- 1.General requirements for labor protection and safety.

- Safe operation of the boiler on gas

- 2. Requirements for labor protection and safety before starting work.

- Safety regulations

- 3.Requirements for labor protection and safety during work.

- General recommendations

- Rules for the use of gas stoves

- Complaint when gas is cut off

- General conditions for the use of gas

- Fire hazard of industrial premises

- gas cut off

- Why equip a separate boiler room at home?

1.General requirements for labor protection and safety.

1.1. Persons at least 18 years of age who have undergone professional training, have passed a medical examination and have no contraindications, introductory and primary briefings on labor protection, fire and industrial safety, trained technologies for carrying out gas hazardous work , rules for the use of personal protective equipment (gas masks, life belts), methods of providing first (pre-medical) aid, certified and tested knowledge in the field of industrial safety.Before being allowed to independently perform gas-hazardous work (after checking knowledge), a mechanic for the operation and repair of gas equipment undergoes an internship under the supervision of an experienced worker during the first ten work shifts. Internship and admission to independent work in the gas sector is issued by order of the enterprise.

1.2. Periodic certification (testing the knowledge of the production instructions, as well as safe labor methods and work performance methods) is carried out at least once every 12 months in a permanent examination committee of the enterprise; repeated briefing on labor protection, fire and industrial safety is carried out at least 1 time in 3 months.

1.3. On the territory of the enterprise, it is necessary to comply with the requirements of the labor protection instructions, observe the internal labor regulations, be attentive to moving vehicles and working hoisting machines. Smoking on the territory of the enterprise is allowed only in places specially designated for this purpose.

1.4. It is necessary to observe the work and rest regime established at the enterprise. Working on a 12 hour shift. Normal working hours may not exceed 40 hours per week.

1.5. When servicing gas equipment, an employee may be exposed to the following hazardous and harmful production factors:

Physical - moving machines and mechanisms (may lead to injury), increased or decreased ambient temperature, increased or decreased air mobility, insufficient illumination of the workplace (can lead to colds and diseases of the organs of vision); increased value of voltage in el.circuit, the closure of which can pass through the human body, can lead to email. trauma; sharp edges, burrs and roughness on the surfaces of tools and equipment, the impact of which can lead to injury;

Chemical - high content of saturated hydrocarbons - methane (explosiveness and danger of poisoning).

1.6. A mechanic for the operation and repair of gas equipment should only work in special clothing. In accordance with the standard industry standards, the worker is issued:

| Individual protection means | Issuance rate per year |

| Cotton suit GOST 27575-87 | 1 |

| Leather boots GOST R 12.4.187-97 | 1 pair |

| Used mittens. GOST 12.4.010 | 6 pairs |

| Goggles GOST 12.4.013 | Before wear |

| Respirator GOST 12.4.004 | Before wear |

| Gas mask hose PSh-1B TU6-16-2053-76 | duty |

| In winter additionally: cotton jacket with insulated lining GOST 29335-92 | 1 for 2.5 years |

1.7. The employee must undergo fire-fighting instruction, know the rules of behavior in case of fire and when signs of burning are detected.

1.8. The employee is obliged to immediately notify his immediate or superior manager of any situation that threatens the life and health of people, of each accident that occurred at work, or of a deterioration in his health, including the manifestation of signs of an acute occupational disease (poisoning).

1.9. It is necessary to provide first aid to victims of injury, poisoning or sudden illness.

1.10. If any malfunctions are found, immediately stop work and inform the master about it. It is forbidden to repair any malfunctions on your own, if such work is not included in the scope of your duties.

1.11. Know and follow the rules of personal hygiene. Wash hands with soap when soiled, before smoking and eating.

1.12. Guilty of violating the Safety Rules in the gas industry, production instructions and instructions for labor protection, are liable in accordance with the legislation of the Russian Federation.

Safe operation of the boiler on gas

Methane is lighter than air, while propane (LPG) is heavier. When leaking, the first rises to the ceiling, and the second falls to the floor. In order to exclude a dangerous concentration of gas and avoid an explosion, it is necessary to provide natural ventilation in the first case with an exhaust hole at the top, and in the second with a vent at the bottom of the wall.

In winter, when the heating boiler is turned off for a long time, the water from the device and pipes must be drained so that it does not freeze and, when expanding, does not damage the heating system

When cleaning, use only non-aggressive detergents to clean and wash the outside of the column. Also, do not use abrasive powders and coarse brushes.

