- How to connect polypropylene pipes?

- Work process

- Tools

- Mounting

- Pros and cons of metal-plastic

- How to install heating from polypropylene pipes?

- Choose the diameter for your heating

- Do-it-yourself heating installation from polypropylene pipes

- Heating wiring

- Installation of radiators

- Battery connection

- Required data for calculation

- Advantages of polypropylene pipes

- How can heating be installed from polypropylene pipes

- Rated pressure

- Installation and wiring of the system - installation

- The main types of plastic (polypropylene) pipes

- Types of reinforced pipes

- Practical recommendations

- The main criteria for choosing pipes

How to connect polypropylene pipes?

It is easy and simple to work with any propylene pipes, their connection by soldering or threaded mates, when required, is not particularly difficult, and everyone can learn it. The material is cut with special scissors or a hacksaw, and the pipes are connected to each other by auxiliary connecting parts and soldering. Soldering is a fairly reliable connection - such lines may well be embedded in walls, without fear for their integrity.If the threaded joints of metal pipes were the weakest point in the heating system, they required careful “packaging”, then the appearance of propylene products and the method of their connection - high-quality soldering, got rid of this problem forever.

Work process

Mounting by soldering is quite easy if you use high-quality tools and clean, not defective connecting parts. An important condition for high-quality installation is compliance with the desired temperature. For each specific pipe diameter, a specific soldering temperature must be applied. If the pipes were outdoors or indoors with low or high temperatures, they must be kept indoors for at least 12 hours to adapt them to the conditions in which they will be installed.

Tools

Mounting kit

For installation work, you will need special tools, and some of them cannot be replaced with other, improvised devices:

1. An apparatus for welding propylene pipes, having nozzles (couplings and mandrels) of different standardized diameters.

Welding machine in working position

2. Scissors for cutting pipes - if they are not available, a hacksaw or a jigsaw will do.

3. Folding rule and tape measure, as well as a marker for marks.

4. A sharp knife for cleaning the ends of pipes after they have been cut from burrs and chips. In addition, for these purposes, for trimming, you can use a special tool - a shaver, with well-honed and set knives.

5. In addition, it is necessary to have a pre-compiled and carefully thought-out scheme of the heating circuit.

Mounting

- Starting work, the drawn up scheme-plan must be kept in front of your eyes all the time and, relying on it, prepare individual parts of the contour.To do this, it is better to lay out the pipes along the walls along which the highways will go, and, measuring on the spot, prepare individual parts.

- Having prepared the pipes in a certain area, the required nozzle is installed on the welding machine and heated to the desired temperature, which depends on the diameter and type of material. Most modern welding machines have an extremely clear gradation on the built-in thermostat.

- Next, a connecting element is tried on the pipe - it can be a coupling, a tee, a branch, a faucet, and other shaped products.

Variety of shaped elements

To control with a marker, make a mark on the depth of penetration. The pipe should not go too deep into the connection, but should be held tightly in it. If it is a straight coupling, then there is a protrusion inside it that will stop the pipe in the right place.

The process of heating the mating parts

The shaped connecting element and the end of the pipe are placed respectively on the mandrel and the coupling of the welding machine, so that they warm up at the same time, and the required heating time is noted, which depends from the size of the pipe diameter and on the thickness of its walls. After waiting for the required interval, the parts are removed from the nozzles of the apparatus, then the pipe is progressively inserted into the coupling - twisting movements should not be made. The depth of penetration and holding time are shown in the table:

Parameters taken into account when welding polypropylene pipes

The fastened parts must cool down - this happens quite quickly (the data is also given in the table).

Pros and cons of metal-plastic

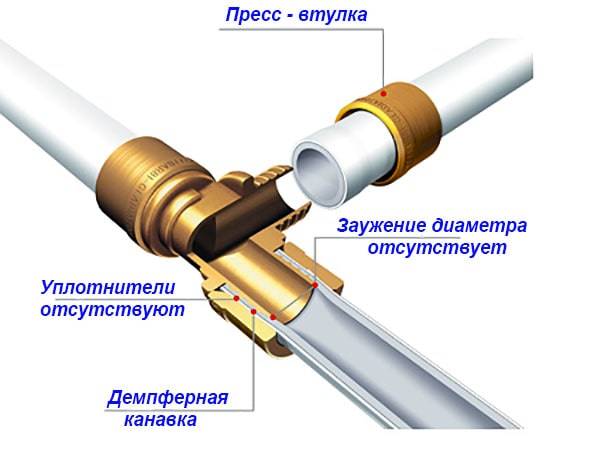

Let's make a reservation that metal-plastic pipes for heating should be compared with polypropylene pipes on an equal footing.Therefore, detachable joints on collapsible fittings are not considered - it is expensive and unreliable, although it is convenient for craftsmen without experience. Good tightness will be ensured only by a joint with a press fitting.

The condition also applies to the method of strengthening the pipe, for comparison, we take metal-plastic and PPR, reinforced with aluminum. Now about the advantages of metal-plastic:

- Having special pliers, it is quite simple to install heating from metal-plastic parts.

- The pipe is bent and supplied in coils, and therefore cut into sections of the required length, no unnecessary joints.

- The thermal elongation of the material is insignificant and does not require a scrupulous approach when fixing long sections.

- Installation in any weather is possible.

- Laying in any hidden way is allowed, including under the screed along with the joints.

