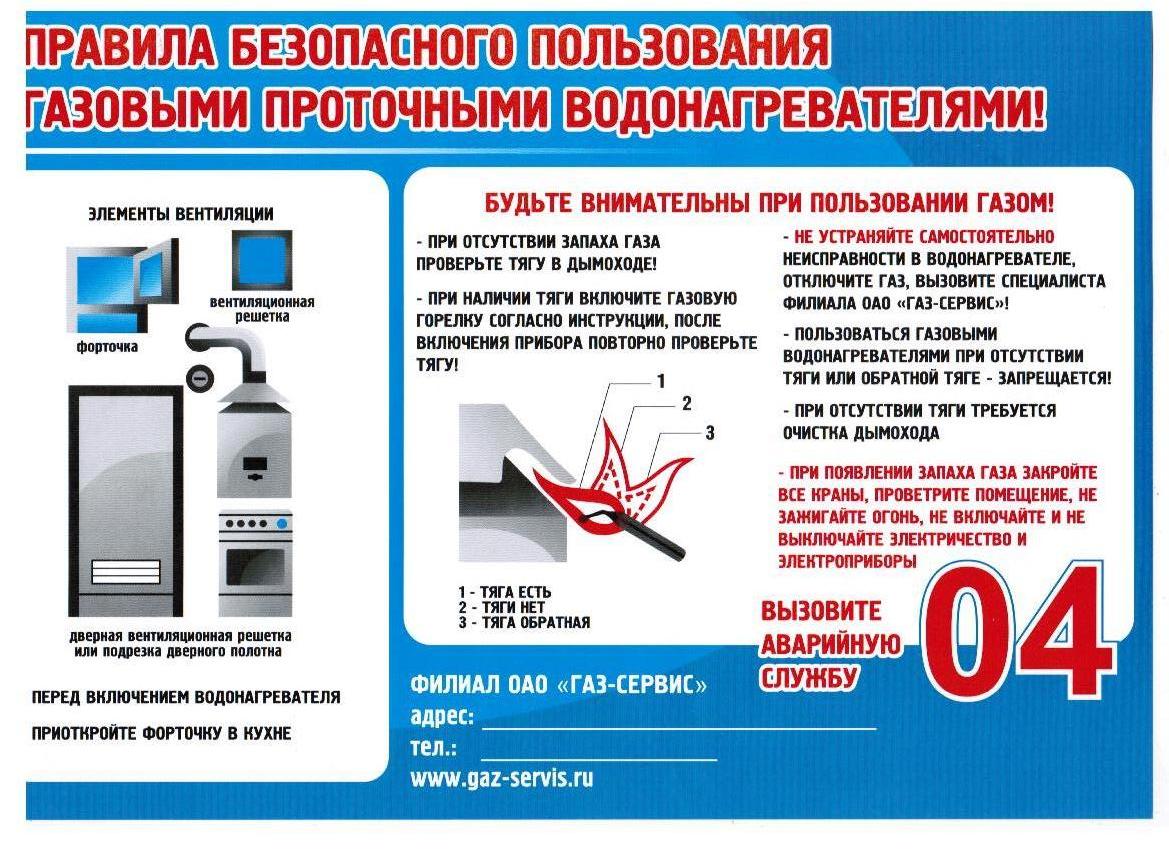

Safety regulations

Gas is a cheap type of fuel, burns without residue, has a high combustion temperature and, as a result, a high calorific value, however, when mixed with air, it is explosive. Unfortunately, gas leaks are not uncommon. In order to protect yourself as much as possible, you must strictly follow the safety rules.

First of all, it is necessary to study the operating instructions for gas equipment and follow them, monitor the normal operation of gas appliances, chimneys and ventilation.

The owners of residential premises are prohibited from disturbing the ventilation system of residential premises during the redevelopment and reorganization of the apartment.

Before lighting the gas stove, the room must be ventilated, the window should be left open for the entire time of working with the stove. The valve on the pipe in front of the stove is opened by moving the flag of the handle to the position along the pipe.

The flame should light up in all holes of the burner, have a bluish-violet color without smoky tongues.If the flame is smoky - the gas does not burn completely, it is necessary to contact the specialists of the gas supply company and adjust the air supply

Please note: if the flame detaches from the burner, this means that too much air is supplied, and in no case should you use such a burner!