To avoid problems during the operation of a gas boiler, you should:

- Purchase the device and fittings for it only from a trusted company.

- All equipment must be installed exclusively factory-made.

- Entrust the primary installation and connection of the column to the masters from the gas service serving the house or village.

- Carry out a regular inspection of the boiler for corrosion and deterioration, as well as at least once a year carry out its full technical check.

- Ensure sufficient air exchange (with a small air supply or with poor exhaust, the burner in the combustion chamber may go out).

- Avoid placing various foreign objects on the gas appliance.

- Constantly, in order to avoid overheating of the unit, monitor the level of coolant and water in the boiler.

- For a volatile boiler, provide an uninterruptible power supply with a capacity of at least 12 hours and a separate line with an RCD.

- It is mandatory to connect any gas equipment to the ground loop.

Also, in addition to the built-in automation, it is recommended to install various security systems that shut off the gas supply when certain problems are identified.

By law, the mandatory installation of methane (propane) leakage sensors in rooms with a boiler is not fixed. But by all safety rules, their installation is highly recommended.

2. Requirements for labor protection and safety before starting work.

2.1. It is necessary to put on a serviceable and clean spec. clothing, special shoes and other personal protective equipment. Specialist. clothing should not have hanging ends, sleeve cuffs should be buttoned.

Before using safety goggles:

a) check the serviceability of spectacle glasses (if there are cracks, they are not allowed to be used); glasses should be protected from mechanical damage, kept clean;

b) adjust the tension of the headband.

Before using a respirator:

a) put it on the face so that the chin and nose are placed inside the half mask;

b) adjust the bands of the headband for a snug fit of the half-mask to the face; when turning the head, the tightness along the contact strip should not be violated; make sure that the respirator fits properly to the face during work.

Before using a gas mask, an external inspection checks serviceability and completeness, paying special attention to the valves (especially exhalation valves), sealing angles and the integrity of the hose braid. Be guided by the operating instructions - for checking and operating hose gas masks complete with rescue belts and ropes

2.2. Before starting work in the hydraulic fracturing safety training work, and before performing gas-hazardous work, receive targeted briefing with the issuance of a work permit.

2.3. Familiarize yourself with the conditions, nature and scope of work at the place of their implementation.

2.4. Prepare the necessary tools, materials, plugs, fixtures.

2.5. Check the availability, completeness and condition of fire extinguishing equipment at the site. Check the serviceability of communications, lighting, ventilation.

2.6. Check that the gas analyzer is working.

2.7. Ventilate the room by opening the front door, windows and ventilation openings. Check the presence of gas residues with a gas analyzer.

2.8. Report all detected shortcomings in the workplace or malfunctions of the tool to the manager, and do not start work until his instructions.