The reinforcing layer of the metal-plastic pipeline is only aluminum

What is better in metal-plastic systems is the technology of connecting elements. The end of the cut section is calibrated, pulled onto the fitting and crimped with tongs, that's all. You need a minimum of space, since there is no need to stick a healthy soldering iron between the parts to be joined, the pliers are applied after docking. With the help of a spring, metal-plastic bends well under a safe radius, which greatly simplifies the installation.

Separately, it should be said about the warm floor, where it is customary to lay metal-plastic or cross-linked polyethylene, but not PPR. These materials do not need compensation and feel good inside the monolith, providing efficient heating of the entire surface. It is worth imagining polypropylene in their place with its thick walls, elongation and 90 ° joints, and it immediately becomes clear which pipes are better use in warm floors.

Pliers for press connection - the tool is not cheap, it is better to rent them for 1-2 installations

Now about the disadvantages of metal-plastic, of which there are really two:

- high cost of all elements;

- pipe range is limited to a maximum diameter of 63 mm (DN50).

Proponents of heating from polypropylene constantly pay attention to another minus of metal-plastic - a decrease in the flow area at the joints where there are brass fittings. Like, this leads to an increase in the hydraulic resistance of the network and the rapid "overgrowth" of passages when working in the central heating system, where the coolant is dirty

The statement is true regarding collapsible fittings, they really have a narrowing of the diameter relative to the passage in metal-plastic.

high quality fittings for press joining metal-plastic pipes also have a narrowing, but it is not so large as to significantly affect the hydraulics of the system. It is better to put them on heating, especially with hidden laying of highways. The same opinion is shared by our expert Vladimir Sukhorukov, whose video we recommend watching:

How to install heating from polypropylene pipes?

Let's look at some practical examples soldering of the pipeline from a polypropylene pipe.

Soldering is done with a special soldering iron:

Each soldering iron has a temperature regulator (1). The temperature for soldering polypropylene is set to 270 degrees. Heating the pipe with a soldering iron is carried out for no more than 5 seconds.

The following should be taken into account.If the work takes place outside in cold weather, or in a cold room, the soldering time increases, because the soldering iron cools down quickly.

In this case, you need to either increase the heating temperature of the soldering iron, or increase the heating time. The heating time also increases when soldering pipes with larger diameters, as the following table illustrates:

Actually soldering. There are two nozzles on the soldering iron: one for heating the inner diameter, the other for the outer diameter. At the same time, both parts that are supposed to be connected are heated:

We evenly press on both parts, as if towards each other - in the direction of the red arrows in the photo:

As it heats up, the coupling reaches the rim, and a flanging also appears on the pipe. After heating, remove the parts from the nozzles and dock them with each other:

After connecting the heated parts, they need to be fixed for a while

After docking, hold the parts for up to 30 seconds - so that they cool down and the connection hardens. The flanging on the pipe must be uniform over the entire circumference of the connection.

This is how all polypropylene is soldered, regardless of the pipe diameter and purpose, whether it be a heating or water supply system. The only difference, as mentioned above, is the soldering time: the larger the diameter of the tube, the longer it takes to heat and fix after connection.

A soldering iron attachment has been developed to further facilitate the already simple life of an installer.

The nozzle allows you to accurately determine the time when the parts to be soldered are already sufficiently heated. In such a nozzle there is a special hole:

- through which melted polypropylene exits. As soon as he appeared in the hole:

- this is a signal: we remove and dock the parts.You don't have to use a clock or count the seconds yourself.

There is also a ceramic nozzle that will prevent this kind of molten pipe:

The advantage of such a connection (without the use of metal) is that due to the absence of metal compounds, hardness salts do not grow in such areas. And also after soldering, a monolithic connection is obtained.

When working with polypropylene, you need to take into account all the steps in advance - in order not to get into some uncomfortable moments. Such "moments" can occur when, for example, you need to solder in some kind of limited space, etc.

Therefore, before soldering, it is better to draw a pipeline diagram on a piece of paper (starting from the boiler) and write down the sequence of steps.

Choose the diameter for your heating

Do not count on the fact that you will immediately be able to choose the right pipe diameter for heating your home. The fact is that you can get the desired efficiency in different ways.

Now in more detail

What is the most important thing in a proper heating system? The most important thing is uniform heating and delivery of liquid to all heating elements (radiators)

In our case, this process is constantly supported by a pump, due to which, for a specific time period, the liquid moves through the system. Therefore, we can choose from only two options:

- buy large-section pipes and, as a result, a low coolant supply rate;

- or a pipe of small cross section, naturally the pressure and velocity of the fluid will increase.

Logically, of course, it is better to choose the second option for the diameter of pipes for heating a house, and for these reasons:

with external pipe laying, they will be less noticeable;

with internal laying (for example, in a wall or under a floor), the grooves in the concrete will be more accurate, and it is easier to hammer them;

the smaller the diameter of the product, the cheaper it is, of course, which is also important;

with a smaller pipe section, the total volume of the coolant also decreases, thanks to which we save fuel (electricity) and reduce the inertia of the entire system.

Yes, and working with a thin pipe is much easier and easier than with a thick one.

Do-it-yourself heating installation from polypropylene pipes

Polypropylene pipes are connected at threaded or non-threaded fittings. Threaded fittings are both detachable and one-piece.