If you catch the characteristic smell of gas in the room, you should not turn on or off any electrical appliances in order to avoid an electrical spark that can lead to a gas explosion. In this case, it is urgent to shut off the gas pipeline and ventilate the room. In case of departure to the country or on vacation, it is necessary to turn off the gas by turning the tap on the pipe. Ideally, turn off the gas valve after each use of the stove or oven.

It is necessary to immediately contact the emergency gas service in the following cases:

- there is a smell of gas in the entrance;

- if you find a malfunction of the gas pipeline, gas valves, gas appliances;

- when the gas supply suddenly stops.

Remember that inspection and repair of gas equipment can only be carried out by employees of gas facilities. Their authority is confirmed by service certificates, which they must present to the owner of the apartment.

Basic rules for using a gas unit

It is necessary to use heating gas appliances in compliance with certain rules:

- The boiler room or other room should always be dry.

- Filters for the heat carrier should be cleaned of dirt in a timely manner in order to extend the life of the heat exchanger.

- It is strictly forbidden to make independent changes to the structural device of the boiler.

- Cleaning of the flue structure pipe from the combustion products deposited on its walls should be carried out in a timely manner.

- In a private household or boiler room, it is advisable to install a gas analyzer that helps to identify malfunctions in the functioning of gas equipment.

- Timely maintenance of the heating unit should not be avoided, which experts recommend to carry out before the start of the heating season and after its completion. To do this, you need to invite a master who will comprehensively check the condition and operation of the chimney, ventilation system, filters, burner and boiler as a whole.

A qualified installation and compliance with preventive measures can ensure the long and trouble-free operation of gas equipment, and, accordingly, the entire heating system of a household.

Can I install the equipment myself?

In short, the installation of a gas boiler in a private house can be carried out by any person, but putting the equipment into operation - acceptance and testing should be carried out by specialists from the gas service, connecting a gas boiler in a private house and operating it without their permission is impossible.

It is most reliable to entrust the installation of gas equipment to qualified representatives of a specialized organization. Only they will be able to carry out the necessary work competently, in accordance with the requirements of SNiP, and ensure the safe operation of the equipment. In addition, a competent specialist always works under a contract, which indicates who, when and what kind of work was done.

Air duct materials in gas boiler rooms

Properly selected material for the duct ensures longer ventilation operation.

In accordance with the current standards, the following can be used as a material for organizing ventilation of rooms with gas equipment:

- brick;

- ceramics;

- asbestos;

- galvanized and stainless steel.

It is undesirable to use plastic for air ducts, because. this reduces the fire resistance of structures. In some regulations (for example, paragraph 7.11 of SNiP 41-01-2003) indicates that air ducts can be partially made of combustible materials.

When using plastic elements, it must be remembered that the presence of combustible elements in the structure will complicate the commissioning of boiler equipment and its acceptance by gas service employees

Regardless of what material will be used, all ventilation ducts passing through cold areas must be insulated. In these places, draft may decrease, condensate may form, and the ventilation duct of the boiler room with a gas boiler may freeze and cease to perform its functions. That is why it is better to stretch pipes along a warm contour, excluding the possibility of their freezing.