Safety regulations

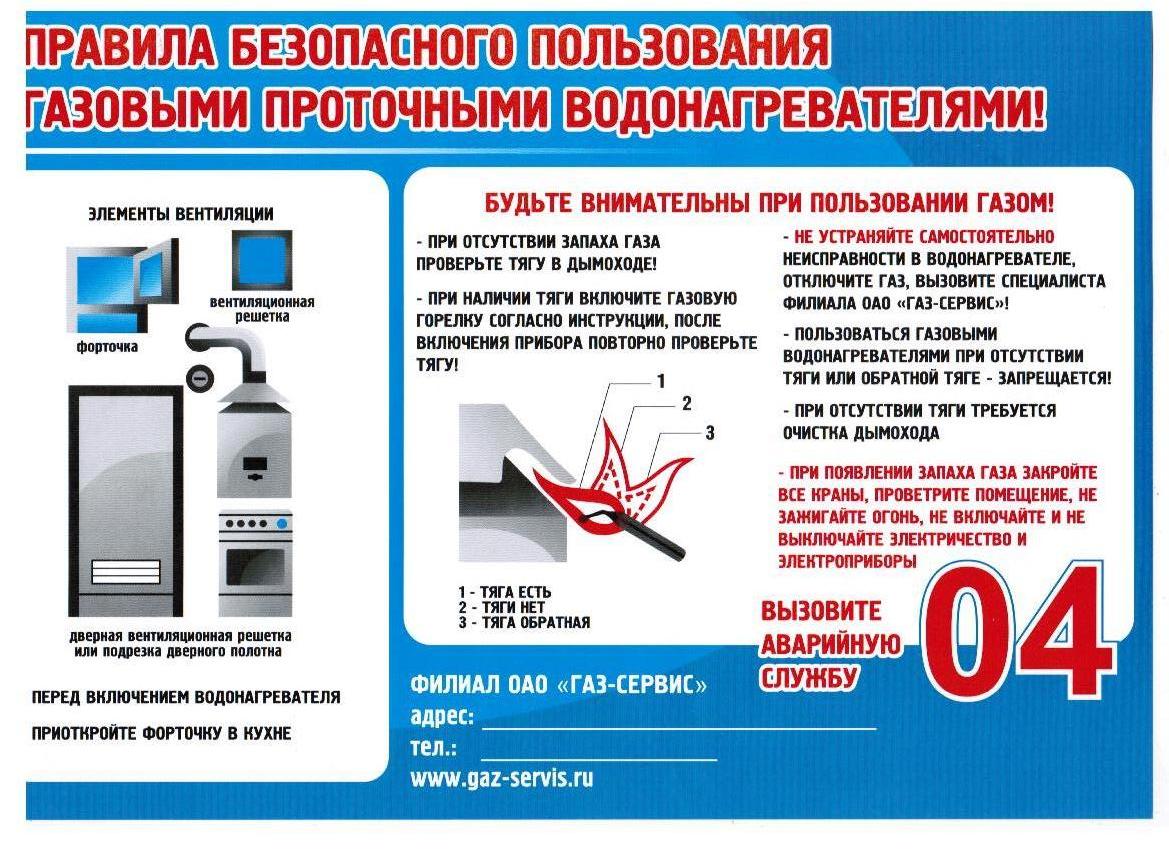

Gas is a cheap type of fuel, burns without residue, has a high combustion temperature and, as a result, a high calorific value, however, when mixed with air, it is explosive. Unfortunately, gas leaks are not uncommon. In order to protect yourself as much as possible, you must strictly follow the safety rules.

First of all, it is necessary to study the operating instructions for gas equipment and follow them, monitor the normal operation of gas appliances, chimneys and ventilation.

The owners of residential premises are prohibited from disturbing the ventilation system of residential premises during the redevelopment and reorganization of the apartment.

Before lighting the gas stove, the room must be ventilated, the window should be left open for the entire time of working with the stove. The valve on the pipe in front of the stove is opened by moving the flag of the handle to the position along the pipe.

The flame should light up in all holes of the burner, have a bluish-violet color without smoky tongues. If the flame is smoky - the gas does not burn completely, it is necessary to contact the specialists of the gas supply company and adjust the air supply

Please note: if the flame detaches from the burner, this means that too much air is supplied, and in no case should you use such a burner!

If you catch the characteristic smell of gas in the room, you should not turn on or off any electrical appliances in order to avoid an electrical spark that can lead to a gas explosion. In this case, it is urgent to shut off the gas pipeline and ventilate the room. In case of departure to the country or on vacation, it is necessary to turn off the gas by turning the tap on the pipe. Ideally, turn off the gas valve after each use of the stove or oven.

It is necessary to immediately contact the emergency gas service in the following cases:

- there is a smell of gas in the entrance;

- if you find a malfunction of the gas pipeline, gas valves, gas appliances;

- when the gas supply suddenly stops.

Remember that inspection and repair of gas equipment can only be carried out by employees of gas facilities. Their authority is confirmed by service certificates, which they must present to the owner of the apartment.

3.Requirements for labor protection and safety during work.

3.1. Comply with the safety requirements set forth in the operational documentation of the equipment manufacturer, as well as the instructions for labor protection and fire safety in force at the enterprise.

3.2. When manually moving loads, do not lift or carry the load above the permissible norms. Maximum permissible norms for lifting and moving / one-time / weights constantly during a work shift

for women -7 kg.

for men - 15 kg

gas analyzer. 55001, hours up to 32 hours. the engine is turned off and when alternating with other work / up to 2 times per hour /

for women up to 10 kg

for men up to 30 kg.

3.3. Operating instructions must be followed

TR allows personnel certified for knowledge of the safety rules for gas distribution and gas consumption systems PB 12-529-03, safe methods and techniques for performing work.

3.5. Maintenance and repair work is carried out during the daytime. Work on maintenance without shutting off the gas is carried out without a work permit, and according to TR on a work permit for gas hazardous work, which is recorded in a special journal of the unit.