When installing heating from polypropylene pipes, you must be guided by the following technical conditions:

-

polypropylene pipes must be laid away from open sources of fire;

-

if there is a need to install a tank or water meter, it is better to use threaded and split fittings. One-piece fittings are used only with flexible hoses;

-

the use of dirty and deformed fittings, as well as self-threading is not allowed;

-

in the case of joining even segments or polypropylene pipe connections different diameters, you need to use couplings;

-

not to bend polypropylene pipe in places of rotation, during installation, you need to use a special square;

-

tees are used at branching points.

Having familiarized yourself with the mandatory conditions for the work, you can begin the installation process.

Heating wiring

As we said earlier, for the convenience of work, saving time and money, as well as to achieve the maximum efficiency of the assembled system, it is necessary to indicate the location of the following elements in the project:

-

corners;

-

couplings;

-

heating equipment;

-

fasteners.

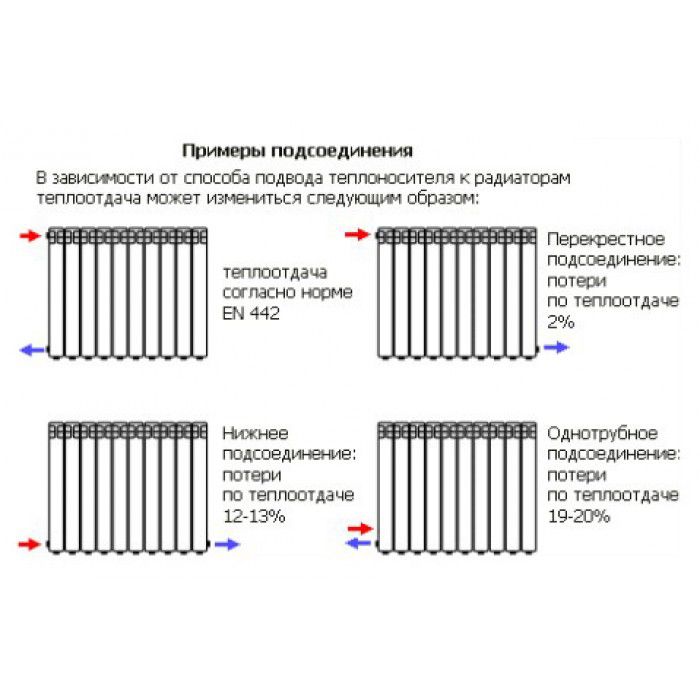

The pipeline approaches the batteries from below or from the side, and is carried out according to a one- or two-pipe scheme.

Installation of radiators

Before connecting the polypropylene pipe to the battery, the battery must first be assembled, equipped with the necessary adjustment elements, and fixed to the wall.

Installation of a heating radiator is carried out as follows:

-

We apply markings in the places where the batteries will be installed. According to SNiP, there should be a gap of at least 2 cm between the heating radiator and the wall, and the distance from the battery to the floor should be 10-15 cm.

-

We install brackets for hanging the heating radiator. To do this, you will need a level so that the radiator hangs evenly, and dowel-nails to attach the brackets to the wall.

-

Next, the heating radiator is installed on the brackets.

According to this scheme, the installation all batteries in the room.

Battery connection

The procedure for connecting a polypropylene heating pipe to a radiator will be as follows:

-

We start by attaching the adapter to the radiator. It must be remembered that to connect polypropylene pipes to an aluminum heating radiator, special couplings are used, which differ from those that connect polypropylene pipes to cast-iron batteries.

-

We connect a ball valve, a radiator valve or an adjusting valve to the installed coupling.

-

We connect polypropylene pipes to this crane.

-

According to the above steps, the battery outlet is connected to the heating pipe.

These are the main stages of connecting PP pipes to heating radiators.

Read the material on the topic: How to change the heating radiator without errors

Required data for calculation

The main task of heating pipes is to deliver heat to the heated elements (radiators) with minimal losses. From this we will build on when choosing the correct pipe diameter for heating a house. But to calculate everything correctly, you need to know:

- pipe length;

- heat loss in the building;

- element power;

- what will be the piping (natural, forced, one-pipe or two-pipe circulation).

The next item after you have all the above data on hand, you will need to sketch out a general scheme: how, what and where it will be located, what heat load each heating element will carry.

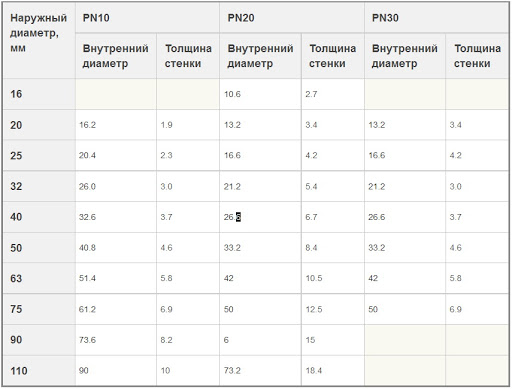

Then it will be possible to begin to calculate the desired section of the diameter of the pipe for heating the house. You should also be careful when buying:

- metal-plastic and steel pipes are marked by the size of the inner diameter, there are no problems here;

- but polypropylene and copper - according to the outer diameter. Therefore, we need to either measure the inner diameter ourselves with a caliper, or subtract the wall thickness from the outer diameter of the pipe for heating the house.

Do not forget about this, because we need exactly the "inner diameter of the pipe for heating the house" in order to calculate everything correctly.

Advantages of polypropylene pipes

You can save on home heating by installing a heating system made of polypropylene pipes. After all, polymer products and their installation cost less compared to metal parts.

Construction concept

Construction concept

This allows you to lay low-cost durable engineering communications, since PP pipes under standard conditions will last 50 years. They also differ:

- Light weight, which simplifies the installation process and reduces the load on the supporting structures of the building.