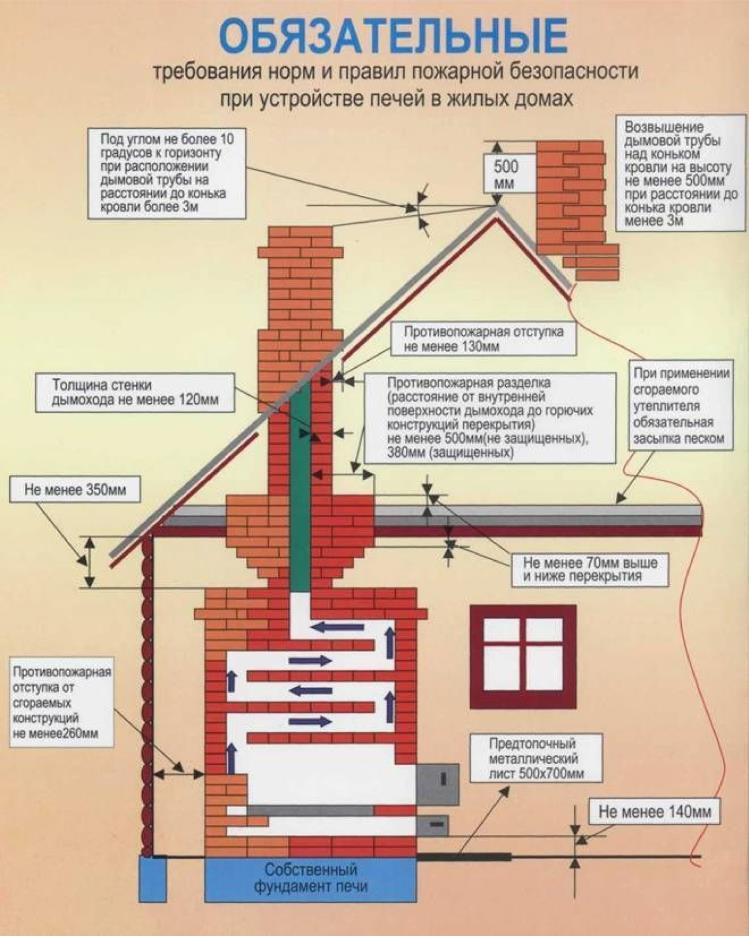

Brick exhaust ducts

Brick is short-lived, because. due to temperature differences, condensation forms on its surface, leading to the destruction of the material. If brickwork is taken as a material for the mine, then the chimney is assembled from single-circuit galvanized metal pipes, the thickness of which depends on the temperature of the emitted gases.

Ceramic ventilation pipes

Air ducts made of ceramics are versatile, easy to use and durable. The principle of their assembly is similar to the technology of ceramic chimneys.Due to the high gas density, they are resistant to strong pollution of various types and aggressive chemical environments.

But in such hoods it is necessary to install steam traps, because. Ceramic absorbs moisture well. Structurally, such an extract consists of 3 layers:

- ceramic inner layer;

- middle insulating layer of stone and mineral wool;

- outer expanded clay concrete shell.

This ventilation system cannot have more than three elbows. At the bottom of the ceramic chimney, a drip and a revision are installed.

Steel air ducts

Steel exhaust channels are convenient and practical.

A metal chimney in a gas boiler room may have a rectangular or rounded cross-sectional shape, but in this case, the width of one of its sides should not exceed the width of the second by 2 times

When installing a steel ventilation system, you must adhere to the following recommendations:

- The segments are collected using the pipe-to-pipe method.

- Wall brackets are fixed in increments of no more than 150 cm.

- The length of the horizontal segments should be no more than 2 m, unless forced draft is provided in the system.

According to the standards, the thickness of the steel walls should be at least 0.5-0.6 mm. The temperature of the gas that boilers produce is 400-450 C, which is why thin-walled metal pipes can quickly burn out.

Installation: recommendations and diagrams, the main stages of the installation of the chimney

The installation of the chimney is divided into several stages - this is the preparatory work, the installation itself, then the connection, start-up and, if necessary, debugging of the entire system.

General requirements

When combining several heat generating installations, a separate chimney is created for each of them.In exceptional cases, a tie-in to a common chimney is allowed, but at the same time, a difference in height of at least one meter must be observed.

First, the parameters of the chimney are designed and calculated, which are based on the recommendations of the manufacturers of gas boilers.

When summarizing the calculated result, the inner section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to the check according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m / s. And besides, the cross section of such a channel must correspond to the overall performance of the unit (8 cm2 per 1 kW of power).

Installation steps

Chimneys for gas boilers are mounted outside (add-on system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney

Installing a chimney at a wall-mounted boiler is done as follows:

- A hole is cut in the wall. Then a piece of pipe is inserted into it.

- A vertical riser is assembled.

- The joints are sealed with a refractory mixture.

- Fixed with wall brackets.

- An umbrella is attached to the top to protect it from rain.

- An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and prevents soot from accumulating. Installation performed by specialists will significantly reduce the cost of maintaining this system.

In the case of arranging an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

- The material from which the pipe is made.

- Exterior design of the chimney.

- Type of roofing.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to the standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced is the assembly system by segments, where all elements are assembled by cold forming.

Video description

How the chimney pipe is installed, see the following video:

Connecting a ceramic chimney

Ceramic chimneys themselves are almost eternal, but since this is a rather fragile material, you need to clearly imagine how the connection (docking) of the metal part of the chimney and the ceramic one is correctly performed.