3.6. When performing gas-hazardous work, it is necessary to have respiratory protection, rescue belts and ropes. Use a tool that does not give sparking, do not allow the use of open fire, smoking, strangers to the place of gas hazardous work.

3.7.It is forbidden to disconnect gas pipelines under pressure without shutting it off and installing plugs that must correspond to the maximum gas pressure in the gas pipeline, have shanks protruding beyond the flanges, and a stamp indicating the gas pressure and the diameter of the gas pipeline.

3.8. When gas is started, gas pipelines must be purged with gas until all air is expelled. The end of the purge is determined by analyzing or incinerating the samples taken. The volume fraction of oxygen in the gas sample should not exceed 1% by volume, and the combustion of the gas should occur smoothly without pops. Gas pipelines, when freed from gas, must be purged with compressed air or inert gas until the gas is completely expelled. The end of the purge is determined by chemical analysis. The residual volume fraction of gas in the purge air must not exceed 20% of the lower flammable limit. When purging gas pipelines, it is forbidden to release the gas-air mixture into rooms, stairwells, as well as into ventilation and smoke exhaust systems. The gas-air mixture when purging gas pipelines should be released in places where the possibility of it getting into buildings, as well as ignition from a fire source, is excluded.

3.9. When performing gas-hazardous work, portable rechargeable explosion-proof lights should be used, which should be turned on and off 10 meters from the gas distribution station and from gas pipelines.

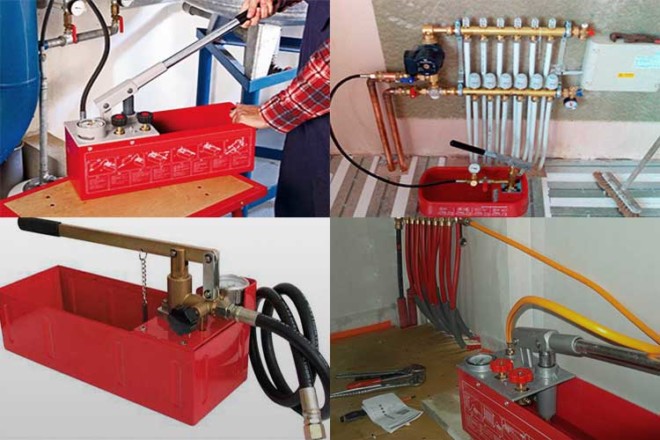

3.10. Before starting repair work in the hydraulic fracturing room, it is necessary to check it for the presence of gas in the air with a gas analyzer.

3.11. During the repair work in the hydraulic fracturing room, continuous supervision from the street through the open door should be organized. For this purpose, a duty officer is appointed from the team working in the PIU, whose duties include:

- be at the entrance to the hydraulic fracturing room and keep in touch with those working in the room, monitor their condition;

- do not allow smoking and open flames near hydraulic fracturing

- make sure that when working in gas masks, the hoses do not have fractures, and their open ends are located outside the building on the windward side at a distance of at least 5 m from the hydraulic fracturing station and secured. The length of the hose must not exceed 15 m.

3.12. If the presence of gas in the air of the hydraulic fracturing room is established, it must be ventilated. Under these conditions, the entrance to the premises is allowed only in gas masks.

3.13. The need to tighten bolts of flanges, glands or threaded connections on gas pipelines of medium and low pressure is determined by washing these connections and can be performed at operating gas pressure with control of the result by washing.

3.14. Work on the repair of hydraulic fracturing electrical equipment and the replacement of burned-out electric lamps should be carried out with the voltage removed. When using explosion-proof portable lamps, they must be switched on outside the GRP room

3.15. It is strictly forbidden to store combustible, flammable materials and gas cylinders in the hydraulic fracturing room.

It is prohibited for outsiders to enter the GRP premises.