- Good ductility to prevent rupture when water freezes inside tubular parts.

- Low clogging due to smooth walls.

- Resistant to high temperatures.

- Easy assembly with special soldering equipment.

- Excellent soundproof properties. Therefore, noise from moving water and water hammer is not heard.

- Neat design.

- Low thermal conductivity, which allows not to use insulating material.

Unlike pipes made of crosslinked polypropylene polyethylene cannot be bent due to increased elasticity. Bending of communication is carried out using fittings.

Polypropylene also has a high linear expansion. This property makes it difficult to lay in building structures. After all, the expansion of pipes can cause deformation of the main and finishing material of the walls. To reduce this property during open installation, compensators are used.

How can heating be installed from polypropylene pipes

Among the many ways to install polypropylene pipes, we note those that have proven their effectiveness for years. Here are the most popular pipe layouts and installations:

• Installation with top spill. With this method of installation of heating pipes, the installation of a circulation pump is not required, since the coolant moves through the pipes by gravity.

This method is good in homes prone to frequent power outages.

• Installation with bottom spill and radial piping. With this method of mounting heating pipes, plastic or metal-plastic pipes are used, which are easy to bend. Thus, a branched pipeline is obtained.

This method is used more widely than the previous one, as it allows you to ergonomically mount the pipeline in almost every room, regardless of the type of walls, floors, slopes, lifts, piping and other nuances of the room.

At choosing the second installation method heating systems made of polypropylene pipes, you will get the following benefits:

-

high efficiency of the heating system;

-

when installing a pump that can give the necessary pressure, you can use smaller diameter polypropylene pipes without losing the efficiency of the heating process;

-

you can remove the pipes to the floor, fill them with a screed, without fear that they will break or lose their functionality.

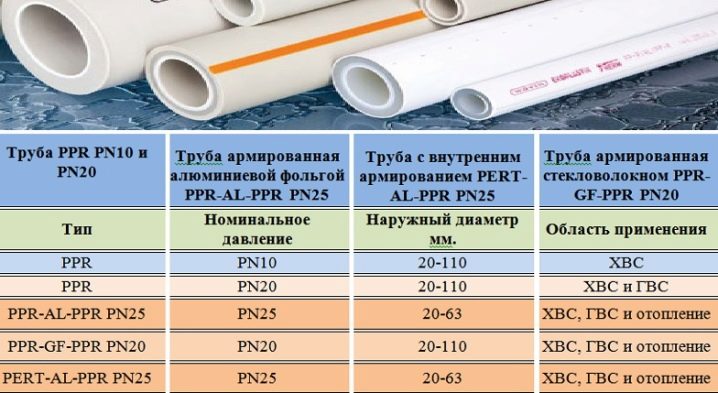

Rated pressure

The letters PN are the designation of the permitted working pressure. The next figure indicates the level of internal pressure in bar that the product can withstand during a service life of 50 years at a water temperature of 20 degrees. This indicator directly depends on the wall thickness of the product.

p, blockquote 11,0,0,0,0 –>

PN10. This designation has an inexpensive thin-walled pipe, the nominal pressure in which is 10 bar. The temperature maximum that it can withstand is 45 degrees. Such a product is used for pumping cold water and underfloor heating.

p, blockquote 12,0,0,0,0 –>

PN16. Higher nominal pressure, higher limiting fluid temperature - 60 degrees Celsius. Such a pipe is significantly deformed under the influence of strong heat, therefore it is not suitable for use in heating systems and for supplying hot liquids. Its purpose is cold water supply.

p, blockquote 13,0,0,0,0 –>

PN20. A polypropylene pipe of this brand can withstand a pressure of 20 bar and temperature up to 75 degrees Celsius. It is quite versatile and is used for hot and cold supply water, but should not be used in the heating system, because it has a high coefficient of deformation under the influence of heat. At a temperature of 60 degrees, a segment of such a pipeline of 5 m is extended by almost 5 cm.