Docking can only be done in two ways:

By smoke - a metal pipe is inserted into a ceramic

It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of the metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply break the ceramic one.

For condensate - a metal pipe is put on a ceramic one.

For both methods, specialists use special adapters, which, on the one hand, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped with a ceramic cord.

Docking should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little before it reaches the adapter, which ultimately extends the life of all materials.

Video description

Read more about connecting to a ceramic chimney in the following video:

VDPO shows great requirements for chimneys for gas boilers, because of this, it must be installed by specialized teams. Since competent installation guarantees not only long-term operation of the device, but also makes living conditions in a private house safe.

Apparatus classification

The basic criterion for choosing a boiler is its ability to heat the designated area. In order for the device not to work at maximum loads, you need to choose an economical gas boiler with a small power reserve.

This indicator is conditional, but with its help it will be possible to choose the right equipment.

It is worth choosing according to the accommodation option, because there are two large groups:

- floor boilers;

- wall boilers.

floor standing

The first option is in demand for heated rooms, the area of which is more than 200 m 2. These units are used not only for direct heating of housing, but also to create a special microclimate in the room. It should be noted that the efficiency of such a gas boiler will be lower than that of their wall-mounted counterparts. However, this is offset by a significantly longer service life, which, with proper care, reaches several decades.

Such indicators are achieved through the use of optimal materials involved in the manufacture of the heat exchanger. As a result, due to low operating costs for large areas, floor-standing devices are classified as economical gas boilers for heating a private house.

Most of them use cast iron heat exchangers. Due to the physical and chemical characteristics of the used grades of cast iron can withstand most of the negative internal factors.A good helper is the use of anti-corrosion materials that have effective additives that reduce the appearance of rust.

wall

The wall-mounted gas heating boiler has a significantly smaller mass and smaller dimensions, so it easily fits on a vertical surface. Such a module must be connected simultaneously to several systems:

- gas supply for supplying fuel to the combustion chamber;

- power supply to start the automation and circulation of the water pump;

- heating system with an expansion tank and the required number of consumers.

All economical gas boilers have a process control unit concentrated in a single place. Here you can set the temperature, get information about the current pressure, or turn off the device completely.

Wall-mounted boilers are characterized by the use of two types of thrust:

Most economical gas boilers have a forced system installed. For its implementation, an electric fan and a discharge spiral cavity are used.

The main operational processes are regulated by automation. The positive factors of wall-mounted boilers are as follows:

- saving usable space in the room;

- the minimum mass that does not load the wall;

- in some cases they can be converted to LPG operation.

VIDEO: Which boiler to choose - wall or floor

Service life of units

Most modern economical gas boilers last about 7-12 years. Their service life is affected by the quality of the working elements in direct contact with water, such as the heat exchanger and the pump.

Gas boiler connection diagram

In the presence of high indicators of water hardness, salt deposits occur. To improve the quality of the coolant, polyphosphate filters are used. Due to the use of polymer salts in them, it is possible to reduce the stiffness value to acceptable levels. This reduces the cost of heating the coolant and thus contributes to fuel savings.

The period of operation is affected by the intensity of the work of mechanical elements, for example, in a pump. In this regard, it will be necessary to carry out regular maintenance of it, changing oil seals, gaskets and rubbing elements.

Also, the quality of electricity affects the life of a gas economical boiler. Weak or excessively strong voltage is equally detrimental to the operation of such nodes:

- automation;

- gas valve;

- ignition module, etc.

You can correct the situation by using voltage stabilizers. They are able to withstand parameters with an accuracy of 3-5%, which will save the boiler from failures.

Rules and regulations for installing a gas boiler in a private house

The choice of installation location for a gas boiler depends on its power:

- with a power of up to 60 kW, installation is possible in the kitchen (subject to certain requirements);

- from 60 kW to 150 kW - in a separate room, regardless of the floor (subject to the use of natural gas, they can be installed in the basement and basement as well);

- from 150 kW to 350 kW - in a separate room on the first or basement floor, in an annex and a separate building.