3.16. It is forbidden to smoke and use fire in the hydraulic fracturing room and at a distance of 10 meters from it.

3.17. The duration of work in a gas mask without a break should not exceed 30 minutes.

3.18. Discharge of gas from the gas pipeline in the hydraulic fracturing room is not allowed.

General recommendations

- Check the condition of the supply devices (flexible hoses), which should not be twisted, stretched, and also have direct contact with household electrical appliances;

- Keep any gas equipment clean;

- In houses on the first floors, it is forbidden to wall up or close the gas riser taps in other ways;

- Do not prohibit employees of gas services from inspecting, repairing gas appliances and a gas pipeline at any time of the day;

- Ensure good ventilation of the room where gas equipment is used;

- It is forbidden to use gas appliances for other purposes;

- It is not allowed to change the layout, in places where gas appliances are installed, without the consent of the relevant organizations;

- Disable safety and regulation automation, use gas with faulty gas appliances, automation, fittings and gas cylinders, especially if a gas leak is detected;

- Use gas in violation of the density of masonry, plaster (cracks) of gasified stoves and chimneys. Use heating stoves with ovens and open burners for cooking. Arbitrarily install additional dampers in chimneys and on flue pipes from water heaters;

- Use gas after the expiration of the act on the inspection and cleaning of smoke and ventilation ducts.

IMPORTANT: the use of liquefied gas cylinders in apartments can lead to an explosion, fire, and in the worst case, destruction of the house

Household gas and the causes of the explosion

REMEMBER: design, installation, commissioning of gas equipment should be carried out by specialized organizations that have a license for this type of activity.

It is STRICTLY PROHIBITED to install and put gas equipment into operation on your own.

Rules for the use of gas stoves

- Ensure the room is ventilated when cooking;

- Do not leave unattended the cooking process, as well as the burning of the flame;

- At the end of the use of gas, close the taps on gas appliances and in front of them;

- Before turning on gas equipment in everyday life, first bring the flame source to the burner, and then turn on the gas;

- If the flame through the burner does not come from all holes, has a smoky color instead of bluish-violet, and detachments of flames are also visible, it is necessary to stop using this type of equipment;

- Check the serviceability of the gas stove regularly, having previously concluded an agreement with a service organization;

- Do not make changes to the design of the equipment (self-repair);

- If the equipment does not work properly, be sure to notify the gas service.

It is forbidden:

- Use gas stoves for heating;

- Arrange rest rooms in places where there is gas equipment;

- Allow children and people in a state of intoxication to the equipment;

- Carry out equipment repairs independently, without the involvement of specialized organizations;

- Detect gas leaks with fire (use soapy water).

Actions for the smell of gas in the room

Requirements of the Fire Regulations in the Russian Federation:

When operating gas appliances, it is prohibited (clause 46):

- a) use faulty gas appliances;

- b) leave them switched on unattended, with the exception of gas appliances, which can and (or) must be in round-the-clock operation in accordance with the manufacturer's instructions;

- c) install (place) furniture and other combustible objects and materials at a distance of less than 0.2 meters from household gas appliances horizontally and less than 0.7 meters vertically (when these items and materials hang over household gas appliances).

It is forbidden to connect gas heaters to the air ducts (item 48).

When using household gas appliances, it is prohibited (clause 95):

- a) operation of household gas appliances in case of gas leakage;

- b) attaching parts of gas fittings using a sparking tool;

- c) checking the tightness of connections using open flame sources.

Complaint when gas is cut off

In the event of an illegal interruption of gas supply, apartment owners, personally or through the head of the entrance or house, must demand an explanation from the management company. The justification for shutting off the gas must be provided in writing.

If the management company does not take measures to restore gas supply or cannot explain the reasons for the interruption of gas supply, it is necessary to write an application to the local authorities and ask for an examination.

After conducting an examination and obtaining a specialist opinion, you need to apply to the judicial authorities for proceedings. The statement of claim must be accompanied by an expert opinion, an agreement with the management company, a title document for an apartment with a disconnected gas supply, a certificate about no debt for utilities.

In the event of a positive decision on the issue, the court, having considered the case materials, must decide to reduce the amount gas supply fees within the limits established by law.

General conditions for the use of gas

There are two types of gas equipment: in-house (gas pipeline, metering devices gas apartment buildings) and intra-apartment (stove, hob, oven, water heating equipment). The responsibility for maintaining the gas networks of an apartment building lies with the management company.

In order for the room to become gasified, several conditions must be met.

- The apartment must have at least two isolated rooms (a one-room studio apartment cannot be gasified).

- It is necessary to have good exhaust ventilation in the corridors of the house.

- The gas inlet device must comply with the requirements of fire and explosion safety.

- In the corridors where the gas pipeline will be laid, the ceiling height must be at least 1.6 m, while the ceilings themselves must be fire resistant.