p, blockquote 14,0,0,1,0 –>

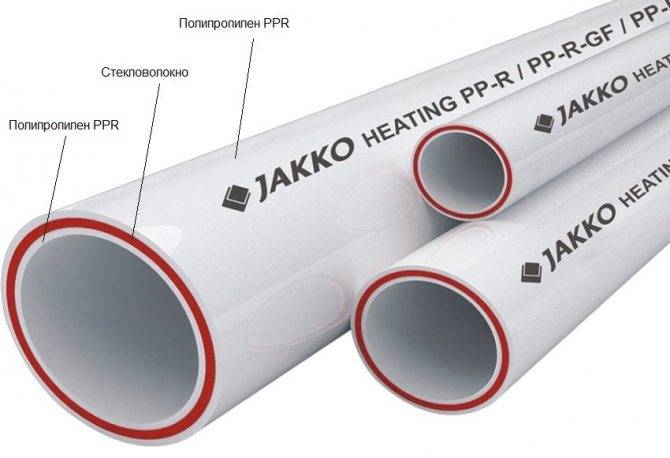

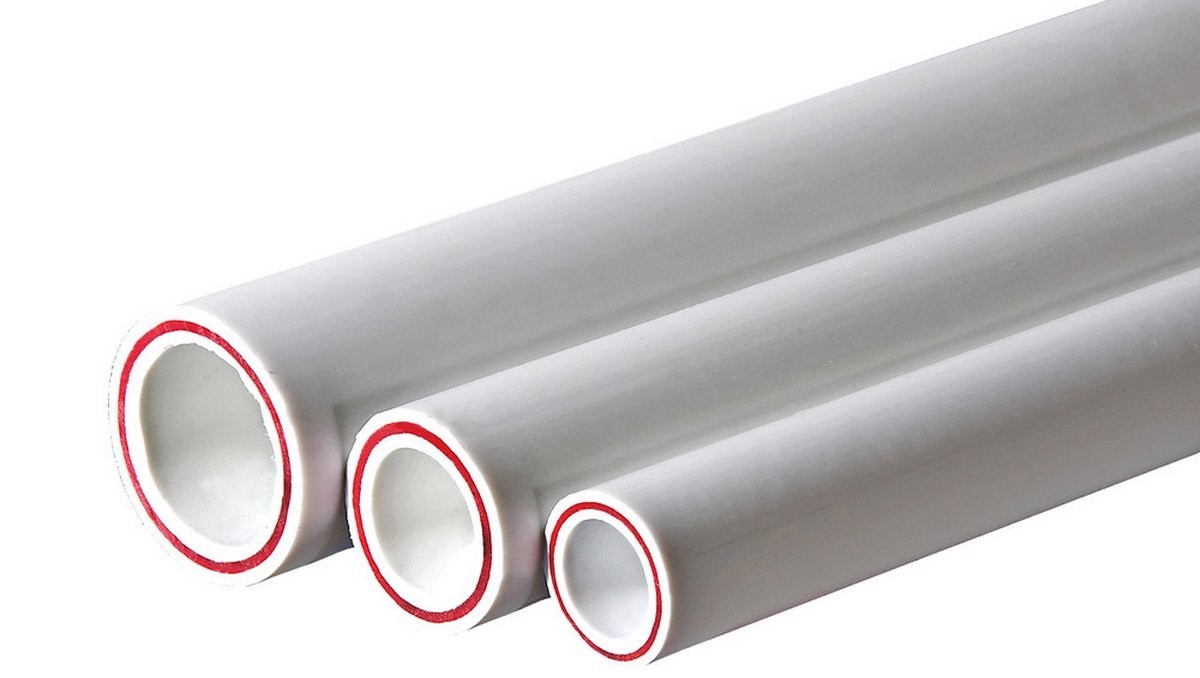

PN25. This product has a fundamental difference from the previous types, since it is reinforced with aluminum foil or fiberglass. In terms of properties, the reinforced pipe is similar to metal-plastic products, is less susceptible to temperature effects, and can withstand 95 degrees. It is intended for use in systems of heating, and also in GVS.

p, blockquote 15,0,0,0,0 –>

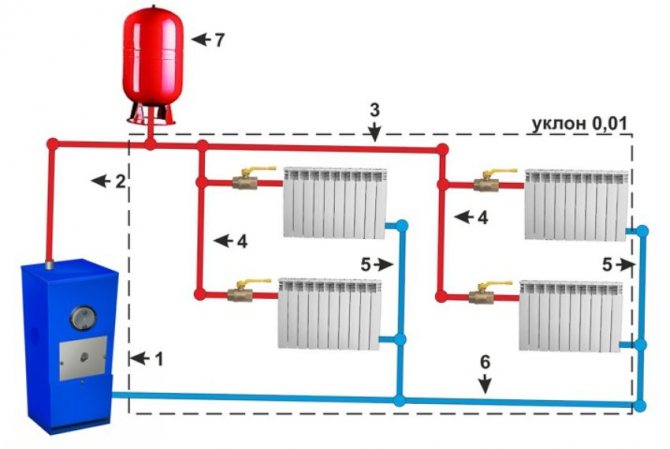

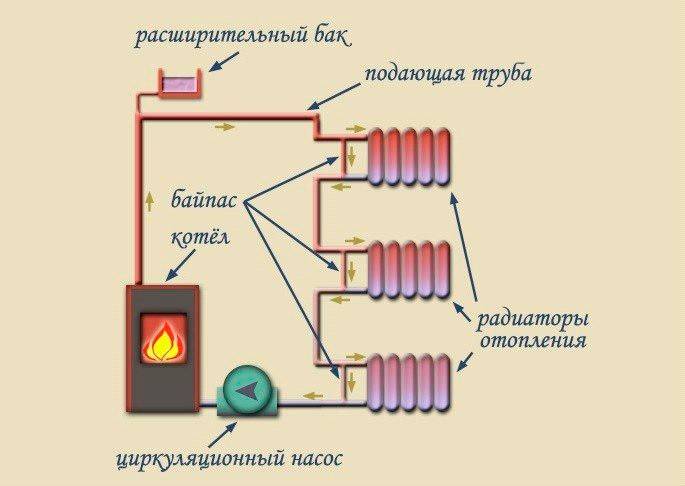

Installation and wiring of the system - installation

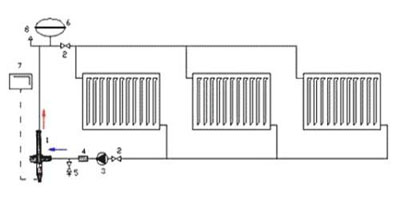

For the construction of a heating circuit in a private house, you need to take into account some details. There are different wiring diagrams of the system

It is important to choose and design the most optimal option. Carrier circulation can be natural or forced

In some cases, the first option is convenient, in others, the second.