This does not mean that a 20 kW boiler cannot be installed in a separate boiler room. You can, if you want to collect all life support systems in one place. That's just the volume of premises there are requirements. The minimum size of a boiler room in a private house should be:

- for boilers with a power of up to 30 kW, the minimum volume of the room (not the area, but the volume) must be 7.5 m3;

- from 30 to 60 kW - 13.5 m3;

- from 60 to 200 kW - 15 m3.

Only in the case of installing a gas boiler in the kitchen, other standards apply - the minimum volume is 15 cubic meters, and the ceiling height is at least 2.5 m.

Installation option for a wall-mounted gas boiler - up to the wall at least 10 cm

For each variant of the premises for a gas boiler room, certain requirements are imposed. Some of them are common:

Any boiler room in a private house should have natural light. Moreover, the area of windows is normalized - at least 0.03 m2 of glazing should fall on 1 m3 of volume

Please note that these are the dimensions of the glass. In addition, the window should be hinged, open outward.

The window should have a window or transom - for emergency ventilation in case of gas leakage.

Mandatory ventilation and removal of products combustion through the chimney

The exhaust of a low-power boiler (up to 30 kW) can be led through the wall.

Water must be connected to the boiler room of any type (feed the system if necessary) and sewerage (heat carrier drain).

Another general requirement that appeared in the latest version of SNiP. When installing gas equipment for hot water supply and heating with a capacity of more than 60 kW, a gas contamination control system is required, which, in the event of a trigger, will automatically stop the gas supply.

If there is a boiler and a heating boiler, when determining the size of the boiler room, their power is summed up

Further requirements differ depending on the type of boiler room.

This is interesting: The design of hanging rafters: we learn in detail

Boiler room in a private house in a separate room (built-in or attached)

Separate boiler rooms for the installation of gas boilers with a power of up to 200 kW must be separated from the rest of the rooms by a non-combustible wall with a fire resistance limit of at least 0.75 hours. These requirements are met by brick, cinder block, concrete (light and heavy). The requirements for separate furnaces in a built-in or attached room are as follows:

- The minimum volume is 15 cubic meters.

- Ceiling height :

- with power from 30 kW - 2.5 m;

- up to 30 kW - from 2.2 m.

- There must be a window with a transom or window, the glass area is not less than 0.03 square meters per cubic meter of volume.

- Ventilation should provide at least three air exchanges in one hour.

If the boiler room is organized in the basement or basement, the minimum size of the boiler room will be larger: 0.2 m2 is added to the required 15 cubic meters for each kilowatt of power that goes to heating. A requirement is also added to walls and ceilings adjacent to other rooms: they must be vapor-gas-tight. And one more feature: when installing equipment with a capacity of 150 kW to 350 kW, a furnace in the basement or basement must have a separate exit to the street. Access to the corridor leading to the street is allowed.

It is not the area of \u200b\u200bthe boiler room that is normalized, but its volume, the minimum height of the ceilings is also set

In general, it is advisable to choose the size of a boiler room in a private house based on the convenience of maintenance, which, as a rule, far exceeds the standards.

Special requirements for attached boiler rooms

There are not very many of them. Three new requirements are added to the points above:

- The extension should be located on a solid section of the wall, the distance to the nearest windows or doors should be at least 1 meter.

- It must be made of non-combustible material with a fire resistance of at least 0.75 hours (concrete, brick, cinder block).

-

The walls of the extension must not be connected to the walls of the main building. This means that the foundation must be made separate, incoherent and not three walls should be built, but all four.

What to keep in mind. If you are going to arrange a boiler room in a private house, but there is no room of a suitable volume or the ceiling height is slightly lower than the requirements, you may be met and demanded in return to increase the glazing area. If you are planning to build a house, then you must meet all the requirements, otherwise the project will never be approved for you. They are also tough on the construction of attached boiler houses: everything must comply with the standards and nothing else.

Conclusions and useful video on the topic

The video will introduce the basic requirements of gas services for the ventilation equipment of boiler houses in the Russian Federation:

Installation of exhaust equipment requires precision. But you need to understand that each gas service has its own interpretation of norms, standards and laws.

Before installing the heating equipment of a private house and the ventilation system in a gas boiler room, it is better to consult the gas service in which you will have to obtain permission for commissioning.

Tell us about your own experience gained during the arrangement of a gas boiler house. Share the technological nuances that helped you in her trouble-free air exchange system. Please leave comments in the block form below, post photos on the topic of the article, ask questions.