The use of gas input devices installed directly in apartments, elevators, ventilation systems of a residential building is strictly unacceptable. Gas risers are installed vertically in kitchens and stairwells; their installation in other parts of the apartment is not possible. Throughout the gas pipeline, special valves are being made to turn off certain sections.

The gas hose for connecting the stove must be certified; its length should not exceed 5 m. Experts warn that it is better to refrain from painting the gas hose, as the paint can cause it to crack.

There should be no extra connections when connecting a gas stove. The hose connects directly at one end to the faucet and the other end to the stove.

When installing the stove, it must be taken into account that the hose and gas riser must be accessible for inspection. Therefore, gas communications cannot be removed under drywall, stationary false panels or interior details.

Fire hazard of industrial premises

We sorted out the premises of single-family and multi-apartment buildings. Now let's talk about heat generators for industrial and storage purposes. According to Federal Law No. 123 TR on fire safety requirements.

The designation helps to determine what and in what cases is necessary to ensure the safety of people and their property in buildings in the event of an emergency. For example, equipping a building with a fire alarm, fire extinguishing system, degree of fire resistance of finishing materials, type of emergency evacuation, and so on.

The designation helps to determine what and in what cases is necessary to ensure the safety of people and their property in buildings in the event of an emergency. For example, equipping a building with a fire alarm, fire extinguishing system, degree of fire resistance of finishing materials, type of emergency evacuation, and so on.

To determine the degree of explosion / fire hazard of an object, use the division into classes and categories.

According to PP No. 390, a gas boiler house is classified as a hazardous production facility and belongs to category F5. According to the regulations, premises of this type are normalized to the category of fire hazard from the most dangerous under the letter A, to the least, denoted by the letter D:

- Increased fire/explosion hazard is A.

- Explosion and fire hazard B.

- Fire hazard belongs to category B - from B1 to B4.

- Moderate fire hazard - under the letter G.

- For a reduced fire hazard, to which it is difficult to attribute such a gas installation, the symbol is D.

As a rule, it is difficult to coordinate the arrangement of a gas facility with the D-subclass, so we will consider boiler houses from A to D.

It is not so easy to take and define a specific subclass.To do this, it is necessary to carry out the necessary studies and calculations with the help of specialists with experience in designing gas-using heat generators.

It is not so easy to take and define a specific subclass.To do this, it is necessary to carry out the necessary studies and calculations with the help of specialists with experience in designing gas-using heat generators.

The subclass should be calculated based on:

- The type of fuel used.

- According to the degree of fire resistance (I, II, III, IV and V).

- The equipment that is installed in the room.

- Design features of the boiler house itself (hazard class according to the design of the gas boiler house C0, C1, C2 and C3). Defined by Article 87 of the Federal Law No. 123.

- Characteristics of ongoing processes.

The subclass is also conditionally determined on the basis of SP 12.13130.2009, NPB 105-03, SP 89.13330.2011, Federal Law No. 123. In principle, it is not necessary to determine which hazard class a particular gas boiler room belongs to, if the task is simply to determine whether it is a hazardous production facility.

The boiler room, in any case, is a gas consumption network. OPO is determined by the following features:

- The presence of boilers under excess pressure or temperature indicators of the working environment over 115 degrees.

- If the gas boiler house contains gas pipelines with a pressure of 0.005 MPa or more.

- The boiler house is a centralized system or installation serving socially significant segments of the population.

The class of fire hazard according to all signs is determined by specialists-designers.

gas cut off

The list of reasons why gas supply may be temporarily terminated is fixed in the contract with the management company or gas supply organization. Due to certain circumstances, this list may be changed.

Here is an approximate list of reasons for shutting down gas supply:

- the subscriber of the gas network has independently installed or retrofitted gas appliances;

- the gas service has detected malfunctions in gas communications, or there is no stable exhaust in the chimneys (ventilation), or an insufficient concentration of gas in the pipes has been detected when it is supplied to gas-using equipment;

- signs of illegal access to gas supply networks were found;

- an emergency (emergency) situation has arisen that cannot be eliminated without disconnection;

- in the process of planned (including major) repairs of gas equipment and communications;

- an agreement has not been concluded that provides for emergency maintenance;

- tenants of an apartment building are evicted due to the demolition of the house;

- the amount of consumer debt exceeds the amount of payments for two billing periods;

- the consumer regularly violates the clauses of the agreement with the management company and creates all sorts of obstacles in obtaining the data necessary to determine the actual volume of gas consumption;

- the consumer uses equipment that does not meet legal standards or does not comply with the one prescribed under the contract;

- there is no maintenance agreement between the management company and the subscriber.