Natural circulation occurs by changing the density of the fluid. Hot media is characterized by a lower density index.The water on the way back is denser. Thus, the heated liquid rises along the riser and moves along horizontal lines. They are mounted at a slight angle of no more than five degrees. The slope allows the media to move by gravity.

The heating scheme, which works on the basis of natural circulation, is considered the simplest. To perform its installation, you do not need to be highly qualified. But it is only suitable for small buildings. The length of the line in this case should not exceed thirty meters. Of the minuses of this scheme, one can distinguish low pressure inside the system and the need to use channels of a significant cross section.

Forced circulation implies the presence of a special circulation pump. Its function is to ensure the movement of the carrier along the highway. When implementing a scheme with forced fluid movement, it is not necessary to create a contour slope. Of its shortcomings, one can single out the energy dependence of the system. If a power outage occurs, media movement in the system will be hindered. Therefore, it is desirable that the house has its own generator.

The wiring happens:

- Single pipe.

- Two-pipe.

The first option is implemented through the sequential flow of the carrier through all radiators. This scheme is economical. For its implementation, a minimum number of pipes and fittings for them is required.

To do this, you need to use the so-called "Leningrad" wiring diagram.

It involves the installation of bypass pipes and valves on each radiator. This principle makes it possible to ensure uninterrupted circulation of the carrier when any battery is cut off.

Installing a two-pipe heating scheme in a private house consists in connecting reverse and direct current to each radiator. This increases the channel consumption by about two times. But the implementation of this option allows you to adjust the heat transfer in each battery. Thus, it will be possible to adjust the temperature regime in each individual room.

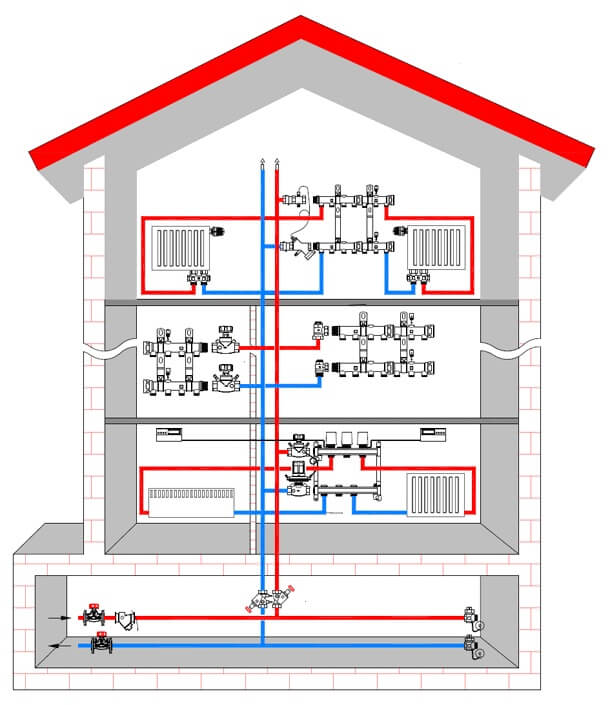

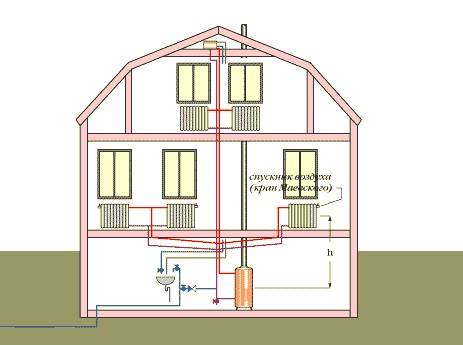

Two-pipe wiring is of several types:

- lower vertical;

- top vertical;

- horizontal.

The lower vertical wiring means starting the supply circuit along the floor of the lower floor of the building or its basement. Then, from the main line, the carrier goes up through the risers and enters the radiators. From each device there is a "return", delivering the cooled liquid to the boiler. Implementing this scheme, you need to install an expansion tank. There is also a need to install Mayevsky cranes on all heating devices located on the upper floors.

The top vertical wiring is arranged differently. From the heating unit, the liquid goes to the attic. Next, the carrier moves down through several risers. It goes through all the radiators and returns to the unit along the main circuit. An expansion tank is needed to remove air from this system. This scheme is more efficient than the previous one. Since there is a higher pressure inside the system.

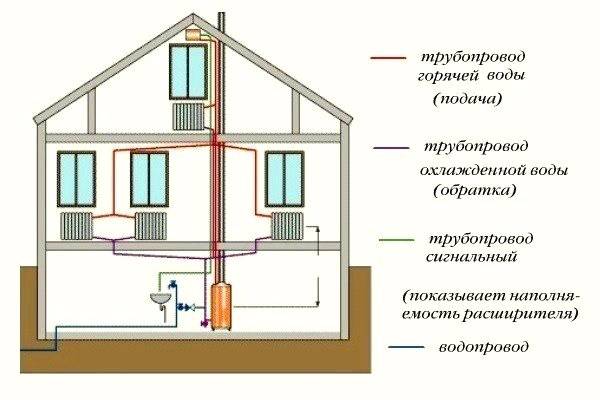

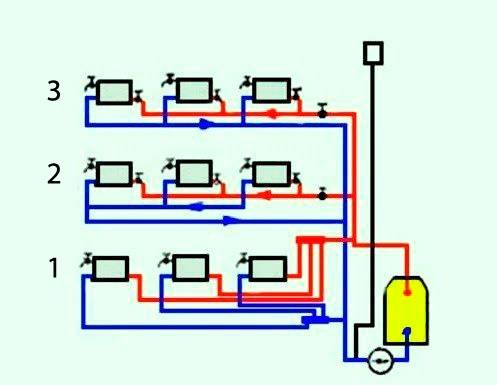

Horizontal two-pipe wiring diagram the forced circulation type is the most popular.

It comes in three varieties:

- with radial distribution (1);

- with associated movement of fluid (2);

- dead end (3).

The variant with beam distribution consists in connecting each battery to the boiler.This principle of operation is the most convenient. Heat is evenly distributed in all rooms.

The option with associated fluid movement is quite convenient. All lines going to the radiators are of equal length. Adjustment of such a system is quite simple and convenient. To install this wiring, you need to purchase a significant number of channels.

The latter option is implemented by using a small number of channels. Minus - a significant length of the circuit from the distant battery, which complicates the adjustment of the system.

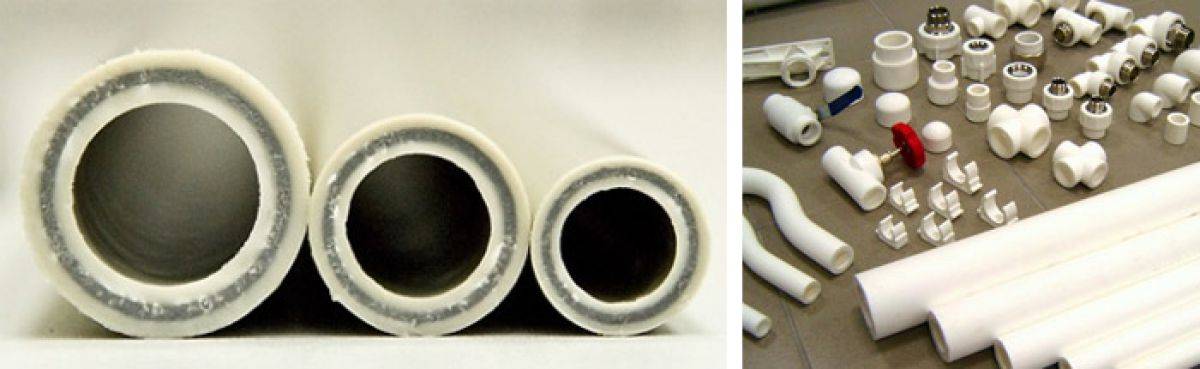

The main types of plastic (polypropylene) pipes

According to GOST, there are four main types of polypropylene pipes:

- polypropylene homopolymer (PPH) is a solid material that is not resistant to low temperatures. Made from such material, for the most part, they are used in the construction of pipelines in industry. The diameter varies from 20 to 110 mm;

- block copolymer (PPB) is one of the types of polymer, which often includes 20-30% polyethylene additives. This gives the products the ability to withstand low temperatures, and excellent communication flexibility. This material is used to create fittings and impact-resistant PP pipes;

- static propylene copolymer with ethylene (PPRC, PPR). GOST rules and marking recommend the use of such pipes at a working fluid temperature of no more than 70 ° C. The technical characteristics of the material allow it to be used in the installation of heating or water supply pipelines. Diameter - from 16 to 110 mm;

- Special PP. Has high thermal stability and operational characteristics. Suitable for liquids with a temperature not exceeding 95°C. This type has gained great popularity.

The disadvantage of polypropylene lines is that with an increase in the temperature of the working fluid, their thermal expansion (elongation) occurs. To avoid this, polypropylene pipes for heating is additionally reinforced.

Reinforced polypropylene pipes for heating have a higher efficiency and increase the overall service life of the pipeline.

According to GOST experts, metal analogues of polypropylene products become ineffective after a year, due to the fact that elevated temperatures cause internal erosion of the metal pipeline system.

Installation of metal-plastic pipes using press fittings

Of course, this fact significantly affects the process of heating a house, making steel heating pipelines not complying with GOST conditions. Labeling will help you choose the right type of product for you.