In the event of a planned shutdown of gas supply, the service provider is obliged to notify the subscriber in writing, and this must be done no later than 20 days before the proposed shutdown with an explanation of the reason (or reasons). In the event of an emergency, the gas supply is turned off without warning.

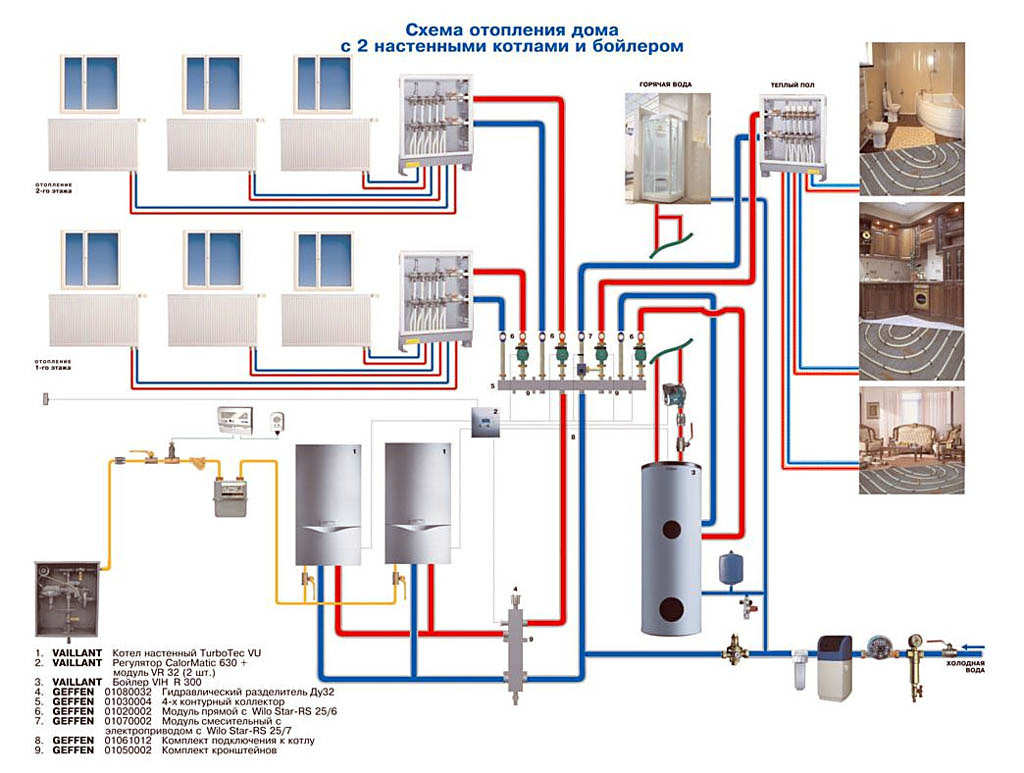

Why equip a separate boiler room at home?

When arranging the heating system, the owner of the house faces a choice where the gas-using equipment will be located.

The decision may be due to aesthetic and design considerations, the issue of security (in the presence of disabled persons at home, as well as children). But in addition, this may be dictated by the current standards for equipment power.

Consider the types of location of boiler rooms.

Boilers can be located:

- inside the house - usually provided for even at the stage of building a house, since in the built one there may not be a free room that is suitable in terms of parameters;

- on a separate foundation as an extension, along a blank wall and observing a distance from the nearest door and window of 1 meter without a major connection to a residential building;

- detached - located at some distance from the main house.

The regulations determine that if the power of gas-using equipment does not exceed 60 kW, it can be placed in the kitchen (except for the kitchen niche), in the kitchen-dining room, and in other non-residential premises, except for bathrooms and bathrooms.

The minimum volume of furnace for 30 kW of power is at least 7.5 cubic meters. m. From 60 to 150 kW require the arrangement of a separate room. The minimum volume of the room is 13.5 cubic meters. m. From 150 to 350 kW. The minimum volume of the room is from 15 cubic meters. m.

A freestanding gas boiler room must be designed before construction or installation. Follow all the rules for its arrangement, otherwise, the location of gas-using equipment in it will not be approved

We are talking about individual boiler houses, that is, with equipment power from 60 to 350 kW.