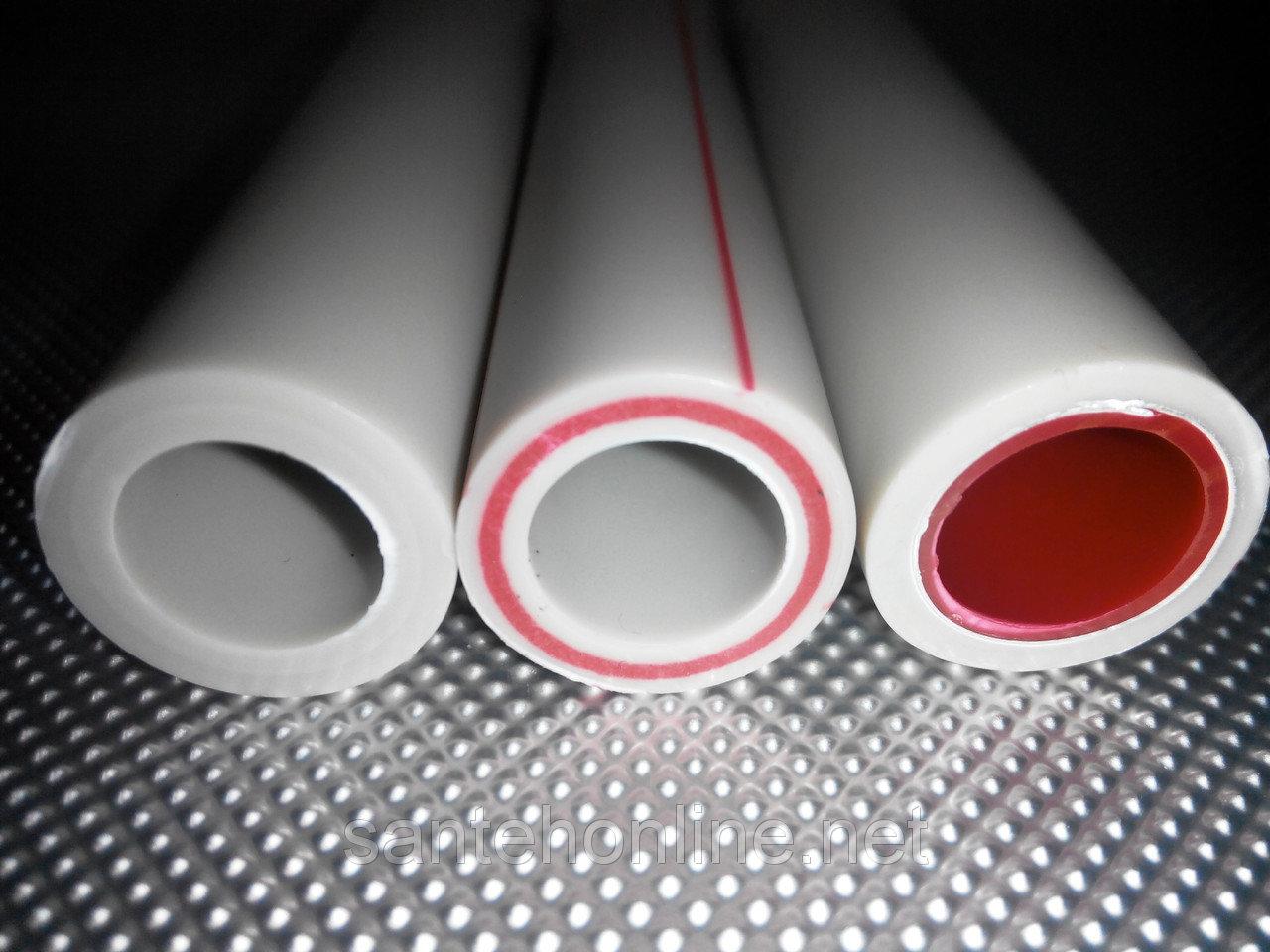

Types of reinforced pipes

For the optimal choice of a polypropylene pipe, you first need to familiarize yourself with the methods of reinforcing this product.

There are five types of increasing the efficiency of polypropylene pipes:

- Reinforcement with solid sheet aluminum. The outer side of the polypropylene pipe is covered with a solid aluminum sheet, during the connection process, the aluminum layer is removed at a distance of about 1 millimeter.

- Reinforcement with perforated aluminum sheet is also carried out along the outer surface and the sheet is cut in the same way: when splicing by 1 millimeter.

- Internal reinforcement of the pipe with aluminum. The walls are reinforced closer to the inside or in the middle of the technical product. According to the manufacturers, this type does not need pre-cleaning before welding.

- Fiberglass reinforcement.The process takes place in the middle part, and the outer and inner parts are made of polypropylene.

- Composite reinforcement. In order to strengthen pipelines, a composite material is used: a mixture of polypropylene with fiberglass. In pipes of this type, polypropylene is used for the production of internal and external surfaces, between which a composite (polypropylene bonded to fiberglass) is laid.

The optimal type for heating systems are pipes reinforced with composite. PP pipes with fiberglass maximize strength and minimize linear expansion.

Technical violations of integrity due to linear expansion lead to swelling and rupture of the material along the seam line.

It is unlikely that you will want the project to become more expensive due to the poor-quality installation of the heat supply system with your own hands, so choose high-quality technical products and calculate your strength.

In addition, it is important to consider the diameter of the polypropylene pipe. Large-sized PPs are not used to move the heat carrier, due to the large load that can soften the polymer lines

Practical recommendations

The wrong choice of product diameters is fraught with many troubles: leaks (due to hydrodynamic shocks or excess pressure in the line), increased consumption of electricity (fuel) due to low system efficiency, and a number of others. Therefore, it should not be mounted according to the principle “like a neighbor (godfather, brother-in-law)”.

If the circuit consists of dissimilar pipes, then special calculations will have to be made for each section (line) of the route. Separately - for plastic, metal (steel, copper), apply different coefficients and so on.

Only a specialist can solve such a problem. In such situations, it is not worth doing the calculations yourself, since the error can be very significant. The services of a professional will cost much less than the subsequent alteration of communications, and even during the heating season.

Connection of all devices (expansion tank, batteries and others) of the circuit is carried out by pipes of the same section.

For exclusion formation of air pockets (in case of some errors in the calculations) so-called air vents should be installed on each line.

The main criteria for choosing pipes

In order to reasonably and correctly select pipes for a home heating system, the following items are taken into account:

- type of installation of the pipeline complex - surface or hidden (internal);

- estimated pressure power - an assessment of the range from basic to the maximum possible indicators;

- type of heating system - autonomous or central communications with gravity or forced circulation of the heating composition;

- the maximum temperature for which the coolant is designed;

- configuration features of heating equipment - one-pipe or two-pipe complex.

Only knowing all these factors, they begin to choose the type of material that will most effectively manifest itself in the specific specified conditions.